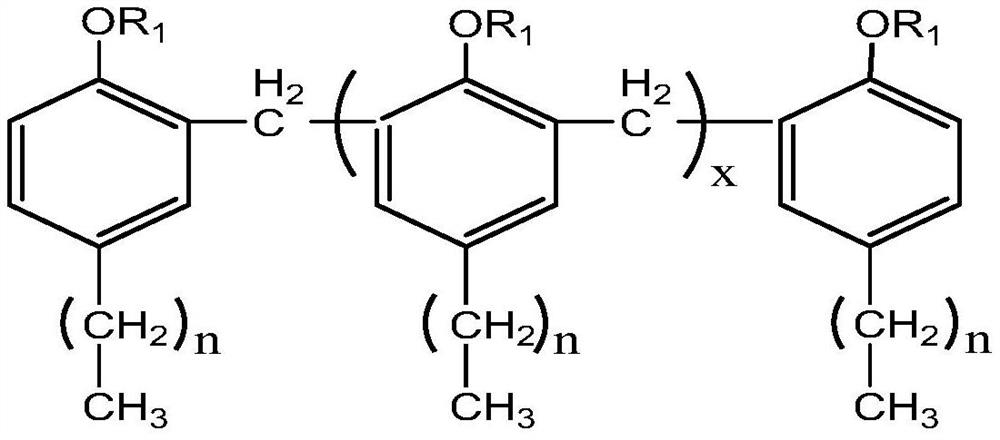

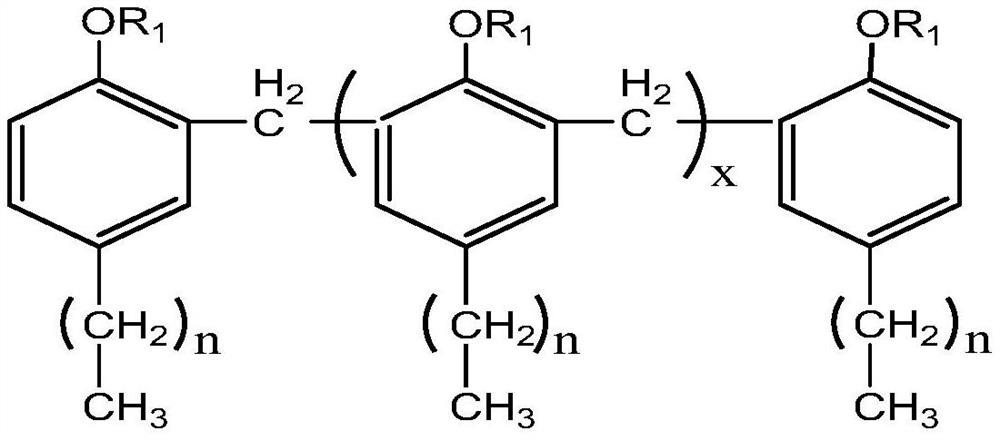

Comb-type alkylphenol polyoxyethylene ether aqueous dispersant and preparation method thereof

A technology of alkylphenol polyoxyethylene ether and water-based dispersant, which is applied in chemical instruments and methods, bulk chemical production, dissolution, etc. It can solve the problems that cannot meet the dispersion and stability of pigments, reduce surface tension, etc., and achieve excellent coloring Strength and water resistance, excellent emulsification, reduced floating and blooming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

