Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Hue stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of fine-denier porous POY black yarn

InactiveCN102443859AImprove spinnabilityReduced stabilitySpinnerette packsMelt spinning methodsProduction rateYarn

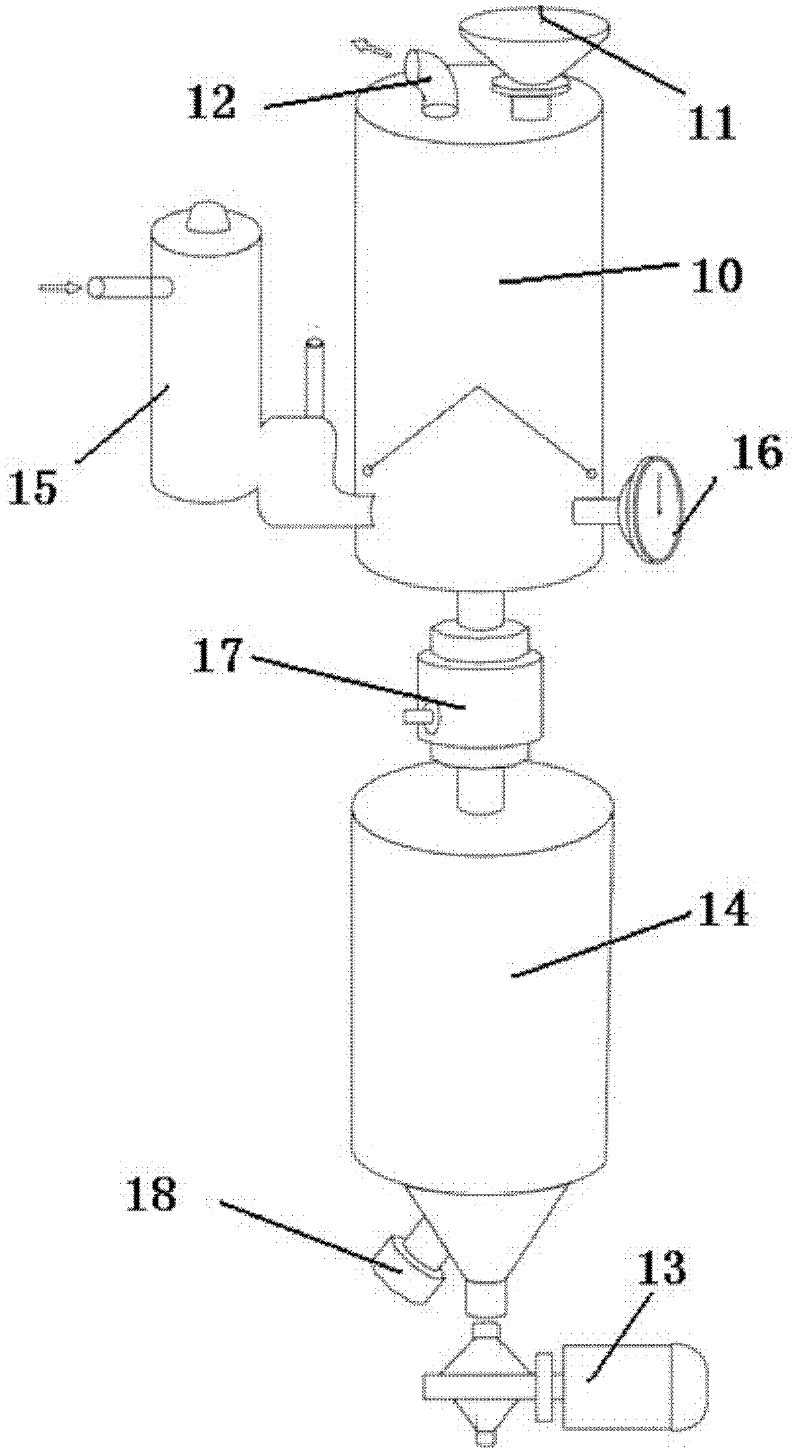

The invention discloses a production method of a fine-denier porous POY black yarn. The method comprises the following steps of: drying semi-dull slices, drying black masterbatch, adding the slices and the black masterbatch material into a screw extruder, fusing the added materials in the screw extruder, respectively processing the fused materials in a metering pump and a spinning beam, spinning on a pack, cooling the materials by lateral blowing, applying oil on strands, processing the strands in draw-off godets GR1 and GR2, winding and shaping, and inspecting products. The method is characterized in that the step of drying the black masterbatch comprises the following sub-steps of: based on a continuous drying mode, firstly, adding the black masterbatch into a crystallization and drying tank, introducing heated dry air from the lower part of the crystallization and drying tank, and blowing out the heated dry air from the top of the crystallization and drying tank so as to dry the black masterbatch, wherein the drying time is 2 hours, the dried black masterbatch falls into an intermediate material storage bin for storage under the crystallization and drying tank, and the black masterbatch is further injected by a masterbatch injector under the intermediate material storage bin. The production method of the fine-denier porous POY black yarn has high masterbatch spinnability and better cooling effect, and can improve the oil application uniformity of spinning cakes and the productivity.

Owner:桐乡市中洲化纤有限责任公司

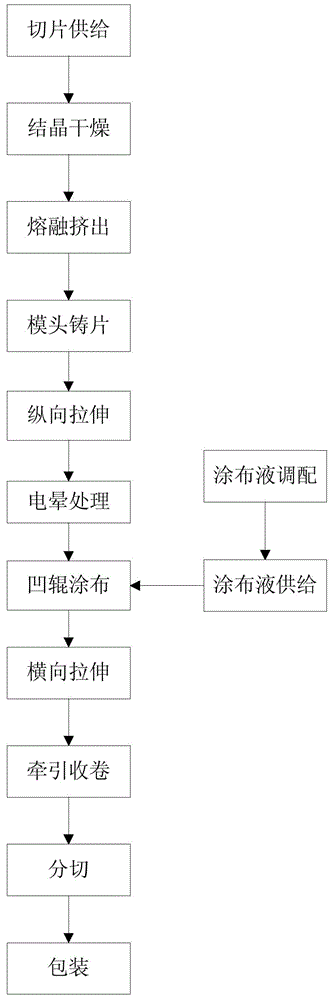

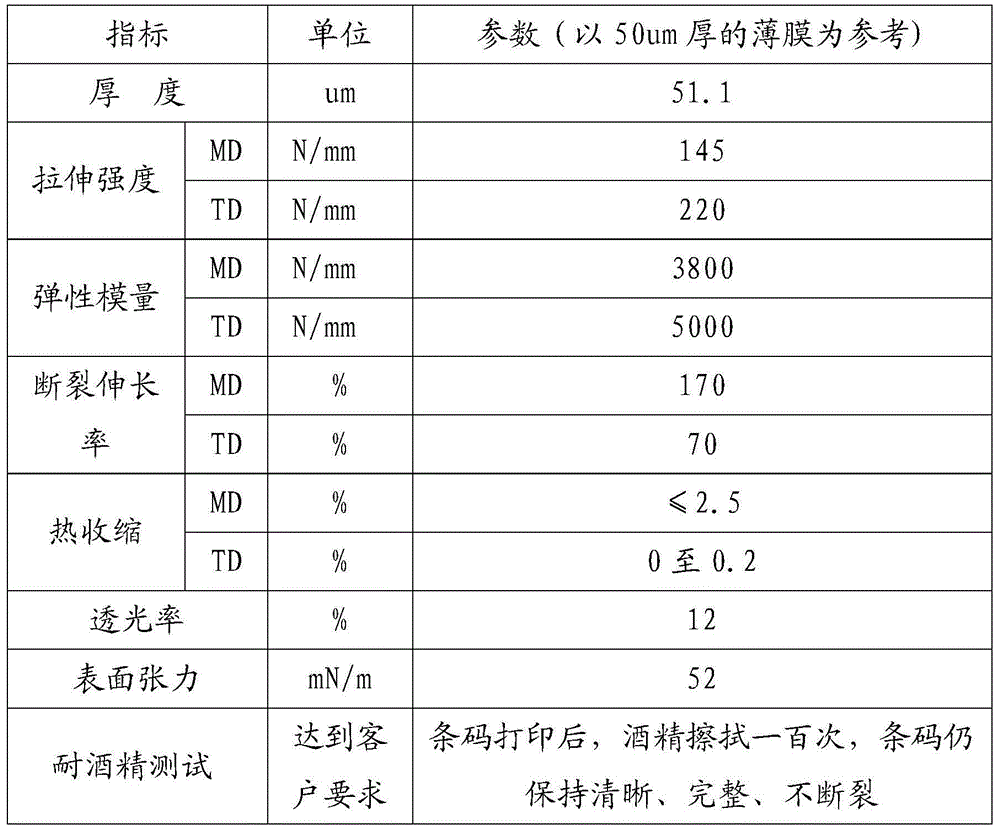

Preparation method of polyester film for coating tag

The invention discloses a preparation method of a polyester film for coating a tag. Functional coating is performed on the surface of the polyester film to increase the adhesive force of the surface of the film, and the problem of corona attenuation of a common corona film can be effectively prevented, so that convenience is brought for downstream manufacturers to carry out UV ink printing, conductive ink printing and barcode printing. Tag films are mainly white, customers demand much on the hue, high-temperature resistance, no deformation and high tensile strength are required during later processing, and meanwhile, the ink adhesive force has to be guaranteed for the customers. Therefore, the polyester film for coating the tag has the main technical characteristics of stable hue, high-temperature resistance and high strength and ink adhesive force.

Owner:TIANJIN WANHUA CO LTD

Preparation method of gold imitated card paper, bar code printing method and packaging product processing method

The invention provides a preparation method of gold imitated card paper. According to the preparation method provided by the invention, gravure printing is adopted for transferring gold imitated gravure ink composition onto the surface of a silver card paper, and drying and curing are carried out, so that the gold imitated card paper is obtained. When the gold imitated card paper is taken as a printing stock during printing, the gold imitated card paper is not influenced by a printing process, hue of the gold imitated card paper is consistent with the hue of standard sample manuscript gold card paper, stable hue of the gold imitated card paper can be guaranteed, and a printing technology of the gold imitated card paper is simple. The invention also provides a bar code printing method. According to the bar code printing method provided by the invention, the gold imitated gravure ink composition is printed on the surface of the sliver card paper except a region in which a bar code is required to be printed, so that the region in which the bar code is required to be printed can not contain the gold imitated gravure ink composition and is in the colour of the silver card paper; and white gravure ink is overprinted in the region in which the bar code is required to be printed, and sign contrast between black bars is increased, so that the grade standard of the bar code is met.

Owner:CHANGDE JINPENG PRINTING

Colorful oily fertilizer anticaking agent and application thereof

InactiveCN105418246AUniform colorUniform color inside and outsideFertilizer mixturesBrilliant blackAnticaking agent

The invention relates to a colorful oily fertilizer anticaking agent and an application thereof. The colorful oily fertilizer anticaking agent comprises components in percentage by mass as follows: 1%-3% of allura red aluminum lake, sunset yellow aluminum lake, indigo blue aluminum lake, fast green aluminum lake, purple aluminum lake, chocolate brown aluminum lake or brilliant black aluminum lake and 97%-99% of an oily anticaking agent, the components are milled by a horizontal milling machine and are mixed uniformly, and the colorful oily fertilizer anticaking agent is prepared; the colorful oily fertilizer anticaking agent is applied to fertilizer packaging, and accordingly, the fertilizer appearance color is corresponding red, yellow, blue, green, purple, brown or black. The colorful oily fertilizer anticaking agent and the application thereof have the advantages that the corresponding red, yellow, blue, green, purple, brown or black oily fertilizer anticaking agent is provided according to different colors of the fertilizer appearance, so that the fertilizer hue is stable, the packaging capacity is high, inner and outer colors are consistent, chromatic aberration and uneven dyeing are avoided, the color is uniform, and besides, the colorful oily fertilizer anticaking agent can be resistant to light and heat, is fadeless and non-discoloring and is taken as a fertilizer variety distinguishing and fertilizer anti-counterfeiting mark; the method is simple, the use cost is low, the anticaking performance is good, when the fertilizer is coated with the agent, the fertilizer loosening rate is up to or higher than 90%, biodegradation can be realized, and environmental protection is facilitated.

Owner:HUBEI FORBON TECH

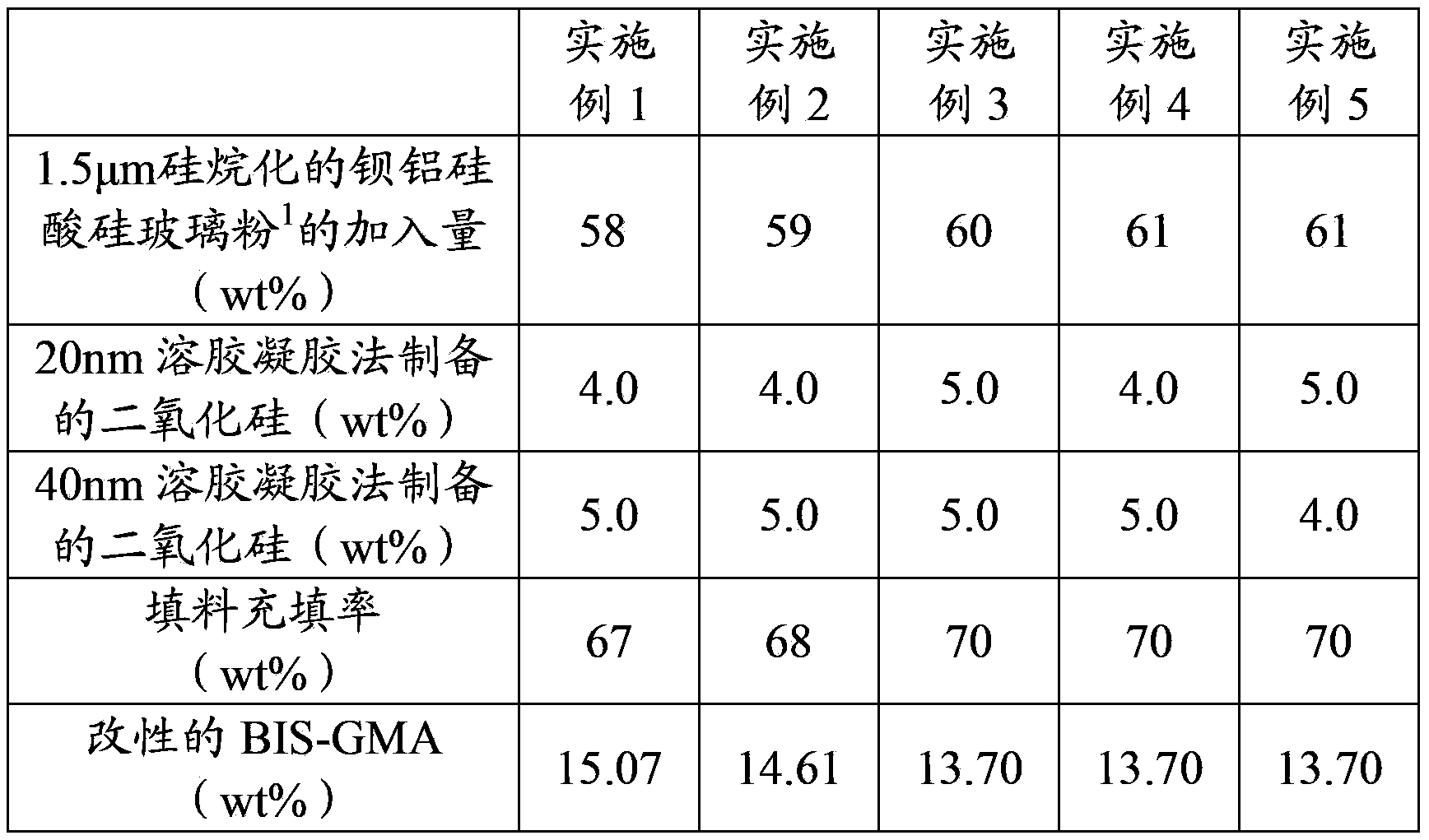

Dual curing crown nuclear resin for dentistry and preparation method thereof

InactiveCN103356391AMake up for the defect of poor infiltrationLow hydroxyl contentImpression capsDentistry preparationsFilling rateDual curing

