Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Guaranteed seal strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

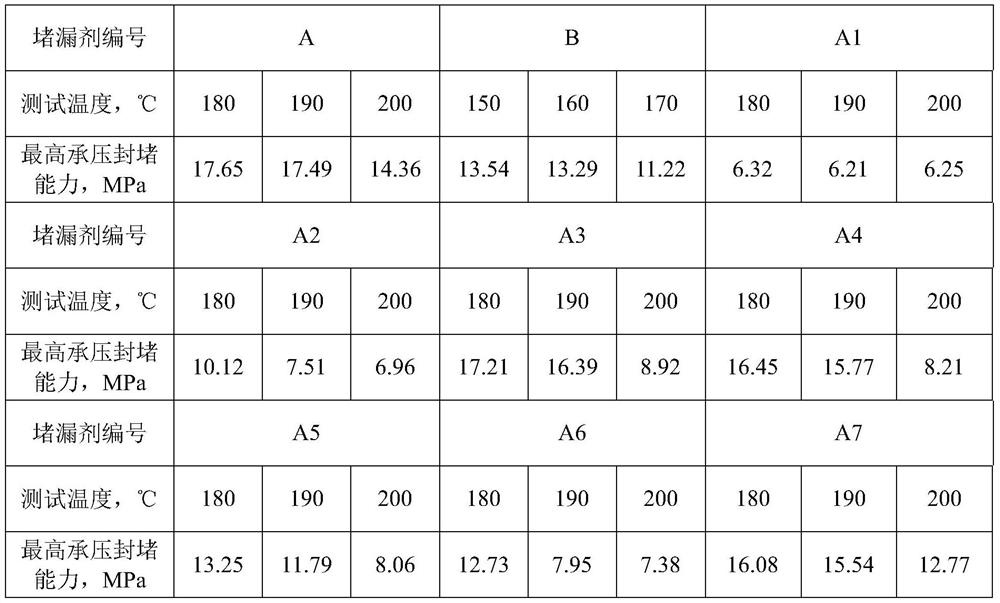

Composite temporary plugging agent for refracturing of horizontal well and temporary plugging method

ActiveCN107245330AImprove seal strengthImprove the blocking effectDrilling compositionSealing/packingFiberPolyester

The invention provides a composite temporary plugging agent for refracturing of a horizontal well. The composite temporary plugging agent comprises a component A and a component B, wherein the component A is selected from at least one type of polyester polymers; the component B is selected from at least one type of acrylamide polymers, polymethyl fibers and polyvinyl alcohol. The composite temporary plugging agent has quick temporary plugging and lasting temporary plugging functions.

Owner:北京斯迪莱铂油气技术有限公司

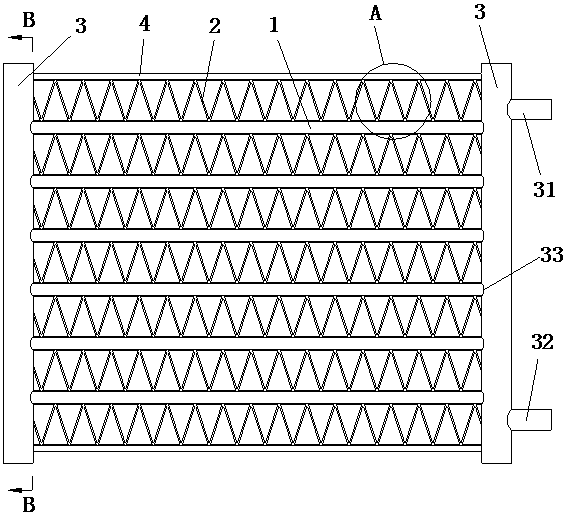

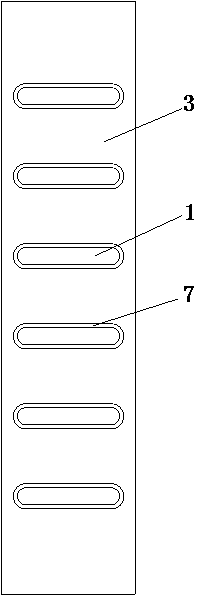

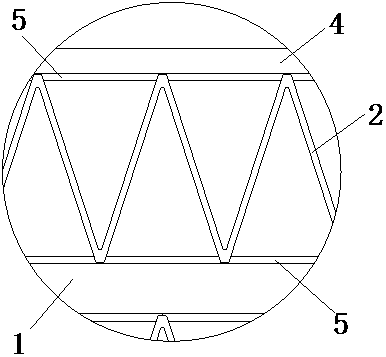

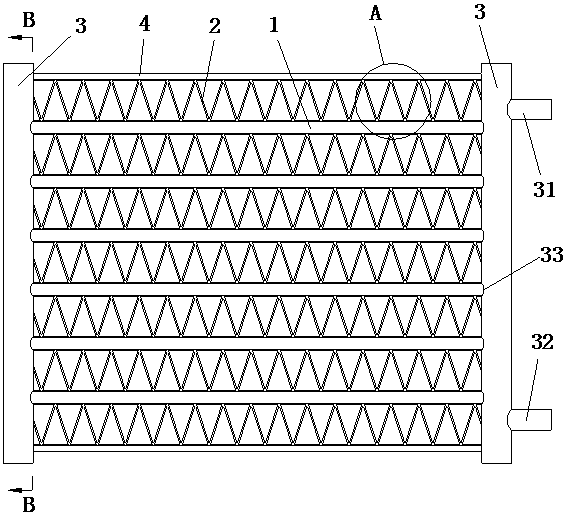

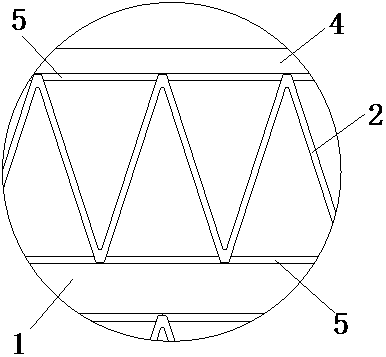

Wave finned heat exchanger and manufacturing method thereof

InactiveCN106524785AElimination of finless areasImprove heat transfer effectStationary conduit assembliesHeat exhanger sealing arrangementAdhesive cementEngineering

The invention discloses a heat exchanger and a manufacturing method thereof. The heat exchanger is characterized by comprising flat tubes, fins and liquid collection cavities, wherein the flat tubes and the fins are alternately arranged, and in addition, each flat tube is adhered to the corresponding fin through a first adhesive layer; the side wall of each liquid collection cavity is provided with a plurality of sequentially arranged slot holes; the two ends of each flat tube are inserted into the corresponding slot holes respectively; the end parts of each flat tube are adhered to the corresponding slot holes by second adhesive layers in a sealing manner respectively; or the liquid collection cavities are formed by stacking the ends of the flat tubes; and in addition, the ends of two adjacent flat tubes are adhered to each other by the corresponding second adhesive layer in the sealing manner. According to the heat exchanger, the adhesion effects between each flat tube and the corresponding fin as well as between each flat tube and the corresponding liquid collection cavity are both stable and firm, the sealing strength between each flat tube and the corresponding liquid collection cavity is fully guaranteed, and the heat exchange performance of the heat exchanger can also be greatly improved.

Owner:谢彦君

Wavy fin type heat exchanger and manufacturing method thereof

InactiveCN106247821AElimination of finless areasImprove heat transfer effectStationary conduit assembliesHeat exhanger sealing arrangementPulp and paper industryUltimate tensile strength

The invention discloses a heat exchanger and a manufacturing method thereof. The heat exchanger comprises a plurality of flat tubes, a plurality of groups of fins, and at least two liquid collection cavities, wherein the flat tubes and the fins are sequentially arranged at intervals; the flat tubes and the fins are bonded through a first adhesive layer; a plurality of sequentially arranged slot holes are formed in the side walls of the liquid collection cavities; the two ends of the flat tubes are inserted into the corresponding slot holes; the end parts of the flat tubes and the slot holes are bonded and sealed through a second adhesive layer; or the liquid collection cavities are formed through stacking the ends of the flat tubes; and the ends of every two adjacent flat tubes are bonded and sealed through the second adhesive layer. According to the heat exchanger, a stable and firm bonding effect is achieved between the flat tubes and the fins, and between the flat tubes and the liquid collection cavities, the sealing strength between the flat tubes and the liquid collection cavities is fully guaranteed, and the heat exchange performance of the heat exchanger can be greatly improved.

Owner:谢彦君

High-temperature-resistant and high-pressure-bearing packer special for oil drilling

The invention provides a high-temperature-resistant and high-pressure-bearing packer special for oil drilling. The high-temperature-resistant and high-pressure-bearing packer comprises an upper connector, a pressing cap, a trapezoidal sealing ring, a central pipe, an upper plastic cylinder seat, an upper plastic cylinder, a spacer ring, a middle plastic cylinder, a bushing, a lower plastic cylinder, a bushing shear pin, a lower plastic cylinder seat, a fixing screw, an adjusting sleeve, an upper piston, an upper cylinder sleeve, a sealing ring, an O-shaped sealing ring, a lower piston, a lower cylinder sleeve and a centralizer connector. The upper end of the central pipe is connected with a backwashing valve assembly, the upper end of the backwashing valve assembly is connected with the upper connector, the backwashing valve assembly comprises a backwashing valve seat and a valve body, the valve body is sleeved with the backwashing valve seat, the bushing shear pin is connected between the valve body and the backwashing valve seat, the backwashing valve seat is provided with a backwashing well arched passageway, and the backwashing well arched passageway comprises the pressing cap, the central pipe, the bushing and the lower plastic cylinder seat. By means of the high-temperature-resistant and high-pressure-bearing packer, in the seat seal process, an annular sealing oil sleeve space is divided into an upper-layer segment and a lower-layer segment, the backwashing well arched passageway rapidly unseals the packer, and inverse well-flushing, sand washing and the like are conducted.

