Yellow near-infrared high reflective coating and preparation method thereof

A near-infrared, high-reflection technology, applied in the direction of reflection/signal coatings, coatings, etc., can solve the problems of cost increase, complex preparation process, popularization, and difficulty in use, and achieve improved heat resistance, good comprehensive performance, and excellent performance. Effect of near-infrared reflectance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A yellow high near-infrared reflective coating, the specific preparation steps are as follows:

[0037] 1. According to the mass, take 30 parts of silicone resin TSR-180, 15 parts of ethanol, 20 parts of isopropanol, 1 part of dispersant BYK-161, 1 part of defoamer BYK-066, and 1 part of leveling agent BYK-333 , 1 part of lubricant BYK-103, 1 part of film-forming aid BYK-358N, disperse at high speed for 2 hours with a high-speed disperser;

[0038] 2. Add 30 parts of yellow near-infrared reflective pigment during stirring, and continue to disperse for 2 hours;

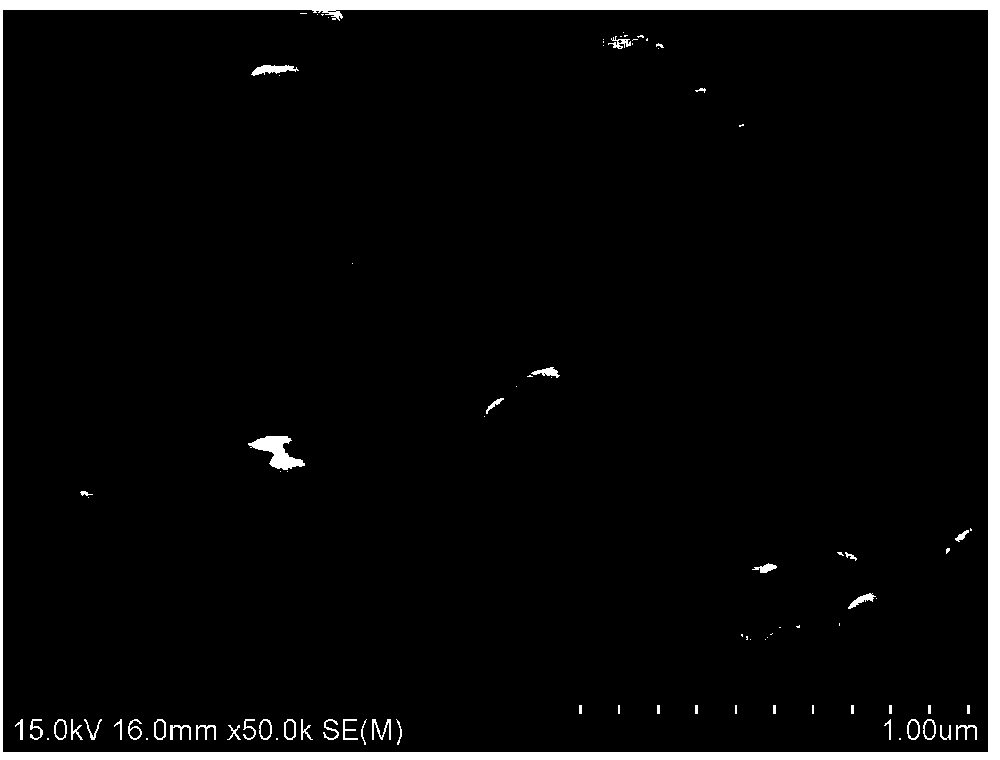

[0039] The yellow near-infrared reflective pigment is obtained by ball-milling 60 parts of yttrium oxide, 25 parts of neodymium oxide and 15 parts of molybdenum oxide, and then calcining at 1400° C. for 150 minutes.

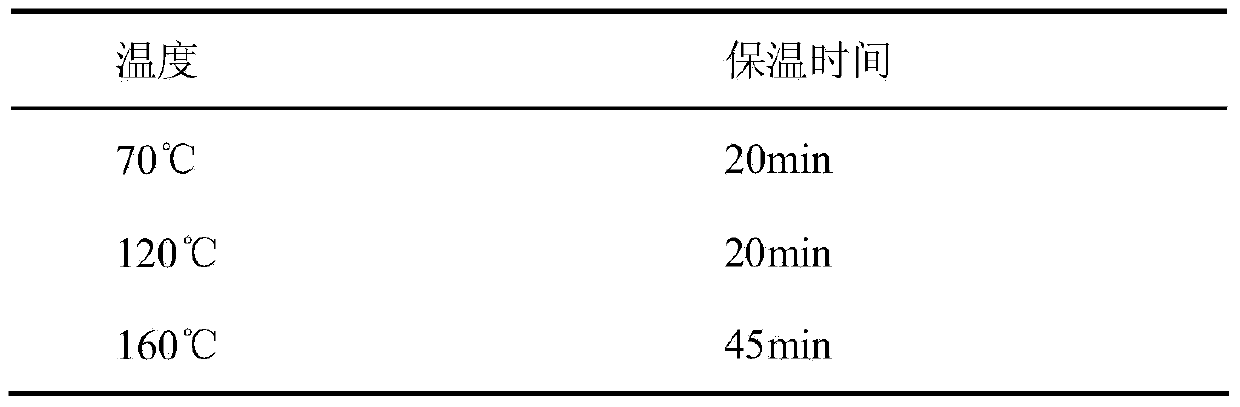

[0040] 3. After the dispersion is uniform, change the grinding head, add glass beads, grind at a speed of 600r / min for 2 hours, stop grinding, filter the glass beads for grinding, and obtain a uni...