The invention relates to dual curing crown nuclear resin for dentistry and a preparation method thereof. The dual curing crown nuclear resin comprises the following components in percentage by weight: 50-80 wt% of structured packing, 4.0-5.0 wt% of chemical curing initiator, 0.5-1.0 wt% of photocuring initiator, and the balance of two or more polymerizable acrylic monomers, wherein the mean grain size of the structured packing is 0.02-10 microns; and the structured packing contains the particles of which the volume fraction is less than 50% and the mean grain size is greater than 1.5 microns. The resin displays low cure volume shrinkage, high packing filling rate and high strength, so that the performance of the resin is greatly improved.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

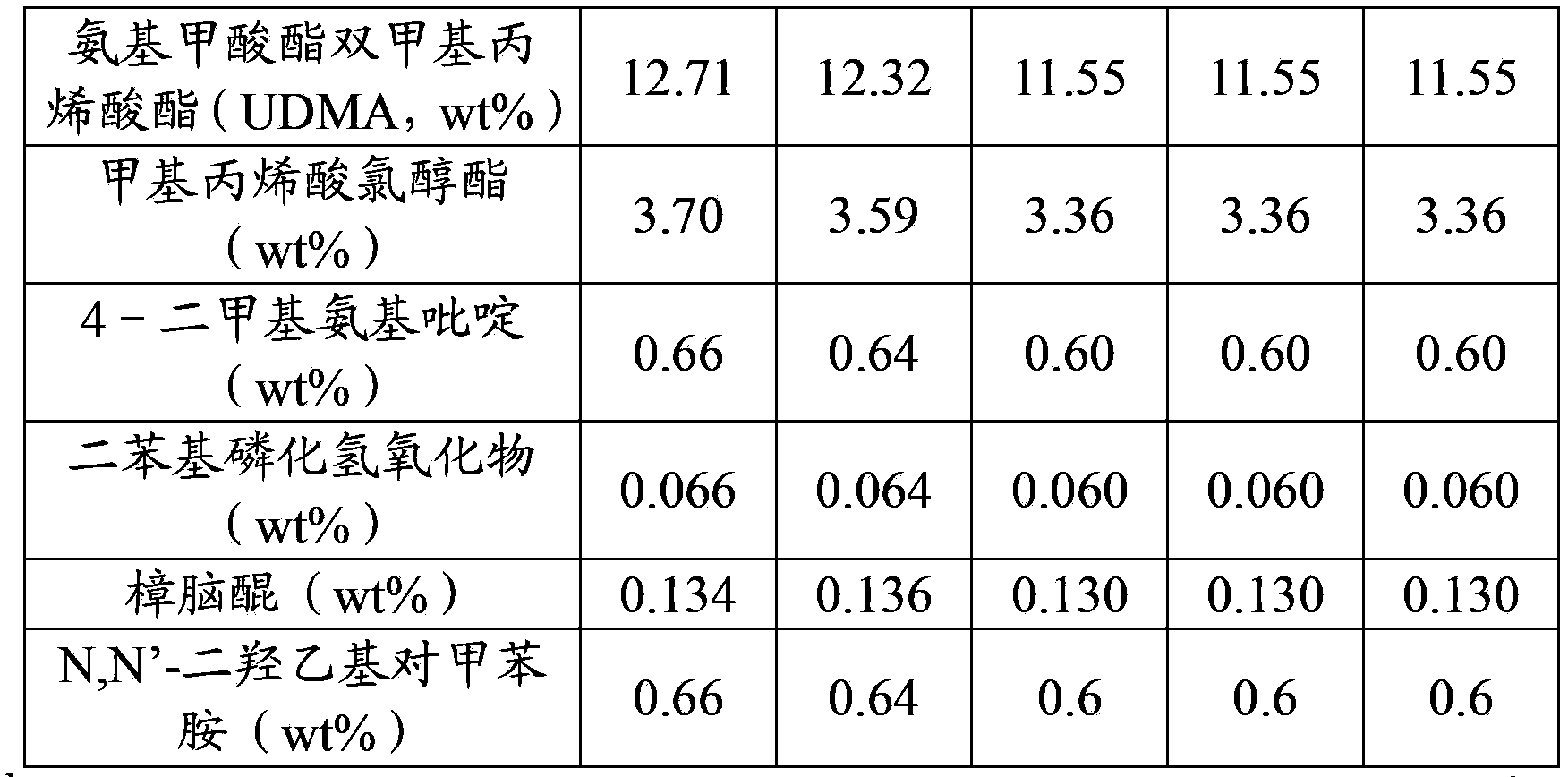

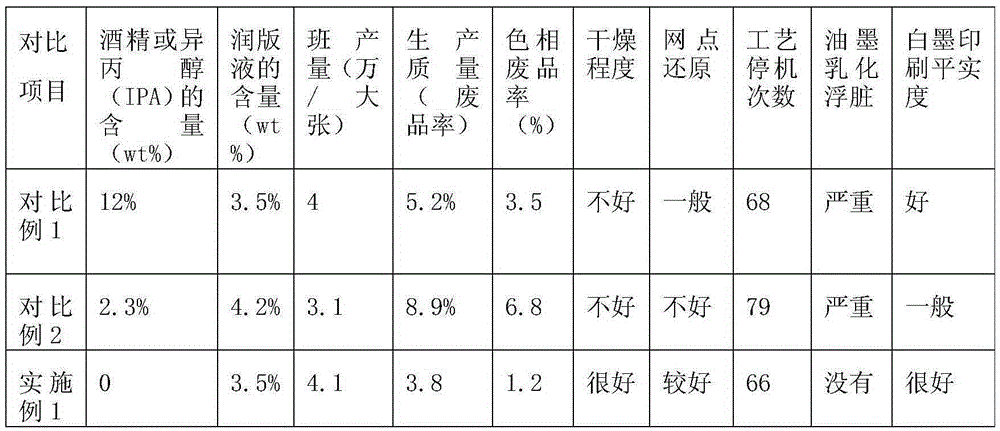

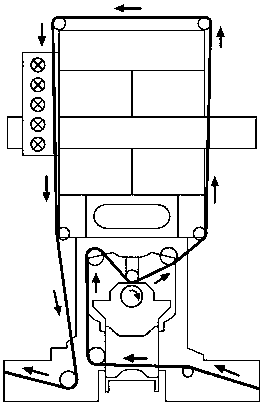

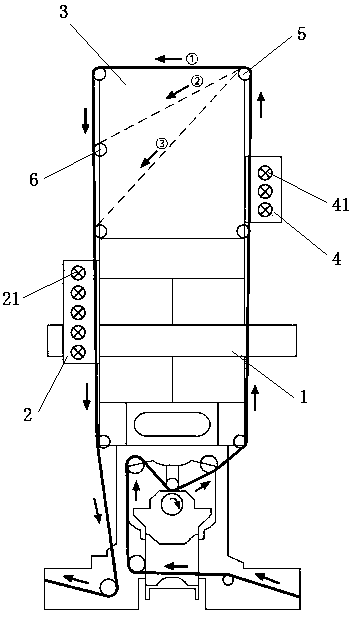

Zero alcohol type lithographic printing system

ActiveCN106585071AImprove the environmentGood for healthInking apparatusPrinting roller shellsWater sourceEther

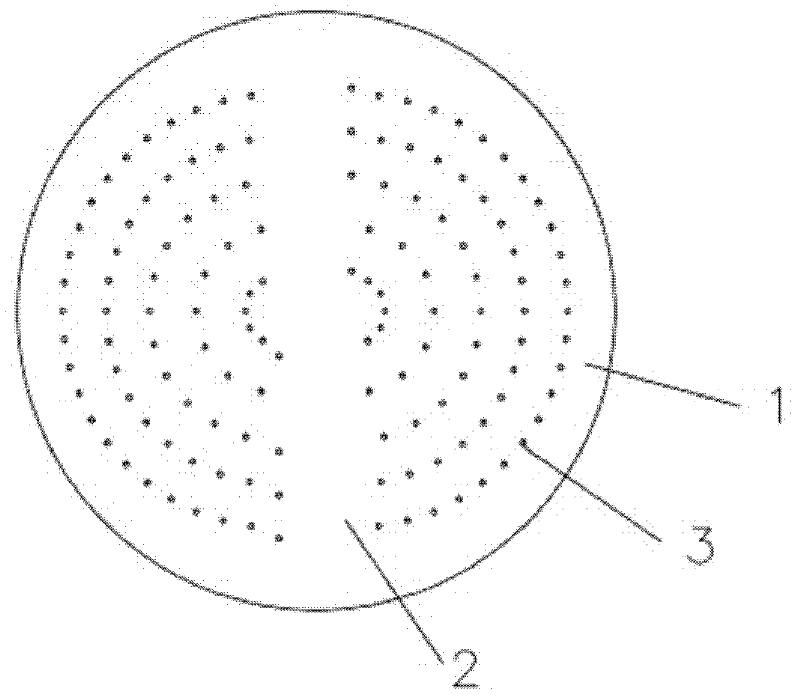

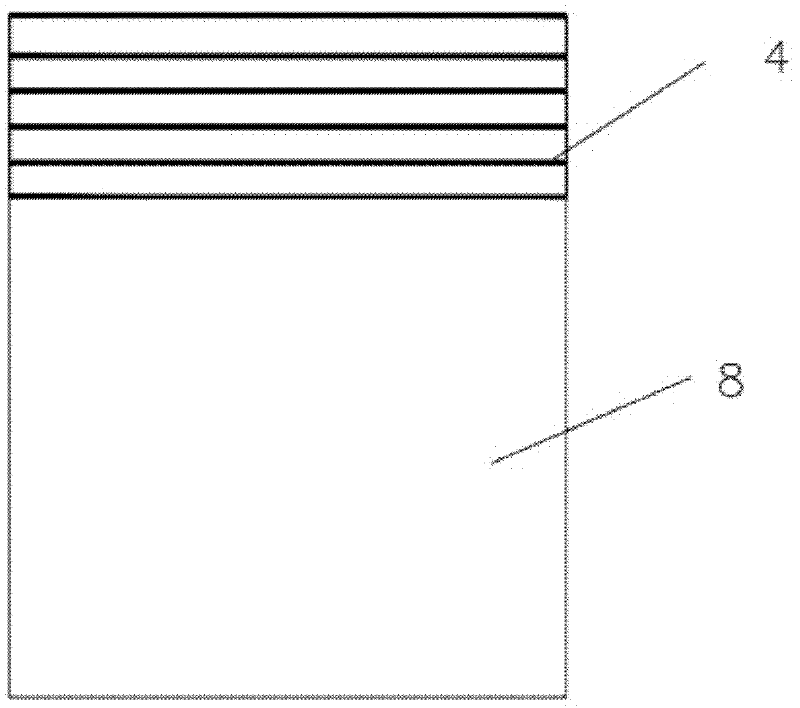

The invention relates to a zero alcohol type lithographic printing system. The zero alcohol type lithographic printing system comprises the following parts of a plate cylinder (3), a printing ink applying system (1) and a plate wetting water applying system (2), wherein the cylindrical outer surface of the plate cylinder (3) is provided with a printing plate (4); the printing ink applying system (1) comprises a printing ink source (8) and a plurality of printing ink rollers, and is used for applying printing ink onto the printing plate; the plate wetting water applying system (2) comprises a plate wetting water source (7) and a plurality of plate wetting water rollers, and is used for applying plate wetting water onto the printing plate; the plurality of plate wetting water rollers include a dampening vibrator (6); and the structure of the dampening vibrator (6) as follows includes a metal roller and a ceramic layer covering the outer surface of the metal roller; the outer surface of the ceramic layer is provided with a net pattern; and the content of alcohol type substances or ether type substances in plate wetting water is zero.

Owner:YUNNAN JOY PRINTING TECH CO LTD

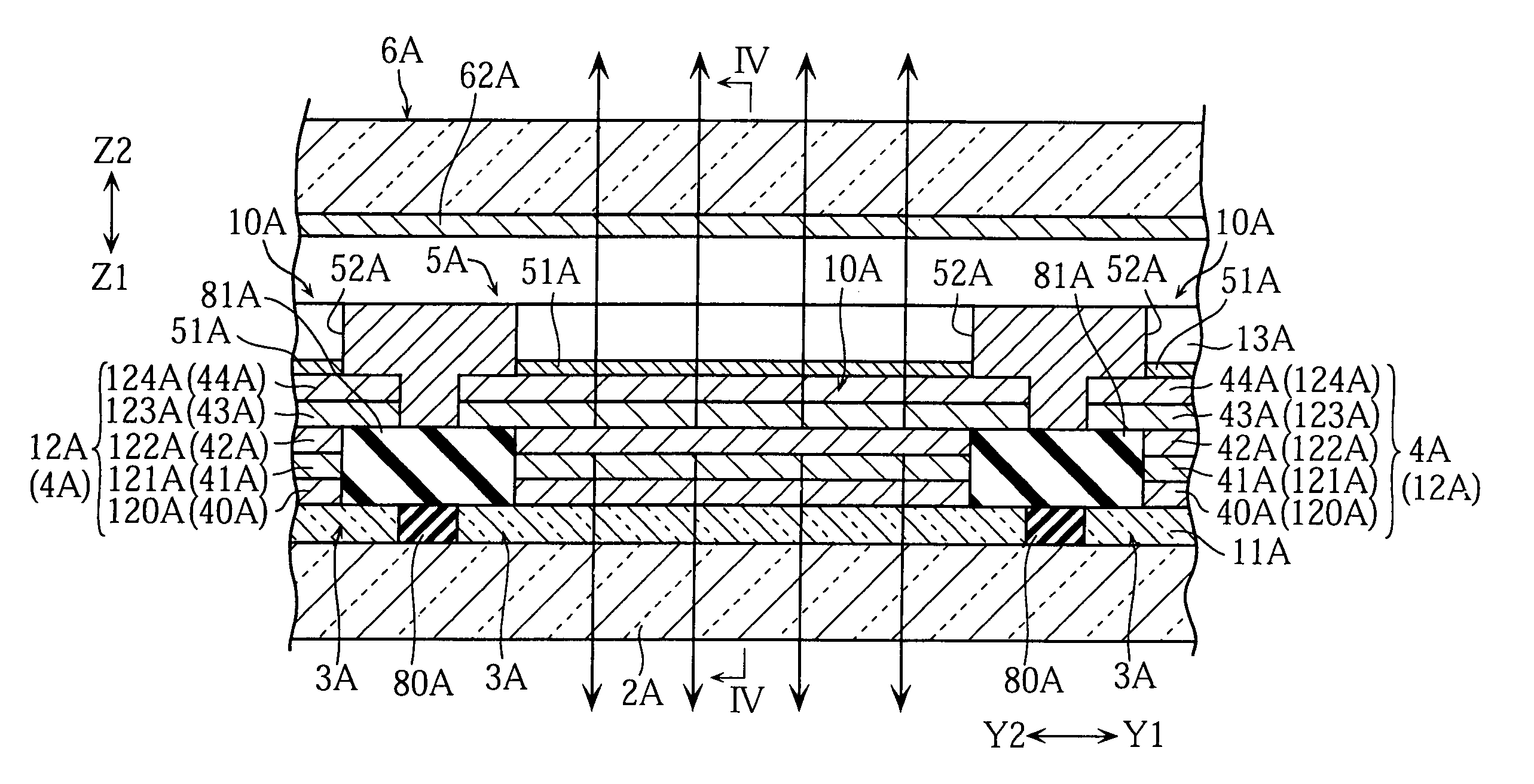

Organic EL display device with plural electrode segments

ActiveUS7129635B2Hue stabilitySmall driving voltageDischarge tube luminescnet screensElectroluminescent light sourcesElectric fieldOptoelectronics

The present invention relates to a display device (1A) including a plurality of display elements (10A) formed on a substrate (2A). Each of the display elements (10A) includes an organic segment (4A) containing an organic compound which generates light upon application of an electric field, and a first and a second electrode elements (3A, 5A) for applying the electric field to the organic segment (4A). The first electrode segment (3A), the organic segment (4A) and the second electrode segment (4A) are formed on the substrate (2A). In this case, the second electrode segment (5A) is provided with an opening (52A) for allowing passage of light generated in the organic segment (4A). The first and second electrode segments may be formed adjacent to each other in a plane parallel to the substrate. In this case, the organic segment is formed so as to cover both the first and second electrode elements.

