Flotation collecting agent, flotation reagent and flotation method for improving separation efficiency of ilmenite and gangue of ilmenite

A technology of flotation agents and separation efficiency, applied in flotation, solid separation, etc., can solve problems such as environmental pollution, high cost, unsatisfactory separation selectivity of ferro-titanium ore and its gangue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

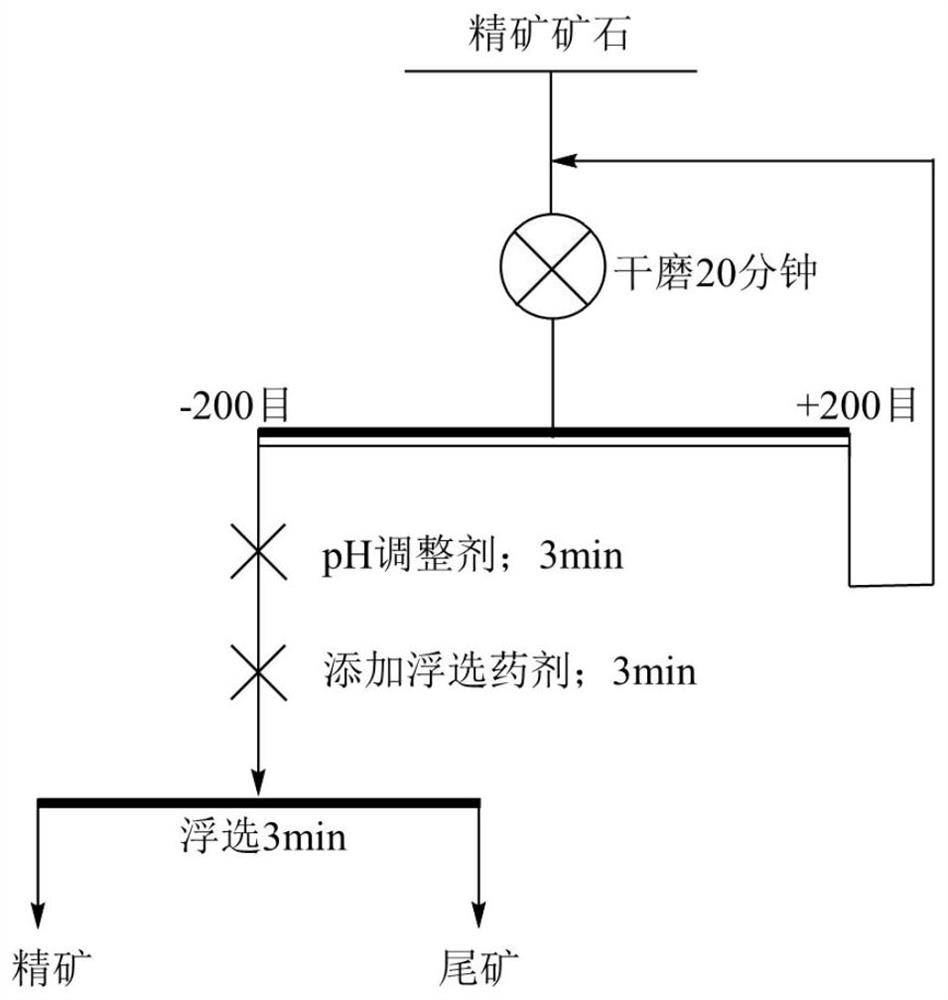

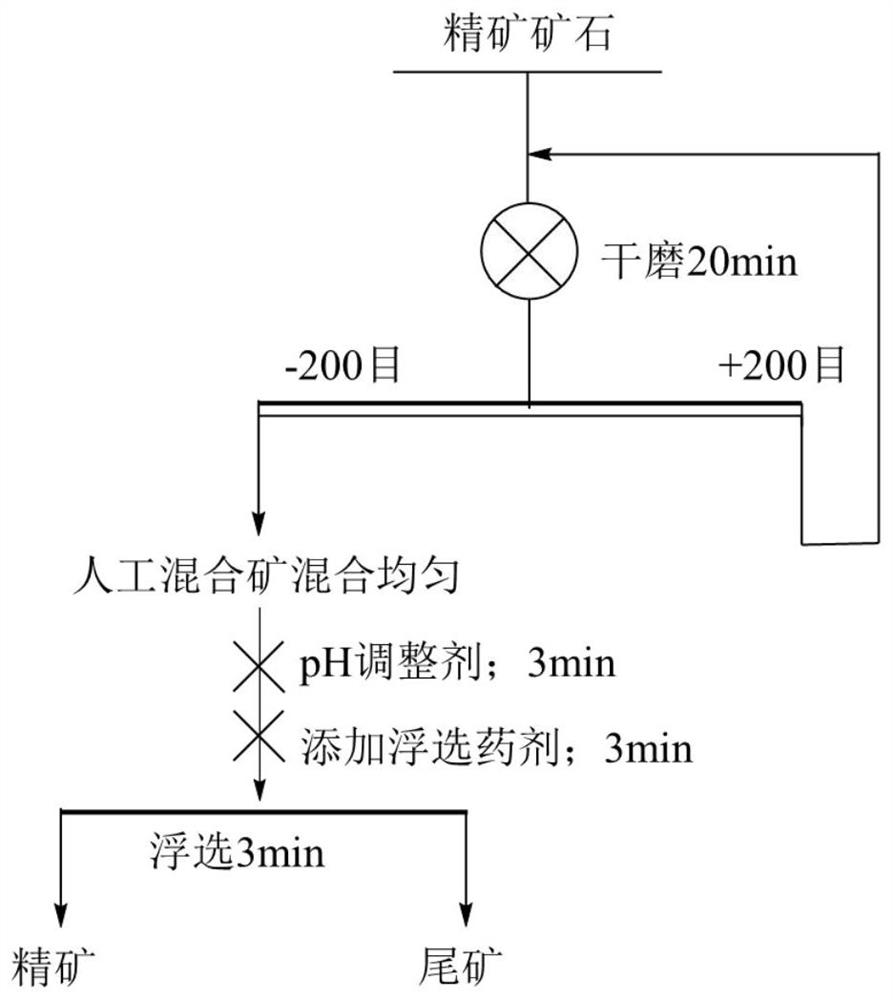

[0047] In order to verify the sorting effect in each component mixed mineral when the flotation main collector (collector A) of the present invention is used alone, adopt the ferro-titanium ore, titanolite and olivine concentrate of Panzhihua, Sichuan in Table 1, and adopt figure 1 Flotation is carried out in the flotation process of the single ore shown. Use the collector A (see Table 2) and foaming agent 2# oil in this embodiment as the flotation agent to carry out flotation to the above three different minerals respectively. The parameters of each group of flotation process are the same, the difference is only in the collection Collector A is different, so as to compare the flotation and sorting effects of different collectors A of the present invention.

[0048] The flotation agent in the present embodiment consists of collector A (in formula I, R 1 and R 2 is a variable), 2# oil is composed in the ratio of 0.095mol:0.005mol. Add the above molar ratio of collector A an...

Embodiment 2

