Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Highly selective separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Affinity chromatography fixed phase of immobilization metal and its preparation method

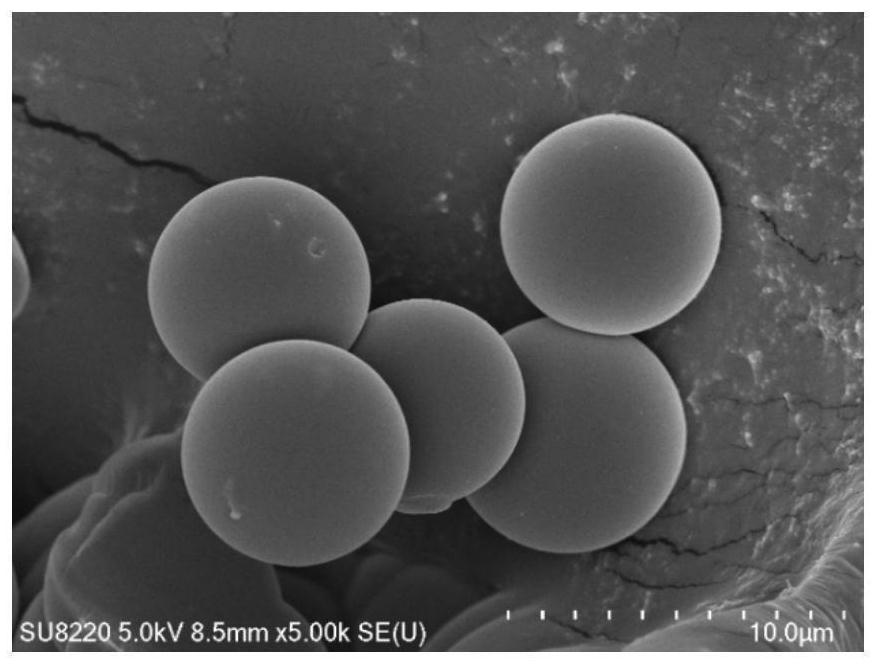

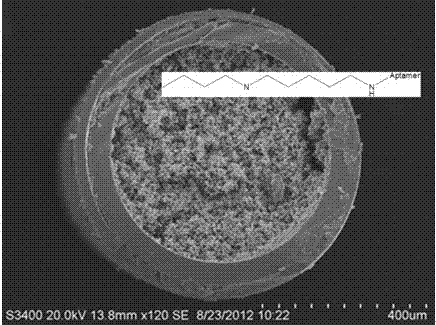

InactiveCN101288844AImprove selective enrichment effectReduce non-specific adsorptionOther chemical processesSynthesis methodsMicrosphere

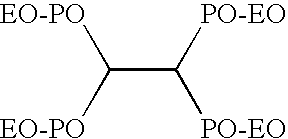

The invention relates to a separation and purification technique, in particular to an affinity chromatography stationary phase of immobilized metal and a preparation method thereof. The structure of the stationary phase is shown in the drawing; wherein, the particle size of GMAPolymer micro-sphere is 10nm-50um; the GMAPolymer micro-sphere is poly-methacrylic acid glycidyl esters micro-sphere. By carrying out amination and phosphoric esterification, a synthesis method of the high-performance poly-methacrylic acid glycidyl ester-group novel affinity chromatography stationary phase is gained and used for the research in phosphorylation proteomics and highly-selective separation, enrichment and purification of phosphopeptide by the chelation with zirconium ions and iron ions; meanwhile, compared with the traditional stationary phase, the affinity chromatography stationary phase reduces the nonspecific adsorption on the non-phosphopeptide.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

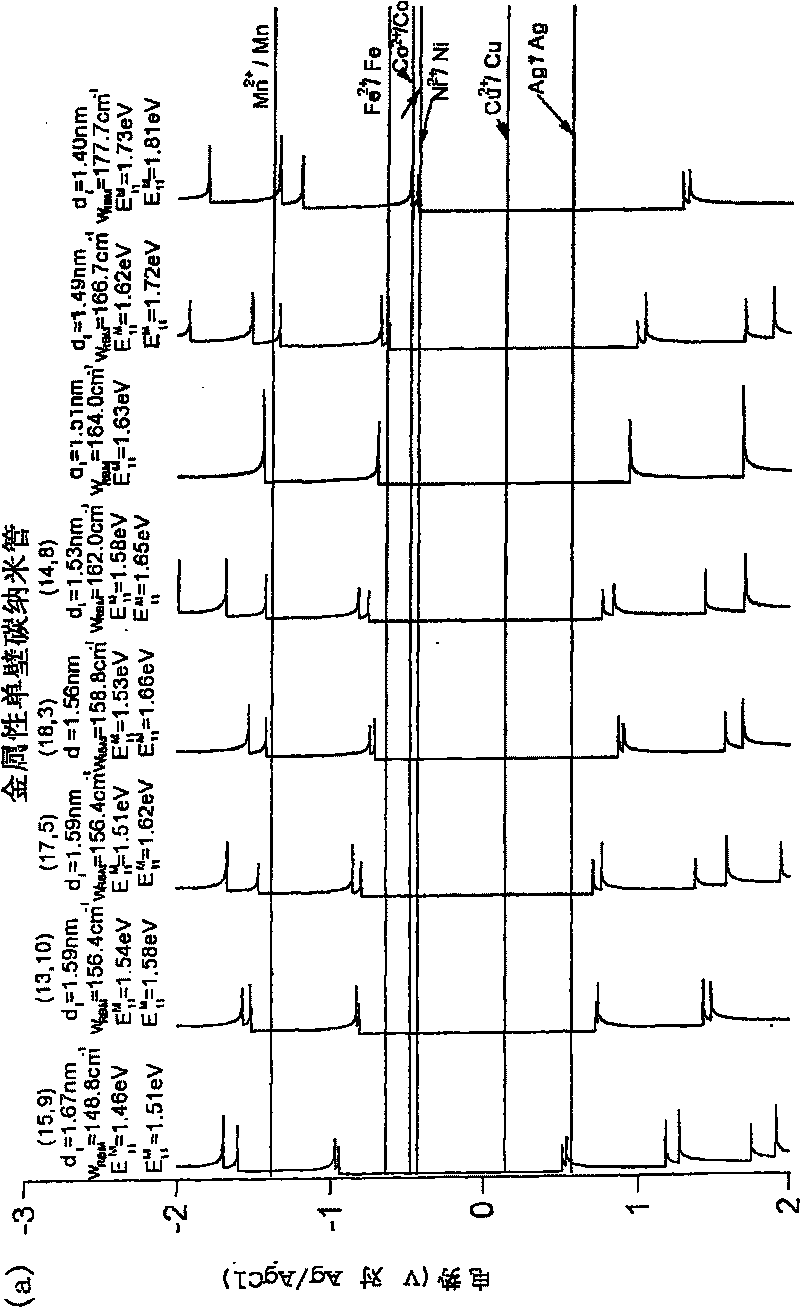

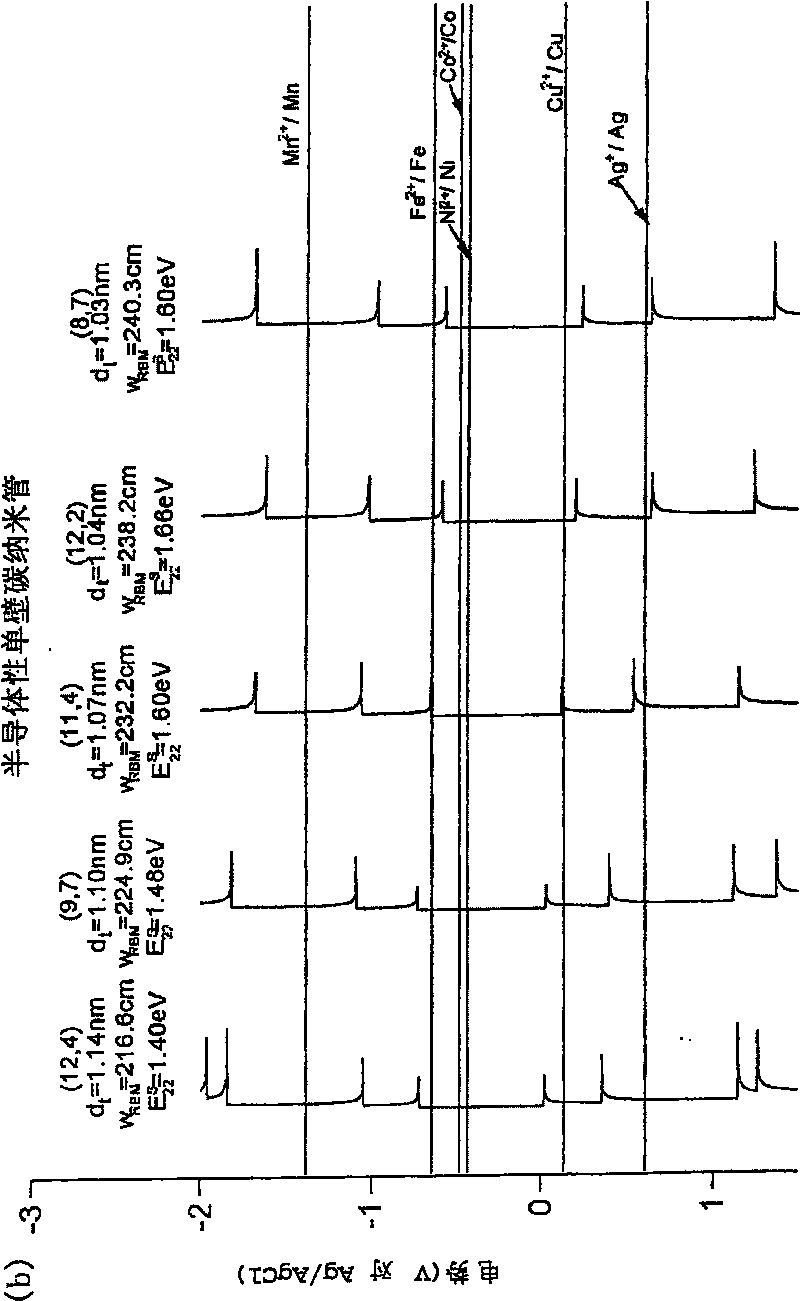

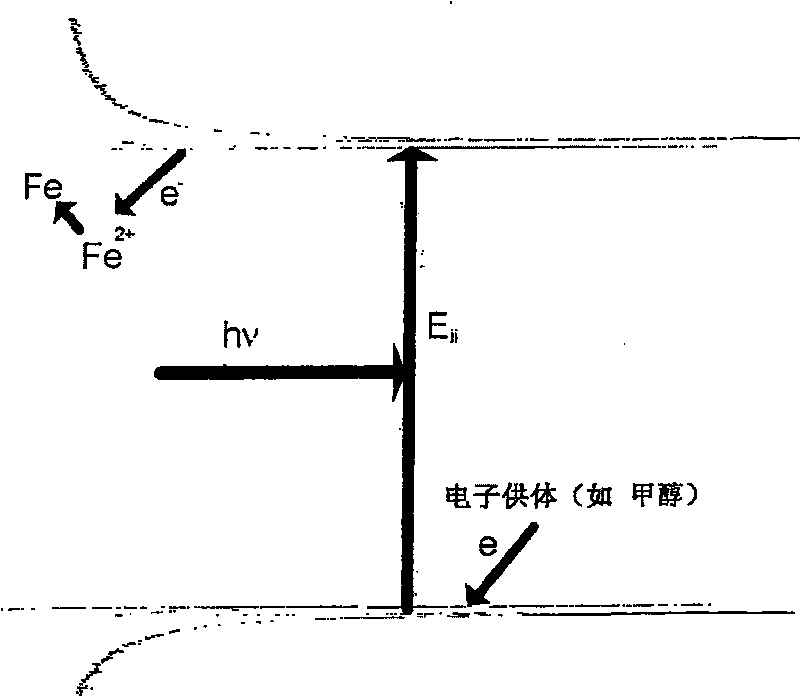

Carbon nanotube structure-selective separation and surface fixation

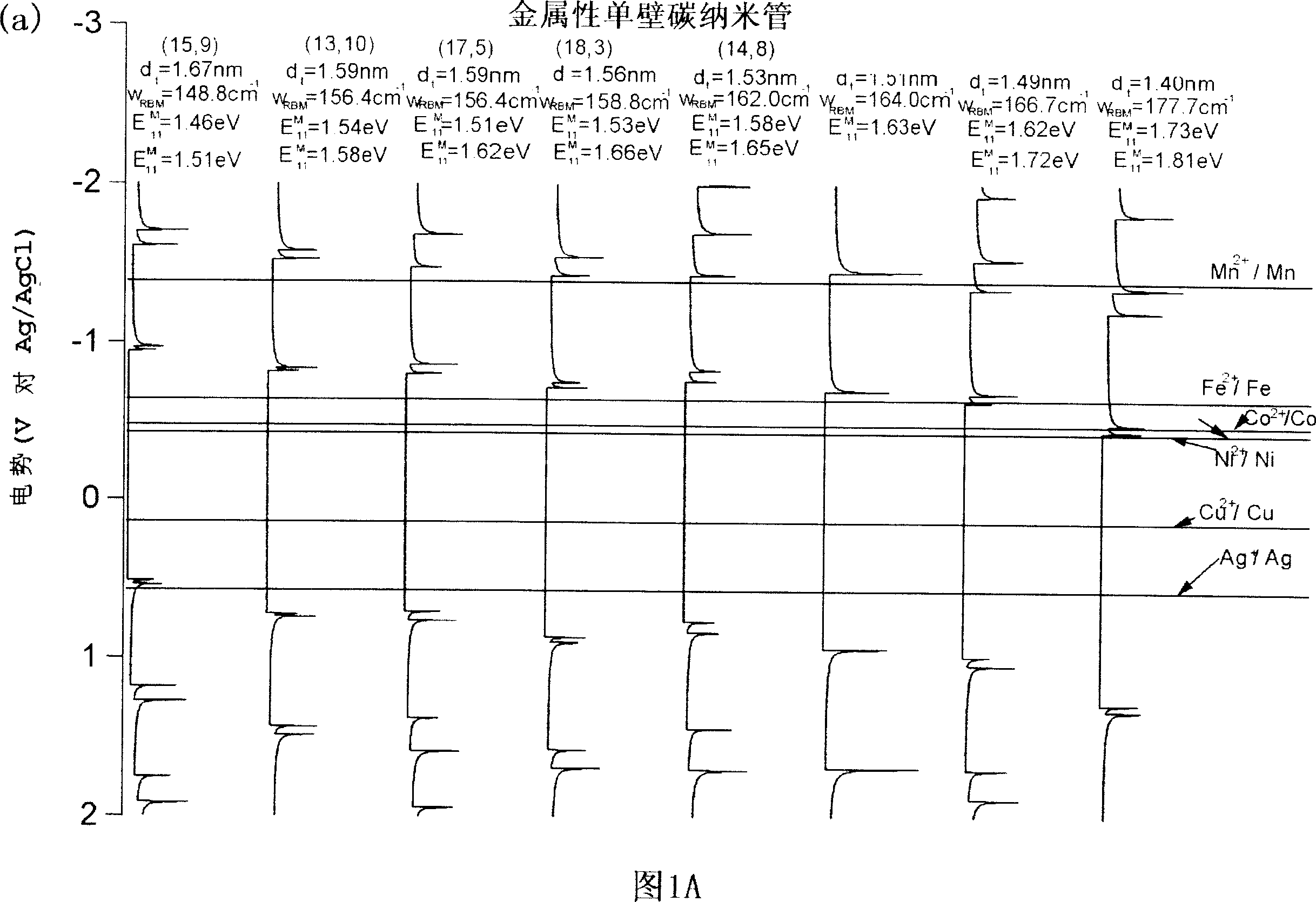

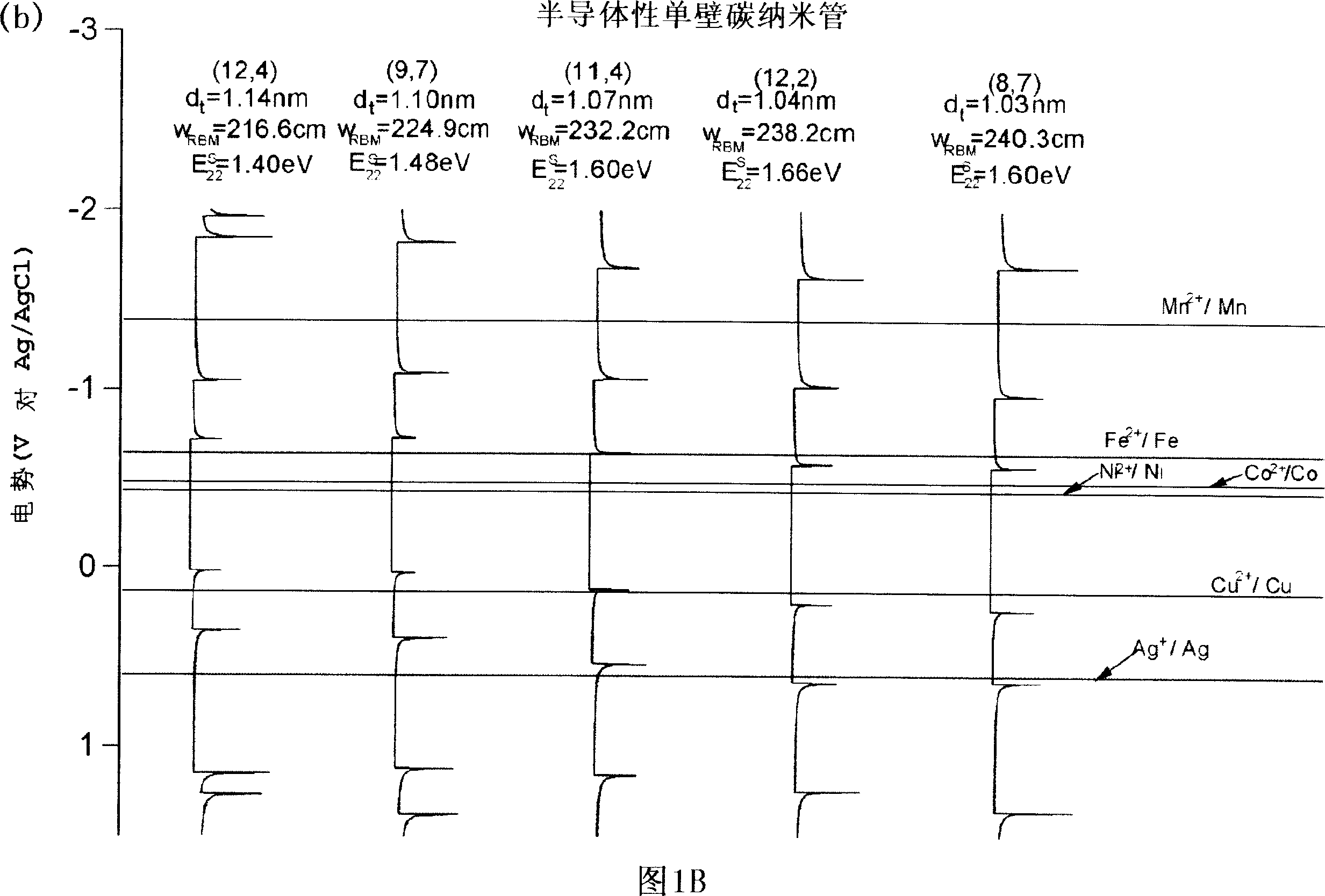

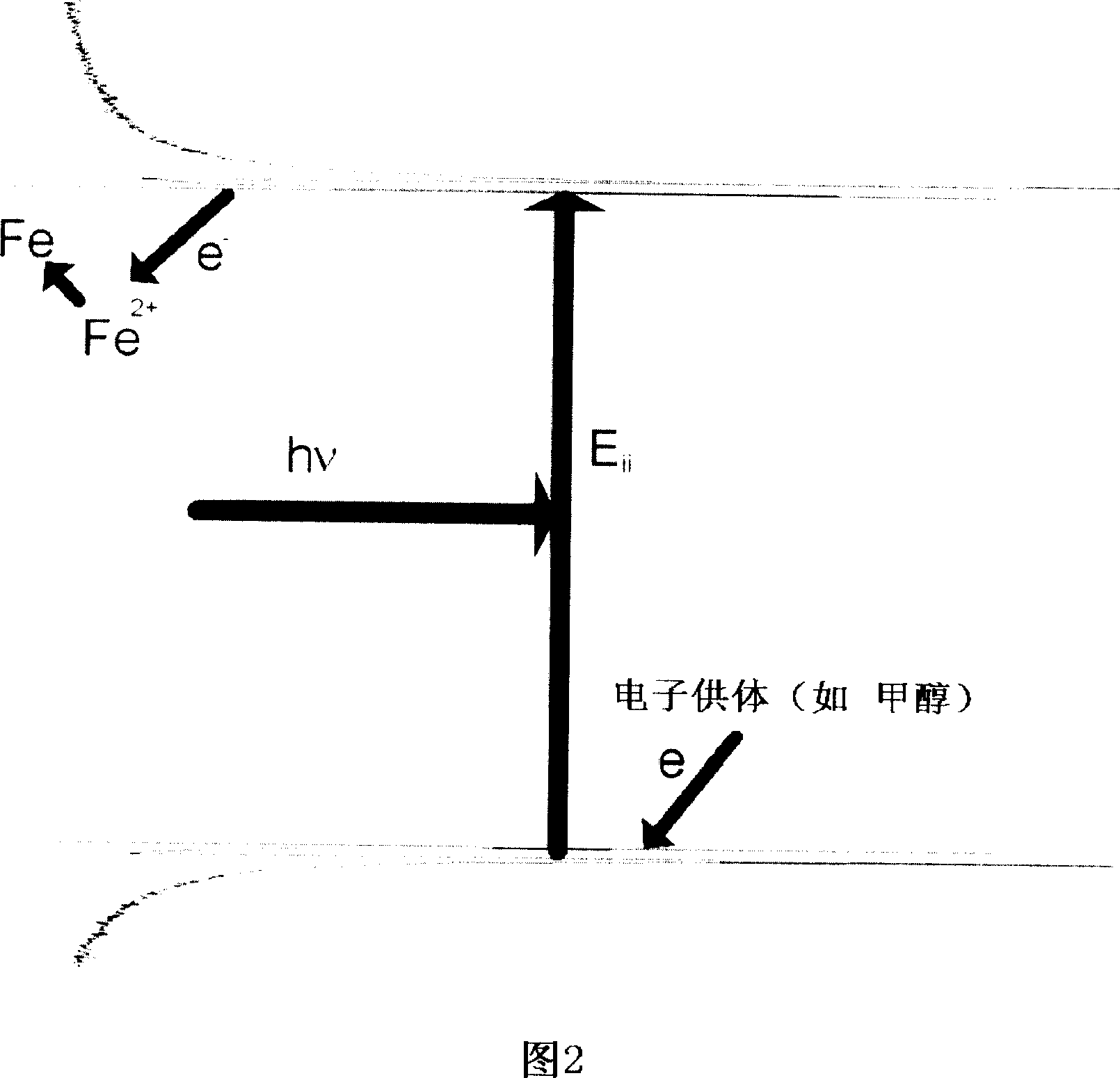

InactiveCN1922106AHighly selective separationImprove concentrationMaterial nanotechnologyAcceleration measurement using interia forcesLight irradiationPhotocatalytic reaction

A method of separating, concentrating or purifying uniform carbon nanotubes with desired properties (diameter, chiral vector, etc) in a highly sensitive manner by the use of structure-sensitive properties peculiar to carbon nanotubes; and an apparatus therefor. There is provided a method of separating, concentrating, or purifying carbon nanotubes with the desired properties contained in a sample, comprising the steps pf (a) irradiating a sample containing carbon nanotubes with light; and (b) selecting carbon nanotubes with desired properties. In a preferred embodiment, the light irradiation of the step (a) can be carried out in the presence of a metal so as to cause specified carbon nanotubes to selectively induce a photocatalytic reaction, resulting in metal deposition. Further, in a preferred embodiment, a given magnetic filed can be applied in the steps (b) so as to attain accumulation or concentration or carbon nanotubes with metal deposited.