Owner:天津市正瀚石油设备制造有限公司

Composition containing polyglycolic acid and application of composition

ActiveCN111748331AReduce harmImprove power efficiencyDrilling compositionPolymer scienceGlycolic acid

The invention discloses a composition containing polyglycolic acid and an application of the composition. The composition is prepared from the following raw materials: polyglycolic acid, a functionalthickener and a degradation regulator, wherein the polyglycolic acid is a homopolymer of glycolic acid or / and a copolymer taking glycolic acid as a main repeating unit. The composition can be used forfracturing modification of oil and gas fields.

Owner:PUJING CHEM IND SHA

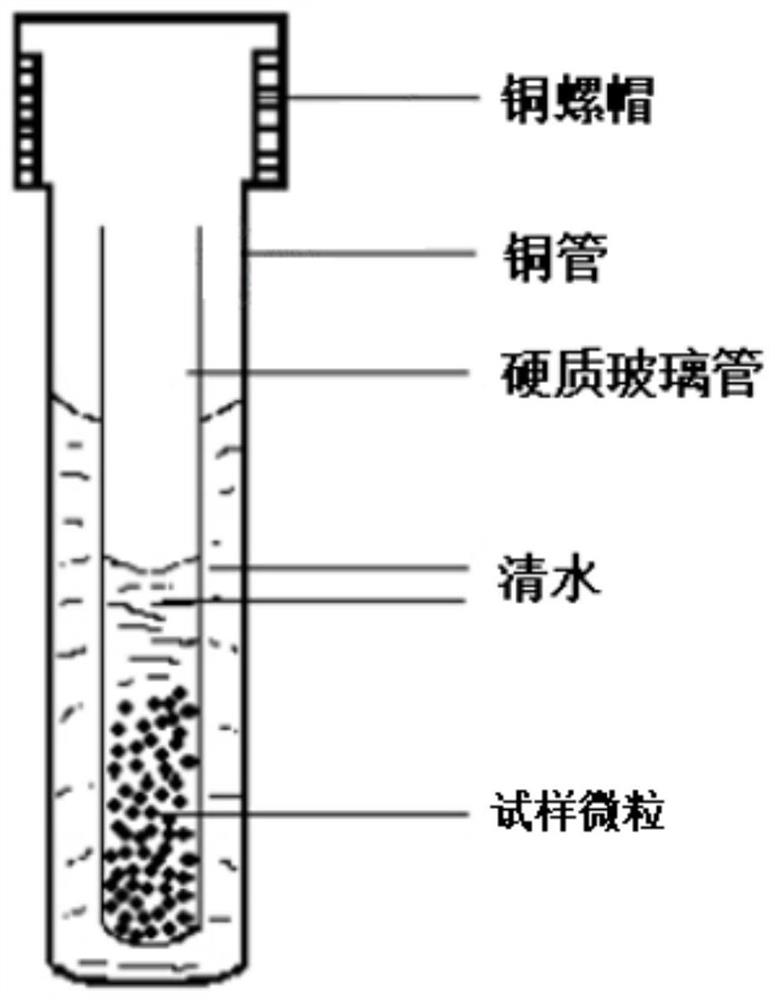

Temperature-sensitive adhesion type resin plugging agent as well as preparation method and application thereof

ActiveCN113150756AEnhance residencyImprove overall strengthDrilling compositionPigment treatment with organosilicon compoundsMelt temperaturePolymer chemistry

The invention provides a temperature-sensitive adhesion type resin plugging agent as well as a preparation method and application thereof. The temperature-sensitive adhesion type resin plugging agent comprises the following raw materials in parts by mass: 75-90 parts of a thermoplastic resin matrix, 5-15 parts of a melting temperature regulator, 2-8 parts of an organic lipid melting range regulator, 0.5-6 parts of a modified solid-phase filling melting range regulator and 0-30 parts of a modified density regulator. According to the temperature-sensitive adhesion type plugging agent disclosed by the invention, different types of thermoplastic resins are taken as matrixes, when the temperature reaches the melting point of plugging agent particles in a water phase, the surfaces of the plugging agent particles start to melt and have certain viscosity, the plugging agent particles can be mutually adhered, and the plugging agent particles can also be adhered to the wall surface of a drilling fluid leakage channel; the retention capacity of the plugging agent in a leakage channel is enhanced, the overall strength of the plugging agent among particles of a plugging layer is improved, the plugging agent is not prone to being influenced by pressure fluctuation, the one-time plugging success rate is increased, and re-leakage is effectively avoided.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Dustproof rod end joint bearing and dustproof rod end joint bearing production method

ActiveCN110735855AGuaranteed tightnessEnsure connection stabilityBearing componentsSliding contact bearingsStructural engineeringMechanical engineering

The invention provides a dustproof rod end joint bearing and a dustproof rod end joint bearing production method. The dustproof rod end joint bearing and the dustproof rod end joint bearing productionmethod can solve the problems of the weak sealing effect and weak reliability caused by easy falling due to influences on a sealing cover by external force in the prior art. The dustproof rod end joint bearing comprises a rod end body provided with a rod end hole, a bearing outer ring, a bearing inner ring, a dustproof cover comprising an inner edge and an outer edge positioned at the inner and outer peripheries of a ring body correspondingly, an inner edge support structure arranged near the bearing inner ring, and an outer edge support structure arranged near the bearing outer ring and comprising a fixed support ring; the fixed support ring is fixed on the rod end body or on the bearing outer ring or between the rod end body and the bearing outer ring, and is clamped and fixed by the rod end body and the bearing outer ring; and fixed matching surfaces are arranged on the inner peripheral surface and / or the outer peripheral surface of the fixed support ring, and are used for being infixed sealing connection with the outer edge of the dustproof cover to form peripheral surface sealing between the dustproof cover and the fixed support ring.

Owner:台州科锦轴承有限公司 +1

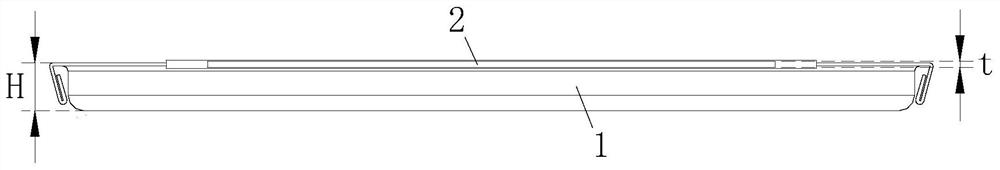

HEV soft package battery cell and battery pack

InactiveCN112349950AGuaranteed high rate charge and discharge capabilityGuaranteed powerFinal product manufactureLi-accumulatorsPlastic filmBattery cell

The invention provides an HEV soft package battery cell and a battery pack, the HEV soft package battery cell comprises a battery cell main body and a battery cell tab, the battery cell main body is provided with an aluminum-plastic film shell, and a pole group and an electrolyte which are sealed in the aluminum-plastic film shell, the battery cell tab is provided with a positive pole tab and a negative pole tab, one ends of the positive pole tab and the negative pole tab are positioned in the aluminum-plastic film shell and are connected with pole group, and other ends of the positive pole tab and the negative pole tab extend out of the aluminum-plastic film shell. The battery cell is characterized in that the battery cell main body is of a cuboid structure, the length L of the battery cell main body is smaller than or equal to 250 mm, the width W and the thickness H of the battery cell main body meet the conditions that 20%L <= W <= 60%, and 1%L <= H <= 5%L. According to the HEV softpackage battery cell, the high-rate charging and discharging capacity of the battery cell can be guaranteed, the power performance of the battery cell is guaranteed, the safety performance of the battery cell can also be improved, and the HEV soft package battery cell has good practicability.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

