Method for separating of metal fullerene m@C82 and isomer thereof

A technology for separating metal fullerenes and metals, applied in the chemical field, can solve problems such as inability to separate fullerenes, unfit for industrial production, harsh reaction conditions, etc., and achieve high-selectivity separation, fast separation speed, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

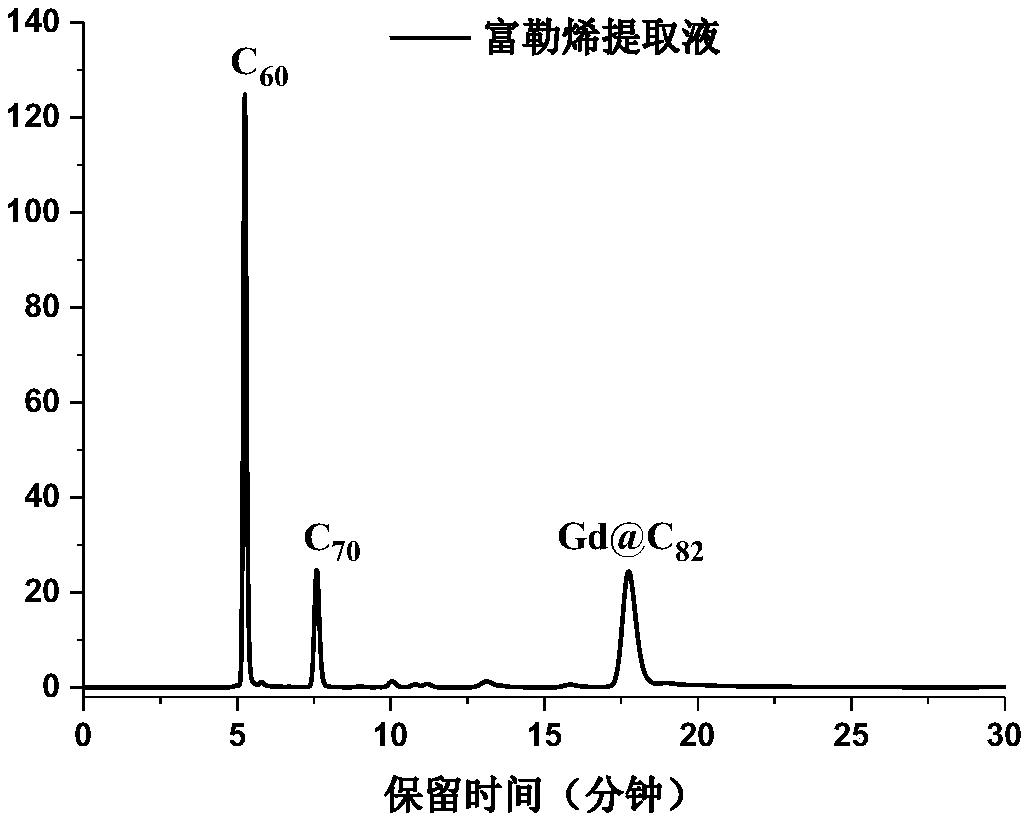

[0055] Example 1: Metal fullerene Gd@C 82 separation and extraction of

[0056] (1) copper bromide (CuBr 2 ) to metallofullerene Gd@C 82 separation

[0057] (a) The metal Gd powder and spectroscopically pure graphite powder were mixed, filled into hollow graphite tubes and compacted, and arc discharge method was used to obtain soot containing fullerene products. Put the soot into a filter paper bag, put it into a Soxhlet extractor, and use N,N-dimethylformamide (DMF) as a solvent to extract at 150°C and low vacuum for 24 hours to obtain a black solution.

[0058] (b) Filter the above solution to remove a large number of suspended particles, take 500 mL of the filtrate in a round bottom flask, and use a rotary evaporator to completely evaporate the filtrate to dryness. Add 500mL of toluene, put it into an ultrasonic reactor (model: KQ-300DB; power: 300W; ultrasonic frequency: 40KHz) for ultrasonic reaction for 2h, and filter to obtain a clear brown-yellow filtrate, which is...

