Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about How to "Has water reducing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-durability concrete

The invention discloses a high-durability concrete which comprises the following raw materials: cement, river sand, macadam, water, fly ash, nano microbead, natural zeolite micropowder, aluminum oxide, sodium sulfate, diethanolamine, sodium hydroxide, methyl trichlorosilane, ethanol, an air entraining agent, a lignosulfonate water reducing agent, polyvinyl alcohol, mixed fiber, sodium nitrate and polyvinylpyrrolidone. The mixed fiber is the combination of carbon fiber, steel fiber, polypropylene fiber and polyvinyl alcohol fiber in a weight ratio of 1:(2-5):(3-7):(3-6). The high-durability concrete has the advantages of high strength, favorable water impermeability, favorable freezing resistance and favorable durability, and has long service life when being applied to hydrotechnics, harbors, roads and other projects.

Owner:WUWEI HENGJI COMML CONCRETE

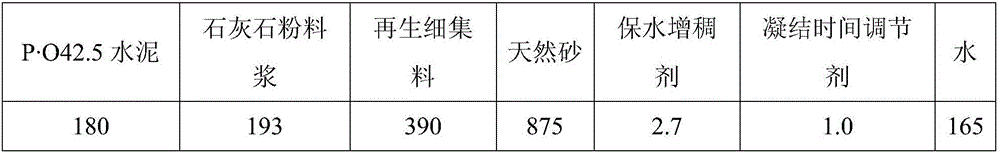

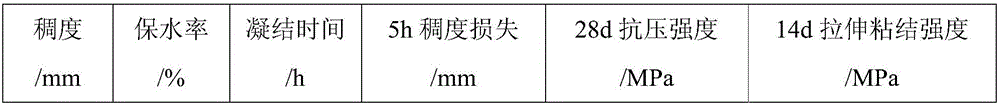

Recycled wet-mixed mortar and preparation method thereof

ActiveCN105948653AGreat social significanceImprove the state of the mixtureSolid waste managementSetting timeMoisture

The invention discloses recycled wet-mixed mortar and a preparation method thereof. The recycled wet-mixed mortar is prepared from the components in parts by weight as follows: 180-260 parts of cement, 130-240 parts of limestone flour slurry with the moisture content being 30%-60%, 380-650 parts of recycled fine aggregate, 650-900 parts of natural medium sand, 2.7-3.9 parts of a water-retention thickener, 0-3.0 parts of a setting time regulator and 120-210 parts of water. The recycled fine aggregate produced with waste concrete test cubes through crushing is applied to wet-mixed mortar, a technical method of pre-stirring of the recycled fine aggregate and stone powder slurry as well as utilization of a special additive is used, the problems of high water absorptivity of the recycled fine aggregate, and quick workability loss, reduced strength and the like are solved; not only is the problem of treatment of waste concrete test cubes solved, but also higher economic benefit is produced.

Owner:XIAMEN TIANRUN JINLONG BUILDING MATERIAL

Production method of non-residual slurry non-autoclaved prestressed concrete pipe pile

ActiveCN103434020AReduce pollutionReduce energy consumptionShaping reinforcementsLow speedPre stress

The invention relates to a production method of a non-residual slurry non-autoclaved prestressed concrete pipe pile. The production method comprises the following steps: (1) sequentially adding fine aggregate, coarse aggregate, cement, mineral powder, a mineral additive, water and a water reducing agent into a reaction kettle, and evenly stirring to obtain a concrete mixture; (2) prestressed tensioning the concrete mixture after material distribution and die assembling; (3) centrifuging the concrete mixture after prestressed tensioning, and sequentially carrying out low speed, low medium speed, medium speed and high speed centrifugation steps in centrifugation without producing residual slurry in the centrifugation process; (4) placing the centrifuged concrete mixture into a steam maintenance pool for steam maintenance. According to the production method, after multiple experiments, through contrastive analysis, the nanoscale mineral additive is added, and by matching with the compound high-performance water reducing agent and adjusting existing pipe pile centrifugation and steam maintenance steps, the non-residual slurry centrifugation and one-time demoulding strength of C80 are realized, so that the working procedures of pouring residual slurry and steam maintenance are eliminated, and the environmental pollution and energy consumption of enterprises are greatly reduced.

Owner:TIANJIN YONGSHENG XINHE PILE

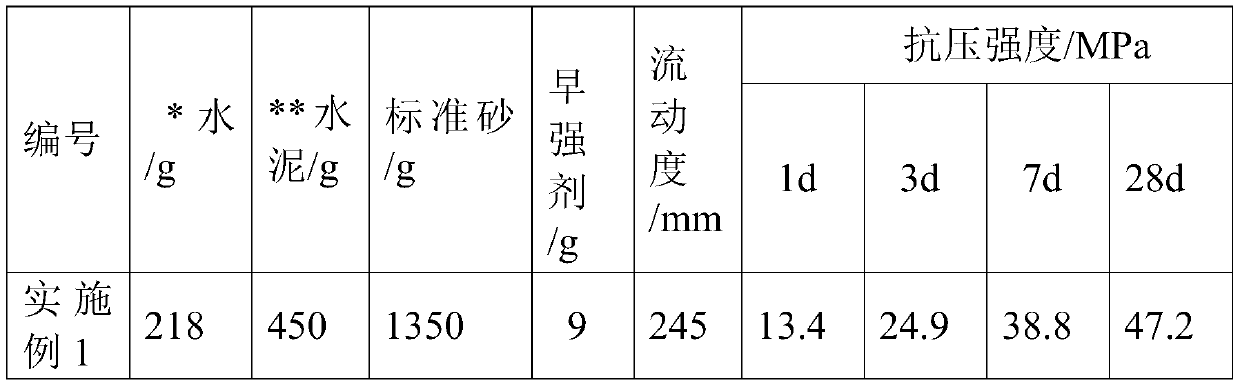

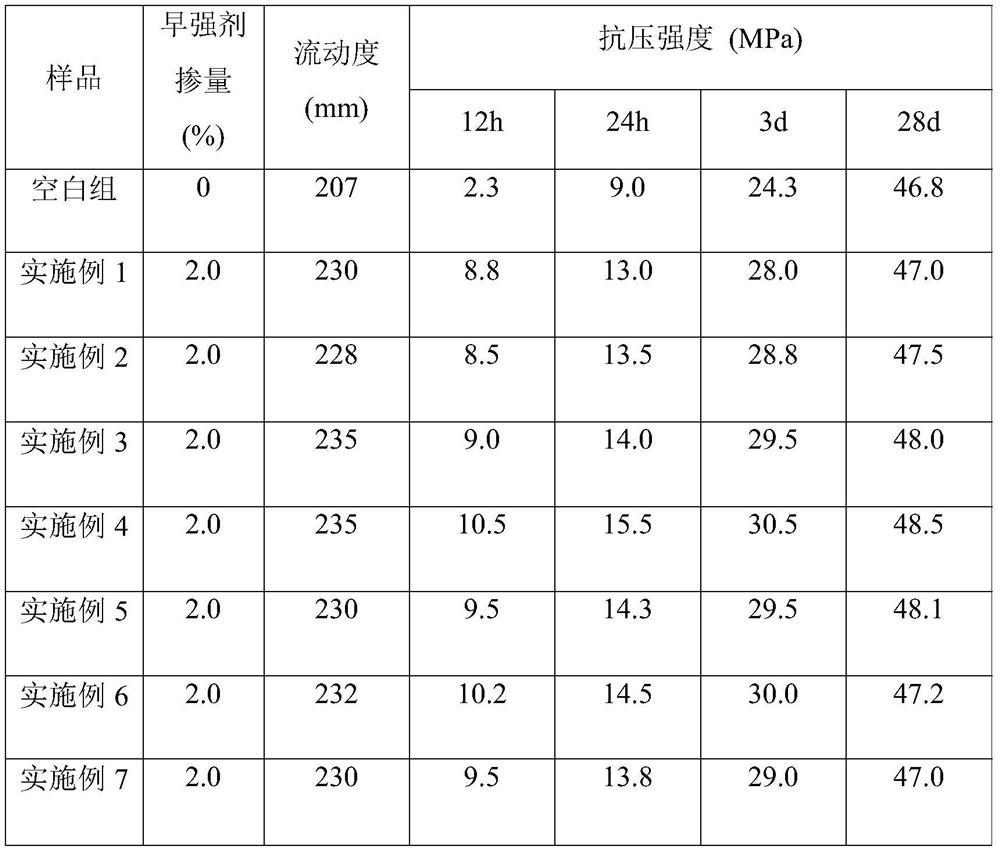

Nano seed crystal early strength agent and preparation method thereof

Provided is a nano seed crystal early strength agent and a preparation method thereof. The method comprises the steps of first preparation of high molecular polymer dispersion liquid, and then the preparation of the nano seed crystal early strength agent; the high molecular polymer dispersion liquid is prepared from, by weight, 100 parts of polyether macromonomer, 2.5-4.5 parts of silane couplingagent, 7.5-12 parts of unsaturated carboxylic acid, 0.4-0.6 part of chain transfer agent, 0.6-1.2 parts of evocating agent and deionized water; the polyether macromonomer is one of prenol polyethyleneglycol monomethyl ether and methyl allyl alcohol polyethylene glycol monomethyl ether; the silane coupling agent is vinyl triethoxysilane, the unsaturated carboxylic acid is one of acrylic acid, methacrylic acid and fumaric acid, the chain transfer agent is mercaptopropionic acid, and the evocating agent is at least one of ascorbic acid and hydrogen peroxide. The invention also provides a preparation method. The agent has obvious early strength effect on concrete, effectively shortens the demoulding time of the concrete, and improves the mold turnover rate and the production efficiency.

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

Multifunctional ceramic composite additive

The invention discloses a multifunctional ceramic composite additive, which is prepared by mixing layered crystalline sodium disilicate, modified 4A zeolite, sodium metasilicate, sodiumtripolyphosphate, sodium hexametaphosphate, polycarboxylate, sodium lignin sulfonate and sodium humate, has various functions of assisted grinding, slushing, plastifying and the like, and is suitable for preparation of ceramic mud added in various forming methods. The additive can lower the moisture content of the mud to 28-32%, improves the ball milling efficiency to a large extend, shortens the ball milling time by 20-30%, reduces the power consumption for raw material grinding by more than 40%, obviously enhances batch plasticity, increases the dried green strength of the product by 10-15%, and has the obvious functions of increasing production, saving energy and reducing consumption.

