Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64results about How to "Rich touch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

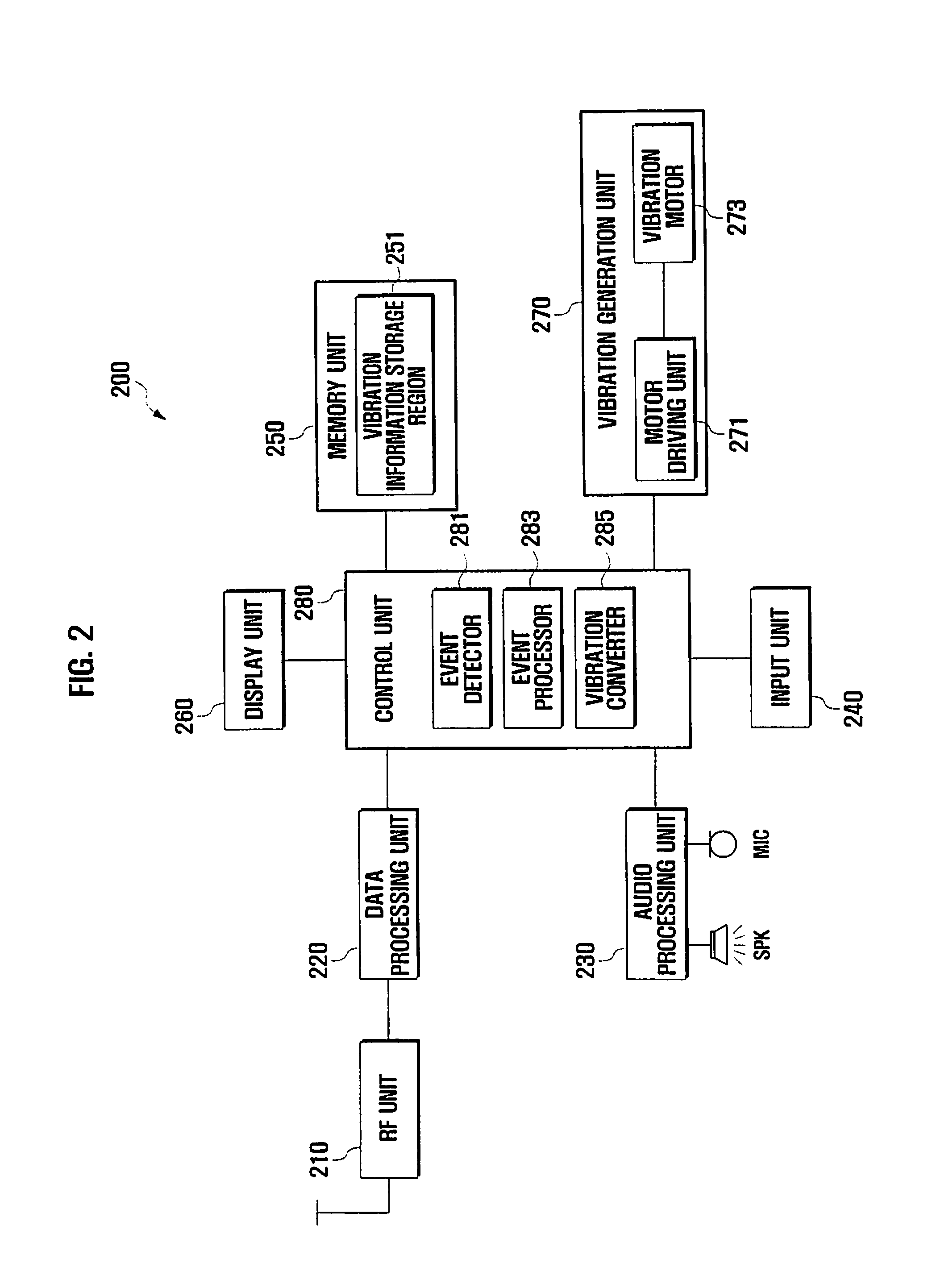

Haptic generation method and system for mobile phone

ActiveUS20080153554A1Enriching tactile feelingRich touchCurrent supply arrangementsSubstation equipmentOperation modeEmbedded system

A haptic generation method and system for a mobile phone is provided. A vibration event is detected in an operation mode. A vibration code corresponding to the vibration event is retrieved from a mapping table. A control message containing the vibration code is generated, and the control message is transmitted to at least one destination mobile phone.

Owner:SAMSUNG ELECTRONICS CO LTD

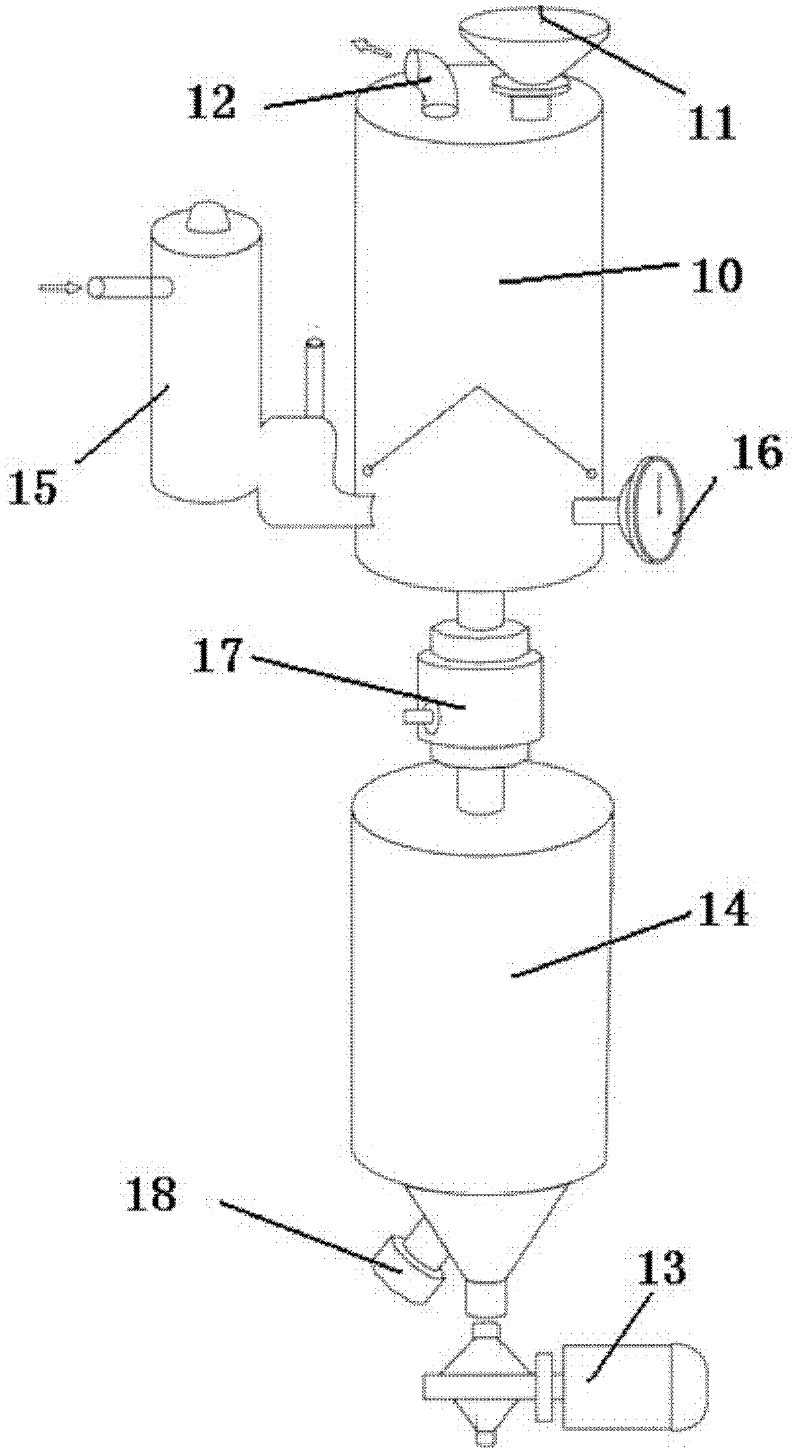

Production method of fine-denier porous POY black yarn

InactiveCN102443859AImprove spinnabilityReduced stabilitySpinnerette packsMelt spinning methodsProduction rateYarn

The invention discloses a production method of a fine-denier porous POY black yarn. The method comprises the following steps of: drying semi-dull slices, drying black masterbatch, adding the slices and the black masterbatch material into a screw extruder, fusing the added materials in the screw extruder, respectively processing the fused materials in a metering pump and a spinning beam, spinning on a pack, cooling the materials by lateral blowing, applying oil on strands, processing the strands in draw-off godets GR1 and GR2, winding and shaping, and inspecting products. The method is characterized in that the step of drying the black masterbatch comprises the following sub-steps of: based on a continuous drying mode, firstly, adding the black masterbatch into a crystallization and drying tank, introducing heated dry air from the lower part of the crystallization and drying tank, and blowing out the heated dry air from the top of the crystallization and drying tank so as to dry the black masterbatch, wherein the drying time is 2 hours, the dried black masterbatch falls into an intermediate material storage bin for storage under the crystallization and drying tank, and the black masterbatch is further injected by a masterbatch injector under the intermediate material storage bin. The production method of the fine-denier porous POY black yarn has high masterbatch spinnability and better cooling effect, and can improve the oil application uniformity of spinning cakes and the productivity.

Owner:桐乡市中洲化纤有限责任公司

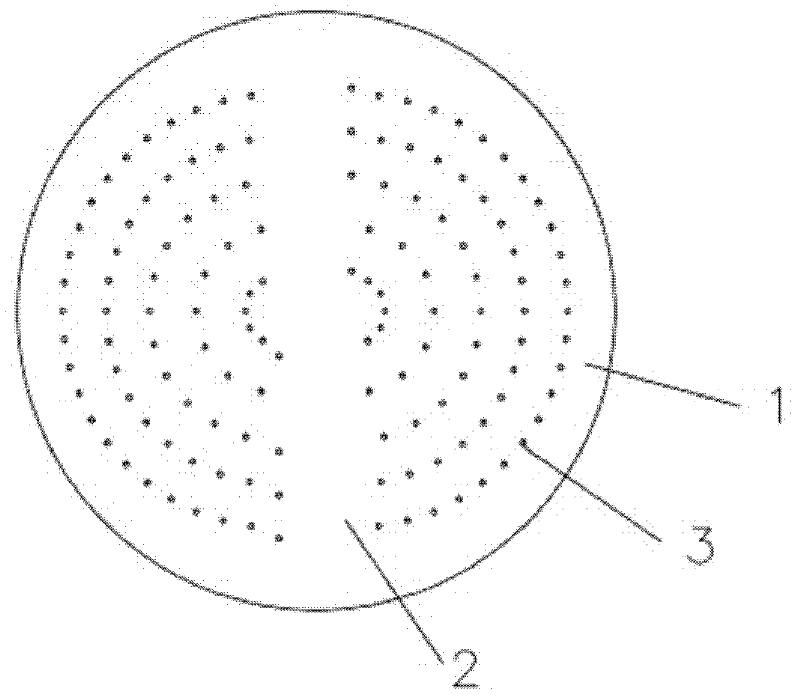

Preparation method of ceramic plate decorative painting through colored engraving

The invention relates to a preparation method of a ceramic plate decorative painting through colored engraving. The method comprises the following steps: 1), a protective film is attached to the surface of a ceramic plate; 2), sidelines of a specified figure are engraved on the surface of the ceramic plate by a laser engraving machine; 3), the protective film at a to-be-etched part is removed so as to expose an engraving surface; 4), the surface of the ceramic plate is eroded by an abrasive material at a high flow rate, so that an uncolored solid figure is formed through engraving on the ceramic surface with the protective film removed, the pressure is 1-10 kg / m<3>, and the flow is 5-20 m<3> / min; 5), sand blasting is at least performed on a to-be-colored part of the surface of the ceramic plate so as to at least remove a glaze layer of the to-be-colored part and form a frosted surface, the sand blasting pressure is 1-10 kg / m<3>, and the flow is 5-20 m<3> / min; 6), the frosted surface of the ceramic plate prepared in the step 5) is cleaned and dried, a pattern is spray-printed and drawn, and a protective glaze layer is spray-printed; 7), the ceramic plate prepared in the step 6) is sintered rapidly.

