Zero alcohol type lithographic printing system

A lithographic printing system, zero alcohol technology, applied in lithographic printing equipment, lithographic rotary printing machine, printing and other directions, can solve the problem of eroding ink, difficult to control hue, damage to operator's health, etc., to exempt VOC emission tax , The effect of good dot hue restoration and natural environment improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

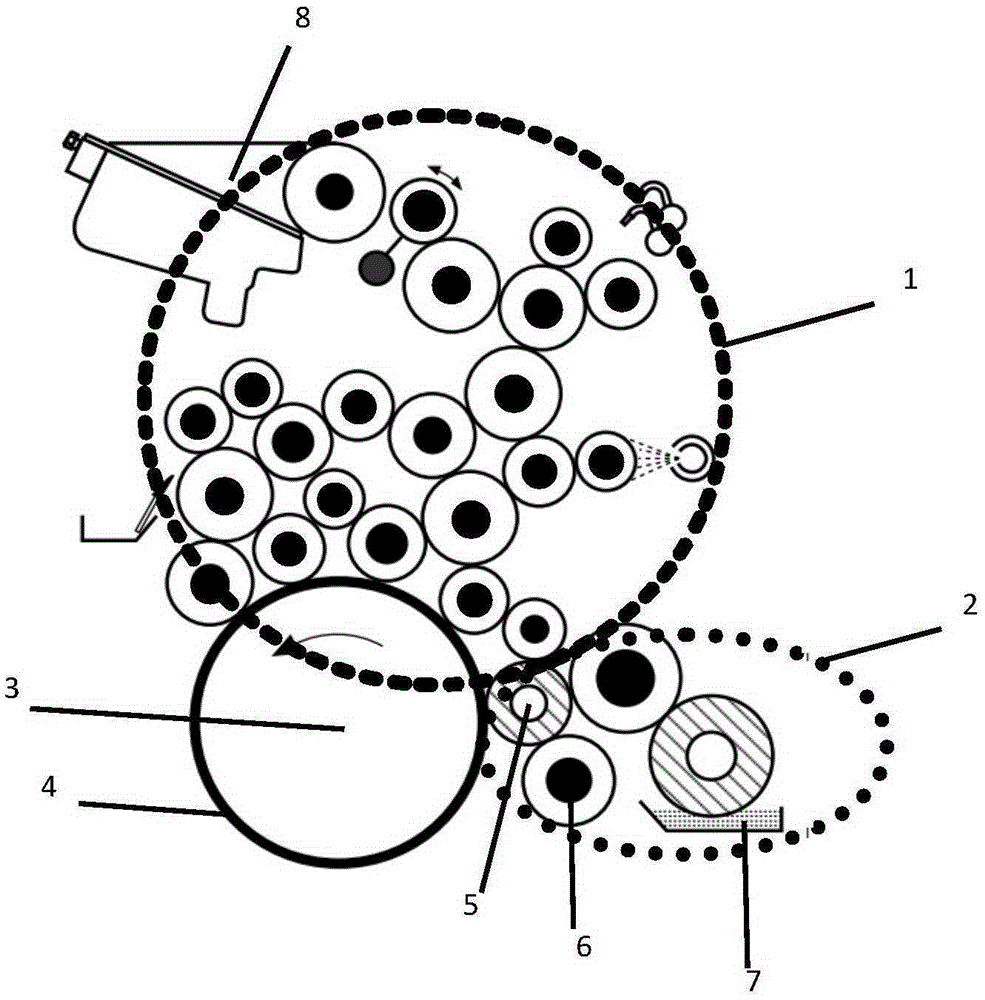

Method used

Image

Examples

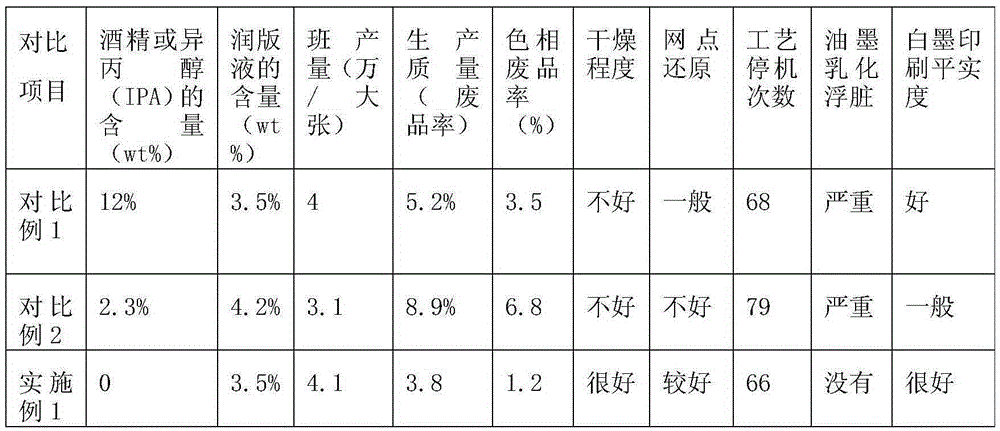

Embodiment 1

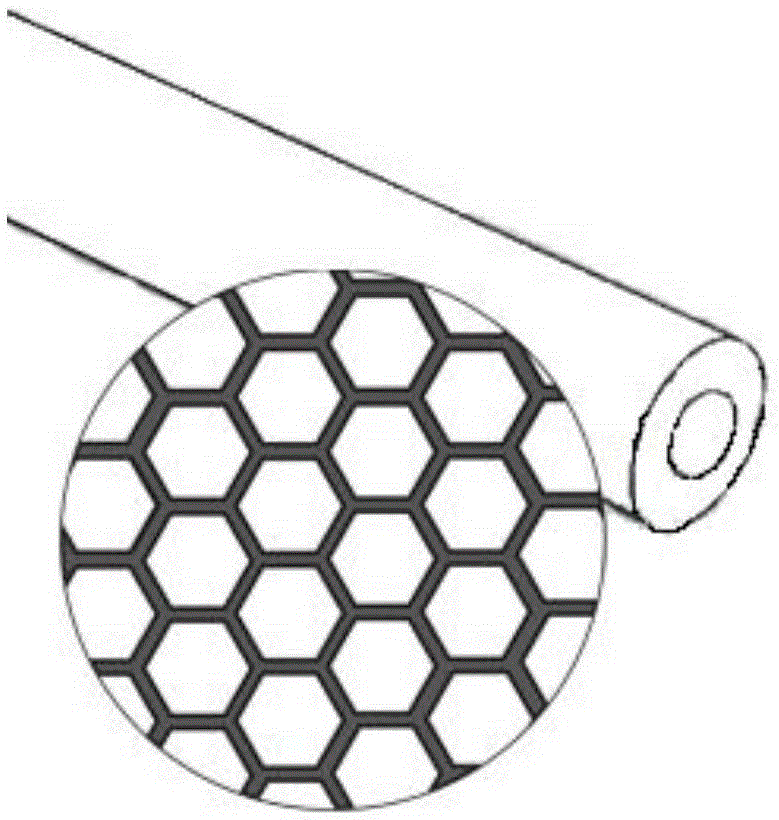

[0056] Still use German Heidelberg company CD102 model lithographic printing machine in the present embodiment, and wherein water roller (6) is the water roller of new invention, and the structure and shape feature of its roller surface are as follows: metal roller blank, it comprises metal roller and cover The ceramic layer on the outer surface of the metal roller has a regular layer on the outer surface of the ceramic layer, and after the ceramic layer is prepared on the metal roller, the ceramic layer can also be finely processed to improve its surface smoothness, Then engrave the mesh pattern by means of laser electronic engraving. There is no sandblasting layer between the metal roller and the ceramic layer of the cross-water roller, that is, the ceramic layer is in direct contact with the metal roller. It does not erode the surface of the ink during printing, the printing performance is good, and the printing failure can be better improved.

[0057] The content of alcoh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com