Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64results about How to "High solder joint strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cleaning-free solid-state scaling powder for aluminum low-temperature soldering and preparing method

ActiveCN104607826AFacilitate spreadingBarrier against electrochemical corrosionWelding/cutting media/materialsSoldering mediaActive agentAluminium

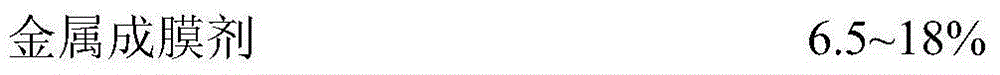

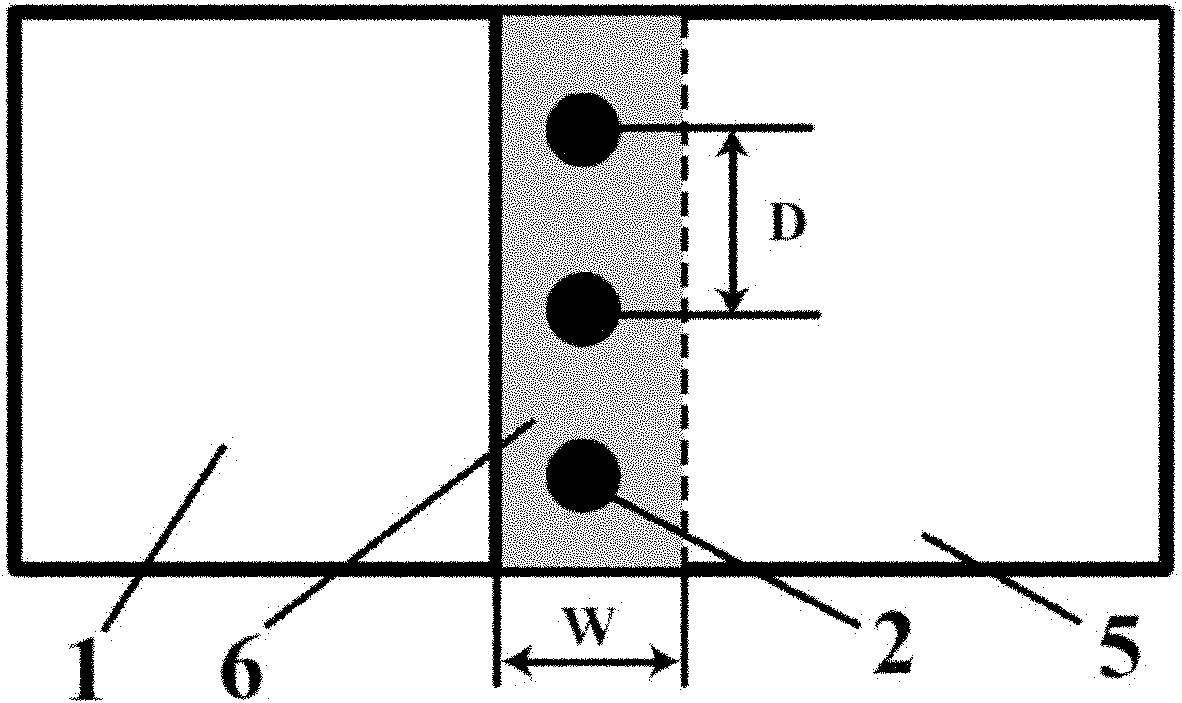

The invention discloses cleaning-free solid-state scaling powder for aluminum low-temperature soldering and a preparing method. According to the weight percentage, the cleaning-free solid-state scaling powder comprises raw materials of 6.5%-18% of metal film-forming agents, 5%-18% of organic carriers, 0.1%-1.8% of corrosion inhibition agents and the allowance of film removing active agents. The film removing active agents are composite salt of organic amine and acid. The cleaning-free solid-state scaling powder is suitable for lead-free solder wires with solid-state scaling powder contained in a core, and the powder can be used for automatic welding, manual soldering iron welding or flame spraying welding. The core-contained solder wires prepared with the scaling powder have the advantages that tinning speed is high, splashing is low, irritating smoke is avoided, post-welding residues do not have corrosiveness, a welding point has great electrochemical corrosion resistance, a contact service time is long, the wires are suitable for assembling welding of an aluminum coated layer circuit board and an aluminum soldering pin electronic element and brazing of an aluminum electric cable wire, an aluminum radiator and aluminum heat exchanging equipment.

Owner:SOUTH CHINA UNIV OF TECH

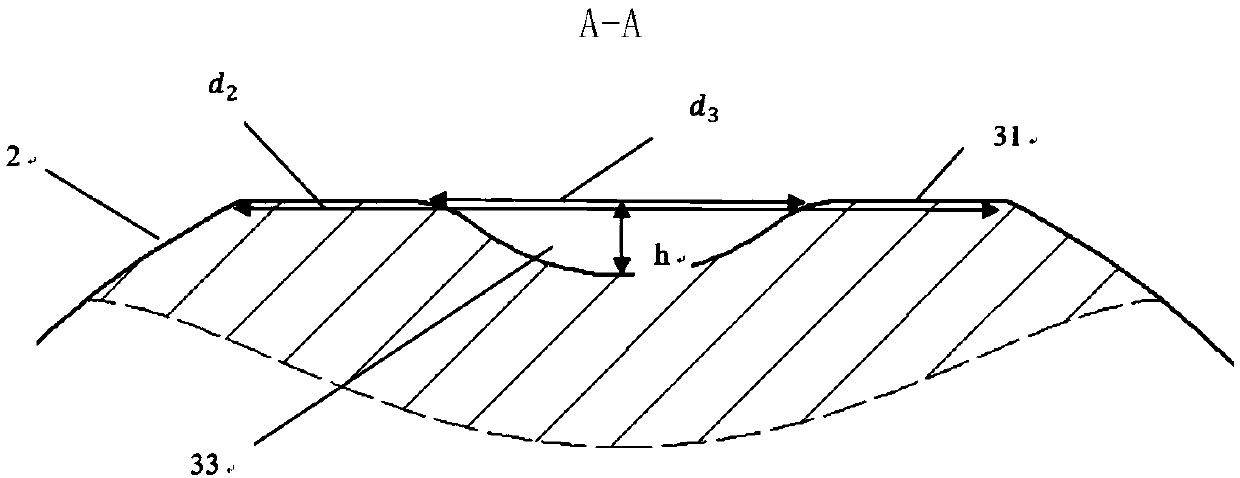

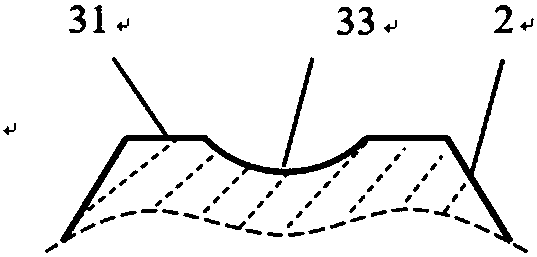

Adhesive jointing and electric arc spot welding combined connection method for metals

InactiveCN102059460AHigh solder joint strengthImprove stabilityArc welding apparatusJoint surfaceElectric arc

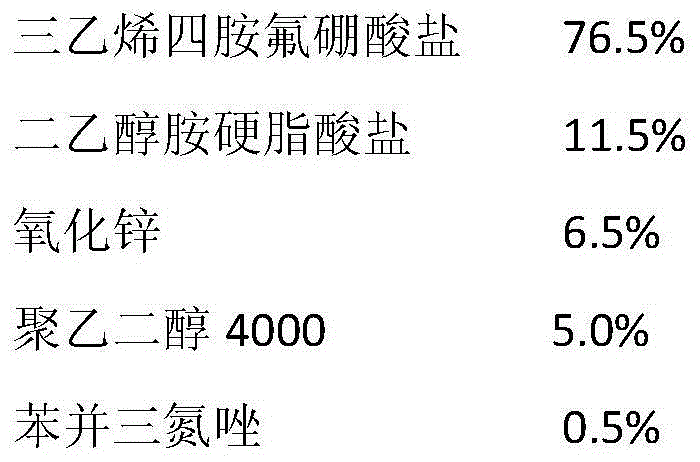

The invention belongs to the technical field of material engineering and relates to a connection technique for metals, in particular to a welding and adhesive jointing combined connection technique for metals, which comprises: applying adhesive for structural curing on the joint surfaces of materials to be welded; jointing the materials; and welding. The technique is characterized in that: an adhesive layer which is 0.02 to 1 millimeter thick is uniformly applied between the jointing surfaces of the materials to be connected; after joining, through holes with an aperture of 3 to 10 millimeters are formed on a jointed part at 15 to 50 millimeter intervals along a joint, and performing double-sided filler wire spot welding at the holed part with an arc weld; and heating the jointed parts between which a glue layer is applied to 50 to 500 DEG C before welding and after welding, and keeping the temperature for 10 to 180 minutes. The method can increase the strengths of the welded spots, avoid surface collapse caused by other adhesive bonding, improve the bearing load, fatigue strength and shearing performance of difficult-to-weld welded structure made of one kind of metal and different kinds of metals, and meet actual engineering needs.