Owner:MONALISA GRP CO LTD

Haptic generation method and system for mobile phone

ActiveUS8412282B2Rich touchCurrent supply arrangementsCathode-ray tube indicatorsOperation modeEmbedded system

A haptic generation method and system for a mobile phone is provided. A vibration event is detected in an operation mode. A vibration code corresponding to the vibration event is retrieved from a mapping table. A control message containing the vibration code is generated, and the control message is transmitted to at least one destination mobile phone.

Owner:SAMSUNG ELECTRONICS CO LTD

Manufacturing method of aluminum alloy appearance piece

ActiveCN102691085ANot easy to fall off and rustWith anodic color effectAnodisationColor effectVideo player

The invention provides a manufacturing method of an aluminum alloy appearance piece, and the method is characterized by mainly comprising the steps of: (1) press-molding; (2) degreasing; (3) anodic oxidation; (4) dyeing; and (5) hole sealing. Compared with the prior art, the manufacturing method of an aluminum alloy appearance piece of the invention has the following advantages that: the product has an anode color effect, metal highlight texture, as well as an appearance effect of gradient color change; due to the employment of anodic oxidation surface treatment, the product surface is difficult to drop and rust, and the color always seems like new; the product has a surface with high abrasion resistance, and mild and smooth handfeel; and the method provides diversified product appearance choices for industrial design, and can meet more consumption demands. The manufacturing method of an aluminum alloy appearance piece of the invention can be used for producing the appearance pieces of various 3C products, especially laptops, tablet personal computers, mobile phones and digital audio and video players, etc.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

Formula and preparation process for multifunctional surface treating agent applied to aqueous leather

InactiveCN108047906ARich touch and visual experienceImprove physical performanceFireproof paintsWax coatingsWaxChemistry

The invention discloses a formula for a multifunctional surface treating agent applied to aqueous leather. The formula comprises 3 to 35% of an aqueous polyurethane emulsion, 0.5 to 20% of a multifunctional finishing agent, 2 to 15% of aqueous wax, 0.3 to 3% of a leveling agent, 0.5 to 1.5% of a thickening agent, 0.5 to 1% of an antifoaming agent and 24.5 to 93.2% of water. The preparation processcomprises the following steps: adding all the above raw materials except the thickening agent into a container in proportion, carrying out uniform mixing through a dispersator, then carrying out filtering and adding the thickening agent to adjust viscosity so as to obtain the surface treating agent. The surface treating agent provided by the invention endows synthetic leather with special performances like antibacterial, sterilizing, anti-ultraviolet, anti-radiation, flame-retardant, temperature-adjusting, color-changing, self-cleaning and anti-doodling performances without any influence on the fastness and handfeel of the synthetic leather, and substantially prolongs the service life of the synthetic leather; a product having been treated with the surface treating agent has better handfeel and presents better visual impression; and the surface treating agent greatly improves the physical properties of the synthetic leather and allows the synthetic leather to have more excellent scrape resistance, water resistance, fire resistance and the like.

Owner:宋林涛

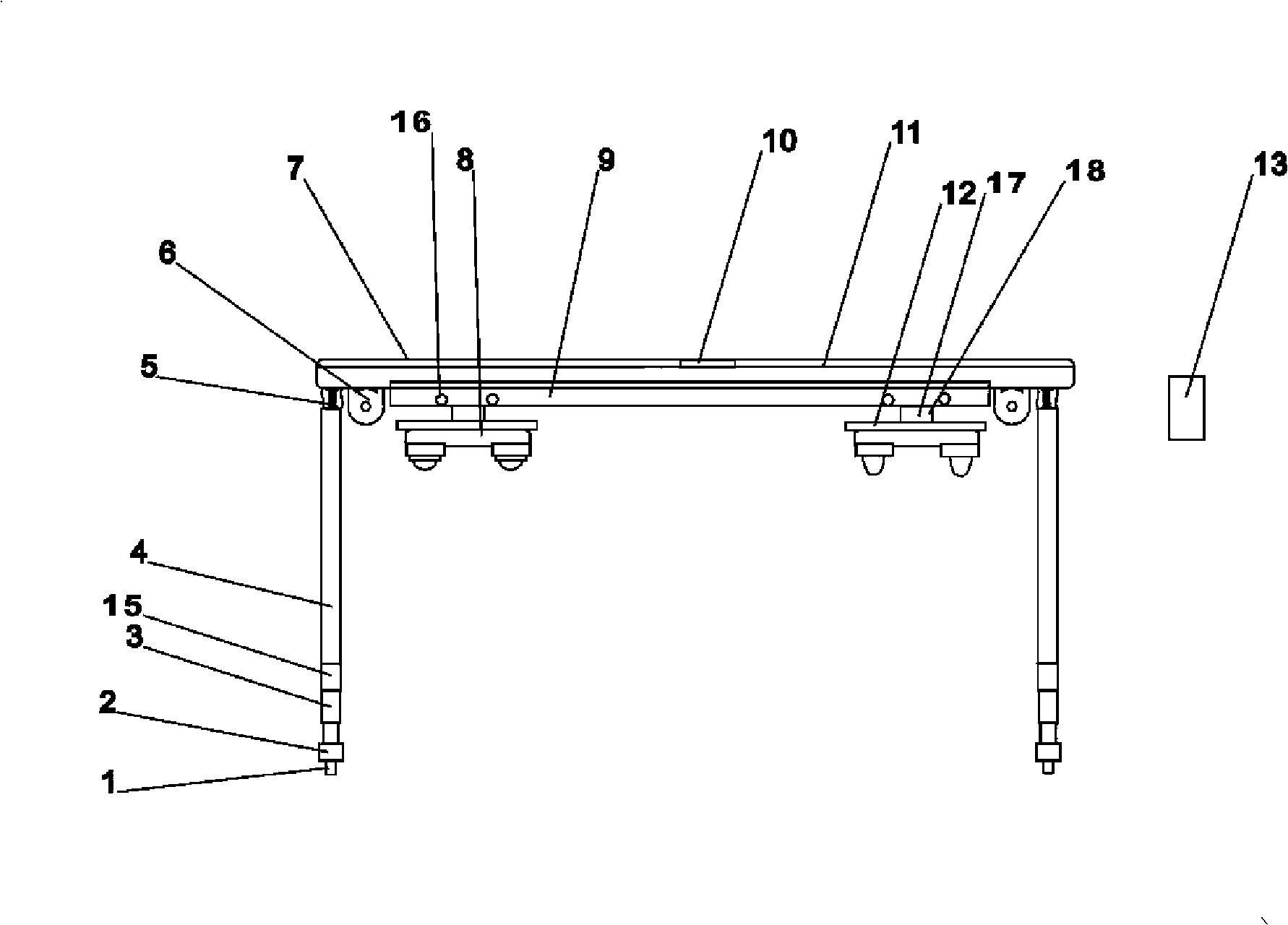

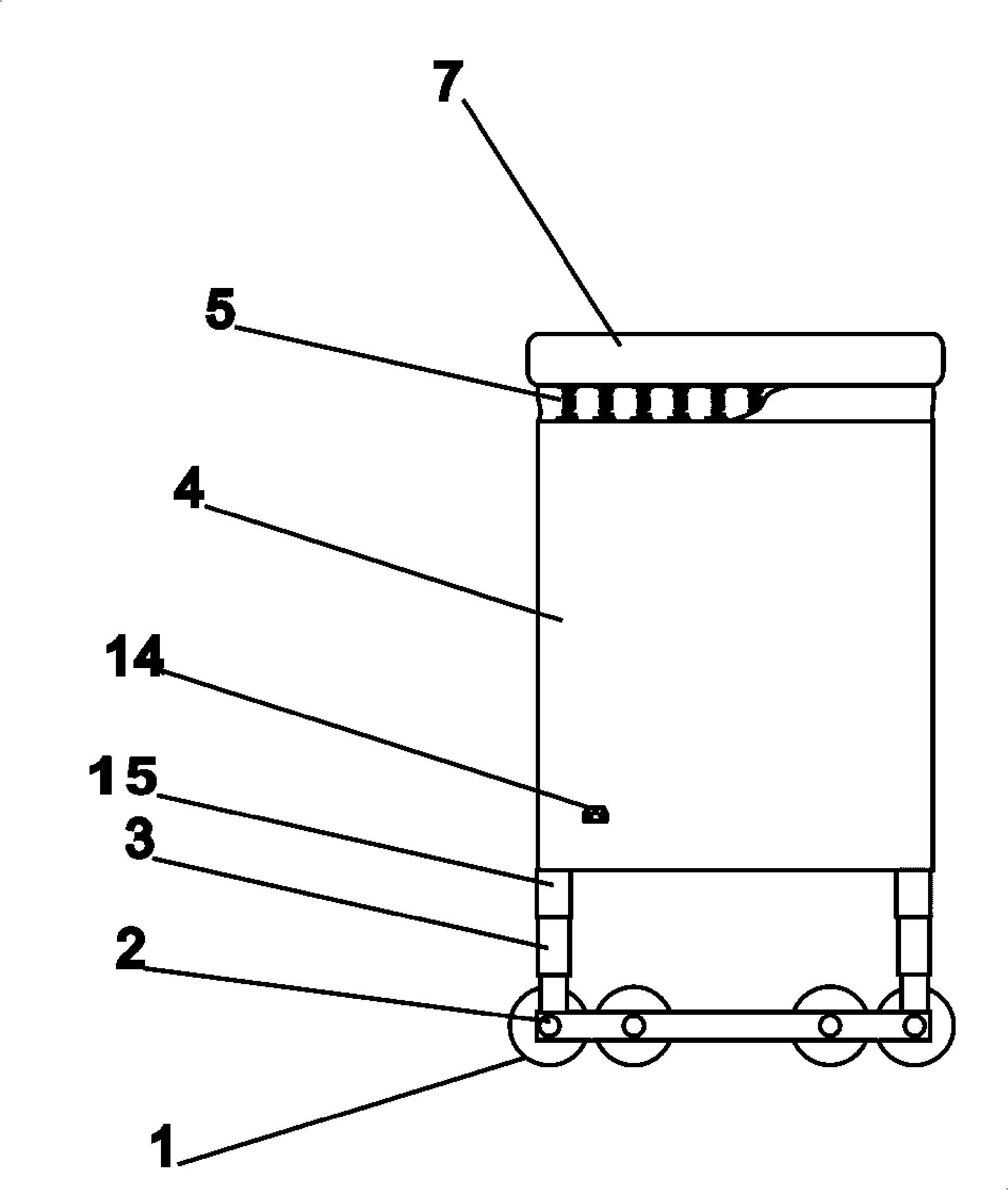

Remote numerical control electric hot door type overbed massage table

InactiveCN101559020AComfortable temperatureRich sex positionsVibration massageNumerical controlElectro hydraulic