Owner:ROHM CO LTD

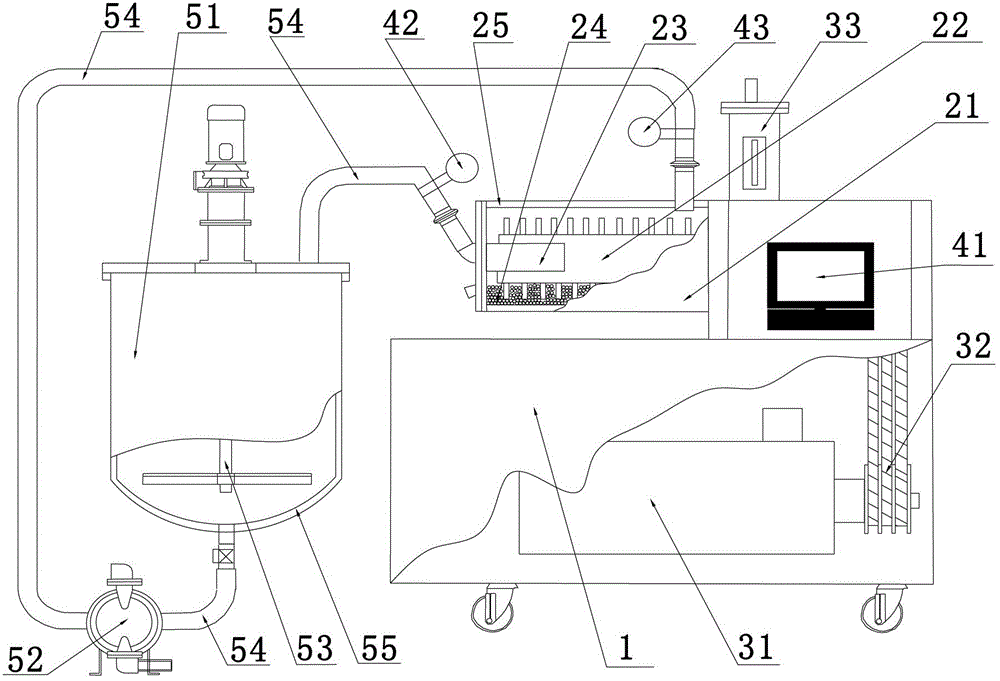

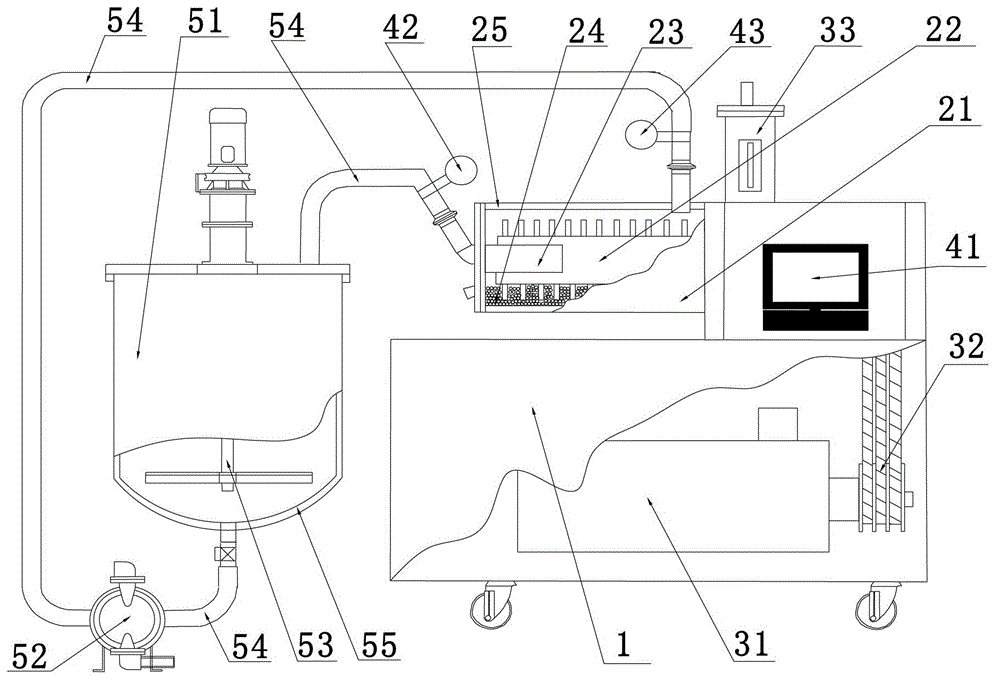

Grinding device and grinding process for grinding heat transfer printing color paste

The invention provides a grinding device for grinding a heat transfer printing color paste. The grinding device comprises a base rack, wherein the base rack is fixedly provided with a sand mill, a control assembly and a power assembly; the power assembly comprises a motor, and the sand mill comprises a grinding barrel and a plurality of grinding media positioned in the grinding barrel. The grinding device further comprises a circulating assembly, wherein the circulating assembly comprises a circulating barrel, a circulating pump and a plurality of conduits. The discharge port of the grinding barrel is communicated with the feed port of the circulating barrel by virtue of the conduit, and the feed port of the grinding barrel and the discharge port of the circulating barrel are respectively connected with the outlet and inlet of the circulating pump. The invention further provides a grinding process utilizing the grinding device. The grinding device provided by the invention has the characteristics of simple structure, favorable heat dissipation effect, low noise, capability of continuous production, low production cost, high grinding efficiency, and high quality of grinded products.

Owner:ZHUHAI FREE TRADE ZONE NEOJET APOLLOJET IMAGING MATERIALS

Yellow card paper and manufacturing method thereof

InactiveCN104195877AGuaranteed evennessAvoid strong dryingWater-repelling agents additionLuminescent/fluorescent substance additionSulfateHue

The invention relates to a yellow card paper and a manufacturing method thereof. The manufacturing method is mainly characterized by comprising the following steps: respectively preparing bleached sulfate softwood pulp, bleached sulfate reed pulp and poplar PRC-APMP pulp; making paper from the bleached sulfate softwood pulp, the bleached sulfate reed pulp and the poplar PRC-APMP pulp according to the weight ratio of (15%-25%) to (35%-45%) to (35%-40%); optimizing dye types and different dye ratios; and with a CPAM and cationic starch retention system, carrying out soft roll calendaring treatment. The prepared yellow card paper has the characteristics that the fixed amount is 103-106g / m<2>, the thickness is greater than or equal to 140 microns, the moisture content is 4%-6%, the hygroscopic property is smaller than or equal to 30g / m<2>, the transverse folding strength is greater than or equal to 6 times, the transverse expansion rate is smaller than or equal to 3.2%, the longitudinal fracture length is greater than or equal to 3500m, the smoothness is greater than or equal to 20s, the two side difference is smaller than or equal to 30%, the b value is 26, and the content of dust of 0.2mm<2> to 1.5mm<2> is smaller than or equal to 60 / m<2>. The yellow card paper disclosed by the method is stable in hue and low in cost.

Owner:YUEYANG FOREST & PAPER CO LTD

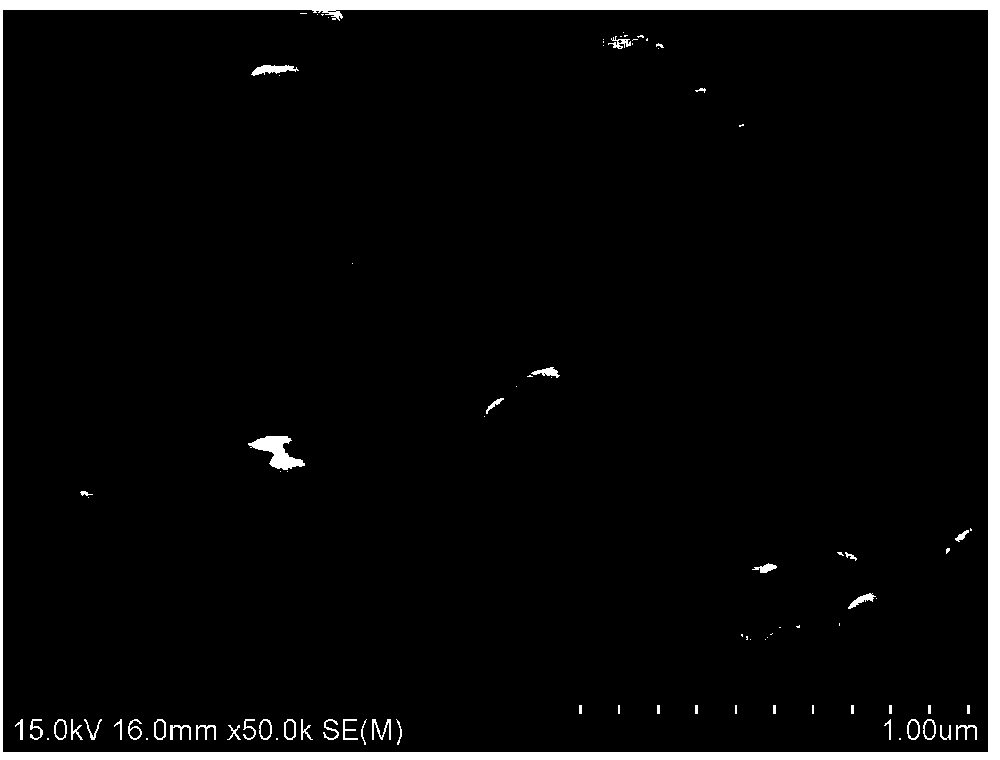

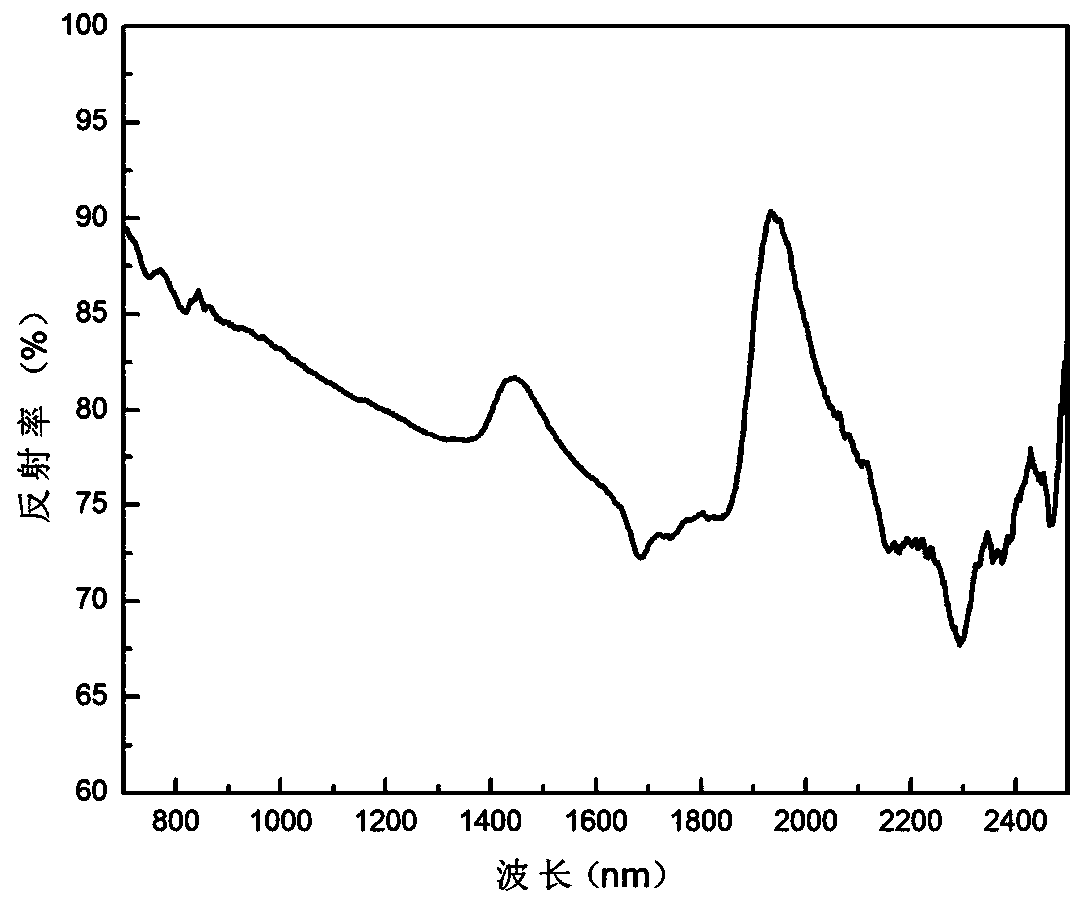

Yellow near-infrared high reflective coating and preparation method thereof

InactiveCN104194624AGood thermal stabilityPrevent reflocculationReflecting/signal paintsAlcoholSolvent

The invention relates to a yellow near-infrared high reflective coating and a preparation method of the yellow near-infrared high reflective coating. The yellow near-infrared high reflective coating comprises the following components in percentage by weight: 20 to 50% of yellow near-infrared reflective pigments, 10 to 50% of a film-forming matter, 30 to 60% of a solvent and 4 to 30% of an additive. The film-forming matter is organic silicon resin, and the solvent is water or C1-C4 alcohol. The invention further provides the preparation method of the yellow near-infrared high reflective coating. The yellow near-infrared high reflective coating is high in reflectivity, bright in yellow chrominance and good in mechanical properties, and applied to outer surfaces of building exterior facades and top layers or oil storage tanks, vehicles and aircraft shells and ship decks to obviously lower temperature inside a coating material.