Owner:DALIAN UNIV OF TECH

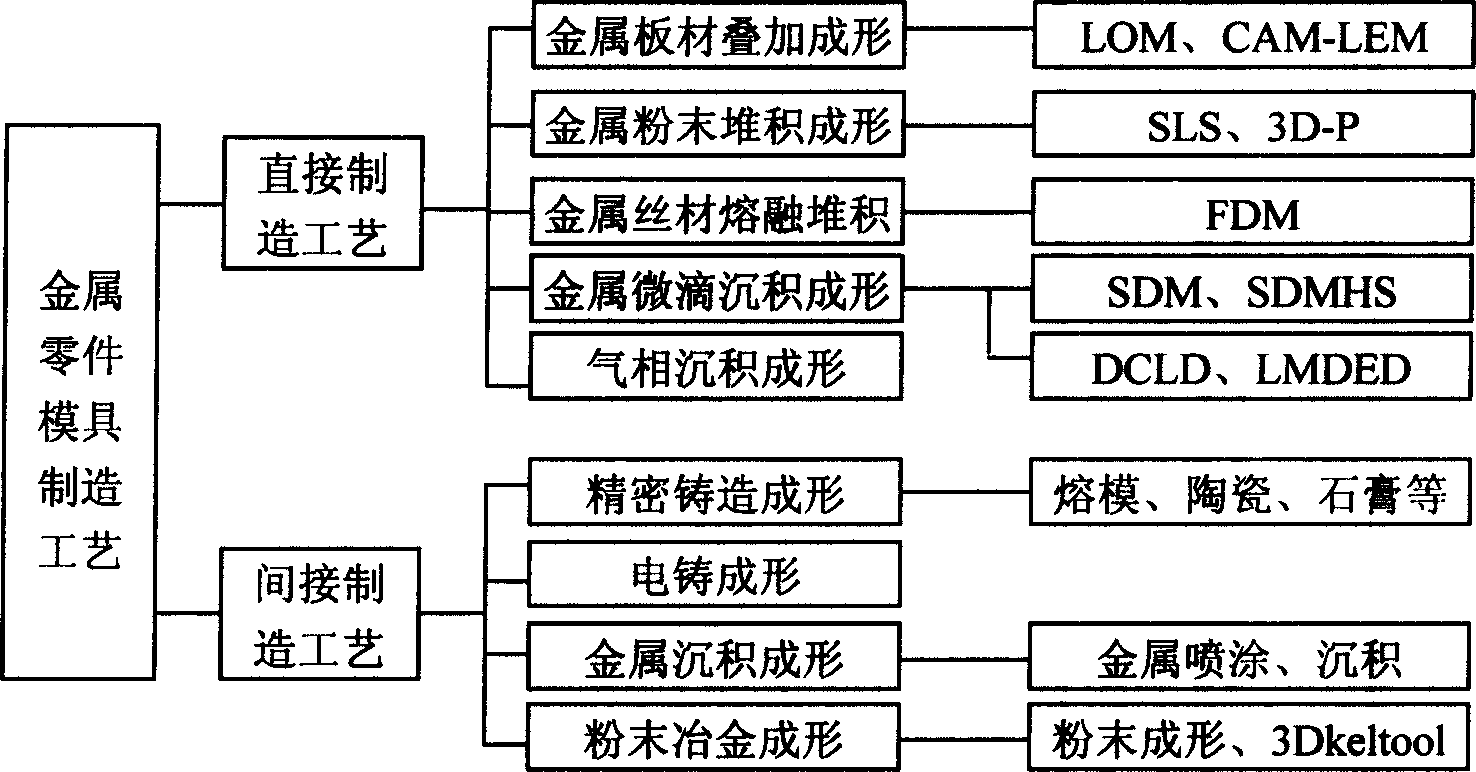

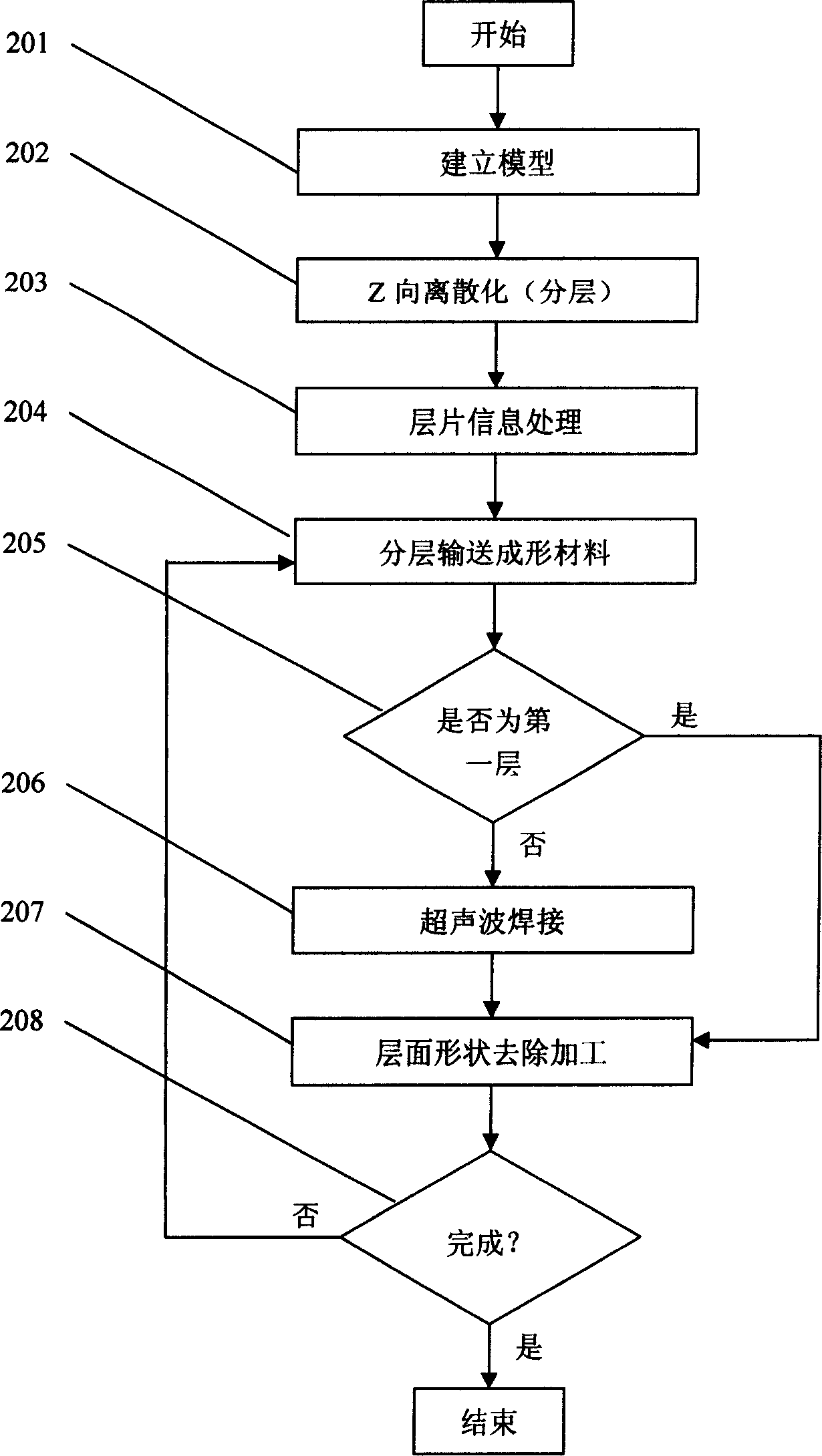

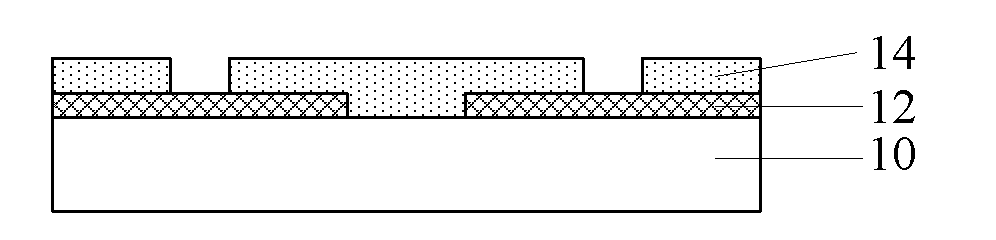

Layered manufacturing method of metal parts

InactiveCN1907643AReduce pollutionReduced requirements for high-dimensional manufacturingProgramme controlComputer controlEngineeringUltimate tensile strength

The invention relates to a laminated method for producing metal element, which comprises: building model, dispersing the model, processing layer; based on the data document, using material transmitter to transmit the laminated material; using ultra-sonic welding technique to weld nearby two layers; based on the laminated information, removing the layer surface of welded material, to realize the horizontal and vertical motions; processing the next layer. The inventive ultra-sonic welding has less power consumption, small deformation of welding element, and high strength of welding point. Therefore, the product has high accuracy and lower cost.

Owner:CHINA ACADEMY OF MACHINERY SCIENCE & TECHNOLOGY

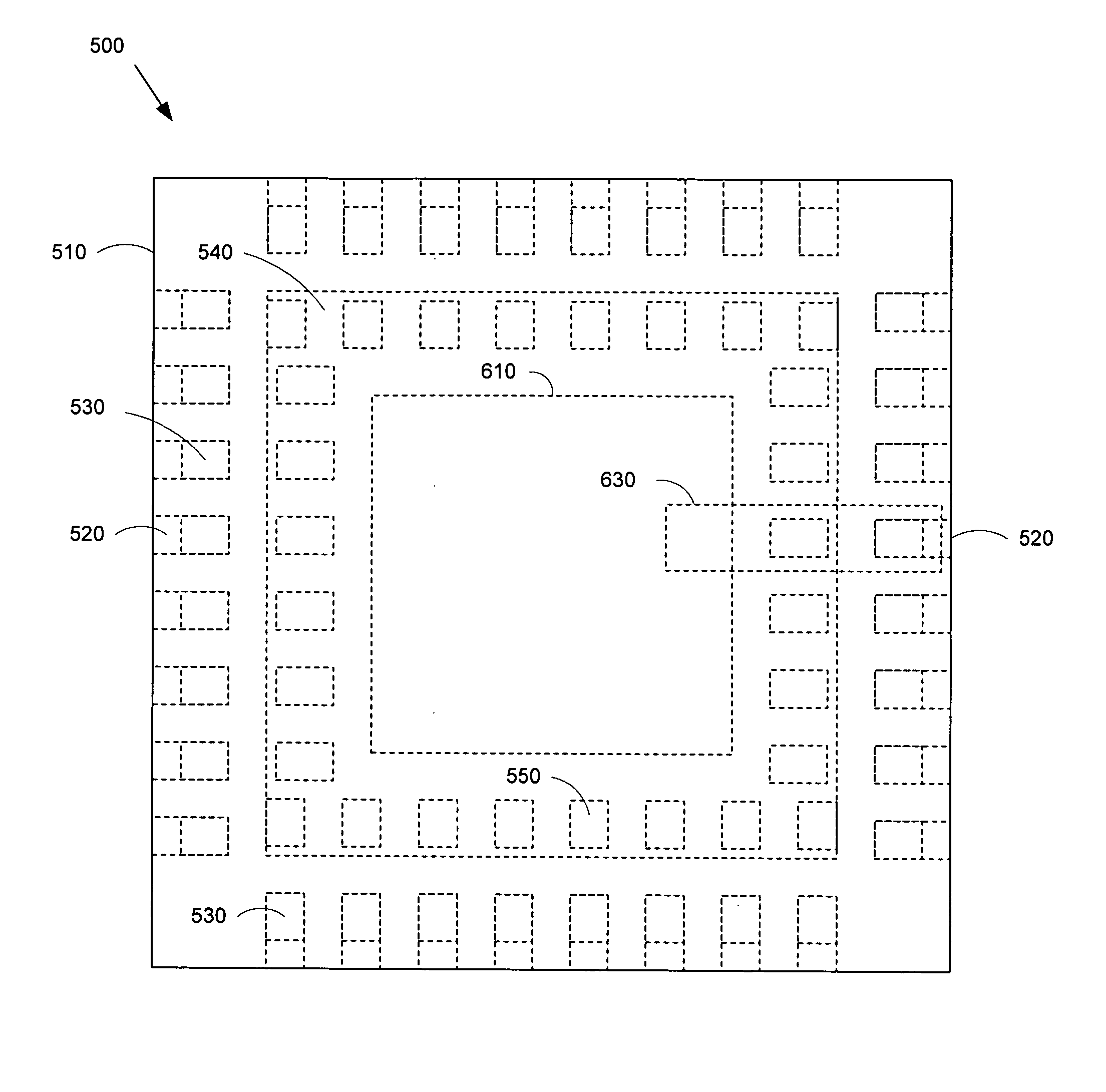

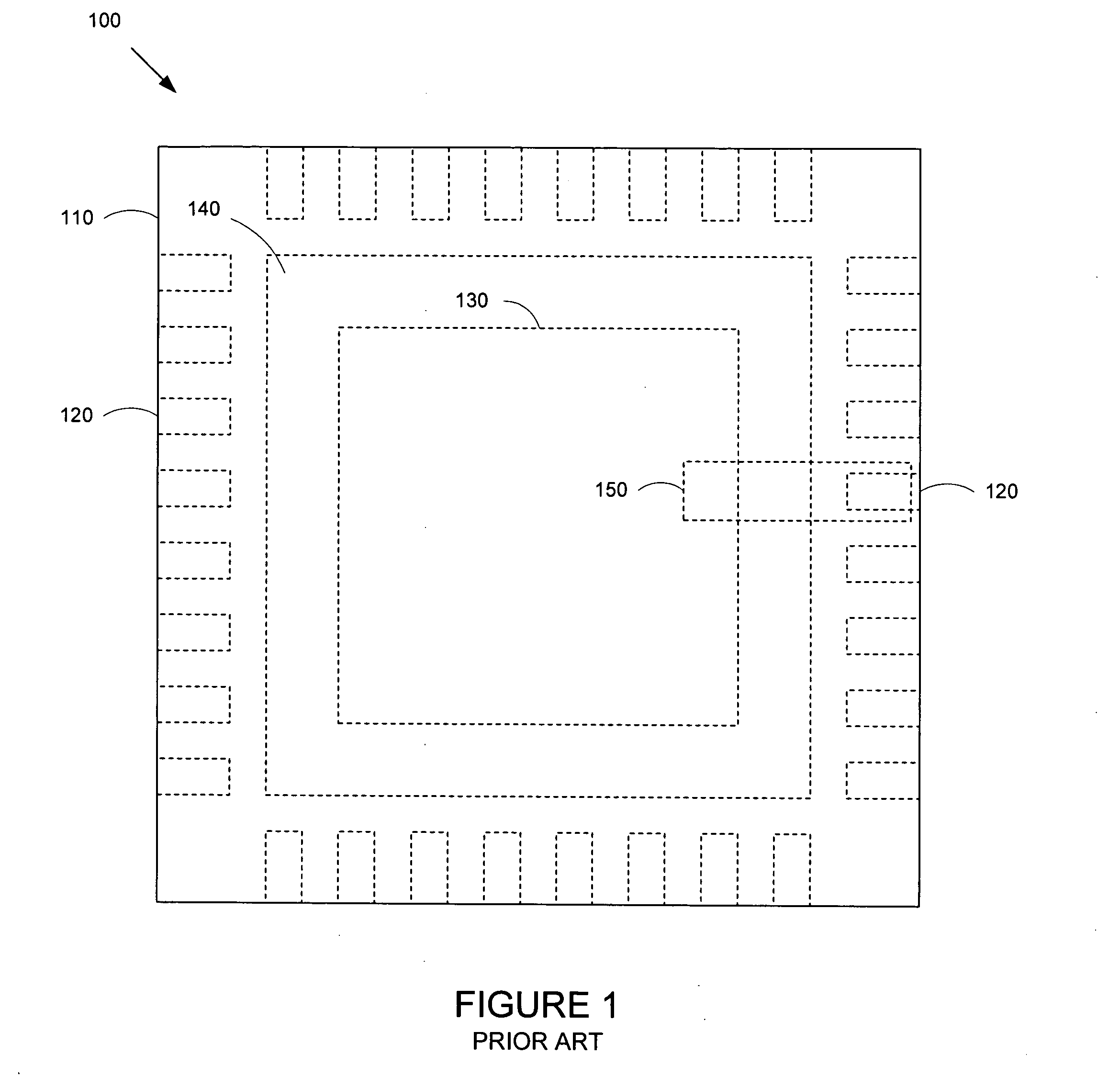

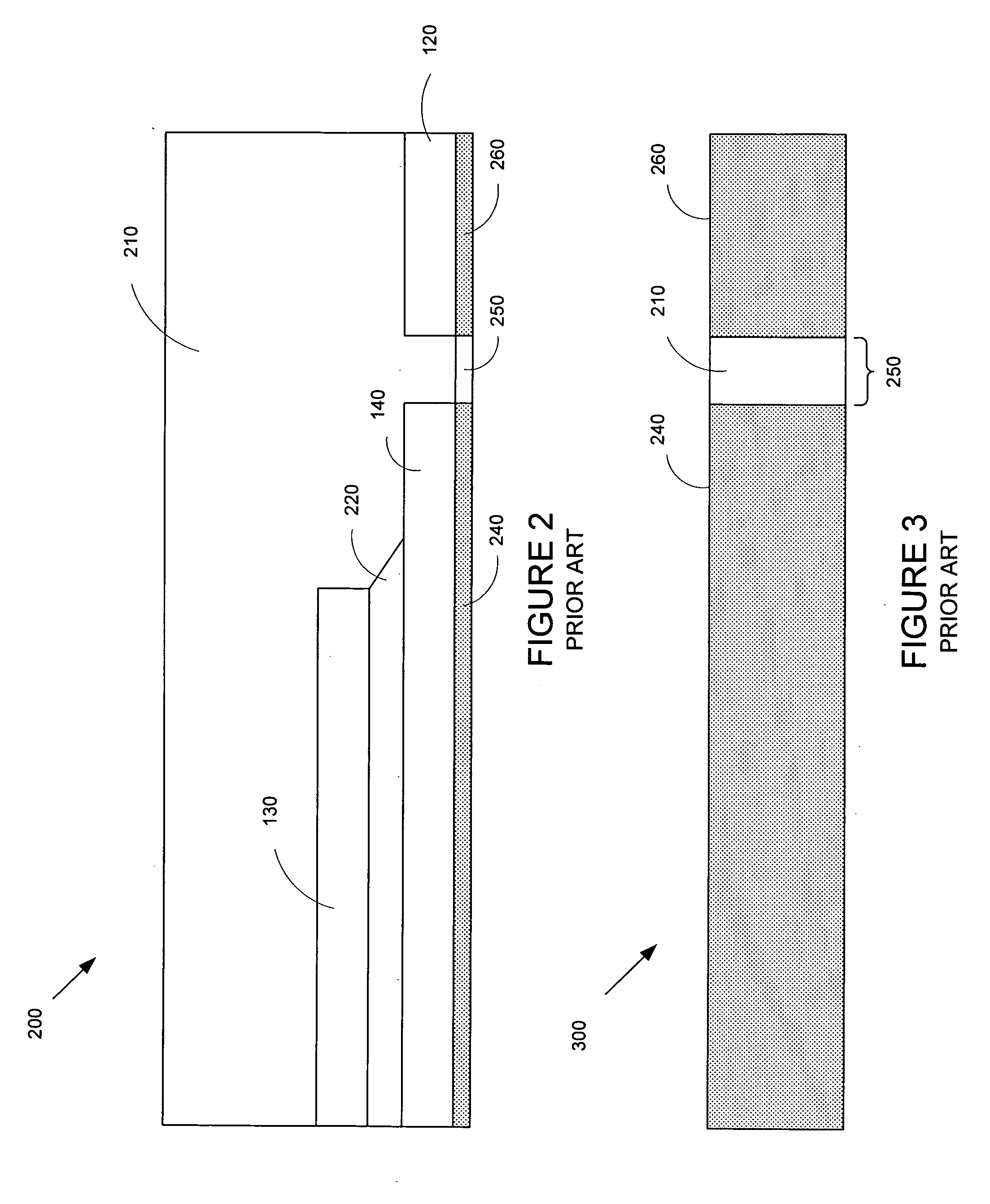

System and method for improving solder joint reliability in an integrated circuit package

ActiveUS20050139972A1Improve solder joint reliabilityHigh solder joint strengthPrinted circuit assemblingFinal product manufactureIntegrated circuit packagingEngineering

A system and method is disclosed for improving solder joint reliability in an integrated circuit package. Each terminal of a quad, flat, non-leaded integrated circuit package is formed having portions that define a solder slot in the bottom surface of the terminal. An external surface of the die pad of the integrated circuit package is also formed having portions that define a plurality of solder slots on the periphery of the die pad. When solder is applied to the die pad and to the terminals, the solder that fills the solder slots increases the solder joint reliability of the integrated circuit package.

