High-temperature lead-free solder paste and preparation method

A technology of lead-free solder paste and lead-free tin is used in the preparation of high-temperature lead-free solder paste and the field of high-temperature lead-free solder paste. resistance, strong activity, and the effect of reducing the surface tension of metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

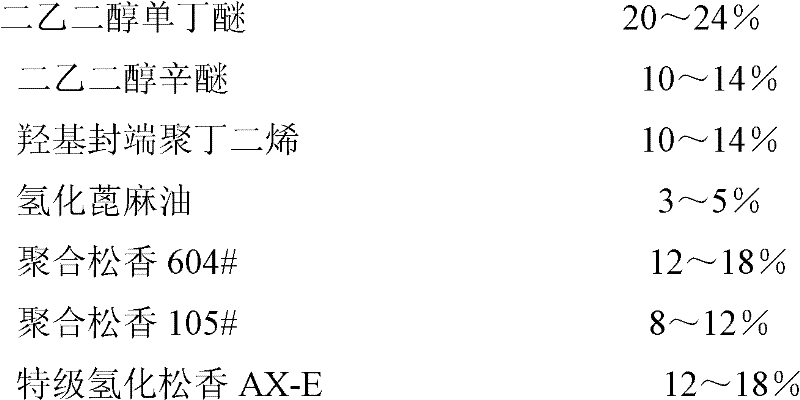

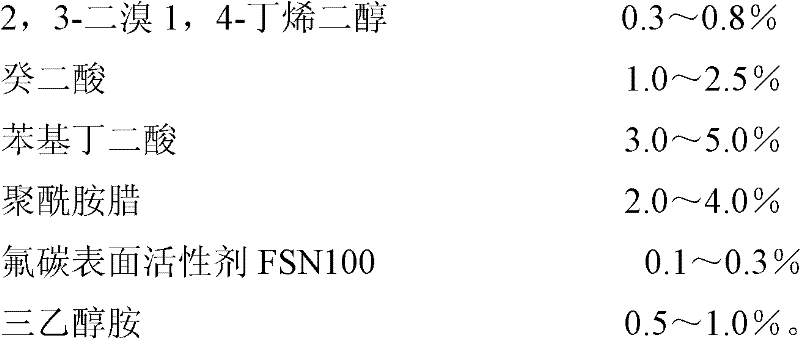

Method used

Image

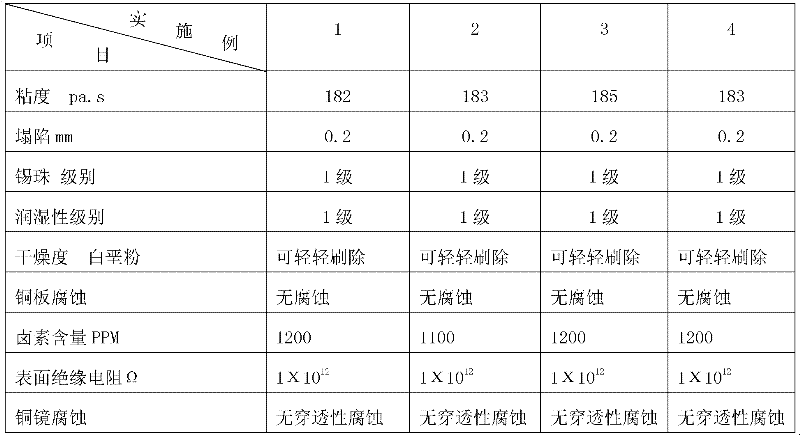

Examples

Embodiment 1

[0026] Take 20g of diethylene glycol monobutyl ether, 10g of diethylene glycol octyl ether and 10g of hydroxyl-terminated polybutadiene and add them into a temperature-controlled emulsifier for heating, stir at 120°C at a speed of 200r / min for 10 minutes, and then put Add 5g of hydrogenated castor oil, 18g of polymerized rosin 604#, 9.4g of polymerized rosin 105# and 18g of special-grade hydrogenated rosin AX-E and stir for another 10 minutes at a speed of 800r / min to prepare a mixed solution and cool it down to 105°C. Add 0.8g of 2,3-dibromo-1,4-butenediol, 1.0g of sebacic acid and 5.0g of phenylsuccinic acid in sequence and stir for another 5 minutes at a speed of 1000r / min to obtain a secondary mixed solution for cooling To a temperature of 75°C, add 2.0g of polyamide wax, and then stir at a speed of 1200r / min for 5 minutes to obtain three mixed solutions; cool down to a temperature of 50°C, add 0.3g of fluorocarbon surfactant FSN100 and 0.5g of triethanolamine in sequence ...

Embodiment 2

[0028]Take 24g of diethylene glycol monobutyl ether, 14g of diethylene glycol octyl ether, and 11.9g of hydroxyl-terminated polybutadiene and add them into a temperature-controlled emulsifier for heating, stir at 125°C at a speed of 200r / min for 5 minutes, and then Add 3.0g of hydrogenated castor oil, 12g of polymerized rosin 604#, 12g of polymerized rosin 105# and 12g of special-grade hydrogenated rosin AX-E and stir for another 5 minutes at a speed of 800r / min to prepare a mixed solution and cool it down to 100°C. Add 0.3g of 2,3-dibromo-1,4-butenediol, 2.5g of sebacic acid and 3.0g of phenylsuccinic acid in sequence and stir for another 10 minutes at a speed of 1000r / min to obtain a secondary mixed solution Cool down to 70°C, add 4.0g of polyamide wax, and stir at 1200r / min for 10 minutes to prepare three mixed solutions; cool down to 55°C, add 0.3g of fluorocarbon surfactant FSN100 and 1.0g of triethanolamine in sequence Add and stir at a speed of 1200r / min for another 10 ...

Embodiment 3

[0030] Take 21.5g of diethylene glycol monobutyl ether, 12g of diethylene glycol octyl ether and 12g of hydroxyl-terminated polybutadiene and add them into a temperature-controlled emulsifier for heating, stir at 120°C at a speed of 200r / min for 10 minutes, and then Add 4.0g of hydrogenated castor oil, 15g of polymerized rosin 604#, 10g of polymerized rosin 105# and 15g of special-grade hydrogenated rosin AX-E and stir for another 10 minutes at a speed of 800r / min to prepare a primary mixed solution and cool it down to 105°C. Add 0.5g of 2,3-dibromo-1,4-butenediol, 2.0g of sebacic acid and 4.0g of phenylsuccinic acid in sequence and stir for another 5 minutes at a speed of 1000r / min to obtain a secondary mixed solution Cool down to 75°C, add 3.0g of polyamide wax, and stir at 1200r / min for 5 minutes to prepare three mixed solutions; cool down to 50°C, add 0.2g of fluorocarbon surfactant FSN100 and 0.8g of triethanolamine in sequence Add and stir at a speed of 1200r / min for ano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com