Preparation method of slump retaining type aliphatic water reducing agent

An aliphatic water-reducing agent and slump-preserving technology, which is applied in the field of preparation of slump-preserving aliphatic water-reducing agents, can solve the problems of low dosage, low sodium sulfate content, poor slump-preserving performance and adaptability, etc. Good, prevent hydration, improve the effect of slump retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

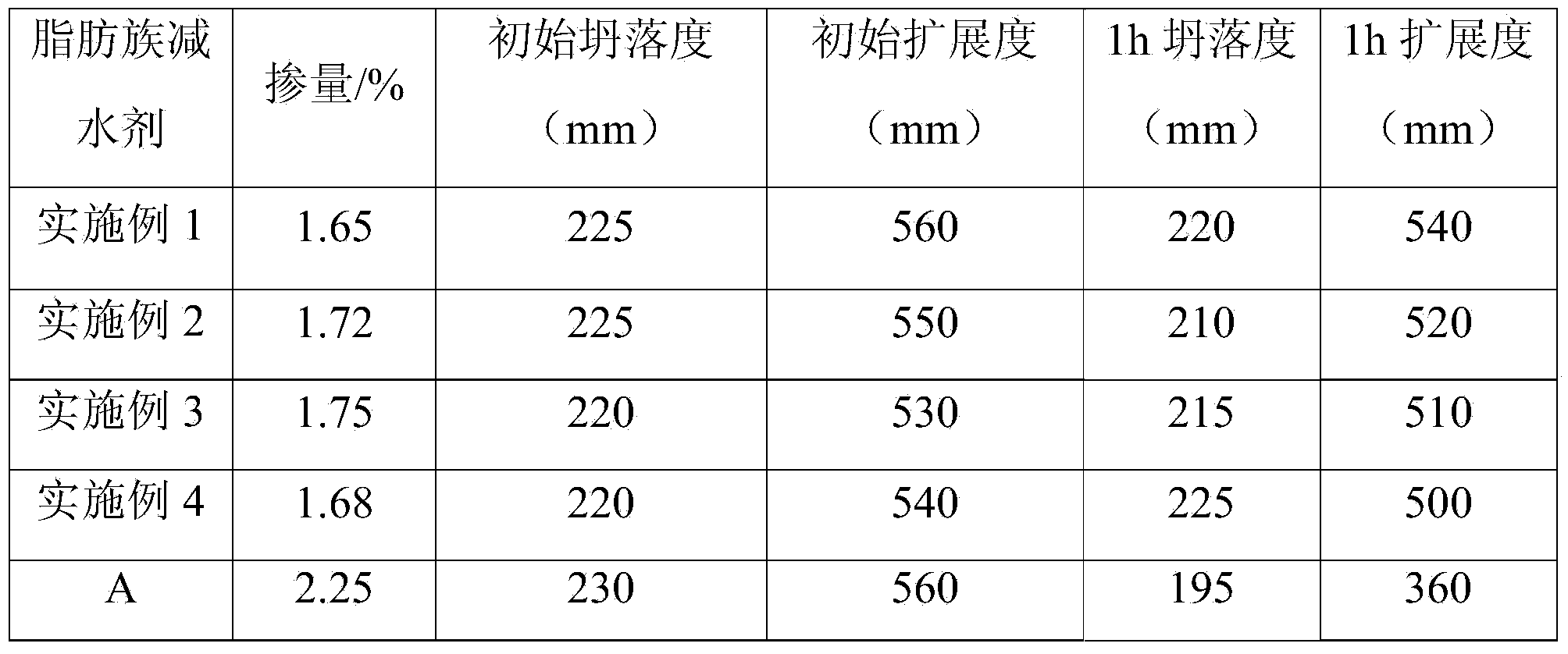

Examples

Embodiment 1

[0036] (1) prepare modified starch ether, specifically as follows:

[0037] a, get starch, add water and be mixed with the starch milk that the weight percentage composition of starch is 30%;

[0038] b. Add concentrated sulfuric acid with 3% starch weight in starch milk, stir evenly, then slowly add potassium permanganate solution with a concentration of 5%, wherein the amount of potassium permanganate added is 6% starch weight, at 35°C Stir and react for 3 hours at a certain temperature, add precipitant methanol after the solution becomes pure white, pour the precipitate and solution into a sand core crucible for vacuum filtration, and wash repeatedly with methanol for 3 times, and dry the filter cake at 40°C , to produce oxidized starch;

[0039] c. Disperse the oxidized starch in absolute ethanol, prepare a suspension with a weight percentage of oxidized starch of 30%, adjust the pH value of the suspension to 9 with lye, and then add ethylene oxide and anhydrous ethanol t...

Embodiment 2

[0046] (1) prepare modified starch ether, specifically as follows:

[0047] A, get starch, add water and be mixed with the starch milk that the weight percentage composition of starch is 35%;

[0048] b. Add concentrated sulfuric acid with 2% starch weight in starch milk, stir evenly, then slowly add hydrogen peroxide solution with a concentration of 35%, wherein the amount of hydrogen peroxide added is 5% starch weight, at a temperature of 40°C Stir and react for 3 hours, add precipitant methanol after the solution becomes pure white, pour the precipitate and solution into a sand core crucible for vacuum filtration, and wash repeatedly with methanol for 3 times, and dry the filter cake at 40°C with air blast to prepare get oxidized starch;

[0049] c. Disperse the oxidized starch in absolute ethanol, prepare a suspension with a weight percentage of oxidized starch of 30%, adjust the pH value of the suspension to 10 with lye, then add ethylene oxide and absolute ethanol to mi...

Embodiment 3

[0056] (1) prepare modified starch ether, specifically as follows:

[0057] A, get starch, add water and be mixed with the starch milk that the weight percentage composition of starch is 40%;

[0058] b. Add concentrated sulfuric acid with 3% starch weight in starch milk, stir evenly, then slowly add sodium hypochlorite solution with a concentration of 9%, wherein the amount of sodium hypochlorite added is 10% starch weight, and stir for 3 hours at a temperature of 40°C , after the solution becomes pure white, add methanol as a precipitating agent, pour the precipitate and solution into a sand core crucible for vacuum filtration, and repeatedly wash with methanol for 3 times, and dry the filter cake at 40°C by blowing air to obtain oxidized starch;

[0059] c. Disperse the oxidized starch in absolute ethanol, prepare a suspension with a weight percentage of oxidized starch of 30%, adjust the pH value of the suspension to 10 with lye, then add ethylene oxide and absolute ethano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nominal particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com