Owner:STMICROELECTRONICS SRL

High-temperature lead-free solder paste and preparation method

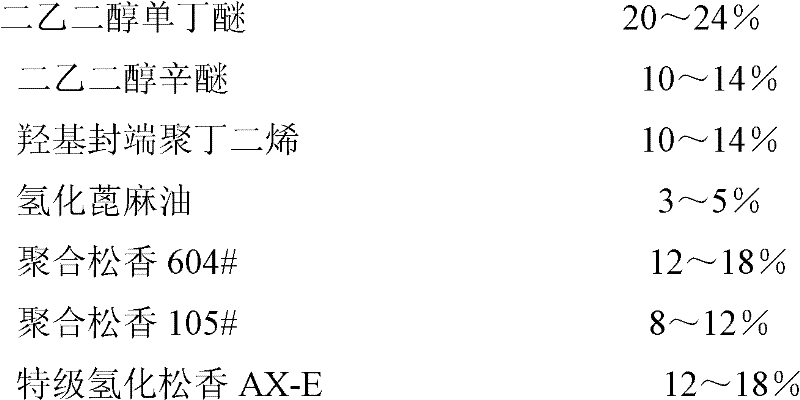

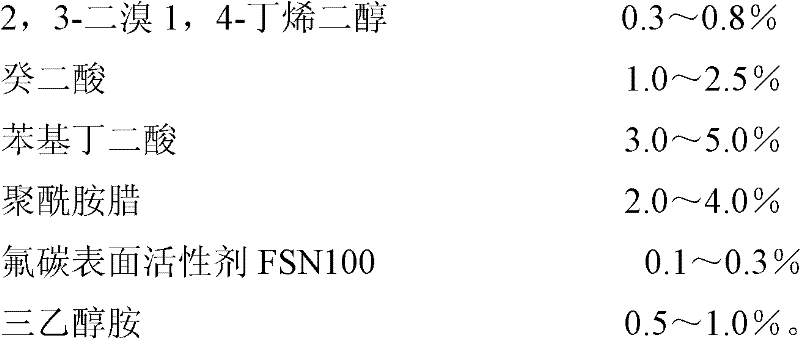

ActiveCN102528327AImprove adhesionProtects and prevents re-oxidationWelding/cutting media/materialsSoldering mediaDiethylene glycol monobutyl etherButanedioic acid

The invention relates to high-temperature lead-free solder paste and a preparation method. The high-temperature lead-free solder paste comprises lead-free electronic grade tin alloy powder and flux. Diethylene glycol monobutyl ether, diethylene glycol octyl ether and hydroxyl-terminated polybutadiene are added into a temperature control emulsifying machine and are heated and mixed, hydrogenated castor oil, polymerized rosin CLEARON105# and hydrogenated rosin are added into the temperature control emulsifying machine and are mixed to obtain primary mixed liquor, the primary mixed liquor is cooled, 2,3-dibromo 1,4-butylene glycol, sebacic acid and phenyl-butanedioic acid are added into the primary mixed liquor and then are mixed to obtain secondary mixed liquor, the secondary mixed liquor is cooled, polyamide wax is added into the secondary mixed liquor and then is mixed to obtain tertiary mixed liquor, the tertiary mixed liquor is cooled, fluorocarbon surfactant and triethanolamine areadded into the tertiary mixed liquor and then are mixed and vacuumized until the temperature returns to room temperature, the lead-free electronic grade tin alloy powder Sn95Sb5 is added into the prepared flux after standing at the temperature of 22-25 DEG C, and the lead-free electronic grade tin alloy powder and the flux are mixed for 15-20 minutes to obtain the high-temperature lead-free solder paste. The high-temperature lead-free solder paste has the advantages of fine solderability and wettability, high solder joint strength, high reliability and solderability in air and nitrogen protection.

Owner:惠州市斯泰尔科技有限公司

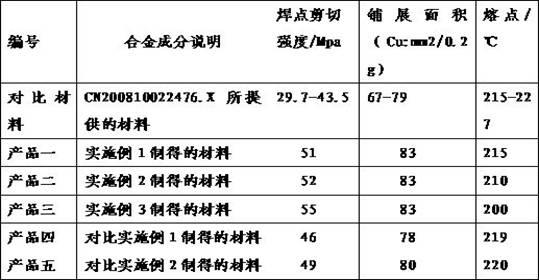

Beryllium-containing low-silver cadmium-free silver solder

ActiveCN103817456APrevent oxidationAvoid intensityWelding/cutting media/materialsSoldering mediaMetallic materialsSoldering

The invention belongs to a metal material and specifically relates to a beryllium-containing low-silver cadmium-free silver solder. The beryllium-containing low-silver cadmium-free silver solder is characterized in that the ingredient proportion by mass percent is as follows: 12%-16% of Ag, 39%-41% of Cu, 1%-8% of In, 0.5%-4% of Ga, 0.0001%-0.05% of Be and the balance of Zn, wherein the ratio of In to Ga is equal to 2:1. The beryllium-containing low-silver cadmium-free silver solder which is obtained by adopting the ingredient proportion has the characteristics of good mobility, excellent wettability, high welding spot strength, and the like, also has a melting temperature range approaching to the melting temperature range of a BAg20CuZnCd solder, and is especially suitable for the soldering of some products in the household appliance industry and hardware industry. The problems of workpiece oxidation, reducing of the soldered joint strength, and the like, caused by ultrahigh soldering temperature, are avoided.

Owner:JINHUA SHUANGHUAN BRAZING ALLOYS

Aluminum-powder resistance spot welding method for filling titanium-powder tempering nugget strength

InactiveCN101073847ASuppress replyInhibition of recrystallizationWelding/cutting media/materialsWelding/soldering/cutting articlesCopper electrodeSpot welding

The invention is concerned with aluminum alloy resistance spot welding method with filled titanium powder to melody the intension of melting core, belonging to aluminum alloy resistance spot welding technology. Dip the aluminum alloy plate into the NaOH liquid and clear with water and dip the plate into HNO3 liquid and clear with water and airing. Spread filled titanium powder at the welding spot of the two disposed aluminum alloy plate and carry the spot welding to the aluminum alloy plate with copper electrode with certain current, welding time and welding pressure. The method adds titanium powder in the core forming process of the resistance spot welding to form tiny compound spot of titanium powder among the metals and to restrain the restore and recrystallization of aluminum alloy. It refines the structure of melting core of aluminum alloy by enhancing the welding intension to over 2500 N.