[0055] In order to verify the separation effect of the main collector (collector A) and auxiliary collector (collector B) in the mixed minerals of each component when the main collector (collector A) and the auxiliary collector (collector B) are used in combination in the present invention, the iron and titanium in Panzhihua, Sichuan in Table 1 are adopted. ore, titanopyroxene and olivine concentrates, and using figure 1 The process shown is for flotation. The experiment was divided into 4 groups, two of which used the combination of main collector (collector A) and auxiliary collector (collector B) and 2# oil, in which collector B was benzohydroxamic acid or dodecylamine. The other two groups of experiments are: using the main collector (collector A), and oleic acid (assistant collector), 2# oil combined medication; using the main collector (collector A) and styrene phosphoric acid ( collector), 2# oil in combination.

[0056] Then each flotation reagent is used to float t...

Embodiment 3

[0063] In order to verify the sorting effect of the change in the ratio of the main collector (collector A) and auxiliary collector (collector B) in the present invention in the mixed minerals of each component, the table 1 ferro-titanium ore, titanopyroxene and olivine concentrates from Panzhihua, Sichuan, and used figure 1 The process shown is for flotation. The flotation reagents with different proportions of reagents in this example are used to carry out flotation of the above three different minerals respectively. The parameters of the flotation process in each group are the same. The flotation and sorting effects of flotation reagents with different reagent ratios.

[0064] Each flotation reagent in this embodiment: by collector A (in formula I, R 1 is phenyl, R 2 hydrogen), collector B (dodecylamine), and 2# oil in different proportions (0.1mol in total, see Table 4 for specific proportions). Add collector A, collector B and 2# oil in the above molar ratio to 1L dei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com