Carbon nanotube structure-selective separation and surface fixation

A technology for carbon nanotubes and nanotubes, which is used in the field of concentrating and refining carbon nanotubes, high-selectivity separation, and can solve the problems of low accuracy of single-walled tubes, undescribed carbon nanotubes, and poor separation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0201] 1.1 Metal deposition on carbon nanotubes

[0202] Carbon nanotubes (CarboLex AP-Grade SWNT (SWNT: purity 50-70%)) in 1% sodium dodecyl sulfate (SDS) aqueous solution were ultrasonically dispersed at 24°C and 12,000 rpm for 15 minutes, and injected The supernatant was filtered with a filter (0.2 μm pore size filter) and subjected to additional sonication and centrifugation under the same conditions to obtain a micellar dispersion.

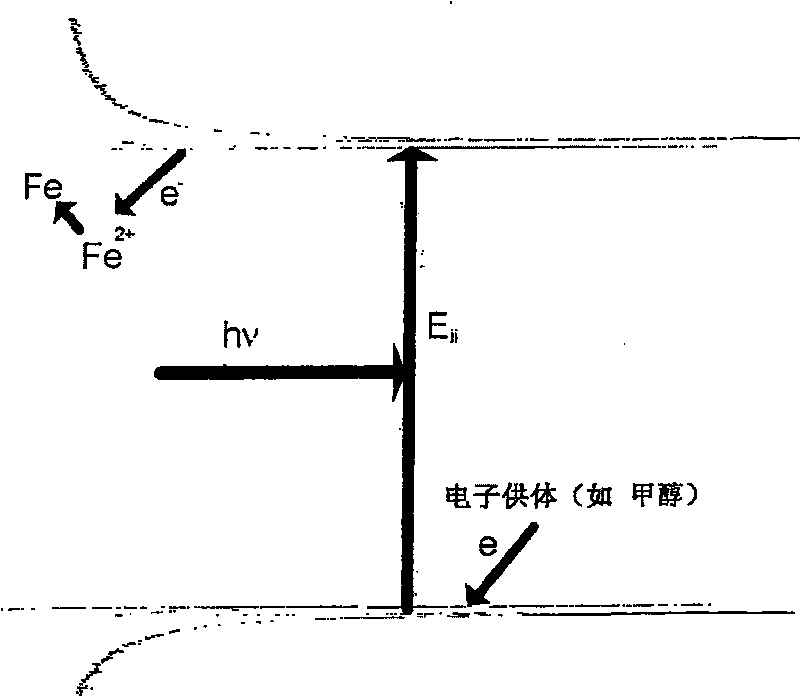

[0203] Next, methanol (methanol: 99.8% purity, Infinity Pure Grade; commercially available from Wako Pure Chemical Industries, Ltd.) was added as an electron donor to the dispersion to a concentration of 0.1%. The following three different metal ion solutions were added to the above obtained solution to prepare three solutions with different metal ions.

[0204] I) 0.1M Fe(NH 4 ) 2 (SO 4 ) 2 aqueous solution

[0205] II) 0.1M CoCl 2 aqueous solution

[0206] III) 0.1M MnCl 2 aqueous solution

[0207] The three solutions prepared in ...