Owner:JAPAN SCI & TECH CORP

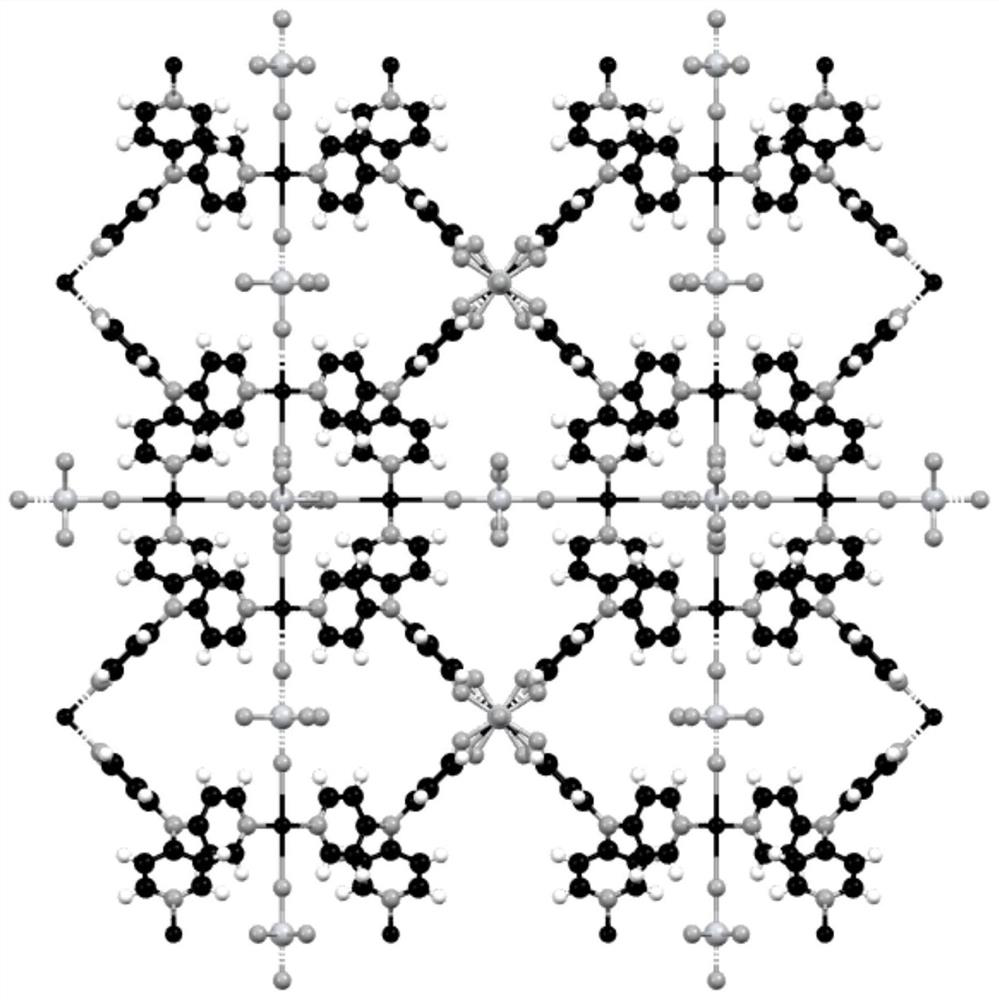

Layered fluorine-containing metal-organic framework material for adsorbing and separating ethynyl ethylene and preparation method and application thereof

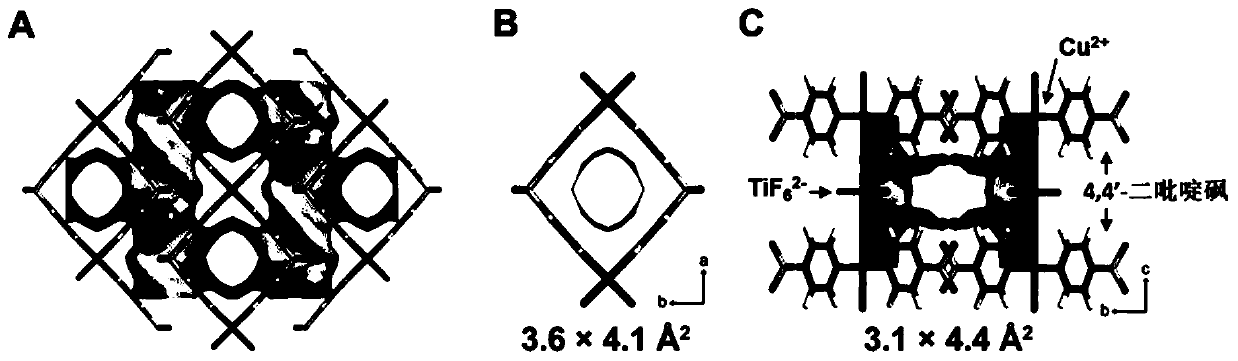

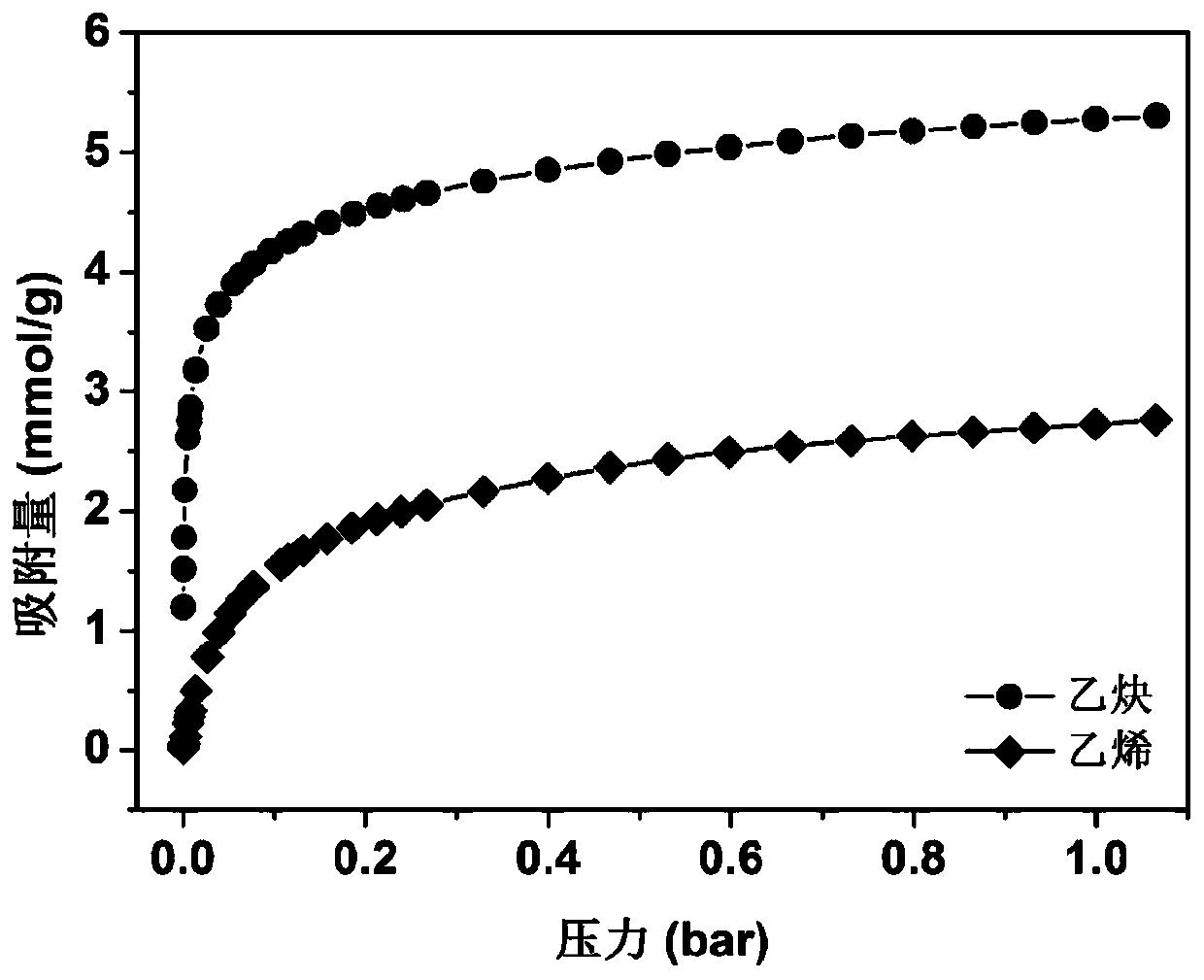

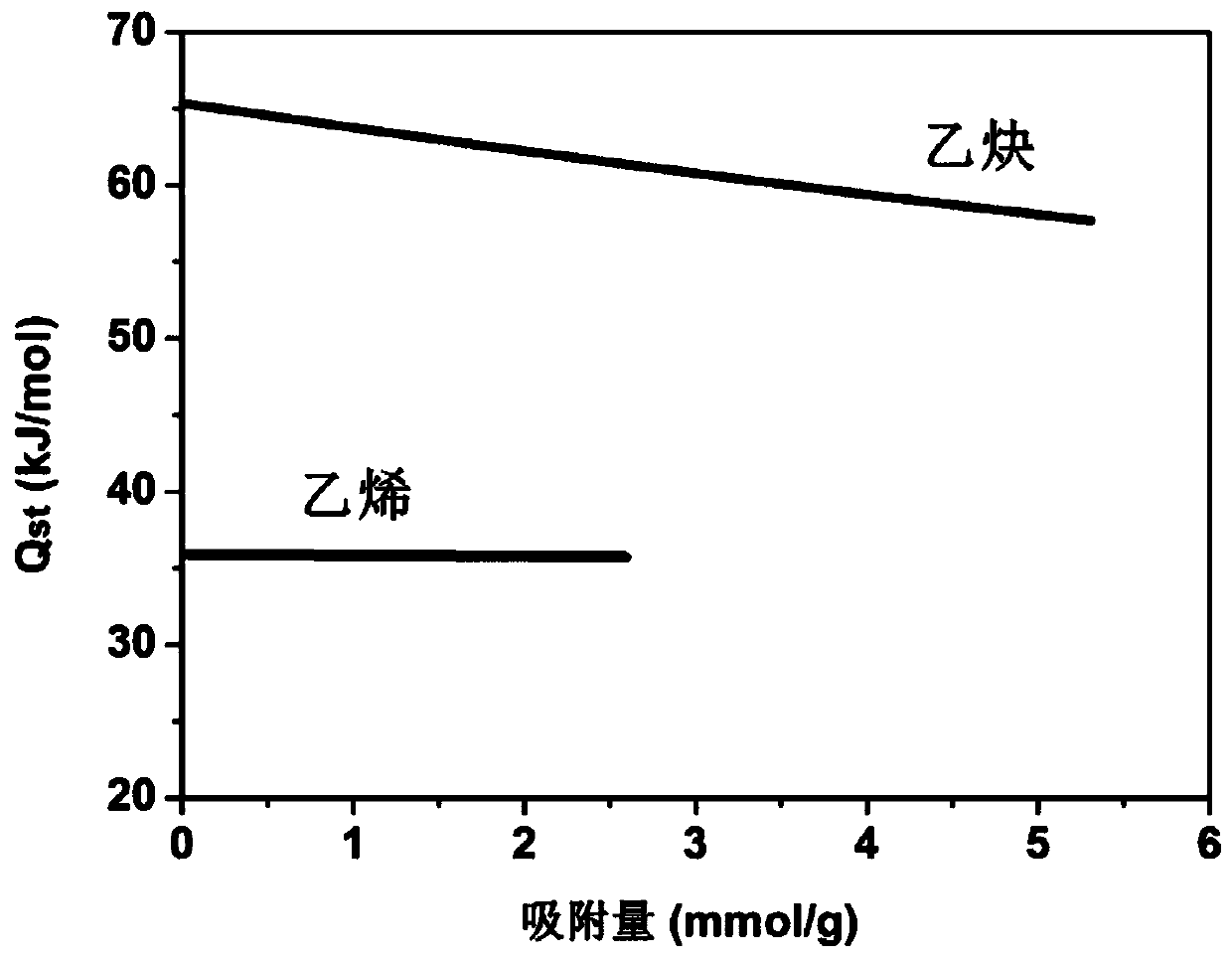

ActiveCN111298771AGood stabilityEasy to prepareOther chemical processesAdsorption purification/separationPyridyneAdsorption separation

The invention discloses a layered fluorine-containing metal-organic framework material for adsorbing and separating acetylene ethylene, the structural general formula is ML2A, M is a metal ion, L is abroken line type organic ligand, A is an inorganic fluorine-containing anion, and the metal ion M is at least one of Cu<2+>, Fe<2+>, Co<2+>, Ni<2+> and Zn<2+>, wherein the broken line type organic ligand L is at least one of 4, 4'-dipyridylsulfoxide and 4, 4'-dipyridylsulfone, and the inorganic fluorine-containing anion A is at least one of SiF6<2->, GeF6<2->, ZrF6<2->, SnF6<2->, TiF6<2->, NbOF52<->, WO2F4<2-> and MoO2F4<2->. The layered fluorine-containing metal-organic framework material can be prepared by adopting an interface diffusion method, a solvothermal method or a room-temperature stirring method. The layered fluorine-containing metal-organic framework material is used as an adsorbent and is in contact adsorption with a gas mixture containing acetylene and ethylene, and efficient separation of acetylene / ethylene can be realized at normal temperature, low acetylene content and low acetylene partial pressure.

Owner:ZHEJIANG UNIV

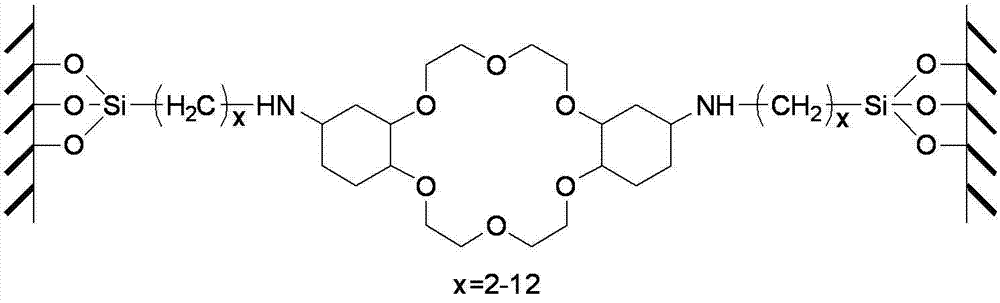

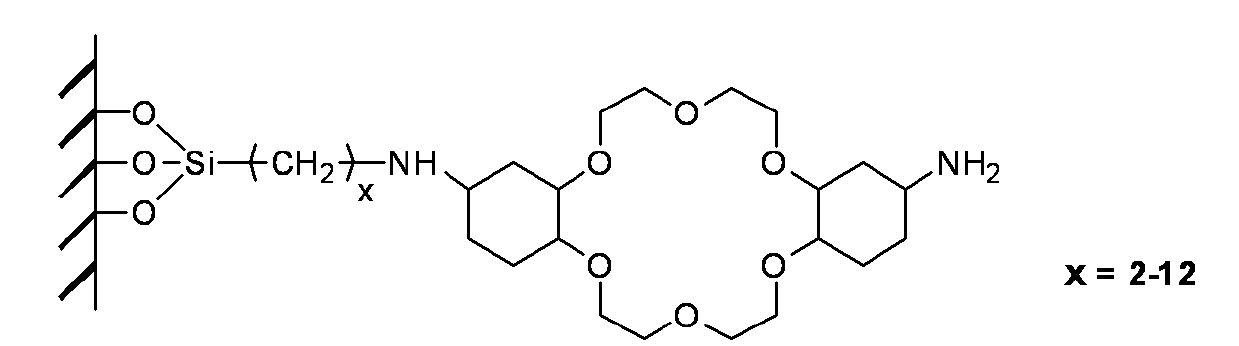

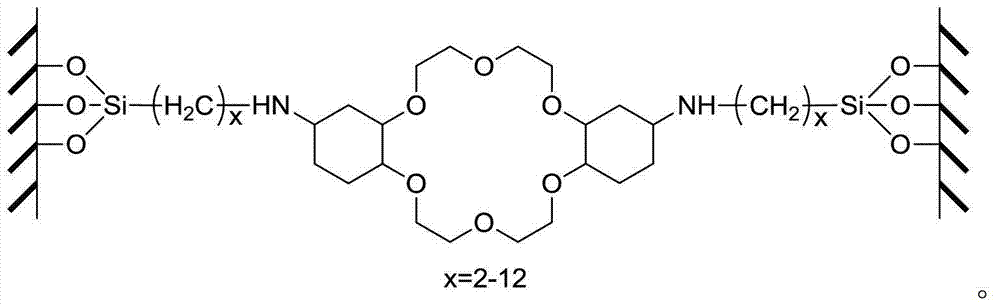

Method for separating palladium from waste water by double-arm bonding-type alicyclic crownether silicon resin

ActiveCN102849823AImprove separation efficiencyGuaranteed removal rateWater contaminantsWater/sewage treatment by ion-exchangeFluid phaseOrganic chemistry

The invention discloses a method for separating precious metal palladium through selective adsorption from palladium-containing waste liquid by using double-arm bonding-type alicyclic crownether silicon resin, and belongs to the technical field of heavy metal ion separation. The method comprises the following steps: firstly adding double-arm bonding-type alicyclic crownether silicon resin into palladium-containing waste liquid according to a ratio of 0.01-1.0 of the weight of the double-arm bonding-type alicyclic crownether silicon resin to the volume of the palladium-containing waste liquid, then stirring or oscillating at a temperature of 5-50 DEG C for 20-300 min; filtering and separating the solid phase from the liquid phase, determining the residual concentration of palladium ions in the liquid phase, comparing with an initial concentration to calculate the separation recovery rate; eluting the double-arm bonding-type alicyclic crownether silicon resin with a nitric acid solution of 0.01-3 mol / L, repeatedly washing with deionized water, drying to obtain regenerated resin. The method provided by the invention is high in separation speed for palladium ions in the palladium-containing waste liquid, high in separation efficiency, strong in adaptability, recyclable in materials, and low in cost.

