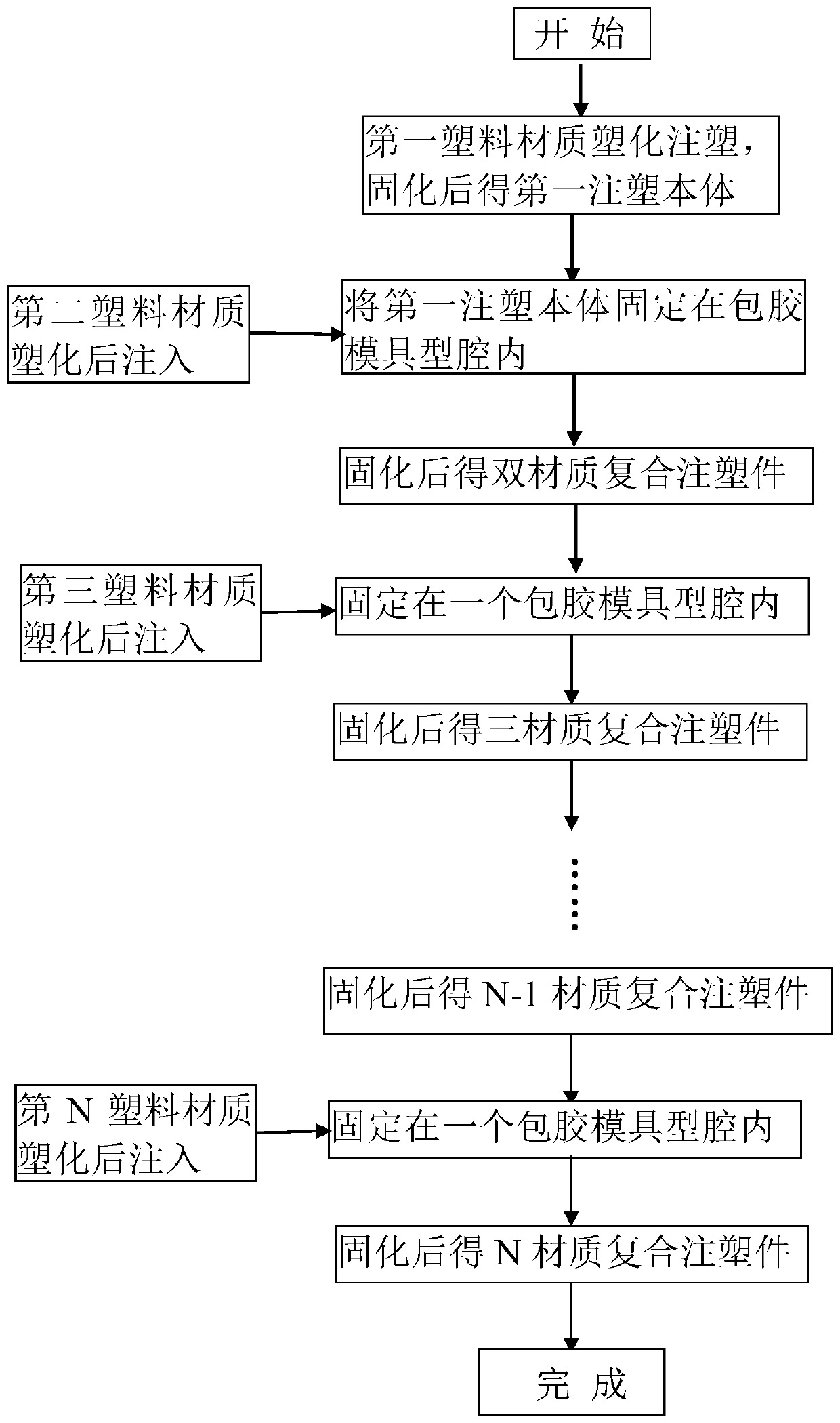

Multi-color multi-material injection molding method

A multi-material injection molding and molding method technology, applied in household components, applications, household appliances, etc., can solve the problems of large color differences between individual products, poor product consistency or stability, and difficulty in environmental protection and non-toxic thinners. To achieve the effect of reducing unstable factors, comfortable touch, and diversified visual gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Use an injection molding machine to heat the off-white ABS to 170°C to 200°C, inject it into the mold cavity after plasticizing, and form ABS plastic parts after cooling and molding (such as figure 2 A) is the head, face and neck of a cartoon doll.

[0051] Then put the molded ABS plastic part into an overmolding mold cavity and fix the position so that it cannot move. Use an injection molding machine to heat the brown PVC to 150°C to 190°C, and inject it into the cavity of the overmolding mold after plasticization, so that the PVC melt can be coated on the upper part of the ABS plastic part (specifically, it can be determined by designing the overmolding mold The structure of the cavity is realized), and after cooling, ABS+PVC plastic parts are formed (such as figure 2 B). After the PVC melt cooled, it formed the brown hair of the cartoon doll.

[0052] Put the ABS+PVC plastic parts formed above into the cavity of a new overmolding mold, and fix it so that it cann...

Embodiment 2

[0054] Use an injection molding machine to heat the blue ABS to 170°C to 200°C, inject it into the mold cavity after plasticizing, and form an ABS plastic part after cooling and molding, which is the basic background color of a Beijing opera mask (such as image 3 shown).

[0055] Then put the molded ABS plastic part into an overmolding mold cavity and fix the position so that it cannot move. Heat the white PVC to 150°C to 190°C with an injection molding machine, inject it into the cavity of the overmolding mold after plasticizing, so that the PVC melt covers the partial surface of the ABS plastic part, and form an ABS+PVC plastic part after cooling. Among them, after the PVC melt is cooled, it forms the eye area of Peking Opera facial makeup, a part of the Tai Chi pattern on the forehead, the white encapsulating parts of the ears, chin and other areas (such as image 3 shown).

[0056] Put the ABS+PVC plastic parts formed above into the cavity of a new overmolding mold, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com