Preparation method of polyester film for coating tag

A polyester film and coating technology, applied in the field of polyester film, can solve the problems of low bonding force between ink and film surface, corona value attenuation, no water resistance and alcohol resistance, etc., to avoid corona attenuation, ink High adhesion and stable hue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

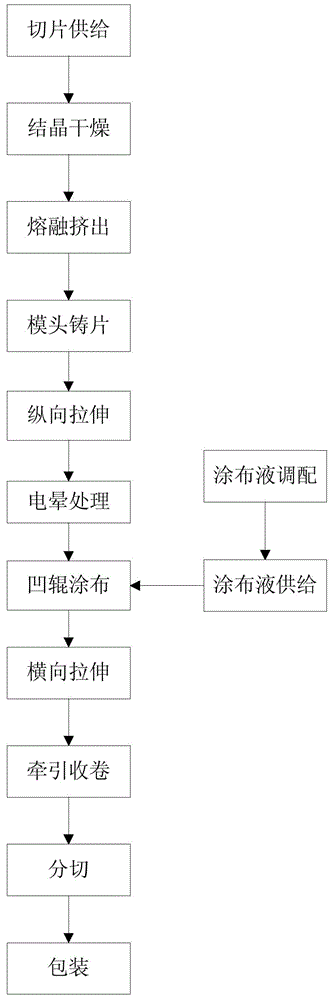

[0031] Such as figure 1 Shown, the preparation method of coated polyester film for label of the present invention comprises the following steps:

[0032] 1) Raw material ratio

[0033] The coated polyester film for labels is co-extruded in three layers: the core layer is made of white polyester chips with titanium dioxide additive mixed with PET polyester chips; the two surface layers are made of polyester chips with silica additives and PET polyester chips mix;

[0034] 2) Melt extrusion

[0035] The extrusion temperature is controlled at 276-278°C, the filter temperature is 280-282°C, and the extrusion speed is controlled at 45-47r / min;

[0036] 3) Die cast sheet

[0037] After the melt is extruded from the die, it is chilled by a cold roll with a surface temperature of 28-30°C, and the crystallinity is greatly increased to form a cast sheet, and static electricity above 8KV is applied through the electrostatic attachment system;

[0038] 4) Longitudinal stretching

[...

Embodiment 1

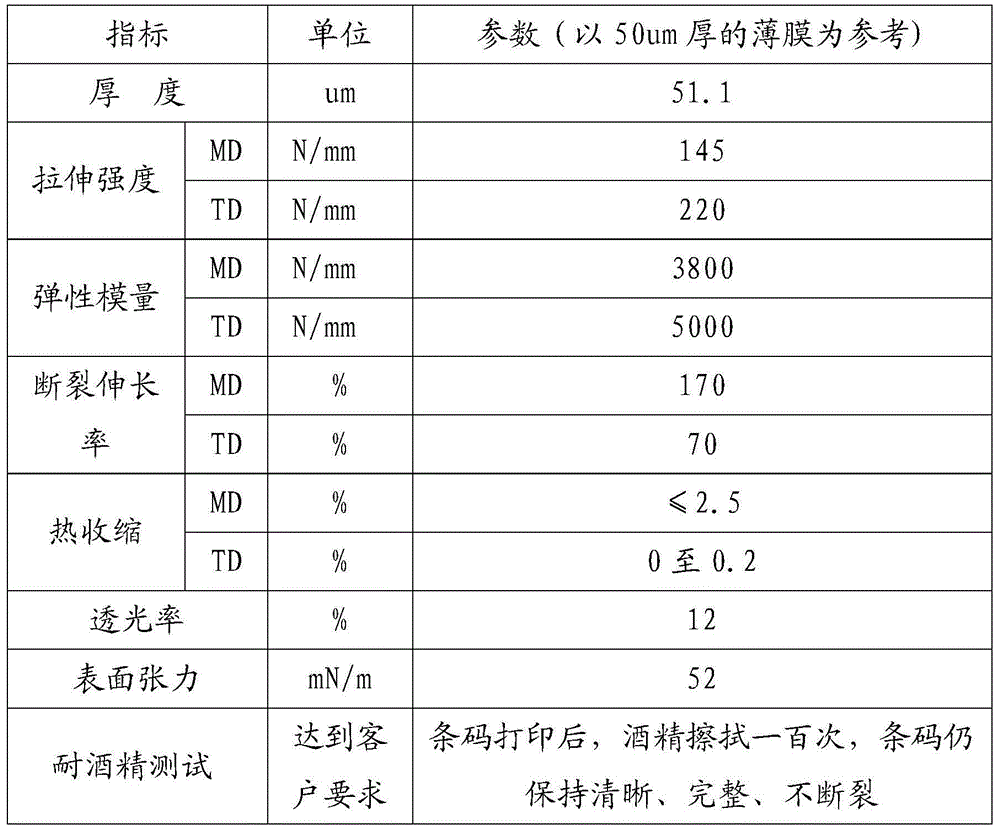

[0056] Example 1: Taking a 50 μm white label film as an example, the preparation method includes the following steps:

[0057] 1. Raw material supply

[0058] The coated polyester film for labels adopts three-layer co-extrusion: the core layer is made of white polyester chips (Sukarno TA40) containing titanium dioxide additives mixed with PET polyester chips (Yizheng Chemical Fiber FG600), and different mixing ratios are used for different thicknesses , taking the 50μm white label film as an example, the content of white polyester chips containing titanium dioxide additives is controlled between 17-19%; the surface layer is made of polyester chips containing silica additives (Yizheng Chemical Fiber FG610) and PET polyester chips Mixing, taking 50μm white label film as an example, the content of polyester chips containing silica additives is controlled between 70-85%.

[0059] The printing process of the label film often has dense information such as barcodes, and the fineness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com