Aqueous bronze pigment and preparation method thereof

A copper-gold and pigment technology, which is applied in the field of water-based copper-gold pigment and its preparation, can solve the problems of incomplete coating, unstable hue, uneconomical and environmental protection, etc., and achieve stable hue, simple preparation method, and firm coating full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

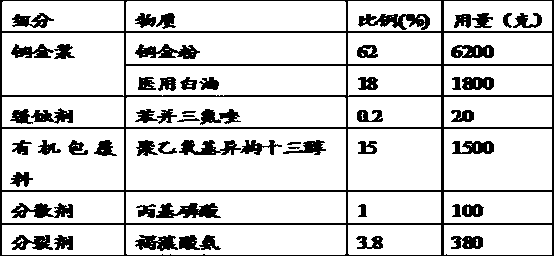

[0032] Water-based copper-gold pigments have the following components:

[0033]

[0034] The preparation method of water-based copper-gold pigment is as follows:

[0035] Step 1: Add 1,800 grams of medical white oil to 6,200 grams of copper-gold powder, and stir in a kneader for half an hour to form a copper-gold slurry.

[0036] Step 2: Add 20 grams of benzotriazole corrosion inhibitor, stir for half an hour, and mix well.

[0037] Step 3: Add 1500 grams of polyethoxy isomeric tridecanol and 100 grams of propyl phosphoric acid, stir for two hours, and mix well.

[0038] Step 4: Add 380 grams of ammonium alginate, stir for one hour, and mix well.

[0039] Step 5: Take out the slurry mixture, and use screw extrusion to granulate. The diameter of the particles is 3mm.

[0040] Step 6: Vacuum-dry the manufactured pellets in a baking tray to remove the solvent, the baking temperature is 70°C, and the vacuum degree is -100kPa.

Embodiment 2

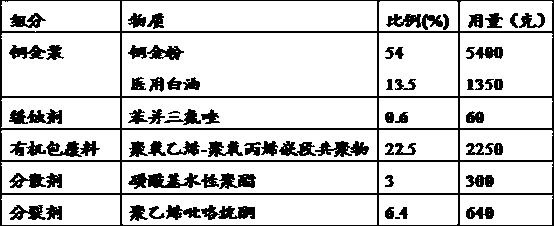

[0042] Water-based copper-gold pigments have the following components:

[0043]

[0044] The preparation method steps of water-based copper-gold pigment are as follows:

[0045] Step 1: Add 1,350 grams of medical white oil to 5,400 grams of copper-gold powder, and stir in a kneader for half an hour to form a copper-gold paste.

[0046] Step 2: Add 60 grams of benzotriazole corrosion inhibitor, stir for half an hour, and mix well.

[0047] Step 3: Add 2250 grams of polyoxyethylene-polyoxypropylene block copolymer and 300 grams of sulfonic acid-based water-based polyester, stir for two hours, and mix well.

[0048] Step 4: Add 640 grams of polyvinylpyrrolidone, stir for one hour, and mix well.

[0049] Step 5: Take out the slurry mixture, and use screw extrusion to granulate. The diameter of the particles is 5mm.

[0050] Step 6: Vacuum-dry the manufactured pellets in a baking tray to remove the solvent, the baking temperature is 50°C, and the vacuum degree is -90kPa.

Embodiment 3

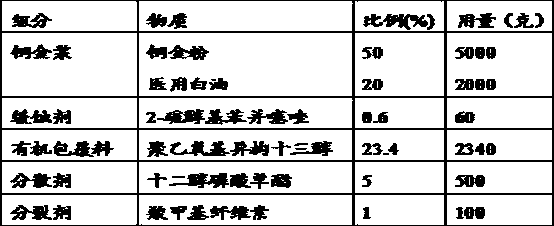

[0052] Water-based copper-gold pigments have the following components:

[0053]

[0054] The preparation method steps of water-based copper-gold pigment are as follows:

[0055] Step 1: Add 1,200 grams of medical white oil to 4,300 grams of copper-gold powder, and stir in a kneader for half an hour to form a copper-gold paste.

[0056]The second step: add 100 grams of 2-mercaptobenzothiazole corrosion inhibitor, stir for half an hour, and mix well.

[0057] Step 3: Add 3000 grams of polyoxyethylene-polyoxypropylene block copolymer and 400 grams of sodium polyacrylate, stir for two hours, and mix well.

[0058] Step 4: Add 1000 grams of cross-linked polyvinylpyrrolidone, stir for one hour, and mix well.

[0059] Step 5: Take out the slurry mixture, and use screw extrusion to granulate. The diameter of the particles is 4mm.

[0060] Step 6: Vacuum-dry the produced pellets in a baking tray to remove the solvent, the baking temperature is 90°C, and the vacuum degree is -80kP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com