Owner:TSINGHUA UNIV

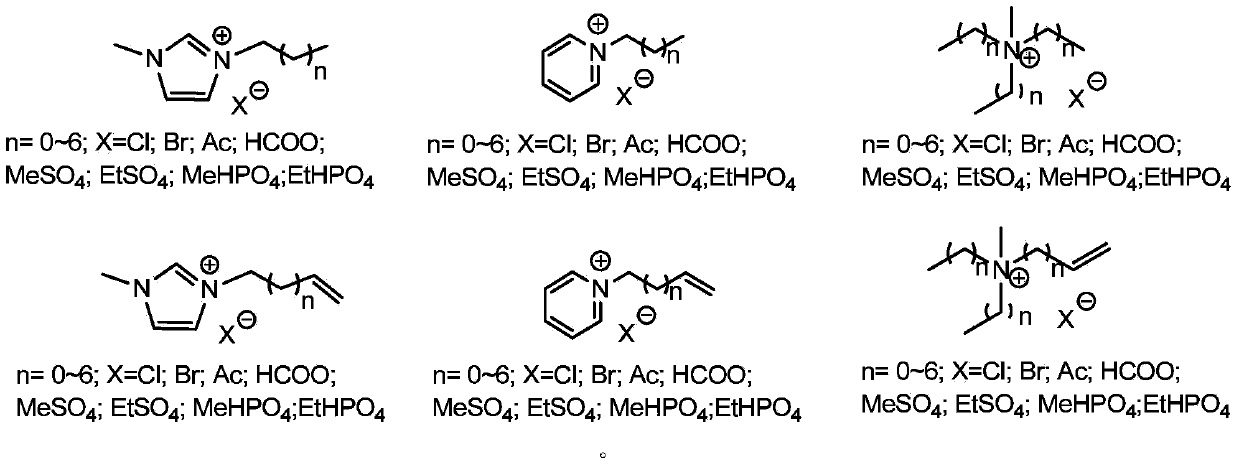

Method for separating lignin from agricultural waste by using composite ionic liquid

The invention discloses a method for efficiently separating lignin from agricultural waste by using a composite ionic liquid system. The method comprises the following steps: (1) preparation of composite ionic liquid: subjecting composite ionic liquid with cooperative effect to mechanical mixing or double-anion ion exchange; (2) pretreatment of agricultural waste: fully drying the agricultural waste, then crushing the agricultural waste to a size of 20 to 60 meshes by using a mechanical crushing method, washing the soluble components of crushed agricultural waste with acetone and deionized water successively and thoroughly drying the agricultural waste for subsequent usage; and (3) and delignification of the agricultural waste: fully mixing 5 to 500 g of the composite ionic liquid with 1.5 to 60 g of the agricultural waste and carrying out a reaction in an inert atmosphere at a temperature of 120 to 260 DEG C under stirring so as to obtain high-purity lignin and biological micromolecular substances. According to the method, the content of the obtained lignin is high; the usage amount of the ionic liquid is low; and the composite ionic liquid is cyclically usable and does not need addition of deionized water.

Owner:威海印九红果蔬种植专业合作社

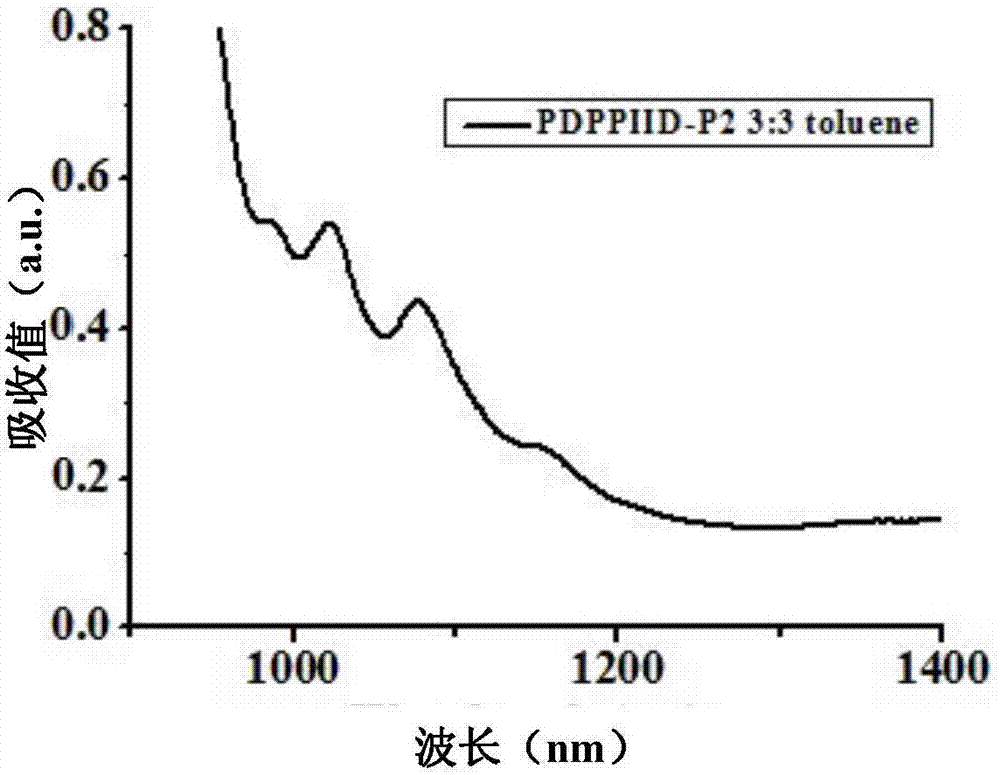

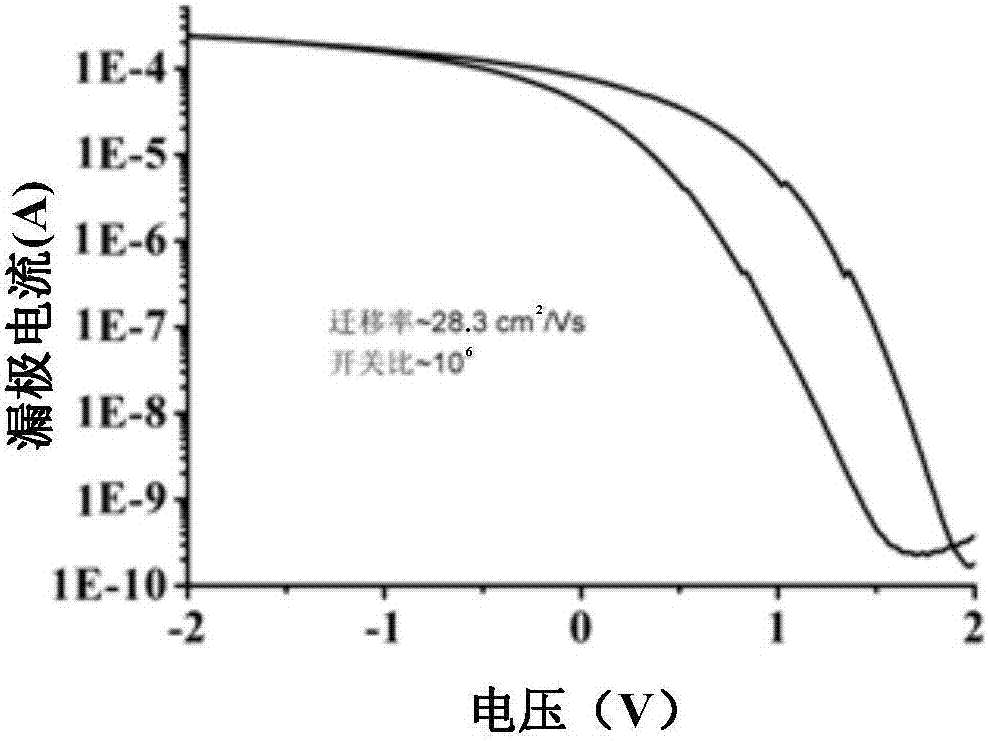

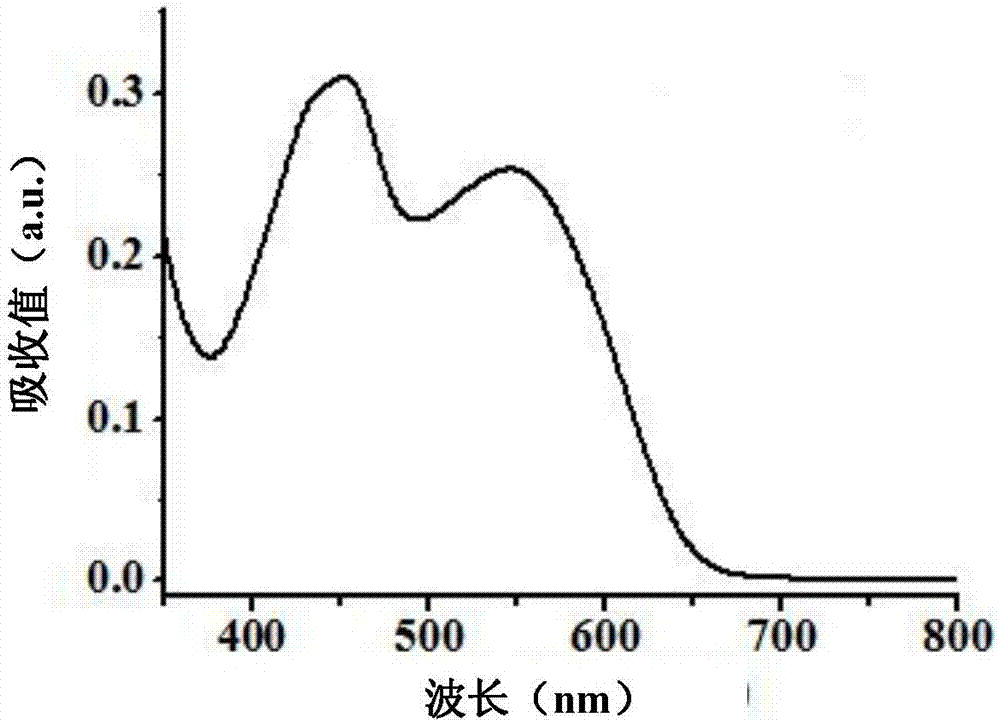

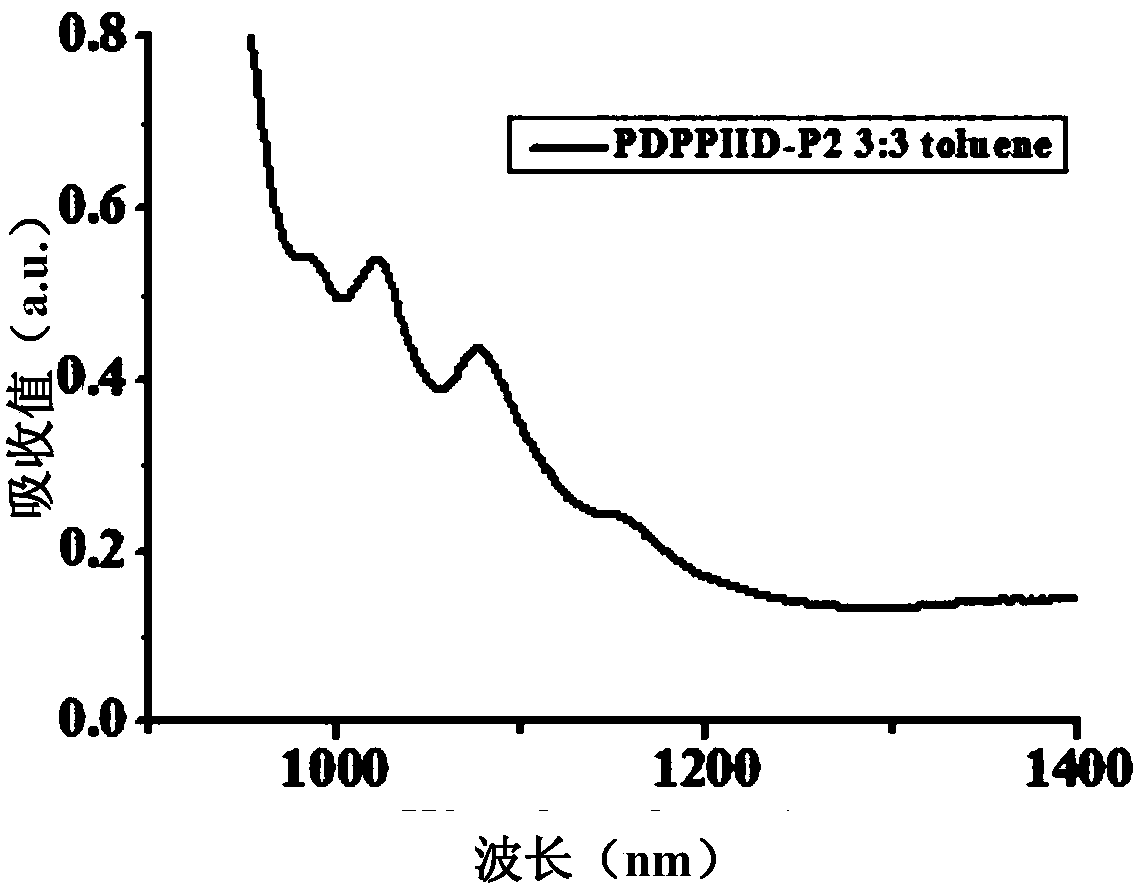

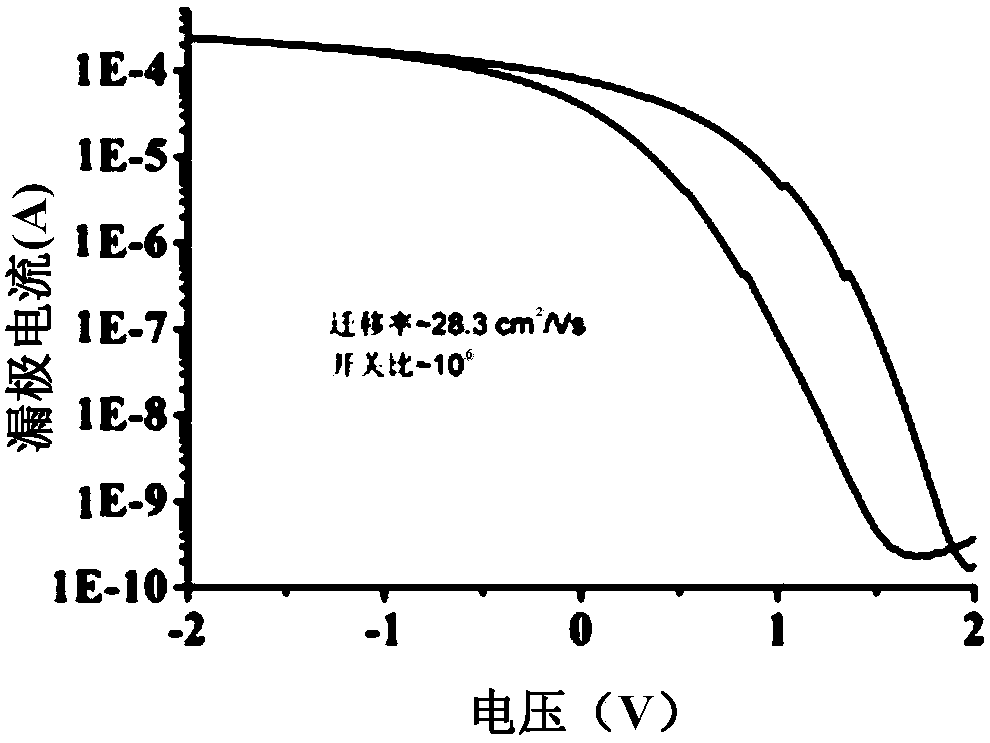

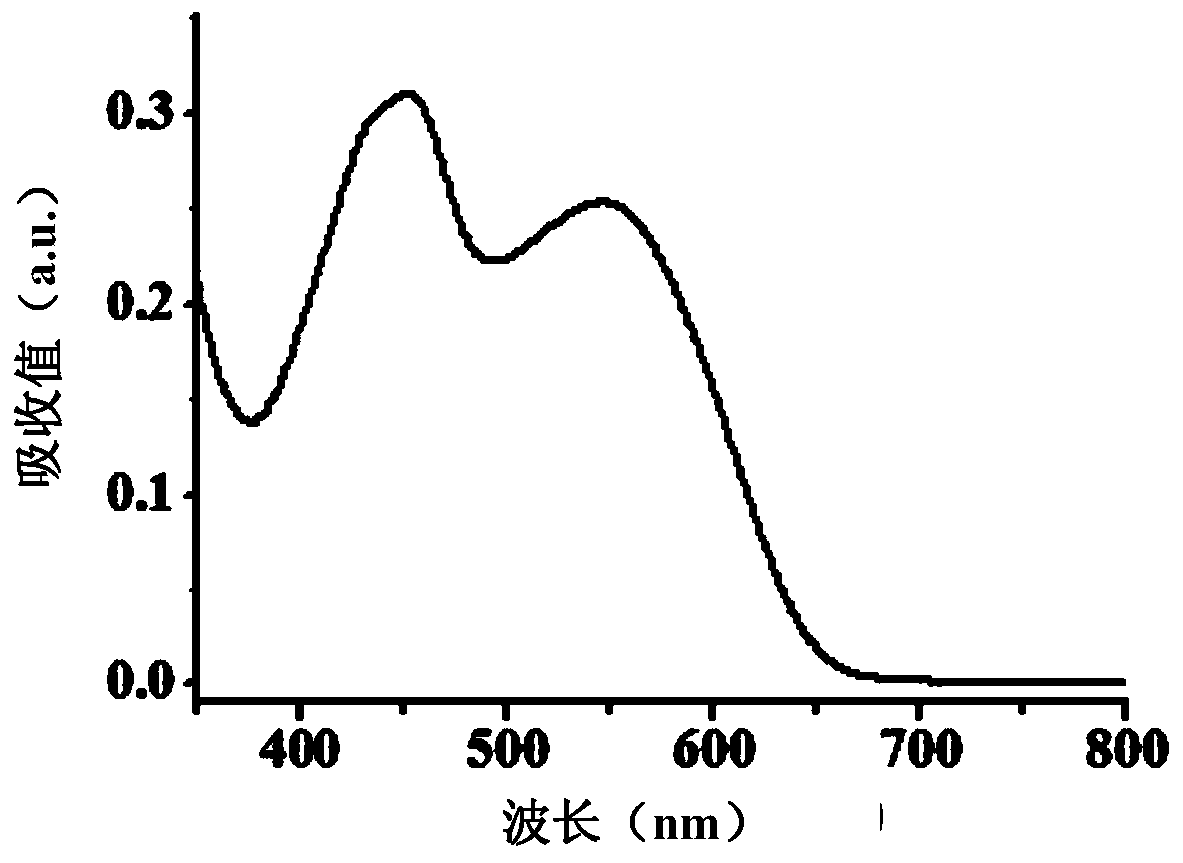

Isoindigo conjugated polymer, semiconductor CNT ink, and preparation method and application of polymer

ActiveCN107151311AEasy to prepareWide range of usesMaterial nanotechnologySolid-state devicesHydrogen atomHalogen

The invention discloses an isoindigo conjugated polymer, a semiconductor CNT ink, and a preparation method and an application of the polymer. The isoindigo conjugated polymer comprises a composition unit represented by a formula shown in the description; and in the formula, R1 comprises any one of a heteroalkyl group, and a C1-20 linear or branched alkyl group, R2 comprises any one of a hydrogen atom, a heteroalkyl group, a halogen atom, a C1-20 linear or branched alkyl group, Ar comprises a conjugate unit composed of any one or two or more of one to four five- or six-membered aromatic ring, five- or six-membered aromatic heterocyclic group and a polybasic aromatic fused ring, and n is any integer in a range of 2-500. The isoindigo conjugated polymer can specifically bind to semiconductor carbon nanotubes, so the isoindigo conjugated polymer can be used in the highly selective separation of the semiconductor carbon nanotubes in commercial carbon nanotubes; and the isoindigo conjugated polymer can form the semiconductor carbon nanotube (CNT) ink having high purity, and the ink can be used for constructing a semiconductor device having superior performances.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Hydrothermally stable column cage type metal organic framework material as well as preparation method and application thereof

InactiveCN114177890AGood hydrothermal stabilityImprove cycle performanceGas treatmentOther chemical processesAlkyneAdsorption separation

The invention discloses a hydro-thermal stable column cage type metal organic framework material, a preparation method thereof and application of the hydro-thermal stable column cage type metal organic framework material in the field of selective adsorption separation of gas. The column cage type metal organic framework material is formed by self-assembly of metal ions M, nonlinear multidentate nitrogen-containing ligands L and high-coordination-number inorganic anions through coordination bonds. The column cage type metal organic framework material disclosed by the invention has good hydrothermal stability and cyclicity, and can be used for high-selectivity adsorption separation of acetylene / ethylene, propyne / propylene and other alkyne olefins.