Embodiment 2

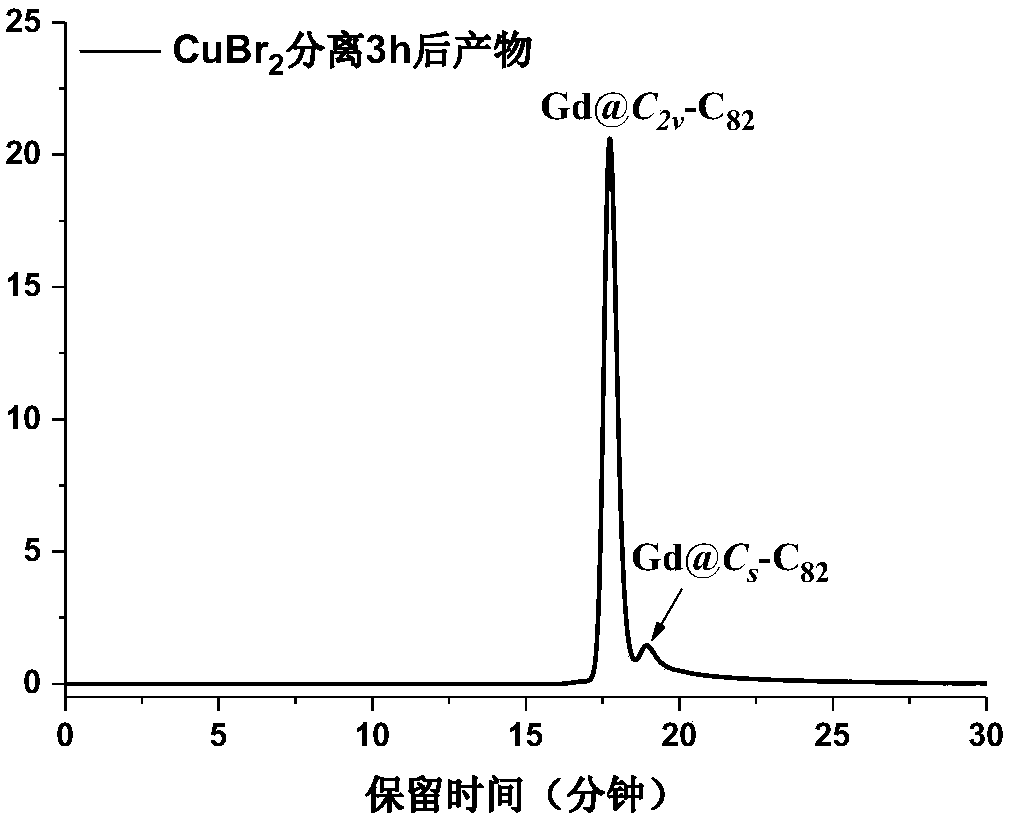

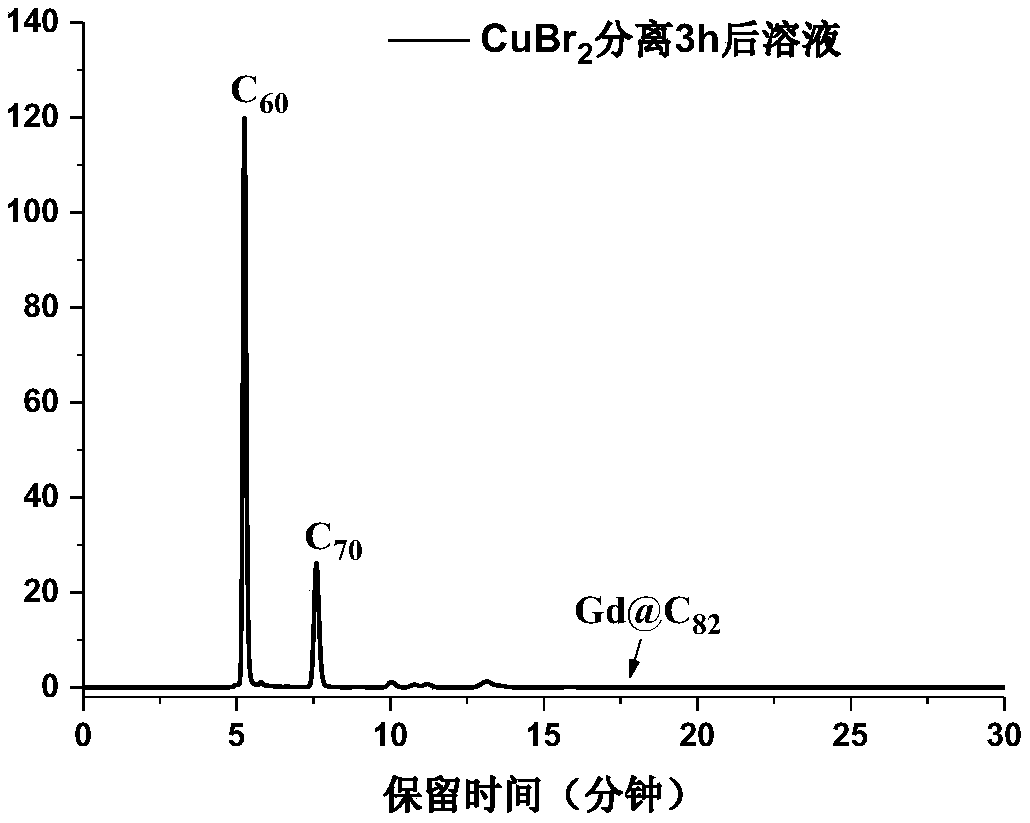

[0073] Example 2: Selective separation of Gd@C 82 isomer

[0074] (1) copper bromide (CuBr 2 ) to metallofullerene Gd@C 82 Separation of isomers

[0075] (a) Metallofullerene Gd@C prepared by traditional arc discharge method 82 Usually contains two isomers with relatively stable chemical properties: Gd@C 2v -C 82 and Gd@C s -C 82 , such as, the bright yellow filtrate obtained in step (d) of Example 1(1) contains two Gd@C 82 isomers, such as figure 2 shown. Take 500mL of this solution, add 10mg of CuBr 2 , precisely control the stirring (speed: 1000rpm) time to 40min. CuBr 2Priority with Gd@C s -C 82 The isomer reaction produces a complex precipitate, which is filtered through a solvent filter to collect the precipitate, and the filtrate contains only another isomer Gd@C 2v -C 82 .

[0076] (b) Washing in a solvent filter using aqueous sodium carbonate solution containing only Gd@C s -C 82 Precipitation of isomers three times, suction filtration completely r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| process yield | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com