Preparation method of imitation gold cardboard, printing method of barcode and processing method of packaging products

A processing method and barcode technology, which are applied in the processing of packaging products, the preparation of imitation gold cardboard, and the printing of barcodes, can solve the problems of low barcode level, narrowing the difference between white and black stripes, yellowing, etc. Stable, simple printing process results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

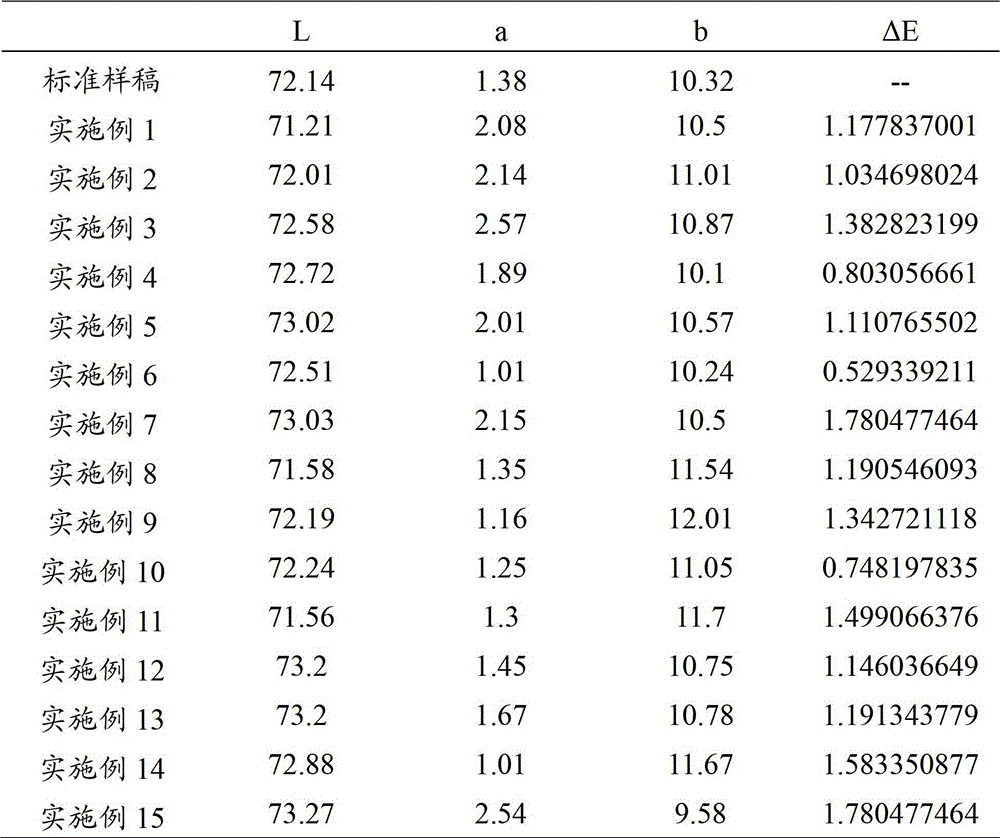

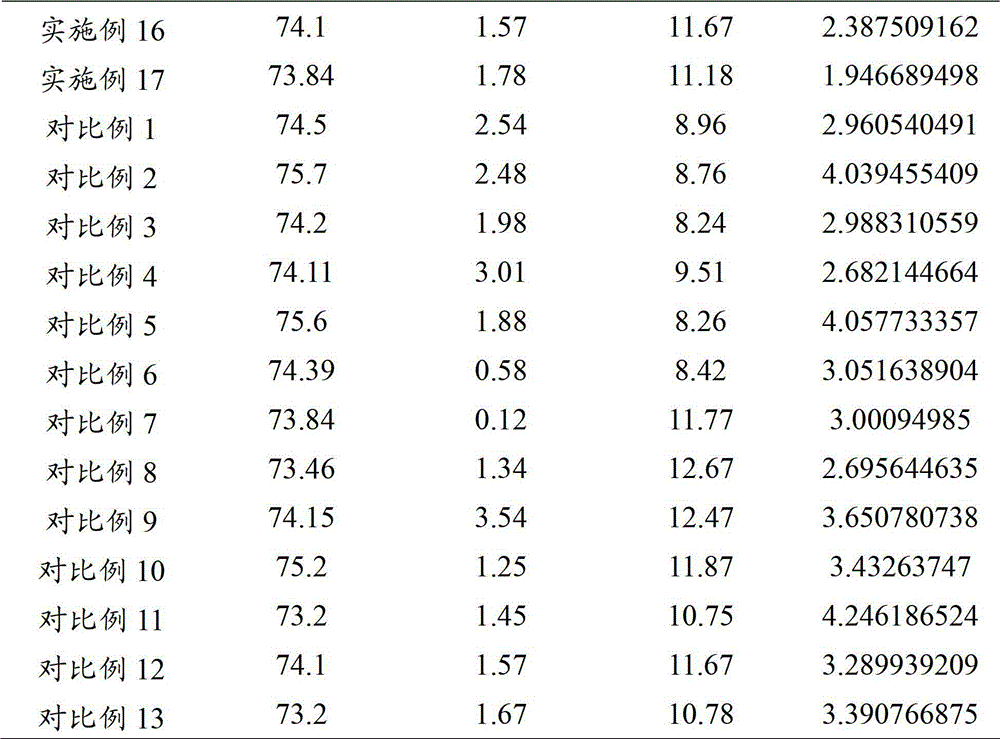

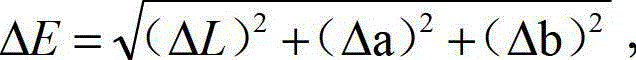

[0046] The invention provides a method for preparing imitation gold cardboard, which uses gravure printing to transfer a gold imitation gravure ink composition to the surface of silver cardboard, and obtains the imitation gold cardboard after drying and curing.

[0047] The present invention uses silver cardboard as a raw material to prepare imitation gold cardboard with the effect of gold cardboard. The silver cardboard is a kind of matte paper, and the present invention does not have any restrictions on its source. Paper will do.

[0048] In the present invention, gravure printing is used to transfer the imitation gold gravure ink composition to the surface of the silver cardboard. The gold imitation gravure ink composition is a gravure ink composition prepared according to the hue of the standard sample, which is consistent with the surface color of the standard sample. The golden-like gravure ink composition provided by the present invention can be the golden-like gravure...

Embodiment 1

[0095] Mount the silver card stock on the web gravure press.