The invention relates to a remote numerical control electric hot door type overbed massage table which mainly comprises a power interface (14), a roller wheel (1), a table leg electric hydraulic lifting device (3), a table top (7), a table top heating system (11), a vibration motor (6), a massor (8), massage head automatic switching devices (12), (17) and (18), a remote controller (13) and a numerical control device (10). The massage table can do relative motion along Z axis direction (up and down) and Y axis direction (forwards and backwards) between beds; the massor is arranged under the massage table and can do relative motion along X axis direction (left and right) between the beds; and the motions are controlled by the numerical control device (10) and the remote controller (13) simultaneously. The vibration motor (6) and the massor (8) can be controlled by the numerical control device (10) to conduct composite linked massage to designated positions. The remote numerical control electric hot door type overbed massage table can be used by matching with common beds, and lead the common beds to have the sexual helping function of erotic beds.

Owner:罗轶

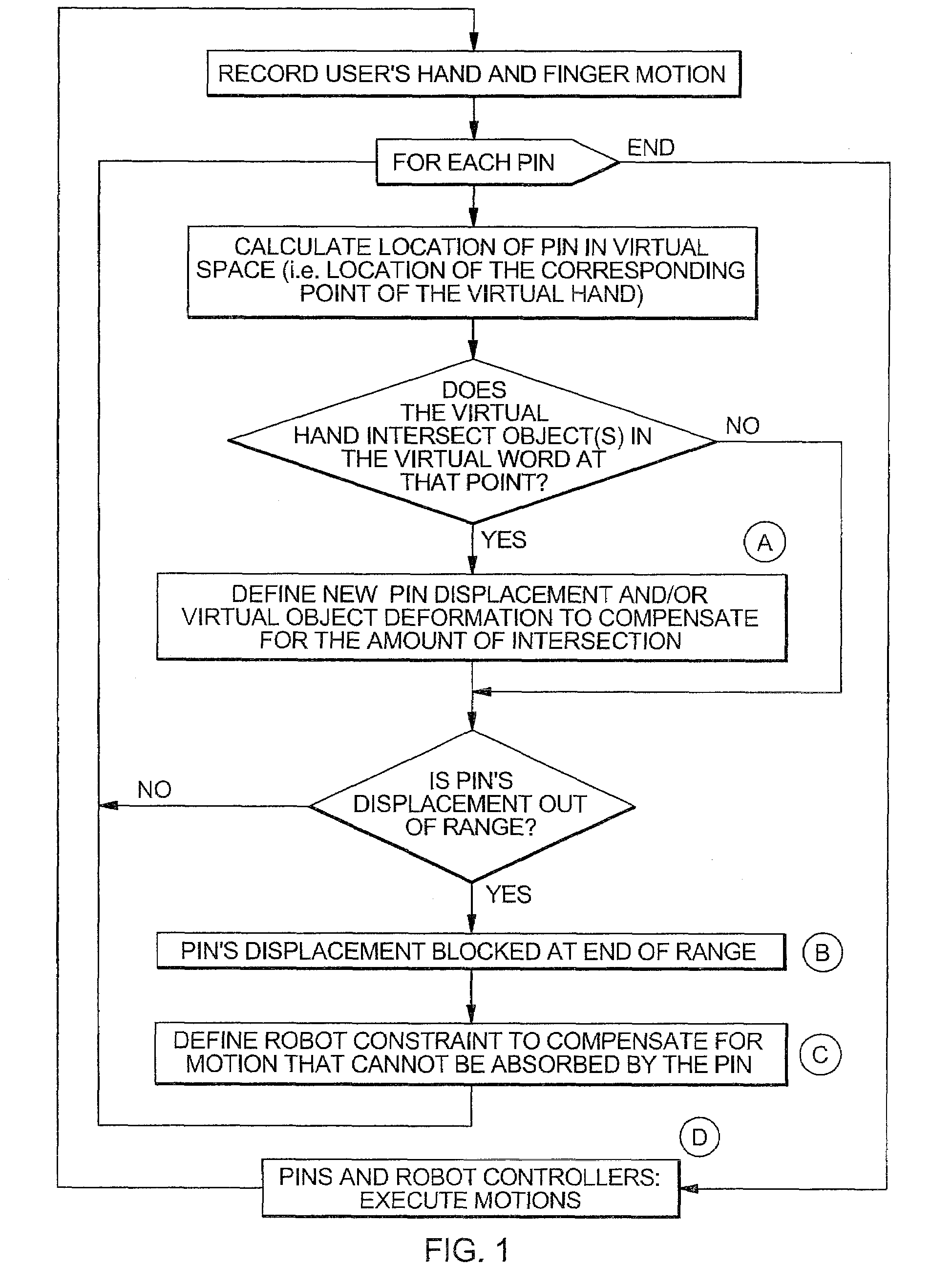

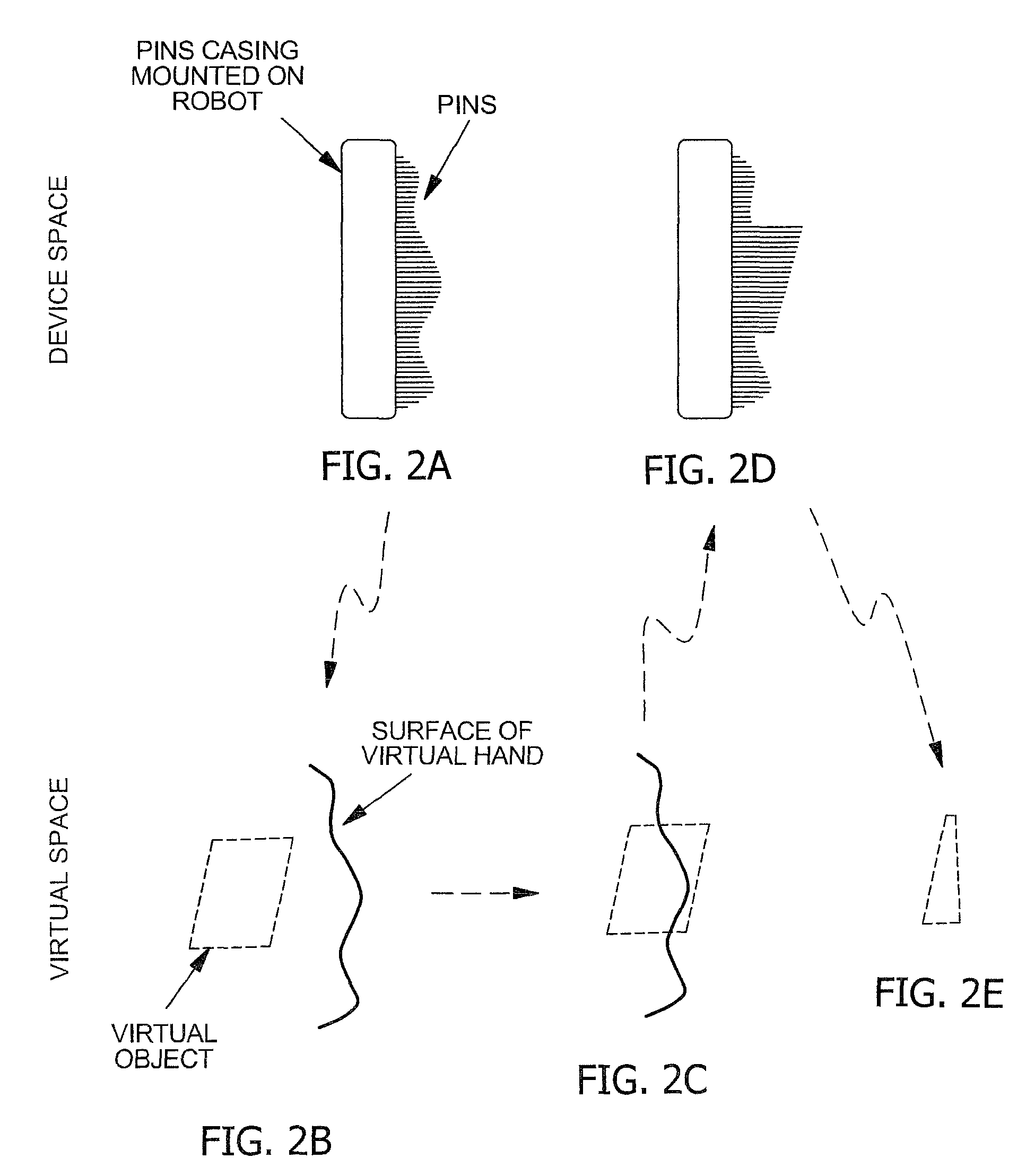

Virtual hand: a new 3-D haptic interface and system for virtual environments

InactiveUS8350843B2Rich touchRealistic sensationCathode-ray tube indicatorsInput/output processes for data processingComputerized systemVirtual world

The present invention discloses a creation of a virtual hand, body part, or tool in a virtual environment, controlled by a new 3-D haptic interface for virtual environments. There is also the provision of a method and arrangement applicable to computer systems for creating a virtual environment, which facilitates a user to touch, feel, edit, and interact with data about the objects, surfaces, and textures in the environment. There is also a provision for multiple virtual hands operating in the same virtual world, so that users can work collaboratively in the virtual world; they can touch, feel and edit the data in the virtual world, including data about the other users' virtual hands.

Owner:IBM CORP

Preparation method of stereoscopic natural bright microfiber material and products thereof by lustring

InactiveCN106544883AStrong three-dimensional senseNatural lusterFibre typesPolyurethane dispersionPolymer science

The invention discloses a method for preparing a stereoscopic natural bright microfiber material by lustring, comprising the following steps: step one, preparing a fiber bat; step two, preparing base cloth; step three, carrying out impregnation via polyvinyl alcohol; step four, carrying out impregnation via PU by dipping an intermediate product prepared by the step three via wet polyurethane size, solidifying, washing at normal temperature, pre-drying for a second time, dipping via dispersoid, drying for a second time, washing with water at high temperature, drying and shaping to prepare a semi-finished product, wherein a solidification solution is dimethylformamide, and the dispersoid is water-soluble polyurethane dispersoid; step five, carrying out alkali minimization; and step six, carrying out leather facing effect treatment and treating via a functional agent. The invention also discloses a preparation method of the microfiber material and the products thereof. The prepared microfiber material and the products thereof are strong in texture stereoscopic feeling, natural in gloss and rich and full in hand feeling; various physical indexes such as peeling strength, abrasion resistance, tearing resistance, maximum tension force, yellowing resistance and breathability and the like are significantly higher than that of the similar products; the microfiber material and the products thereof can be widely applied to high-grade fashionable clothes, household articles and working articles.

