Method for improving mechanical property of medium-manganese steel welding joint

A technology for welding joints and manganese steel, which is applied in the field of medium manganese steel welding process and manganese steel welding process, can solve the problems of high alloy content, complete interface fracture, high cost, etc., achieve simple equipment conditions, improve solder joint strength, and improve toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

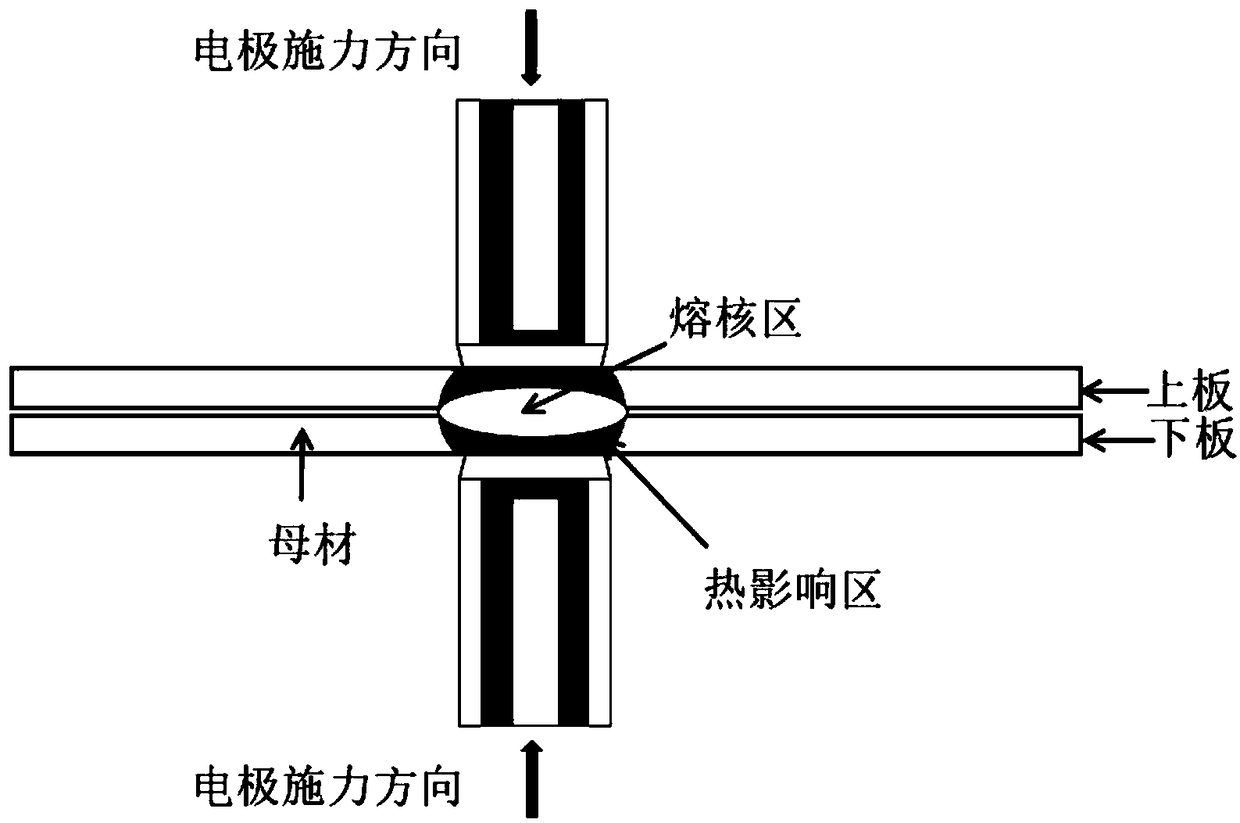

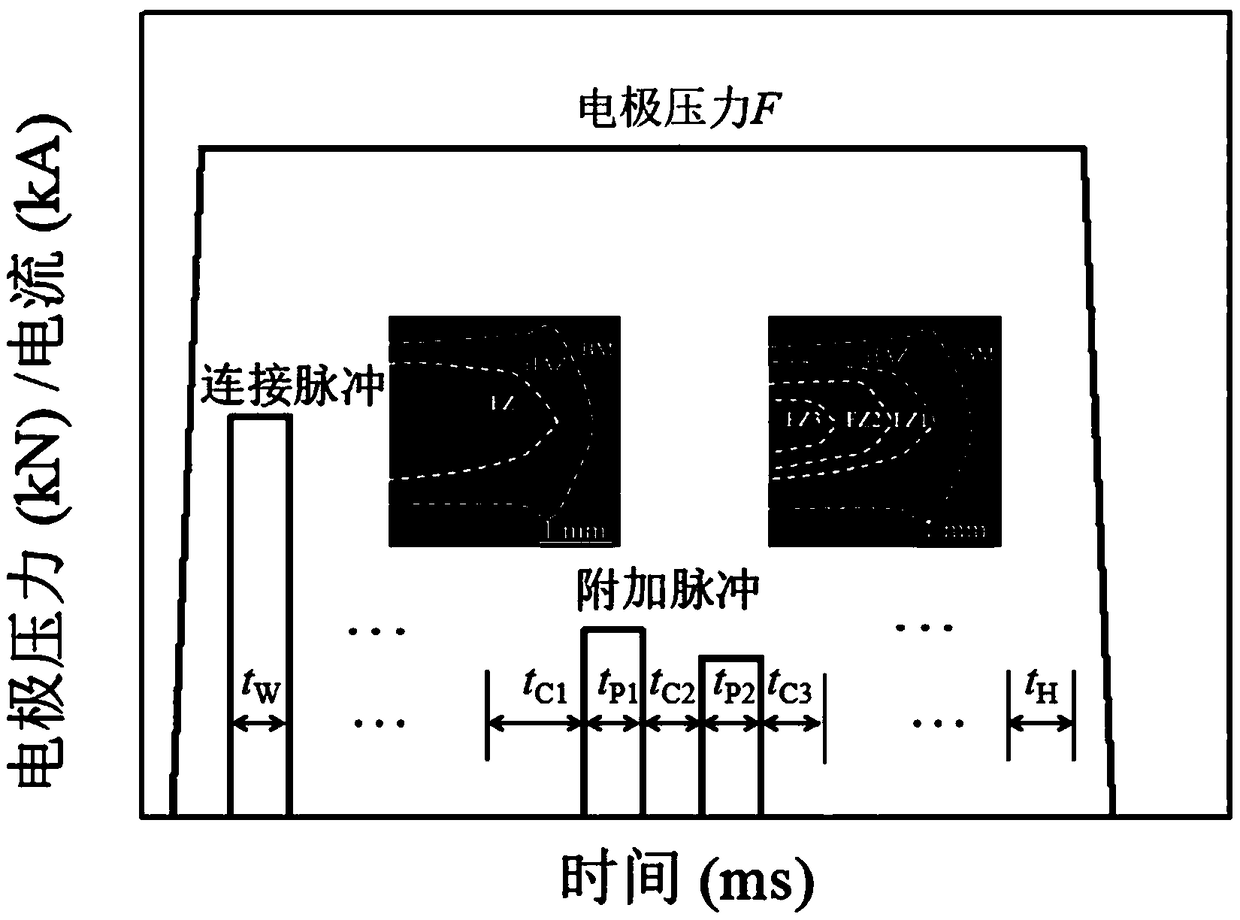

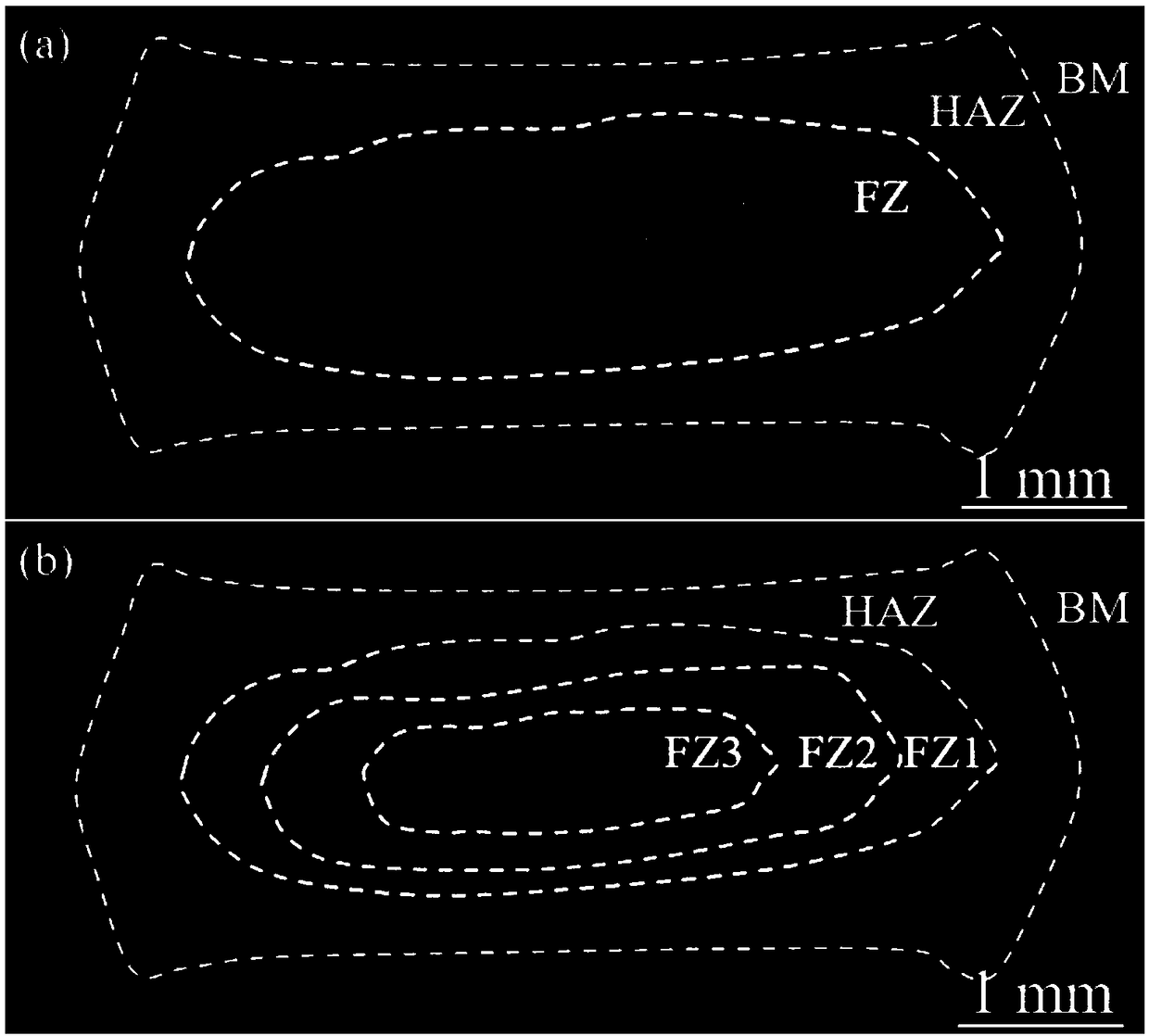

[0031] In this example, see Figure 1 ~ Figure 3 , a method for improving the mechanical properties of medium manganese steel welded joints, for medium manganese steel steel, applying a resistance spot welding process that can form an inner layer nugget, thereby obtaining a multilayer molten nugget with two or more layers of nuggets Nuclear solder joints, the steps are as follows:

[0032]a. Select medium manganese steel plates with a thickness of 1.4 mm and a mass fraction of manganese element of 7% for resistance spot welding of the same steel, pre-treat the medium manganese steels that need to be welded, and clean the surface of the medium manganese steels. Obtain clean welding base metal;

