A special admixture for water-reducing type steam curing shield tunnel segment concrete

A shield segment, steam-free curing technology, applied in the field of concrete admixtures, can solve the problems of unfavorable segment concrete air bubble discharge, concrete viscosity increase, affecting segment installation, etc., to reduce demoulding time and reduce porosity rate, and the effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

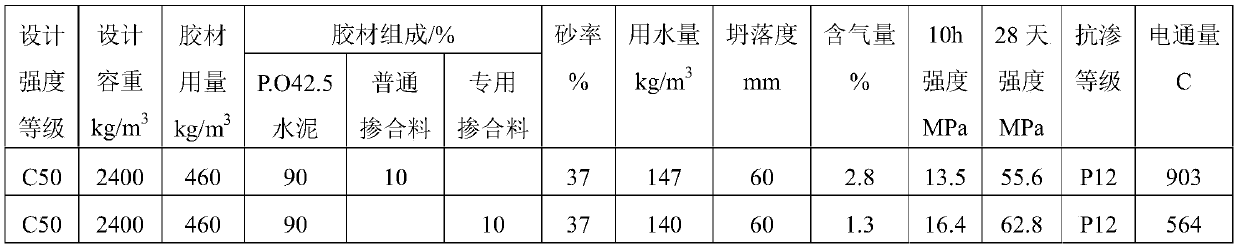

[0030] When P.O42.5 cement is used for cement, C50 segment concrete is made with water-reducing non-steam curing shield segment concrete admixture.

[0031] 1) Preparation of special admixture for water-reducing non-steam curing shield segment concrete

[0032] Prepare water-reducing non-steam curing shield segment concrete admixture according to the ratio of each component in Table 1.

[0033] Table 1 The mass percent of each component of the admixture

[0034] Example Fly Ash Microbeads Silica fume early strength agent Defoamer 1 82% 10% 7% 1%

[0035] Fly ash microbeads are global, continuous gradation distribution, ultrafine, solid, aluminosilicate fly ash microbeads, the water demand ratio is less than 90%, and the 28-day activity index is greater than 110%. The fly ash microbeads of this implementation select the "fine microbeads" product of Shenzhen Daote Technology Co., Ltd.

[0036] The specific surface area of silica fume in the pres...

Embodiment 2

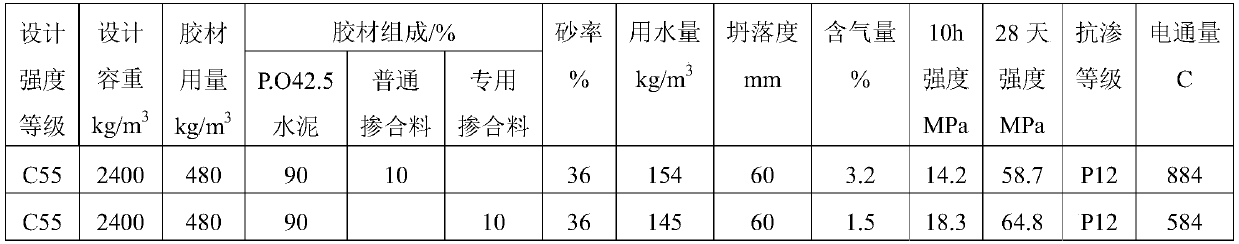

[0044] When P.O42.5 cement is used for cement, C55 segmental concrete is made with water-reducing non-steam curing shield segmental concrete admixture.

[0045] 1) Preparation of special admixture for water-reducing non-steam curing shield segment concrete

[0046] Prepare water-reducing non-steam curing shield segment concrete admixture according to the ratio of each component in Table 3.

[0047] Table 3 The mass percentage of each component of the admixture

[0048] Example Fly Ash Microbeads Silica fume early strength agent Defoamer 2 83% 9% 7% 1%

[0049] Fly ash microbeads are global, continuous gradation distribution, ultrafine, solid, aluminosilicate fly ash microbeads, the water demand ratio is less than 90%, and the 28-day activity index is greater than 110%. The fly ash micro-beads of this embodiment select the "fine micro-beads" product of Shenzhen Daote Technology Co., Ltd.

[0050] The specific surface area of silica fume in the ...

Embodiment 3

[0059] When the cement is P.II52.5 cement, use the special admixture for water-reducing non-steam curing shield segment concrete to make C50 segment concrete.

[0060] 1) Preparation of special admixture for water-reducing non-steam curing shield segment concrete

[0061] Prepare water-reducing non-steam curing shield segment concrete admixture according to the ratio of each component in Table 5.

[0062] Table 5 The mass percentage of each component of the admixture

[0063]

[0064]

[0065] Fly ash microbeads are global, continuous gradation distribution, ultrafine, solid, aluminosilicate fly ash microbeads, the water demand ratio is less than 90%, and the 28-day activity index is greater than 110%. The fly ash microbeads of this implementation select the "fine microbeads" product of Shenzhen Daote Technology Co., Ltd.

[0066] The specific surface area of silica fume in the present embodiment is at 15000m 2 / kg~20000m 2 / kg range, the 28-day activity index is g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com