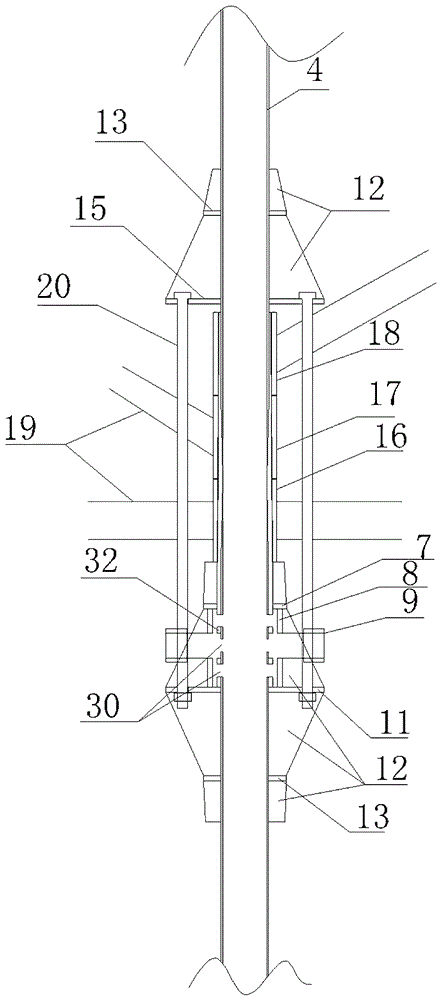

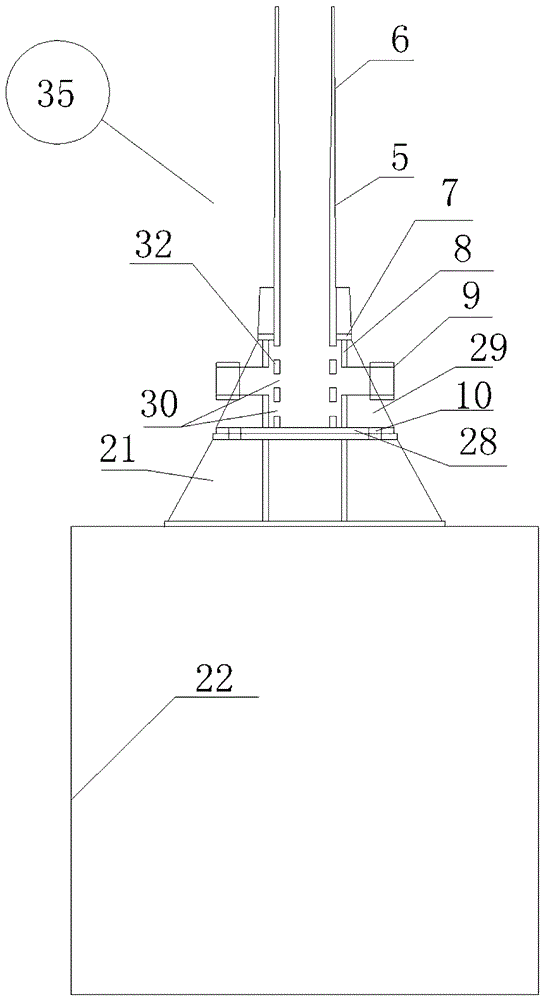

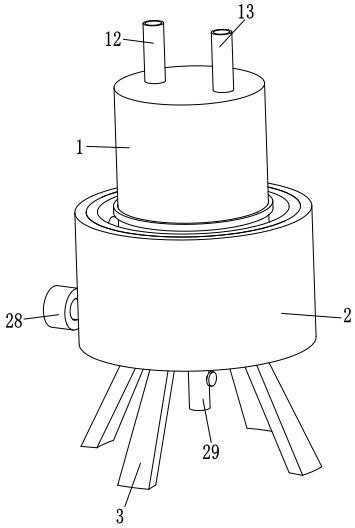

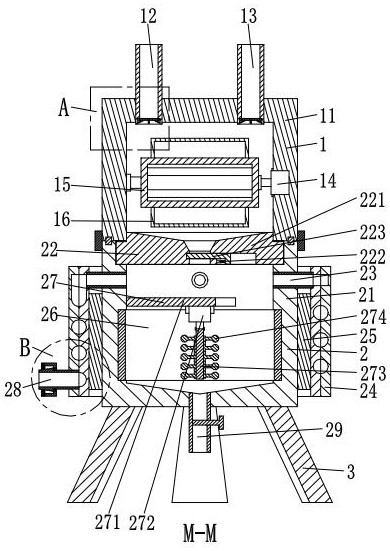

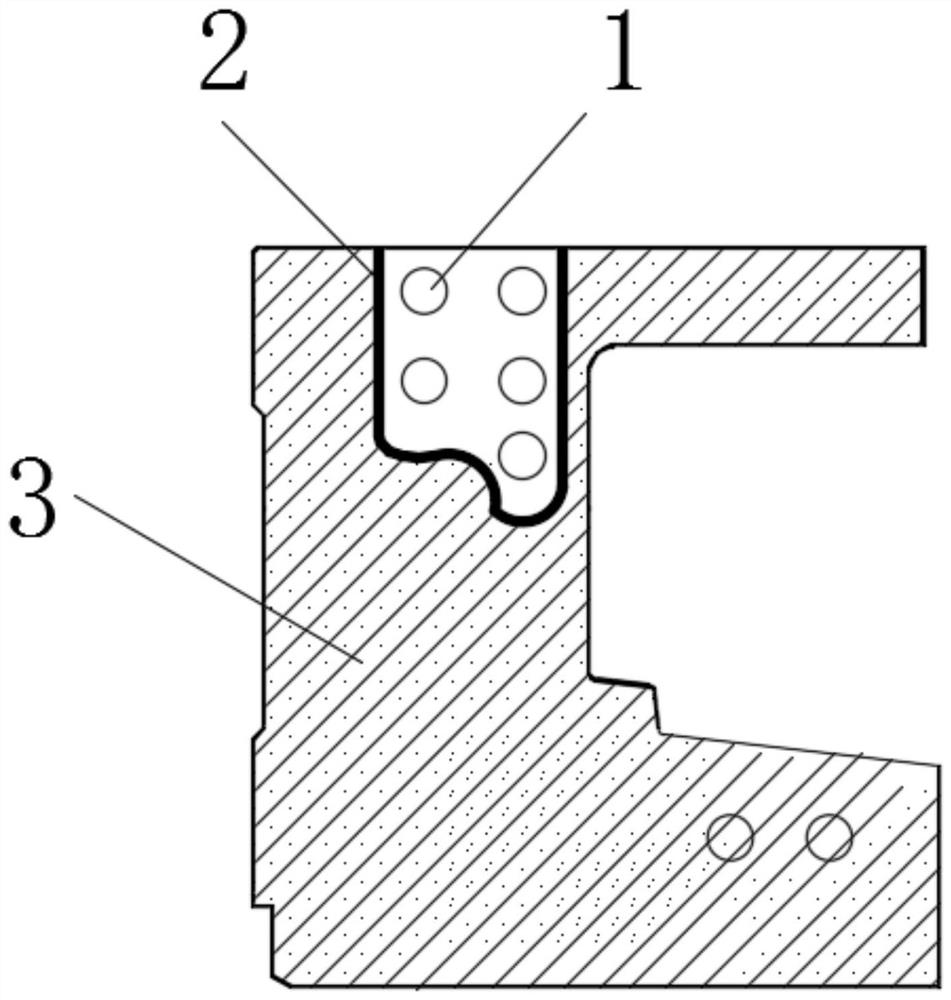

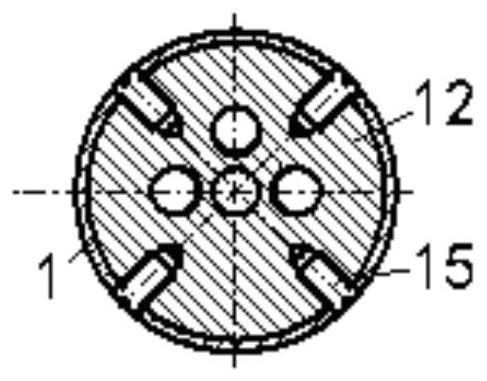

Separate layer fracturing packer

InactiveCN102758596AForce balanceGuaranteed seal strengthSealing/packingDirectional wellField development

The invention relates to the technical field of separate mini-layer fracturing of vertical wells and directional wells for oil and gas field development, in particular to a separate layer fracturing packer. An upper joint, a center cylinder and a lower joint of the separate layer fracturing packer are sequentially connected, an unsetting mechanism, a packing element and a setting mechanism are sequentially sheathed on the center cylinder from top to bottom, the unsetting mechanism and the center cylinder are connected with each other through a slideway and fixed through a shear pin, the setting mechanism comprises a hydraulic cylinder, and a locking mechanism is mounted between the hydraulic cylinder and the lower joint. The separate layer fracturing packer disclosed by the invention has the advantages of great packing and sealing intensity, stable performances and easiness in unsetting, and can meet the requirements of a separate mini-layer fracturing process. The separate layer fracturing packer can overcome the deficiencies of non-tight packing, difficulty in unsetting and incapability of realizing the separate mini-layer fracturing process of the existing packer.

Owner:CNPC GREATWALL DRILLING ENG

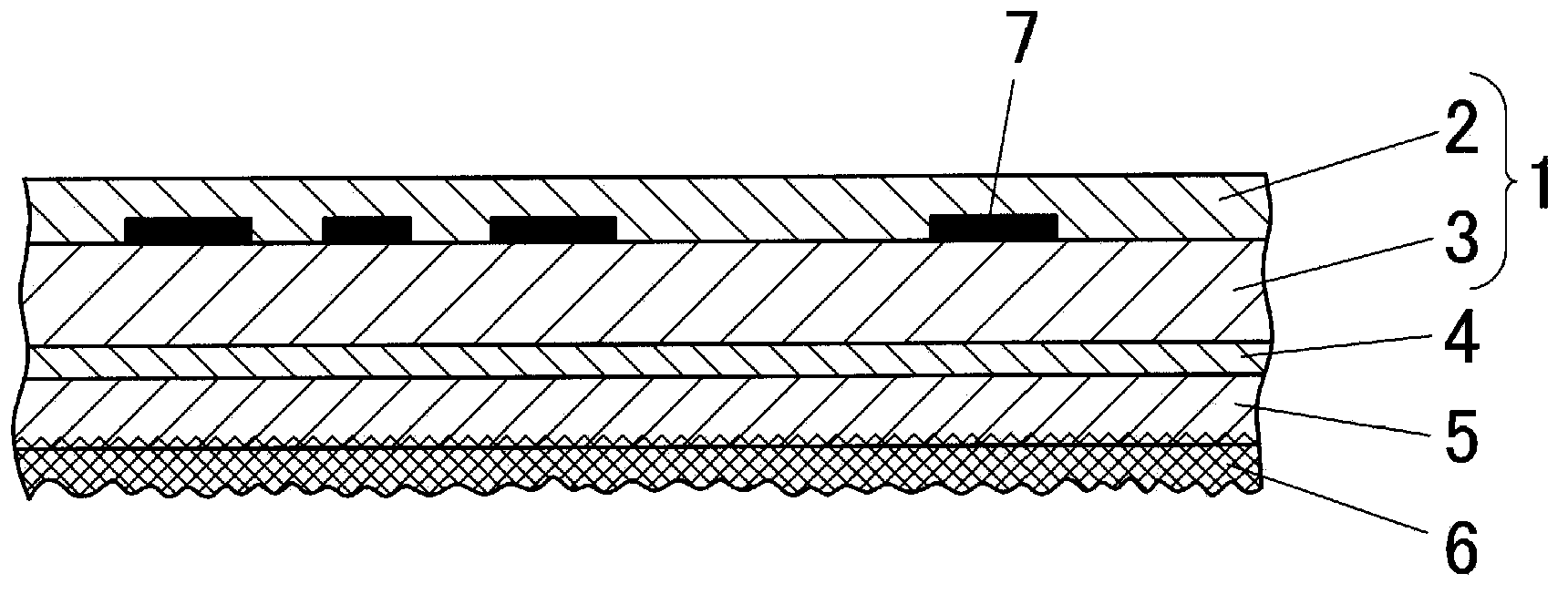

Cover piece for preventing contents adhering

ActiveCN103569491APrevents reduction in anti-adhesion performanceExcellent anti-adhesion performanceSynthetic resin layered productsSealingMaterials scienceViscosity

The invention provides a cover piece for preventing contents adhering. The outer surface of a thermal heating layer (5) stacked on a substrate layer (1) adopts wet silicon dioxide particles to form an anti-adhering layer (6). The wet silicon dioxide particles are formed by conducting hydrophobic treating on polyorganosiloxane having over 100cst of viscosity and especially dimethyl polysiloxane, which are used as treating agents. Or the outer surface of the thermal heating layer (5) stacked on the substrate layer (1) adopts the following wet silicon dioxide particles to form an anti-adhering layer (6). The wet silicon dioxide particles are hydrophobic wet silicon dioxide particles, whose di-n-butylamide adhering amount (DBA adhering amount) is below 200mmol / kg. The cover piece for preventing contents adhering is advantageous in that thermal sealing performance and sealing performance are well maintained; content like yoghourt can be effectively prevented from being adhered to the back face of the cover.