Owner:HUNAN HANLIN NEW MATERIALS

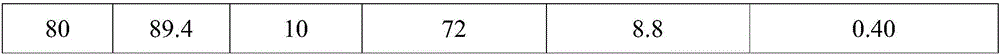

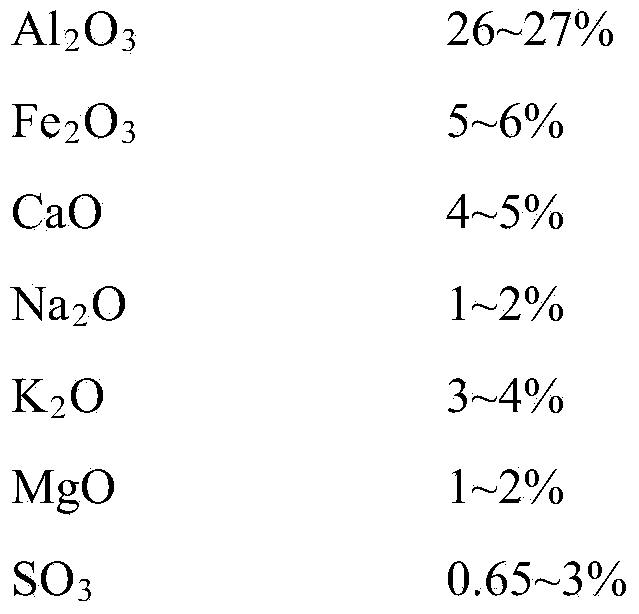

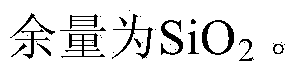

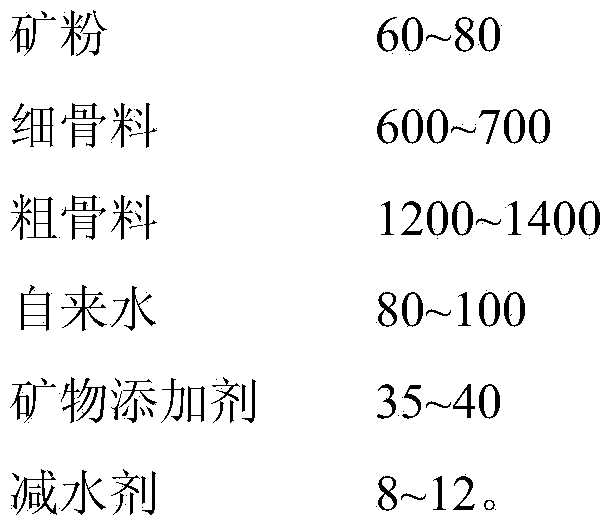

Remained slurry-free and non-autoclaved prestressed concrete pipe pile

The invention relates to a remained slurry-free and non-autoclaved prestressed concrete pipe pile, comprising the following raw components in parts by weight: 300-350 parts of cement, 60-80 parts of mineral powder, 600-700 parts of fine aggregate, 1200-1400 parts of coarse aggregate, 80-100 parts of running water, 35-40 parts of mineral additive, and 8-12 parts of water reducer. After a lot of experiments and contrastive analysis of the remained slurry-free and non-autoclaved prestressed concrete pipe pile, remained slurry-free centrifugation is achieved and one-time demoulding strength achieves C80 by adding a nano-sized mineral additive, matching with complexed high-performance water-reducer, and adjusting the centrifuging and steaming steps of the existing pipe pile. The procedures of removing the remained slurry and steaming are removed; the environmental pollution and energy consumption of enterprises are greatly reduced; the endurance quality of concrete is greatly improved.

Owner:TIANJIN YONGSHENG XINHE PILE

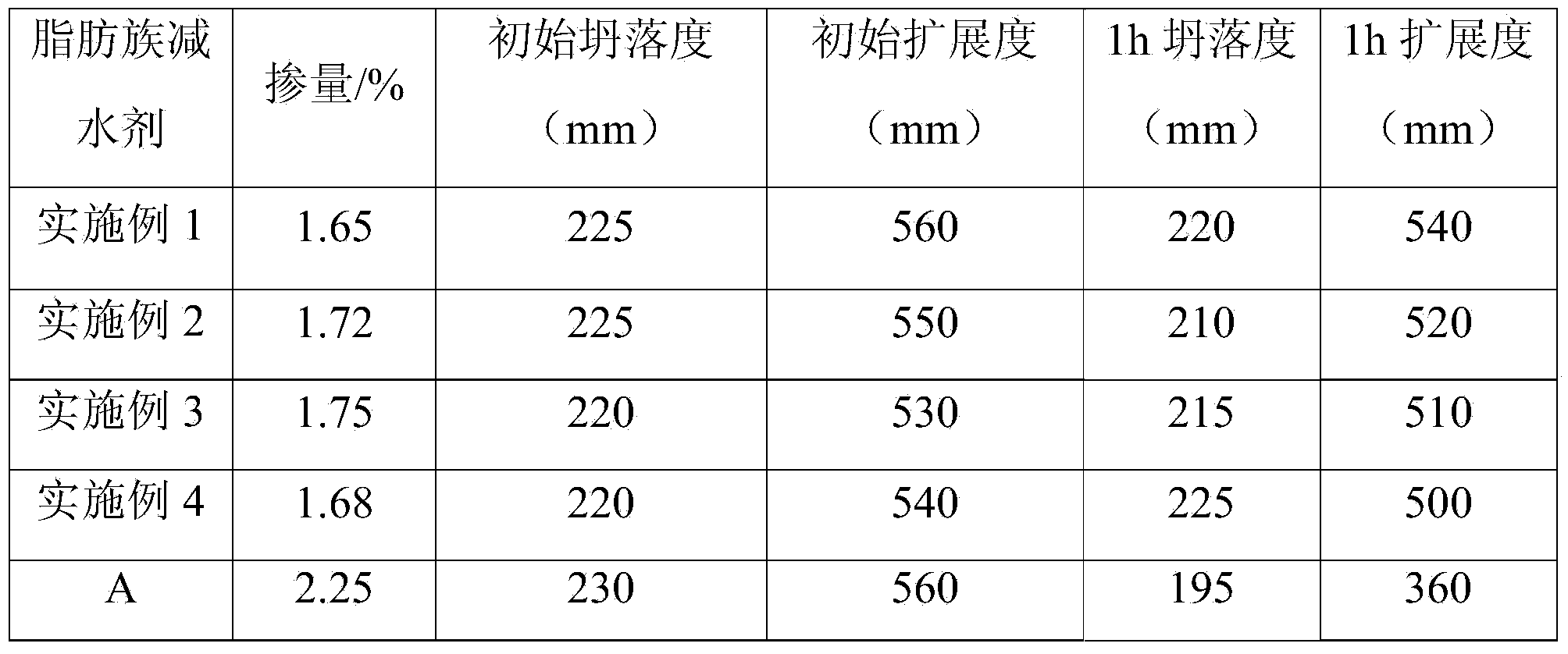

Preparation method of slump retaining type aliphatic water reducing agent

The invention discloses a preparation method of a slump retaining type aliphatic water reducing agent. The preparation method comprises the following steps: (1) preparing modified starch ether; (2) uniformly mixing the modified starch ether prepared in the step (1) with an aliphatic water reducing agent to obtain the slump retaining type aliphatic water reducing agent, wherein the weight of the modified starch ether is 2-10% of the aliphatic water reducing agent. In the method disclosed by the invention, the prepared modified starch ether contains a lot of hydroxyl to prevent hydration of cement; furthermore, the cold water solubility of the modified starch ether is lower than that of the aliphatic water reducing agent, the molecular weight of the modified starch ether is large, and the modified starch ether can be slowly dissolved and completely clad in an alkaline environment, so that the slump retaining property of the aliphatic water reducing agent can be improved, and the water reducing agent can still keep a high fluidity after two hours, and is convenient to transport and construct.

Owner:科之杰新材料集团河南有限公司 +1

Plastic stabilizer and preparation method thereof

The invention discloses a plastic stabilizer and a preparation method thereof. to obtain The plastic stabilizer is prepared by carrying out polymerization onto four component monomers in the presence of an initiator for 4-8 hours at 60-95 DEG C, wherein the component A is alkenyl polyether acrylate, the component B is alkenyl polyether, the component C is one or a mixture of two of methacrylic acid, acrylic acid, maleic acid, maleic anhydride and corresponding salts thereof; the component D is one of acrylamide, methyl acrylamide and N-hydroxymethyl acrylamide; the mass of component A accounts for 1%-10% of mass of the monomers; an oxidization-reduction system is adopted for initiation, wherein the total mass of an initiator accounts for 0.1%-8% of the total mass of the monomers; after the copolymerization reaction is completed, sodium hydroxide is added into a copolymerization product to neutralize, so that a pH value is regulated to 7-8. The plastic stabilizer prepared by the preparation method has good dispersion and water-retaining property, good plasticity-retaining property, plasticization time up to 24-48 hours while being applied to mortar, and is an environment-friendly type product.

