A kind of flotation separation method of galena and pyrite

A separation method and technology of pyrite, applied in flotation, solid separation and other directions, can solve the problems of target mineral flotation effect, increase human and material resource consumption, difficult to achieve separation, etc., and achieve improved flotation selectivity and improved capture. Yield and grade, the effect of improving recovery and grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

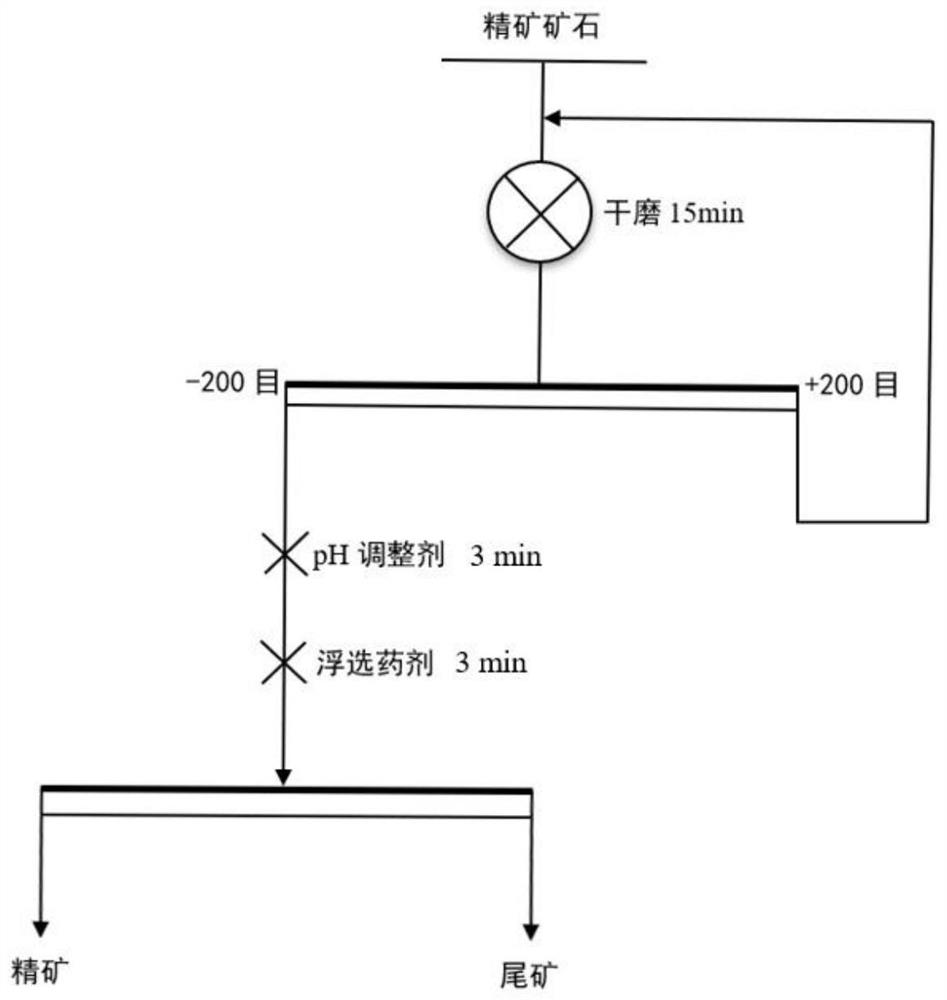

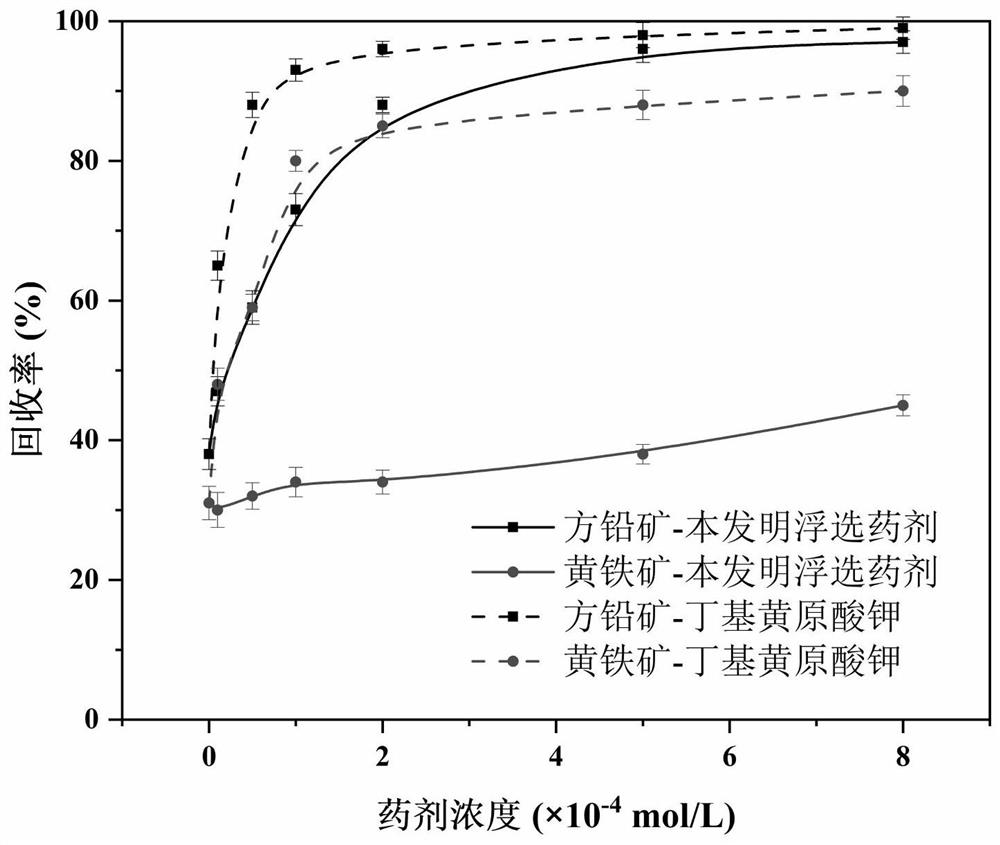

[0048] In order to verify the separation effect of flotation collectors in various components of sulfide minerals in this case, we use galena in Hunan or pyrite concentrate in Hubei (the composition is shown in Table 1), and use figure 1 The process shown in this case uses the flotation collector or potassium butyl xanthate as the collector to flotation different sulfide minerals. The parameters of the flotation process in each group of cases are the same, the only difference is the type of flotation sulfide minerals Different, so as to compare the flotation and sorting effect of the flotation collector in this case.

[0049] The compound of formula 1-1 is used as a collector (according to the dosage specified in Table 2), 2# oil is used as a foaming agent (25 μ L / L), and potassium butyl xanthate is selected as a contrast collector, and butyl xanthogen The dosage of potassium acid potassium is consistent with the dosage of flotation agent dosage (formula 1-1) of the present in...

