Preparation and applicationof aflatoxin B1 aptameraffinity capillarymonolithic column

A capillary monolithic column, aflatoxin technology, which is applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of antibody inactivation, the antibody is easily affected by external conditions, and the flexible application of limited methods, etc., to achieve the effect of rapid detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

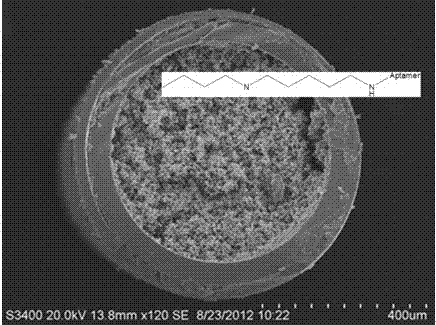

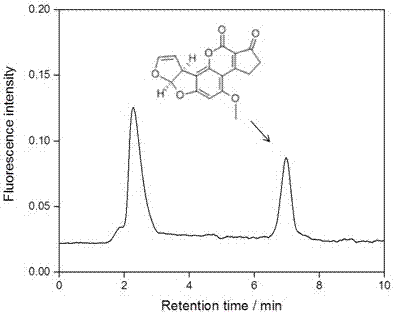

[0021] Example 1 Preparation of Aflatoxin B1 Aptamer Affinity Capillary Monolithic Column

[0022] (1) Capillary activation: the inner diameter of the quartz capillary used to prepare the monolithic column is 530 μm, and the outer diameter is 690 μm. Rinse the capillary with 1.0mol / L sodium hydroxide solution for 4h, deionized water for 30min, and 1.0mol / L hydrochloric acid solution for 4h, then wash with deionized water until neutral, and blow dry with nitrogen at 160°C.

[0023] (2) In situ synthesis of monolithic columns: firstly, 25 mg CTAB was dissolved in a mixed solution of 225 μL absolute ethanol and 100 μL deionized water. Then 150 μL TEOS and 80 μL APTES were quickly added to the above mixed solution. Vortex at room temperature for 30 s, then place in an ice-water bath at 0°C and sonicate for 30 s, then pour the mixed solution into the above-mentioned activated capillary. Finally, both ends of the capillary were sealed with silicone rubber and placed in an oven at ...

Embodiment 2

[0031] Firstly, the capillary activation treatment was carried out in the same steps as in Example 1. Then, 10 mg CTAB was dissolved in a mixed solution of 150 μL absolute ethanol and 50 μL deionized water, and then 100 μL TEOS and 50 μL APTES were quickly added to the above mixed solution. Vortex at room temperature for 5 minutes, then place in an ice-water bath at -5°C and sonicate for 5 minutes, then pour the mixed solution into the above-mentioned activated capillary. Both ends of the capillary were sealed with silicone rubber, and placed in an oven at 30°C for 10 h. After the reaction is complete, rinse the capillary thoroughly with methanol and deionized water.

[0032] Prepare a phosphate buffer solution containing 5% glutaraldehyde, and pass the solution into the capillary at a rate of 10 μL / min for continuous reaction. In the process of aptamer modification, the aflatoxin B1 aptamer was made into a phosphate buffer solution with a concentration of 4 nmol / L, and then...

Embodiment 3

[0034] Firstly, the capillary activation treatment was carried out in the same steps as in Example 1. Then, 30 mg CTAB was dissolved in a mixed solution of 350 μL absolute ethanol and 150 μL deionized water, and then 200 μL TEOS and 100 μL APTES were quickly added to the above mixed solution. Vortex at room temperature for 2 min, then place in a water bath at 5° C. and sonicate for 2 min, then pour the mixed solution into the activated capillary. Both ends of the capillary were sealed with silicone rubber, and placed in an oven at 60°C for 30 h. After the reaction is complete, rinse the capillary thoroughly with methanol and deionized water.

[0035]Prepare a phosphate buffer solution containing 20% glutaraldehyde, pass the solution into the capillary at a rate of 20 μL / min, and react continuously. In the aptamer modification process, the aflatoxin B1 aptamer was made into a phosphate buffer solution with a concentration of 8 nmol / L, and then passed into the capillary at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com