Owner:TIANJIN UNIV

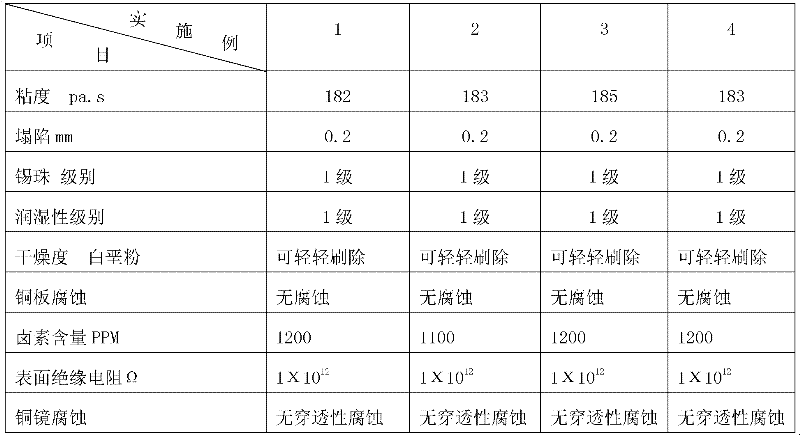

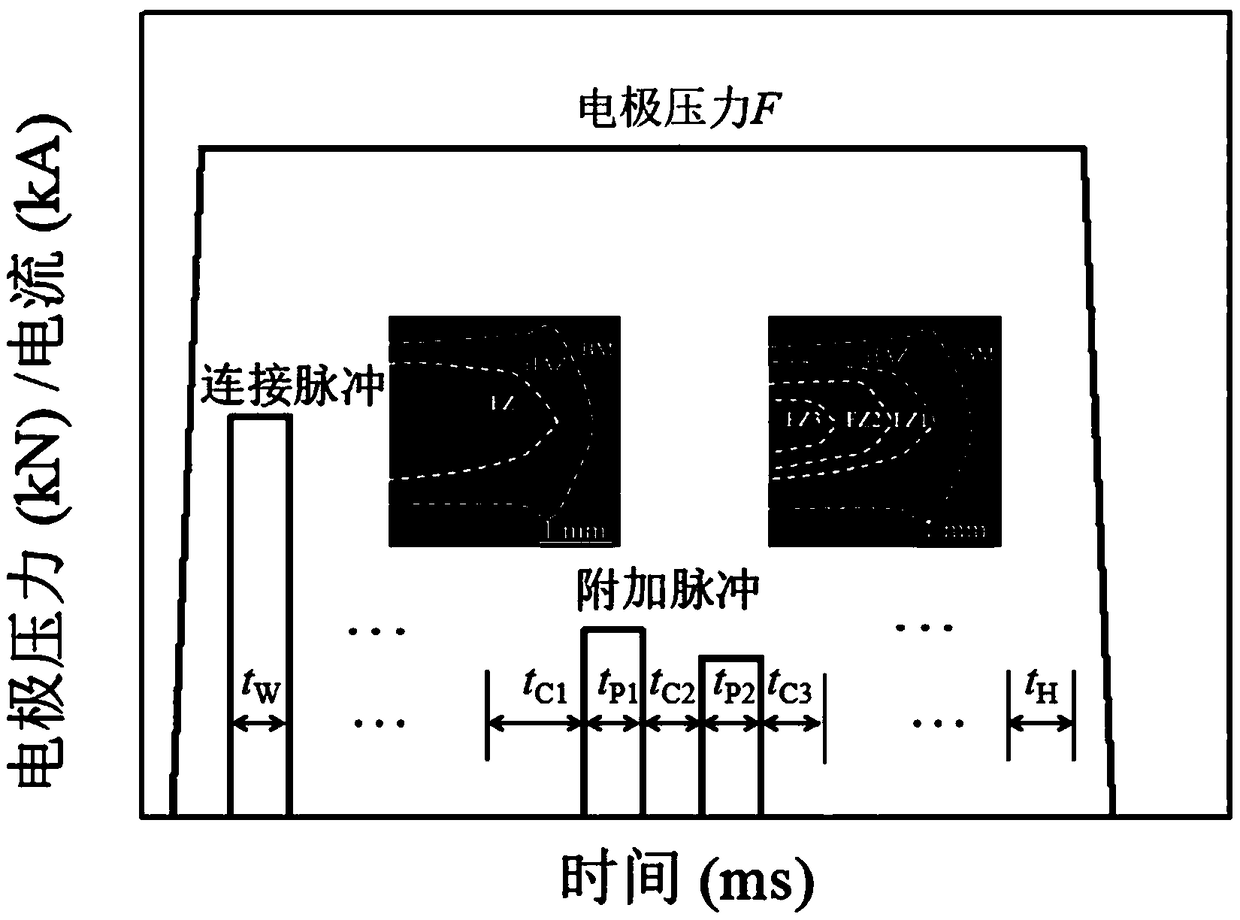

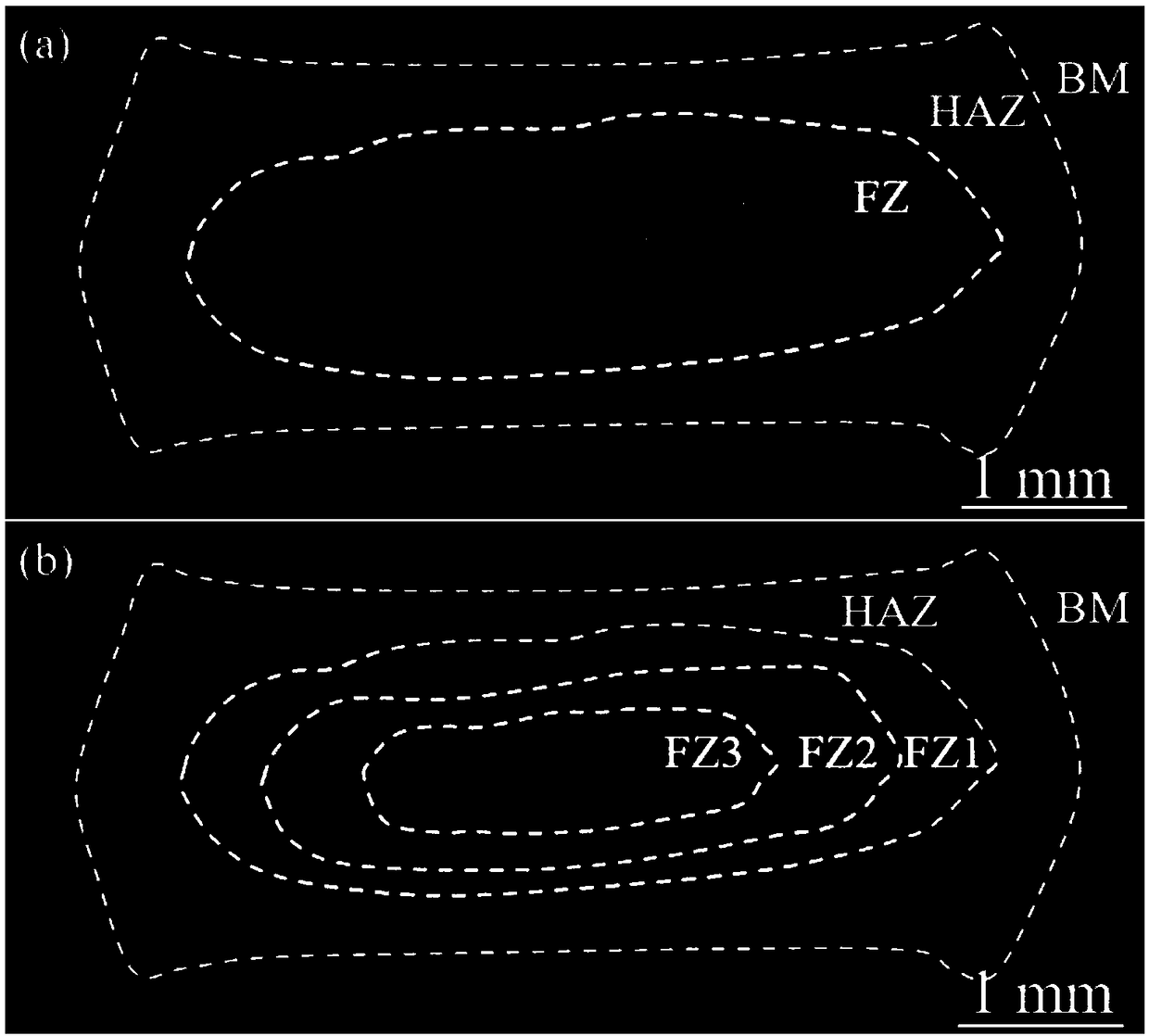

Method for improving mechanical property of medium-manganese steel welding joint

InactiveCN109500483AImprove toughnessPrevent crack growthResistance welding apparatusHeat-affected zoneManganese

The invention provides a method for improving a mechanical property of a medium-manganese steel welding joint. An additional pulse method capable of generating inner-layer nuggets is added after the pulse which is mainly used for connection is utilized, medium-manganese steel with the manganese element mass fraction of 4-13% can obtain two or more layers of nuggets at a welding point, and thus thepurpose of improving the joint strength of the welding spot is achieved. Compared with a traditional welding process which only obtains the single-layer nugget, after two or more layers of nuggets are formed, the grain shape in the original nuggets is changed, and the structure in the original nuggets and the heat affected zone changes, so that multiple structures exist at the same zone at the same time, and thus cracks can be better prevented from expanding; and therefore, under the occasion that the requirement for the joint strength is high, the welding process capable of forming the inner-layer nuggets has more application potential.

Owner:SHANGHAI UNIV

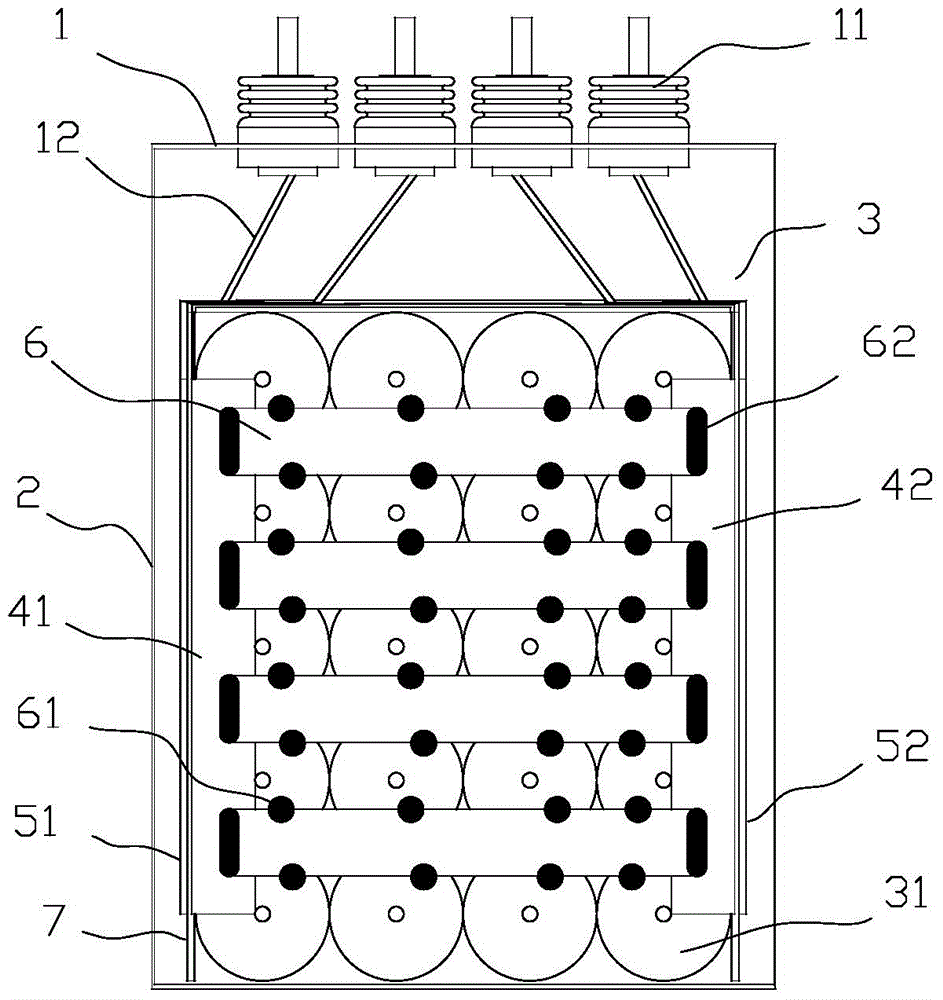

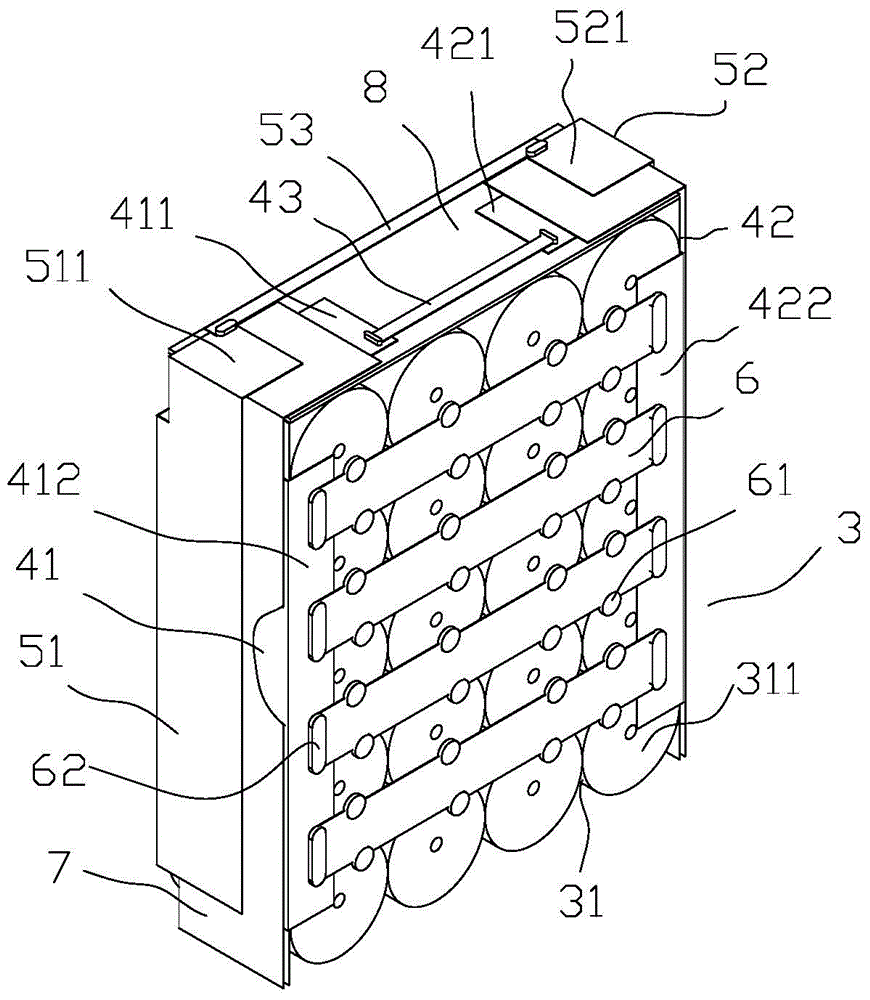

Low-inductance power capacitor

ActiveCN104465082AHigh solder joint strengthLower self-inductanceFixed capacitor terminalsCapacitanceElectricity

The invention relates to a low-inductance power capacitor which comprises a cover plate assembly, a shell and a capacitor core set fixed into the shell. The capacitor core set is formed by overlapping a plurality of capacitance cores in a layering mode. A positive electrode leading copper strip and a negative electrode leading copper strip are mutually overlapped and arranged on the two sides of the non-metal-spraying face of the capacitor core set. Insulating layers are arranged between overlapped parts of the connecting parts of the positive electrode leading copper strip and the negative electrode leading copper strip and a terminal. The metal spraying faces of the two ends of each capacitor core are electrically connected to auxiliary leading copper strips respectively in a welding mode, wherein the auxiliary leading copper strips are transversely arranged. The two ends of each auxiliary leading copper strip of each end of the capacitor core set are fixed to the positive electrode or negative electrode leading copper strip through welding. The double leading copper strips are arranged on the two sides of the capacitor core set, the path for leading currents to the copper strips is the shortest, the current density is reduced, the self-inductance of the capacitor can be reduced obviously, and the safety performance of equipment like a current transformer can be improved.

Owner:ANHUI TONGFENG ELECTRONICS

High-strength tin cadmium lead-free solder alloy and preparation method thereof

InactiveCN102500947AGood spreadabilityEasy to weldWelding/cutting media/materialsSoldering mediaTinLow melting point

The invention provides a high-strength tin cadmium lead-free solder alloy and a preparation method thereof. The alloy material has a low melting point, high spreadability, and high tensile strength, so the alloy has good weldability. The preparation method has a simple process and a low production cost, and is suitable for industrial production. The high-strength tin cadmium lead-free solder alloy is characterized by comprising the following components: 20-40wt% of Cd, 0.01-0.03wt% of Bi, 0.01- 0.03wt% of Sb, 0.01-0.03wt% of Sr, 0.01- 0.03wt% of La, and the balance being Sn.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

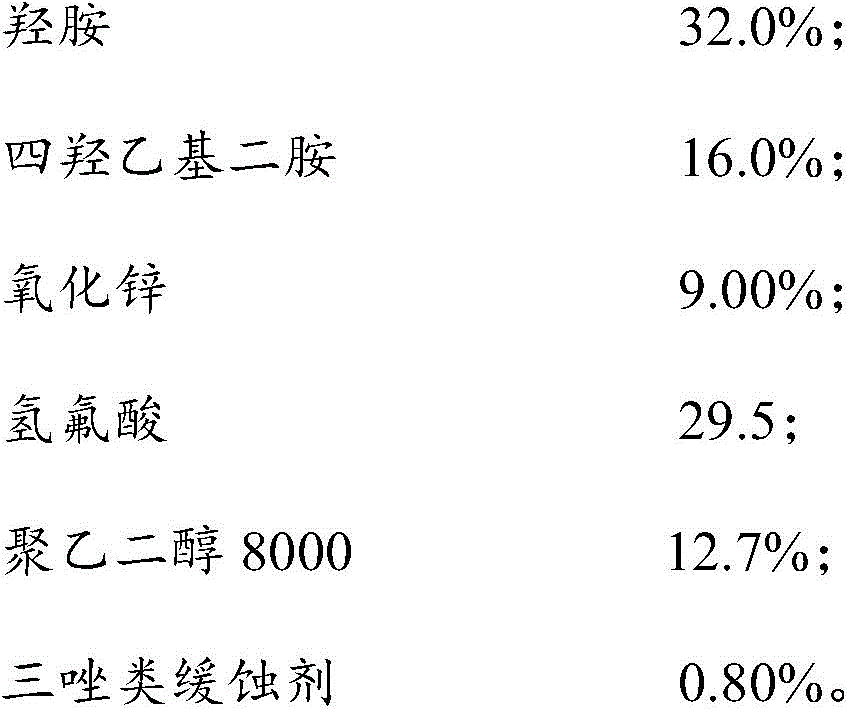

Solid state scaling powder for stainless steel soldering and preparing method

ActiveCN104942480AHigh expansion rateNot corrosiveWelding/cutting media/materialsSoldering mediaActive agentSoldering

The invention discloses solid state scaling powder for stainless steel soldering and a preparing method. The solid state scaling powder comprises 0-68.5% of organic cosolvent, 0-19.8% of a metal active agent, 0-39.8% of an acids active agent, 0.1-0.8% of inhibiter and the balance is an organic vehicle. The preparing method comprises the steps that firstly, according to the weight ratio, the organic cosolvent and the metal active agent are mixed and stirred; secondly, the acids active agent is added into a solution disposed in the first step, standing is carried out on the solution for 24 hours. The solid state scaling powder for stainless steel soldering and the preparing method can be applied to the field of scaling powder, the problem that the welding performance is unstable can be effectively solved, and the problems that the spreading condition of soldering materials is poor, and the spreading rate is low can be effectively solved.