Owner:FUKE TECH (SUZHOU) CO LTD

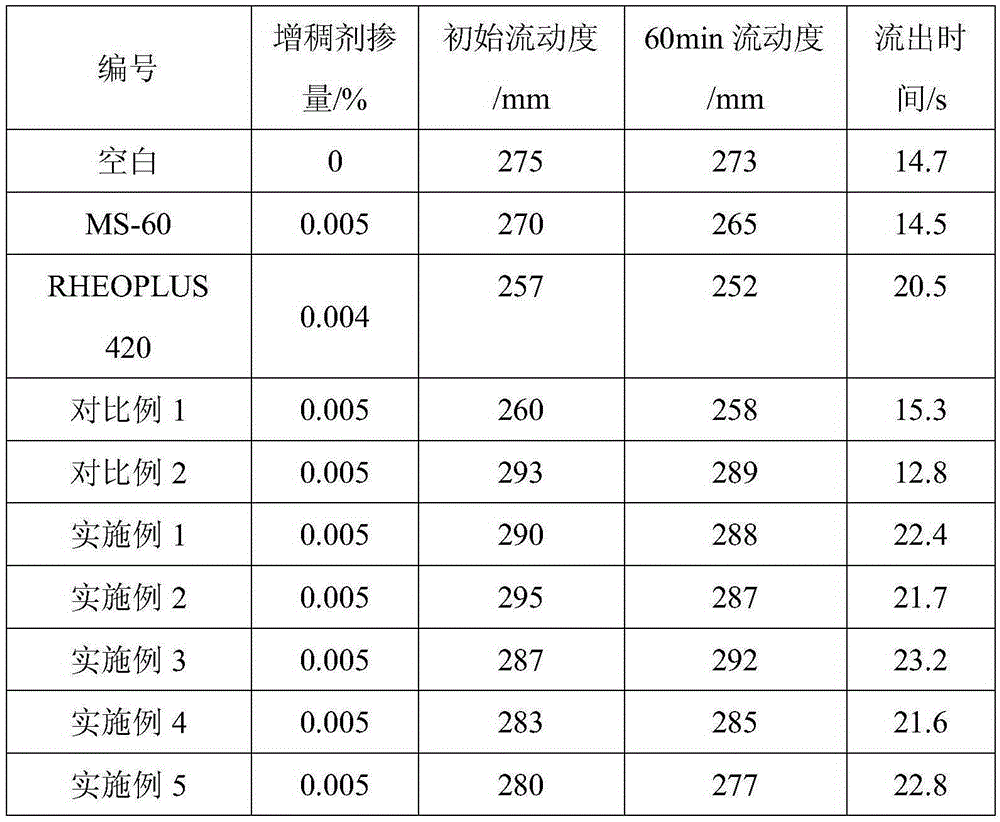

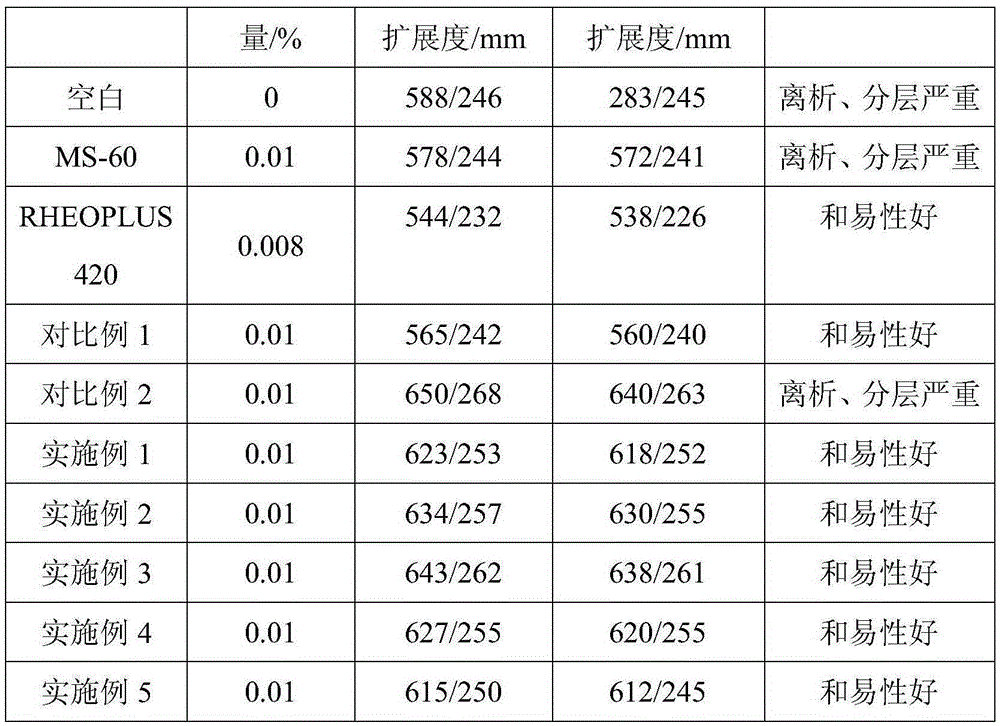

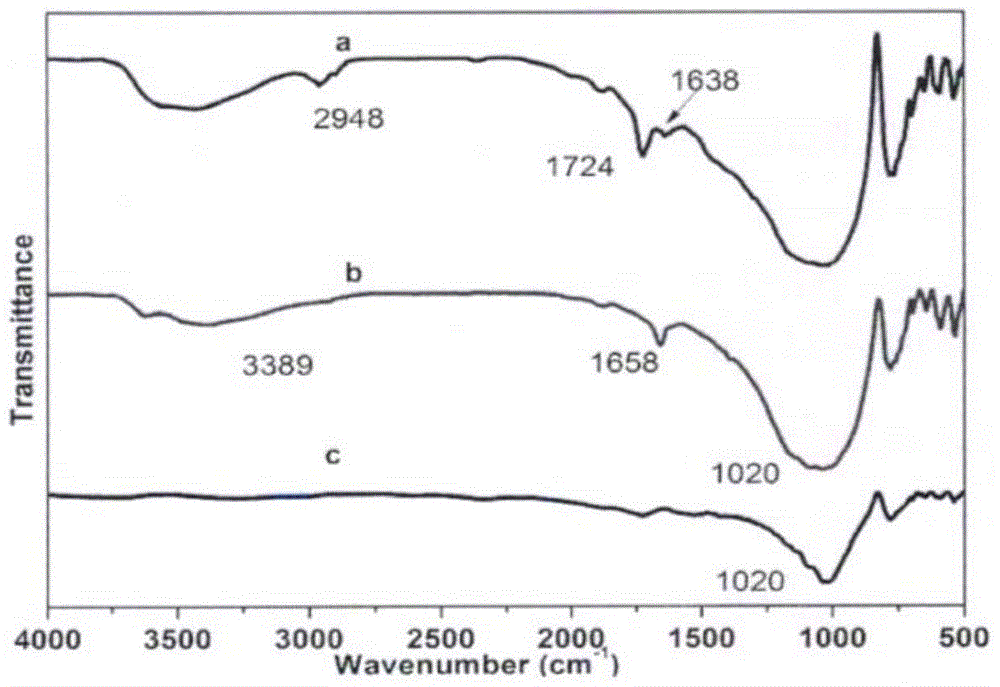

Water-reducing compound modified starch thickener and preparation method and application thereof

ActiveCN105271883AHas water reducing effectNo reduction in slump/spreadReducing agentSulfonic acid ester

The invention provides a water-reducing compound modified starch thickener and a preparation method and application thereof. According to the water-reducing compound modified starch thickener provided by the invention, after maltodextrin molecules are subjected to etherifying modification, sulfonic acid groups are introduced. The water-reducing compound modified starch thickener provided by the invention has a good thickening effect on concrete so as to obviously improve workability of concrete, also has a certain water reducing effect and shows good adaptability to a water reducing agent, an air entraining admixture, a retarder and the like.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

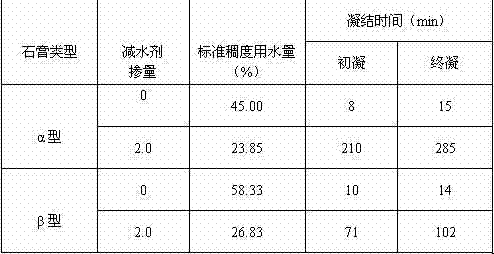

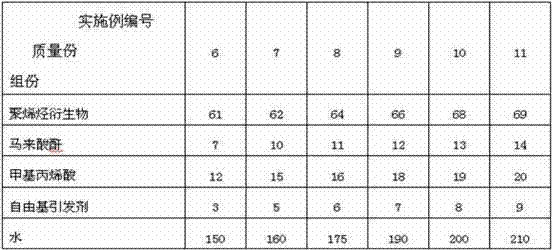

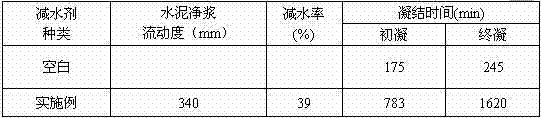

Preparation method of retarding and efficient water reducing agent for silicate cement and calcined gypsum

The invention discloses a preparation method of retarding and efficient water reducing agent for silicate cement and calcined gypsum. The preparation method is characterized by comprising the steps of feeding 60 to 70 mass parts of polyolefine derivative, 5 to 15 mass parts of maleic anhydride, 10 to 20 mass parts of methylacrylic acid and 2 to 10 mass parts of radical initiator into a reaction kettle, adding 140 to 220 mass parts of water into the reaction kettle, stirring, raising the temperature to 60 to 90 DEG C, reacting for 3-6h at 60 to 90 DEG C, reducing the temperature to room temperature after the reaction, then adjusting the pH value of reacted material to 6 to 8 with alkaline pH regulator, and then obtaining yellowish retarding and efficient water reducing agent products, wherein the mass percent of solids in the products is 30-50%. The preparation method has the advantages that the production process and equipment are simple, mass industrial production is easy to realize, the retarding effect on silicate cement and calcined gypsum material is obvious, and the water-reducing rate is high.