Owner:株式会社乐索纳克包装

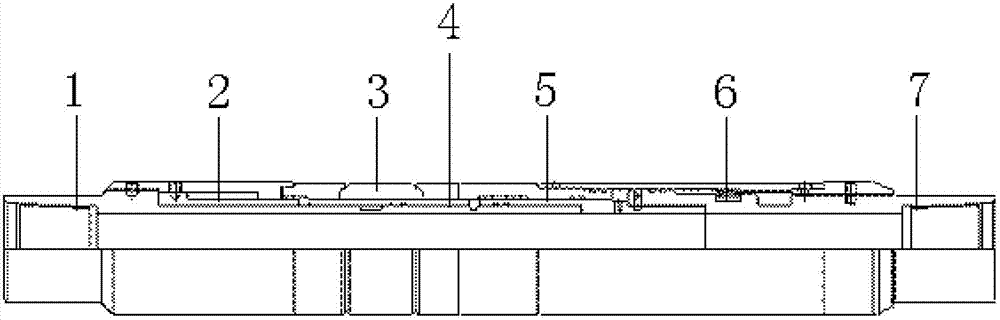

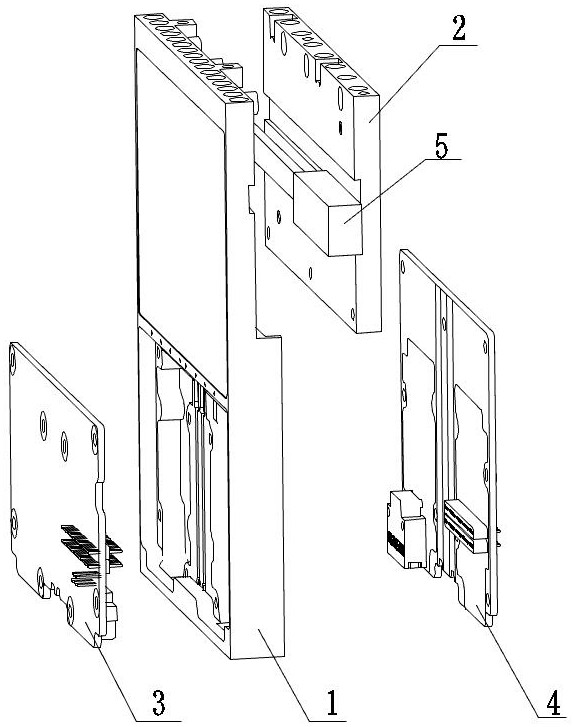

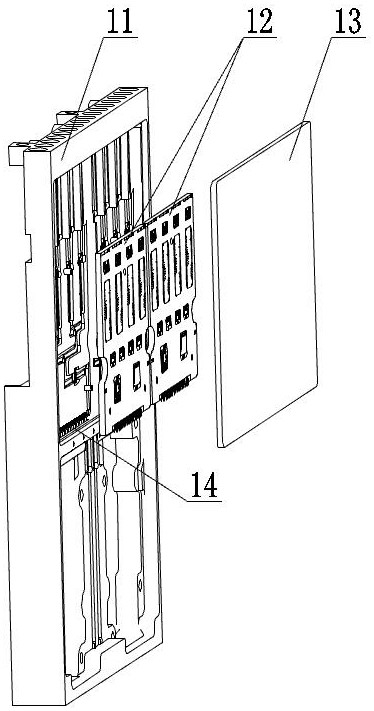

Dual-frequency dual-polarization TR module

ActiveCN113271118AReduce volumeExtended service lifeCircuit arrangements on support structuresTransmissionControl signalBack-to-back connection

The invention discloses a dual-frequency dual-polarization TR module which comprises a first radio frequency processing module, a second radio frequency processing module, a first daughter board and a second daughter board. The first radio frequency processing module and the second radio frequency processing module are connected back to back; both the first radio frequency processing module and the second radio frequency processing module carry out airtight processing; the first daughter board is connected below the first radio frequency processing module, the second daughter board is connected below the second radio frequency processing module, the first daughter board is interconnected with the second daughter board, and the first daughter board or the second daughter board accesses power supply and control signals from the bottom; the first radio frequency processing module and the second radio frequency processing module introduce and output radio frequency signals from the longitudinal direction; and the first radio frequency processing module and the second radio frequency processing module respectively comprise a polarization switching chip. According to the invention, the upper and lower cavities of the radio frequency processing link and the low frequency processing line are arranged in a partitioned manner, so that the thickness space is fully utilized, the integration level of the module is improved, and dual-frequency working and polarization switching capabilities are realized.

Owner:成都雷电微力科技股份有限公司

Button lithium ion battery and shell

PendingCN111341951AIncrease capacityEnsure rigiditySecondary cellsCell sealing materialsElectrical batteryLithium-ion battery

The invention relates to the field of lithium ion batteries, and discloses a button type lithium ion battery and a shell. The shell comprises: a negative electrode shell comprising a negative electrode top cover and a negative electrode shell wall, and the negative electrode shell wall surrounds the edge of the negative electrode top cover, is perpendicular to the negative electrode top cover andis located on one surface of the negative electrode top cover; the sealing ring is sleeved on the negative electrode shell; the positive electrode shell comprises a positive electrode top cover and apositive electrode shell wall, and the positive electrode shell wall surrounds the edge of the lower bottom shell, is perpendicular to the positive electrode top cover and is located on one surface ofthe positive electrode top cover; wherein the anode shell wall is sleeved outside the cathode shell wall, the sealing ring is arranged between the anode shell and the cathode shell at intervals, thetail end of the anode shell wall is an anode shell thick-wall annular section, the anode shell thick-wall annular section is bent and pressed outside the anode shell to form an annular seal, and the wall thickness of the anode shell thick-wall annular section is greater than that of other positions of the anode shell. By adopting the technical scheme, the air tightness of the shell is ensured on the basis of improving the capacity of the button lithium ion battery.

Owner:SHENZHEN GREPOW BATTERY CO LTD

Temperature-sensitive adhesion type bridging leaking stoppage system, leaking stoppage slurry and preparation method and application of temperature-sensitive adhesion type bridging leaking stoppage system and leaking stoppage slurry

ActiveCN113214806AOvercome the problem of plugging failureHigh strengthDrilling compositionComputational materials scienceFiberSlurry

The invention provides a temperature-sensitive adhesion type bridging leaking stoppage system, leaking stoppage slurry and a preparation method and application of the leaking stoppage slurry. The temperature-sensitive adhesion type bridging leaking stoppage system is characterized by being prepared from the following raw materials in percentage by mass: 20 to 50 percent of temperature-sensitive adhesion type resin particles, 20 to 30 percent of rigid particle materials, 20 to 30 percent of elastic particle materials and 10 to 20 percent of fiber materials. The invention also provides a preparation method of the leaking stoppage slurry, which comprises the following steps: adding the temperature-sensitive adhesive resin particles, the rigid particle material and the elastic particle material into clear water or drilling fluid, and stirring at a high speed until the materials are uniformly dispersed; and then adding the fiber material, and stirring at a low speed until the fiber material is uniformly dispersed to obtain the temperature-sensitive adhesion type bridging leaking stoppage slurry. The leaking stoppage slurry provided by the invention is high in one-time leaking stoppage success rate, effectively avoids re-leakage, and overcomes the problems that a stacked leaking stoppage layer formed by a conventional bridging leaking stoppage material in a crack is low in strength and is easily influenced by pressure fluctuation to cause leaking stoppage failure.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