Owner:THOUSAND ISLAND METAL FOIL

Chip pin correction tooling and chip installation method

InactiveCN109462974AImprove bindingHigh solder joint strengthPrinted circuit assemblingElectrical componentsEngineeringUltimate tensile strength

The invention discloses a chip pin correction tooling. Since a guiding hole array composed of the guiding holes corresponds to a lead column array composed of lead columns, the guiding holes are onlyslightly larger than the diameter of the lead columns, and the texture of the lead columns is soft, the lead columns can be slowly pressed into the guiding holes of the calibration tooling to adjust the spacing among the lead columns and the morphology of the lead columns, so as to make the spacing among the lead columns and the topography of the lead columns meet preset standards; therefore, accurate positioning between chip pins and a PCB surface bonding pad can be realized, the combination degree of a solder and the pins is improved, the solder joint strength is improved, and the solderingreliability is improved. The invention also provides a chip installation method. The spacing among the lead columns and the topography of the lead columns can be corrected through the correction tooling; therefore, the accurate positioning between the chip pins and the PCB surface bonding pad can be realized when soldering the chip to the surface of the PCB, the combination degree of the solder and the pins is improved, the solder joint strength is improved, and the soldering reliability is improved.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Cobalt-containing low-silver cadmium-free silver solder

ActiveCN103846569APrevent oxidationAvoid intensityWelding/cutting media/materialsSoldering mediaSolderingCobalt

The invention belongs to metal materials, in particular to a cobalt-containing low-silver cadmium-free silver solder. The cobalt-containing low-silver cadmium-free silver solder is characterized by comprising the following components in percentage by mass: 12 to 16 percent of Ag, 39 to 41 percent of Cu, 1 to 8 percent of In, 0.5 to 4 percent of Ga, 0.01 to 1.2 percent of Co, and the balance of Zn, wherein In:Ga=2:1. The cobalt-containing low-silver cadmium-free silver solder obtained by the component proportion has the characteristics of high fluidity, high wettability, high welding spot strength and the like, has the melting temperature range close to that of the Bag20CuZnCd solder, and is particularly suitable for soldering some products in household electrical appliance industry and hardware product industry; the problems of workpiece oxidization, reduction of soldering joint strength and the like caused by over-high soldering temperature are avoided.

Owner:ZHEJIANG GLOBAL JOINING TECH

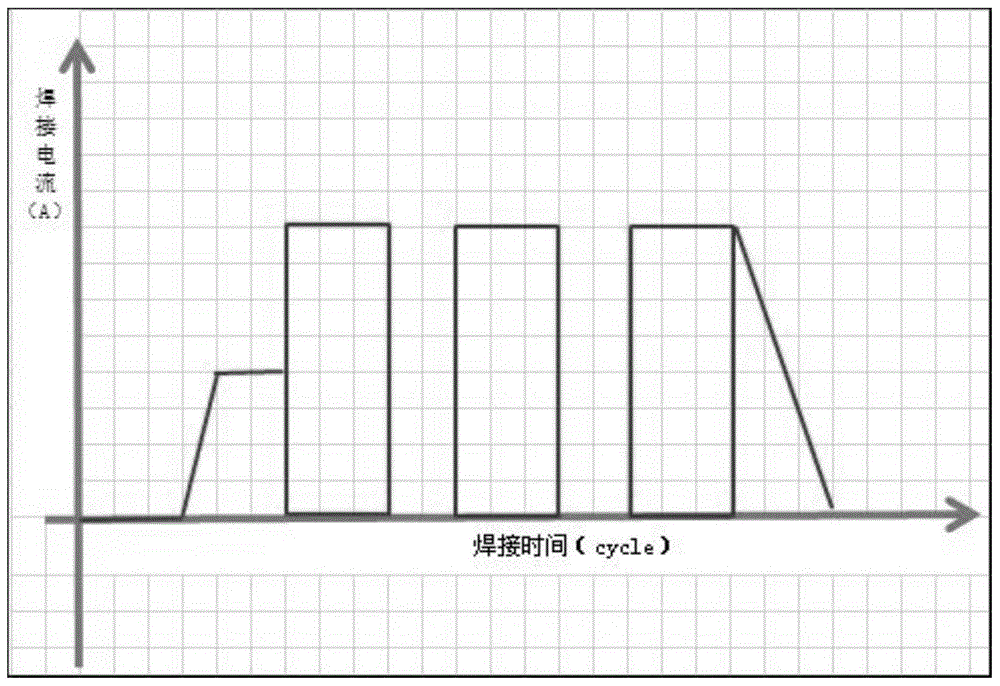

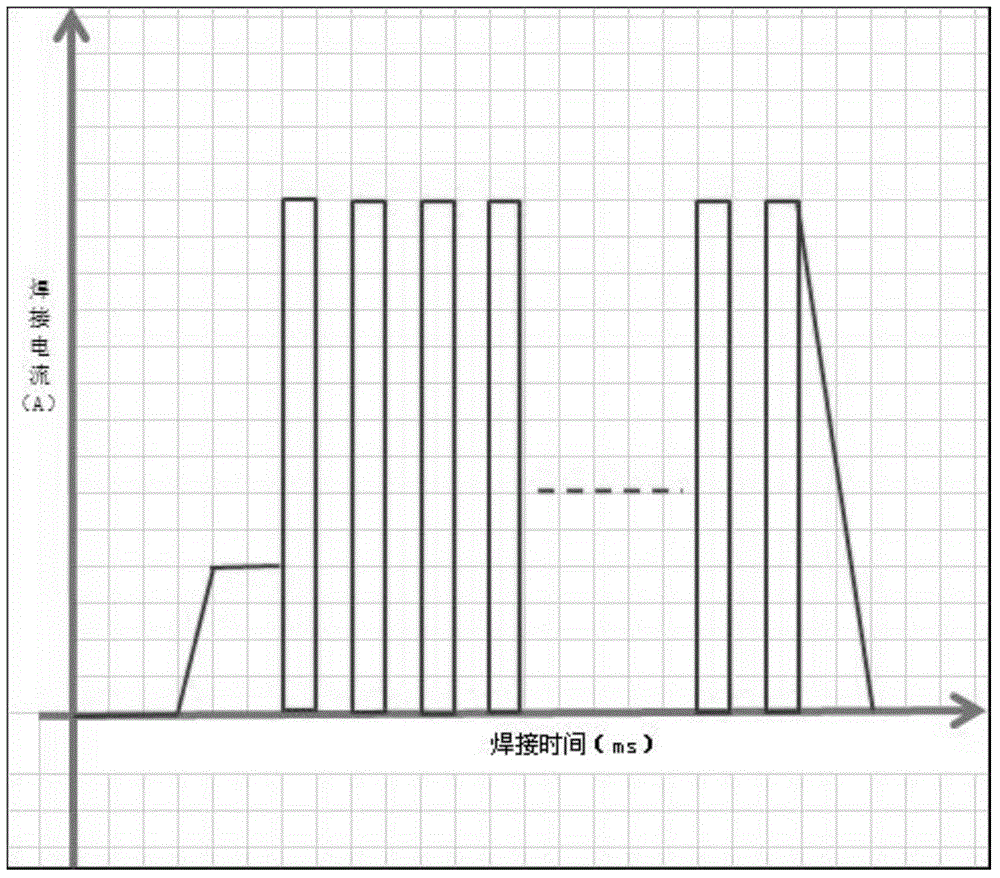

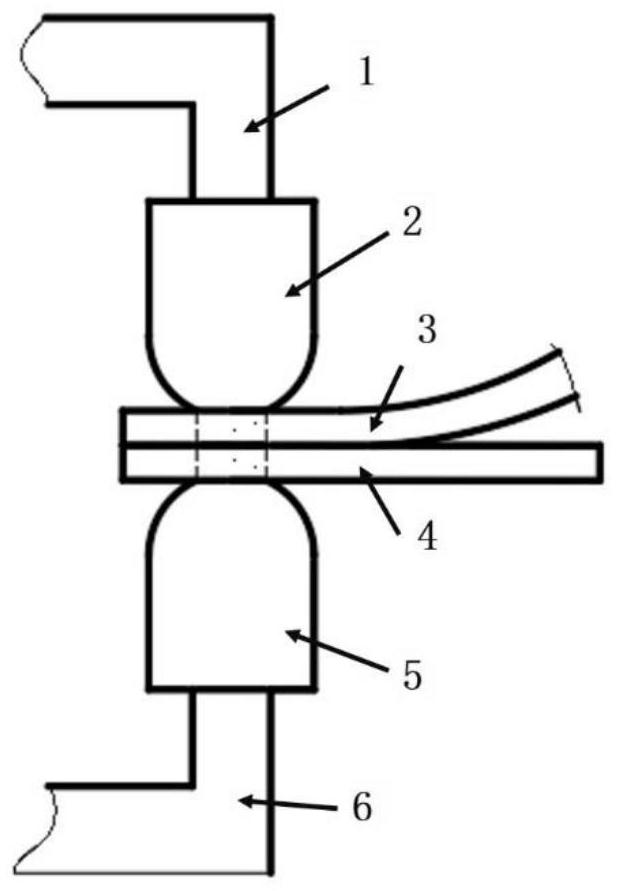

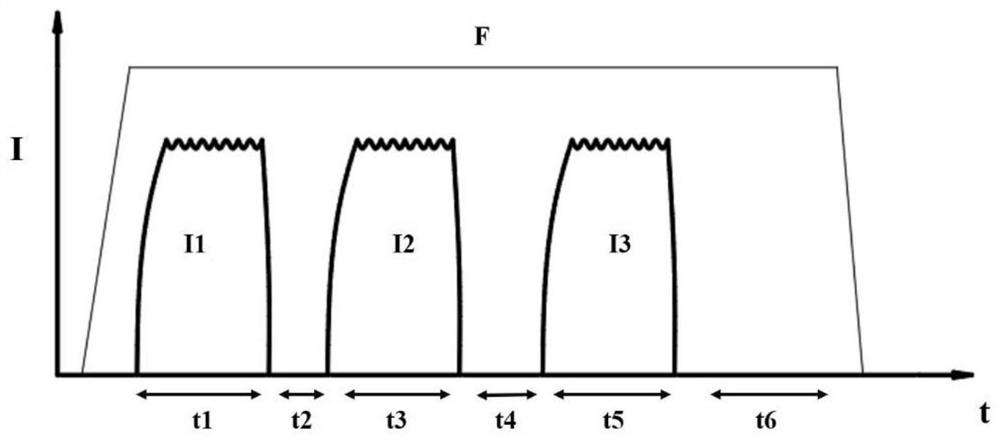

Pressure welding process for lowering welding spatter

ActiveCN104646818AGood lookingHigh solder joint strengthNon-electric welding apparatusEngineeringSpot welding

The invention provides a pressure welding process for lowering welding spatter. The pressure welding process comprises spot welding and convex welding, wherein the spot welding or convex welding parameters set millisecond as a unit; when pressure welding adopts spot welding, the welding time for each pulse is 6 ms-20 ms, the cooling time is 3 ms-20 ms, and the pulse quantity is 10n-40n; when the pressure welding adopts convex welding, the welding time for each pulse is 6 ms-20ms, the cooling time is 3 ms-20ms, and the pulse quantity is 4n-10n. The pressure welding process is full in welding nugget, increased in welding spot strength, and eliminates welding spatter. A follow-up polishing process is not needed, the welding quality is improved, the surface appearance of the welding part is improved, and ineffective labor is eliminated. The pressure welding process is especially suitable for a high-strength plate or a thermally-formed high-strength steel plate, relatively good in using effect and wide in scope of application.

Owner:WUHAN JIEZHONG AUTO PARTS CO LTD

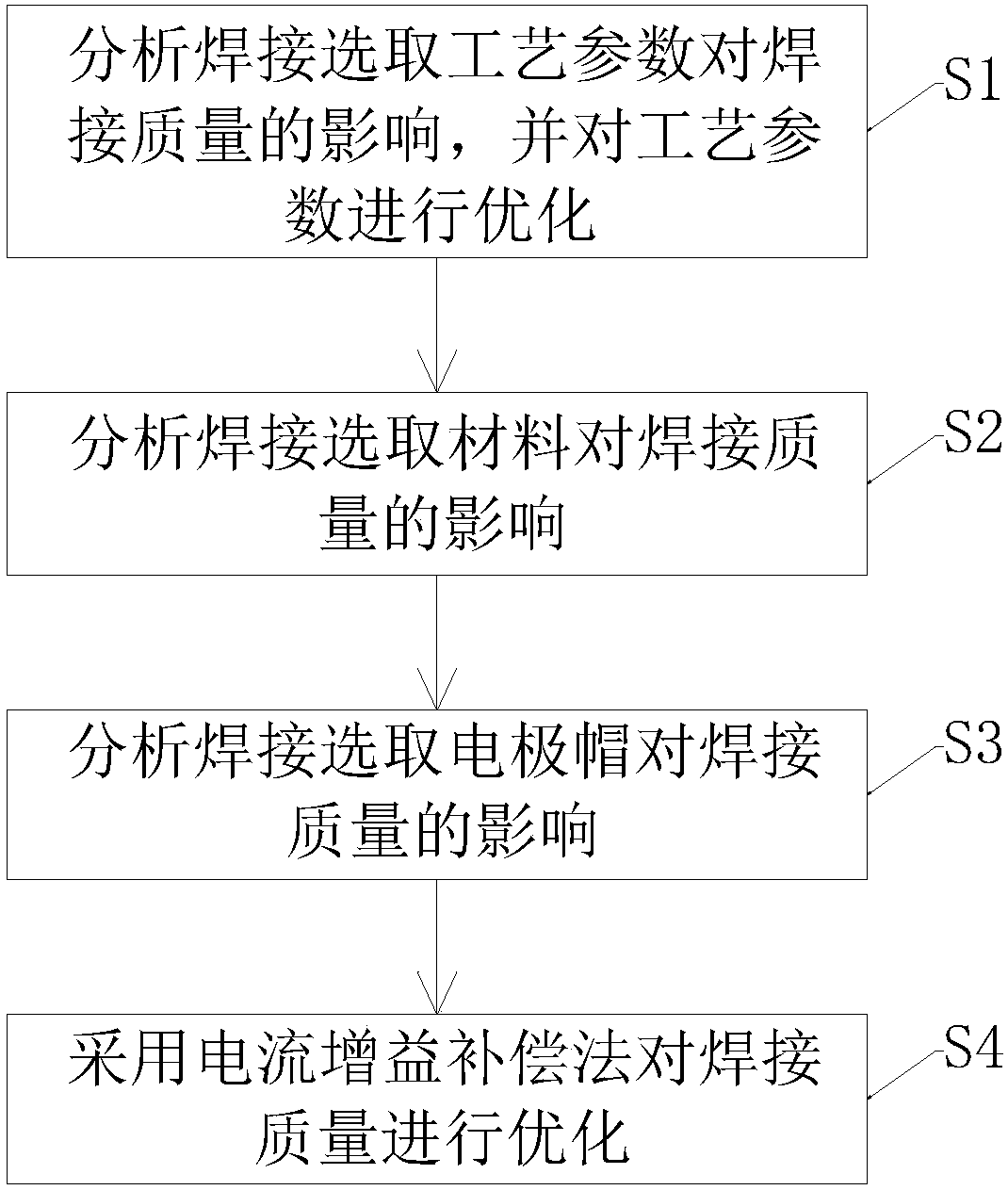

Spot welding quality control method for galvanized steel plate for automobile

ActiveCN108857010AAvoid stickingQuality improvementResistance welding apparatusSheet steelQuality control