Embodiment 2

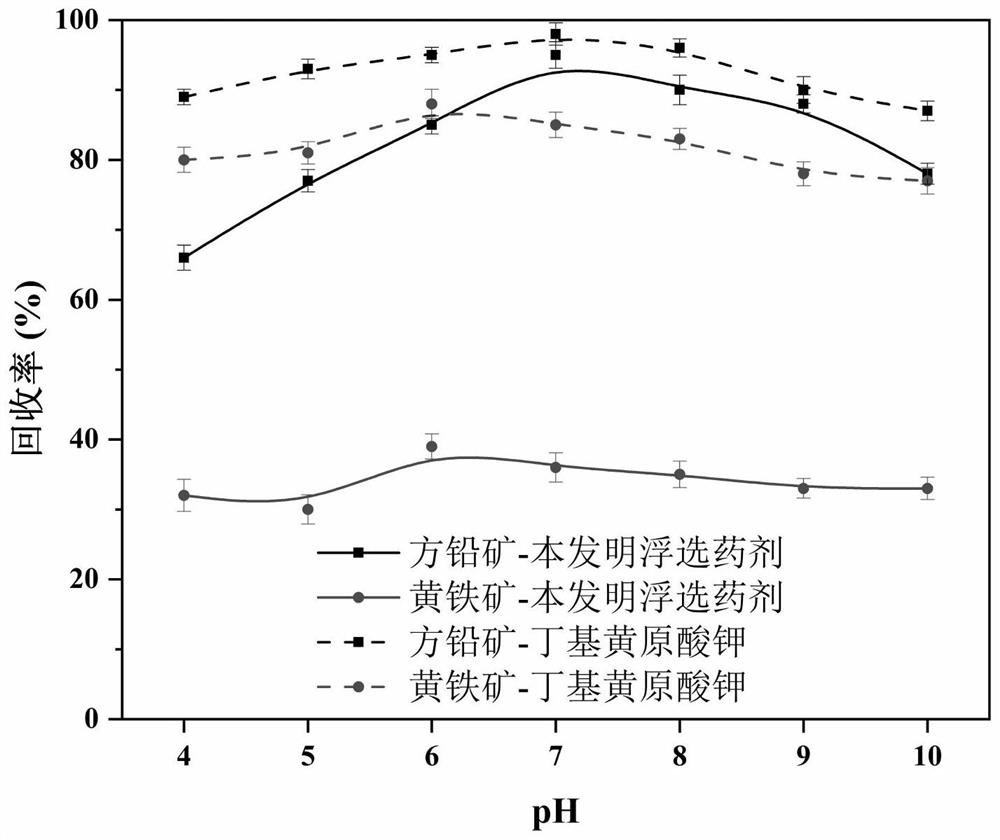

[0057] By carrying out flotation experiments at different solution pHs, the optimal pH of the flotation collector of the present invention for separating galena and pyrite is explored.

[0058] With formula 1-2 compound as collector (5 * 10 -4 mol / L), 2# oil is as foaming agent (25 μ L / L), chooses potassium butyl xanthate as contrast collector, the dosage of potassium butyl xanthate is the same as the dosage of flotation collector of the present invention unanimous.

[0059]

[0060] Use galena in Hunan or pyrite concentrate in Hubei (as shown in Table 1). use figure 1 As shown in the process, the experiment is divided into three groups, using the agent containing the collector of formula 1-2 as the flotation agent. The parameters of the flotation process in the three groups are the same, the only difference is that different types of sulfide mineral single minerals and different The pH of the ore pulp is used to compare the flotation separation effect of the flotation c...

Embodiment 3

[0068] In order to verify the separation effect of the flotation agent in the sulfide mixed minerals of each component in this case, we use galena from Hunan and pyrite concentrate from Hubei (as shown in Table 1), and mix them evenly at a ratio of 1:1. , to obtain lead-iron mixed sulfide minerals, using figure 1 process shown.

[0069] Formula 1-3 compound is used as collector (each group adds 5 * 10 -4 mol / L), 2# oil is used as a foaming agent (25 μ L / L), and the pH of the flotation pulp is 6 / 7 / 8.

[0070]

[0071] The specific operation is: dry-grind the concentrate ore (lead-iron mixed sulfide minerals, particle size 3mm-0.5mm) for 15 minutes (the particle size after grinding is 0.0740-0.0374mm, use a horizontal ball mill for dry grinding, and the grinding concentration is 35-40%), each group weighs 2g of the concentrate that has been ground and mixed uniformly in proportion and pours it into a 40mL flotation tank. After adding 30mL of deionized water, control the pH ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com