[0096] With 40wt% water-based acrylic resin; 12wt% Lisol Baohong BK; 13wt% permanent yellow HR; 10wt% dehydrated alcohol; 1wt% diethylene glycol monobutyl ether; 12wt% isopropanol The water of 9.9wt%; The silicone oil of 2wt% and the polyethylene wax of 0.1wt% are formulated into water-based gravure printing ink, and the printing viscosity of described water-based gravure printing ink is 20s.

[0097] The water-based gravure ink was attached to the surface of the gravure roll, and the ink was scraped evenly, wherein the plate-making depth of the gravure roll was 20 μm.

[0098] A pressure of 20KN was applied to the gravure roll to make the silver cardboard contact with the gravure roll, and the water-based gravure ink was transferred to the surface of the silver cardboard, and the printing temperature was 100°C.

[0099] The silver cardboard printed with the water-based gravure ink is dried and solidified to obtai...

Embodiment 2

[0102] Mount the silver card stock on the web gravure press.

[0103] 40wt% of water-based acrylic resin; 12.1wt% of Lisol Baohong BK; 12.9wt% of permanent yellow HR; 10wt% of absolute ethanol; 1wt% of diethylene glycol monobutyl ether; 12wt% of iso Propanol; 9.9wt% of water; 2wt% of silicone oil and 0.1wt% of polyethylene wax are prepared into water-based gravure ink, and the printing viscosity of the water-based gravure ink is 20s.

[0104] The water-based gravure ink was attached to the surface of the gravure roll, and the ink was scraped evenly, wherein the plate-making depth of the gravure roll was 20 μm.

[0105] A pressure of 20KN was applied to the gravure roll to make the silver cardboard contact with the gravure roll, and the water-based gravure ink was transferred to the surface of the silver cardboard, and the printing temperature was 100°C.

[0106] The silver cardboard printed with the water-based gravure ink is dried and solidified to obtain imitation gold card...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com