Owner:SHANDONG UNIV

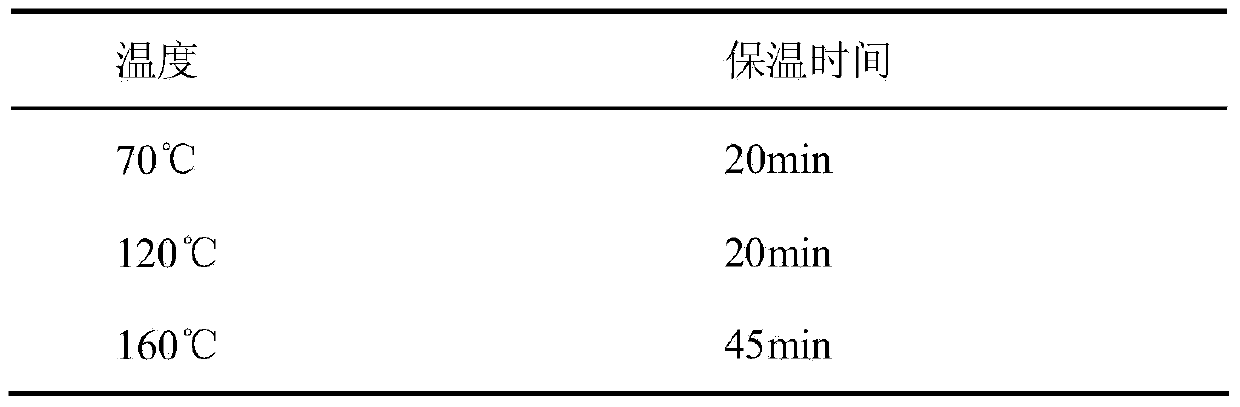

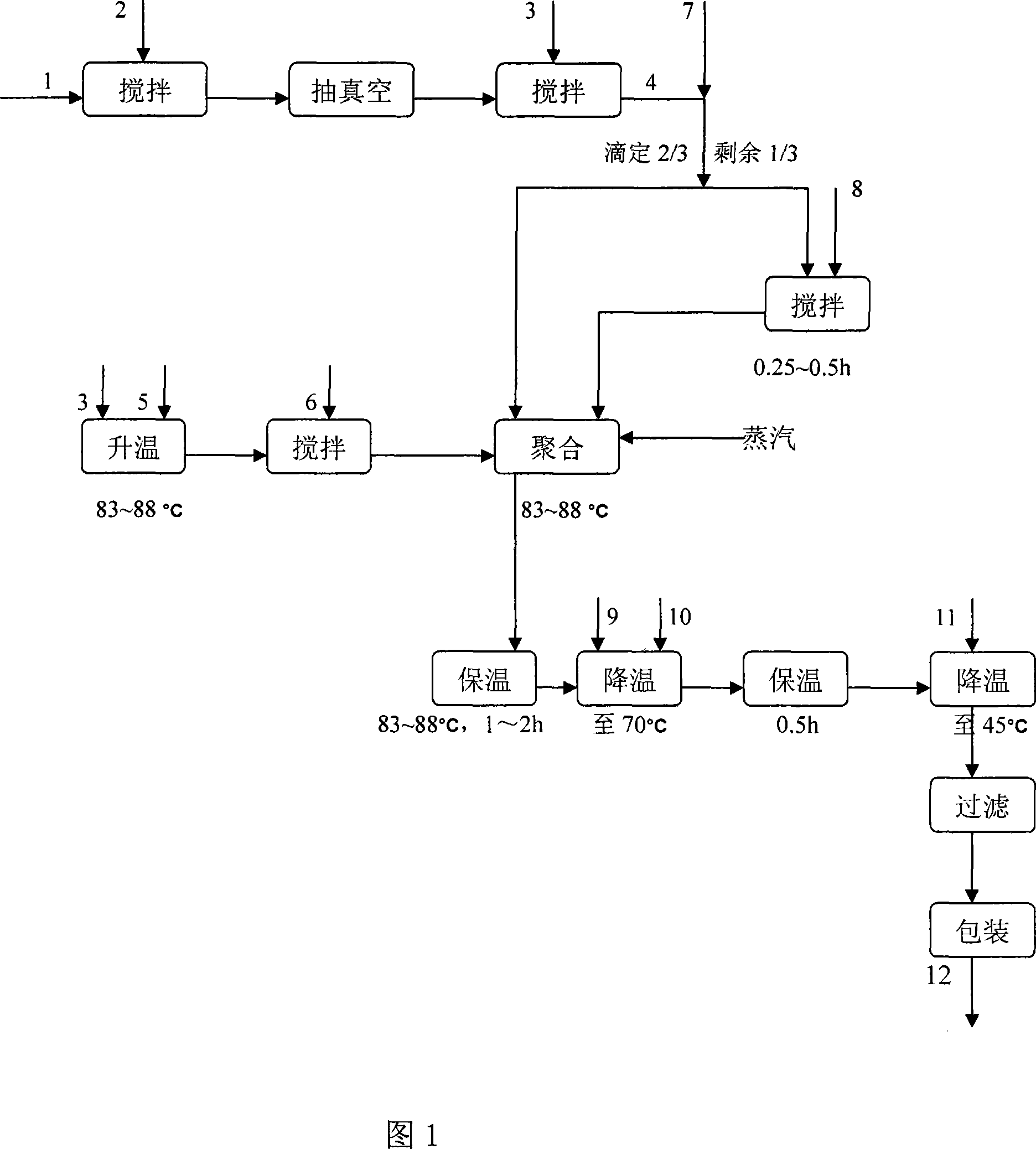

Elastic phenylethylene-ester acrylate water-proof emulsion and preparation method thereof

This invention relates to elasticity styrene - acrylate waterproof latices and its preparation method. It is polymerized by nine kind component and seed emulsion. The preparation method includes as follows steps: whip, vacuumize, whip, polymerization, thermal insulation, cooling, thermal insulation, cooling, filter, casing. This invention has low cost, stable color phase, moderate consistency, good acid and alkaline protection, and lower vitrification point. It can effectively eliminate liberation monomer, avoid enviroment pollution. This invention especially fit for cement group polymer waterproof, waterproofing work as well as impervious seal stuff.

Owner:陈毅曦

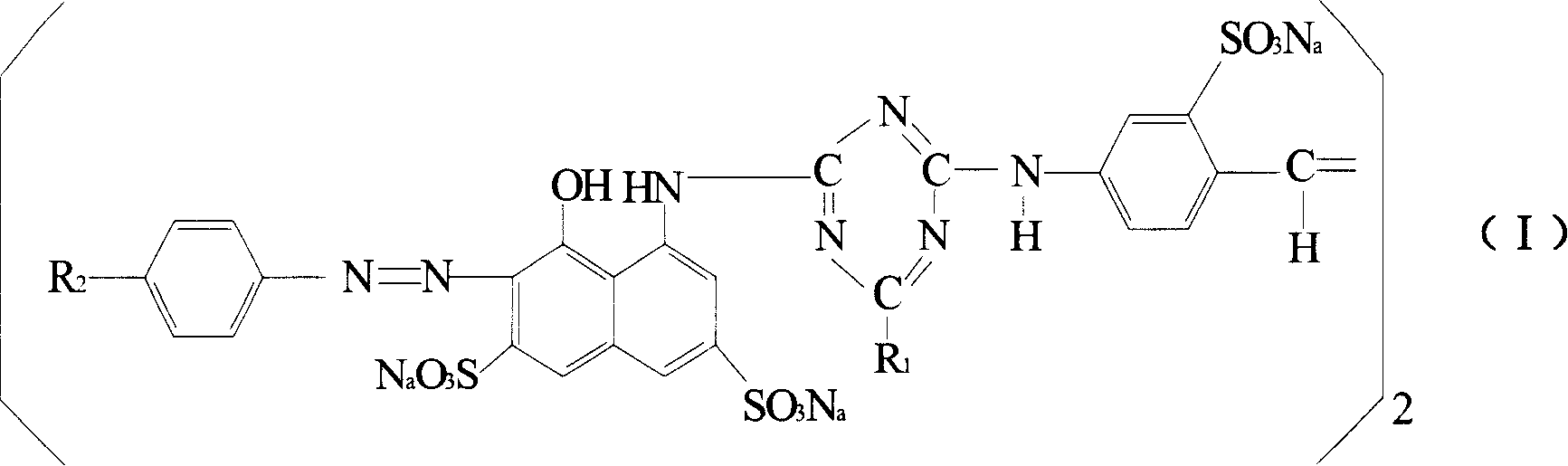

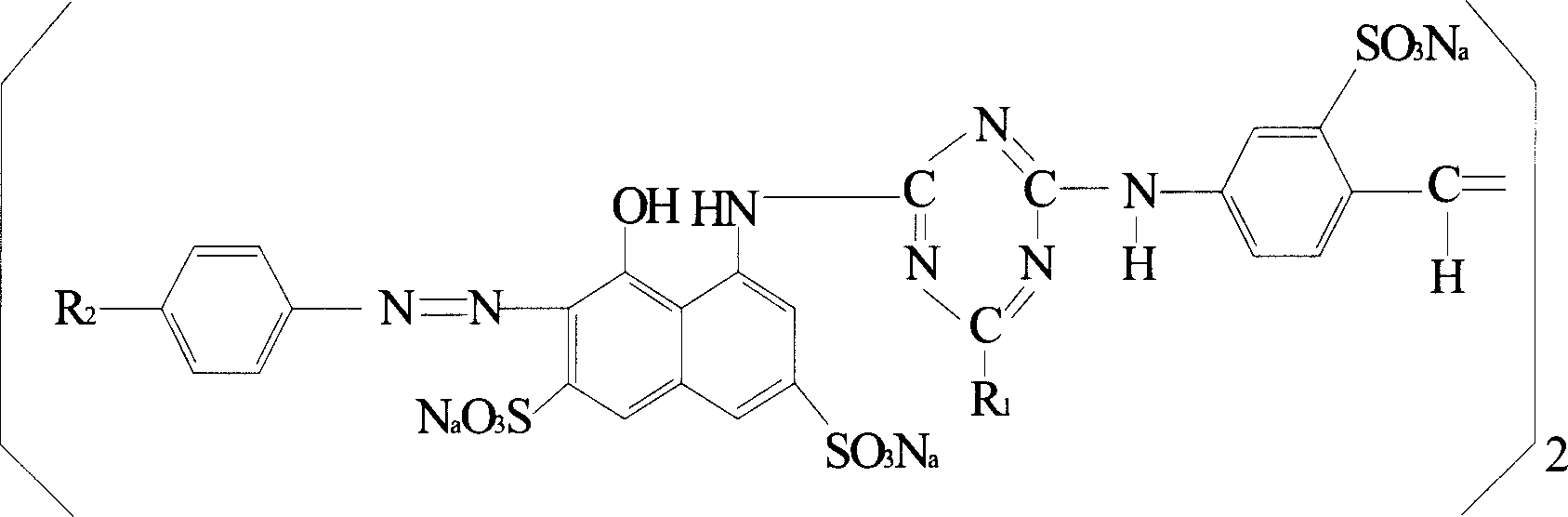

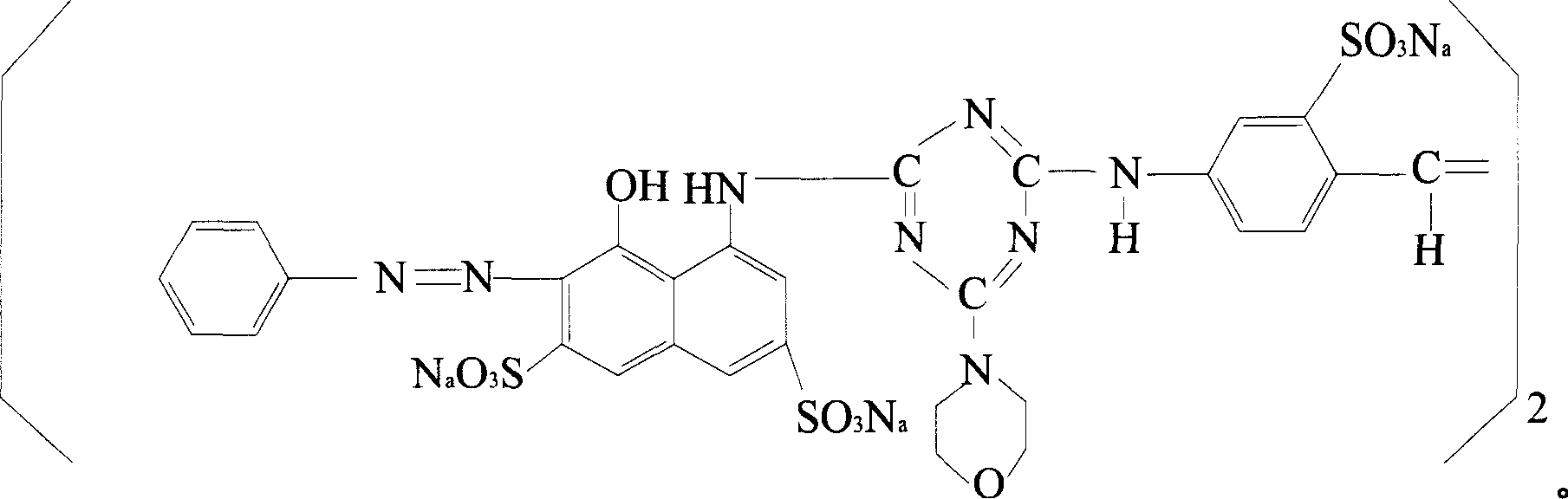

Directly blending rose dye and its preparing process

The directly blending rose dye in the shown chemical structure is prepared through the technological process including the first condensation reaction, aniline diazoniation, coupling reaction, the second condensation reaction and the third condensation reaction. The directly blending rose dye contains no carcinogenic chemical, and may be used in dyeing cellulose, polyester / cotton blended fiber, and polyester / viscose blended fiber. It has the advantages of reduced dyeing steps, shortened dyeing time, reduced dyeing waste water exhaust, lowered dyeing power consumption, lowered dyeing cost, increased dyeing yield.

Owner:吴江市罗林染化有限公司

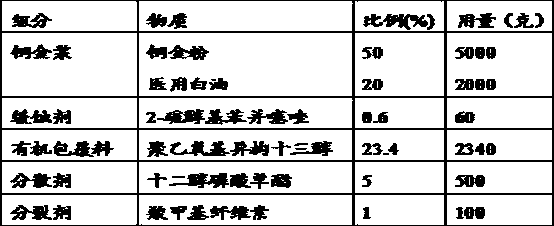

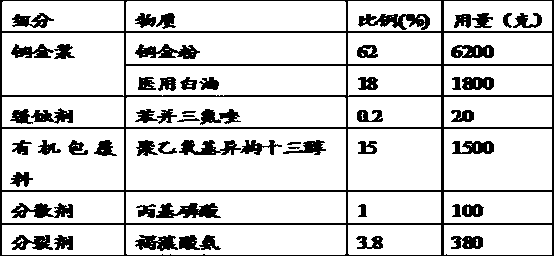

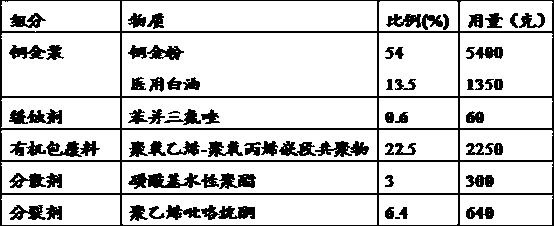

Aqueous bronze pigment and preparation method thereof

The invention discloses an aqueous bronze pigment and a preparation method thereof. The aqueous bronze pigment is prepared from following raw materials in percentage by weight: 55 to 80% of bronze slurry, 0.1 to 1% of corrosion inhibitor, 15 to 30% of organic coating material, 1 to 5% of dispersant, and 1 to 10% of disintegrating agent; wherein the bronze slurry is prepared by adding bronze powderinto a solvent (20-30%). The problems of a conventional bronze powder surface treatment are solved. The provided aqueous bronze pigment has the advantages of complete and firm coating, stable color phase, and economic and environmentally friendly process in an aqueous system.