Owner:泉州众信超纤科技股份有限公司

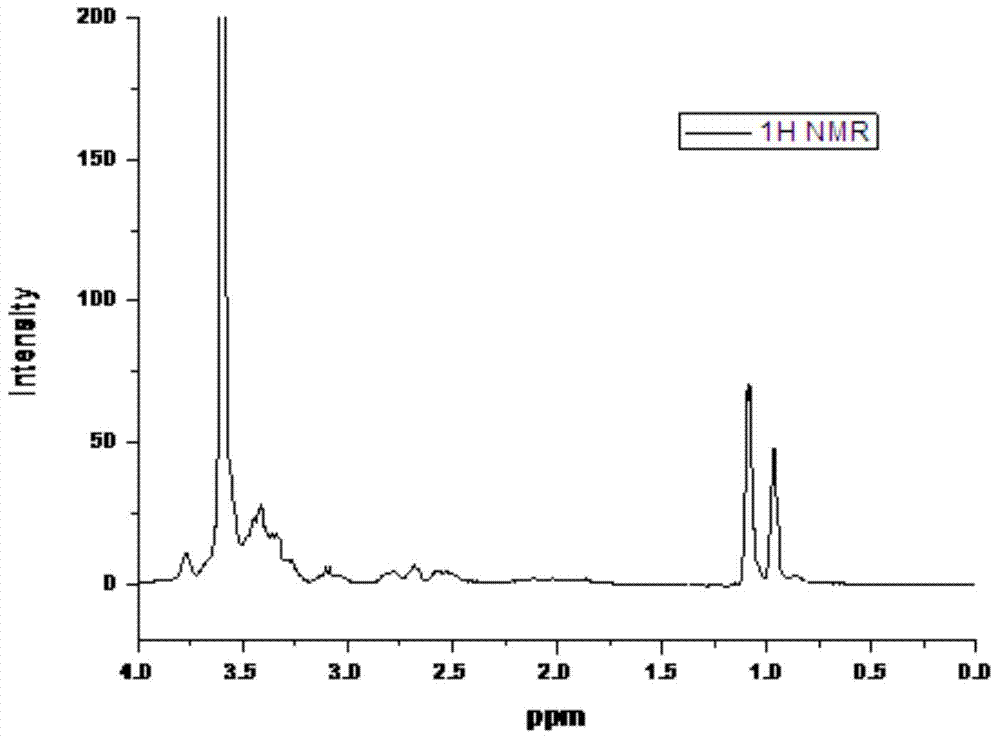

Polyether polyamine, preparation method of polyether polyamine, polyether polyamine block silicone oil and preparation method of polyether polyamine block silicone oil

The invention discloses polyether polyamine which is characterized by having a following general formula: H2NC3H6(OC3H6)a(OC2H4)b(OC3H6)aNHCH2CH(OH)CH2(OC2H4)cOCH2CH(OH)CH2NHC3H6(OC3H6)dNH2, wherein the a, b, c and d are all integers from 2-40. The polyether polyamine provided by the invention contains amino groups at chain ends, has amino groups in the chain middle part, and has the improved content of the amino groups in comparison with that of the amino groups of the conventional polyether polyamine, and the flexibility of polyether polyamine block silicone oil prepared by using the polyether polyamine as one of raw materials is greatly improved.