Owner:ZHEJIANG NORMAL UNIVERSITY

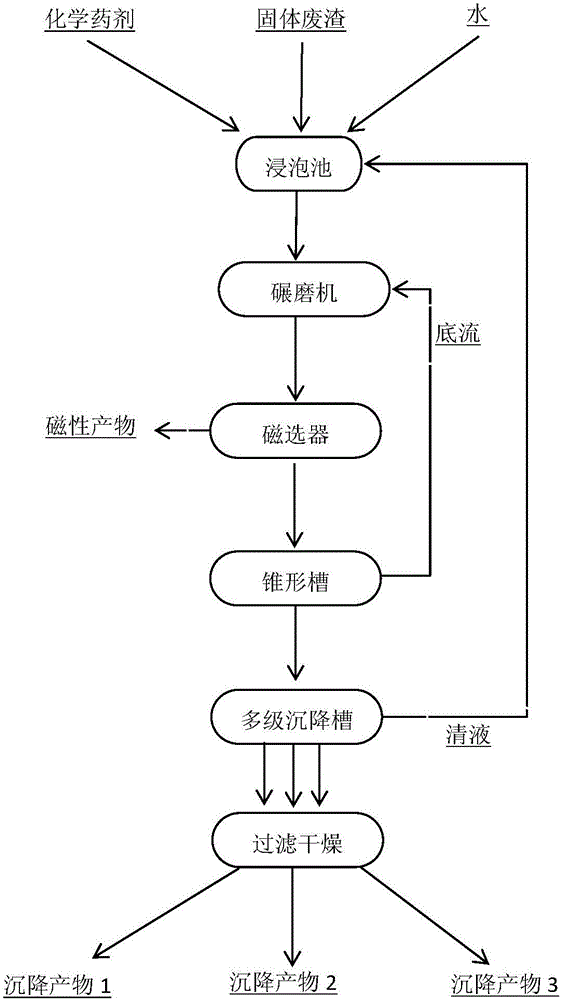

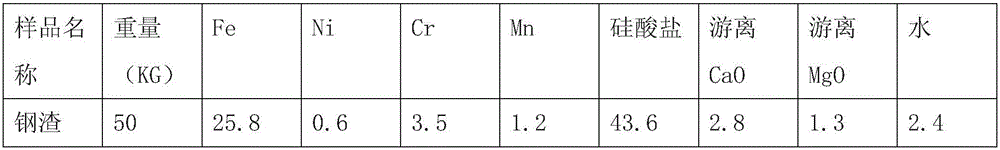

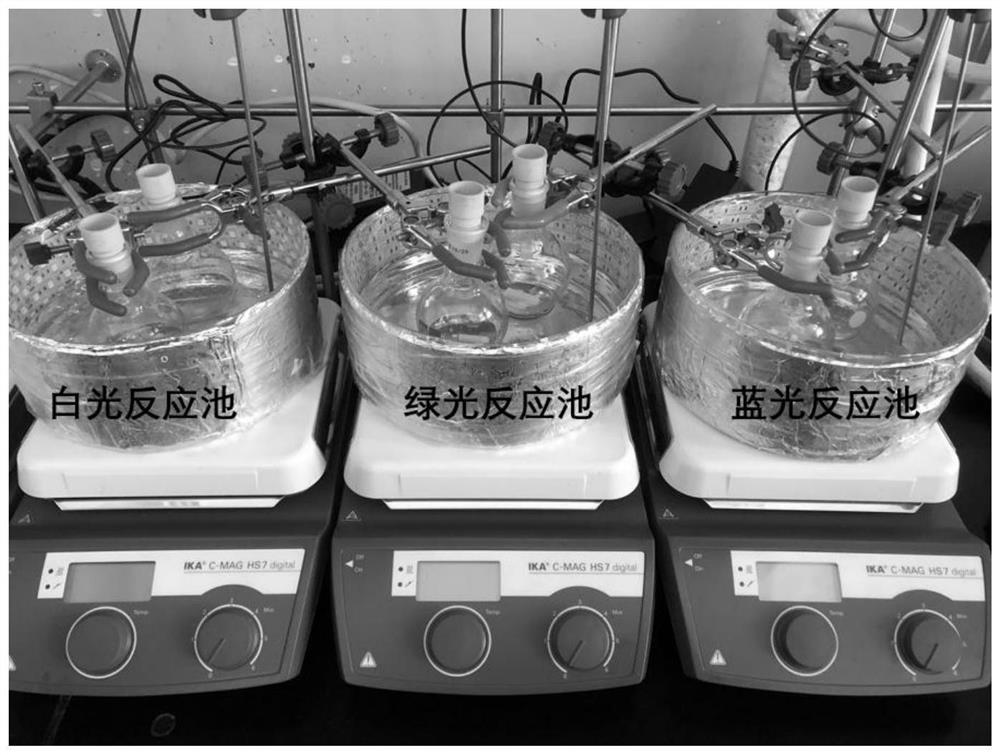

Selective separation and recycling method for industrial solid waste slag

ActiveCN105833985AIncrease percentageAchieve spatial dissociationWet separationChemical industrySlag

Disclosed is a selective separation and recycling method for industrial solid waste slag. The selective separation and recycling method is suitable for recycling the solid waste slag generated in steel, metallurgy and chemical industries. The selective separation and recycling method is based on the systematic study of the microstructure of the industrial solid waste slag, high-selectivity chemical agents are adopted, through soaking, milling, magnetic separation, multistage sedimentation and other process steps, bonding materials between crystalline particles are dissolved or softened, and thus spatial dissociation of the crystalline particles with different components is achieved with a chemical method. Meanwhile, the surface characteristics of certain crystalline particles are changed selectively through the high-selectivity chemical agents, the differences of the sedimentation performance of different components are enhanced, separation of multistage sedimentation is completed conveniently, thus the separation efficiency is improved, energy consumption can be reduced by a large margin, and the treatment process is simplified. The selective separation and recycling method is suitable for recycling steel slag, stainless steel slag, metallurgy waste slag and the like and can also be used for recycling useful components or enrichment of certain trace elements from chemical solid waste slag.

Owner:TSINGHUA UNIV

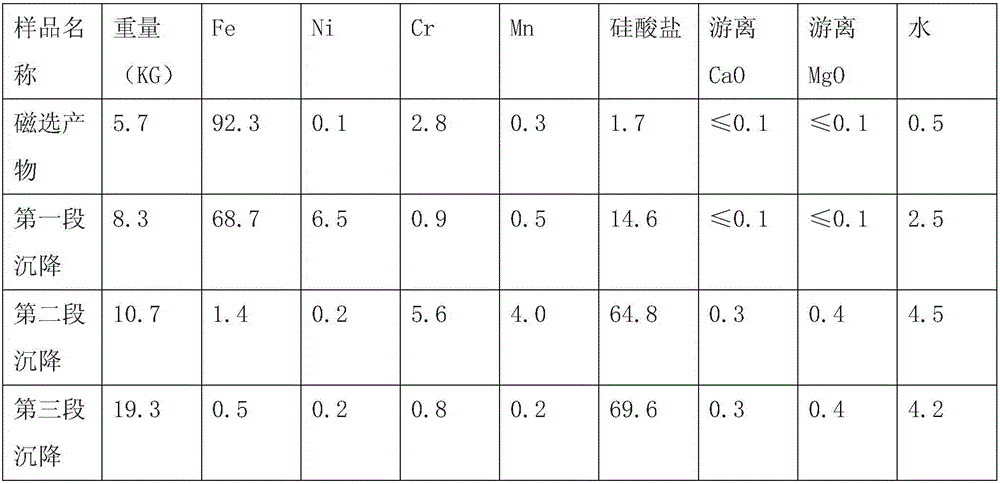

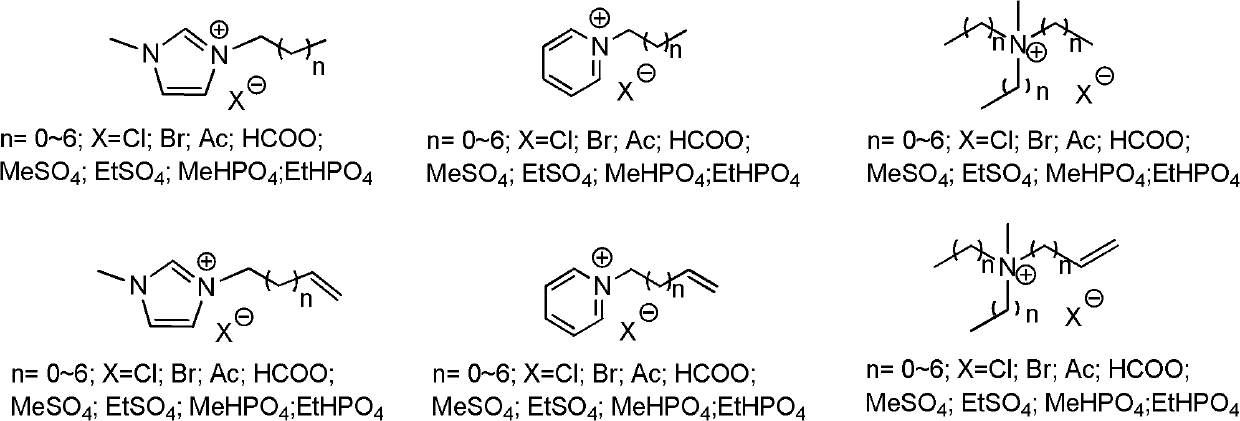

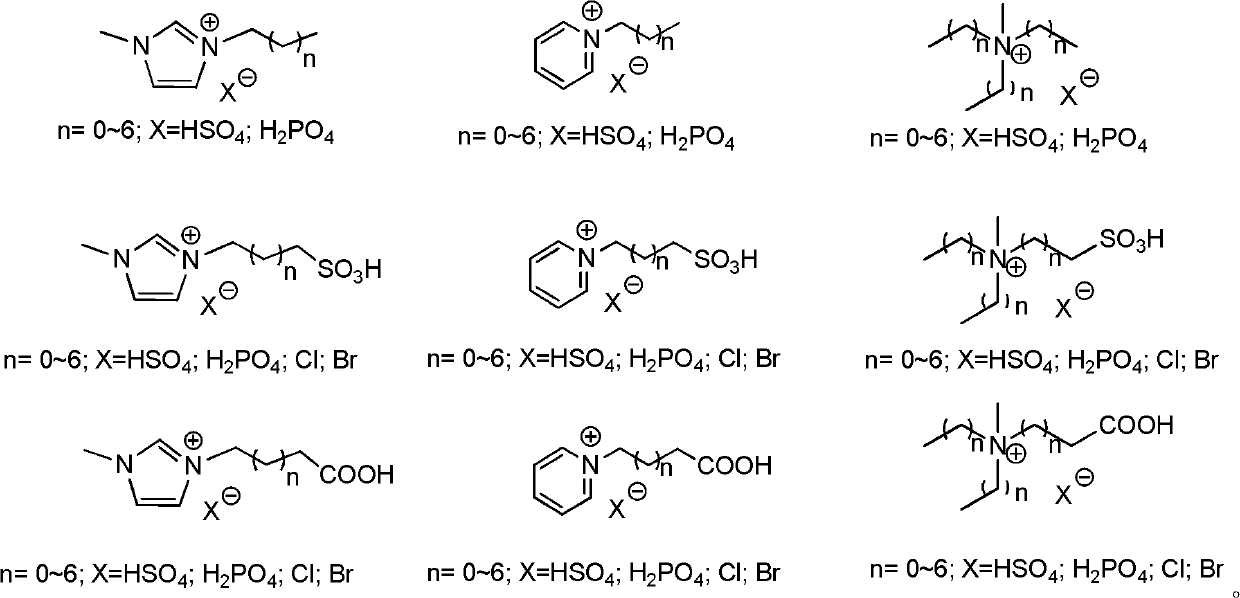

Ultra-microporous ionic polymer material and preparation method and application thereof

ActiveCN111375390AImprove stabilityAir is freshOther chemical processesDispersed particle separationPolymer scienceAlkyne

The invention discloses an ultra-microporous ionic polymer material based on hyperbranched ionic liquid and preparation and alkyne / olefin separation application thereof. The ultra-microporous ionic polymer material has the characteristics of high anion density and narrow pore size distribution, and the structural properties are regulated and controlled by changing a hyperbranched structure and anion and cation types. High-selectivity separation of acetylene and propyne is realized by utilizing a strong hydrogen bond environment constructed by high anion density and a size screening effect, sothat alkyne in alkyne and olefin mixed gas is removed to a very low degree, and olefin gas with extremely low alkyne content is obtained. The material prepared by the method has the advantages of highstability, simple preparation, strong controllability of material structural properties, good adsorption performance, easy desorption, greenness, environmental protection, and good industrial application prospect.