Owner:清远市绚淳环保新材料有限公司

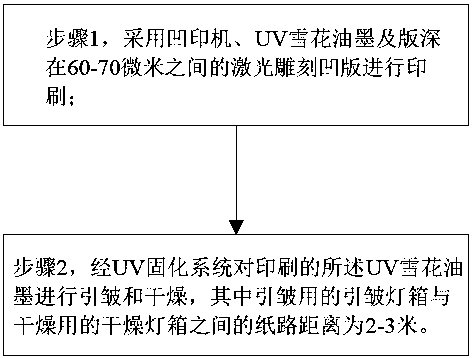

Gravure connection line snowflake technology and curing system thereof

PendingCN107745577ASimple processIncrease productivityInksOther printing apparatusUV curingLaser engraving

The invention discloses a gravure connection line snowflake technology and a curing system of the gravure connection line snowflake technology, and belongs to the technical field of gravure. The technology comprises the steps that 1, a gravure press is adopted, UV snowflake ink and laser engraving gravure with the depth of 60-70 micrometers are adopted for printing; and 2, the printed UV snowflakeink is wrinkled and dried, the paper path distance between a wrinkling lamp box for wrinkling and a drying lamp box for drying is 2-3 m. The curing system comprises a color class, the drying lamp boxarranged on one side of the color class, a color supporting frame arranged above the color class, and the wrinkling lamp box arranged on the side, opposite to the drying lamp box, of the paper supporting frame. The snowflake technology on the gravure press can be achieved with high efficiency and high quality, and therefore the production efficiency is greatly improved.

Owner:WUHAN HONGJINLONG PRINTING

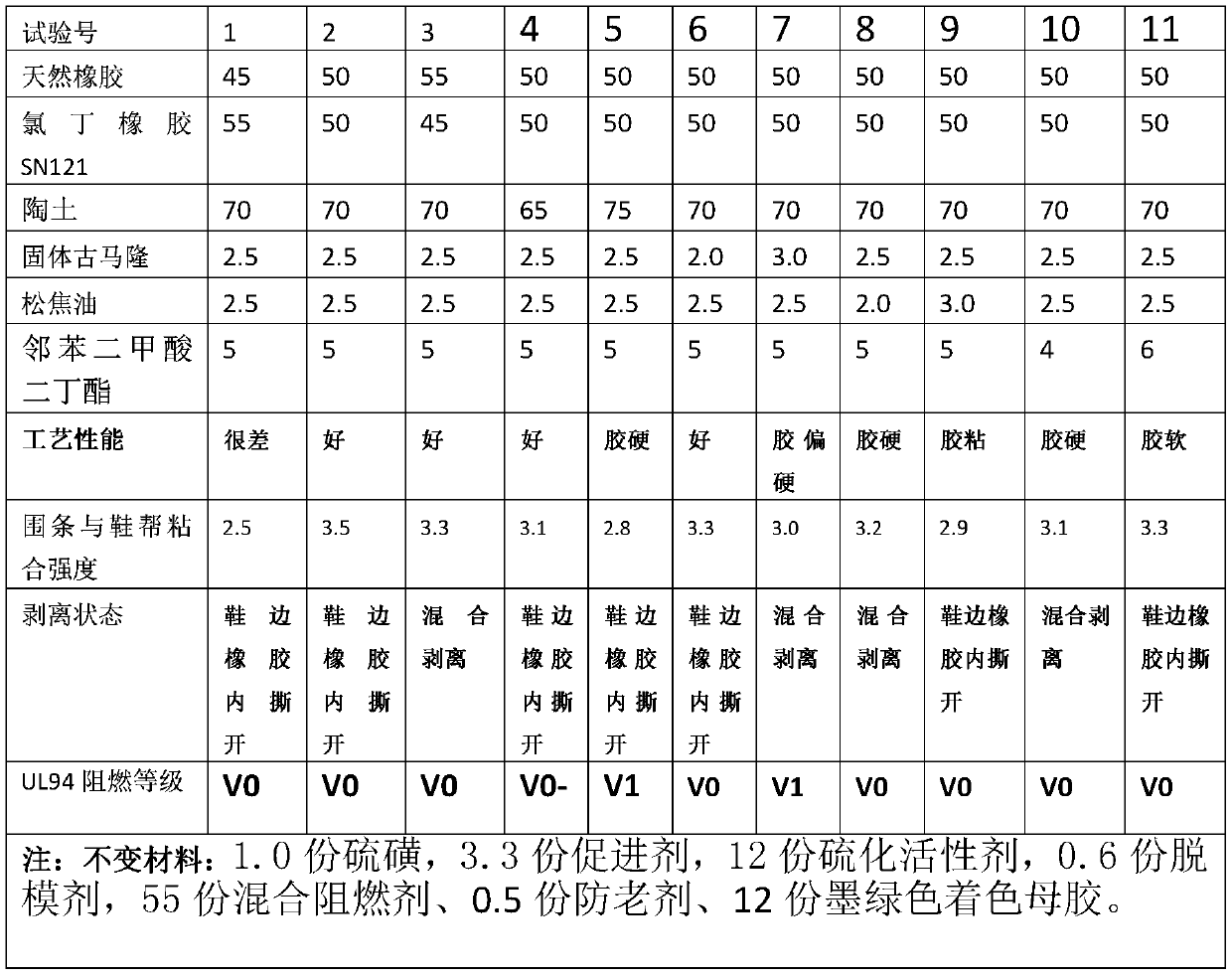

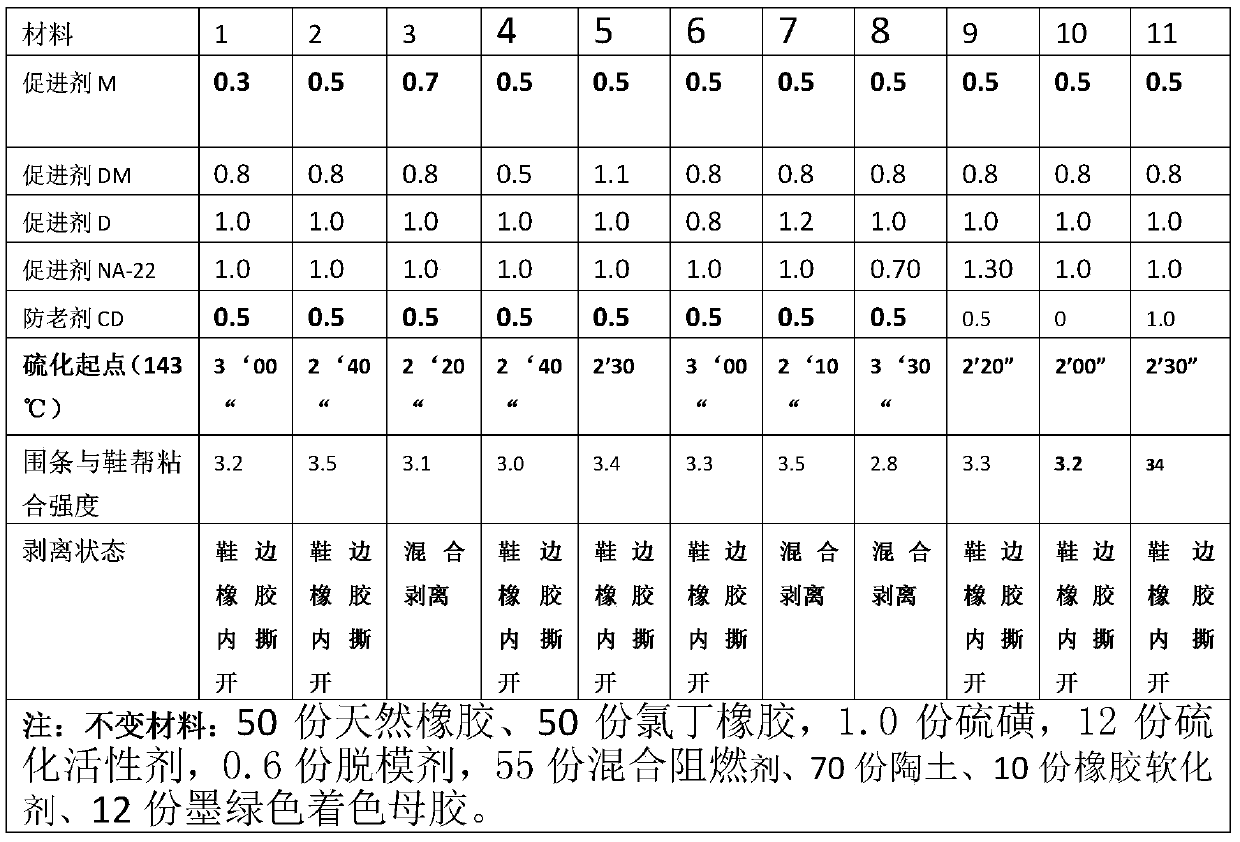

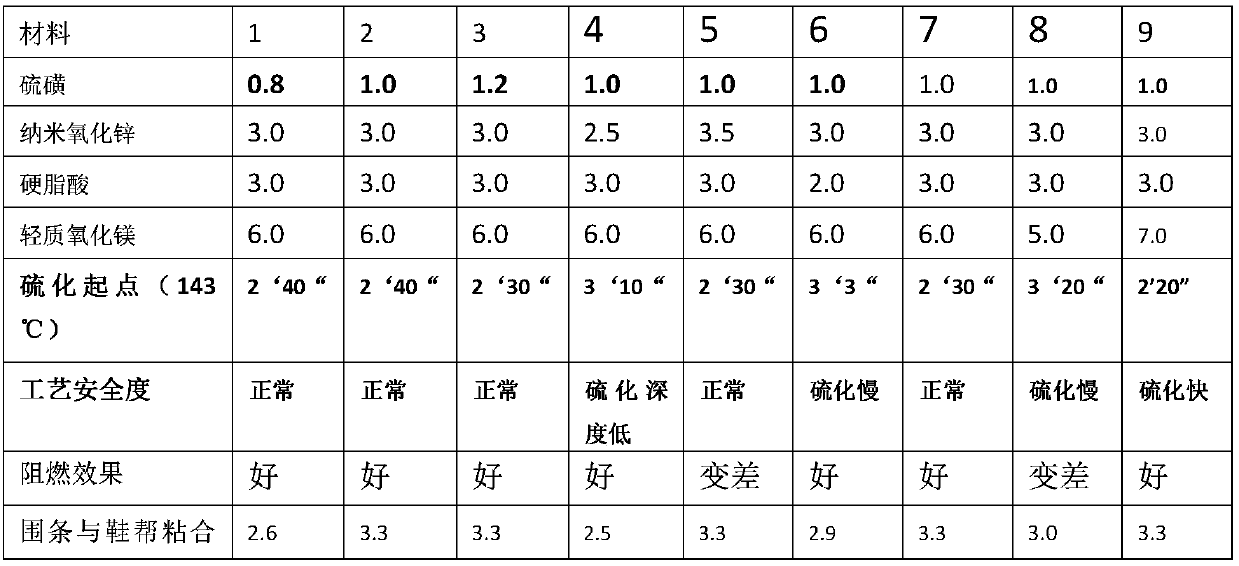

Black green flame-retardant shoe edge rubber for forest fire protection shoes and preparation method thereof

The invention discloses a black green flame-retardant shoe edge rubber for forest fire protection shoes. According to the invention, natural rubber and chloroprene rubber are used as the main materials, reinforcing filler and a softener are added to guarantee the physical properties of the rubber material, and the service life of a rubber sole is ensured, so that the shoe edge rubber has forest green coordination, and efficient flame retardants decabromodiphenyl oxide, chlorinated paraffin and zinc borate are adopted as a flame retardant system together to provide excellent flame retardance tothe product; the shoe edge rubber can generate a carbon layer during combustion, can achieve rapid flame retarding and no liquid drop transfer of fire, overcomes the defect of great flammability of conventional NR rubber compounds, has flame-retardant level up to the UL94V-0 level, and meets the self-extinguishing requirement in vertical combustion test. The shoe edge rubber provided by the invention has the characteristics of simple method, low cost and good use effect.

Owner:JIHUA 3537 SHOE MAKING

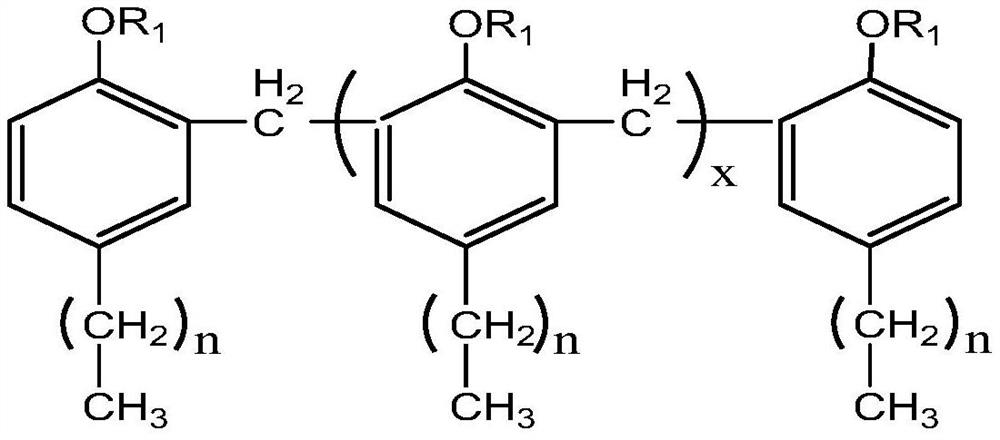

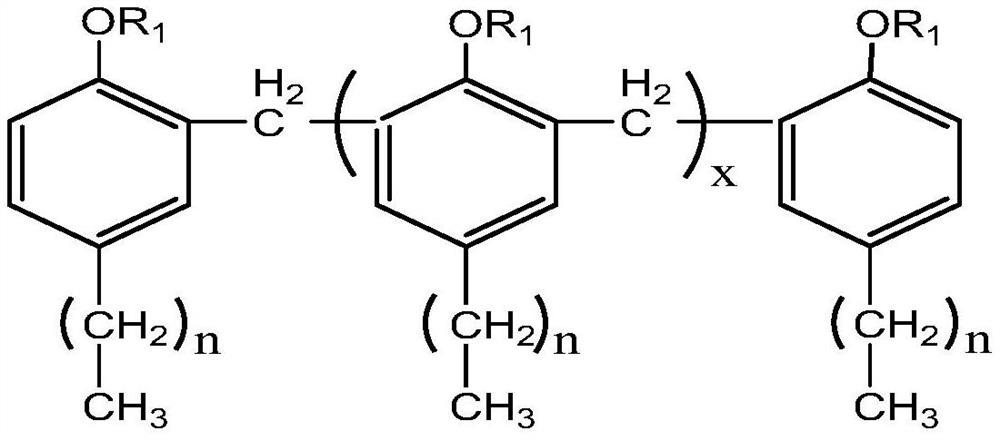

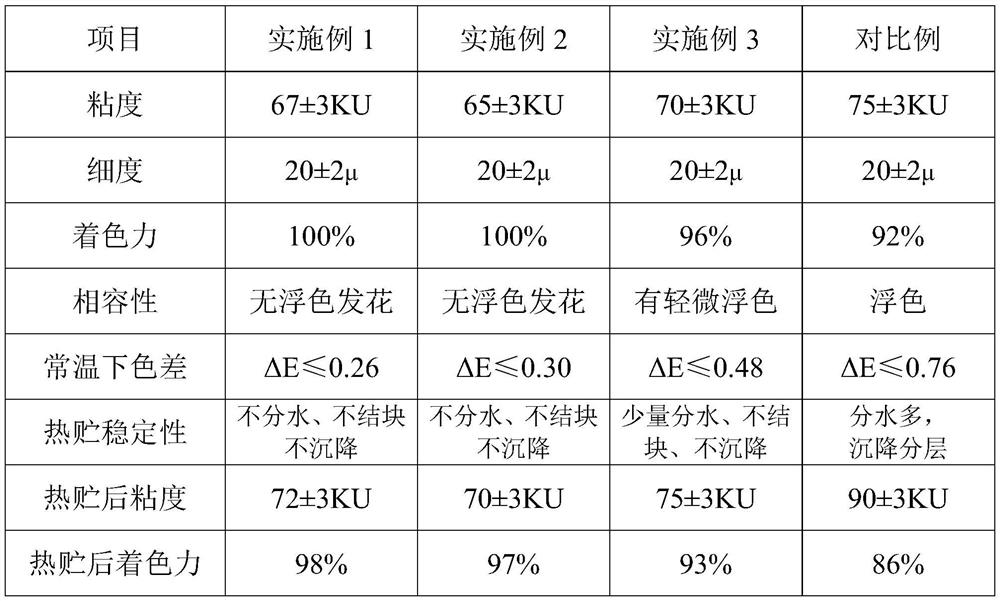

Comb-type alkylphenol polyoxyethylene ether aqueous dispersant and preparation method thereof