Owner:上海硅普化学品有限公司

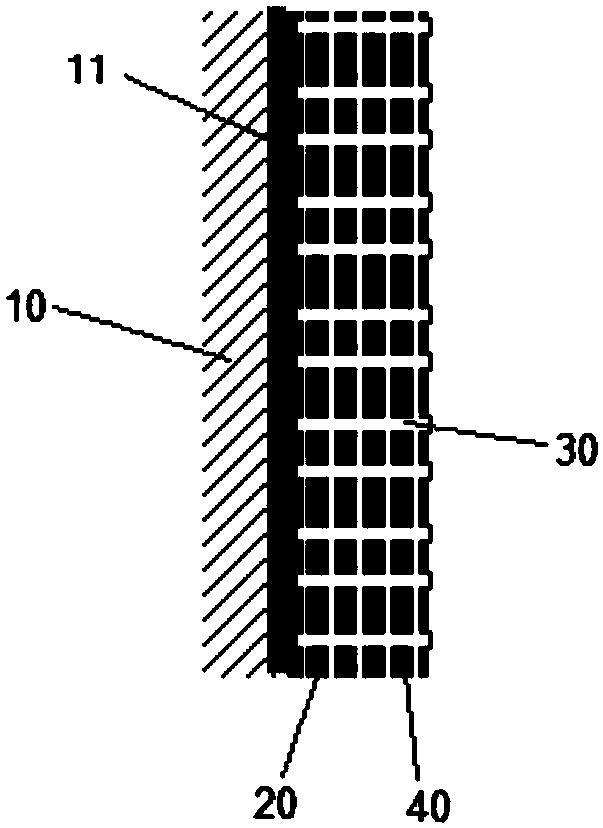

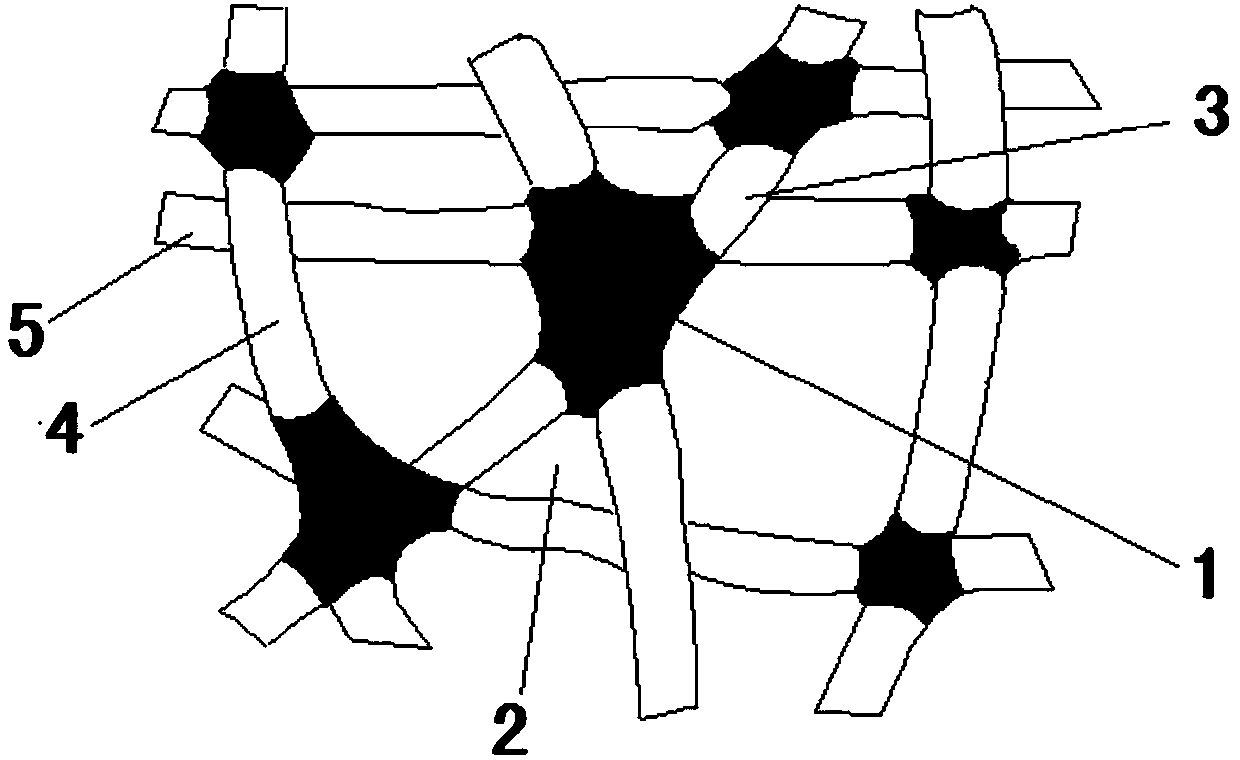

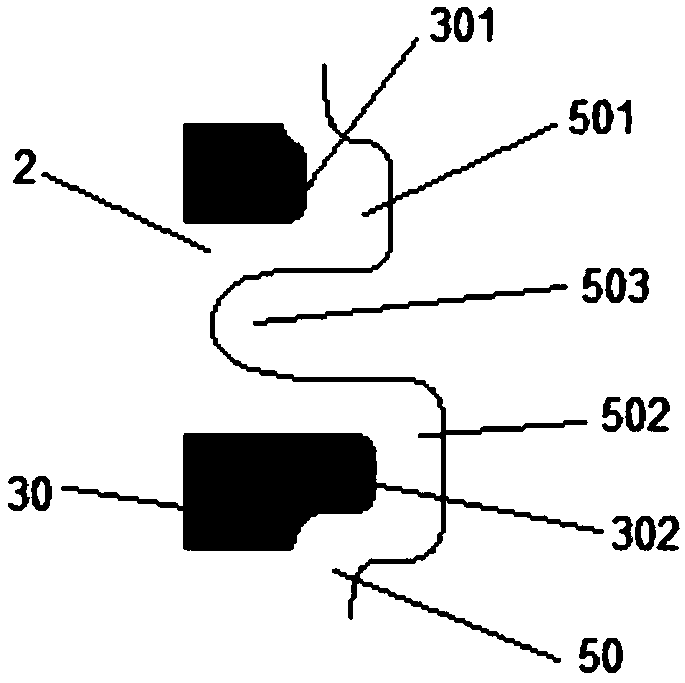

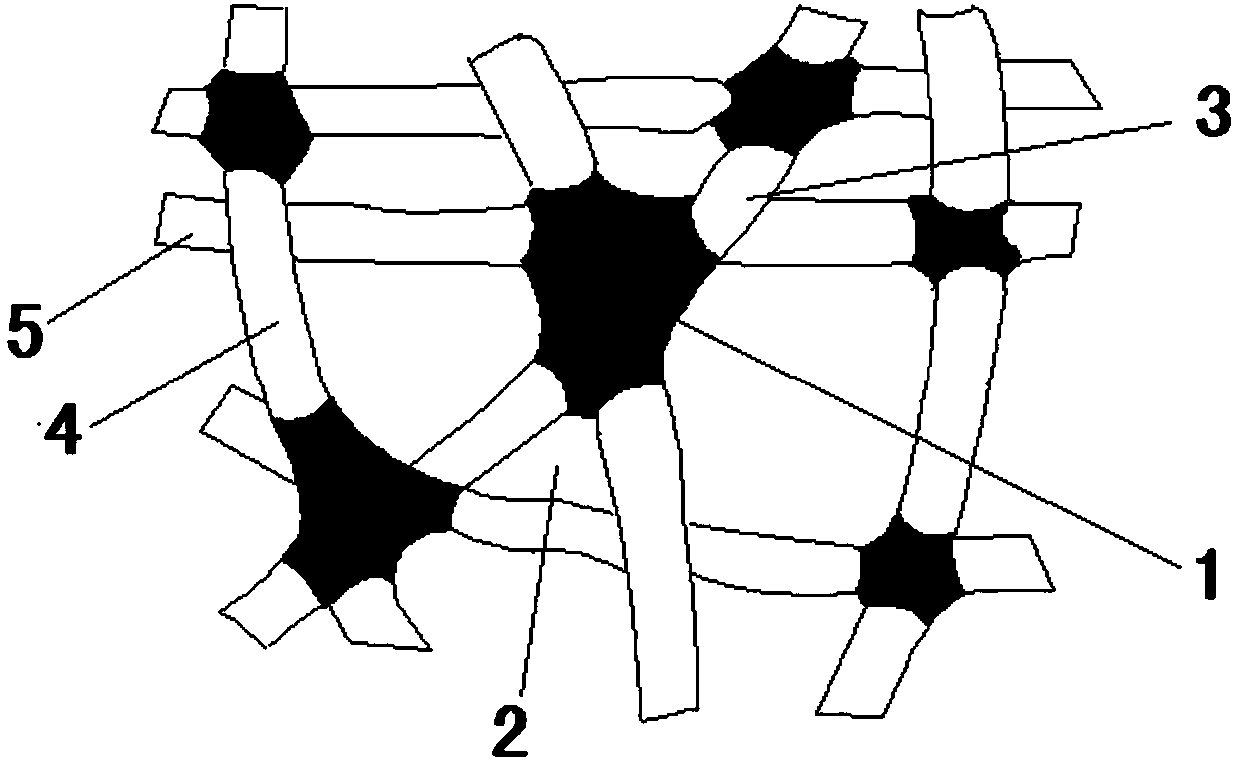

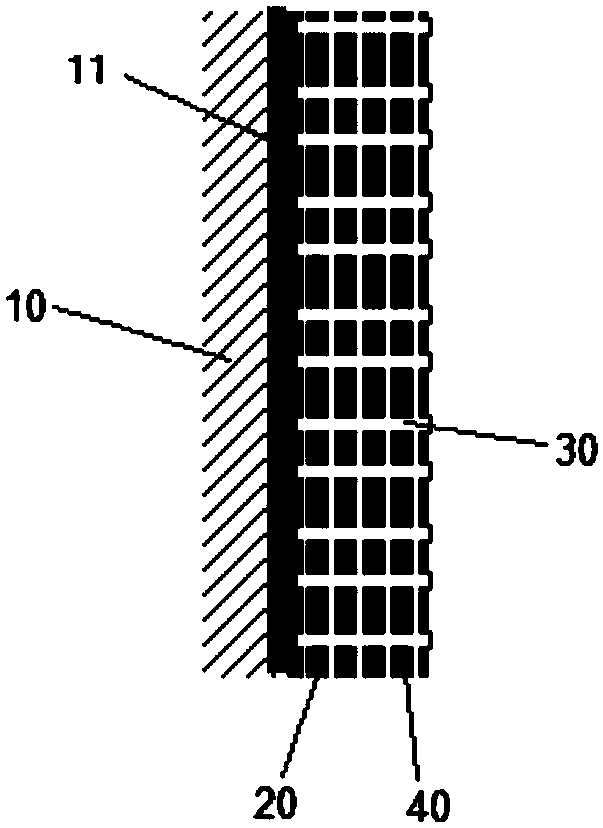

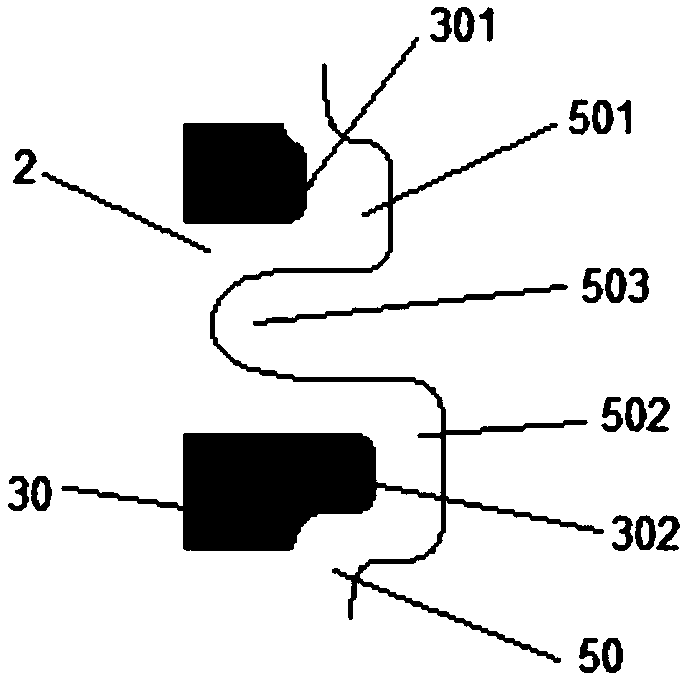

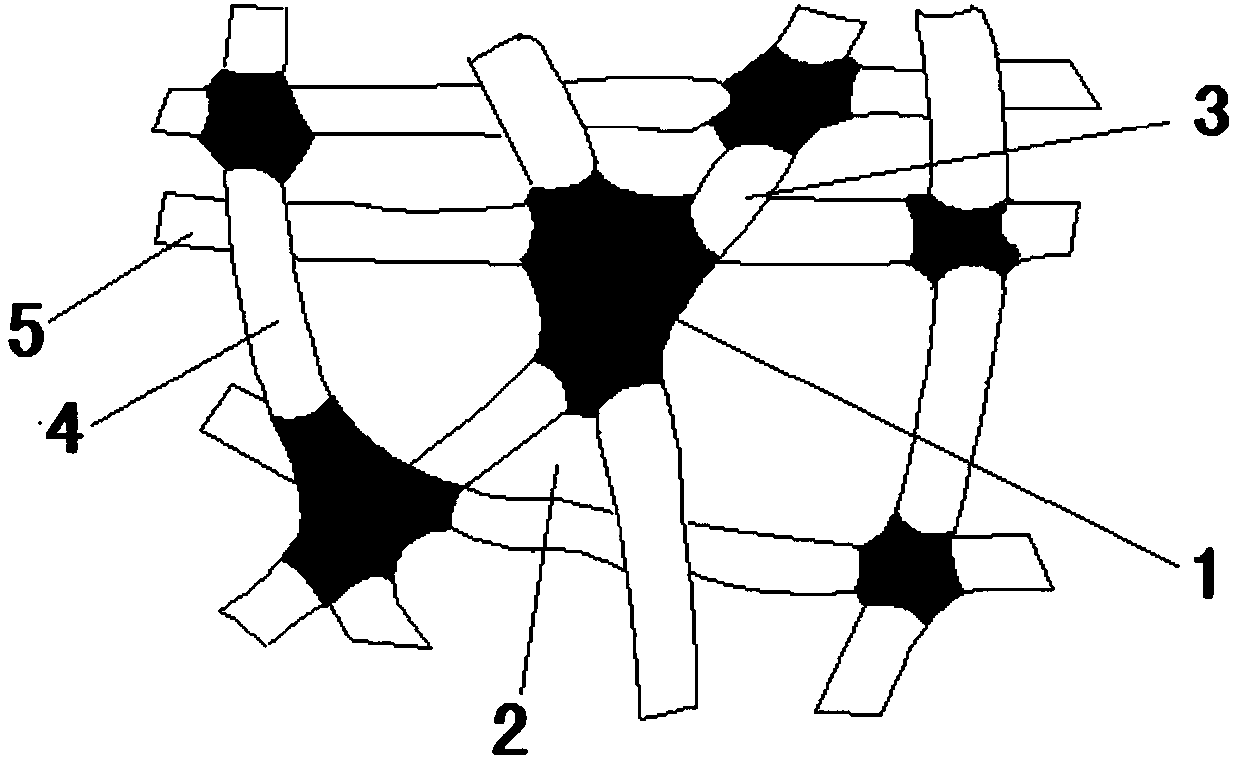

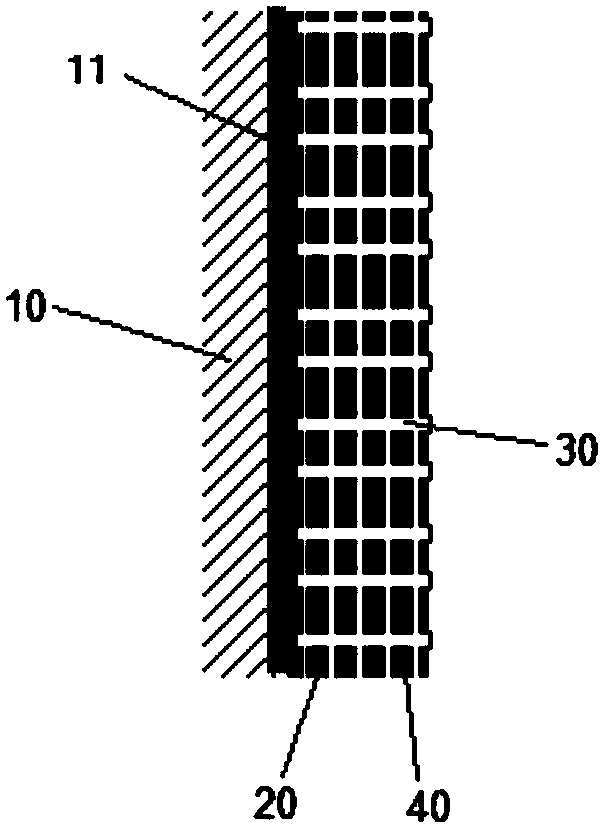

Phase change energy storage infiltration coating sandwich wall cloth and manufacturing method thereof

The invention provides a phase change energy storage infiltration coating sandwich wall cloth, and a method for manufacturing the phase change energy storage infiltration coating sandwich wall cloth,or an object decoration method. The phase change energy storage infiltration coating sandwich wall cloth comprises a bottom coating and an infiltration coating composite sandwich coating compound coated on the surface of the bottom coating; the infiltration coating composite sandwich coating compound comprises a transparent or semi-transparent second coating and a fiber texture network sandwich wrapped by the second coating; the fiber texture network sandwich contains a network structure formed by fibers; the second coating penetrates into meshes of the network structure; and one or more of the second coating, the bottom coating and the fiber texture network sandwich can have a phase change energy storage function. The wall cloth with textures and / or patterns can be manufactured in a standardized and large-scale mode, and has good crack resistance, air permeability and decorative performance.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

Fireproof infiltration coating sandwich wall cloth and manufacturing method thereof

PendingCN110158892AAdequate adhesionObvious connection seamCovering/liningsCoatingsFiberCoated surface