The invention relates to a spot welding quality control method for a galvanized steel plate for an automobile. The spot welding quality control method comprises the following steps that S1, the influence of welding selection process parameters on the welding quality is analyzed, and the process parameters are optimized; S2, the influence of welding selection materials on the welding quality is analyzed; S3, the influence of a welding selection electrode cap on the welding quality is analyzed; and S4, the welding quality is optimized by adopting a current gain compensation method. According tothe spot welding quality control method, the influence of the welding process parameters, welding base materials, spot welding electrodes and the like on the welding quality is studied, and the spot welding quality is controlled by an appropriate method, so that the welding spattering and burrs are reduced, the welding spots are prevented from being over-burnt, the electrodes are prevented from being adhered, and the purposes of improving the strength and the appearance surface quality of the welding spot welding spots and improving the quality of the whole vehicle are achieved; and meanwhile,the production environment of a workshop is also improved, the labor intensity of workers is relieved, the production period is shortened, the production cost is reduced, resources are saved, and themarket competitiveness of enterprises is improved.

Owner:WUHAN JIEZHONG AUTO PARTS CO LTD

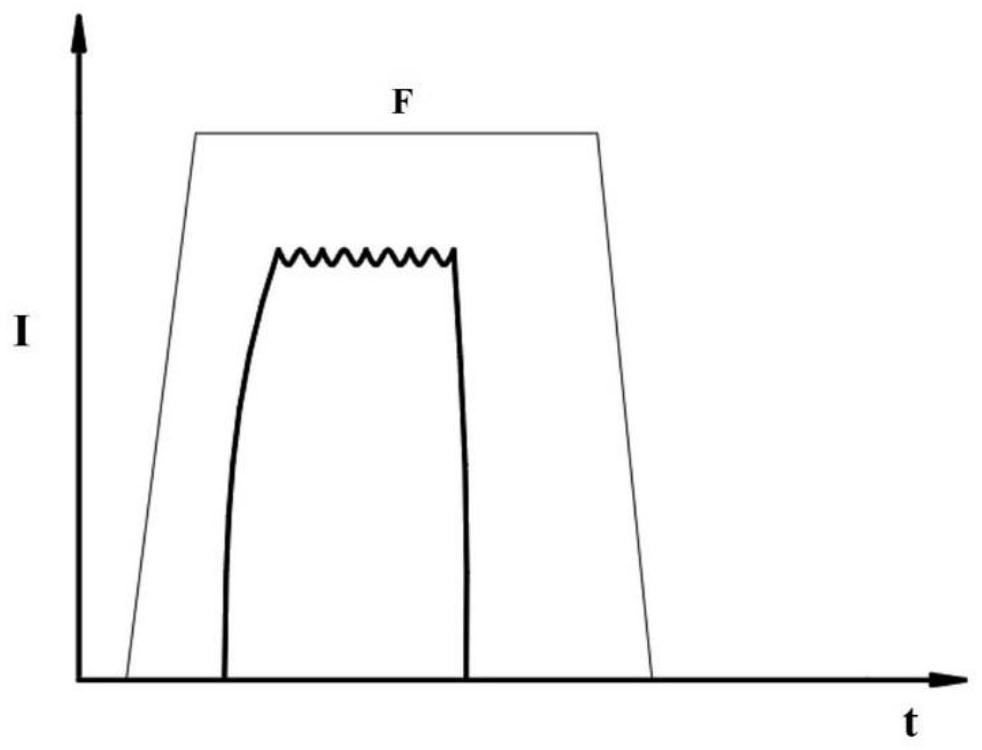

Method for inhibiting generation of internal defects of aluminum alloy resistance spot welding nugget

ActiveCN112570867ALess shrinkage and crystallizationReduce tensile stressWelding electric supplyElectrical resistance and conductanceSpot welding

The invention discloses a method for inhibiting generation of internal defects of an aluminum alloy resistance spot welding nugget, and belongs to the technical field of resistance spot welding. A welding current is divided into an electrifying heating stage, a cooling stage and a pressure maintaining stage, wherein in the electrifying heating stage, the current amplitude of the welding current is15KA-60KA, and the electrifying time is 50ms-200ms; and in the cooling stage, the current is 0-15KA, and the cooling time is 2ms-40ms. According to the welding method, due to the existence of the cooling stage, welding heat input is stable, and internal stress of a welding spot is reduced, so that the generation of the defects such as cracks and air holes in the nugget is inhibited, and the effect of improving the strength of the welding spot is achieved.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

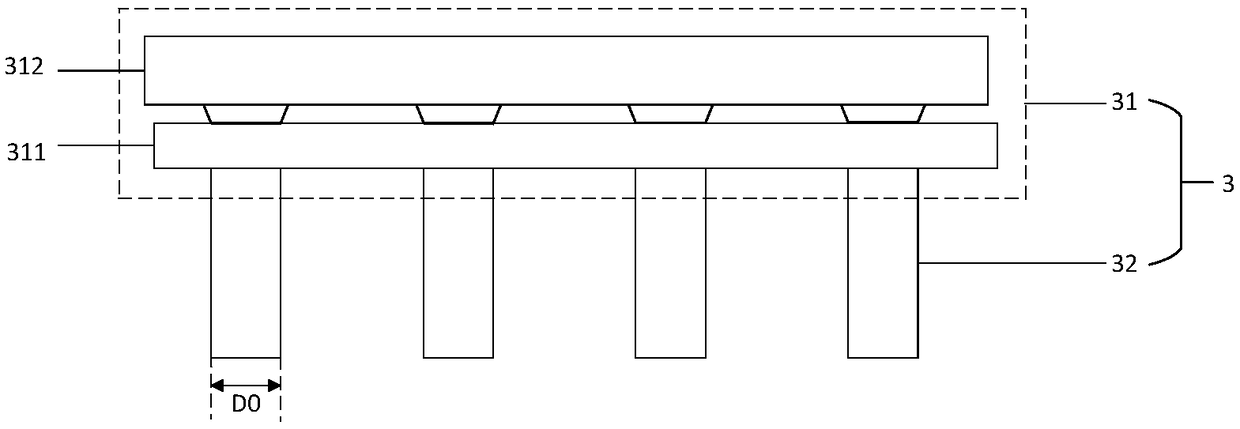

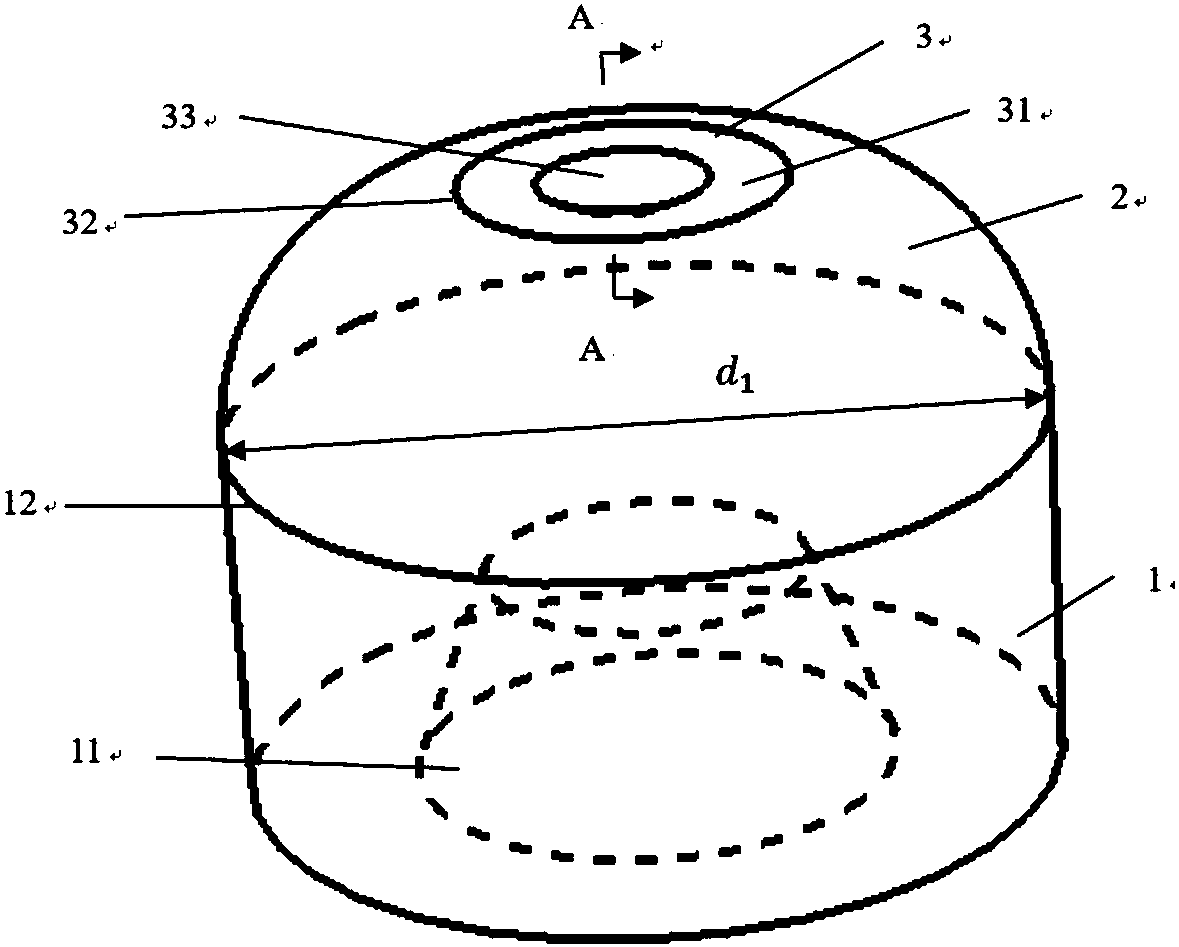

Resistance spot welding electrode cap

ActiveCN110369848AExtend your lifeAvoid it happening againPressure electrodesWelding/cutting media/materialsElectrical resistance and conductanceEngineering

The invention discloses a resistance spot welding electrode cap. A groove is formed in the center of a welding contact surface of the electrode cap; in the welding process, the contact area between the electrode cap and a to-be-welded metal workpiece is reduced due to the existence of the groove; in the initial stage, overall produced heat is concentrated to outer rings of welding spots, so that the heat dissipation speed is low, and formation of molten cores from outside to insideis facilitated; and due to the existence of the groove, the metal workpiece expands towards the sunk part of the center of an electrode, the molten cores of the welding spots areincreased, and splashing and deforming are reduced. Compared with a traditional electrode cap, the welding current needed for forming the welding spots inthe same size by the electrode capis lower, and the electric power cost is reduced; and when the same current is used, the strength and the stability of the obtained welding spots are higher, and the welding defects are fewer.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Lead-free low-temperature solder and preparation method thereof

InactiveCN107877031AImprove liquidityImprove wettabilityWelding/cutting media/materialsSoldering mediaIndiumSlag

The invention belongs to the technical field of solder, and particularly relates to a lead-free low-temperature solder. The solder comprises, by mass, 0.001-58.0% of bismuth, 0.001-1.0% of silver, 0.001-2.0% antimony, 0.001-0.1% of indium, 0.001-0.15% of phosphorus, 0.001-0.08% of germanium, 0.001-0.015% of beryllium, 0.001-0.015% of cerium and the balance tin. Compared with the prior art, when welding is carried out at the temperature of 139DEG C to 200DEG C, little oxidation slag is generated, the surface of a tin furnace can be kept bright basically without oxidation at the temperature, thesolder can not be oxidized within 50 seconds at 200-260 DEG C, so that the welding efficiency is greatly improved, and the damage to electronic components of a PCBA board is reduced; the low-temperature solder is good in oxidation resistance; and in the welding process, compared with a common Sn-Ag-Cu system, the solder has fewer welding defects, the surfaces of welding spots are very light-bright, the welding spots are full, continuous welding does not occur, so that the welding quality is effectively improved, and the solder and the method are environment-friendly and safe.

Owner:THOUSAND ISLAND METAL FOIL

Splashing-free resistance spot-welding method of galvanized steel plates for car

InactiveCN110142492AAvoid destructionAvoid Weld SpatterResistance welding apparatusSpot weldingUltimate tensile strength

The invention discloses a splashing-free resistance spot-welding method of galvanized steel plates for a car. The method is characterized by comprising the following steps that 1, a Cu middle layer isarranged between to-be-welded portions of the two galvanized steel plates to be welded, and the thickness of the Cu middle layer is 0.02-0.20 mm; 2, spot welding pre-pressing is carried out on the two galvanized steel plates to be welded, and pre-pressing time is 1000-2000 ms; and 3, spot welding is carried out on the to-be-welded portions of the two galvanized steel plates to be welded. According to the method, generation of splashing in the welding process can be prevented, strength of welding spots is improved, and the problem of spot welding of the galvanized steel plates is solved.