Owner:SOUTHWEAT UNIV OF SCI & TECH

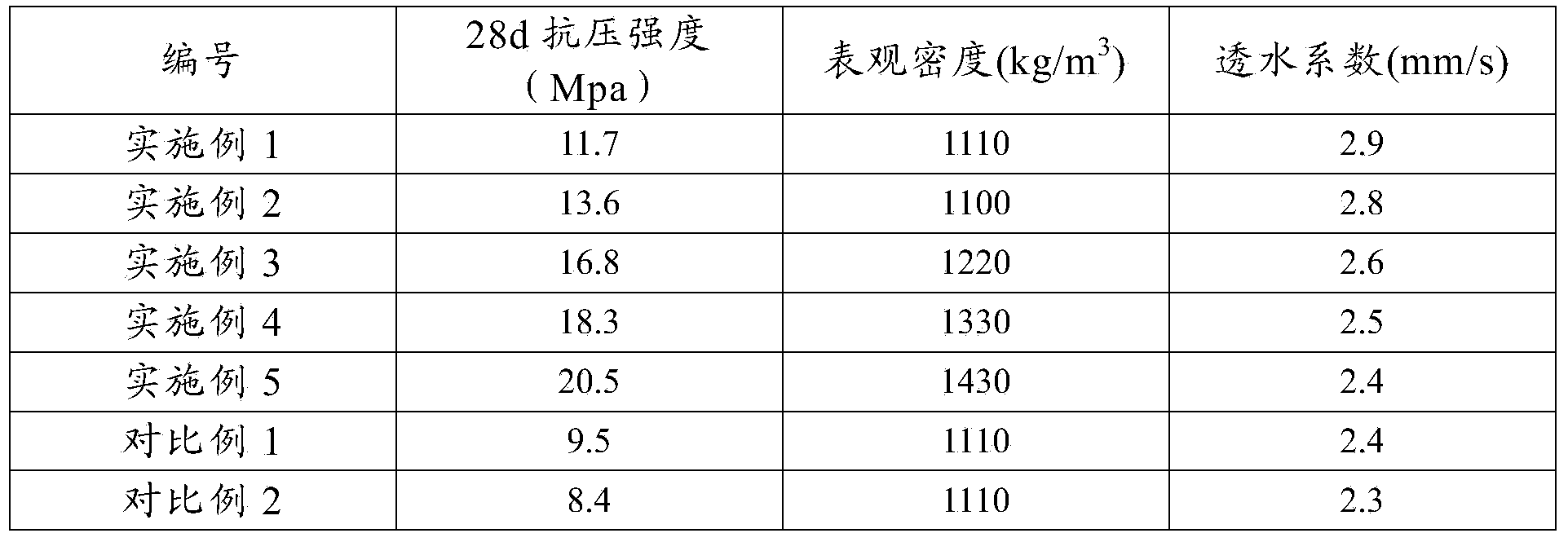

Macroporous concrete containing low grade recycled aggregates and preparation method of concrete

ActiveCN104072061AStrong retardationLower pHSolid waste managementCeramicwareLow gradedConstruction aggregate

The invention discloses macroporous concrete containing low grade recycled aggregates. The macroporous concrete containing low grade recycled aggregates is prepared from the following raw materials: cement, water, low grade recycled aggregates, modified starch and a sugar retarder, wherein the grain size of the low grade recycled aggregates is 5-16mm, and the bulk density is 700-900kg / m<3>. The macroporous concrete containing low grade recycled aggregates is further prepared from additional water, the use level of which is calculated according to the follow formula: delta W=mgr*wgr, wherein delta W is the use level of the additional water of the macroporous concrete containing low grade recycled aggregates; mgr is the use level of the low grade recycled aggregates and wgr is 1h water absorption of the low grade recycled aggregates. According to the invention, the grade recycled aggregates are applied to preparation of the macroporous concrete, so that the mixture state satisfies the using demand under the condition that an additive in an extra amount is not added by virtue of adjusting the raw materials and matching with the sugar retarder and modified starch.

Owner:北京东方建宇混凝土科学技术研究院有限公司

Ready-mixed mortar super-retarder

The invention relates to a ready-mixed mortar super-retarder, which is characterized by being composed of the following components by weight percentage: 10-20% of calcium lignosulphonate, 10-20% of sodium gluconate, 25-45% of white sugar, 1-3% of antiseptic germicide and 30-50% of water, wherein the components are polymerized to form a particular-structure synthetic product in the environment of 30-50 DEG C. After synthesis is finished, purification processes of slag removing, ammonia removing, chlorine removing, and the like are carried out, and a final product is formed after PH adjustment. The ready-mixed mortar super-retarder has the characteristics of high stability, wide cement adaptability, high water-reducing rate, good environment-friendly performance, and the like, and can significantly improve the workability and water retention of mortar and each physical and mechanical property of the mortar after hardening. The low ammonia emission amount and the zero formaldehyde content can not pollute environment, and the ready-mixed mortar super-retarder is especially suitable for super retarding and keeping density of ready-mixed commercial mortar in the summer high-temperature season.

Owner:上海华联建筑外加剂厂有限公司

Heat insulation outer wall putty powder and preparation method thereof

ActiveCN109535811AReduce dry crackingImprove hydrophilicityFilling pastesShrinkage crackingThermal isolation

The invention discloses heat insulation outer wall putty powder and a preparation method thereof, and belongs to the technical field of building materials. Good bonding performance of dopamine is usedfor grafting; the inside structure of hardened putty powder is cured, so that the putty powder forms a hydrated gelling material with good cohesion and good flowing performance.Capric acid, lauric acid and the like are enabled to enter into a heat conduction passage to adsorb or release heat to achieve the heat balance for heat insulation; the heat insulation effect is improved; pores of the putty powder outer wall are charged; the compactness is improved. Polymethyl vinyl siloxane elastomers and introduced vinyl form the crosslinking; the dry-shrinkage cracking is reduced; the mechanical performance of the putty powder is improved. The relatively high light spreading speed is realized; the light can relatively fast transmit through the putty powder to realize photo-thermal conversion; the light effect and the heat storage and heat insulation performance of the outer wall can be further improved. The problem of poor heat insulation and thermal isolation effects of the existing outer wall putty powder can be solved.

Owner:安徽众雁涂料有限公司

High-strength compound cement aeolian mortar

ActiveCN108164197ASolve the construction problems of water conservancy facilitiesGuaranteed durabilityWork performanceFreeze and thaw

The invention relates to desert aeolian sand and in particular relates to a modified high-strength compound cement aeolian mortar product. The modified high-strength compound cement aeolian mortar provided by the invention is prepared from the following components in parts by weight: 100 parts of aeolian sand, 40 to 55 parts of a gel material, 16 to 27.5 parts of water, 6 to 14 parts of a water reducing agent, 0.5 to 2 parts of a water retaining agent and 0.5 to 6 parts of an air entraining agent, wherein the water-gel ratio is 0.4 to 0.5. The high-strength compound cement aeolian sand mortarprovided by the invention takes aeolian sand in the Alxa region as aggregate, Mengxi cement of Inner Mongolia and local abundant fly ash resources as the gel material and a novel additive as a modifying agent; the sand mortar has excellent working performance and has good durability, freezing and thawing resistance, anti-permeability and shrinkage performance; the dosage of cement is less and thecost is low; construction requirements can be completely met.

Owner:内蒙古自治区水利水电勘测设计院有限公司 +1

Ultra-fine soil concrete and preparation method thereof

The invention discloses ultra-fine soil concrete. The ultra-fine soil concrete is mainly prepared from soil, cement, fly ash, silica fume, a concrete regenerant, iron-containing polypropylene fibers and water. The soil is ground into ultra-fine soil containing 90% or more of particles with sizes of less than 1mm. The invention also discloses a preparation method of the ultra-fine soil concrete. The preparation method comprises: uniformly mixing raw materials, uniformly stirring the mixture and the concrete regenerant, pouring the mixture into a mold, orderly carrying out insertion smashing andvibration smashing, carrying out standing, carrying out demolding and carrying out curing. The single mineral particle or agglomerate in the soil is exposed through grinding and then undergoes an active reaction to produce gel under the conditions of cement hydration reaction heat release so that other components in the concrete are firmly cemented together, the tensile strength of the concrete is greatly improved and the raw material cost of the concrete and the pollution damage to the environment are reduced. The preparation method is simple, has low equipment requirements, is easy to implement and is suitable for industrial production.

Owner:XIAN UNIV OF SCI & TECH +1

Crystal nucleus type concrete early strength agent and preparation method thereof

The invention discloses a crystal nucleus concrete early strength agent and a preparation method thereof. 1,000 parts of crystal nucleus concrete early strength agent are prepared from the following raw materials in parts by weight: 100-150 parts of a polymer, 20-50 parts of sodium metasilicate pentahydrate, 60-90 parts of calcium nitrate tetrahydrate and the balance of deionized water. The preparation method comprises the steps of firstly adding the polymer to a three-neck flask, adding the deionized water to form a base solution, putting the flask into a hot water bath, controlling the temperature and stirring; taking the sodium metasilicate pentahydrate, and adding the deionized water to prepare a solution A; taking the calcium nitrate tetrahydrate and adding the deionized water to prepare a solution B; dropwise adding the solution A and the solution B to the base solution at the same rate, carrying out heat preservation on the product, stirring and reacting; and finally quickly cooling a product to a room temperature to obtain the final product, namely the crystal nucleus concrete early strength agent. The crystal nucleus concrete early strength agent is good in performance, is capable of making concrete solidified quickly, is short in demolding time and not easy to collapse and has a certain water reducing effect, and the later strength loss of the concrete is small.