ActiveCN113634191AHigh tinting strengthImprove water resistanceTransportation and packagingMixingPolymer scienceAlkylphenol

The invention relates to a comb-type alkylphenol polyoxyethylene ether aqueous dispersant which is nonionic, the molecular structure of the dispersant contains an anchoring group and a hydrophilic group, the anchoring group is an alkylphenol pentamer chain segment, the hydrophilic group is a polyoxyethylene ether chain segment, and the molar ratio of the anchoring group to the hydrophilic group is 1:(60-75). The invention also provides a preparation method of the comb-type alkylphenol polyoxyethylene ether aqueous dispersant. The comb-type alkylphenol polyoxyethylene ether water-based dispersant prepared by the invention has excellent emulsifying, wetting and dispersing properties, excellent tinting strength and water resistance, stable hue and reduced flooding and floating, and can be used for preparing stable high-solid low-viscosity water-based pigment concentrated slurry. The dispersant can be used for dispersing organic pigments in a resin-free system, especially carbon black and phthalocyanine pigments which are difficult to disperse.

Owner:中山市钧纬新材料科技有限公司

Technology for dyeing silk fabric by using indigo pigment

InactiveCN106811995AUniform dyeing effectImprove working environmentDyeing processWorking environmentHue

The invention relates to a dyeing process of indigo dyed silk fabrics, which comprises the following steps: (1) placing the silk fabrics in an aqueous solution in which an alkali agent is dissolved for pretreatment. (2) placing the pretreated silk fabric in a protease solution for enzyme treatment. (3) Soak the silk fabric after the enzyme treatment in the dye material liquid that is configured with dispersant, dye cosolvent, alkali agent, reducing agent, acid agent, antioxidant, anti-over-reducing agent, leveling agent and dye it. The dyed silk fabric is washed and dried to obtain the dyed silk fabric. The invention adopts pretreatment and enzyme treatment for dyeing, which can make the dyeing effect uniform, and endow the fabric with better dyeing rate, abrasion fastness and washing fastness. The indigo dyeing method of the invention is convenient for automatic operation, has a good working environment and stable hue, and improves the competitiveness of products in the market.

Owner:苑少纯

An outdoor electrical insulation epoxy resin castable for transformer

ActiveCN103709608BGood weather resistanceImprove thermal shock resistancePlastic/resin/waxes insulatorsAntioxidantSilanes

The invention relates to an electric-insulation epoxy resin castable for an outdoor mutual inductor. The epoxy resin castable comprises the following materials by weight percent: 21-26% of resin, 45-55% of filling, 15-25% of a curing agent and 2-6% of other auxiliary agents, wherein the resin is formed by mixing organic silicon modified epoxy resin, phenolic aldehyde epoxy resin, brominated epoxy resin and bisphenol F-type epoxy resin; the filling is silane-processed silica powder; the curing agent is modified methylhexahydrophthalic anhydride; the other auxiliary agents include a curing catalyst, a plasticizer, a reactive diluent, a silane coupling agent, a coloring agent and an antioxidant. The electric-insulation epoxy resin castable has excellent physical and chemical properties and has the performance of heat resistance, low temperature resistance, ultraviolet irradiation resistance, ageing resistance and the like. The electric-insulation epoxy resin castable is applicable to the electric insulation of the outdoor mutual inductor and other electrical equipment.

Owner:JIANGXI TENGDE IND

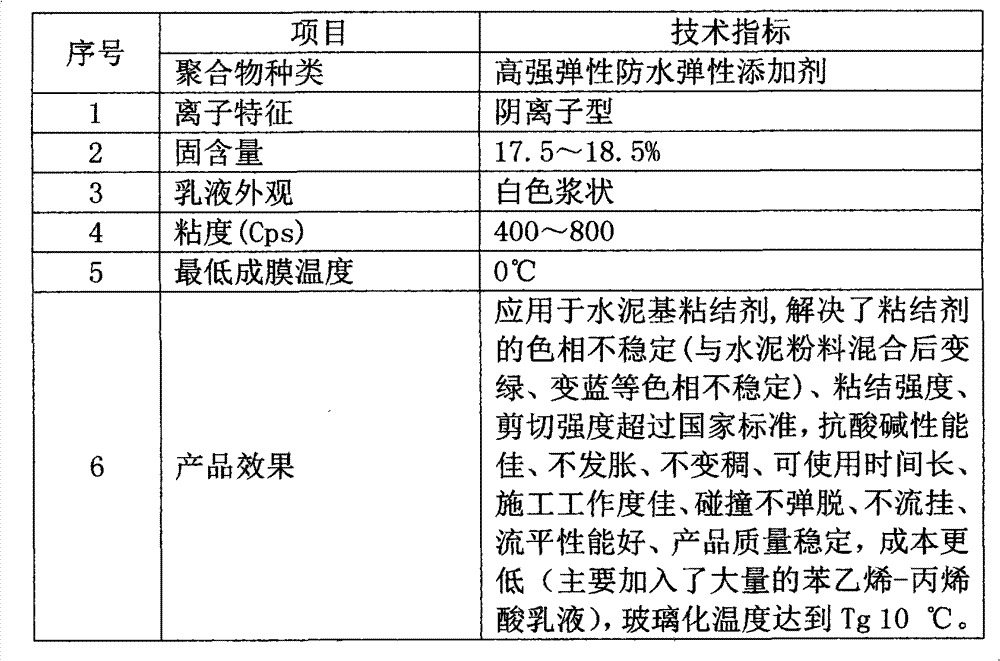

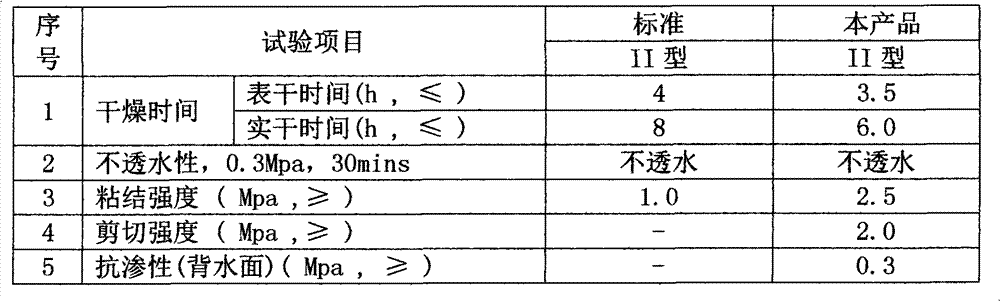

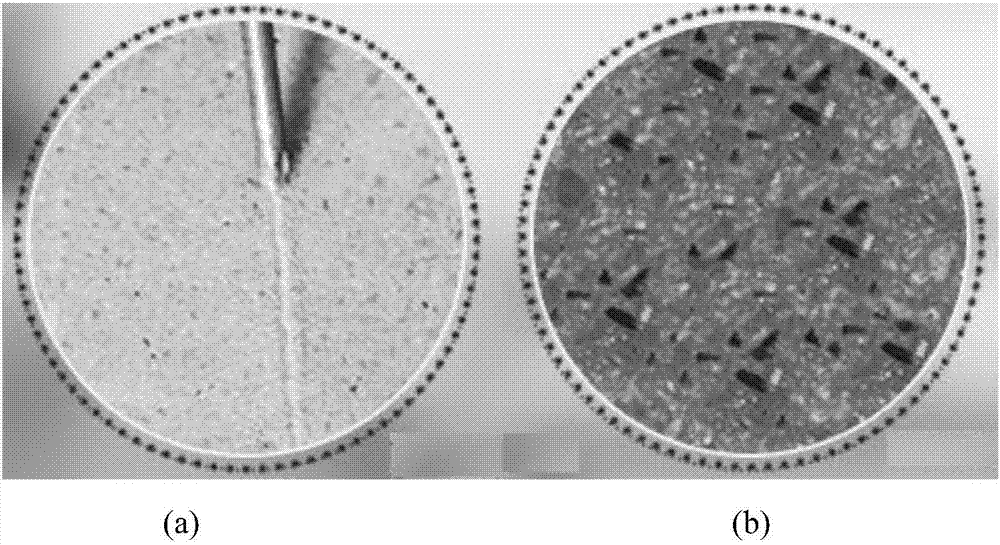

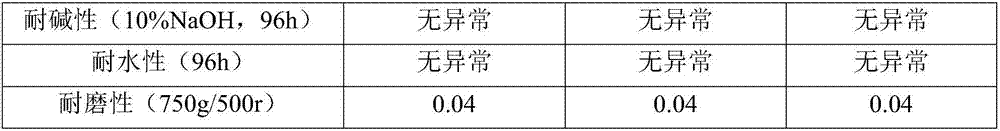

Elastic waterproof binder additive and preparation method thereof

InactiveCN102732184ALow costHue stabilityHydrocarbon polymer adhesivesFreeze thawingNational standard

The invention relates to an elastic waterproof binder additive and a preparation method thereof. The product is an elastic waterproof binder additive with improved performances and prepared by stirring and mixing three components, and the preparation method comprises the following steps of: respectively stirring, mixing, filtering and packaging. The elastic waterproof binder additive disclosed by the invention has the advantages that the additive is soft inside despite its hard shell, stable in hue, moderate in consistency, good in acid resistance and alkaline resistance, and easy to control, and the like; while the elastic waterproof binder additive is used for preparing an elastic cement-base waterproof binder, the elastic waterproof binder additive also has the characteristics that after the elastic waterproof binder additive is mixed with cement powder, the obtained product is stable in hue, the binding strength of the obtained product exceeds the requirements of national standards, and the obtained product is good in acid resistance and alkaline resistance, not bloated, not thickened, long in applicable time, good in construction operating degree, not flowing, strong in flow resistance, stable in product quality, low in cost, and the like; and the elastic waterproof binder additive is applied to the ceramic tile binding of exterior wall marbles, thin porcelain plates and ceramic tiles under high-strength freezing-thawing-resisting alternated bad temperature conditions.

Owner:郭曲玲

Silane concrete staining material and preparation method and application thereof

The invention discloses a silane concrete staining material. The silane concrete staining material consists of the following raw materials in parts by weight: 1-50 parts of alkoxy silane, 1-10 parts of a colorant and 40-96 parts of a solvent. The invention further provides a preparation method of the silane concrete staining material. The preparation method comprises the following steps: pouring the solvent in a stirring machine; adding the alkoxy silane and stirring the components for 3-10 minutes; and then adding the colorant and continuing stirring the components for 15-30 minutes to obtain the silane concrete staining material. The invention further provides an application method of the silane concrete staining material. The application method comprises the following steps: after polishing a concrete ground, spraying the staining material on the concrete ground; and after maintenance of the concrete ground, polishing the concrete ground again. Silicone resin is added in the staining material and is in an alkali system of concrete, when methoxyl or ethyoxyl breaks, the silicone resin and calcium ions or magnesium ion and the like in the concrete react and are polymerized, the colorant is sealed in the concrete, the staining effect is good, and wear resistance and durability are excellent.