Owner:ZHEJIANG UNIV

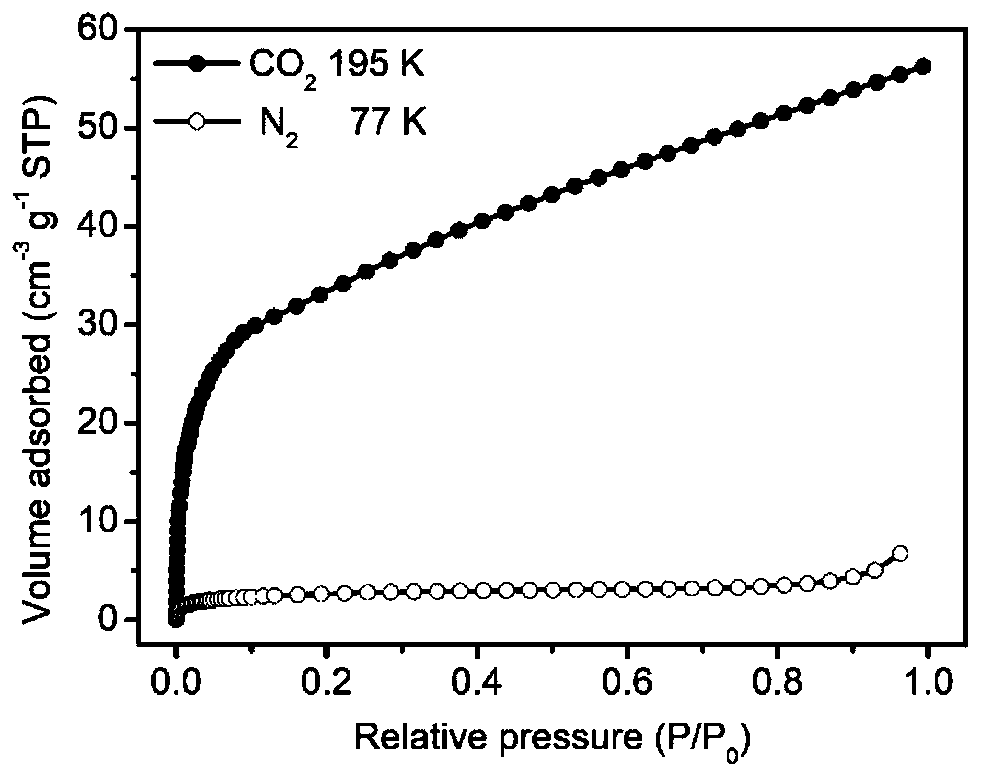

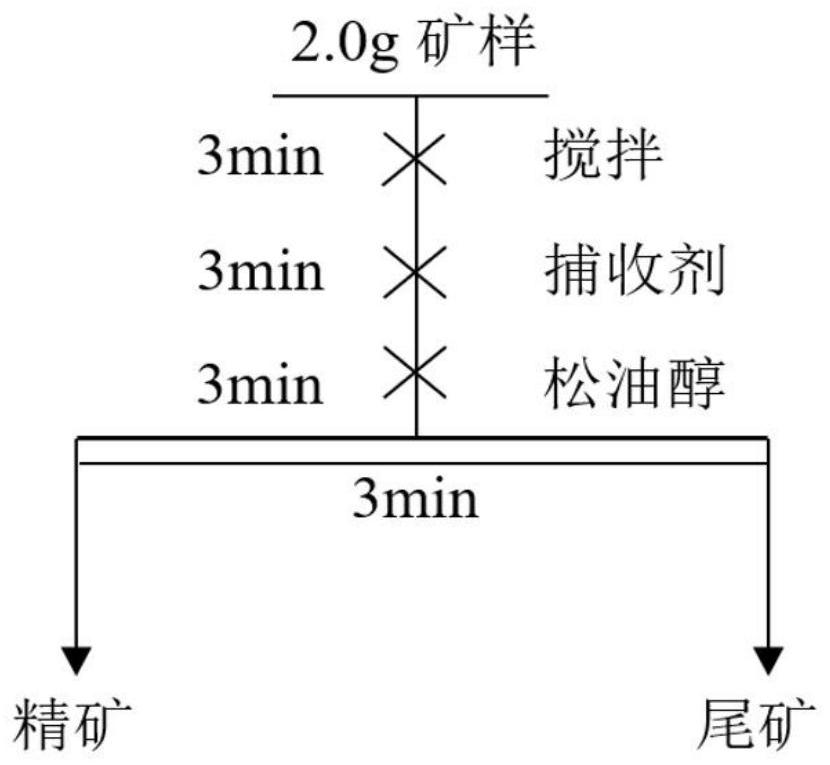

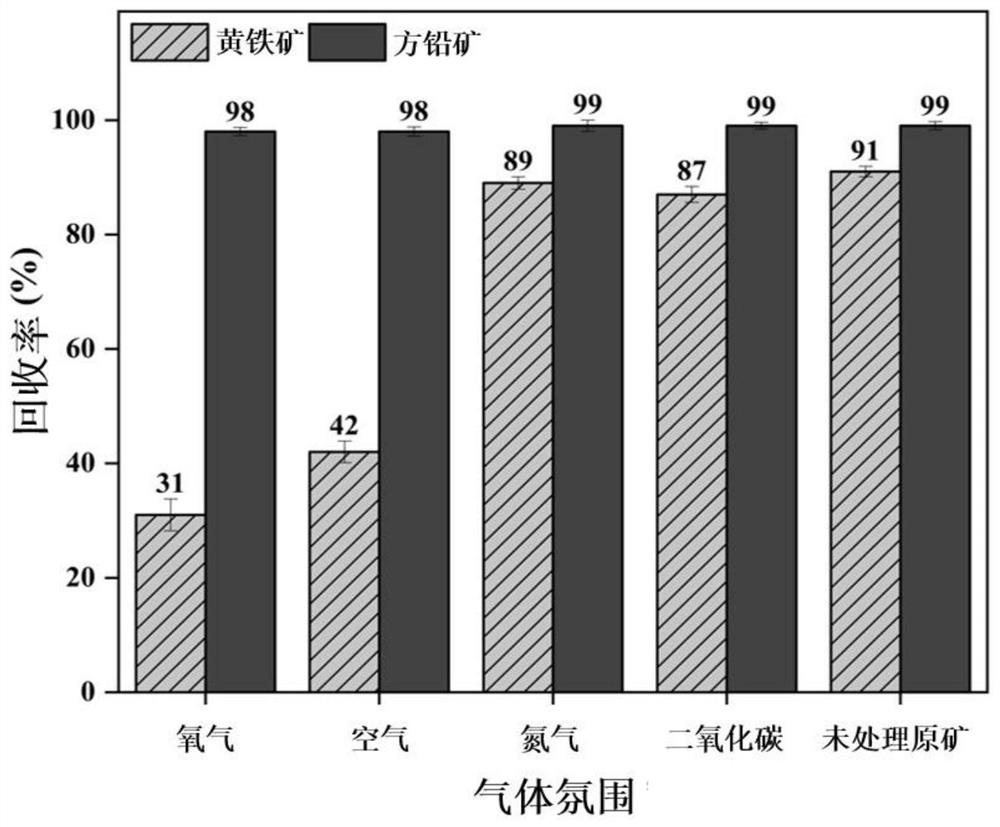

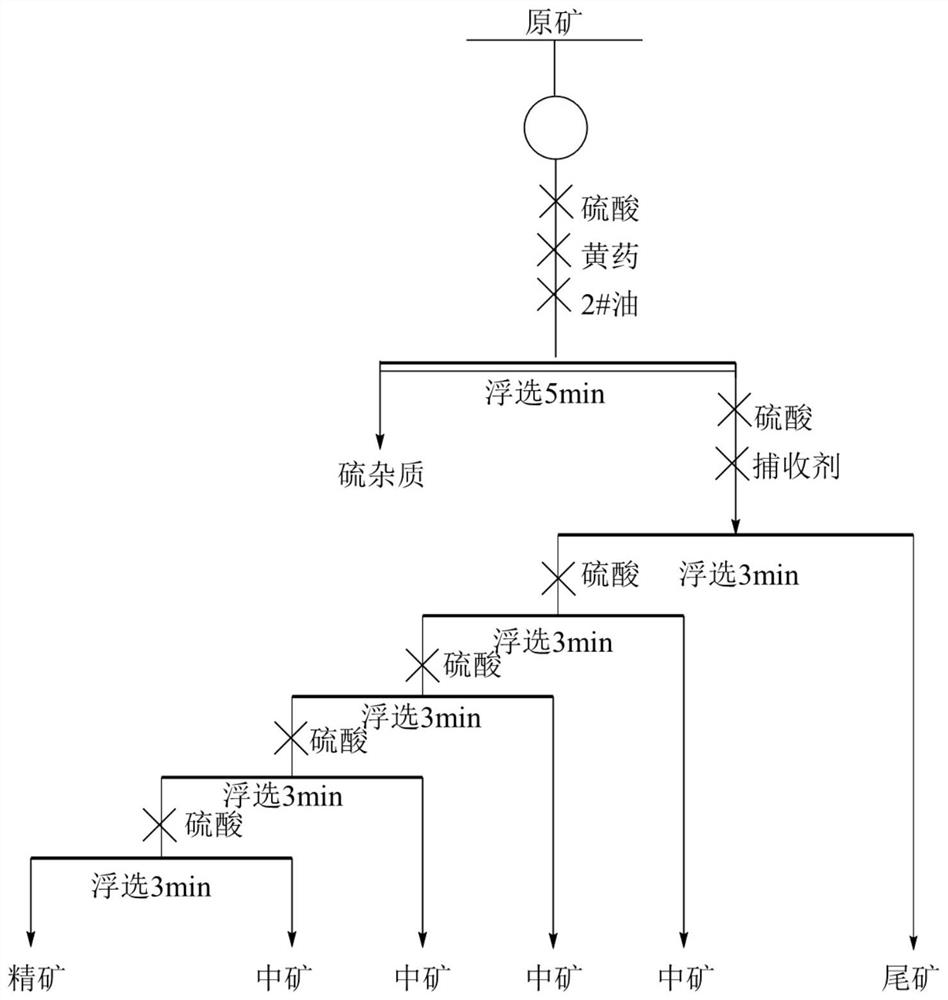

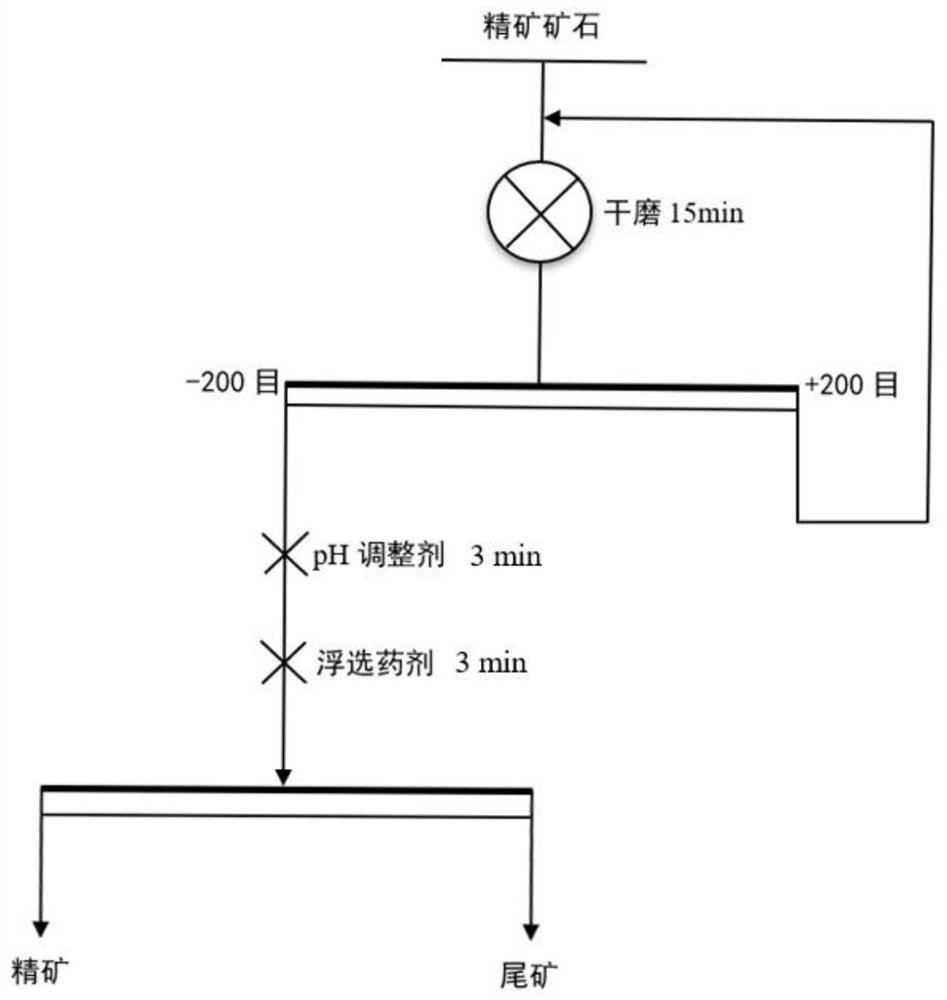

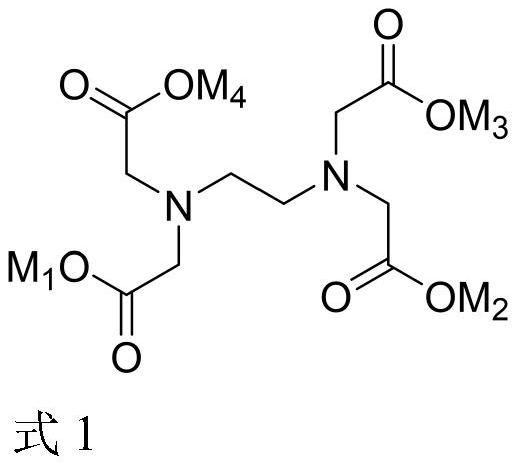

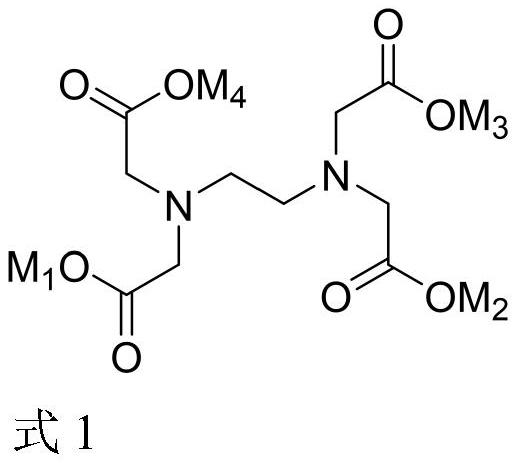

Selective oxidation and flotation separation method for pyrite gangues in sulfide ores

ActiveCN112642576AAchieving Selective Oxidation InhibitionImprove flotation recoveryFlotationEnergy based chemical/physical/physico-chemical processesPtru catalystPhoto catalytic

The invention belongs to the technical field of ore flotation, in particular to a selective oxidation method for pyrite gangues in sulfide ores. The method comprises treating slurry containing the sulfide ores and an oxidant by a catalyst of a structural formula 1 under radiation of light and performing photo-catalytic selective oxidation on the pyrite gangues in sulfide ores. The method further comprises a means of pre-treating the sulfide ores based on the selective oxidation method and then performing flotation separation. According to the technical scheme, photo-catalysis mediated by the formula 1 can oxidize iron sulfide gangue minerals in the sulfide ores specifically, such that it is favorable for flotation separation of iron sulfide gangues and useful sulfide ores.

Owner:CENT SOUTH UNIV

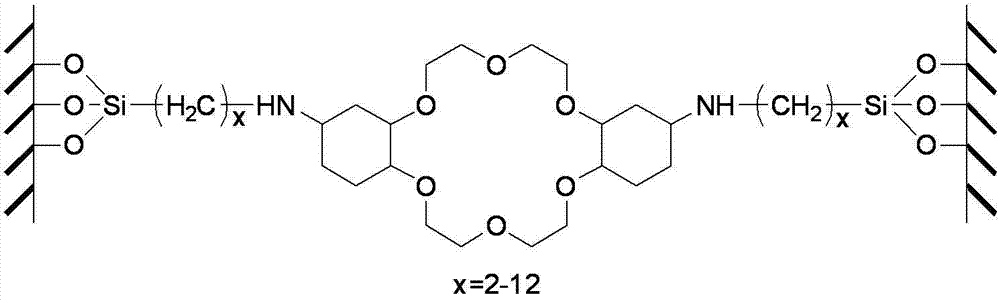

Method for separating lead ions in waste water by utilizing single-arm bonded alicyclic crown ether silicone resin

ActiveCN102874889AImprove separation efficiencyGuaranteed removal rateWater contaminantsWater/sewage treatment by sorptionFiltrationPhysical chemistry

The invention discloses a method for separating lead ions in waste water by utilizing single-arm bonded alicyclic crown ether silicone resin, and belongs to the technical field of heavy metal ion separation. Firstly, the single-arm bonded alicyclic crown ether silicone resin is added into the leady waste water, according to the ratio of 0.01 to 1.0 of the weight of the single-arm bonded alicyclic crown ether silicone resin to the volume of the leady waste water, and the mixture is stirred or oscillated for 20 to 300 min at the temperature of 5 to 50 DEG C; secondly, solid-liquid two-phase filtration and separation are carried out, the residual concentration of lead ions in the liquid phase is measured, and the separation removal ratio is calculated by comparing the residual concentration with the initial concentration; and finally, the single-arm bonded alicyclic crown ether silicone resin is eluted with a nitric acid solution of 0.01-3 mol / L, washed repeatedly with deionized water and dried to obtain regenerated resin. The method provided by the invention has the advantages of high separation speed, high removal ratio and strong suitability for lead ions in heavy metal waste water; and the material can be used repeatedly and is low in cost.

Owner:TSINGHUA UNIV

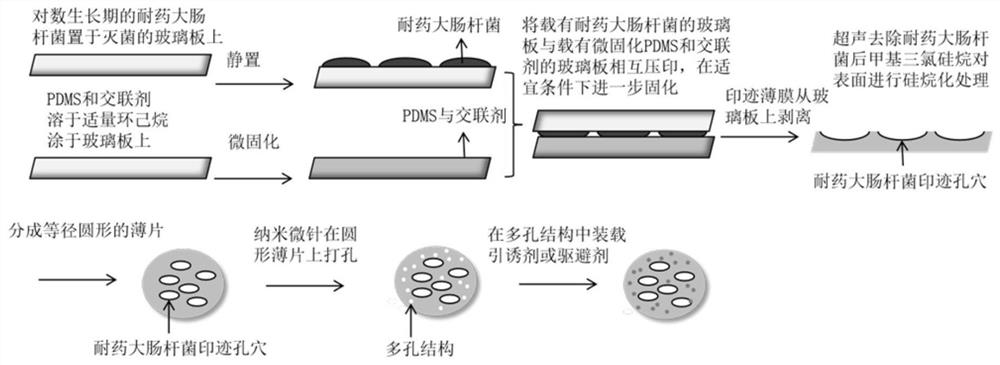

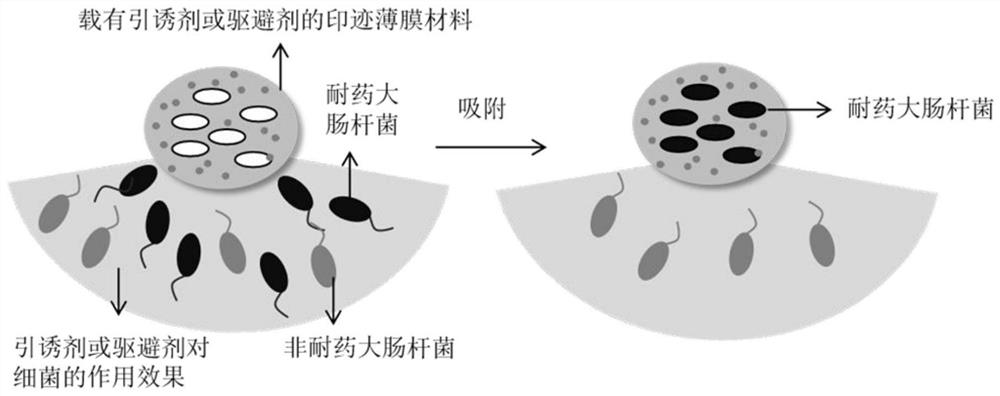

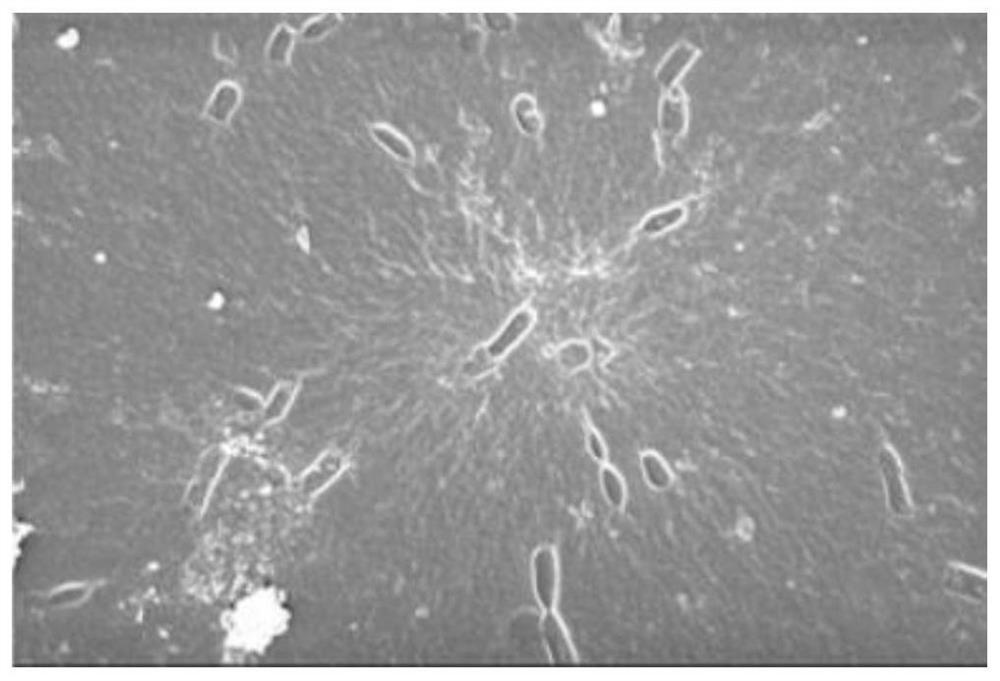

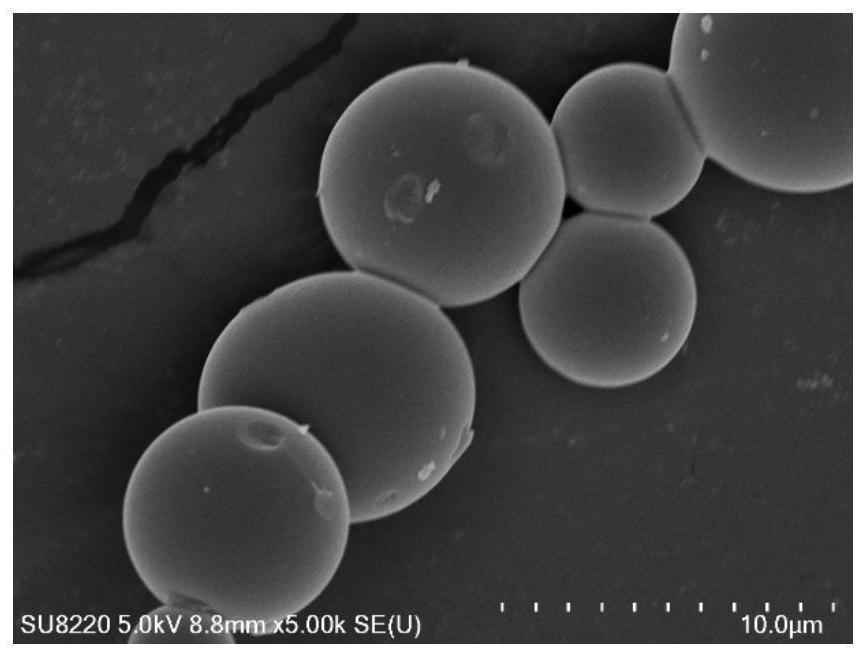

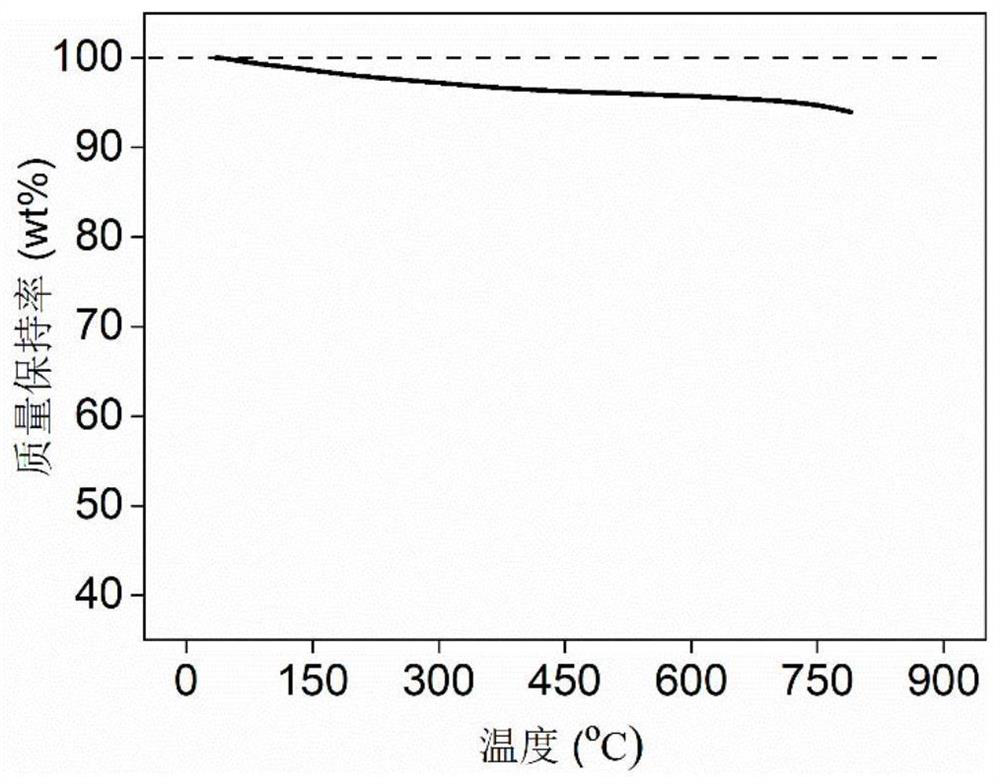

Imprinted thin film material for selectively separating drug-resistant bacillus as well as preparation and application thereof

ActiveCN111909407AAvoid interferenceEfficient separationMicroorganism based processesMicroorganism separationBiotechnologyResistant bacteria

The invention discloses an imprinted film material for selectively separating drug-resistant bacilli as well as preparation and application thereof, and relates to the field of new materials. The method comprises the following steps: preparing a semi-cured film; preparing and dilution a drug-resistant bacillus suspension, dropwise adding the diluted drug-resistant bacillus suspension onto a sterilized substrate, performing standing treatment, and then removing the solvent in a sterile environment; pressing the substrate loaded with the drug-resistant bacilli into the semi-cured film so as to form prints on the semi-cured film with the drug-resistant bacilli as template molecules, and heating and completely curing the film; stripping the imprinted film from the substrate to obtain an imprinted film precursor, washing off drug-resistant bacilli as template molecules on the precursor, and carrying out silanization treatment on the surface of the precursor to enhance the hydrophilicity ofthe film; and forming a microporous structure into the imprinted film to obtain the imprinted film material for selectively separating the drug-resistant bacillus. On the basis of ensuring the recognition capability of the traditional bacterial imprinting material, the interference of non-drug-resistant bacteria can be avoided, and the drug-resistant bacteria are promoted to generate selective movement and recognition so as to achieve the purpose of selectively separating bacteria.

Owner:HUAZHONG UNIV OF SCI & TECH

Biomass-based porous carbon material, preparation method and application of biomass-based porous carbon material in separation of 1, 3-butadiene from C4 olefin mixture

InactiveCN112499628AHighly selective separationImprove adsorption capacityOther chemical processesCarbon compoundsBiomass carbonButadiene Dioxide

The invention discloses a biomass-based porous carbon material, a preparation method thereof, and an application of the biomass-based porous carbon material in separation of 1, 3-butadiene from a C4 olefin mixture. The method mainly comprises the following steps of: carrying out hydrothermal carbonization on a biomass carbon source and an organic acid aqueous solution, carrying out ion exchange onan obtained carbon precursor and a certain amount of alkali liquor, and then putting the product into a tubular furnace for carbonization and activation. The biomass-based porous material prepared bythe invention is a microporous carbon material with a stable structure, the range of raw materials is wide, the price is low, the preparation process is simple, and the regeneration performance of the material is excellent. More importantly, high-purity 1, 3-butadiene can be separated from C4 olefin components, and the method has a good industrial application prospect.