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

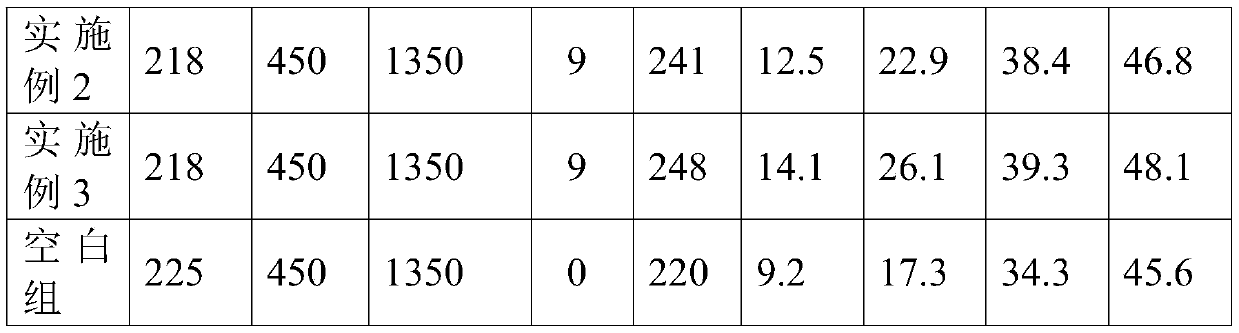

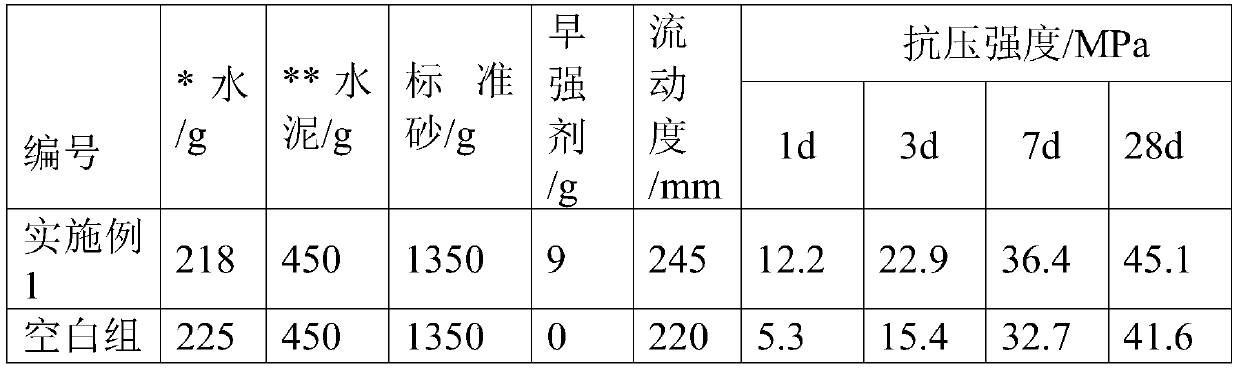

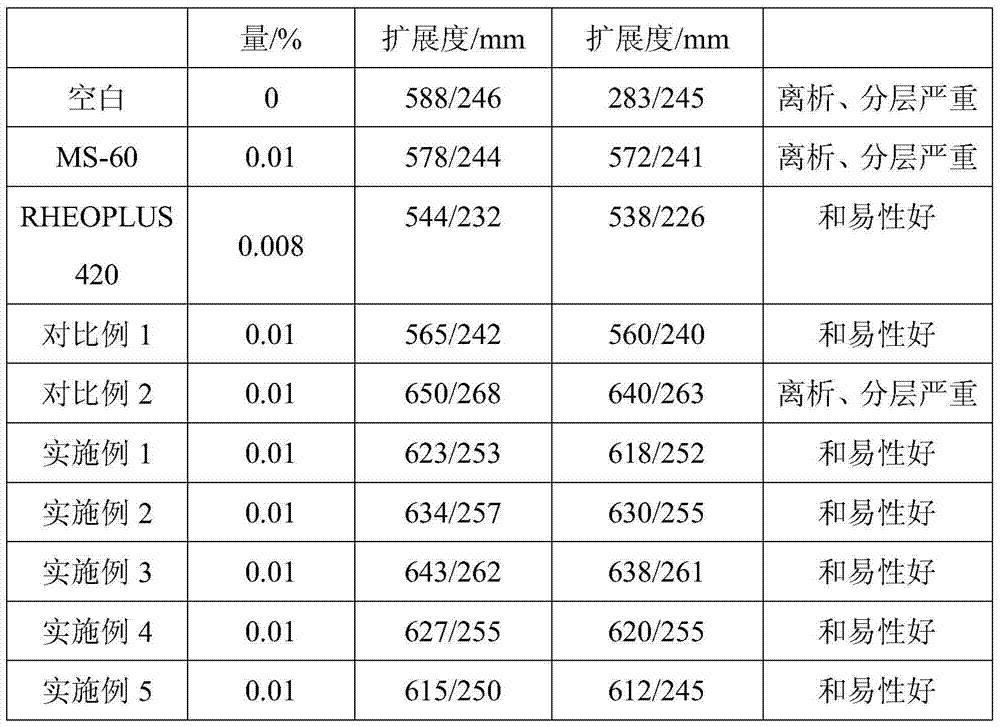

A water-reducing composite modified starch thickener, its preparation method and application

The invention provides a water-reducing composite modified starch thickener, its preparation method and application. The water-reducing composite modified starch thickener of the present invention is after etherification and modification of maltodextrin molecules, and then introducing sulfonic acid groups. The water-reducing composite modified starch thickener of the present invention has a good thickening effect on concrete, significantly improves the workability of concrete, and also has a certain water-reducing effect, showing that it is compatible with water-reducing agents and air-entraining agents. , retarder and other good adaptability.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

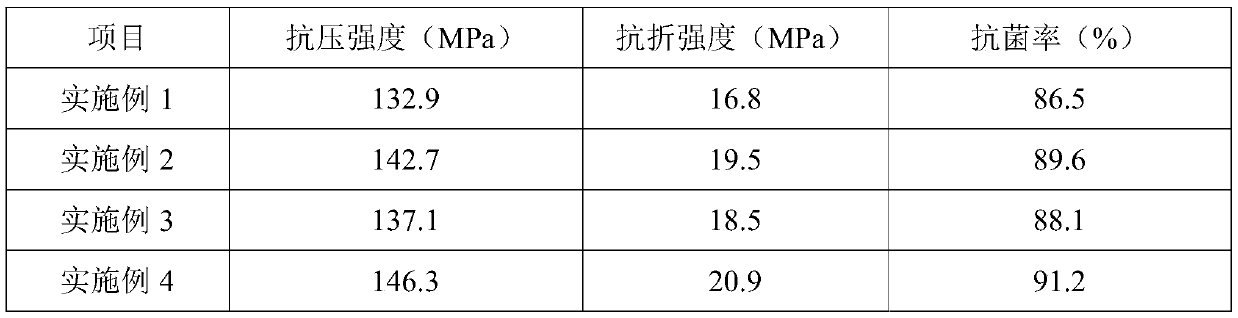

Antibacterial inorganic high-performance mineral artificial slabstone and preparation method thereof

InactiveCN111393089AEvenly dispersedReduce clumpingAuxillary shaping apparatusCement mixing apparatusPhysical chemistryAnti bacterial

The invention discloses an antibacterial inorganic high-performance mineral artificial slabstone and a preparation method thereof. The antibacterial inorganic high-performance mineral artificial slabstone comprises the following raw materials in parts by weight: 60-100 parts of cement with the strength not lower than 32.5 MPa, 50-80 parts of an admixture with an average particle size of 5-30 [mu]m, 80-130 parts of fine aggregate with an average particle size of 0.15-4.75 mm; 0.2-0.8 part of a supported antibacterial agent with an average particle size of 20-100 nm; 0.5-2 parts of a water repellent; 3-10 parts of pigment; 3-5 parts of a high-performance additive, wherein the water-binder ratio is 0.16-0.2. The artificial slabstone is good in volume stability, good in antibacterial performance, low in shrinkage, free of buckling deformation in use, extremely low in water absorption rate, good in durability, free of aging and other problems, good in surface stain resistance, low in overall comprehensive cost and suitable for application and popularization.

Owner:GUANGDONG TOPNICE NEW MATERIALS TECH CO LTD

Montmorillonite internal curing agent modified by vinyl carboxylate copolymer and preparation method for montmorillonite internal curing agent

The invention relates to a montmorillonite internal curing agent modified by vinyl carboxylate copolymer and a preparation method for the montmorillonite internal curing agent. The preparation method comprises the following steps of: 1) batching the following components in percentage by mass: 5%-17% of Na-montmorillonite, 40%-55% of deionized water, 8%-20% of vinyl carboxylate copolymer, 3%-11% of sodium gluconate and 15%-30% of sodium polyacrylate; and taking the components; and 2) dissolving the na-montmorillonite, the vinyl carboxylate copolymer, the sodium polyacrylate and the sodium gluconate into the deionized water, uniformly mixing the components, heating the components by heated air circulation, putting the components into a drying oven, drying the components, and grinding the components, thereby obtaining the montmorillonite internal curing agent. The preparation method for the montmorillonite internal curing agent has the beneficial effects that: firstly, an advanced internal curing method without watering is achieved; secondly, the water-reducing rate is high; thirdly, the pollution of environment is reduced, and the cost is reduced; and fourthly, the preparation method is simple, the curing effect is obvious, slump loss of concrete can be reduced, the strength of the concrete is improved and the service life of the concrete is prolonged.

Owner:WUHAN UNIV OF TECH

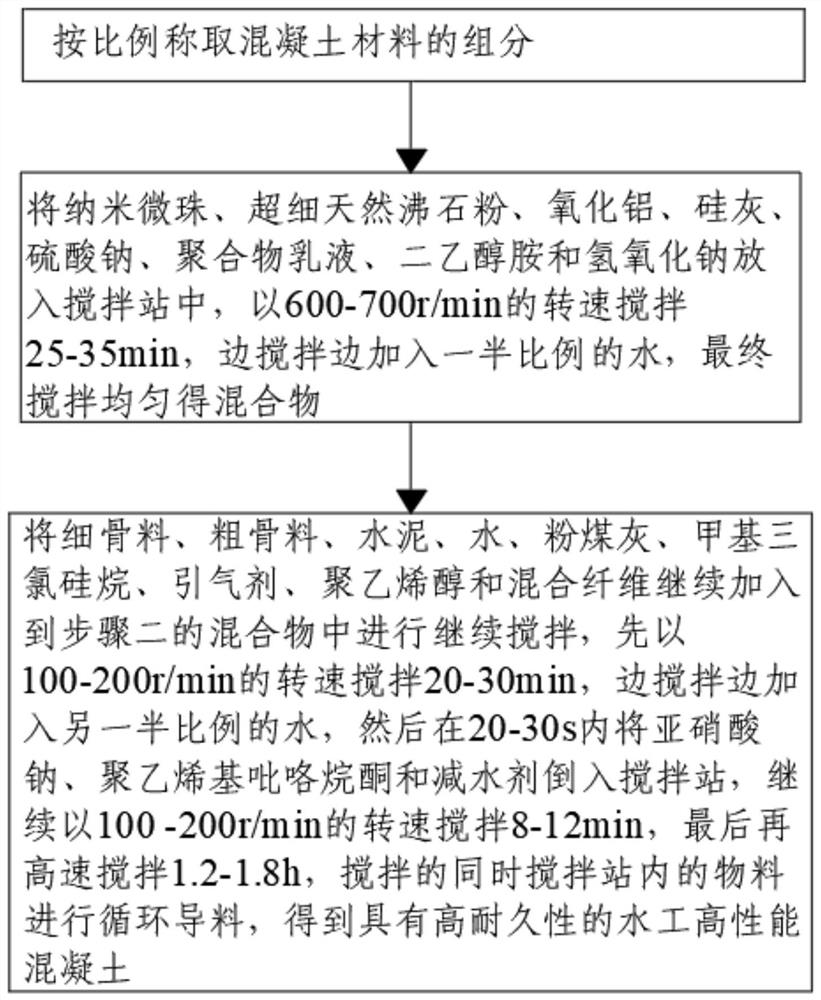

Hydraulic high-performance concrete with high durability as well as preparation process and preparation device thereof

InactiveCN113372051APrevent overflowEasy to handle with dust removalDischarging apparatusCement mixing apparatusFiberPolyvinyl alcohol

The invention discloses hydraulic high-performance concrete with high durability as well as a preparation process and a preparation device thereof, and relates to the technical field of concrete. The hydraulic high-performance concrete with high durability is prepared from the following raw materials in parts by weight: 180 to 240 parts of fine aggregate, 90 to 100 parts of coarse aggregate, 100 to 200 parts of cement, 50 to 120 parts of water, 15 to 35 parts of fly ash, 30 to 80 parts of nano microbeads, 2.5 to 3.7 parts of superfine natural zeolite powder, 10 to 18 parts of aluminum oxide, 5 to 8 parts of silica fume, 2.6 to 4.5 parts of sodium sulfate, 1.3 to 1.8 parts of polymer emulsion, 3.4 to 5.6 parts of diethanol amine, 1.4 to 3.5 parts of sodium hydroxide, 1 to 1.6 parts of methyl trichlorosilane, 2.3 to 3.6 parts of an air entraining agent, 2 to 4 parts of polyvinyl alcohol, 3.5 to 5.6 parts of mixed fibers, 0.3 to 1.2 parts of sodium nitrite, 0.5 to 1.6 parts of polyvinyl pyrrolidone and 1.8 to 2.3 parts of a water reducing agent. The hydraulic high-performance concrete with high durability has a filling effect and a water reducing effect, so that the hydraulic high-performance concrete with high durability has high durability and is beneficial to long-time use, meanwhile, the processing efficiency is improved, and rapid production is facilitated.