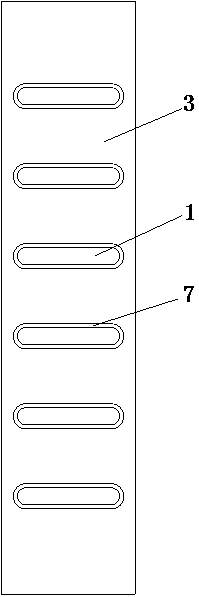

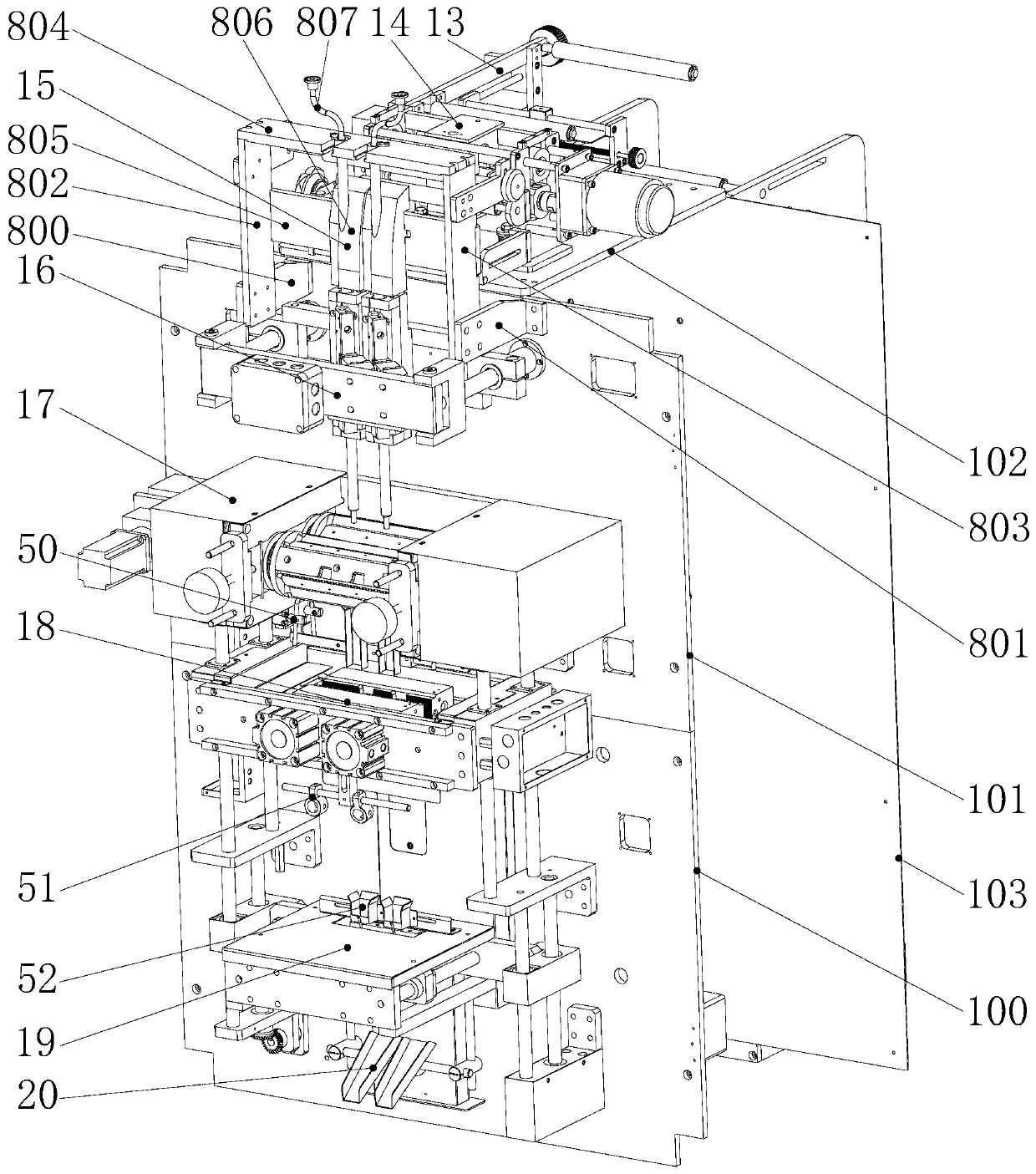

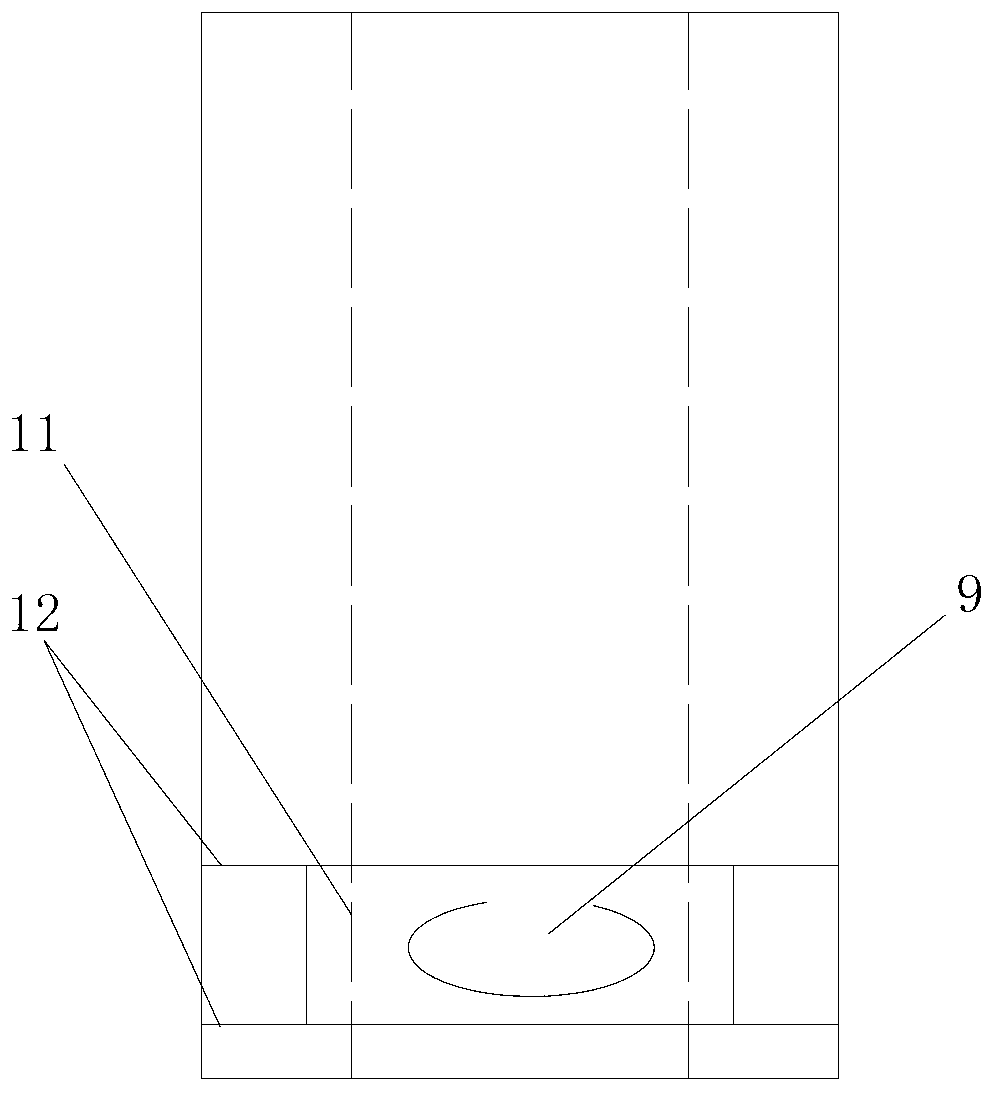

Roller enhancing type strip packing machine

PendingCN110342004AImprove leakageGuaranteed seal strengthWrapping material feeding apparatusWrapper twisting/gatheringColor ScaleThin membrane

The invention relates to a roller enhancing type strip packing machine. According to the moving direction of a film, the strip packing machine comprises a film coiling device, a film connecting device, a film feeding device, a color scale adjusting device, a middle cutting device, a former device, a longitudinal sealing device, a roller device, a transverse sealing device and a cutting device, wherein the film coiling device, the film connecting device and the film feeding device are arranged on the rear side of a rear plate. The front portion of the rear plate is provided with a front base plate, wherein the top ends of the rear plate and the front base plate are provided with top plates, and the front base plate is formed by an upper base plate and a lower base plate in a splicing mode.The color scale adjusting device and the middle cutting device are installed on the top plates, the former device, the longitudinal sealing device, the roller device and the transverse sealing deviceare sequentially arranged from top to bottom on the upper base plate, and the cutting device is installed on the lower base plate. According to the roller enhancing type strip packing machine, compared with the prior art, the roller device is arranged between the longitudinal sealing device and the transverse sealing device, so that the advantages of a roller and a sealing plate can be combined, opening sealing strength and sealing performance of a transverse sealing opening of a package bag is ensured, thus preventing leakage phenomena as well as improving the product yield.