Owner:武汉钢铁有限公司

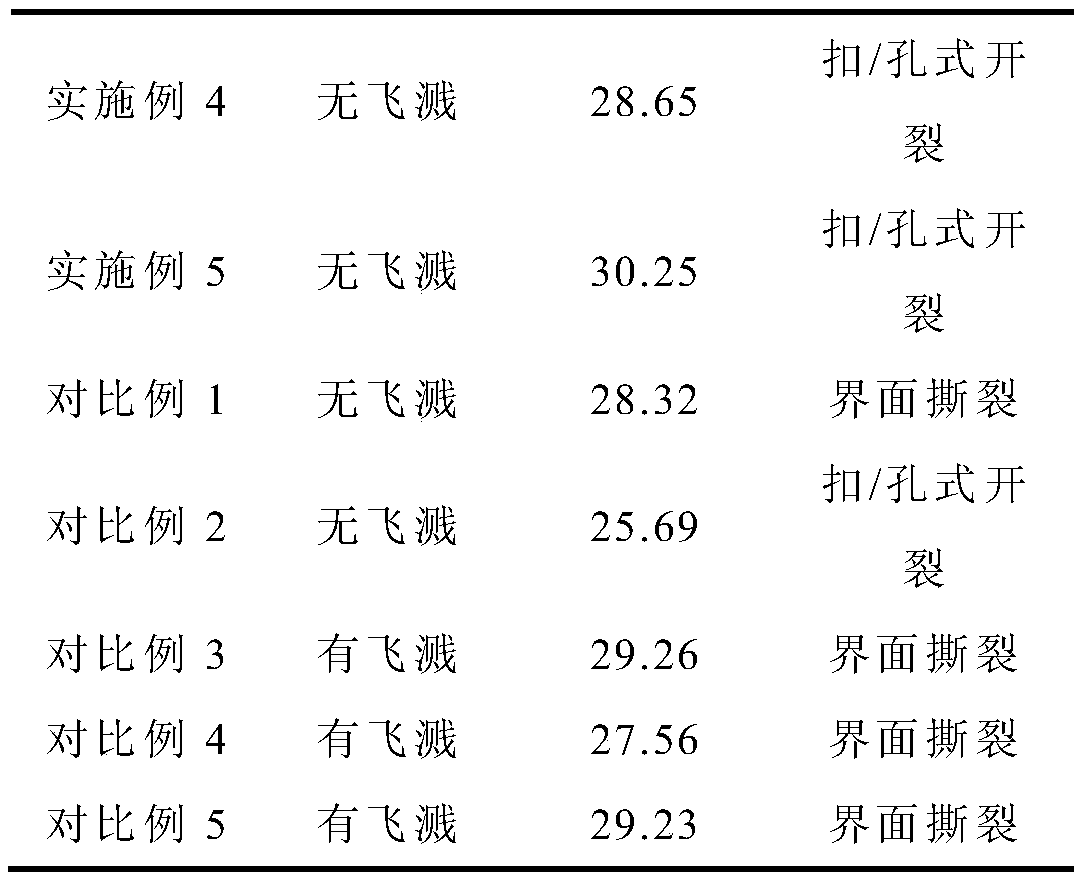

A kind of no-clean solid flux for aluminum low-temperature soldering and its preparation method

ActiveCN104607826BEfficient removalNo corrosionWelding/cutting media/materialsSoldering mediaActive agentElectrochemical corrosion

The invention discloses cleaning-free solid-state scaling powder for aluminum low-temperature soldering and a preparing method. According to the weight percentage, the cleaning-free solid-state scaling powder comprises raw materials of 6.5%-18% of metal film-forming agents, 5%-18% of organic carriers, 0.1%-1.8% of corrosion inhibition agents and the allowance of film removing active agents. The film removing active agents are composite salt of organic amine and acid. The cleaning-free solid-state scaling powder is suitable for lead-free solder wires with solid-state scaling powder contained in a core, and the powder can be used for automatic welding, manual soldering iron welding or flame spraying welding. The core-contained solder wires prepared with the scaling powder have the advantages that tinning speed is high, splashing is low, irritating smoke is avoided, post-welding residues do not have corrosiveness, a welding point has great electrochemical corrosion resistance, a contact service time is long, the wires are suitable for assembling welding of an aluminum coated layer circuit board and an aluminum soldering pin electronic element and brazing of an aluminum electric cable wire, an aluminum radiator and aluminum heat exchanging equipment.

Owner:SOUTH CHINA UNIV OF TECH

High-spreadability tin-antimony-rare earth lead-free solder alloy and preparation method thereof

ActiveCN102321831ALow melting pointGood spreadabilityWelding/cutting media/materialsSoldering mediaMetallic materialsBall mill

The invention belongs to the field of metal materials, in particular to a high-spreadability tin-antimony-rare earth lead-free solder alloy and a preparation method thereof. The alloy is prepared from the following raw materials in percentage by weight: 7.0 to 9.0 percent of Sb, 0.01 to 0.03 percent of In, 1 to 3 percent of Bi, 0.01 to 0.03 percent of Cd, 0.01 to 0.03 percent of Sm, 0.01 to 0.03 percent of Nd and the balance of Sn. The preparation method comprises the following steps of: smelting the raw materials in the ratio in a vacuum induction furnace to obtain a master alloy; remelting in a remelting tubular crucible, wherein the remelting tubular crucible is arranged above a rim of a rotating wheel of a quick quenching furnace, and molten alloy is sprayed through holes with the diameter of 1mm at the bottom of the crucible under the action of argon and forms an alloy strip on the rim of the rotating wheel; properly crushing the alloy strip; and grinding in a ball mill, taking out, and sieving. The alloy has high strength and high spreadability.

Owner:江苏渝鑫科技股份有限公司

A solid flux for stainless steel soldering

ActiveCN104942480BHigh expansion rateNot corrosiveWelding/cutting media/materialsSoldering mediaActive agentSoldering

The invention discloses solid state scaling powder for stainless steel soldering and a preparing method. The solid state scaling powder comprises 0-68.5% of organic cosolvent, 0-19.8% of a metal active agent, 0-39.8% of an acids active agent, 0.1-0.8% of inhibiter and the balance is an organic vehicle. The preparing method comprises the steps that firstly, according to the weight ratio, the organic cosolvent and the metal active agent are mixed and stirred; secondly, the acids active agent is added into a solution disposed in the first step, standing is carried out on the solution for 24 hours. The solid state scaling powder for stainless steel soldering and the preparing method can be applied to the field of scaling powder, the problem that the welding performance is unstable can be effectively solved, and the problems that the spreading condition of soldering materials is poor, and the spreading rate is low can be effectively solved.

Owner:THOUSAND ISLAND METAL FOIL

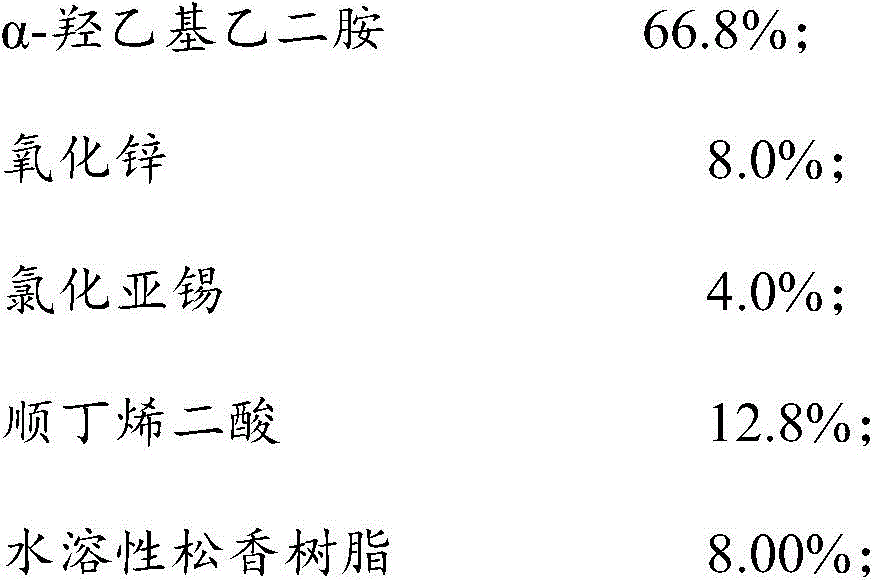

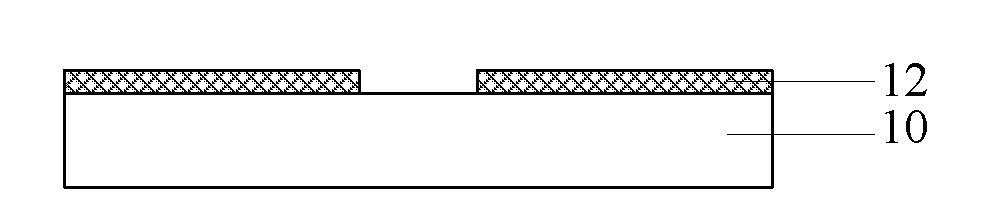

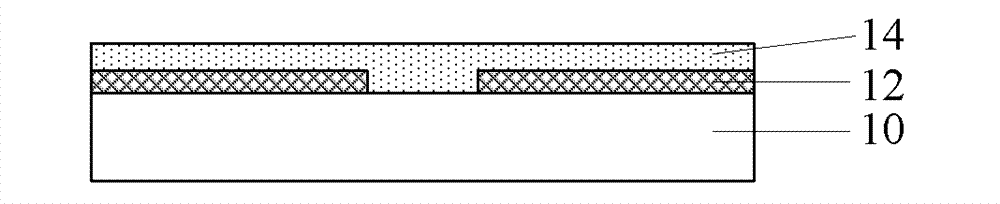

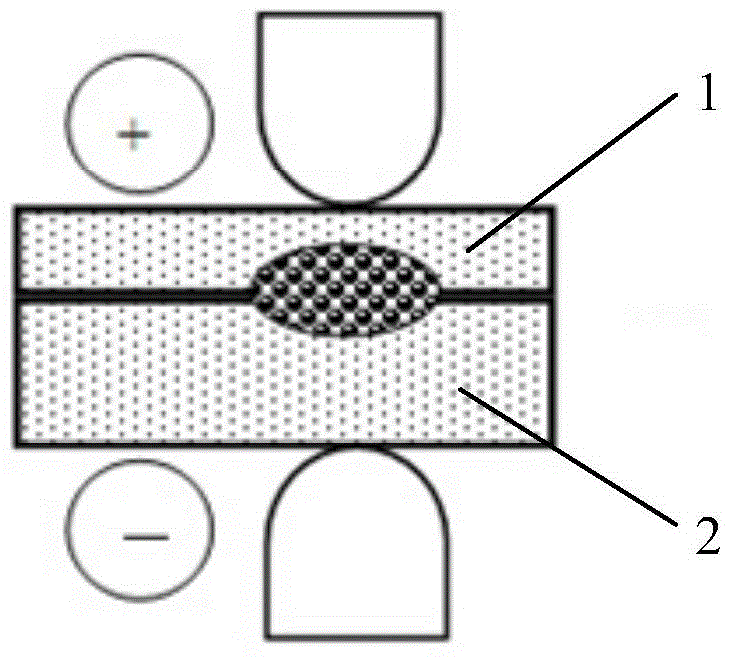

Method for improving conductive solder welding electronic packaging strength based on electrowetting principle

ActiveCN102779766AImprove package strengthReduce power consumptionSoldering apparatusSolid-state devicesMolten stateWeld strength

The invention provides a method for improving conductive solder welding electronic packaging strength based on electrowetting principle, which includes the steps of: making a substrate base plate which is provided with a solder joint structure and a conductive electrode; carrying out electrowetting treatment, heating the substrate base plate to a temperature above the melting point of the solder to enable the solder to be in molten state; and applying voltage to the conductive electrode of the substrate base plate to reduce the surface tension of the solder by making use of the electrowetting effect, so as to increase the contact area of the solder joint structure and the substrate base plate. Compared with the prior art, the method provided by the invention has the advantages that electrowetting principle is adopted in the technical scheme, so the contact area of the solder joint structure can be increased and correspondingly the welding strength of the solder joint structure can be improved and the reliability of a semiconductor device can be improved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

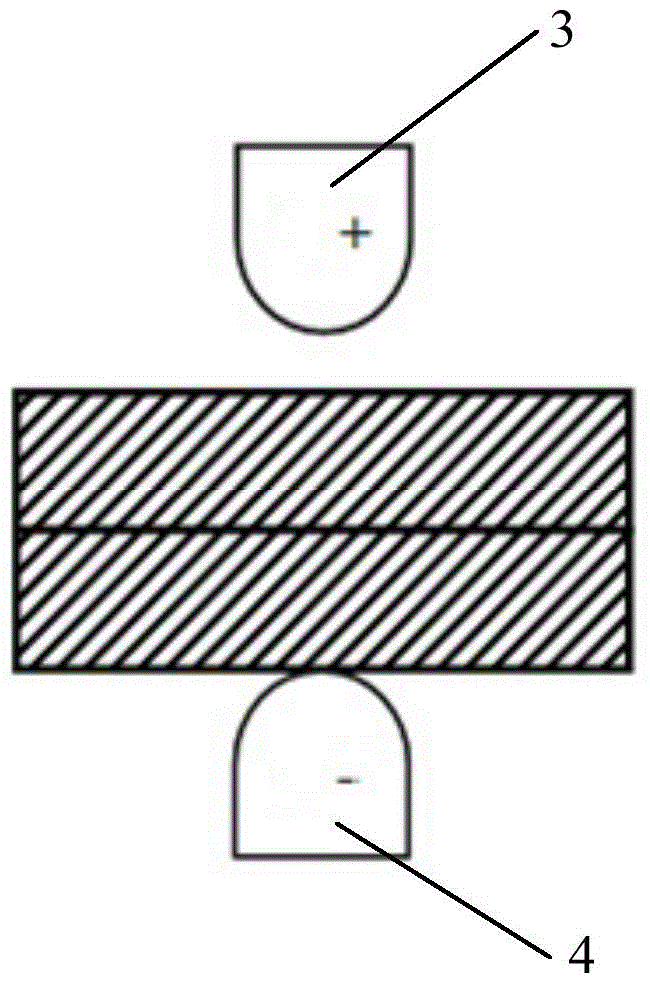

Spot or projection welding method using potential difference between positive and negative electrodes

InactiveCN105436682ASolve the problem of easy virtual weldingStrong penetrating powerResistance welding apparatusTransformerPotential difference

The invention provides a spot or projection welding method using the potential difference between positive and negative electrodes. Two layers of welding boards are clamped between two electrode arms. When the two layers of welding boards are unequal-thickness boards different in thickness, the electrode arm on the thin-board side is connected with the positive electrode of a transformer, and the electrode arm on the thick-board side is connected with the negative electrode of the transformer. When a robot is used for spot welding, the static electrode arm is connected with the negative electrode of the transformer, and the movable electrode arm is connected with the positive electrode of the transformer. During projection welding, the two layers of welding boards are a stamping part and a standard part respectively, the electrode arm on the stamping-part side is connected with the positive electrode of the transformer, and the electrode arm on the standard-part side is connected with the negative electrode of the transformer. Polarity characteristics of medium-frequency direct-current equipment are fully used, and the problem that pseudo soldering is likely to occur during spot welding of the unequal-thickness boards is solved; meanwhile, the depth of fusion of a welding core can be increased during projection welding.

