Water-in-water multicolor coating as well as preparation method and application of coating

A multi-color paint, water-in-water technology, applied in the field of paint, can solve the problems of lack of heat preservation, heat insulation, short storage time, poor coating quality, etc., and achieve the effect of maintaining long-term beauty, simple construction, and high spray pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Correspondingly, the embodiment of the present invention also provides a preparation method of the above-mentioned water-in-water multicolor paint. Described preparation method comprises the steps:

[0034] S01. Measure each component respectively according to the composition and content thereof in the above-mentioned water-in-water colorful paint;

[0035] S02. Adding wetting agent, dispersant, titanium dioxide, kaolin and some other additives to part of the deionized water for the first mixing treatment to obtain the first mixed slurry;

[0036] S03. Add heat insulating powder and infrared reflective pigment to the first mixed slurry to perform a second mixing treatment to obtain a second mixed slurry;

[0037] S04. Add elastic polymer emulsion, film-forming aids, cationic crosslinking agent, thickener, crosslinking stabilizer, protective glue, remaining deionized water and remaining other auxiliary agents to the second mixed slurry to carry out the second step Thre...

Embodiment 1

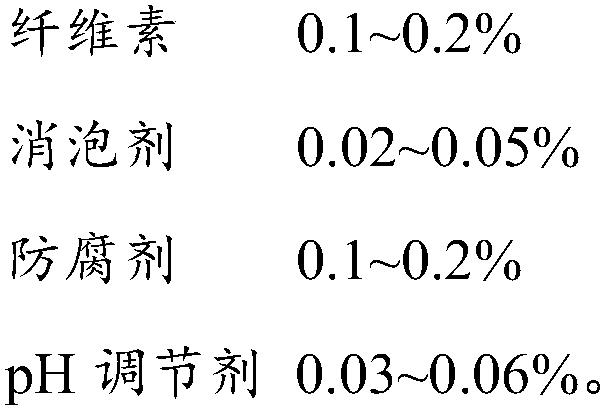

[0046] This embodiment provides a water-in-water multicolor paint and a preparation method thereof. Described water-in-water colorful coating contains following component (weight percentage, altogether 100 parts):

[0047]

[0048] Its preparation method is as follows:

[0049] In the low-speed stage, add 60 parts of remaining deionized water, 0.26 parts of cellulose, and stir for 10-20 minutes at low speed. Disperse for 10-15 minutes; add 8 parts of heat insulation powder, 4 parts of infrared reflective pigment, and disperse at high speed for 10 minutes; then add 20 parts of elastic polymer emulsion, 0.5 part of film-forming aid, 0.05 part of PH regulator, and defoamer 0.06 parts, 0.2 parts of cationic cross-linking agent, 0.3 parts of protective glue, 1 part of cross-linking stabilizer, after the above raw materials are added, disperse at low speed for 10 minutes to obtain base paint slurry; after color adjustment, cut into pellets in the protective glue solution , add ...

Embodiment 2

[0052] This embodiment provides a water-in-water multicolor paint and a preparation method thereof. Described water-in-water colorful paint contains following component (percentage by weight):

[0053]

[0054] Its preparation method is as follows:

[0055] In the low-speed stage, add 56 parts of deionized water, 0.26 parts of cellulose, and stir for 10-20 minutes at a low speed. 10-15 minutes, add 9 parts of heat insulating powder, 5 parts of infrared reflective pigment, disperse at high speed for 10 minutes, then add 22 parts of elastic polymer emulsion, 0.5 part of film-forming aid, 0.05 part of PH regulator, and 0.06 part of defoamer 0.2 parts of cationic cross-linking agent, 0.3 parts of protective glue, 1 part of cross-linking stabilizer. After the above raw materials are added, disperse at low speed for 10 minutes. and other ingredients, stir for another 3-5 minutes, stir well and then weigh and pack.

[0056] Example 1 The relevant performance test results of wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com