Owner:CHONGQING EP ANTICORROSION TECH CO LTD

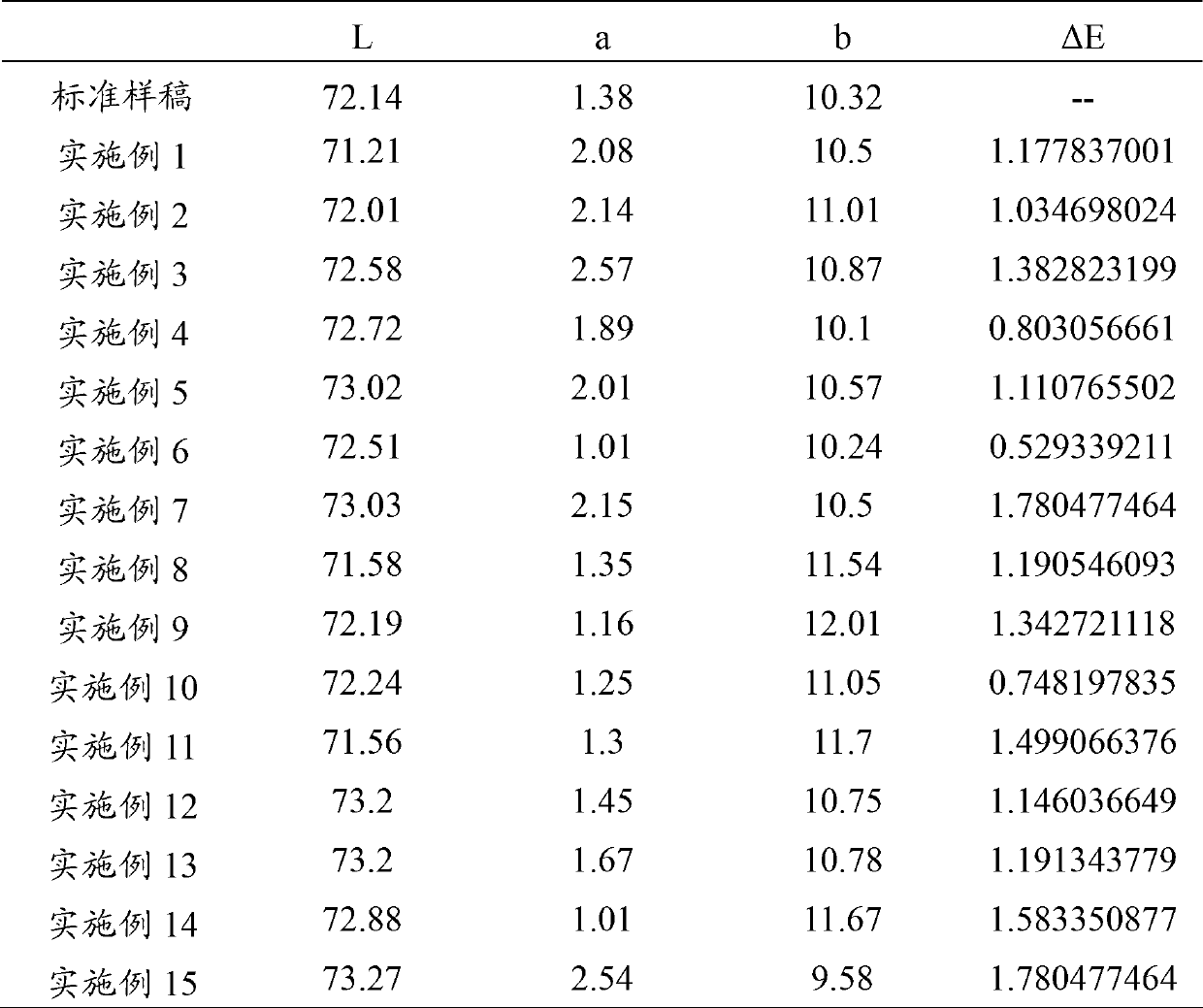

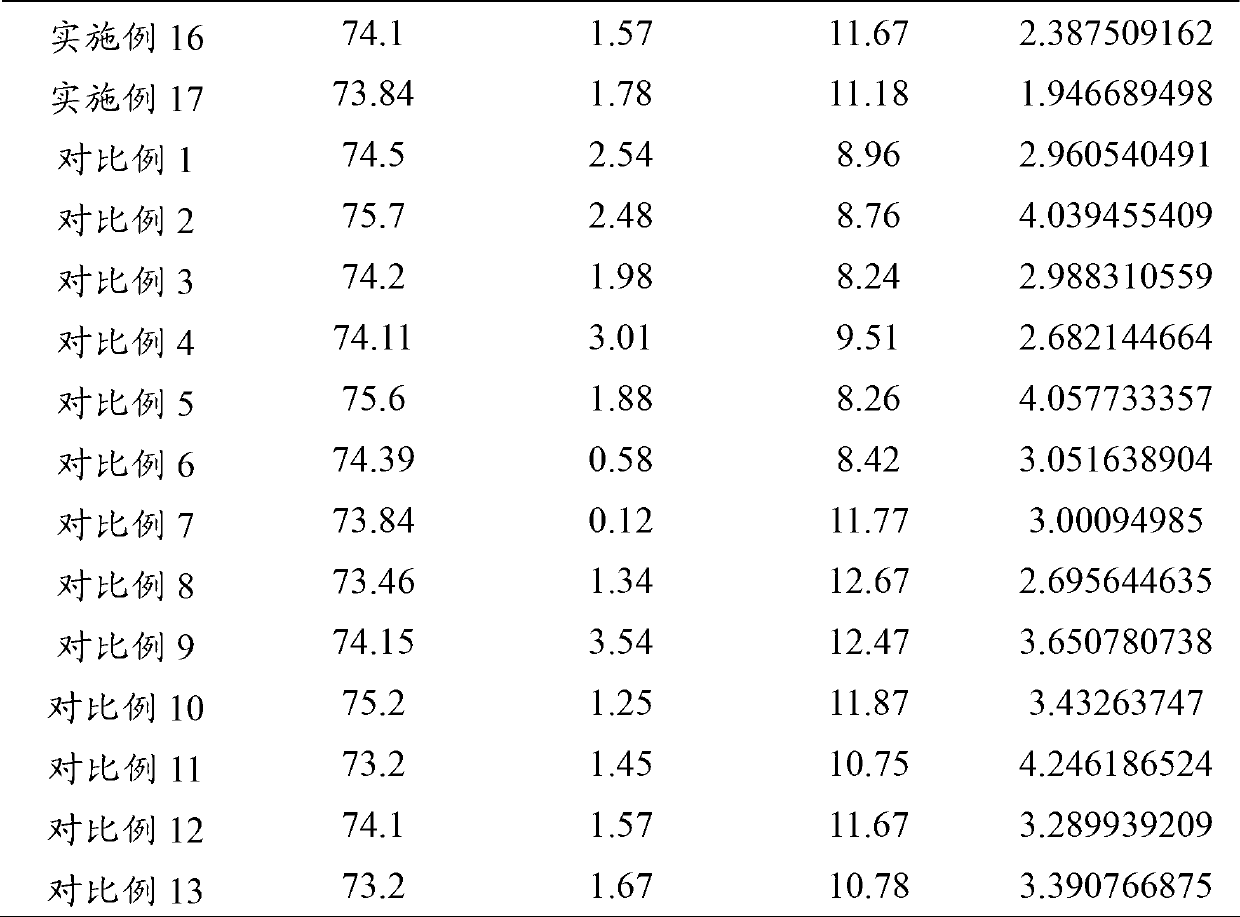

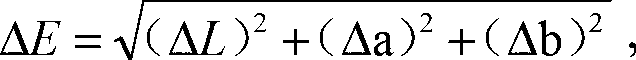

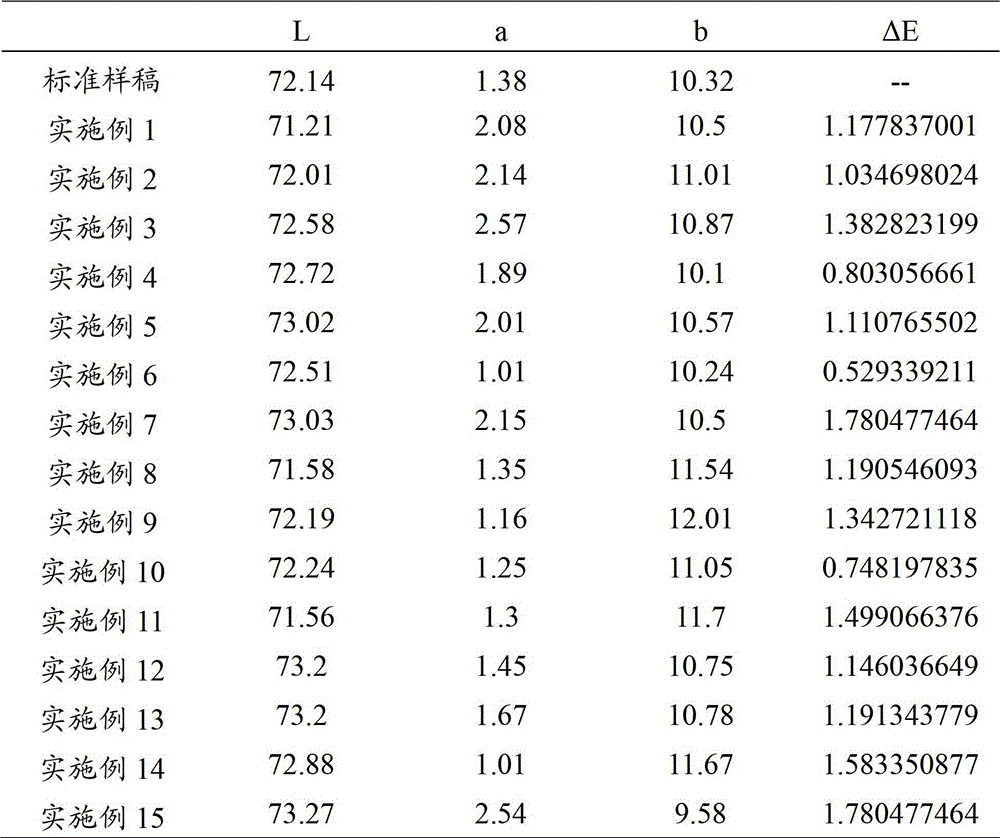

Preparation method of imitation gold cardboard, printing method of barcode and processing method of packaging products

ActiveCN102995487BMeet and exceed grade standard requirementsHue stabilityPaper coatingPattern printingHueStandard samples

The invention provides a preparation method of gold imitated card paper. According to the preparation method provided by the invention, gravure printing is adopted for transferring gold imitated gravure ink composition onto the surface of a silver card paper, and drying and curing are carried out, so that the gold imitated card paper is obtained. When the gold imitated card paper is taken as a printing stock during printing, the gold imitated card paper is not influenced by a printing process, hue of the gold imitated card paper is consistent with the hue of standard sample manuscript gold card paper, stable hue of the gold imitated card paper can be guaranteed, and a printing technology of the gold imitated card paper is simple. The invention also provides a bar code printing method. According to the bar code printing method provided by the invention, the gold imitated gravure ink composition is printed on the surface of the sliver card paper except a region in which a bar code is required to be printed, so that the region in which the bar code is required to be printed can not contain the gold imitated gravure ink composition and is in the colour of the silver card paper; and white gravure ink is overprinted in the region in which the bar code is required to be printed, and sign contrast between black bars is increased, so that the grade standard of the bar code is met.

Owner:CHANGDE JINPENG PRINTING

PET color master batch for water-based superfine fibers and preparation method thereof

InactiveCN110903617ALow costGood coloring effectPigment addition to spinning solutionMonocomponent polyesters artificial filamentNonwoven fabricAnoxomer

The invention discloses a PET color master batch for water-based superfine fibers. The PET color master batch comprises the following raw materials in percentage by mass: 30-80% of a carrier, 10-50% of a coloring agent, 3-15% of a dispersing agent, 3-15% of a compatibilizer, 3-10% of a slip agent, 3-20% of an antistatic agent, 0.5-20% of modified inorganic filler and 0.1-1% of an antioxidant. By adopting the PET color master batch for water-based superfine fibers, the performances of superfine fiber spinning, non-woven fabric processing and the like are guaranteed, and the problems of coloringand color migration of a final product are solved. The PET color master batch for water-based superfine fibers is low in cost, strong in coloring agent and carrier effect, good in coloring effect, simple in production and preparation process, small in environmental pollution, good in compatibility and liquidity in the spinning process and not prone to yarn breakage, and the final product is stable in hue and free of color migration.

Owner:明新梅诺卡(江苏)新材料有限公司

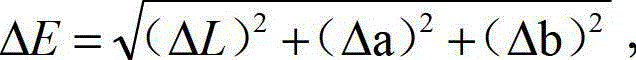

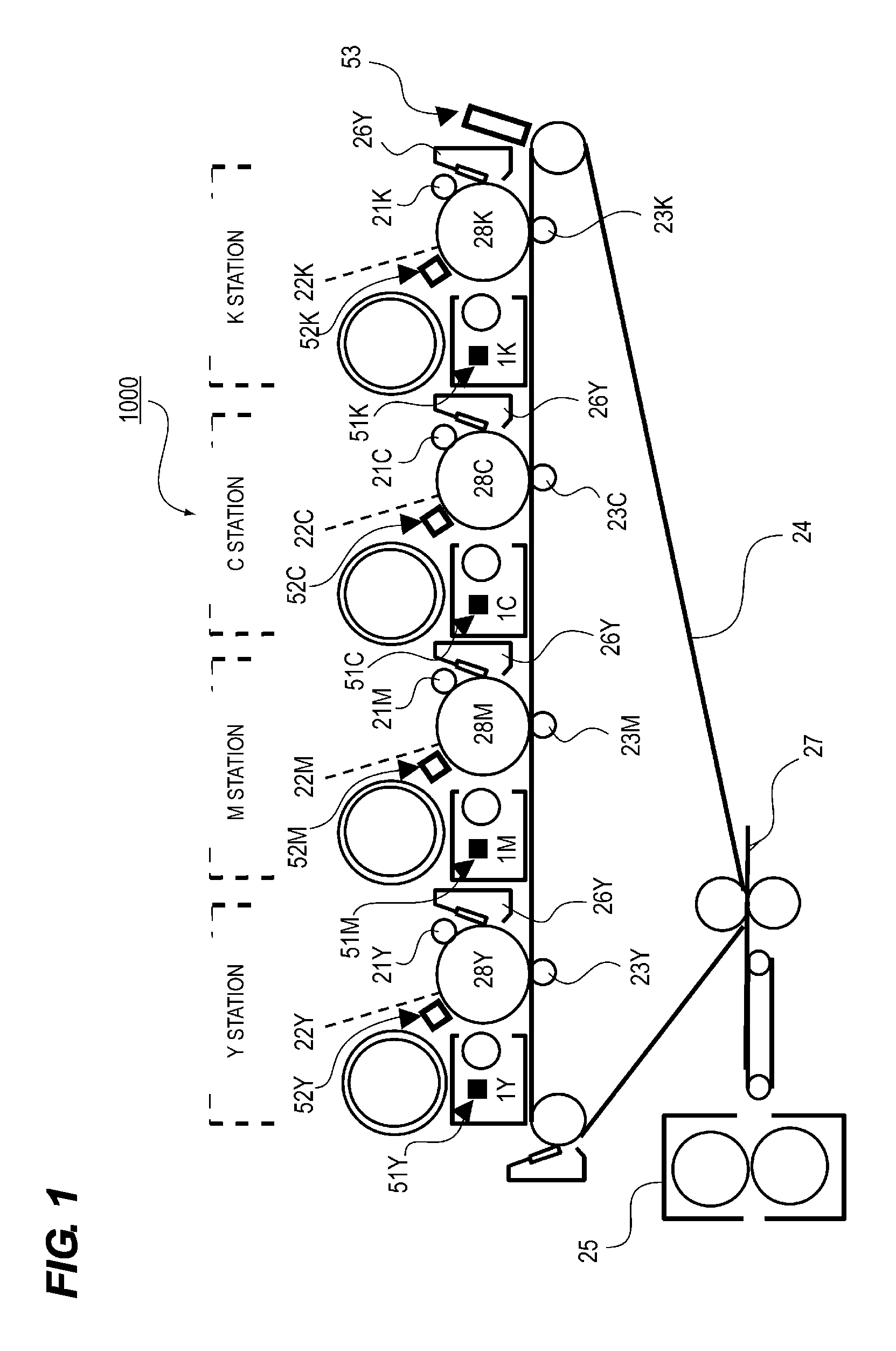

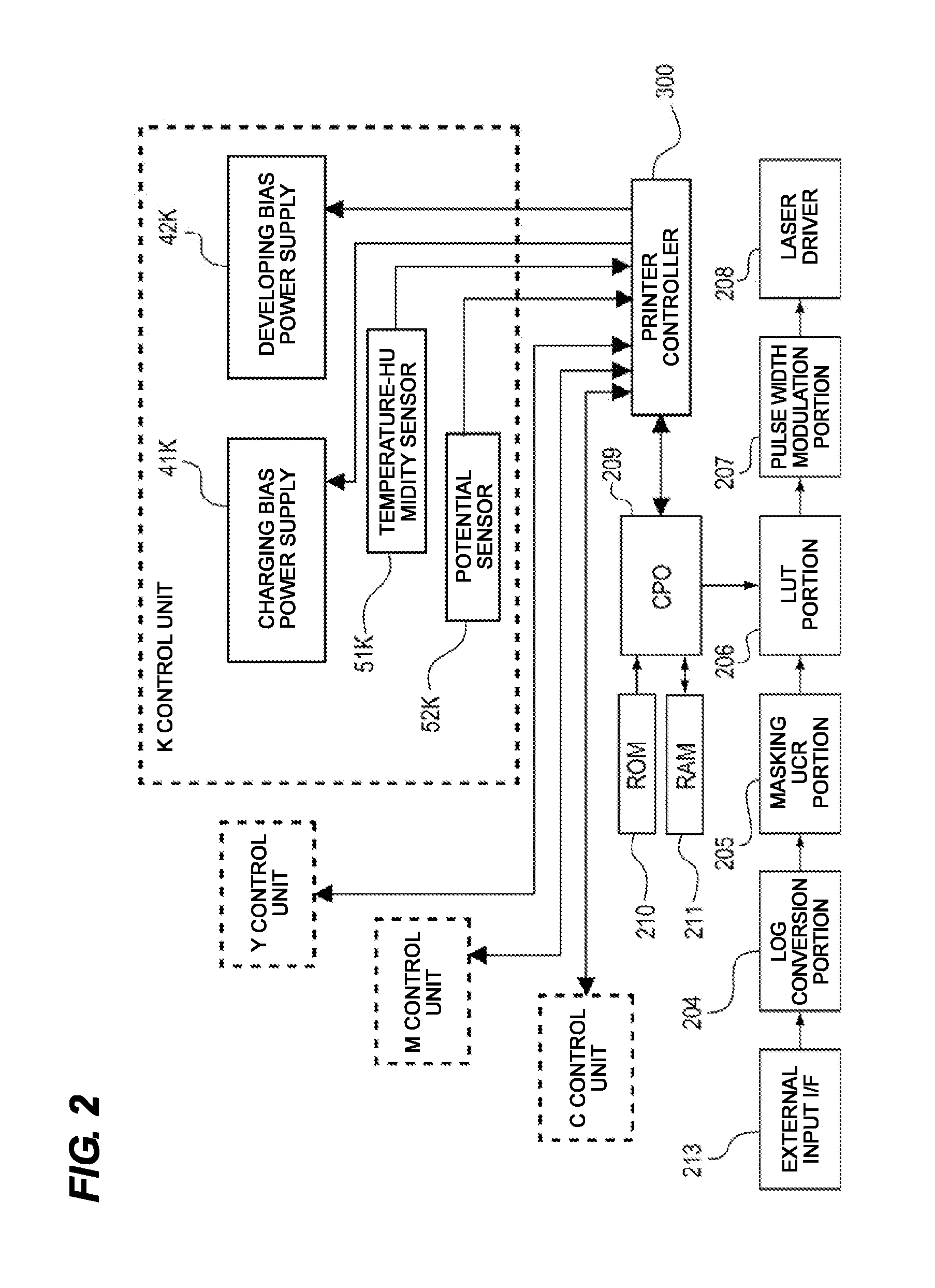

Image forming apparatus

InactiveUS20130136469A1Efficient adjusting operationStay productiveElectrographic process apparatusImage formationImage density

An image forming apparatus includes photoconductor drums, a plurality of development apparatuses, temperature-humidity sensors that detects at least temperatures or humidity of the development apparatuses, image density adjusting units that adjusts an image density of the toner image, and a control unit that adjusts the image density of the toner image by the image density adjusting units based on detection results of the temperature-humidity sensors. The control unit controls the adjusting unit based on information about color differences of detection values of the temperature-humidity sensors so that the adjusting unit adjusts an image density of the toner image or not.