The invention provides a fireproof infiltration coating sandwich wall cloth and a method for manufacturing the fireproof infiltration coating sandwich wall cloth or an object decoration method. The fireproof infiltration coating sandwich wall cloth comprises an undercoat layer and an infiltration coating composite sandwich coating composite body, wherein the surface of the undercoat layer is coated with the infiltration coating composite sandwich coating composite body, the infiltration coating composite sandwich coating composite body comprises a transparent or semitransparent second coatinglayer and a fiber texture network sandwich covered with the second coating layer, the fiber texture network sandwich contains a network structure formed by fibers, the second coating layer penetratesinto meshes of the network structure, and one or more of the second coating layer and the undercoat layer can be a fireproof coating layer. The wall cloth with skin textures and / or patterns can be produced in a standardized and large-scale mode, and good crack resistance, air permeability and decoration performance are achieved.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

Preparation method of multifunctional health-care fancy yarn with antibacterial and skin-care functions

InactiveCN107503012AReflect the advantages of learning from each otherRich and colorfulYarnPolyesterPolypropylene

The invention provides a preparation method of multifunctional health-care fancy yarn with antibacterial and skin-care functions. The yarn is composed of two pieces of core yarn, one piece of decorative yarn and two pieces of fixed yarn, wherein the core yarn is blended yarn formed by blending and processing calotropis gigantea fibers, mulberry bark fibers, Amicor antibacterial fibers and copper fibers, the fixed yarn is composed of far-infrared polyester filaments and tourmaline fiber filaments, and the decorative yarn is blended rough yarn formed by blending and processing tea leaf fibers, banana stem fibers, antibacterial odor-resistant acrylic fibers and rabbit hair fibers; or the core yarn is blended yarn formed by blending and processing sarcandra glabra fibers, luminous fibers, pineapple leaf fibers and silver fibers, the fixed yarn is negative ion polypropylene filaments, and the decorative yarn is blended rough yarn formed by blending and processing lotus fibers, anti-ultraviolet polyester fibers, double-resistant acrylic fibers, yak wool fibers and alpaca fibers. The yarn developed through the method does not generate adverse effects when making contact with the human body, products are not easy to damage by worms or rot, and the yarn is mainly used for various textiles such as yarn-dyed cotton suiting for women, roved and spun fabrics, decorative articles, hand knitted products and shawls.

Owner:ZHONGYUAN ENGINEERING COLLEGE

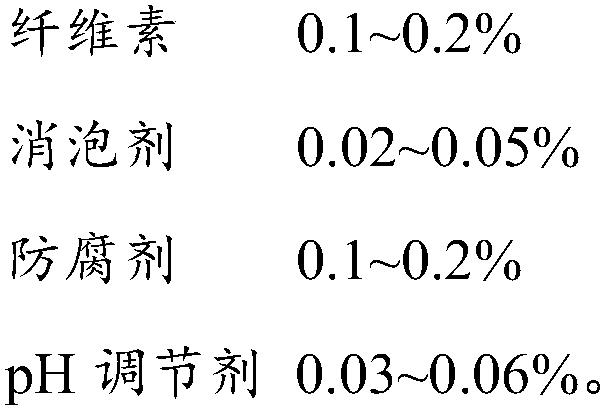

Preparation method of pure natural radix polygoni multiflora liquid shampoo

InactiveCN107929129AReduce dosageRich touchCosmetic preparationsHair cosmeticsPreservativeGleditsia triacanthos

The invention relates to a preparation method of pure natural radix polygoni multiflora liquid shampoo. The method comprises the following steps that oil-tea-cake meal, Chinese honey locust, radix polygoni multiflora and fresh ginger are respectively extracted; then, extraction liquid of the oil-tea-cake meal, the Chinese honey locust, the radix polygoni multiflora and the fresh ginger is sufficiently mixed according to a certain proportion; 0.01 to 0.05 percent of preservative potassium sorbate are added; uniform stirring is performed to obtain the liquid shampoo. The product is healthy and achieves an environment-friendly effect; strong cleaning and bacteriostatic effects are achieved; the efficacies of reliving itching, eliminating dandruff and blackening the hair can also be achieved.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Heat insulation infiltration coating sandwich wall cloth and manufacturing method thereof

PendingCN110158891AAdequate adhesionObvious connection seamCovering/liningsSpecial surfacesFiberCrack resistance

The invention provides a heat insulation infiltration coating sandwich wall cloth, and a method for manufacturing the heat insulation infiltration coating sandwich wall cloth, or an object decorationmethod. The heat insulation infiltration coating sandwich wall cloth comprises a heat insulation coating and an infiltration coating composite sandwich coating compound covering the surface of the heat insulation coating; the infiltration coating composite sandwich coating compound comprises a transparent or semi-transparent second coating and a fiber texture network sandwich wrapped by the secondcoating; the fiber texture network sandwich contains a network structure formed by fibers; and the second coating penetrates into meshes of the network structure. The wall cloth with textures and / orpatterns can be manufactured in a standardized and large-scale mode, and has good crack resistance, air permeability and decorative performance.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

Alkali-resistant infiltration coating sandwich wall cloth and manufacturing method thereof

The invention provides an alkali-resistant infiltration coating sandwich wall cloth, and a method for manufacturing the infiltration coating sandwich wall cloth, or an object decoration method. The alkali-resistant infiltration coating sandwich wall cloth comprises a closed bottom coating, a bottom color coating covering the surface of the closed bottom coating and an infiltration coating composite sandwich coating compound covering the surface of the bottom color coating; the infiltration coating composite sandwich coating compound comprises a transparent or semi-transparent second coating and a fiber texture network sandwich wrapped by the second coating; the fiber texture network sandwich contains a network structure formed by fibers; and the second coating penetrates into meshes of thenetwork structure. The wall cloth with textures and / or patterns can be manufactured in a standardized and large-scale mode, and has good crack resistance, air permeability and decorative performance.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

Preparation technology of natural organism and vegetable fiber microfiber material, and preparation technology of product

The invention discloses a preparation technology of a natural organism and vegetable fiber microfiber material. The technology comprises the following steps: 1, preparing fiber batting composed of dermal fiber-containing composite fibers, modified high-shrinkage polyester fibers and vegetable fibers; 2, preparing a base cloth; 3, carrying out polyvinyl alcohol impregnation treatment; 4, carrying out PU impregnation treatment; 5, carrying out alkali decrement treatment; and 6, carrying out surface effect and function agent treatment: coating the surface of a semi-finished product to form a surface layer, and preparing the microfiber material from the surface layer according to a needed surface effect, wherein the surface layer is coated through the following steps: coating an air-permeable lining film, coating a surface slurry, drying the slurry, coating the surface slurry, and drying the slurry to obtain the finished microfiber material. The invention also discloses the microfiber material prepared through adopting the above technology, and a preparation technology of a product. The microfiber material and the product produced through the above technologies are comparable to derma in physical properties, and has the appearance, quality, strength, softness, air permeability and other physical properties of the derma.

Owner:泉州众信超纤科技股份有限公司

Impregnated coated sandwich wall cloth and manufacturing method thereof

The invention provides an impregnated coated sandwich wall cloth and a method for manufacturing the impregnated coated sandwich wall cloth, or an object decoration method. The impregnated coated sandwich wall cloth comprises a bottom coating and an impregnated coated composite sandwich coating complex, wherein the surface of the bottom coating is coated with the impregnated coated composite sandwich coating complex; and the impregnated coated composite sandwich coating complex comprises a transparent or translucent second coating and a fiber texture network sandwich wrapped by the second coating, wherein the fiber texture network sandwich contains a network structure formed by fiber, and the second coating permeates into net holes of the network structure. The wall cloth with textures and / or patterns can be manufactured in standardized and large-scale modes, and the impregnated coated sandwich wall cloth has good anti-cracking performance, air-permeable performance and decoration performance.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

Preparation method of shoe lining leather

ActiveCN111169123AHigh peel strengthImprove folding resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceFolding endurance

The invention relates to a preparation method of shoe lining leather. The preparation method comprises the following steps: (1) uniformly mixing and stirring PU resin, a thickener, a leveling agent and water to prepare mixed slurry; (2) coating the surface of release paper with the mixed slurry, carrying out drying to obtain a PU surface layer, coating the surface layer with the mixed slurry, carrying out drying, and forming a PU bottom layer on the PU surface layer to obtain a PU dry film; (3) impregnating base cloth with water-based wet resin, and carrying out drying to obtain a base; and (4) coating the PU bottom layer of the PU dry film with a solvent-free adhesive, carrying out pre-drying, laminating the PU dry film with the base, and conducting drying and curing to obtain the shoe lining leather. According to the invention, the PU dry film and the base are compounded by adopting the specific solvent-free adhesive, a formula of the solvent-free adhesive is optimized, and proper raw materials are selected to prepare the PU bottom layer and the PU surface layer, so the peel strength of the shoe lining leather is greatly improved, and the folding resistance and the wear resistance of the shoe lining leather are improved; and the DMF content of the shoe lining leather meets requirements prescribed by the ZDHC organization according to detection results.