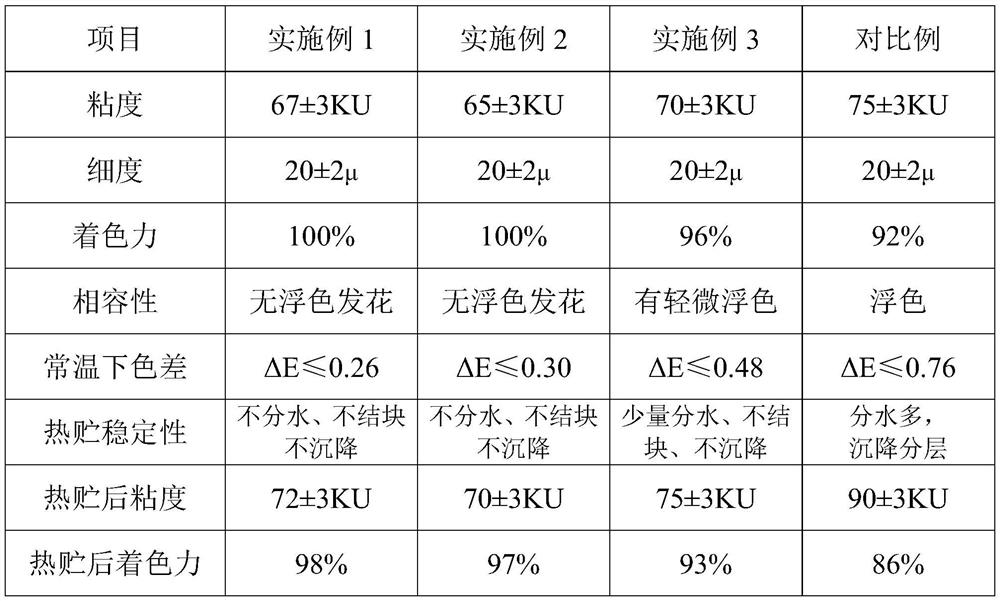

Examples

Embodiment 1

[0027] A comb-type alkylphenol polyoxyethylene ether aqueous dispersant, the preparation steps of which are as follows:

[0028] a), in parts by weight, in a reaction kettle equipped with stirring, reflux water separation, vacuum cooling, and dropping device, add 1100.0 parts of n-nonylphenol and 2.5 parts of p-toluenesulfonic acid catalyst, in N 2 Under protection, start stirring and raise the temperature to 120°C, start to add 328.5 parts of 37% formaldehyde dropwise, finish the drop within 2 hours, raise the temperature to 130°C, add 20.0 parts of D40 dearomatized solvent oil according to the viscosity of the reaction material after reacting for 4 hours, and then raise the temperature to 140°C Continue to react for 2h, lower the temperature to 120°C, turn off the N 2 Open a vacuum and reduce pressure to extract water and unreacted formaldehyde to obtain pentameric nonylphenol;

[0029] b), add pentamer nonylphenol, 7.5 parts of catalyst KOH and 25.0 parts of D40 dearomatiz...

Embodiment 2

[0032] A comb-type alkylphenol polyoxyethylene ether aqueous dispersant, the preparation steps of which are as follows:

[0033] a), in parts by weight, in a reactor equipped with stirring, reflux water diversion, vacuum cooling, and dripping device, add 586.0 parts of n-decylphenol, 2.0 parts of condensation solid acid catalyst, in N 2 Under protection, start stirring and raise the temperature to 120°C, start to add 165.0 parts of 37% formaldehyde dropwise, finish the drop within 2 hours, raise the temperature to 130°C, add 12.5 parts of D40 dearomatized solvent oil according to the viscosity of the reaction material after reacting for 4 hours, and then raise the temperature to 140°C Continue to react for 2h, lower the temperature to 120°C, turn off the N 2 Open vacuum and reduce pressure to extract water and unreacted formaldehyde to obtain pentameric decylphenol;

[0034] b), add pentameric decylphenol, 6.0 parts of catalyst KOH and 15.0 parts of D40 dearomatization solven...

Embodiment 3

[0037] A comb-type alkylphenol polyoxyethylene ether aqueous dispersant, the preparation steps of which are as follows:

[0038] a), in parts by weight, in a reactor equipped with stirring, reflux water separation, vacuum cooling, and dropping device, add 787.2 parts of n-dodecylphenol and 3.0 parts of p-toluenesulfonic acid catalyst, N 2 Under protection, start stirring and raise the temperature to 120°C, start to add 197.5 parts of 37% formaldehyde dropwise, finish the drop within 2 hours, raise the temperature to 130°C, add 16.0 parts of D40 dearomatization solvent oil according to the viscosity of the reaction material after reacting for 6 hours, and then raise the temperature to 140°C Continue to react for 2h, lower the temperature to 120°C, turn off the N 2 Open a vacuum and reduce pressure to extract water and unreacted formaldehyde to obtain pentameric dodecylphenol;

[0039] b), add pentamer dodecylphenol, catalyst KOH 9.0 parts and D40 dearomatization solvent oil 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com