Owner:CANON KK

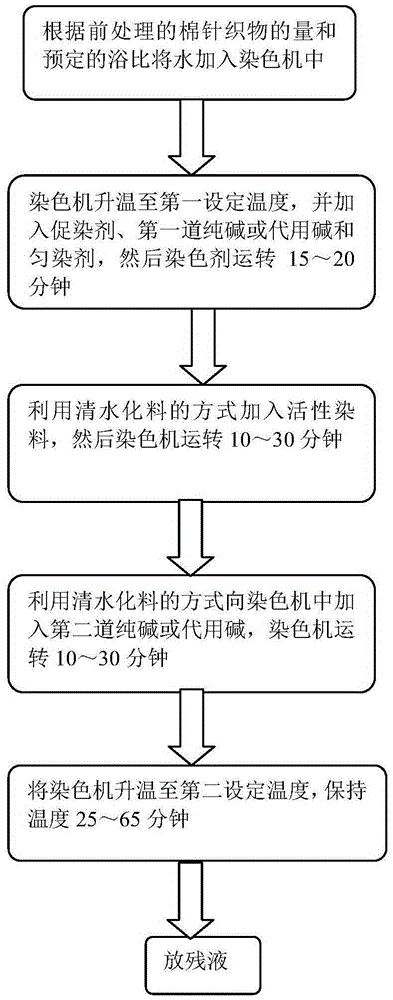

Dyeing Technology of Cotton Knitted Fabric

ActiveCN103924461BGood extensibilityImprove dyeing first time successDyeing processCOTTON WOOLProcedure time

The invention discloses a dyeing process for cotton knitted fabric. The dyeing process mainly aims to improve the one-time success probability of dyeing. The dyeing process at least comprises the steps that dyeing accelerating agents, first sodium carbonate or substitution alkali and levelling agents are added to a dyeing machine; reactive dyes and second sodium carbonate or substitution alkali are added to the dyeing machine in the mode of dissolving materials with clear water; the dyeing machine is heated to a second set temperature, and the second set temperature is kept for 25 to 65 minutes. Before the dyes are added, the dyeing accelerating agents of anhydrous sodium sulphate and the sodium carbonate or the substitution alkali for fixing colors are added, the mode of dissolving the materials with the clear water is adopted twice to add the dyes and the second sodium carbonate or substitution alkali for subsection heating, the general character and the specific characters of the reactive dyes are comprehensively considered, such as proaporphine, temperature types and salt types, the dye yield and levelling property of the process are improved, the number of the adopted dyes is reduced, dyeing defects are overcome, the color phase is stable, the number of the steps is small, the operation is simple and easy to control, the procedure time is short, and the one-time success probability of dyeing is comprehensively improved.

Owner:JIHUA 3543 KNITTING CLOTHING

Water-based ink ball pen

The present invention relates to a water-based ink for ball pens which comprises a water-soluble organic solvent, water, and a polysaccharide and in which two particulate pigments consisting of a colored pigment and a metallic pigment are present in the same pigment phase as aggregates in the form of spots with the aid of the water-soluble polymer serving as a binder to form a spot-form composite aggregate phase in the ink. The water-based ink for a ballpoint pen is excellent in long-term storage stability which prevents a separation-phenomenon of a colored pigment in ink, a color separation-phenomenon where light and shade of developed color appear on handwriting, can give handwriting having stable hue and can prevent generation of an ink leak and overflow of ink during long-term use thereof.

Owner:SAKURA COLOR PRODUCTS CORPORATION

Grinding process for grinding heat transfer printing color paste

The invention provides a grinding device for grinding a heat transfer printing color paste. The grinding device comprises a base rack, wherein the base rack is fixedly provided with a sand mill, a control assembly and a power assembly; the power assembly comprises a motor, and the sand mill comprises a grinding barrel and a plurality of grinding media positioned in the grinding barrel. The grinding device further comprises a circulating assembly, wherein the circulating assembly comprises a circulating barrel, a circulating pump and a plurality of conduits. The discharge port of the grinding barrel is communicated with the feed port of the circulating barrel by virtue of the conduit, and the feed port of the grinding barrel and the discharge port of the circulating barrel are respectively connected with the outlet and inlet of the circulating pump. The invention further provides a grinding process utilizing the grinding device. The grinding device provided by the invention has the characteristics of simple structure, favorable heat dissipation effect, low noise, capability of continuous production, low production cost, high grinding efficiency, and high quality of grinded products.

Owner:ZHUHAI FREE TRADE ZONE NEOJET APOLLOJET IMAGING MATERIALS

Kraft paper production process

ActiveCN105568736BGuaranteed lengthImprove production problemsNatural cellulose pulp/paperPulp beating methodsDry weightMasson pine

The invention discloses a manufacture process of brown paper. According to the manufacture process, logs are taken as raw material, and body paper is obtained by digesting, blanching, screening, beating, sizing, deslagging, forming on a net, squeezing, drying, rolling and calendering. Beating of the logs is performed by respectively beating and mixing oak, birch, cedar, camphor tree, masson pine, sago cycas and bagasse in an absolute dry weight ratio of (20-40):(10-20):(20-40):(10-20):(40-60):(10-20):25 to obtain a mixed pulp. According to the invention, the types, ratio and beating degree of fibers of pulp of the body paper can be regulated, the surface of the body paper is coated with a film, and the fiber strength can be enhanced by changing technological parameters in each step, thereby obtaining better bursting resistance, water proofness and printing performance.

Owner:周庆芬

Aftertreatment method for liquid disperse dye

InactiveCN101724298BNot easy to settleImprove stabilityOrganic dyesDyeing processDisperse dyeSocial benefits

The invention provides an aftertreatment method for a liquid disperse dye. The aftertreatment method for the liquid disperse dye comprises the following steps: adding water to dissolve a filter cake containing the liquid disperse dye, which is obtained by diazotization, coupling and filtering, to obtain slurry with a solid content of 30 to 50 percent; adding polyglyceryl fatty acid ester surfactants of which the mass is 0.1 to 10 percent of that of the slurry and phenyl amines compounds of which the mass is 0.2 to 2 percent of that of the slurry; stirring and pulping for 1 to 5 hours; raisingthe temperature to between 80 and 110 DEG C and keeping the temperature for 1 to 7 hours; cooling to the normal temperature; adding a dispersing agent or dispersing agent of which the mass is 0.3 to 1 time of that of the dry weight of the filter cake; performing particle processing for 1 to 10 hours by a breaking device, and obtaining slurry; adding a thickening agent of which the mass is 0.1 to 0.3 percent of that of the slurry to the slurry with stirring; continuing to stir for 1 to 2 hours after finishing material addition; and filtering to obtain the liquid disperse dye. The method for preparing the liquid disperse dye has the advantages of low cost, simple operation, active role in environmental protection, and greater economic and social benefits.

Owner:浙江龙盛染料化工有限公司 +1

Kraft card production process

ActiveCN105507058BImprove production problemsImprove bindingPaper coatingPulp bleachingUltimate tensile strengthSizing

The invention discloses a production technology for a kraft liner board. The production technology includes the steps that log is used as a raw material, base paper is obtained through cooking, bleaching, screening, beating, sizing, residue removing, forming on forming fabric, squeezing, drying, rolling and calendaring, and according to log beating, oak, moso bamboo, dendrocalamus giganteus, fir, deodar, sago cycas and bagasse by the absolute dry mass ratio of (20-40):(10-20):(10-20):(20-40):(30-50):(10-20):15 are beaten and mixed to obtain mixed pulp. The kind, the ratio and the beating degree of pulp fibers of the base paper can be adjusted, the surface of the base paper is sequentially coated with a glue layer and a coating layer, and technological parameters of all steps are changed to improve the fiber strength and obtain higher pop strength, waterproofness and printing performance.

Owner:周庆芬

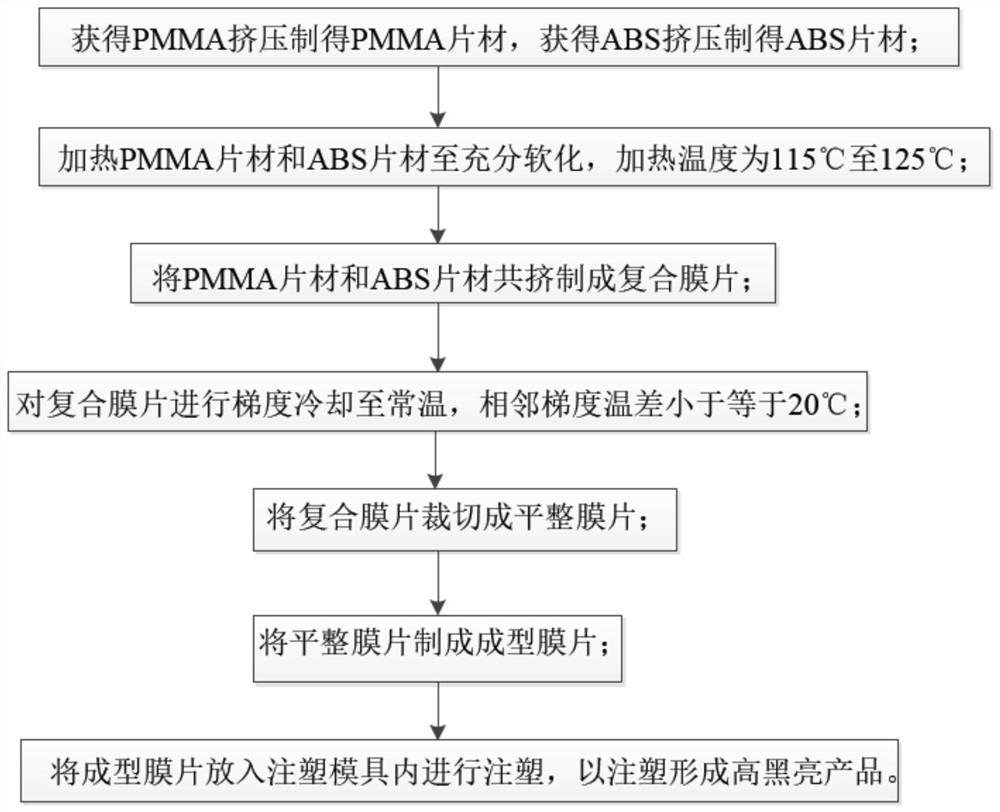

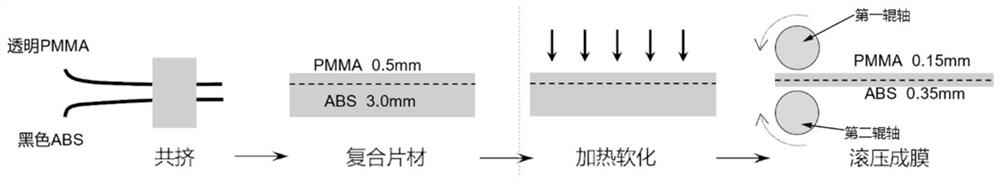

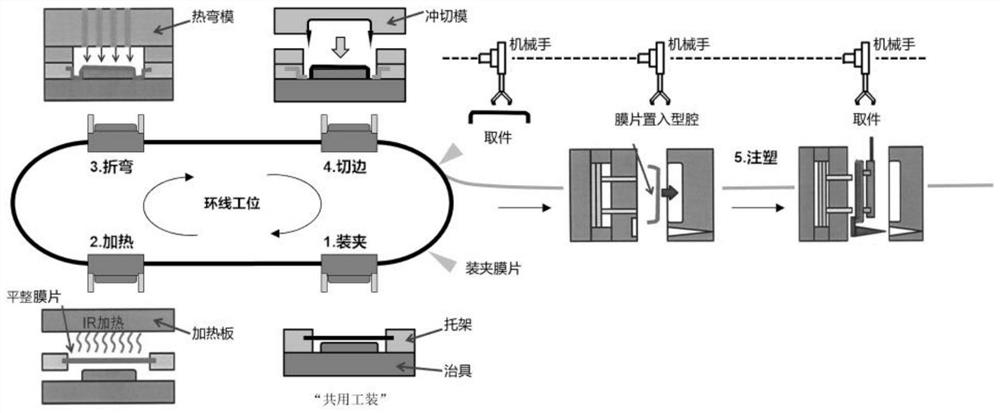

Manufacturing process of high-brightness black product

PendingCN114734579AHue stabilityImprove 3D formabilityCoatingsPolymer sciencePolymethyl methacrylate

The invention provides a manufacturing process of a high-brightness black product. The manufacturing process comprises the following steps: extruding PMMA (Polymethyl Methacrylate) to obtain a PMMA sheet, and extruding ABS (Acrylonitrile Butadiene Styrene) to obtain an ABS sheet; heating the PMMA sheet and the ABS sheet until the PMMA sheet and the ABS sheet are fully softened, wherein the heating temperature is 115-125 DEG C; co-extruding the PMMA sheet and the ABS sheet to prepare a composite membrane; carrying out gradient cooling on the composite membrane to normal temperature, wherein the adjacent gradient temperature difference is less than or equal to 20 DEG C; cutting the composite membrane into a flat membrane; the flat membrane is made into a formed membrane; and putting the formed film into an injection mold for injection molding to form a high-black-and-bright product. According to the manufacturing process of the high-brightness black product, the composite membrane is prefabricated, and injection molding is directly carried out on the composite membrane, so that the hue of the high-brightness black product is stable, the consistency of a mass production stage and a small sample plate stage is good, and the development and debugging period is shortened.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com