Owner:SHANGHAI TRACTOR & INTERNAL COMBUSTION ENGINE

Aluminum-alloy resistance spot welding method for filling chromium-powder tempering nugget strength

InactiveCN101073845ASuppress replyInhibition of recrystallizationWelding/cutting media/materialsWelding/soldering/cutting articlesCopper electrodeSpot welding

The invention is concerned with aluminum alloy resistance spot welding method with filled chrome powder to melody the intension of melting core, belonging to aluminum alloy resistance spot welding technology. Dip the aluminum alloy plate into the NaOH liquid and clear with water and dip the plate into HNO3 liquid and clear with water and airing. Spread filled chrome powder at the welding spot of the two disposed aluminum alloy plate and carry the spot welding to the aluminum alloy plate with copper electrode with certain current, welding time and welding pressure. The method adds chrome powder in the core forming process of the resistance spot welding to form tiny compound spot of chrome powder among the metals and to restrain the restore and recrystallization of aluminum alloy. It refines the structure of melting core of aluminum alloy by enhancing the welding intension to over 2500 N.

Owner:TIANJIN UNIV

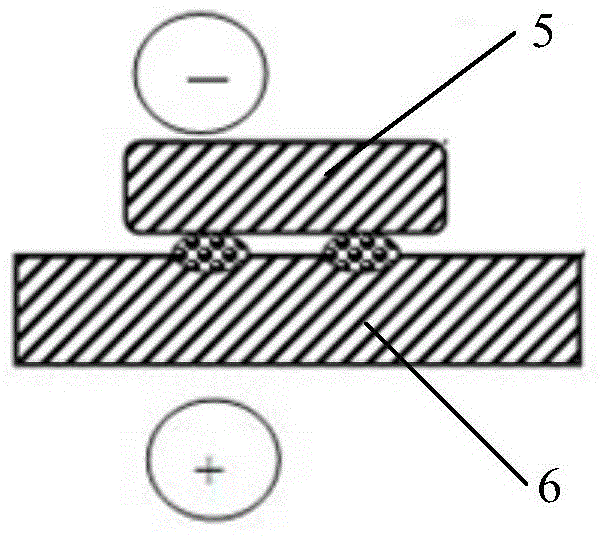

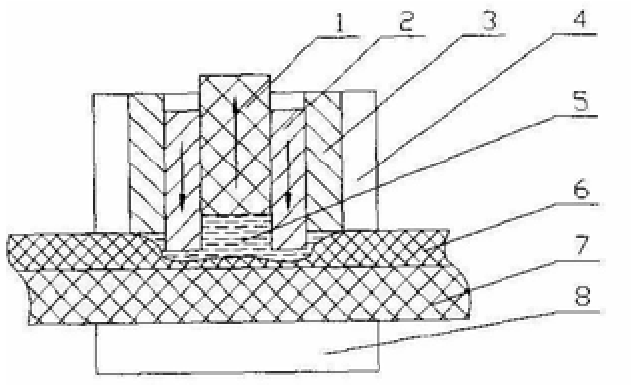

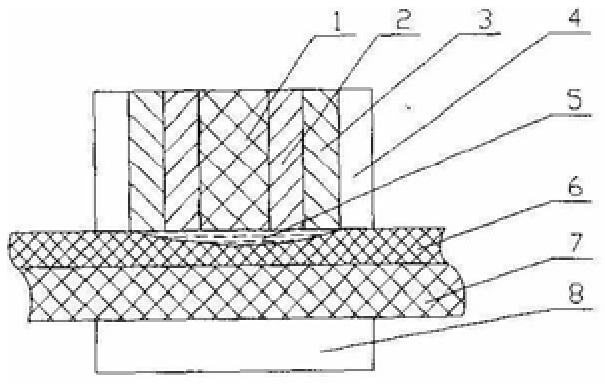

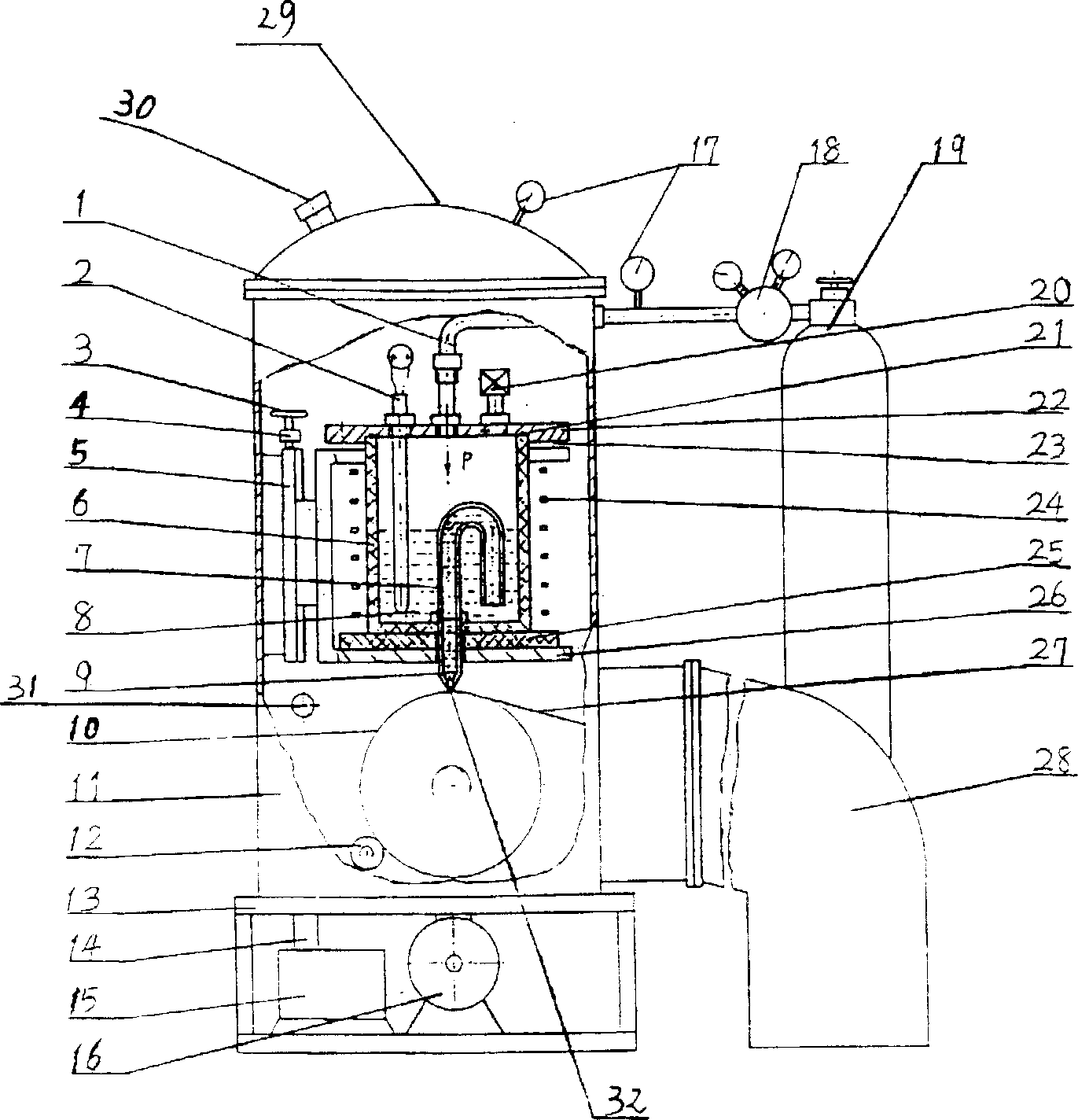

A Filling Type Friction Spot Welding Method with Outer Shaft Rotation

ActiveCN106342013BReduce loadStable structureNon-electric welding apparatusPlastic materialsEngineering

The invention proposes a filling type friction spot welding method in which the outer shaft rotates. The method includes a stirring needle, a stirring sleeve, an outer shaft sleeve, an upper support block, and a lower support block, and the stirring needle is installed in the stirring sleeve, and the stirring sleeve is installed In the outer shaft sleeve, the outer shaft sleeve is installed in the upper support block as a compression sleeve. Stirring needle, stirring sleeve, and the working end surface of the outer shaft sleeve are in contact with the upper surface of the weldment and rotate at a high speed. The friction generated makes the weldment form a plastic area and gradually expands. Through the relative axial movement of the stirring needle and the stirring sleeve, the plastic material flows After the cavity formed by the stirring needle and the stirring sleeve is filled, the rewelding parts are filled again. When the stirring needle, the stirring sleeve and the outer shaft sleeve stop rotating and cooling, a solder joint is formed. In the present invention, because the outer shaft participates in frictional heat generation, the outer contour of the stirring sleeve is no longer the boundary of the friction area, the temperature of the contour interface is reduced, and the structure of the welding spot workpiece tends to be stable, thereby solving the problem of German filled friction spot welding technology The deficiencies in the existing method have achieved beneficial effects such as reducing the load of the spot welding tool, improving the strength of the welding spot, speeding up the welding speed, and ensuring the flatness of the workpiece surface.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

Beryllium-containing low-silver and cadmium-free silver solder

ActiveCN103817456BImprove wettabilitySignificant "purification" effectWelding/cutting media/materialsSoldering mediaMetallic materialsSoldering

The invention belongs to a metal material and specifically relates to a beryllium-containing low-silver cadmium-free silver solder. The beryllium-containing low-silver cadmium-free silver solder is characterized in that the ingredient proportion by mass percent is as follows: 12%-16% of Ag, 39%-41% of Cu, 1%-8% of In, 0.5%-4% of Ga, 0.0001%-0.05% of Be and the balance of Zn, wherein the ratio of In to Ga is equal to 2:1. The beryllium-containing low-silver cadmium-free silver solder which is obtained by adopting the ingredient proportion has the characteristics of good mobility, excellent wettability, high welding spot strength, and the like, also has a melting temperature range approaching to the melting temperature range of a BAg20CuZnCd solder, and is especially suitable for the soldering of some products in the household appliance industry and hardware industry. The problems of workpiece oxidation, reducing of the soldered joint strength, and the like, caused by ultrahigh soldering temperature, are avoided.

Owner:JINHUA SHUANGHUAN BRAZING ALLOYS

Method for preparation of quick setting flat alloy welding wire

InactiveCN1087673CImprove wettabilityGood instant mobilityWelding/cutting media/materialsSoldering mediaCrucibleElectronic industry

A process for preparing the quickly setting flat welding alloy wire used precise welding in electronic industry includes such technological steps as smelting raw materials in vacum or inert gas atmosphere, keeping the temp, passing inert gas into crucible to apply 2-1000 KPa to molten alloy,and forcing the molten alloy to flow via nozzle onto the surface of cooling roller rotating in vacuum chamber. Its advantages are excellent performance of obtained welding alloy wire, shorter productive route and period and low cost.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Inserted inlaid butt welding structure of ceramic metal halide electrode

ActiveCN102148127AAvoid the quality hazard of air leakageReasonable structureGas discharge lamp detailsButt weldingNiobium

The invention discloses an inserted inlaid butt welding structure of a ceramic metal halide electrode. An electrode main pole is a tungsten electrode main pole, molybdenum electrode main pole, alloy tungsten electrode main pole or alloy molybdenum electrode main pole; a lead-out pole is a niobium lead-out pole or niobium / zirconium alloy lead-out pole; one end of the electrode main pole is inserted into the end surface of one end of the lead-out pole; and the outer wall of the inserted end of the electrode main pole and the end surface of the lead-out pole are welded. The inserted inlaid structure disclosed by the invention is reasonable; the electrode main pole and the grain boundary of the niobium lead-out pole are fully melted; no seam or gap exists between a molybdenum sleeve and the niobium / zirconium pole; and the strength of the welding spot is high, and two-segment breakage is prevented in the case of 90-degree bending. Due to the close and perfect connection between the tungsten pole and niobium pole, the resistance consistence of the product is assured to be very high; and the quality hidden danger of air leakage in sealed connection of an electrode and a ceramic tube caused by the problems of rough welding spots, hollow welding, insufficient welding and the like of the current laser welding is effectively avoided.

Owner:佛山宁宇科技股份有限公司

Self-fluxing silver solder containing neodymium, zirconium and gallium

ActiveCN102513727BGood self-brazing performanceImprove plasticityWelding/cutting media/materialsSoldering mediaAppliance componentSoldering

The invention relates to a self-fluxing silver solder containing neodymium, zirconium and gallium. The self-fluxing silver solder is characterized by comprising the following components in percentage by mass: 45.0 to 62.0 percent of Ag, 9.0 to 13.0 percent of Zn, 1.0 to 3.0 percent of P, 0.001 to 0.01 percent of Nd, 0.001 to 0.01 percent of Zr, 0.001 to 0.01 percent of Ga and the balance of Cu. The self-fluxing silver solder is particularly suitable for welding microminiature contacts of microminiature electrical appliance components without use of a soldering flux, so that the problem of cleaning welding spots of the complex electrical appliance components difficultly is solved.

Owner:ZHEJIANG XINRUI WELDING MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com