Embodiment 2

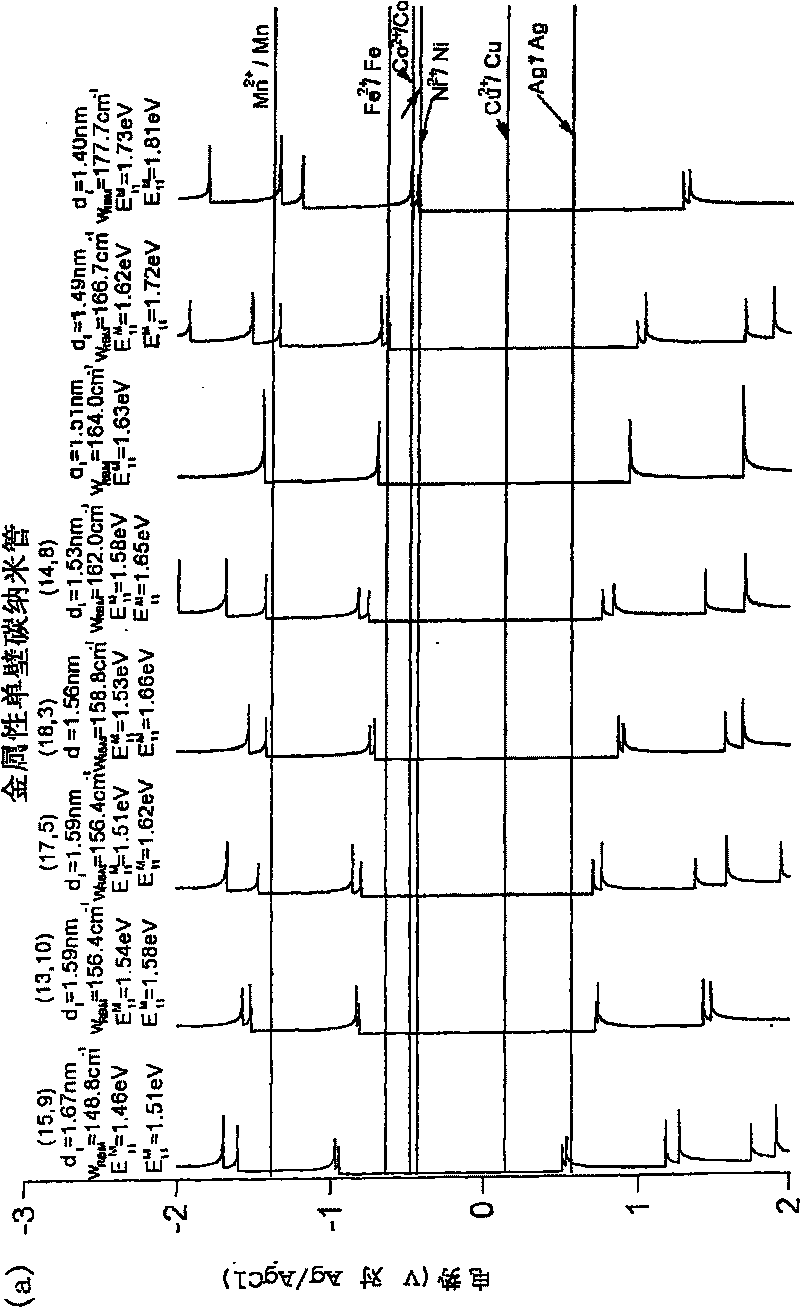

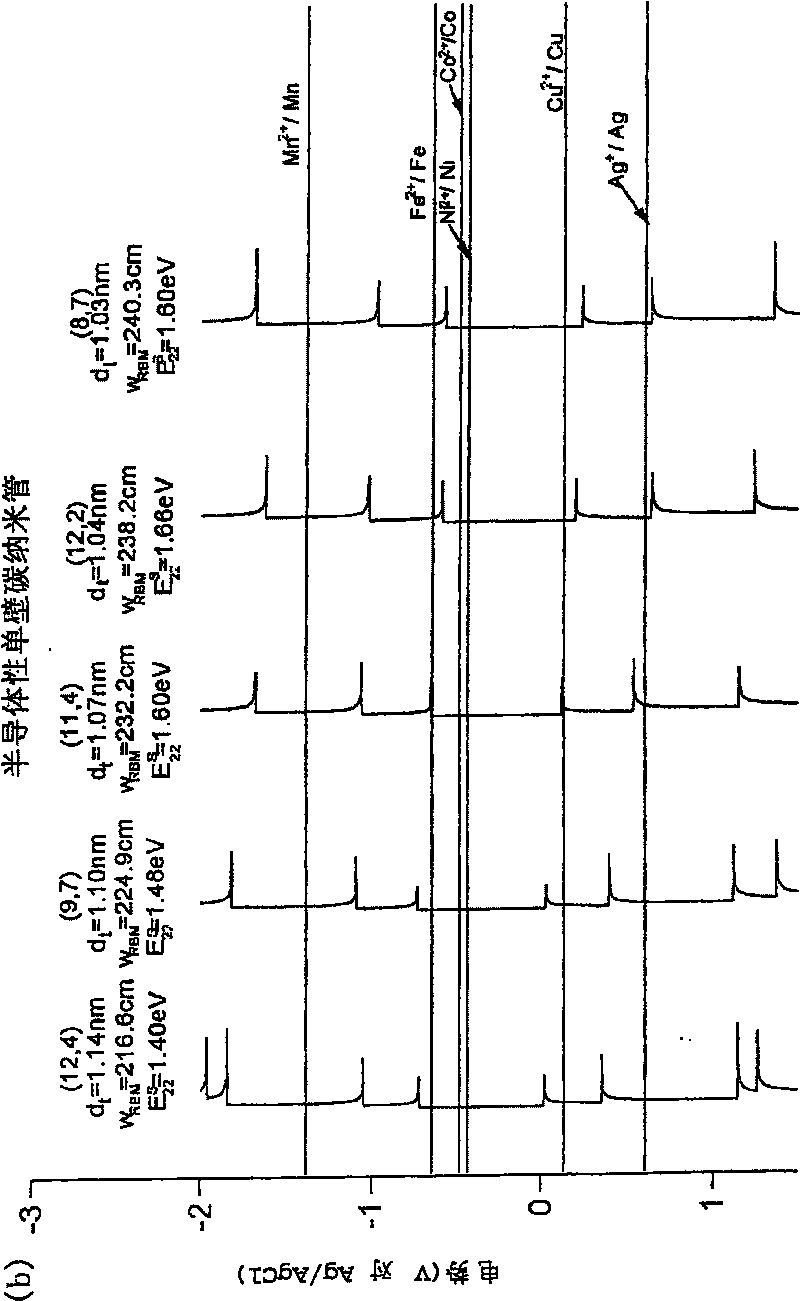

[0213] Figure 8 yes A device structure diagram of an embodiment of the present invention. Light with different wavelength values of 1064nm (λ1), 785nm (λ2) and 514nm (λ3) was used as the light source for photoelectrochemical metal deposition. A micellar dispersion obtained by dispersing the carbon nanotubes before purification in a 1% sodium lauryl sulfate aqueous solution was used as a carbon nanotube-containing solution. Fix the thin film glass in the reaction vessel, and add Fe(NH 4 ) 2 (SO 4 ) 2 To a concentration of 0.1 M, the substrate was irradiated with light of a wavelength (λ1, λ2 or λ3) for 10 minutes. After metal-deposited carbon nanotubes were accumulated on the substrate, the carbon nanotubes were cleaned with sulfuric acid, and Raman spectroscopy measurements were performed in radial breathing mode to determine the chiral vector of the deposited carbon nanotubes. In the part where light was irradiated with the wavelength of λ1, the carbon nanotube was...

Embodiment 3

[0223] Figure 9 A graph showing an experiment performed similarly to Example 2 above, with the additional step of flowing the solution containing carbon nanotubes and continuously supplying the dispersion containing carbon nanotubes. Carbon nanotubes can thereby be selectively deposited similarly to the above, resulting in a two to ten-fold increase in the deposition amount.

PUM

| Property | Measurement | Unit |

|---|---|---|

| composition ratio | aaaaa | aaaaa |

| composition ratio | aaaaa | aaaaa |

| composition ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com