Owner:灌南县水利建筑工程有限公司 +1

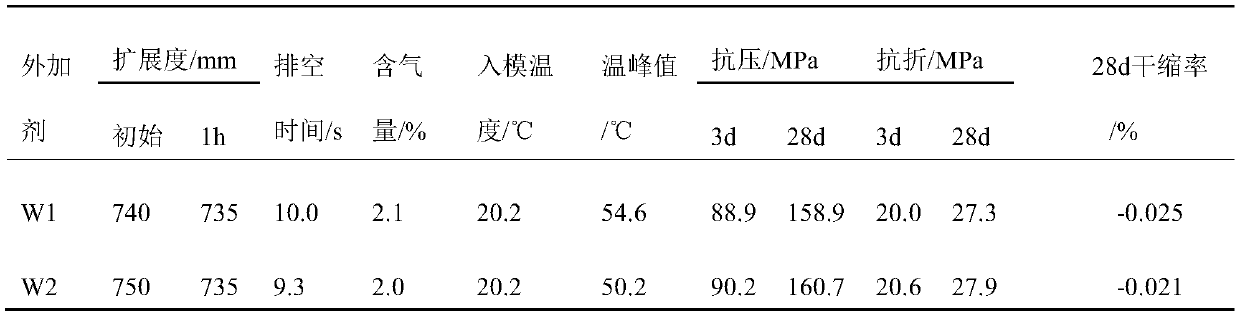

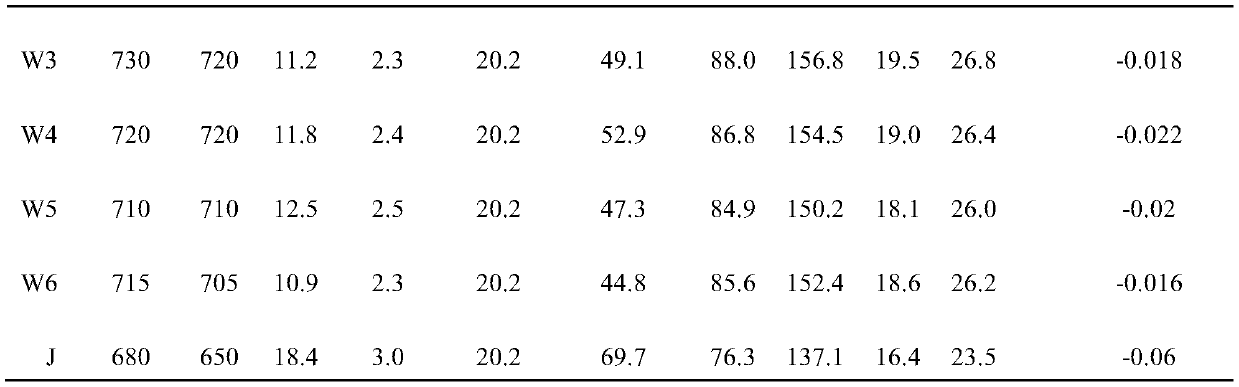

Admixture for ultra-high performance concrete and preparation method thereof

The invention discloses an admixture for ultra-high performance concrete. The admixture is prepared from the following raw materials in percentage by mass: 60-70% of a polycarboxylate water reducing agent, 15-25% of a polycarboxylate slump retaining agent, 5-15% of a viscosity and shrinkage reducing agent and 1-5% of a hydration heat inhibitor. The admixture disclosed by the invention has multiplefunctions of high fluidity, low viscosity, slump loss resistance, early strength, low hydration heat, low shrinkage and the like, and can meet the performance requirements of a mass concrete structure on ultra-high performance concrete.

Owner:CCCC SHEC WUHAN PORT NEW MATERIALS +2

Waterproof fireproof wheat straw-polystyrene particle compounded thermal insulation mortar and preparation method thereof

The invention discloses a waterproof fireproof wheat straw-polystyrene particle compounded thermal insulation mortar and a preparation method thereof. The mortar comprises following raw materials: wheat straw, vitrified beads, cement, fly ash, sand, re-dispersible latex powder, polypropylene glycol fiber, cellulose ether, polystyrene particles, polyvinyl alcohol, paraffin, an emulsifier OP-10, acrylic acid monomers, a K2S2O8 solution, and aqueous epoxy resin emulsion. Polyvinyl alcohol (PVA) is used to modify paraffin, PVA is evenly distributed in paraffin to form a three-dimensional water isolation membrane so as to achieve a waterproof effect; acrylic acid monomers are taken as a modification inter-body, K2S2O8 is taken as an initiator, and OP-10 is taken as an emulsifier to prepare a paraffin-acrylic acid-polyvinyl alcohol waterproof agent. Aqueous epoxy resin emulsion has a water reducing effect and is added into cement mortar to improve the performance of cement mortar. Polystyrene particles and vitrified beads are mixed to enhance the fireproof and thermal insulation performance of mortar.

Owner:倪修俊

Concrete composite type superplasticizer

The invention discloses a concrete composite type superplasticizer, wherein the formula component comprises the following components in parts by mass: 20-35 parts of beta-naphthalene sulfonated formaldehyde condensate, 10-30 parts of polyacrylic acid ether polymer, 3-4 parts of sodium tripolyphosphate, 1-5 parts of potassium sodium tartrate, 1-2 parts of sucrose, 0.5-5 parts of cellulose ether, 2-4 parts of lignin sulfonate, 3-4 parts of acrylic acid, 30-75 parts of hydrogen peroxide and 2-4 parts of mirabilite. The beta-naphthalene sulfonated formaldehyde condensate and the polyacrylic acid ether polymer are set, and under the action of sodium tripolyphosphate, the two kinds of different water reducers are effectively mixed, the slump of concrete is improved and the setting time can be prolonged, and the cellulose ether is added, so that the polycarboxylic acid water reducer can be modified by introducing the cellulose ether-containing monomer and the stereo-hindrance effect of the water reducer can be improved. Meanwhile, the water retention property of cellulose ether can also help disperse cement particles to improve the fluidity of slurry.

Owner:江苏博思通新材料有限公司

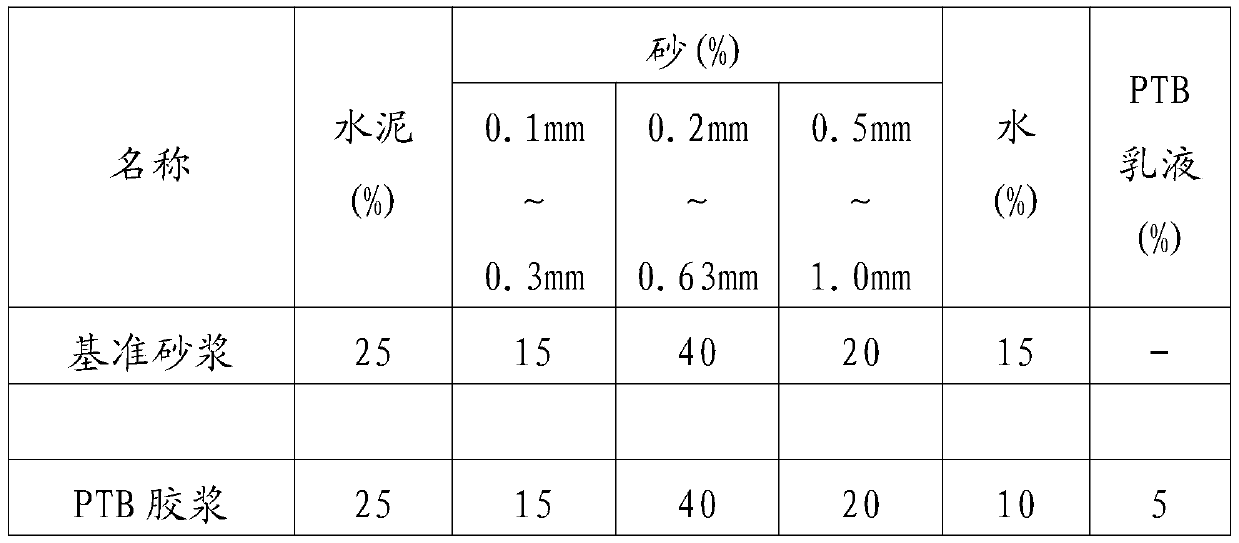

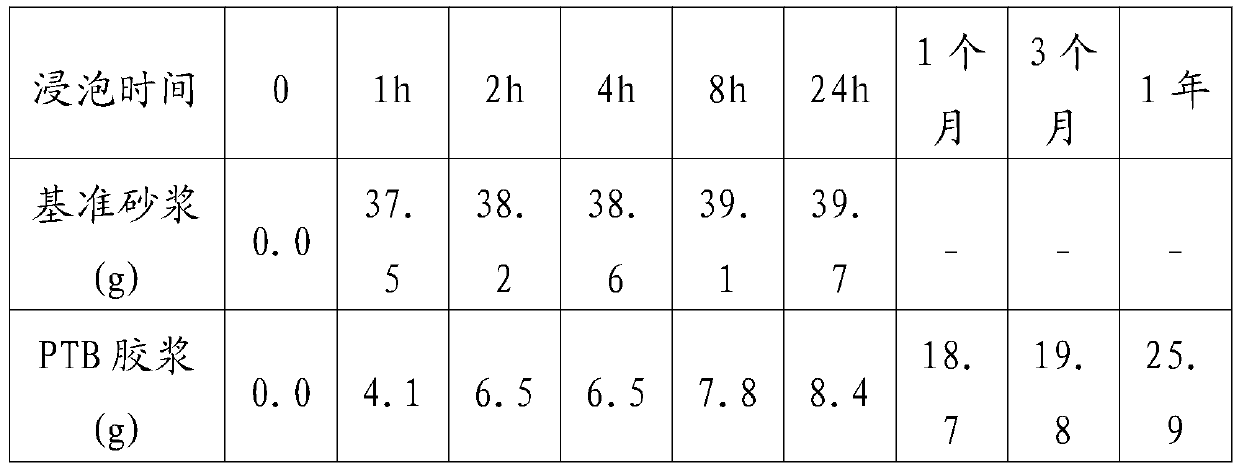

Rustproof and environment-friendly cement-based material as well as preparation method and application thereof