Owner:SHANGHAI KOMATSU PACKAGING MACHINERY

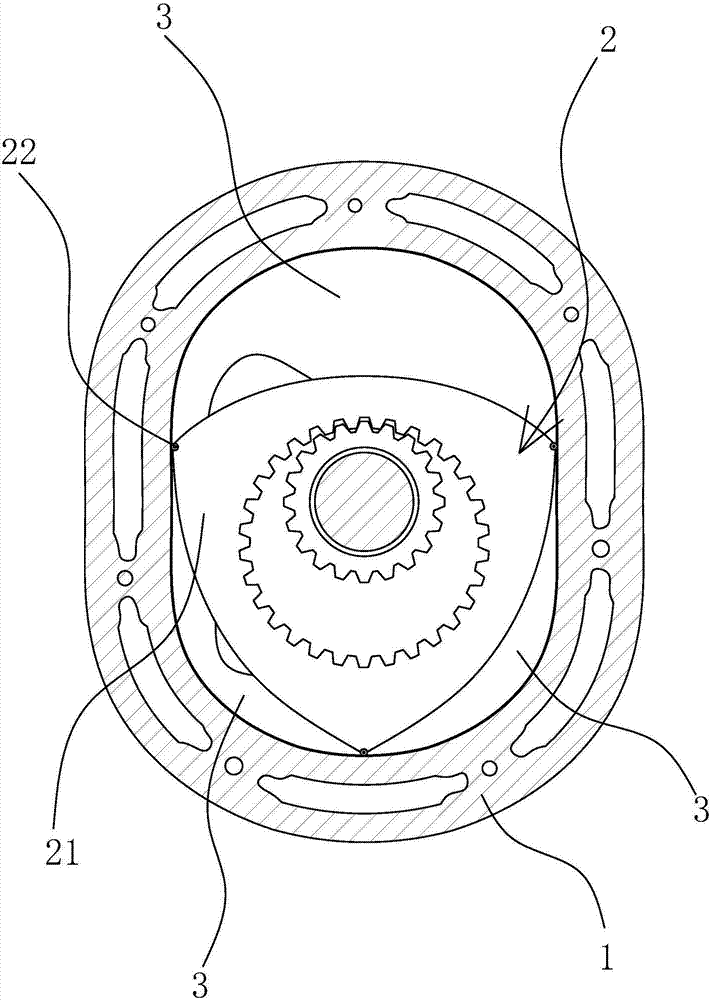

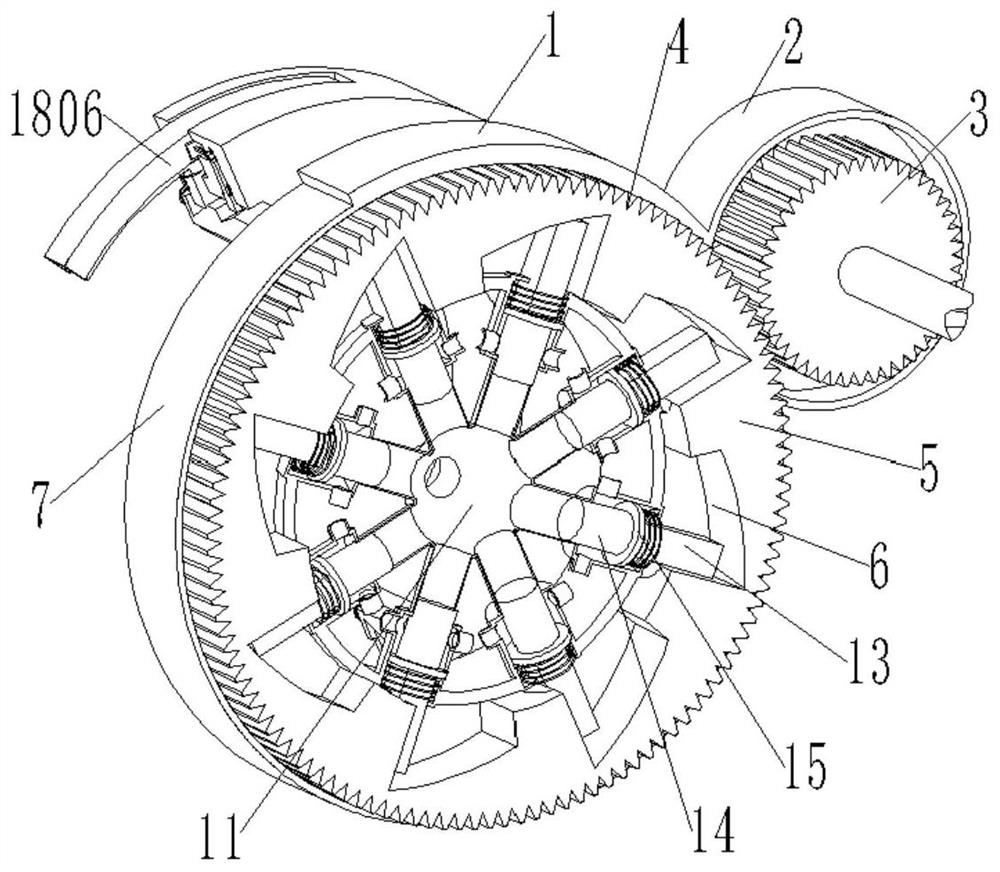

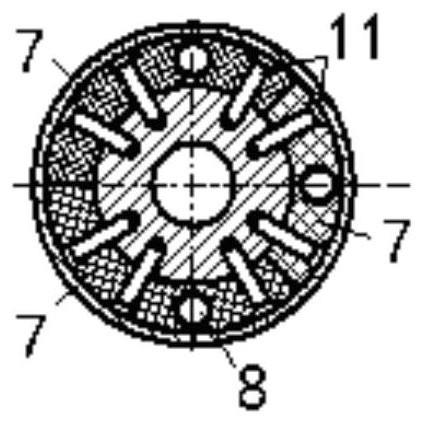

Rotor engine

ActiveCN106968787APlay a guiding roleSolve the sealing problemInternal combustion piston enginesSealing arrangements for enginesCombustion chamberEngineering

The invention provides a rotor engine, belongs to the technical field of engines, and solves such technical problems as bad wear and difficult sealing of a traditional rotor engine. The rotor engine comprises a cylinder, and rotors positioned in the cylinder; the rotors divide the cylinder into three combustion chambers; the rotors include main bodies, and sealing parts respectively positioned at three corners of the main bodies; multiple sealing steel rings are arranged on the inner wall of the cylinder; rotating columns capable of freely rotating are arranged at the sealing parts, and are provided with sealing modules corresponding to the sealing steel rings one to one; the main bodies are provided with hydraulic cavities corresponding to the rotating columns one to one; the main bodies are provided with pressure synchronizing devices capable of keeping synchronization between the pressures in the hydraulic cavities and the higher pressure of the pressures in the two combustion chambers on two sides of seals; and the sealing parts can be pressed with the inner wall of the cylinder under the effect of the pressures in the hydraulic cavities. The rotor engine has such advantages as low wear and excellent sealing.

Owner:HUBEI UNIV OF SCI & TECH

Structural member pipeline for truss support body and overlapping method of pipeline

ActiveCN106523795AGuaranteed seal strengthGuaranteed connection strengthPipe supportsFlanged jointsMultiple formsMulti dimensional

The invention discloses a structural member pipeline for a truss support body and an overlapping method of the pipeline. The pipeline is characterized by comprising communicating member pipelines having a bearing function for stress transfer of a structural member for the truss support body and gas and liquid delivery functions of a common pipeline as well as connecting member pipelines; the communicating member pipelines comprise various forms of communicating pipeline connecting rods; one or more than two communicating pipeline connecting rods are connected mutually to form a pipeline having the gas and liquid delivery functions; the connecting member pipelines comprise connecting pipeline rod bodies (19), connecting pipeline outer joints (26), connecting member connecting heads and pipeline connecting pieces (34); a plurality of the connecting pipeline rod bodies (19) communicate with one another to form a pipeline having the gas and liquid delivery functions; a plurality of the communicating member pipelines and a plurality of the connecting member pipelines are connected mutually to form the truss support body with a plurality of structural layers and the stable multi-dimensional structure.

Owner:周鼎铭

Punch, die and stretching process for stretching battery jar body

PendingCN112157175AHow much to solveSolve the strength problemShaping toolsSecondary cells manufactureMaterial consumptionThin wall

The invention discloses a punch, a die and a stretching process for stretching a battery jar body. The punch characterized in that a step punch is specially designed to serve as a male die, at least one thinning ring serves as a female die, and the wall thickness of the jar body is changed. The variable wall thickness stretching process belongs to thinning stretching, when a sheet or a plate is subjected to at least one-time forming stretching to obtain a cup-shaped stretching piece, the cup-shaped stretching piece is subjected to thinning stretching, particularly, variable wall thickness stretching in which the step punch is matched with at least one thinning ring is adopted to finally obtain a middle-section thin wall, and one or two battery jar bodies with variable wall thickness at theaxial end parts are provided. According to the variable-wall-thickness battery jar body, on one hand, the material consumption of the middle section of the jar body can be reduced, and on the other hand, the seaming strength of one or two ends of the jar body can be ensured; and therefore, the contradictory problem between the amount of used materials and the sealing strength caused by the thickand thin wall of the battery jar body is well solved.

Owner:SUZHOU SLAC PRECISION EQUIP CO LTD

Automatic sealing machine for feed packaging

ActiveCN105752400AGuaranteed seal strengthExtended service lifeWrapper twisting/gatheringDrive wheelEngineering

The invention discloses an automatic sealing machine for feed packaging. The automatic sealing machine comprises a feed weighing and blanking machine, a variable frequency motor and a PLC, wherein a heat sealing laminator is arranged at a blanking opening of the feed weighing and blanking machine, a beam is arranged below the feed weighing and blanking machine, a drive wheel and a driven wheel are arranged at two ends of the beam rotatably, a conveyor belt is arranged on the outer walls of the drive wheel and the driven wheel rotatably, a rubber pad is fixedly arranged on the outer surface of the conveyor belt, a spring set is fixedly arranged at the upper end of the rubber pad, a bag accommodating trough is fixedly arranged at the upper end of the spring set, and a bag sewing sealing machine is arranged above the left side of the beam by a support. The automatic sealing machine has the advantages of high sealing strength, precise sealing, good stability, high automatic level, reduction of production cost and the like, and is worthy of large-scale popularization.

Owner:ANHUI QUANJIAO WEILAI FEEDS CO LTD

Tail gas recovery equipment used in pinacolone production process

ActiveCN113663483AImprove the mixing effectFast absorptionGas treatmentEvaporator accessoriesProcess engineeringPinacolone

The invention relates to the technical field of tail gas recovery, in particular to tail gas recovery equipment used in the pinacolone production process. The equipment comprises an absorption unit, a gas filtering unit and a supporting frame; the absorption unit is mounted at the upper end of the gas filtering unit through a hoop; the problems that the tail gas is easy to leak in the process of treating the tail gas discharged in the existing pinacolone production process, and it is difficult to ensure that the tail gas is completely absorbed by the water solution, in the treatment process of discharged tail gas, the efficiency of evaporating hydrochloric acid gas by adopting a heating mode at present is low, and complete separation of the hydrochloric acid gas and pinacolone gas is difficult to guarantee, the hydrochloric acid gas is easy to leak due to infirm connection between receiving equipment and the pipeline after being collected can be solved. the tail gas recovery treatment effect in the pinacolone production process is guaranteed, and the tail gas treatment efficiency is improved.

Owner:南通鸿富达利化工有限公司

Glass cone for cathode-ray tube

InactiveCN1599019AInhibition of appearanceInhibition of aestheticsCathode-ray/electron-beam tube vessels/containersEngineeringCathode Ray Tube Display

The invention provides a glass cone for cathode-ray tube to avoid problems such as improper mismatch of cross section shape produced between both facing ends of the yoke and the neck tube of a glass funnel for a cathode-ray tube when they are welded, and worsening of the appearance of the periphery of the welded and sealed part, local defective welding and sealing, and the problem of welding and sealing strength. In an end region on a small-opening end 4 side of the square yoke portion 5 of the funnel 1, an extended portion 10 is provided whose external surface 8 and inner surface 9 dimensions in their radial directions gradually increase uniformly extending over the whole periphery, as they approach a large-opening end 6 side. The extended portion 10 is formed making the end face 4a of the small-opening end 4 starting end. The contour lines of the external surface 8 and the internal surface 9 of the extended portion 10 in its cross section containing a tube axis Z, are formed with individual arcs having the centers of curvature A, B respectively in regions which are to the peripheral sides of the surfaces and more to the neck tube 3 side than the end surface 4a of the opening end 4.