Owner:SOUTH CHINA UNIV OF TECH

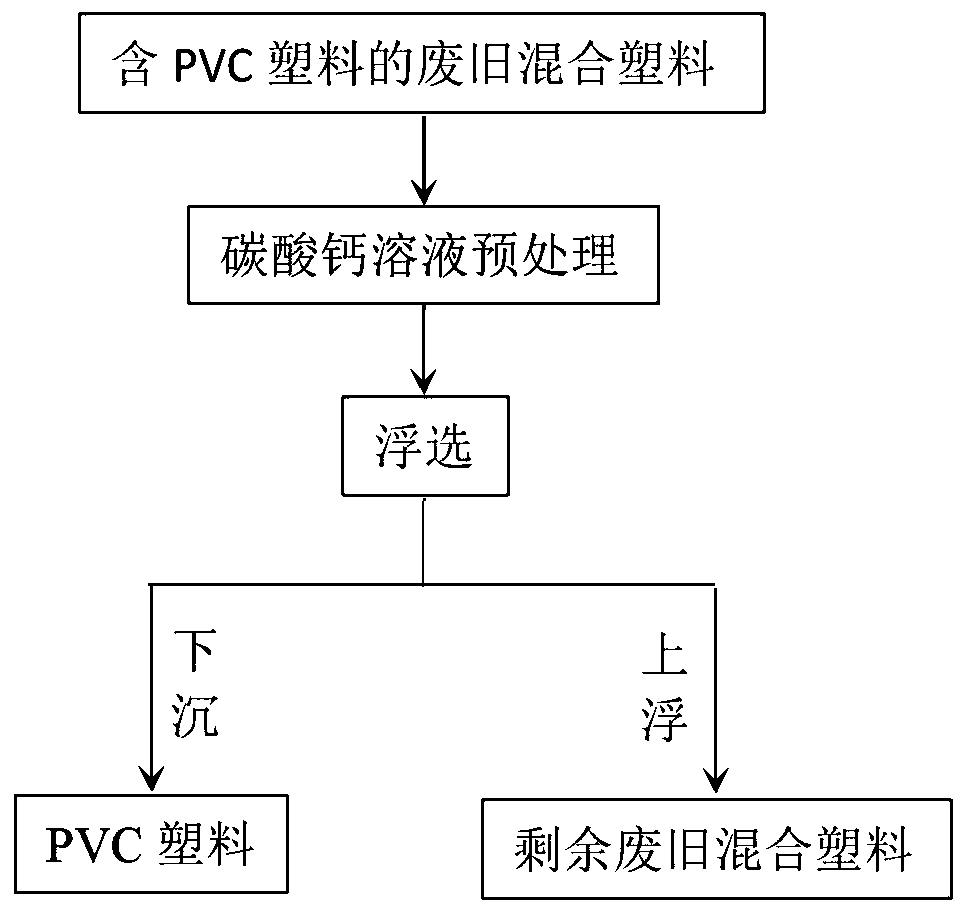

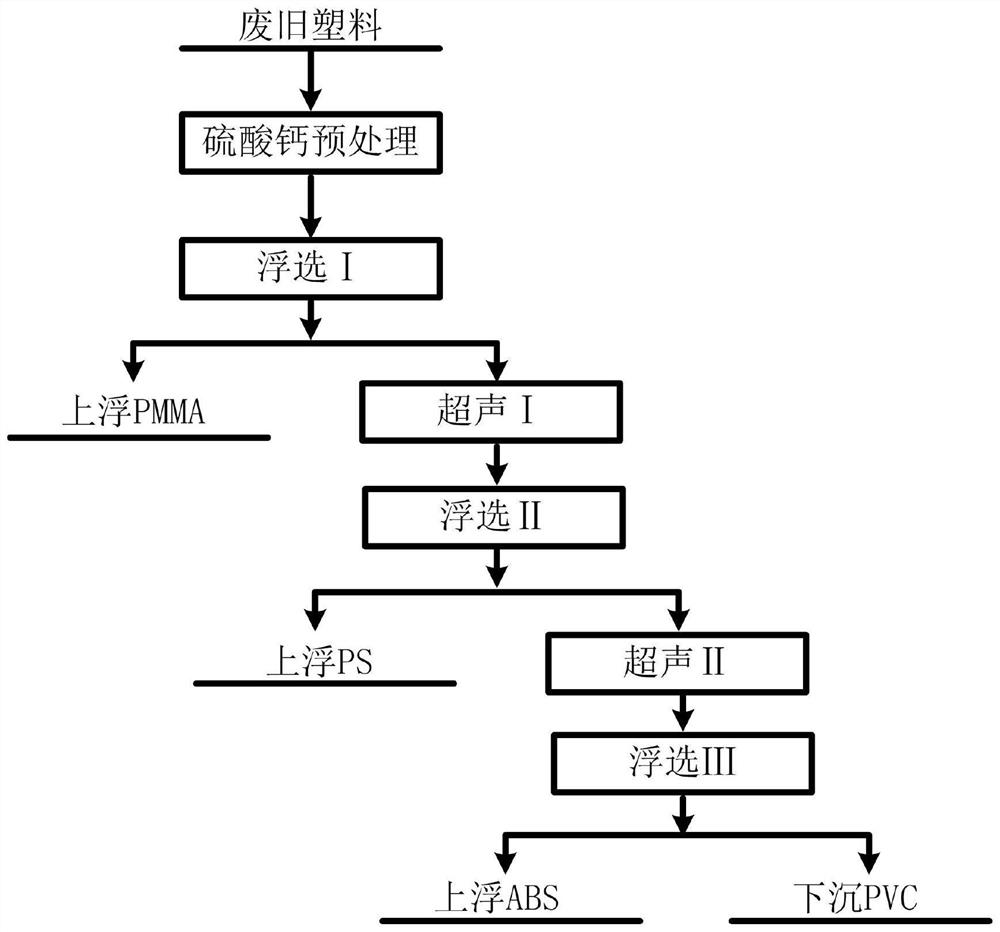

Method for floating and separating polyvinyl chloride from waste mixed plastics based on calcium carbonate pretreatment

ActiveCN110421744AHigh recovery rateHighly selective separationPlastic recyclingChemistryCalcium carbonate

The invention discloses a method for floating and separating polyvinyl chloride from waste mixed plastic based on a calcium carbonate pretreatment. The method comprises the steps that the waste mixedplastic containing PVC plastic is placed into a calcium carbonate solution, pretreatment is carried out at a temperature not lower than 40 DEG C, and the pretreated waste mixed plastic is subjected toa flotation process to achieve the separation between the PVC plastic and other plastic in the waste mixed plastic. According to the method for floating and separating the polyvinyl chloride from thewaste mixed plastic based on the calcium carbonate pretreatment, the pretreatment is carried out through a calcium carbonate solution under a specific temperature condition, so that the difference ofsurface components in the waste mixed plastic can be enlarged; and then through the flotation method, the PVC plastic can be separated from the waste mixed plastic with high selectivity and high recovery rate.

Owner:CENT SOUTH UNIV

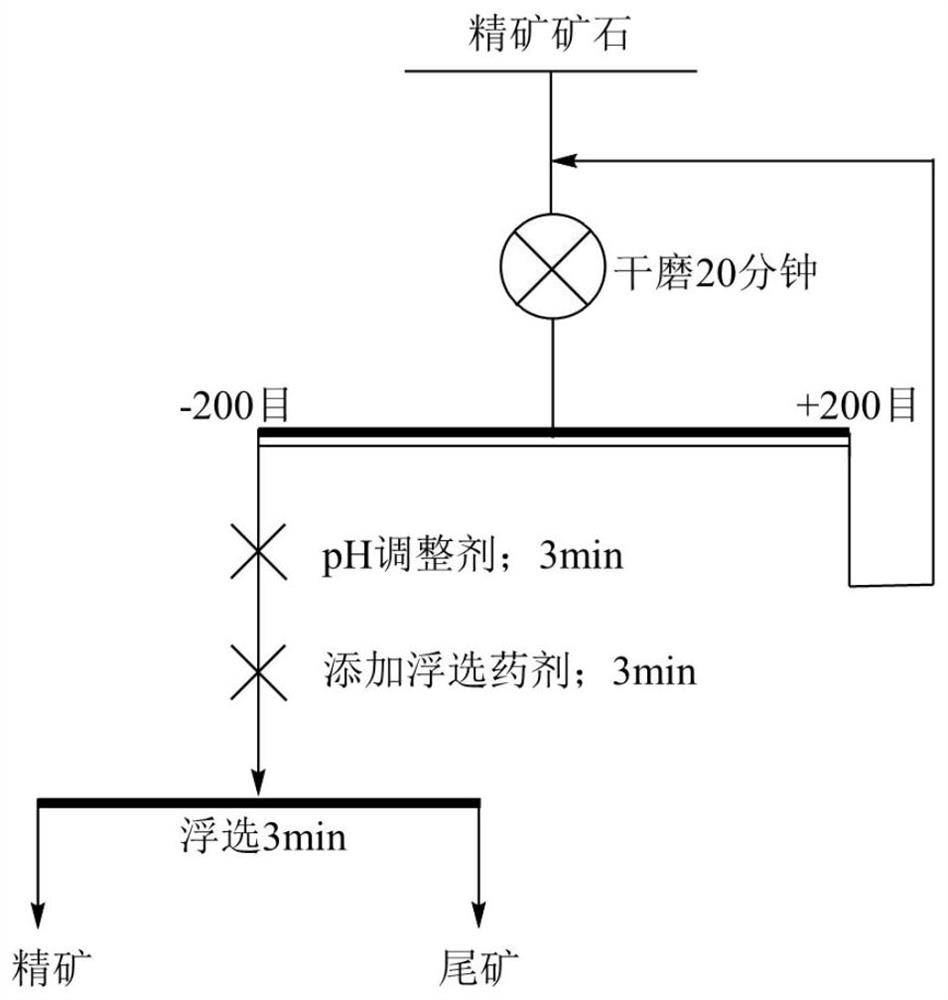

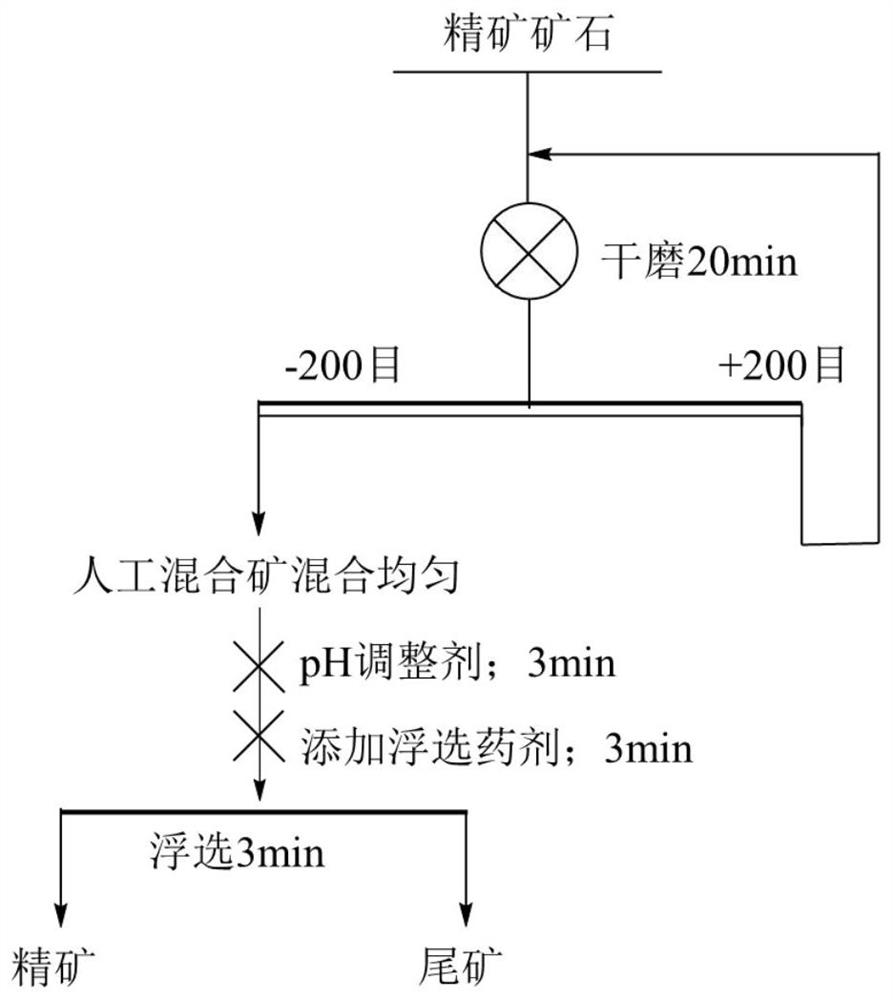

Flotation collecting agent, flotation reagent and flotation method for improving separation efficiency of ilmenite and gangue of ilmenite

The invention provides a flotation collecting agent, a flotation reagent and a flotation method for improving the separation efficiency of ilmenite and gangue of ilmenite.The flotation collecting agent comprises a collecting agent A, the collecting agent A has a formula shown in the specification. In the formula, R1 is C1-C15 alkyl, C4-C15 cycloalkyl, allyl, ethynyl, phenyl, benzyl or benzyloxy; and R2 is hydrogen, C1-C15 alkyl, C4-C15 naphthenic base, propenyl, ethynyl, phenyl or benzyl. The collecting agent A serves as the flotation collecting agent of the ilmenite, benefited from the special synergistic effect of the benzene ring and the phosphate group, the collecting agent A shows good flotation selectivity and recovery rate, and the recovery rate and grade of the ilmenite can be improved.

Owner:CENT SOUTH UNIV

Carbon nanotube structure-selective separation and surface fixation

InactiveCN1922106BHighly selective separationImprove concentrationMaterial nanotechnologyAcceleration measurement using interia forcesPhotocatalytic reactionPhoto irradiation

A method of separating, concentrating or purifying uniform carbon nanotubes with desired properties (diameter, chiral vector, etc.) in a highly sensitive manner by the use of structure-sensitive properties peculiar to carbon nanotubes; and an apparatus therefor. There is provided a method of separating, concentrating or purifying carbon nanotubes with desired properties contained in a sample, comprising the steps of (a) irradiating a sample containing carbon nanotubes with light; and (b) selecting carbon nanotubes with desired properties. In a preferred embodiment, the light irradiation of thestep (a) can be carried out in the presence of a metal so as to cause specified carbon nanotubes to selectively induce a photocatalytic reaction, resulting in metal deposition. Further, in a preferred embodiment, a given magnetic field can be applied in the step (b) so as to attain accumulation or concentration of carbon nanotubes with metal deposited.

Owner:JAPAN SCI & TECH CORP

Method for selectively desorbing and recycling mineral surface medicament

ActiveCN111992336ARealize selective desorption and recyclingAvoid lostFlotationMining engineeringSmelting process

The invention belongs to the technical field of mineral flotation and reagent recycling, and particularly discloses a mineral surface reagent selective desorption method which comprises the followingsteps of: adding a desorption agent into ore pulp of minerals with chelating reagents on the surfaces, desorbing the minerals and the reagents under the assistance of high-speed stirring, and then carrying out solid-liquid separation to obtain the minerals and recycled reagents, wherein the reagent comprises a chelating type collecting agent; the desorbent is acid or alkali; the using amount of the desorbent is 30-100g / t. The invention also provides a method for recycling the recovered medicament. According to the technical scheme of the invention, the chemical-physical synergistic effect of the desorbent and the high-speed stirring is utilized, so that selective desorption and separation of minerals and medicaments can be improved; in addition, the damage to medicaments and loss of the minerals can be avoided, the medicaments on the surfaces of the minerals can be effectively recycled, meanwhile, the subsequent mineral concentrate smelting process is improved, and the corresponding water treatment cost is reduced.

Owner:CENT SOUTH UNIV

Mineral ore flotation aid

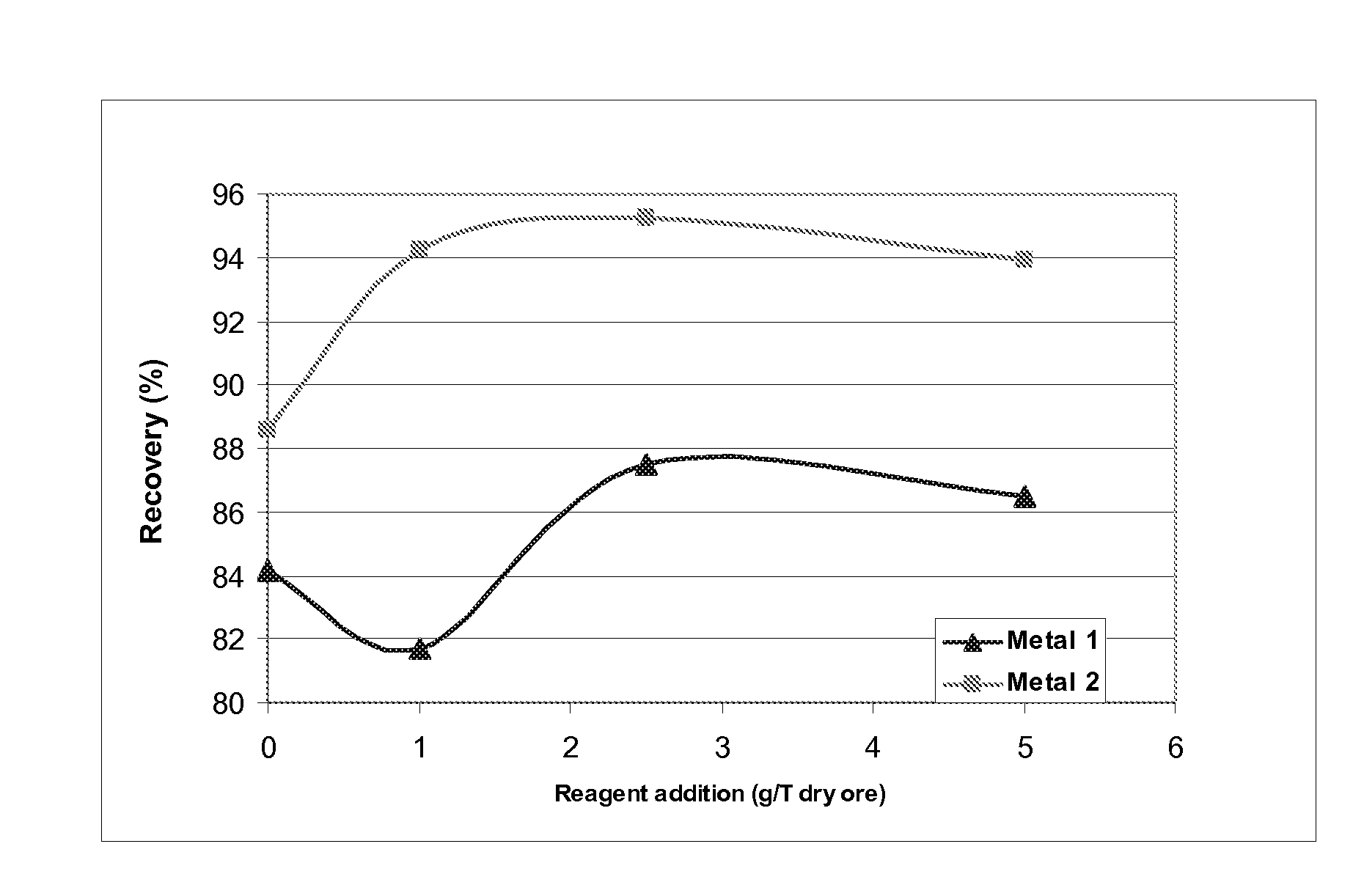

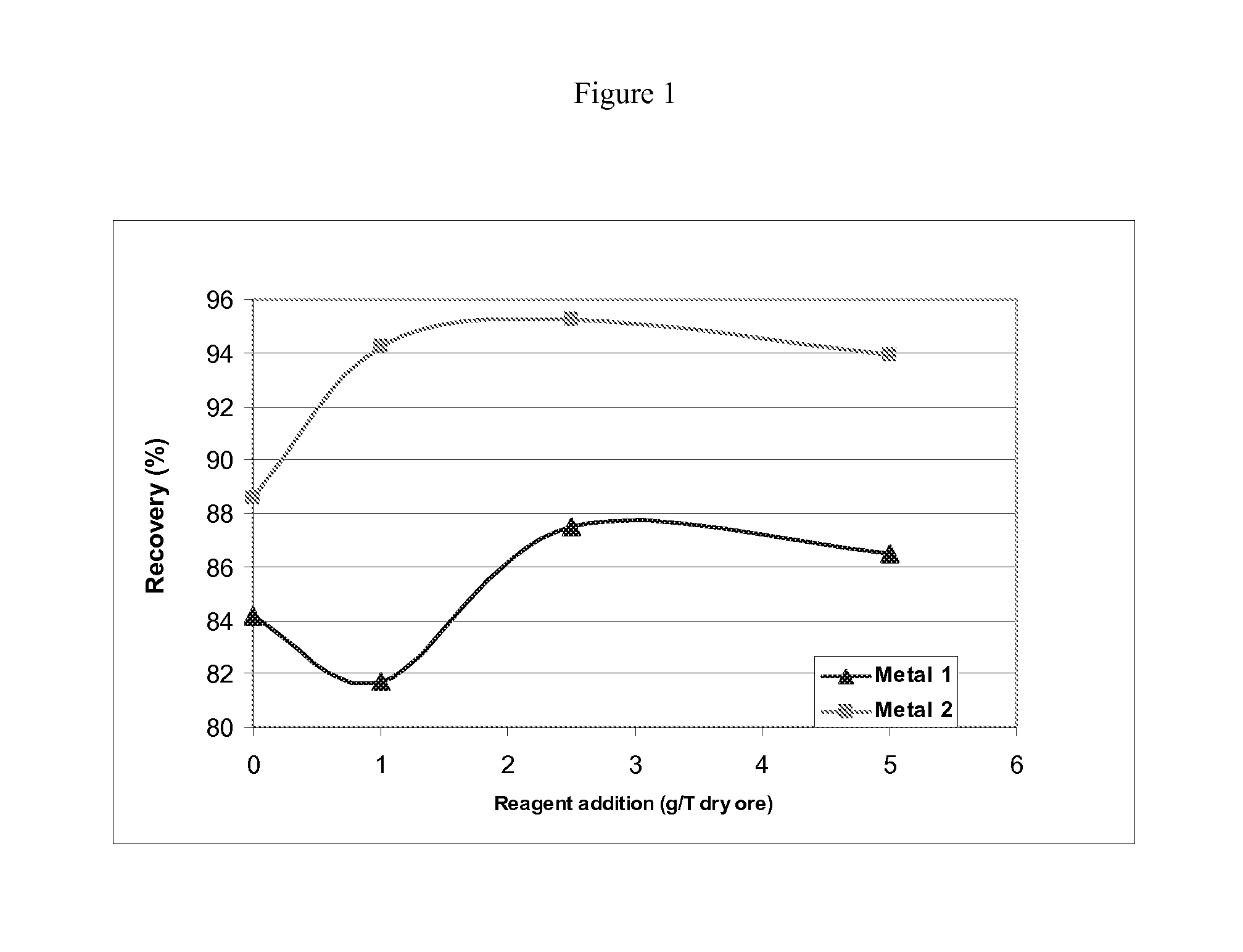

InactiveUS20090266746A1Enhancing selective separationImprove recoveryFlotationFroth flotationWater soluble

A method is provided for enhancing selective separation of ore values by addition of an effective amount of a treatment reagent to the separation process, such as froth flotation. The treatment reagent can be added at different stages, such as to a grinding mill, conditioning tank before flotation, or in the flotation cells before, after or simultaneous to the addition of other conventional flotation reagents. By adding the treatment agent, the recovery of valuable minerals from a froth flotation process is increased. In an embodiment of the present invention, the treatment reagent is a water-soluble ethylene oxide / propylene oxide copolymer.