Embodiment 2

[0043] A yellow high near-infrared reflective coating, the specific preparation steps are as follows:

[0044]1. Take 20 parts of silicone resin TSR-165, 30 parts of isobutanol, 1 part of dispersant BYK-161, 1 part of dispersant BYK-164, 2 parts of defoamer BYK-141, and 2 parts of leveling according to the mass Agent BYK-300, 2 parts of lubricant BYK-P104, 2 parts of film-forming aid BYK-358N, disperse at high speed for 2 hours with a high-speed disperser;

[0045] 2. Add 40 parts of yellow near-infrared reflective pigment during stirring, and continue to disperse for 2 hours;

[0046] The yellow near-infrared reflective pigment is obtained by ball milling and mixing 55 parts of yttrium oxide, 30 parts of neodymium oxide and 15 parts of molybdenum oxide, and calcining at 1600°C for 60 minutes.

[0047] 3. After the dispersion is uniform, change the grinding head, add glass beads, grind at a speed of 600r / min for 2 hours, stop grinding, filter the glass beads for grinding, and...

Embodiment 3

[0049] A yellow high near-infrared reflective coating, the specific preparation steps are as follows:

[0050] 1. According to the mass, take 5 parts of silicone resin TSR-180, 5 parts of silicone resin TSR-165, 5 parts of silicone resin YR-3187, 20 parts of isopropanol, 20 parts of isobutanol, and 2 parts of dispersant BYK -164, 1 part defoamer BYK-066N, 1 part defoamer BYK-141, 2 parts leveling agent BYK-306, 1 part lubricant BYK-103, 1 part lubricant BYK-P104, 2 parts film forming Auxiliary BYK-358N, disperse at high speed for 2 hours with a high-speed disperser;

[0051] 2. Add 35 parts of yellow near-infrared reflective pigment during stirring, and continue to disperse for 2 hours;

[0052] The yellow near-infrared reflective pigment is obtained by ball milling and mixing 65 parts of yttrium oxide, 20 parts of neodymium oxide and 15 parts of molybdenum oxide, and then calcining at 1500° C. for 180 minutes.

[0053] 3. After the dispersion is uniform, change the grinding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

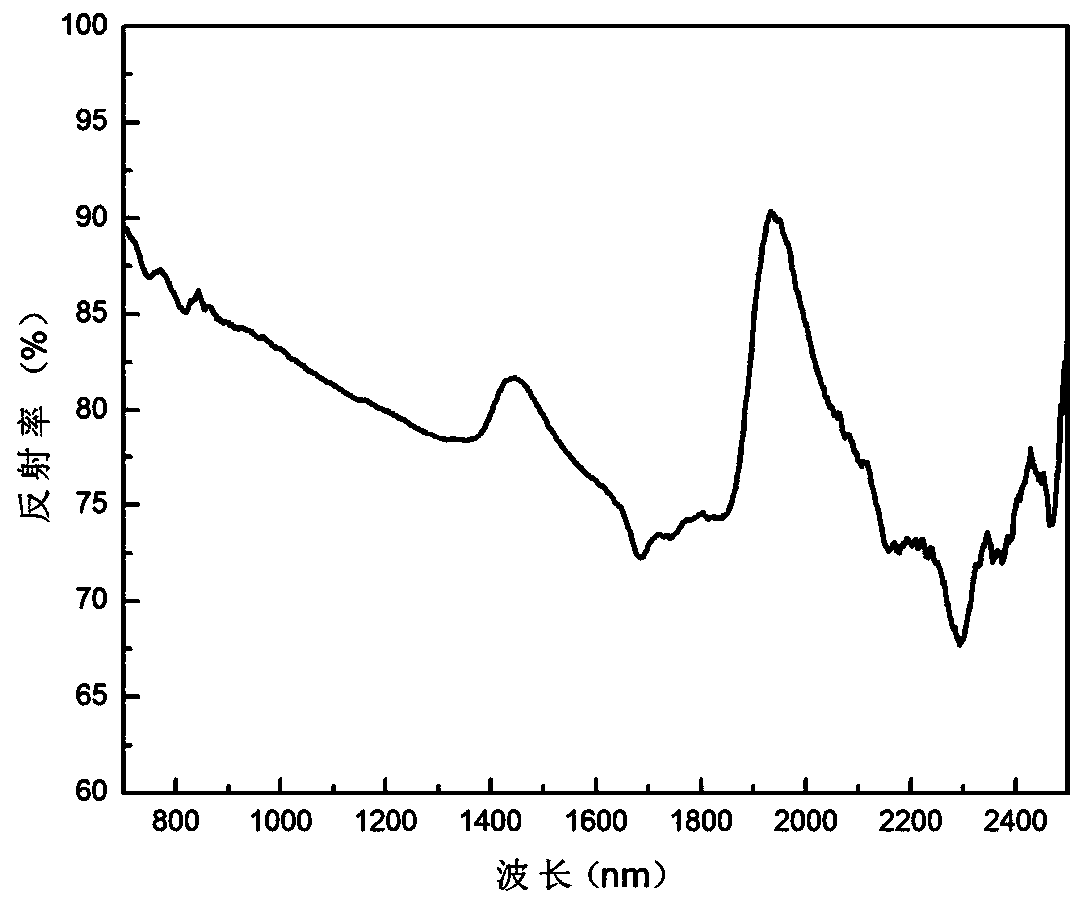

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com