Owner:NIPPON ELECTRIC GLASS CO LTD

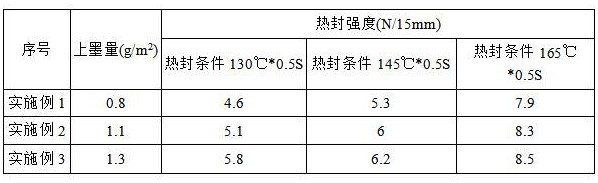

Polystyrene plastic sealing film and preparation method thereof

ActiveCN114015281AImprove tearabilityGuaranteed heat seal strengthInksOther printing apparatusPolymer sciencePolystyrene

The invention discloses a polystyrene plastic sealing film and a preparation method thereof. The sealing film comprises a printing layer and a heat sealing layer which are arranged vertically, the preparation method comprises the following steps that materials are prepared according to the following weight ratio: a component A comprises, in parts by weight, 30-60 parts of polyacrylate, 5-30 parts of propyl acetate, 10-60 parts of ethyl acetate, 0.1-0.5 part of matt powder, 0.1-0.5 part of wax powder, 2-10 parts of methyl cyclohexane, 3-8 parts of rosin and 1-3 parts of chlorinated polypropylene; a component B comprises, in parts by weight, 10-50 parts of polyisocyanate and 20-70 parts of ethyl acetate; uniformly mixing the component A and the component B according to a mass ratio of 15: 0.1-15: 0.8 to obtain an oil material; and (3) adopting the oil material obtained in the step (2) as printing ink, printing on the surface of a printing layer by adopting a gravure high-speed printing machine, and curing after printing to obtain the polystyrene plastic sealing film. According to the method, the sealing strength of the sealing film can be properly adjusted, so that the prepared sealing film has good easy-to-tear property, the production cost is low, the preparation process is simple, and the sealing film has a good application prospect.

Owner:金华市奇昇新材料有限公司

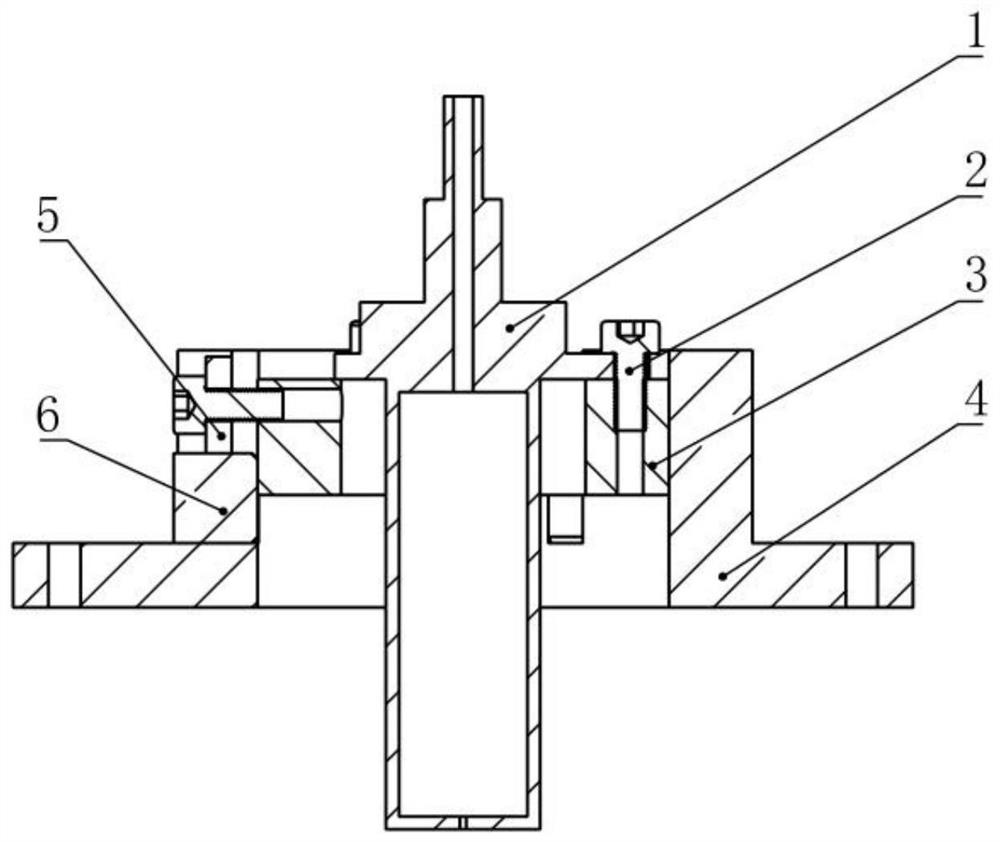

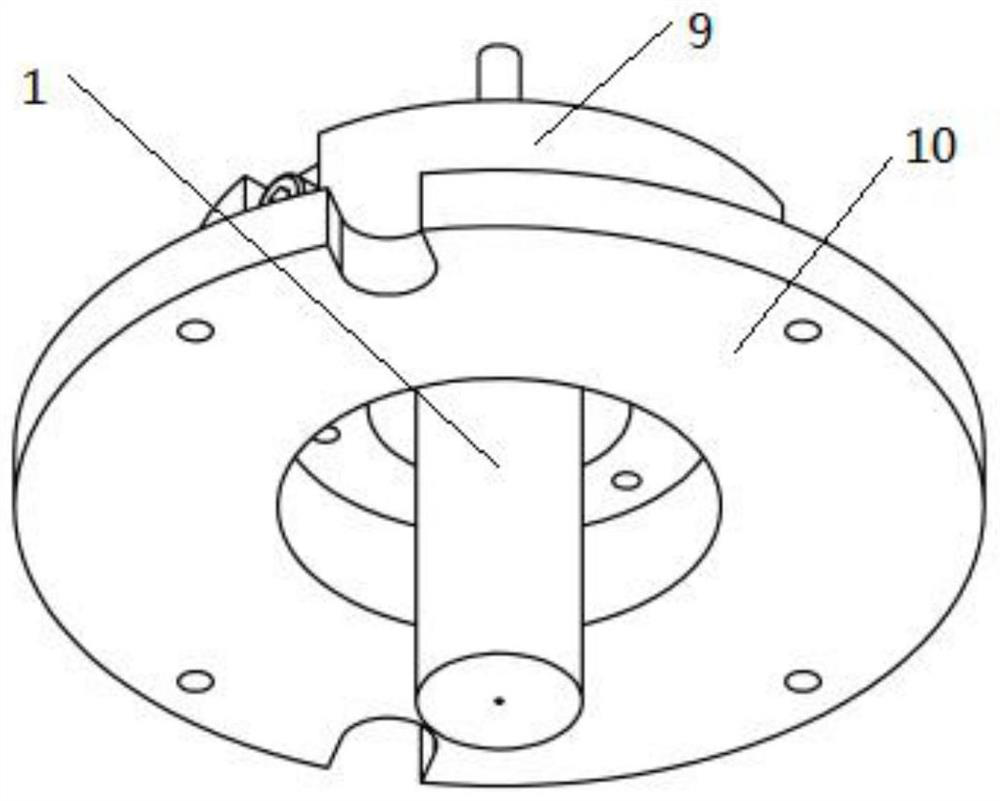

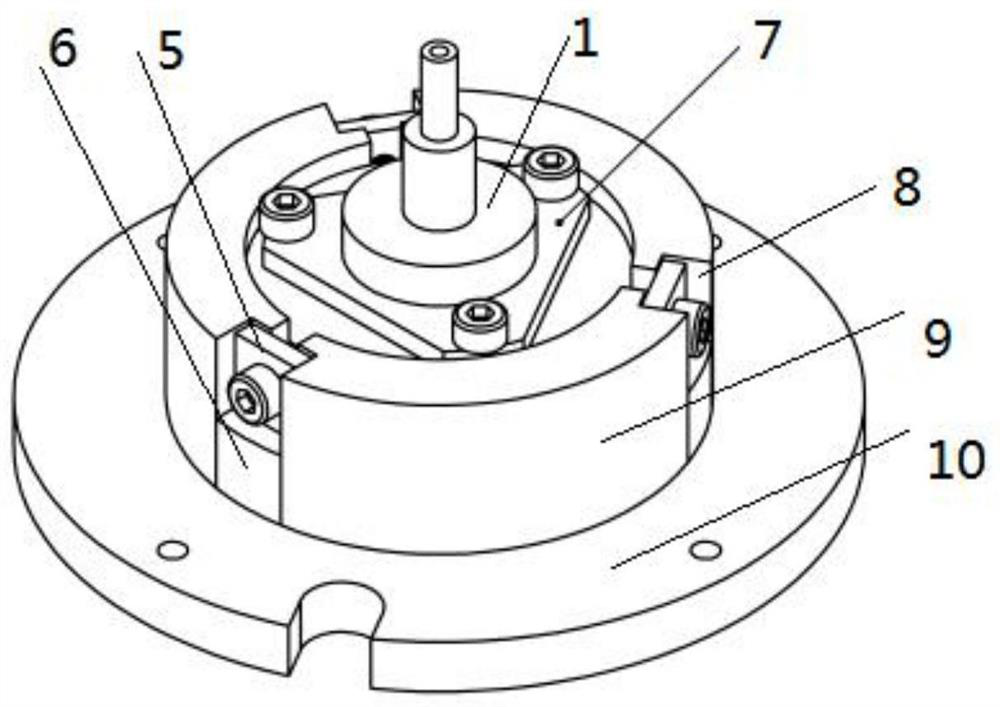

An assembly structure and assembly method of a main cathode applied to a thruster

ActiveCN113357114BAxial position changes frequentlyGuaranteed insulation sealMachines/enginesUsing plasmaEngineeringAssembly structure

The invention discloses an assembly structure of a main cathode applied to a thruster and an assembly method thereof. The main cathode is installed on a connection base through an insulating base, so that the main cathode and the connection base maintain an insulating state. Since the connection base is in a ring structure, And the annular structure is provided with several slots penetrating through its side wall along the circumferential direction. Positioning parts of different lengths can be replaced in the slots. The positioning parts are inserted into the slots and seal the gap between the slots and the insulating base. , the insulating base is lapped on the positioning piece through the connecting piece connected to it, then by changing the positioning pieces of different lengths, the axial position of the connecting piece on the connecting base is changed, and then the insulating base is driven to change its position on the connecting base. The axial position of the main cathode can be ensured to be insulated and sealed between the main cathode and the connection base, and the axial position of the main cathode relative to the discharge chamber of the thruster can be frequently changed to meet the experimental research on the thruster.