Owner:GENERAL ELECTRIC CO

Method for separating of metal fullerene m@C82 and isomer thereof

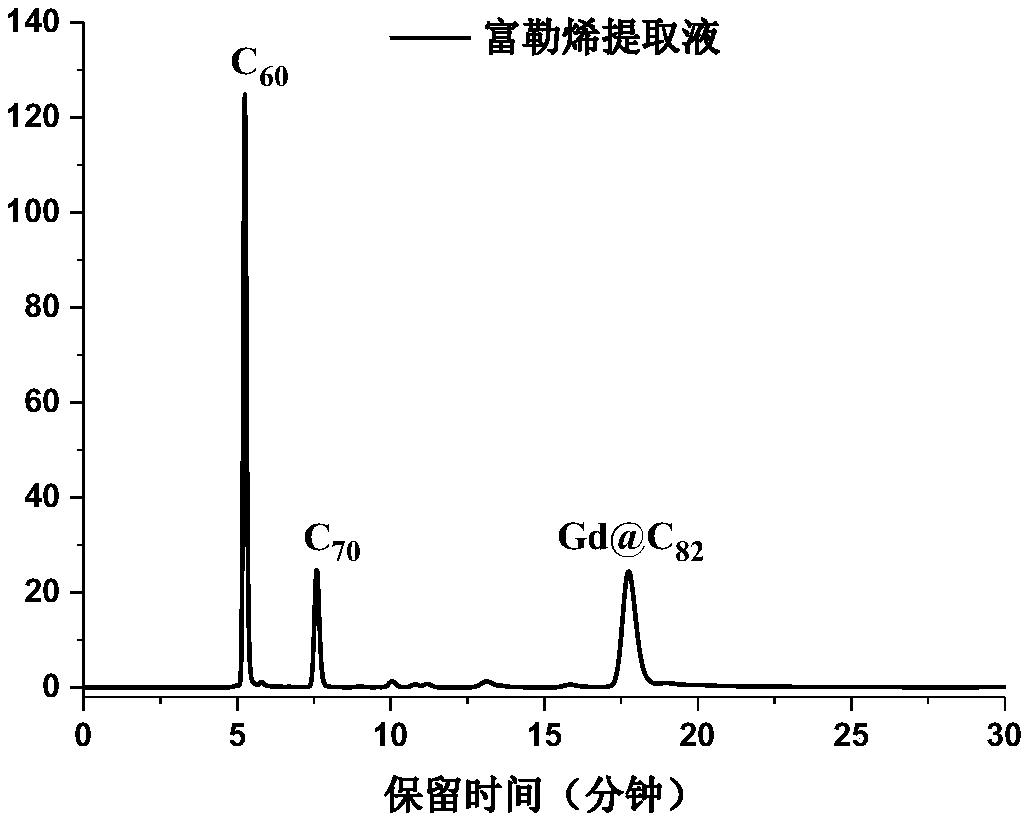

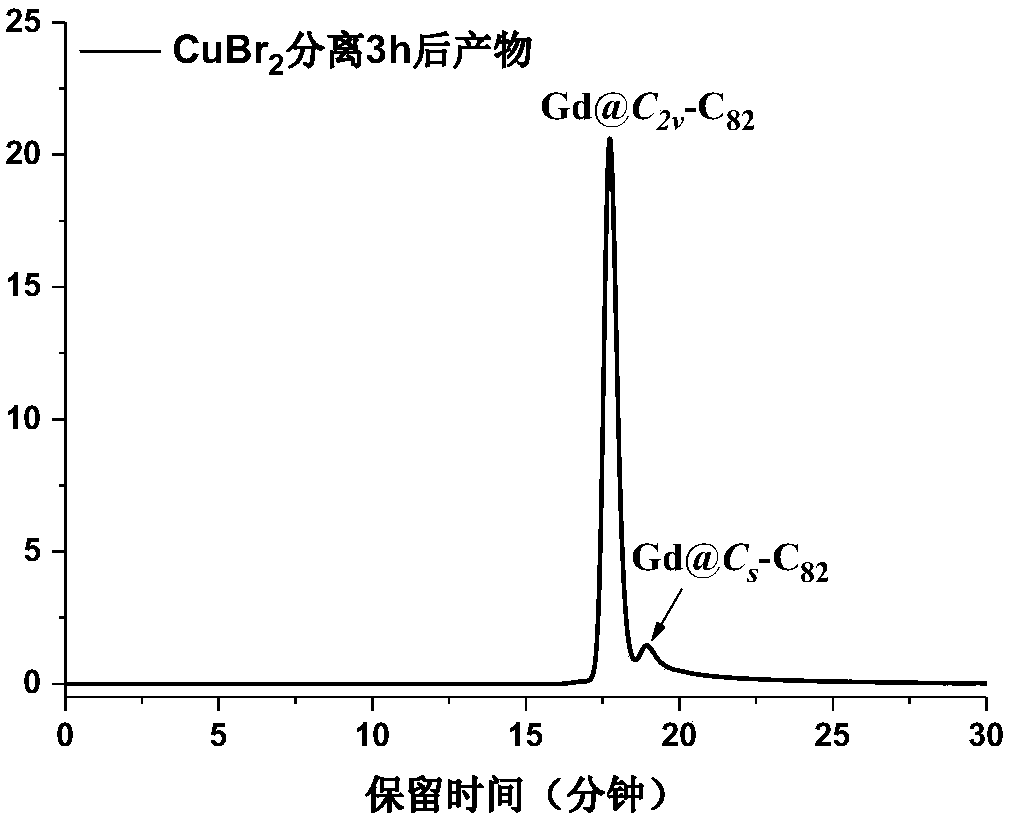

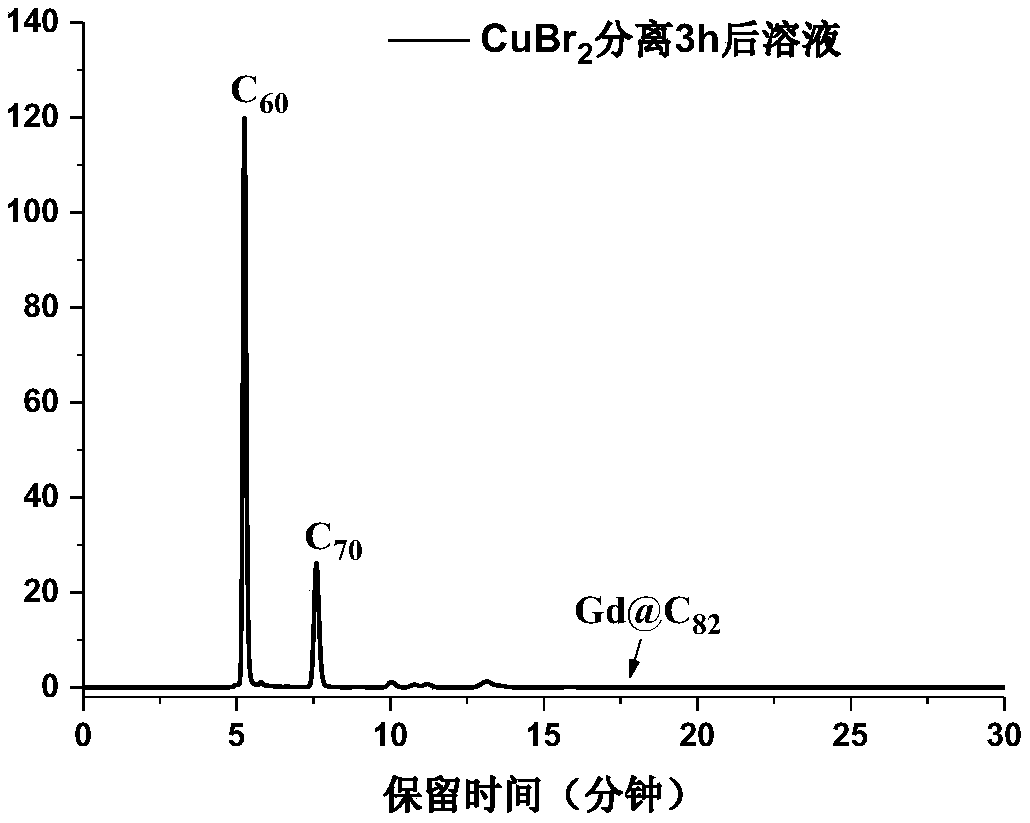

ActiveCN109650378AEasy to separateRapid separation and extractionFullerenesChemical reaction kineticsMetallofullerene

The invention provides a method for realizing high-efficiency, fast, high-selectivity and high-purity separating of metal fullerene m@C82 and an isomer thereof by using a specific lewis acid, the method can be used for simply and rapidly separating the metal fullerene and hollow fullerene, and meanwhile, the high-purity metal fullerene isomer can be further separated by strictly controlling chemical reaction kinetics. The method is simple to operate, low in cost and high in feasibility, and is suitable for large-scale production of the metal fullerene.

Owner:BEIJING FUNAKANG BIOTECH CO LTD +1

A full-priority flotation separation method for waste mixed plastics based on calcium sulfate pretreatment

ActiveCN111409213BAchieve selective separationHigh selectivityPlastic recyclingProcess engineeringEnvironmental engineering

The invention relates to a full-priority flotation separation method for waste and old mixed plastics based on calcium sulfate pretreatment. The technical solution is: crush the mixture of any two or more of the four waste plastics of PMMA, PVC, PS and ABS into mixed plastic particles, and the obtained particles are treated with CaSO 4 After pretreatment, PMMA, PS, ABS and PVC plastics are sequentially obtained through all-priority flotation separation. The method of the invention has the characteristics of simple operation, low cost, high separation efficiency, high recovery rate and purity, and the like.

Owner:CENT SOUTH UNIV

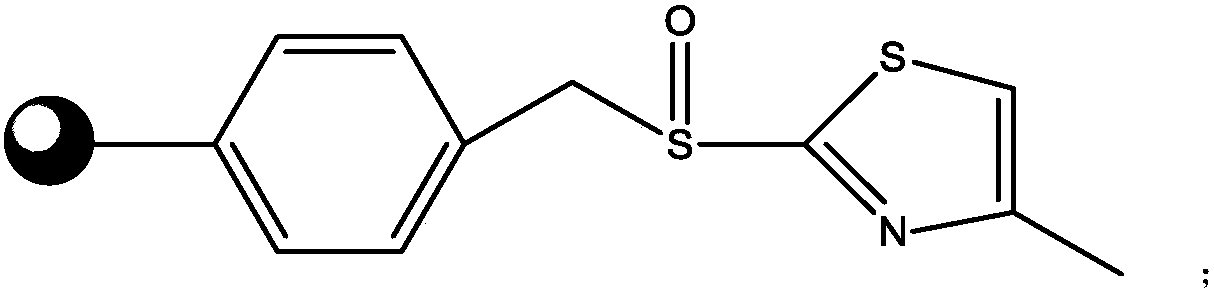

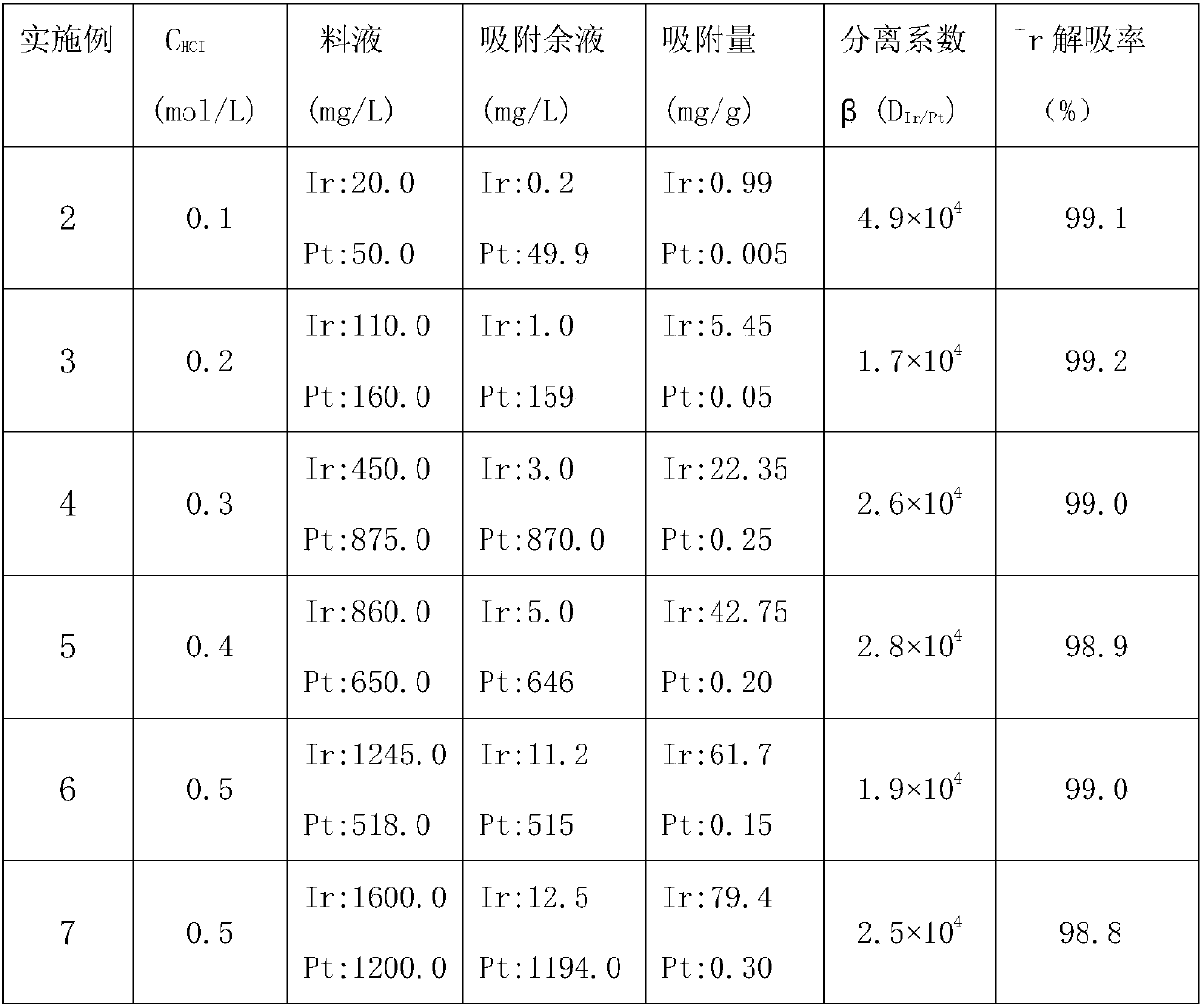

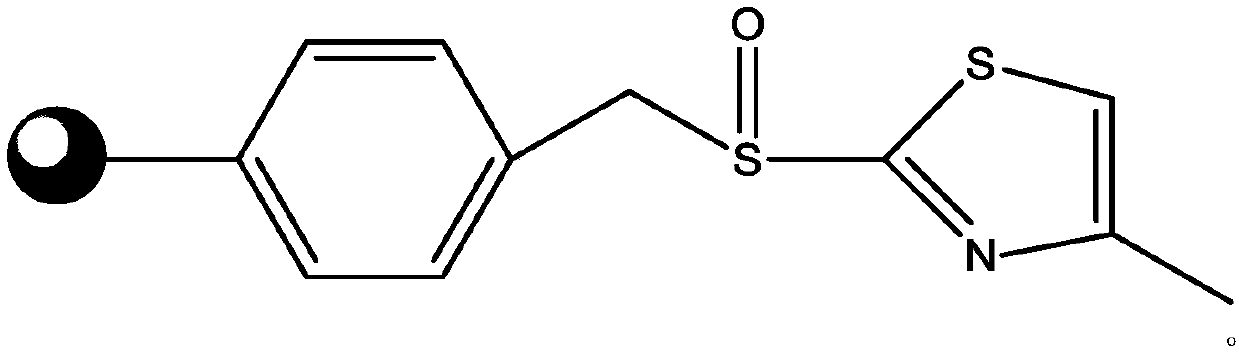

A method for separating iridium and platinum with polystyrene-4-methylthiazole sulfoxide resin

InactiveCN106086450BHigh separation factorHighly selective separationProcess efficiency improvementIridiumSpecific adsorption

Owner:YUNNAN UNIV

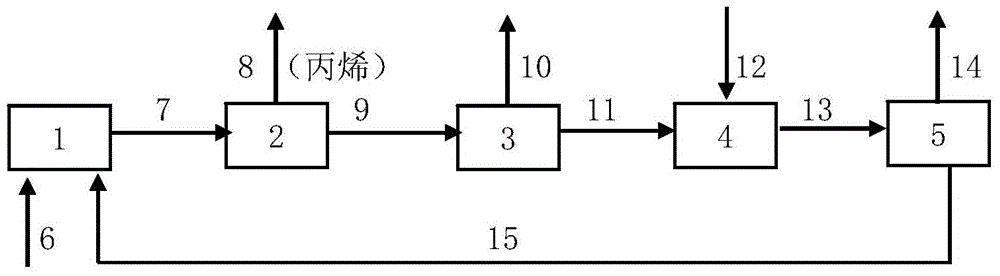

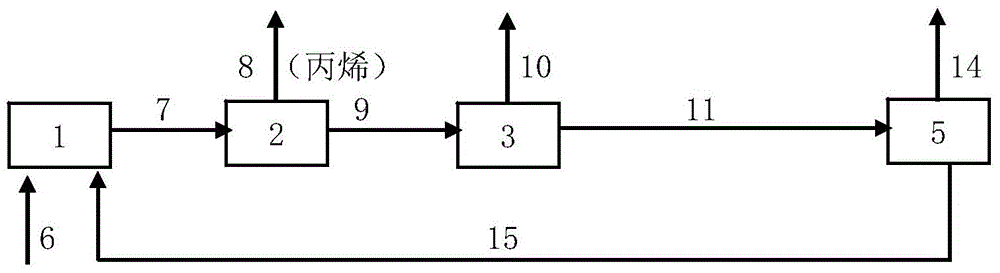

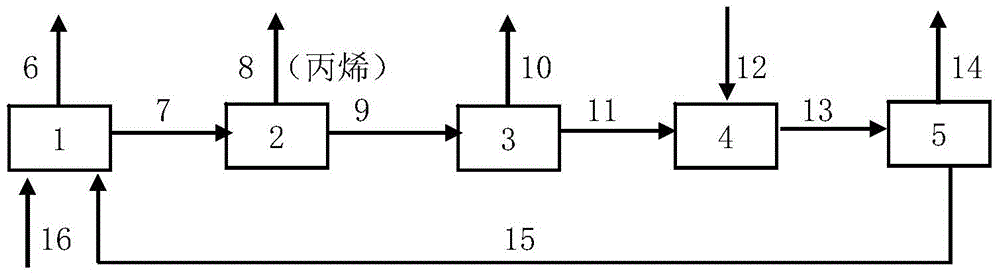

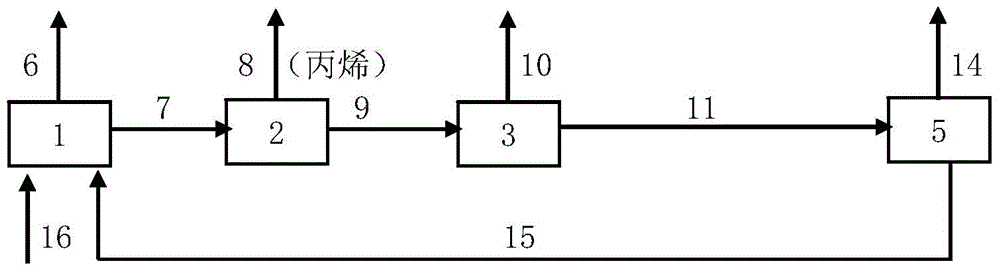

A method for converting olefins with four to six carbon atoms to produce propylene

InactiveCN104672047BHigh selectivityReduce energy consumptionHydrocarbon from oxygen organic compoundsEthylene productionAlcoholGasoline

The invention relates to a method for transforming and producing propylene by employing olefin with 4-6 carbon atoms, and provides a technique for transforming and producing propylene by employing C4 to C6 olefin components contained in liquefied gas and light petrol. According to the method, the olefin oligomerization cracking reaction process is changed by transforming the olefin into corresponding alcohol or ether; generation of low-valent by-products such as dry gas and coke in the reaction process is inhibited; the target product selectivity is improved; the material circulation in the process is reduced; and the energy consumption in the process is reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for separating xylogen from agricultural waste by using compound ion liquid

InactiveCN102321251BHighly selective separationIncrease contentOrganic-compounds/hydrides/coordination-complexes catalystsIon exchangeReaction temperature

The invention discloses a method for efficiently separating xylogen from agricultural waste by using a compound ion liquid system. The method comprises the following steps of: (1) preparing a compound ion liquid: preparing a compound ion liquid with a synergistic effect through mechanical mixing or a dianion initiator ion exchange method; (2) pretreating agricultural waste: fully drying the agricultural waste, smashing to 20-60 meshes by adopting a mechanical smashing method, washing soluble components with acetone and deionized water in sequence, and fully drying for later use; and (3) removing xylogen from the agricultural waste: fully mixing 5-500 grams of compound ion liquid with 1.5-60 grams of agricultural waste in an inertia atmosphere, and reacting at the temperature of 120-260 DEG C under the stirring condition to obtain high-purity xylogen and biological micro-molecular substances. The method has the advantages of high xylogen content, small using amount of ion liquid, circular use and no need of adding deionized water.