Owner:HUALUN LEATHER & PLASTIC SUZHOU

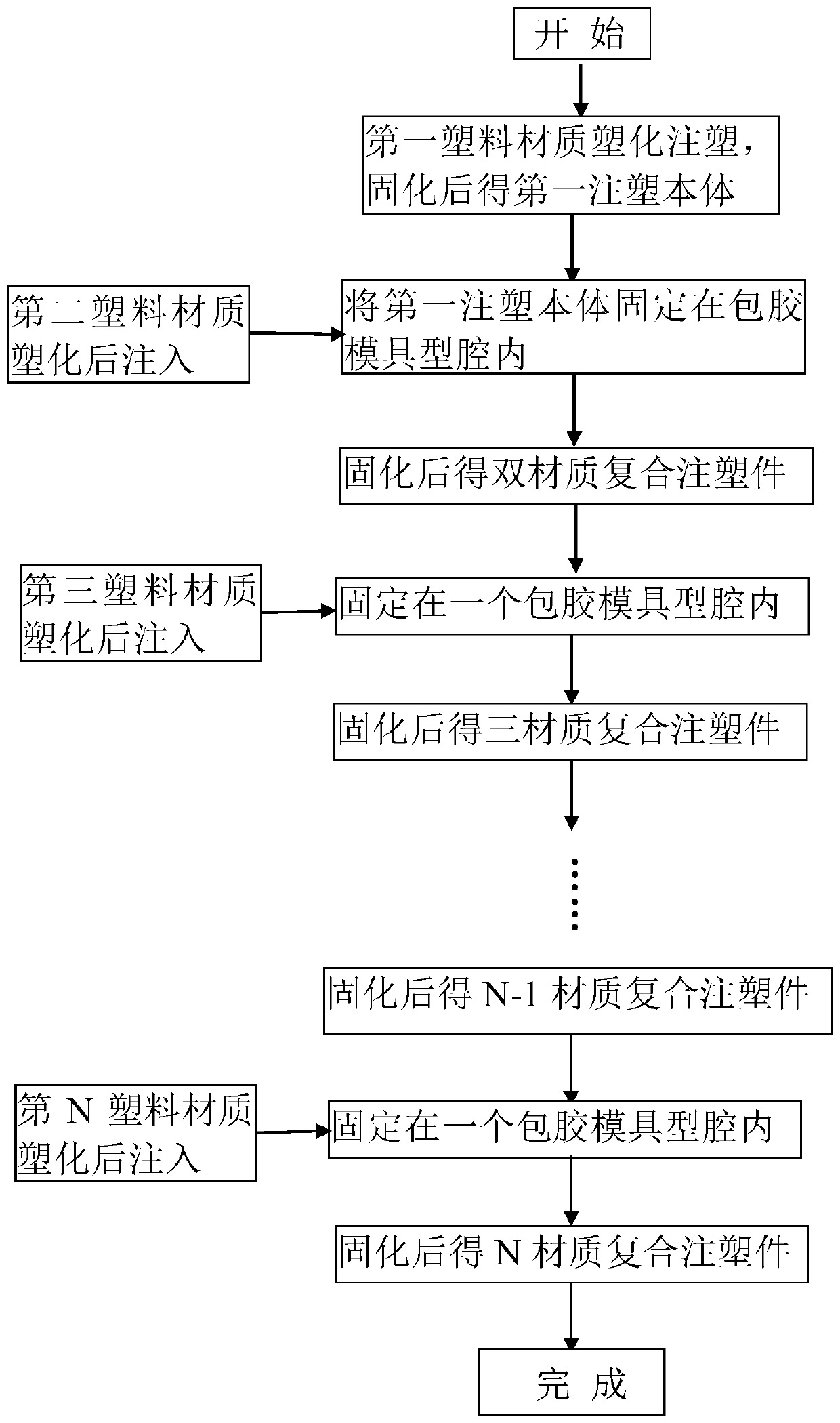

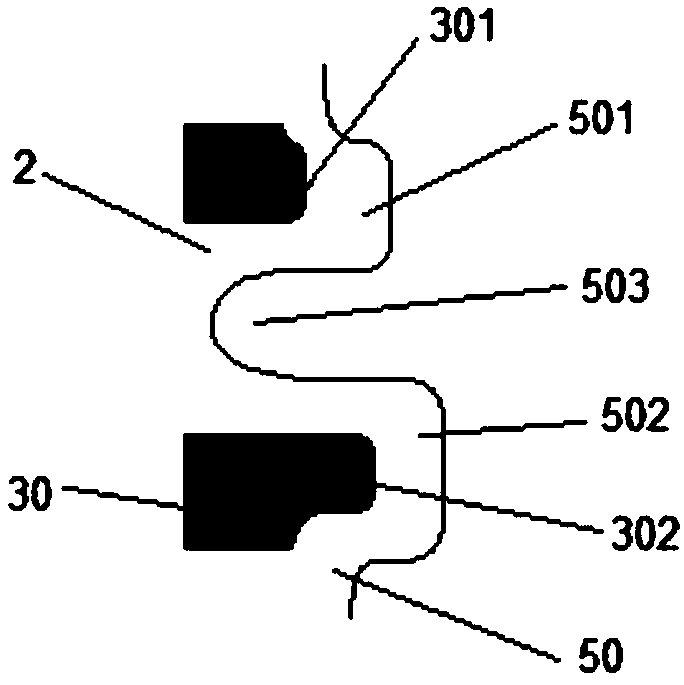

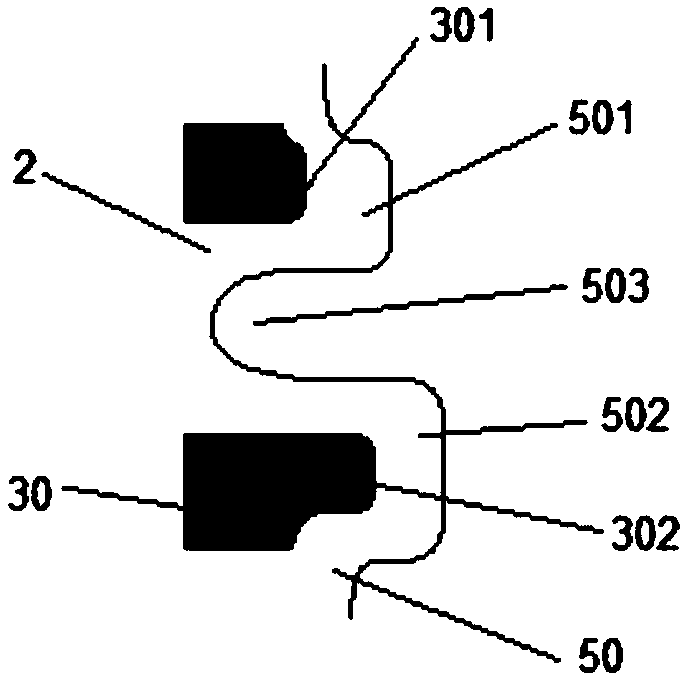

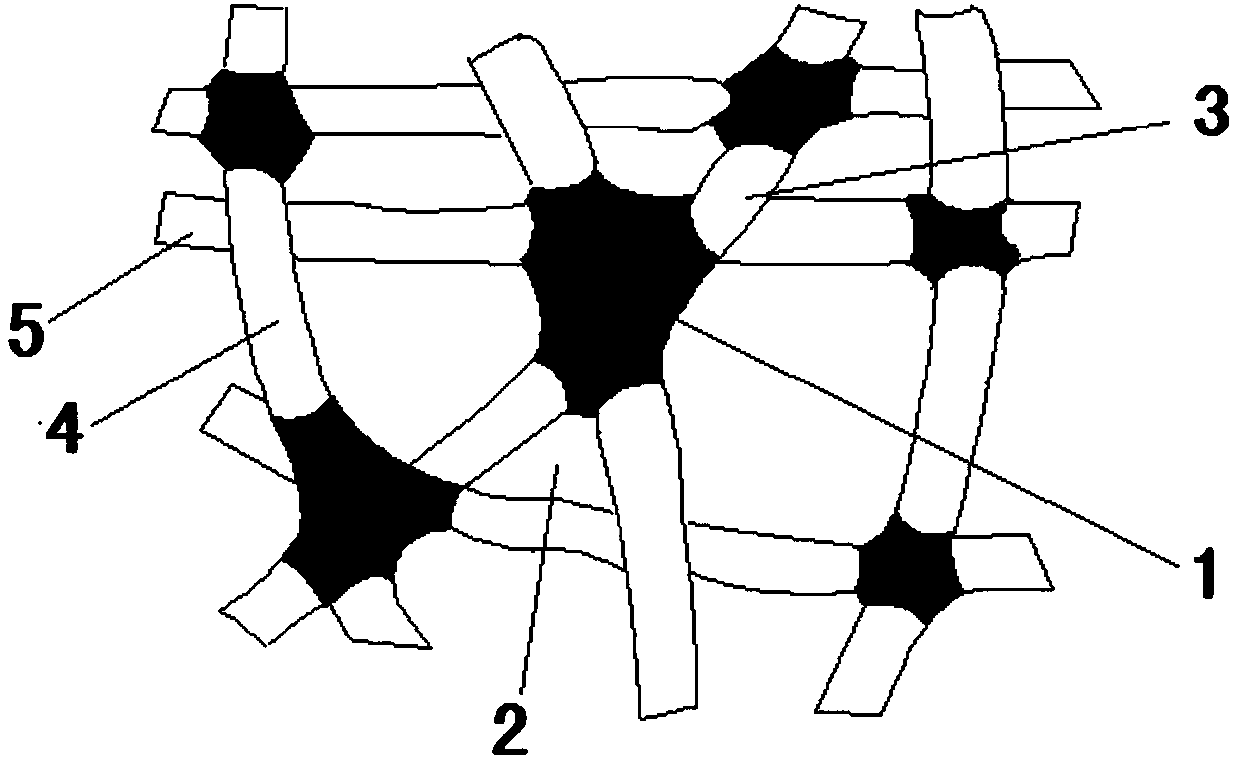

Multi-color multi-material injection molding method

InactiveCN110216838ASimple production operationReduce manufacturing costDomestic articlesMulti materialPlastic materials

The invention relates to a multi-color multi-material injection molding method. The method comprises the following steps of S1, selecting at least a first plastic material and a second plastic material as injection molding materials; S2, heating and plasticizing the first plastic material, injecting the first plastic material into a first mold cavity, and taking out the molded first plastic material to obtain a first injection molding body; S3, placing the first injection molding body into a second mold cavity and fixing the position of the first injection molding body; and S4, heating and plasticizing the second plastic material and then injecting the second plastic material into the second mold cavity, so that the melt of the second plastic material covers the local surface of the firstinjection molding body, and after cooling and curing molding are completed, taking out an obtained double-material composite injection molded part taking the first plastic material as a main body andthe second plastic material as a coating glue; and so on. According to the method, each time the injection molded part molded in the previous step is placed in a novel coating mold cavity for fixing,and the Nth plastic material is plasticized and injected into the mold cavity, so that a novel layer of coating glue is formed on the surface of the injection molded part molded in the previous step until products are completed. According to the method, the production process is simple; and the product is safer and healthier, is more stable in quality and higher in grade.

Owner:湖南桑尼森迪玩具制造有限公司

Waterproof impregnated coated sandwich wall cloth and manufacturing method thereof

The invention provides a waterproof impregnated coated sandwich wall cloth and a method for manufacturing the impregnated coated sandwich wall cloth, or an object decoration method. The waterproof impregnated coated sandwich wall cloth comprises a bottom coating and an impregnated coated composite sandwich coating complex, wherein the surface of the bottom coating is coated with the impregnated coated composite sandwich coating complex; and the impregnated coated composite sandwich coating complex comprises a transparent or translucent second coating and a fiber texture network sandwich wrapped by the second coating, wherein the fiber texture network sandwich contains a network structure formed by fiber, the second coating permeates into net holes of the network structure, and one or moreof the second coating and the bottom coating can be waterproof coatings. The wall cloth with textures and / or patterns can be manufactured in standardized and large-scale modes, and the waterproof impregnated coated sandwich wall cloth has good anti-cracking performance, air-permeable performance and decoration performance.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

Electromagnetic shielding impregnation coating sandwich wall cloth and manufacturing method thereof

The invention provides an electromagnetic shielding impregnation coating sandwich wall cloth and a method of manufacturing the electromagnetic shielding impregnation coating sandwich wall cloth or anobject decoration method. The electromagnetic shielding impregnation coating sandwich wall cloth comprises a bottom coating and an impregnation coating composite sandwich coating composite body applied to the surface of the bottom coating; and the impregnation coating composite sandwich coating composite body comprises a transparent or semitransparent second coating and a fiber texture network sandwich wrapped in the second coating, the fiber texture network sandwich comprises a network structure formed through fibers, the second coating permeates into net holes of the network structure, and one or more of the bottom coating, the second coating and the fiber texture network sandwich have an electromagnetic shielding function. According to the electromagnetic shielding impregnation coatingsandwich wall cloth and the method, the wall cloth with textures and / or patterns can be manufactured in a standardized and large-scale manner, and the wall cloth has the good anti-cracking performance, air permeability and decorative performance.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

Scrawling preventing infiltration coating sandwiched wall cloth and manufacturing method thereof