[0033] b. Use a resistance spot welding machine with a voltage of 380V to closely contact the clean welding base metal that has been cleaned in step a, place the position of the welding base metal that needs to be welded under the electrode, and use the electrode as the clamp Clamping...

Embodiment 2

[0042] This embodiment is basically the same as Embodiment 1, especially in that:

[0043] In this embodiment, a method for improving the mechanical properties of medium manganese steel welded joints, for medium manganese steel, applying a resistance spot welding process that can form an inner layer nugget, so as to obtain a nugget with two or more layers Form multi-layer nugget solder joints, the steps are as follows:

[0044] a. Choose medium manganese steel plates with a thickness of 1.4mm and manganese element mass fractions of 7% and 10% respectively for resistance spot welding of dissimilar steels, and pre-treat the medium manganese steels to be welded. Clean up to get a clean welding base metal;

[0045] b. Use a resistance spot welding machine with a voltage of 380V to closely contact the clean welding base metal that has been cleaned in step a, place the position of the welding base metal that needs to be welded under the electrode, and use the electrode as the clamp...

Embodiment 3

[0050] This embodiment is basically the same as the previous embodiment, and the special features are:

[0051] In this example, see Figure 4 , a method for improving the mechanical properties of medium manganese steel welded joints, for medium manganese steel steel, applying a resistance spot welding process that can form an inner layer nugget, so as to obtain a multilayer molten nugget with two or more layers of nuggets Nuclear solder joints, the steps are as follows:

[0052] a. This step is the same as in Embodiment 1;

[0053] b. This step is the same as in Embodiment 1;

[0054] c. This step is the same as in Embodiment 1;

[0055]d. After the solder joint cooling process in the step c ends, keep the pressure on the end of the electrode, and immediately apply an additional pulse current through the electrode, the pulse of the additional pulse current is a single pulse or multiple current values are equal or unequal Pulse, the control additional pulse current value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com