Owner:SOUTH CHINA UNIV OF TECH

Isoindigo conjugated polymer, semiconductor cnt ink, preparation method and application thereof

ActiveCN107151311BEasy to prepareWide range of usesMaterial nanotechnologySolid-state devicesPolymer scienceDevice material

The invention discloses an isoindigo conjugated polymer, a semiconductor CNT ink, a preparation method and an application thereof. The iso-indigo conjugated polymer comprises constituent units represented by the following formula: wherein R 1 Including any one of heteroalkyl, straight-chain and branched-chain alkyl with 1 to 20 carbons, R 2 Including any one of hydrogen atom, heteroalkyl, halogen atom, straight-chain or branched-chain alkyl with 1-20 carbons, Ar includes 1-4 five-membered or six-membered aromatic rings, five-membered or six-membered A conjugated unit consisting of any one or two or more of membered aromatic heterocycles and multi-membered aromatic condensed rings, n is selected from any integer between 2 and 500. The isoindigo conjugated polymer of the present invention can be specifically combined with semiconducting carbon nanotubes, so it can be used for highly selective separation of semiconducting carbon nanotubes in commercial carbon nanotubes, and can form high-purity semiconducting carbon nanotubes (CNT) ink, which can be used to build semiconductor devices with superior performance.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Method for separating palladium from waste water by double-arm bonding-type alicyclic crownether silicon resin

ActiveCN102849823BImprove separation efficiencyGuaranteed removal rateWater contaminantsWater/sewage treatment by ion-exchangeSolid phasesIon

The invention discloses a method for separating precious metal palladium through selective adsorption from palladium-containing waste liquid by using double-arm bonding-type alicyclic crownether silicon resin, and belongs to the technical field of heavy metal ion separation. The method comprises the following steps: firstly adding double-arm bonding-type alicyclic crownether silicon resin into palladium-containing waste liquid according to a ratio of 0.01-1.0 of the weight of the double-arm bonding-type alicyclic crownether silicon resin to the volume of the palladium-containing waste liquid, then stirring or oscillating at a temperature of 5-50 DEG C for 20-300 min; filtering and separating the solid phase from the liquid phase, determining the residual concentration of palladium ions in the liquid phase, comparing with an initial concentration to calculate the separation recovery rate; eluting the double-arm bonding-type alicyclic crownether silicon resin with a nitric acid solution of 0.01-3 mol / L, repeatedly washing with deionized water, drying to obtain regenerated resin. The method provided by the invention is high in separation speed for palladium ions in the palladium-containing waste liquid, high in separation efficiency, strong in adaptability, recyclable in materials, and low in cost.

Owner:TSINGHUA UNIV

A method for converting carbon tetraolefins to propylene by catalytic cracking or cracking process

InactiveCN104725176BHigh selectivityReduce energy consumptionHydrocarbon purification/separationHydrocarbon from oxygen organic compoundsAlkaneHydration reaction

The invention discloses a method for converting carbon-4 olefin into propylene through a catalytic cracking or pyrolysis process. The technical method comprises the following steps: (1) directly putting the etherified carbon-4 into a reactor, and performing hydration reaction with water to generate a corresponding alcohol; (2) performing regular distillation on the reactor outlet material to obtain the alkane on the tower top and the corresponding alcohol on the tower bottom; and (3) taking the tower bottom material as the raw material for cracking and increasing the propylene, and reentering to a catalytic cracking riser reactor to perform cleavage reaction. A mass separating agent (water) which does not influence the consequent reaction without separation is added, the alkane and the olefin separation process is reinforced, the olefin component with high reactivity is high selectively reprocessed under the condition without separating the mass separating agent. The problem of efficient separation of the alkane and the olefin in the traditional process is solved and the target of increasing the yield of the propylene is realized through reprocessing. The original device is utilized and the utilization rate of the olefin is increased under the condition of low investment.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

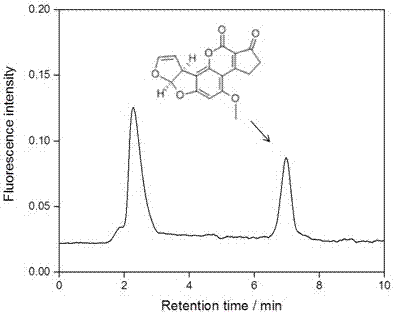

Preparation and applicationof aflatoxin B1 aptameraffinity capillarymonolithic column

The invention discloses the preparation and application of an aflatoxin B1 aptamer affinity capillary monolithic column. An amino-modified aflatoxin B1 aptamer is modified onan organic-inorganic hybridamino capillary monolithic column through glutaraldehyde coupling and grafting, through the specific affinity effect of the aptamer and aflatoxin B1, the organic-inorganic hybrid monolithic column is high in column permeability and large in specific surface area. The trace, ultra-trace aflatoxin B1 in complex food samples can be separated and enriched with high sensitivity and high selectivity. Thesimple, sensitive and rapid detection of the aflatoxin B1 can be achieved by using a detection instrument together.

Owner:NANJING UNIV OF FINANCE & ECONOMICS

a p-ph-so 2 -Application of compounds in mineral flotation

ActiveCN112403683BSpecific capture selectivityHighly selective separationFlotationMineral flotationSulfidation

Owner:CENT SOUTH UNIV

Method for selectively precipitating magnesium in zinc-magnesium solution

ActiveCN114438344AAchieve selective separationHighly selective separationProcess efficiency improvementPhysical chemistryZinc smelting

The invention belongs to the technical field of zinc smelting, and particularly relates to a method for selectively precipitating magnesium in a zinc-magnesium solution, which comprises the following steps of: adding a pre-reaction solution into the zinc-magnesium solution, carrying out pre-reaction to obtain a pre-reaction solution, respectively forming liquid flows by the pre-reaction solution and a combined precipitator solution, and contacting and mixing the liquid flows of the pre-reaction solution and the combined precipitator solution to carry out magnesium precipitation reaction; and controlling the pH value of the liquid flow mixing system to be 9.5-11, and then carrying out solid-liquid separation to obtain magnesium slag and zinc liquid. The method has excellent zinc and magnesium selectivity, magnesium can be selectively precipitated, and high-purity zinc liquid can be obtained at a high recovery rate.

Owner:湖南烯富环保科技有限公司

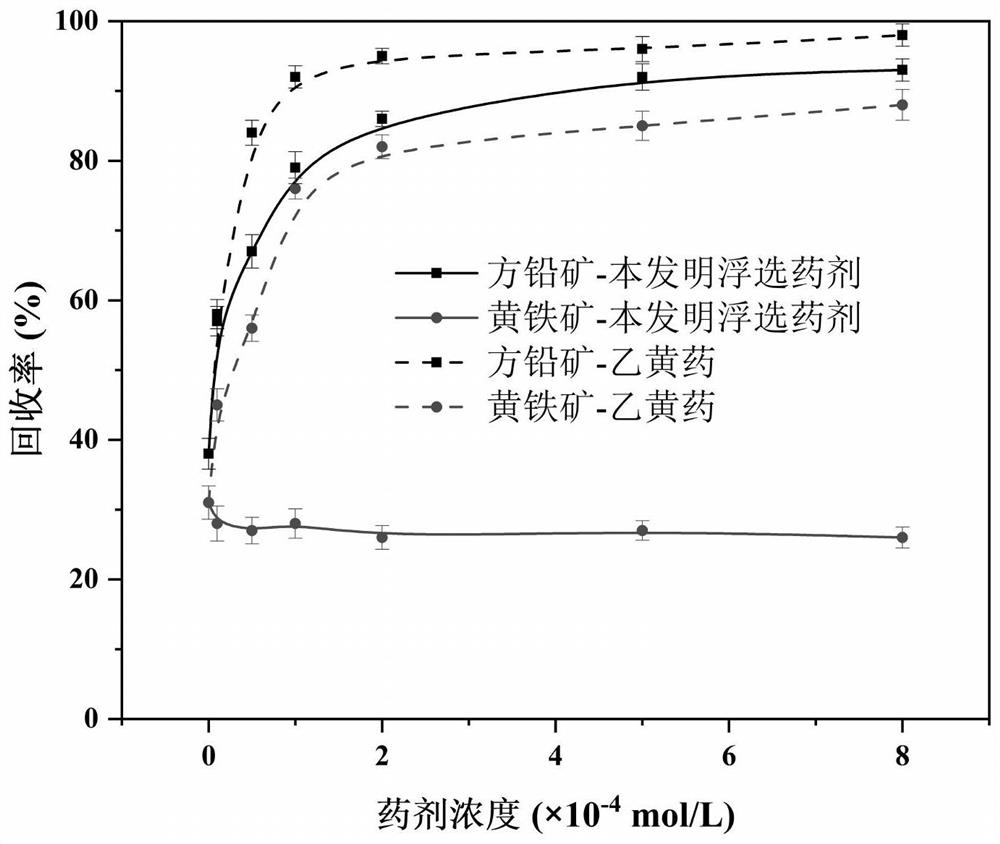

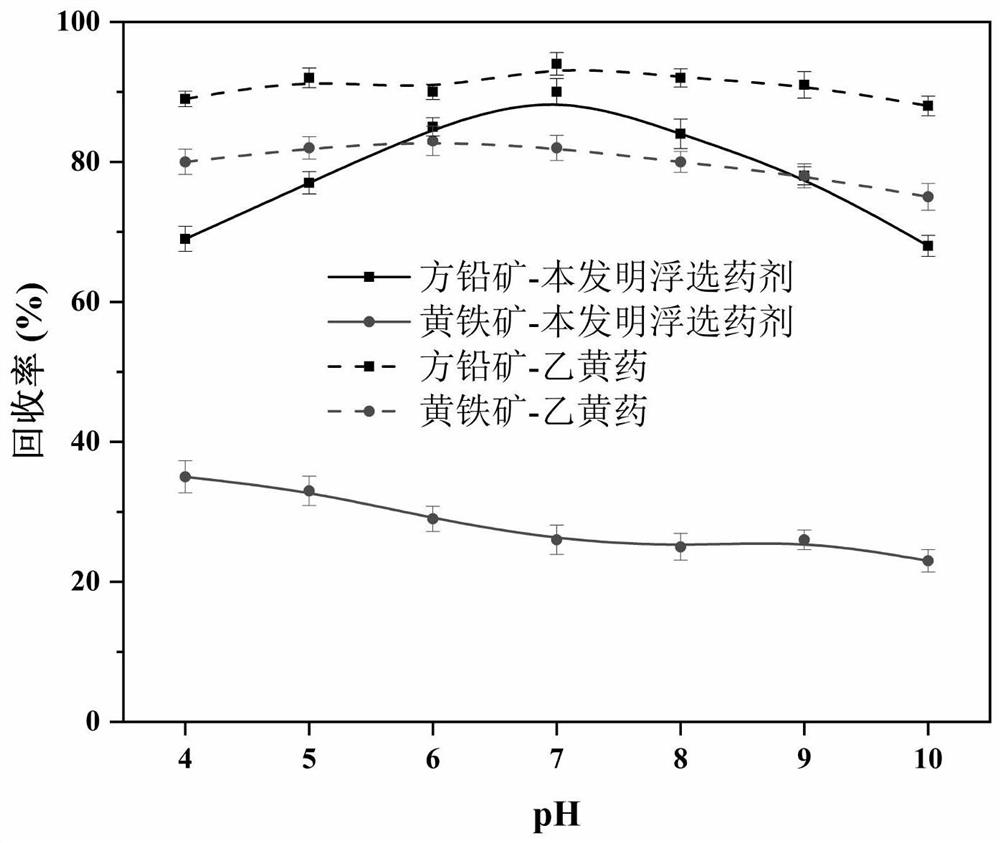

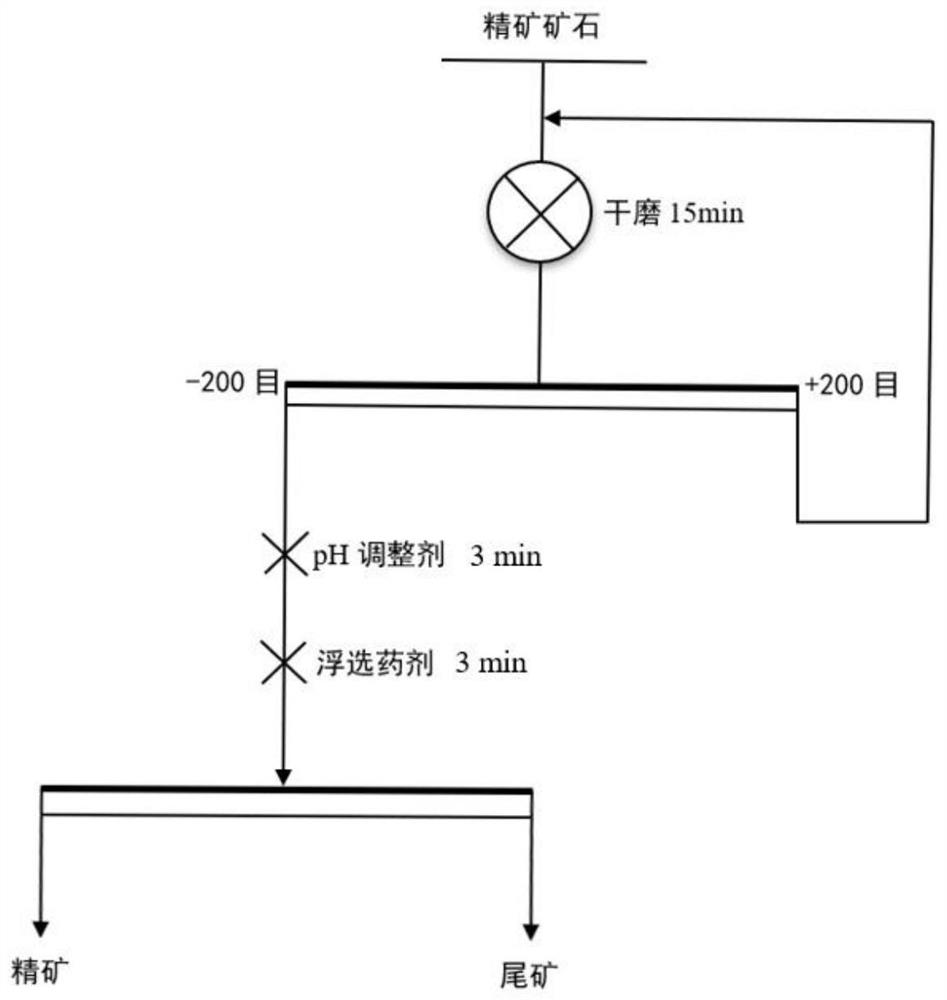

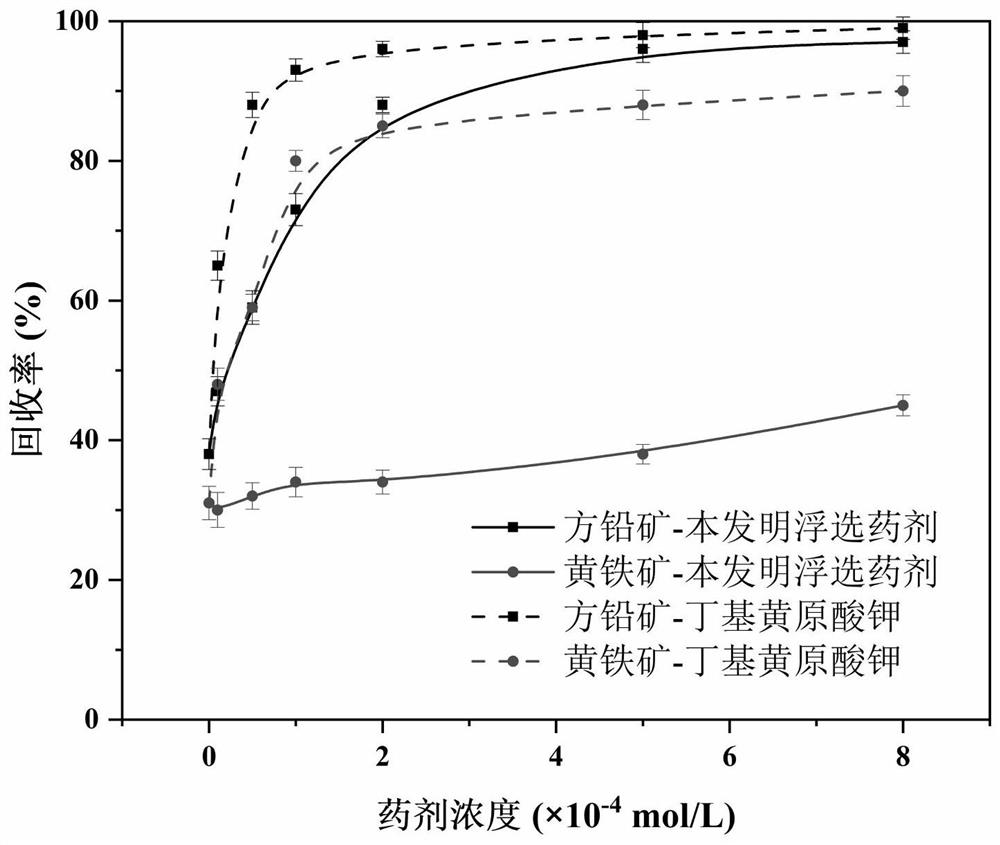

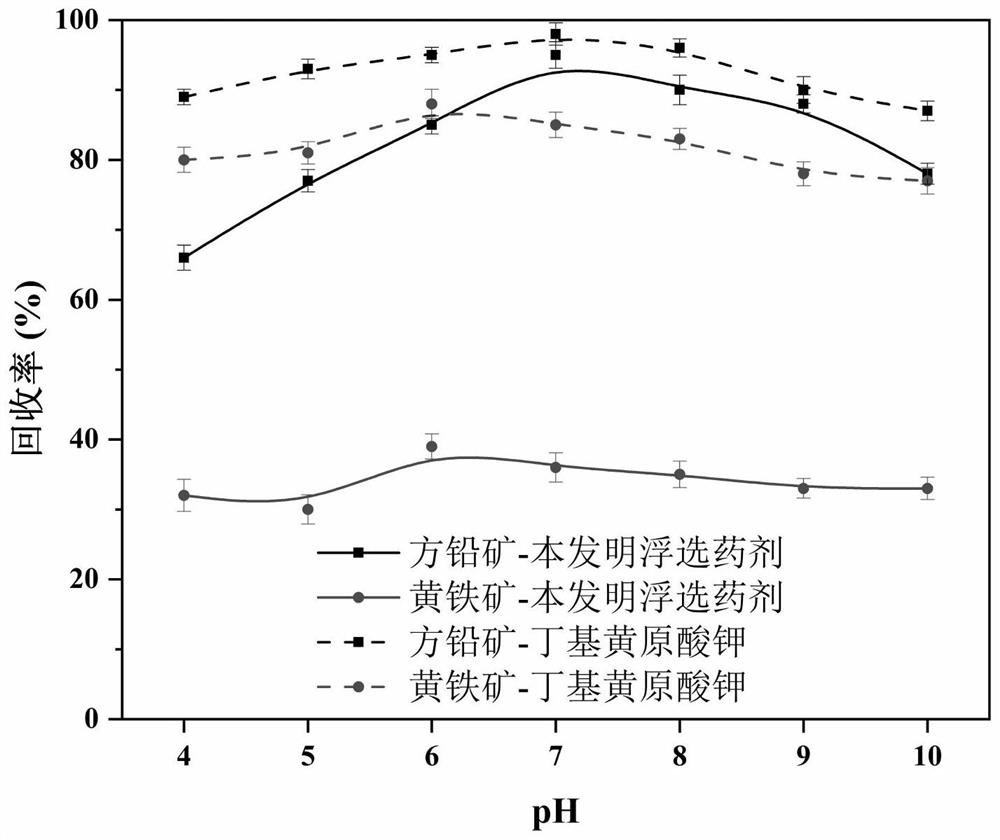

A kind of flotation separation method of galena and pyrite

ActiveCN112427145BHighly selective separationImproved flotation selectivityFlotationOre concentrateMining engineering

The invention belongs to the field of mineral flotation, and specifically discloses a flotation separation method for galena and pyrite, which uses a compound capable of ionizing the structure of formula 1 as a flotation collector, and is used for the flotation of galena and pyrite Flotation is carried out on the mixed ore of iron ore, and the concentrate rich in galena and the tailings rich in pyrite are obtained by separation. The technical solution of the present invention has excellent flotation selectivity of galena and pyrite, and the flotation agent has the advantage of low toxicity, which greatly reduces the cost of subsequent mineral processing wastewater treatment and conforms to the concept of green mines.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com