ActiveCN110746167AImprove stabilityIncreased durabilityLiquid surface applicatorsCoatingsCalcium hydroxideEmulsion

The invention discloses a rustproof and environment-friendly cement-based material as well as a preparation method and application thereof. The rustproof and environment-friendly cement-based materialconsists of sodium carbonate (Na2CO3), calcium hydroxide (Ca(OH)2), sand, slag, a PTB (polytechnisch bedrijf) emulsion and water, wherein the mass percentages of the components are as follows: 1.2-3.2% of Na2CO3, 0.8-2.2% of Ca(OH)2, 31.6-68.2% of sand, 20.2-46.6% of slag, 3.1-5.7% of the PTB emulsion and 6.5-10.7% of water; and the sum of mass percentages of the components is 100%. The rustproofand environment-friendly cement-based material disclosed by the invention has the advantages of being good in environmental protection, good in workability, short in setting time, high in early strength, good in water resistance, excellent in adhesion and durability, and the like, and has a good market application prospect.

Owner:福州市宇心建材科技有限公司

A kind of nano crystal seed accelerator and preparation method thereof

Provided is a nano seed crystal early strength agent and a preparation method thereof. The method comprises the steps of first preparation of high molecular polymer dispersion liquid, and then the preparation of the nano seed crystal early strength agent; the high molecular polymer dispersion liquid is prepared from, by weight, 100 parts of polyether macromonomer, 2.5-4.5 parts of silane couplingagent, 7.5-12 parts of unsaturated carboxylic acid, 0.4-0.6 part of chain transfer agent, 0.6-1.2 parts of evocating agent and deionized water; the polyether macromonomer is one of prenol polyethyleneglycol monomethyl ether and methyl allyl alcohol polyethylene glycol monomethyl ether; the silane coupling agent is vinyl triethoxysilane, the unsaturated carboxylic acid is one of acrylic acid, methacrylic acid and fumaric acid, the chain transfer agent is mercaptopropionic acid, and the evocating agent is at least one of ascorbic acid and hydrogen peroxide. The invention also provides a preparation method. The agent has obvious early strength effect on concrete, effectively shortens the demoulding time of the concrete, and improves the mold turnover rate and the production efficiency.

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

A kind of bleeding-reducing concrete admixture and preparation method thereof

The invention relates to the technical field of building materials, in particular to a bleeding-reducing concrete admixture and a preparation method thereof, wherein the preparation method includes the following preparation steps: adding quicklime to the original ready-mixed concrete waste slurry to perform pressure filtration treatment to obtain a pre-mixed concrete admixture. Mixing waste concrete slurry press filter residue; adding the ready-mix waste concrete slurry filter residue and grinding aid into a ball mill for ball milling to obtain ready-mix waste concrete slurry powder; mixing the ready-mix waste concrete slurry powder and pulverized coal The ash is mixed and stirred to prepare the bleeding-reducing concrete admixture. The invention uses the waste cement slurry produced by the ready-mixed concrete in the concrete mixing plant, and uses it as a raw material to prepare an admixture with reduced bleeding performance, which reduces the amount of other admixtures such as silica fume and mineral powder, and reduces the cost of concrete ; At the same time, high-value reuse of waste slurry from mixing plants has good economic and environmental effects, and is in line with the concept of sustainable development.

Owner:KZJ NEW MATERIALS GROUP CO LTD

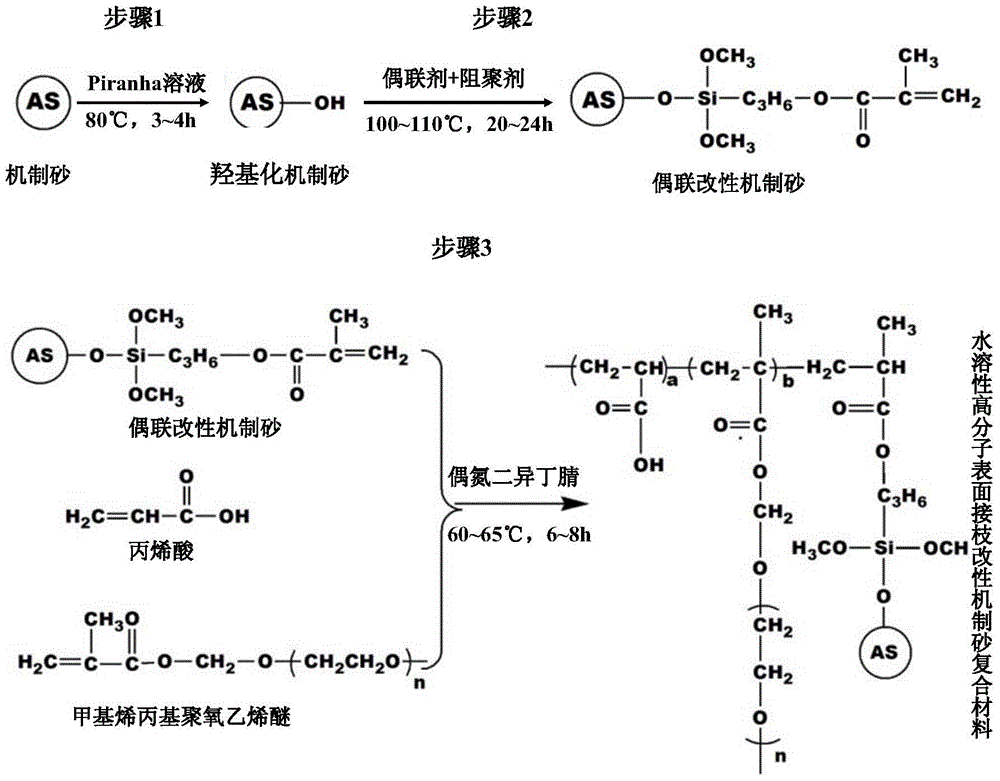

A kind of preparation method of water-soluble polymer surface graft modification machine-made sand

Owner:HEFEI UNIV OF TECH

Environment-friendly fair-faced concrete pumping agent and preparation method thereof

InactiveCN111268939ASimple manufacturing methodImprove production efficiencyPhosphoric Acid EstersEpoxy

The invention discloses an environment-friendly fair-faced concrete pumping agent which comprises the following components in parts by weight: 1 to 3 parts of epoxy group single-terminated silicone oil modified casein, 1 to 3 parts of dihydro- 2,4,6-trioxo-1,3,5-triazine-1,3-(2H,4H)-dipropionic acid / 2-(diethanolamine) sodium ethanesulfonate polycondensate, 2 to 4 parts of humic acid, 0.1 to 0.3 part of phosphate modified starch, 0.2 to 0.5 part of an antifoaming agent, 0.5 to 1.5 parts of magnesite powder, 0.5 to 1.5 parts of sucrose octasulphate sodium and 35 to 45 parts of water. The invention further discloses a preparation method of the environment-friendly bare concrete pumping agent. The environment-friendly fair-faced concrete pumping agent disclosed by the invention can effectivelyimprove the phenomenon of honeycomb pitted surfaces on the surface of fair-faced concrete; according to the pumping agent, the workability and fluidity of concrete in the pumping process are guaranteed, the slump retaining and water reducing effects are remarkable, the mixing amount is small, fair-faced concrete using the pumping agent does not bleed water and is good in impermeability, waterproofness and frost resistance, and the pumping agent is environmentally friendly in the preparation and use process and high in economic value, social value and ecological value.