PendingCN110158885AAdequate adhesionAvoid crackingLiquid surface applicatorsCovering/liningsCoated surfaceFiber

The invention provides scrawling preventing infiltration coating sandwiched wall cloth and a method for manufacturing the scrawling preventing infiltration coating sandwiched wall cloth or an object decoration method. The scrawling preventing infiltration coating sandwiched wall cloth comprises a bottom coating and an infiltration coating composite sandwiched coating composite body applied to thesurface of the bottom coating. The infiltration coating composite sandwiched coating composite body comprises a transparent or semitransparent scrawling preventing coating and a fiber texture networksandwiched core wrapped by the scrawling preventing coating, wherein a network structure formed by fiber is contained in the fiber texture network sandwiched core, and the scrawling preventing coatingseeps into meshes of the network structure. By means of the method, the wall cloth with texture and / or patterns can be manufactured in a standard and large-scale manner, and good crack resisting performance, ventilation performance and decoration performance are achieved.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

Magnetic attracting wall-mounted infiltrated and coated sandwich wall cloth and manufacturing method thereof

The invention provides a magnetic attracting wall-mounted infiltrated and coated sandwich wall cloth and a manufacturing method thereof or an object decorating method. The magnetic attracting wall-mounted infiltrated and coated sandwich wall cloth comprises a bottom coating and an infiltrated and coated compound sandwich painting complex coated on the surface of the bottom coating; the infiltratedand coated compound sandwich painting complex comprises a transparent or semitransparent second coating and a fiber texture mesh sandwich wrapped by the second coating, wherein the fiber texture meshsandwich includes a mesh structure formed by fibers inside; the second coating infiltrates into mesh openings of the mesh structure; and one or several of the second coating, the bottom coating and the fiber texture mesh sandwich can possess magnetic attracting performance. The manufacturing method disclosed by the invention is capable of manufacturing the wall cloth with textures and / or patternson a large scale in a standardizing manner, and the wall cloth has good anti-cracking ability, air permeability and decorating property.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

Water-in-water multicolor coating as well as preparation method and application of coating

InactiveCN107722739AGood stabilityGood toughnessAntifouling/underwater paintsPaints with biocidesThermal insulationTitanium dioxide

The invention discloses a water-in-water multicolor coating as well as a preparation method of the coating. The water-in-water multicolor coating contains the following components in percentage by weight: 20%-22% of elastic polymer emulsion, 1%-2% of a protecting adhesive, 0.1%-0.5% of a crosslinking stabilizer, 0.1%-0.3% of a cationic crosslinking agent, 0.5%-1% of a film forming aid, 0.1%-0.8% of a thickening agent, 8%-10% of thermal insulation powder, 0.01%-0.1% of a wetting agent, 0.05%-0.2% of a dispersing agent, 1%-3% of infrared reflection pigment, 0.1%-0.5% of titanium dioxide, 1%-5% of kaolin, 0.3%-1.5% of other aids and the balance of deionized water. The water-in-water multicolor coating has the beneficial effects that a dispersoid is stable, and a coating layer has good weatherresistance, alkali resistance, durability and pollution tolerance and strong adhesive property and is colorful. According to the preparation method of the water-in-water multicolor coating, the stability of the prepared water-in-water multicolor coating can be effectively guaranteed.

Owner:CHINA PAINT MFG CO SHENZHEN

A color-fixing agent for nylon carpet digital printing and its application

The invention relates to the technical field of spinning, and particularly relates to a formula of a disposable agent for digital printing of a nylon carpet and an application thereof. The formula of the disposable agent for digital printing of the nylon carpet is characterized by comprising the following raw materials by weight percent: 20-40% of amino-modified organic silicon, 15-20% of tricarboxylic acid, 5-10% of water-soluble epoxy crosslinking agent terephthalic acid (EPTA) and 30-60% of water. Compared with the prior art, about more than 70% of softening agent taking the amino-modified organic silicon as a main body is prepared from a copolymer of N-beta-aminoethyl-gamma-ammonia propyl methyl dimethoxy silane and dimethyl siloxane as an active component. An active amino group is contained, so that the friction force between textile fibers can be reduced by the polarity, the formula is stable in size, good in drapability, and anti-pilling, and can restore after being folded. Tricarboxylic acid (PBTC) is a stabilizer with good performance, the colors printed on the nylon carpet can be well preserved, and the disposable agent has a good fixation effect.

Owner:SHANGHAI CCF CARPET & FURNISHING CO LTD

Stereoscopic surface laser printing technology of cowboy brassiere and cowboy brassiere produced by stereoscopic surface laser printing technology

ActiveCN106852516ASimple and fast operationWithout compromising comfortDecorative surface effectsBrassieresLaser technologySurface layer

The invention relates to the technical field of laser technologies, and particularly relates to a stereoscopic surface laser printing technology of a cowboy brassiere and a cowboy brassiere produced by the stereoscopic surface laser printing technology. The laser printing technology comprises the following steps of: (1) lasering: putting a cowboy brassiere in a lasering machine for stereoscopic lasering treatment, cooling to a room temperature to form a laser cowboy brassiere primary product, (2) cleaning and softening treatment: cleaning the cowboy brassiere primary product with a cleaning agent, softening the primary product with a softening agent, airing or drying the primary product to form a laser cowboy brassiere semifinished product, and (3) typing treatment: applying a transparent typing agent on a laser surface of the cowboy brassiere semifinished product to form the laser printing cowboy brassiere. The cowboy laser printing technology is easy and simple to operate; a surface layer of the brassiere is burnt and melt by the stereoscopic lasering on the surface of the cowboy brassiere to form a laser engraving hollow area and a non-laser engraving area; and laser printing with a strong stereoscopic effect, high clarity and high persistency can be presented after post treatment.

Owner:HONGJI UNDERWEAR CO LTD

Long-acting antibacterial infiltration coated sandwich wall covering and manufacturing method thereof

The invention provides a long-acting antibacterial infiltration coated sandwich wall covering and a method for manufacturing the infiltration coated sandwich wall covering, or an object decorating method. The long-acting antibacterial infiltration coated sandwich wall covering comprises a priming coat and an infiltration coated composite sandwich coating composite coated on the surface of the priming coat; and the infiltration coated composite sandwich coating composite comprises a transparent or translucent second coat and a fiber texture network sandwich wrapped with the second coat, whereinthe fiber texture network sandwich contains a network structure formed by fibers, and the second coat infiltrates into meshes of the network structure, meanwhile, the fibers of the fiber texture network sandwich are loaded with an antibacterial substance or a substance capable of releasing an antibacterial substance. The wall covering with textures and / or patterns can be manufactured in large scale in a standardized mode, and has good crack resistance, air permeability and decorative performance. An antibacterial agent is loaded in the fibers and wrapped by coating, and does not fall off, sothat the long-term antibacterial effect can be achieved.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

Non-elasticity hollow core big-belly yarn and preparation method thereof

The invention provides a non-elasticity hollow core big-belly yarn. The big-belly yarn comprises two core yarns, two fixed yarns and one decorative yarn, wherein the core yarns are hollow core yarns processed by water-soluble vinylon filaments, coffee fibers and seashell fibers in a blended mode; the fixed yarns are non-elasticity binder yarns processed by PTT fiber filaments, silk and linen fibers and coconut carbon fibers in a blended mode; the decorative yarn is a blended rough yarn processed by tapa fibers, nettle fibers and yakwool fibers in a blended mode. Multiple-component fiber raw materials are fed, in this way, the multifunctional multi-form multi-color composite fashion yarn can be produced, and the product variety and design can be enriched. At the present, novel weaving raw materials are rich in type and dazzling; through appropriate compatibility and application of the raw materials, kinds of product forms can be obtained, functions are complementary for kinds of fibers,and new varieties high in technical content and additional value can be developed.

Owner:ZHONGYUAN ENGINEERING COLLEGE

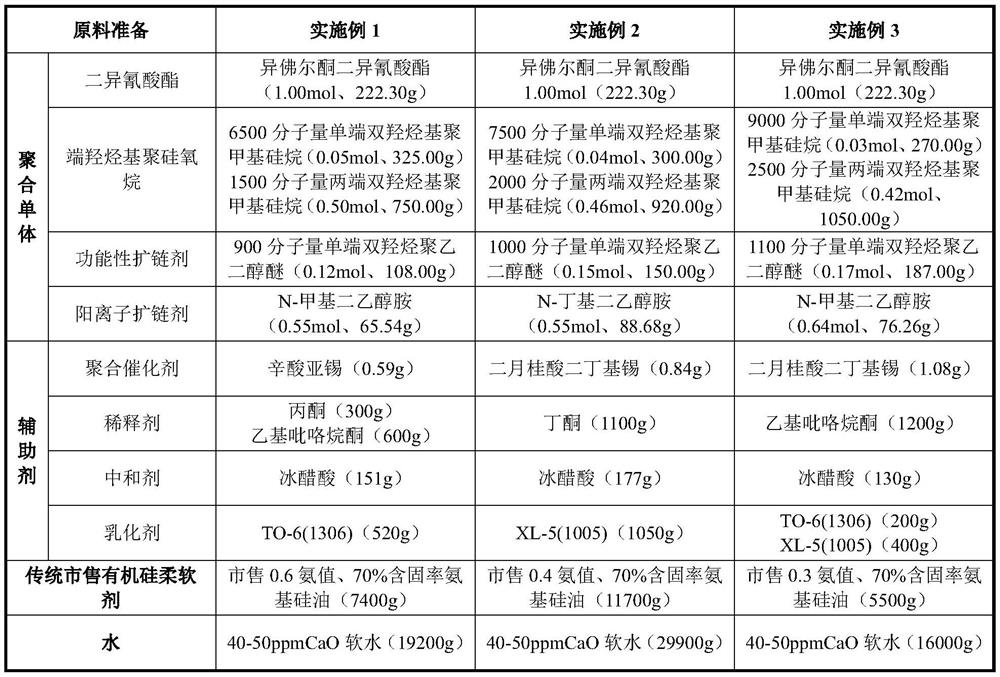

Comb-shaped associative polyurethane composite modified organic silicon softener emulsion and preparation method thereof

The invention relates to the field of polyurethane modified resin type organic silicon softener emulsion for finishing hand feeling styles of various textiles, and discloses comb-shaped associative polyurethane composite modified organic silicon softener emulsion and a preparation method thereof. The method comprises the following steps: preparing raw materials; performing prepolymerization; and carrying out chain extension and mixing emulsification. The softener emulsion disclosed by the invention is novel in structure and remarkable in effect. Various macromolecules in the emulsion can be effectively associated with each other, and blending modification of a traditional organic silicon softener is realized on textile fibers in a molecular blending manner. The self-made polyurethane modified polysiloxane polymer main chain has better extensibility, and polysiloxane long chains and polyether long chains are distributed in the side direction of the self-made polyurethane modified polysiloxane polymer main chain in an echelon manner; compared with a traditional amino modified organic silicon softener, the product provided by the invention can endow various textiles with obviously better hydrophilicity and elastic hand feeling; and the product is low in emulsifier content, safe, environmentally friendly and convenient to use, and has a good market prospect.

Owner:WUHAN TEXTILE UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com