Owner:路雪芹

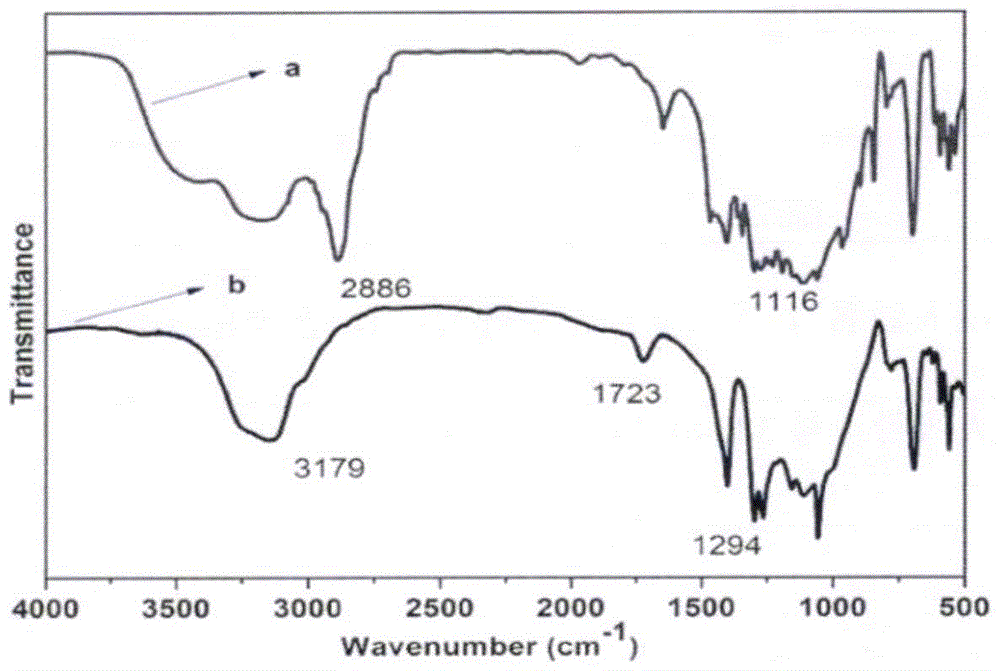

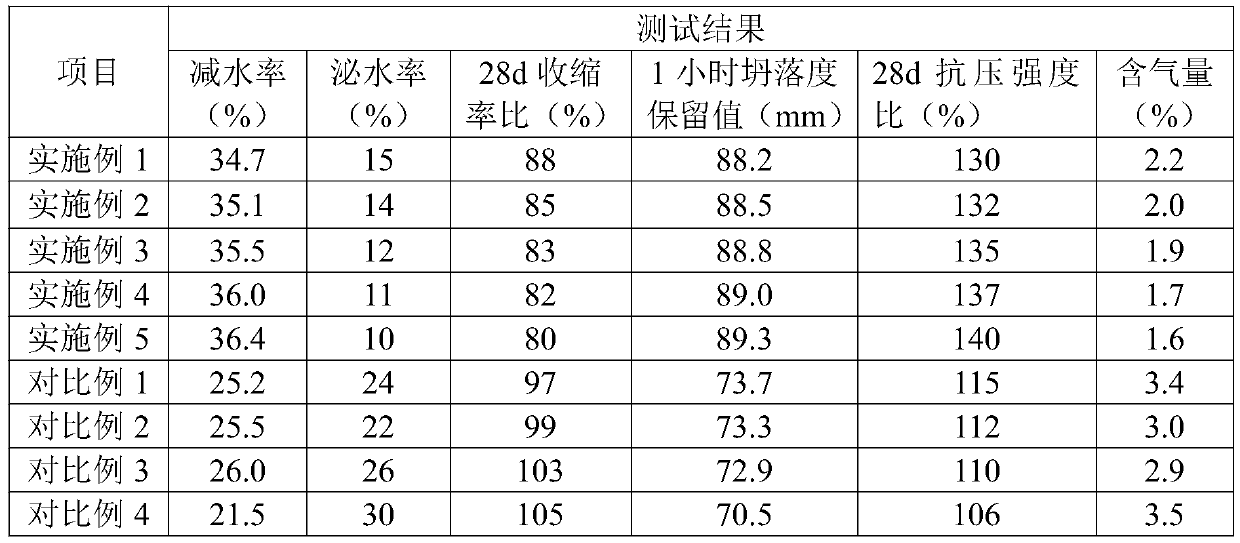

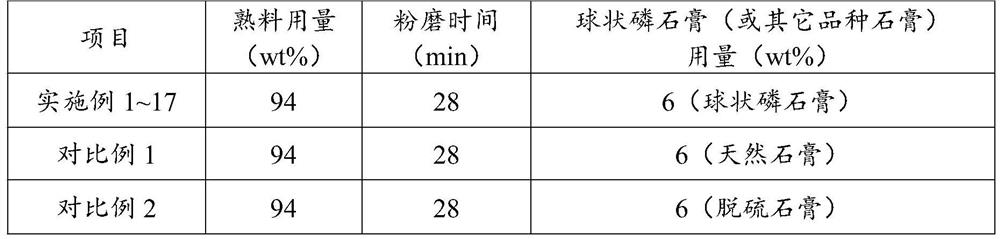

Spherical phosphogypsum as well as preparation method and application thereof

The invention relates to the technical field of comprehensive utilization of solid wastes, and provides spherical phosphogypsum as well as a preparation method and application thereof. The spherical ardealite provided by the invention is prepared from the following raw materials: ardealite powder, cement and a modifier, wherein the modifier comprises alkaline lignin and / or ferrous sulfate. The spherical ardealite provided by the invention is high in physical strength, is not easy to break, and has a good retarding effect, when the modifier comprises lignin, the spherical ardealite can also improve the cement strength and reduce mixing water, and when the modifier comprises ferrous sulfate, the spherical ardealite can also reduce the content of water-soluble hexavalent chromium in cement. The spherical ardealite provided by the invention has a large amount of ardealite powder, is conducive to promoting the balance of production and elimination of ardealite, and fundamentally solves the ecological environmental protection problem caused by ardealite. Furthermore, the alkaline lignin is from the papermaking black liquid, the ferrous sulfate is from the titanium dioxide waste residues, and resource utilization of the papermaking black liquid and the titanium dioxide waste residues can be achieved.

Owner:HUBEI XINYANGFENG NEW BUILDING MATERIAL TECH CO LTD

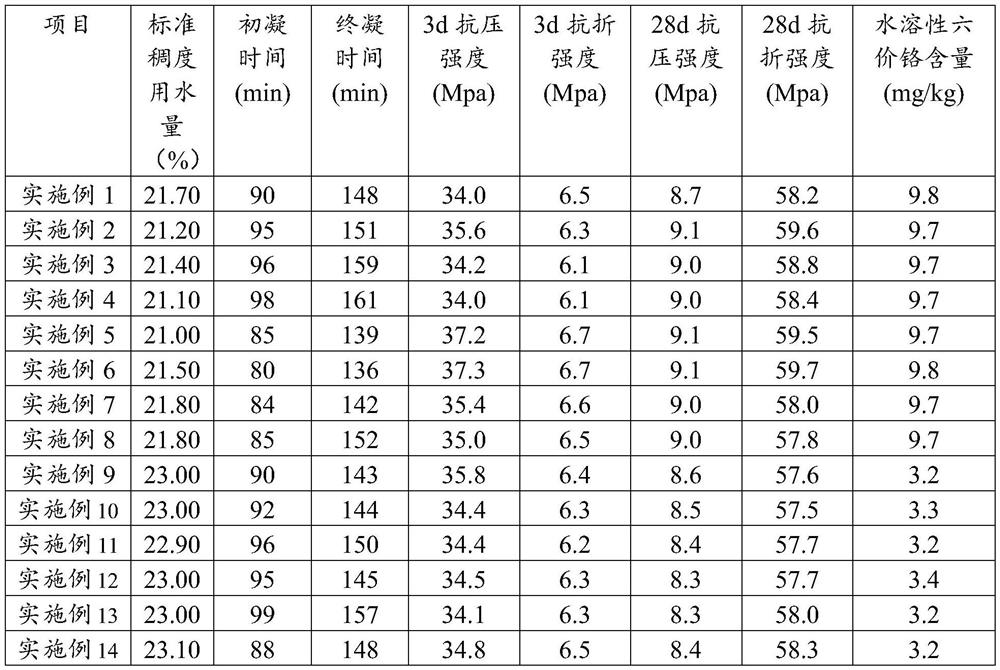

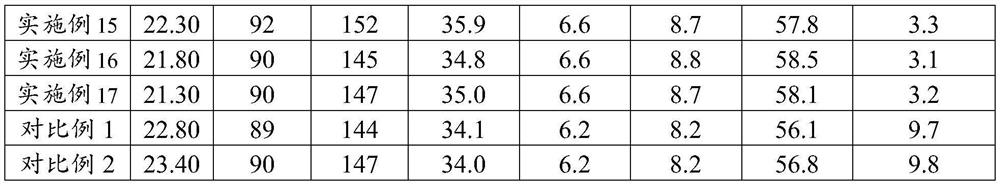

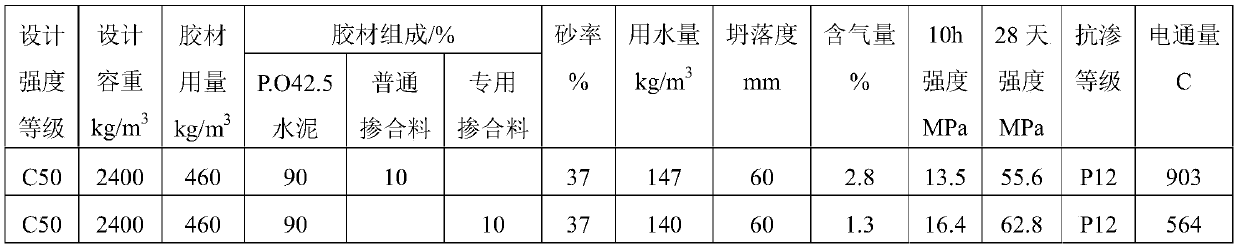

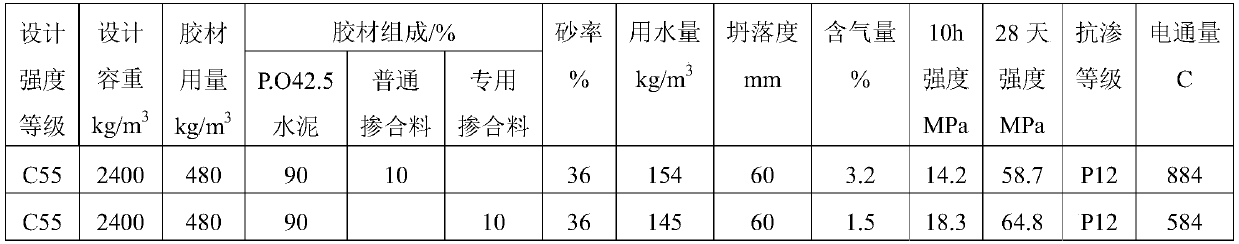

A special admixture for water-reducing type steam curing shield tunnel segment concrete

ActiveCN106830737BImprove early strengthReduce demoulding timeStructural engineeringUltimate tensile strength

The invention relates to an admixture special for water-reducing type autoclaving-free shield segment concrete. The admixture is prepared from the following components in parts by weight: 50 to 100 parts of coal ash microbeads, 5 to 30 parts of silicon ash, 1 to 10 parts of early strength agent and 0.1 to 2 parts of defoaming agent. Compared with the prior art, the special admixture disclosed by the invention has a certain water reducing function; by doping the admixture, the early strength of the shield segment concrete can be improved remarkably under the condition of normal maintenance, the demolding time is shortened, meanwhile long-term mechanical performance and durability are not influenced, the anti-seepage performance of the shield segment concrete is improved, the viscosity of the shield segment concrete is lowered, the surface bubble situation of a shield segment is improved, and the appearance of the shield segment is improved at a certain degree.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com