Owner:HARBIN INST OF TECH

Isolation structure for continuous beam grouting layer and grouting method

PendingCN111705678AEasy to take outGuaranteed seal strengthBridge erection/assemblyPre stressClassical mechanics

The invention discloses an isolation structure for a continuous beam grouting layer and a grouting method. A flexible isolation layer is arranged between every two adjacent simply supported beams, theflexible isolation layers go surround the outer sides of prestress penetrating holes, the flexible isolation layer is connected with the simply supported beams on the two sides in a sealed mode, andconcrete is poured into the area between the simply supported beams and the area on the outer sides of the flexible isolation layer. The isolation structure has the following beneficial effects: the flexible isolation layer is arranged between the two simply supported beams and thus a required shape can be formed by bending according to requirements; the area where the prestress strand penetratingholes are located is isolated from a grouting area; some tiny gaps can be filled by utilizing the elastic deformation of the flexible isolation layer so as to ensure the sealing strength of the flexible isolation layer and the simply supported beam; concrete is prevented from entering the area where the prestressed tendon penetrating hole is located; the flexible isolation layer can avoid the prestressed penetrating hole after being bent, the influence of construction on the prestressed penetrating hole is avoided, and the flexible isolation layer can be conveniently taken out after construction is completed, so that subsequent construction is prevented from being influenced.

Owner:CHINA MCC5 GROUP CORP

Decorative pattern hot plate for two-layer bag making machine

InactiveCN103213315ASmall sealing areaIntegrity guaranteedBox making operationsPaper-makingEngineeringHot plate

The invention relates to the technical field of a bag making machine, and in particular to a decorative pattern hot plate for a two-layer bag making machine. The decorative pattern hot plate comprises a hot plate body (1) and two contact plates (2), wherein the hot plate body (1) and the contact plates (2) are fixedly connected with each other into a whole, a plurality of square decorative patterns (3) are cut on contact surfaces of the bottom ends of the contact plates (2), the square decorative patterns (3) are arranged in a staggered way along the length directions of the contact plates (2), and the centers of the square decorative patterns (3) are provided with circular holes (4). Compared with the prior art, the decorative pattern hot plate is novel and simple in structure, and reasonable in design. The shape of the hot plate is changed, so that the contact surface of the hot plate can be reduced, the seal area of the hot plate can be educed, the decorative pattern hot plate can be well sealed under the condition of large conditional error, the seal strength of a product can be guaranteed, the sealing and cooling can be accelerated, the sealing and crystallizing integrity of a thin film can be guaranteed, a seal wire of the product is hard to lengthen, and the happening of phenomena, i.e. sealing, hole breaking and the like can be avoided.

Owner:SHANGHAI FUKUSUKE IND

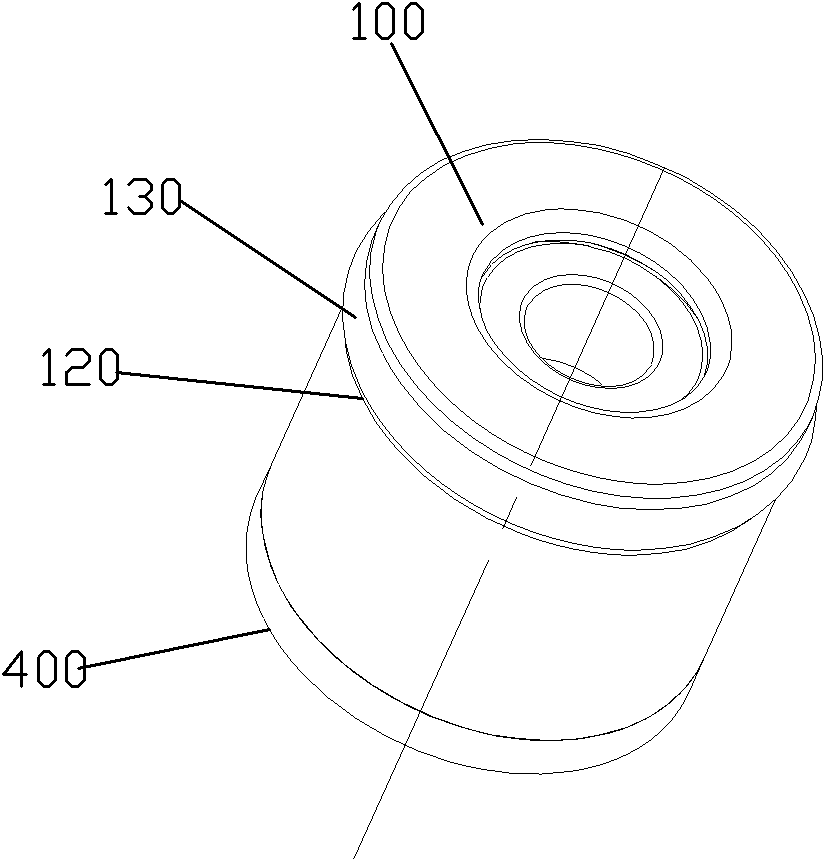

Water-saving non-return valve

InactiveCN102207215BShorten the axial lengthSimple structureCheck valvesLift valveWater savingManufacturing cost reduction

The invention discloses a water-saving non-return valve, which comprises a valve body, a valve core and a spring. A waterway (110) is formed inside the valve body (100); an inner hole face of the waterway (110) comprises a sealing section (111) and a water-saving section (112); a sealing ring (210) is sleeved outside the valve core (200); the spring (300) is pressed against the valve core (200), so that the valve core (200) is subjected to elastic force; if water in the waterway (110) positively flows and water pressure is higher than the elastic force, the valve core (200) moves to make the sealing ring (210) positioned on the water-saving section (112), and the sealing ring (210) radially deforms outwards due to the water pressure so as to reduce the sectional area at the periphery of the sealing ring (210) and between inner hole faces of the water-saving section (112); and if the water in the waterway (110) reversely flows and the water pressure is lower than the elastic force, thesealing ring (210) is positioned on the sealing section (111), and the sealing ring (210) seals an inner hole face of the sealing section (111). The invention has the advantages that: a non-return function and a water-saving function can be realized by a bracket and the sealing ring, the materials can be reduced, the manufacturing cost is reduced, the axial length of the valve core can be shortened, the occupied space is reduced, and the structure of the valve core can be simplified.

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

Low-constant-temperature closed magnesium electrolysis device

The invention relates to the field of magnesium electrolysis devices for magnesium chloride electrolysis, and particularly discloses a low-constant-temperature closed magnesium electrolysis device. The low-constant-temperature closed magnesium electrolysis device comprises a tank shell, a magnesium electrolysis device refractory lining, a partition wall, a flow guide block, an anti-corrosion belt brick, a back wall, a feeding channel, a melt cooler and a heating electrode; and a flexible expansion plate is arranged between the magnesium electrolysis device refractory lining and the tank shell. According to the low-constant-temperature closed magnesium electrolysis device, low-constant-temperature closed electrolysis of magnesium chloride can be achieved, the purity of produced liquid magnesium is high, refining is not needed, the quantity of sublimates and tank slag is small in the electrolysis process, a large number of sublimate treatment devices do not need to be arranged, the construction investment is saved, and the maintenance cost of the equipment and pipelines is reduced; and finally, the purpose of reducing the production cost is achieved. In addition, due to the arrangement of the reaction chamber cover seal and the anode seal, the concentration of produced chlorine is far higher than that of a traditional magnesium electrolysis device, which can be directly applied to downstream production procedures, the additional value of products of the magnesium electrolysis device is further improved, and meanwhile the working environment is improved.

Owner:QINGHAI NORMOON TECH

Centrifugal water pump built-in booster device

ActiveCN112240310BGuaranteed work efficiencyImprove sealingPositive displacement pump componentsPiston pumpsAir compressionEconomic benefits

The invention discloses a built-in pressure boosting device of a centrifugal water pump. When the centrifugal water pump is boosted, the first gas compression tube, the second gas compression tube and the air compression ball provided in the invention can control the impeller side of the centrifugal water pump. The vacuum low-pressure area at the side position is compressed, and then the pressure of the low-pressure area can be boosted, and as the pressure gradually increases, the seal in the inner cavity of the centrifugal water pump can be improved through the set booster auxiliary mechanism. To ensure that the sealing strength in the inner cavity of the centrifugal water pump can meet the increase of pressure, so that the problem of air leakage will not be caused by the increase of pressure, thereby ensuring the normal operation of the boosting work, ensuring the working efficiency and working efficiency of the centrifugal water pump economic benefits.

Owner:东莞市深鹏电子有限公司

Sealing insulation structure for underground high-current female joint

PendingCN112421287AReduce wall thicknessImprove machinabilitySecuring/insulating coupling contact membersCouplings bases/casesPower flowOperability

The invention discloses a sealing insulation structure for an underground high-current female joint, wherein the sealing insulation structure comprises an outer pipe (1), a group of electrified rings(2) which are uniformly distributed along the axial direction are arranged in the outer pipe, and sealing insulation rings (3) are arranged at the upper end and the lower end of each electrified ring;a connecting lug (4) is arranged on one side of each electrified ring, and the connecting lugs on one group of electrified rings are arranged in a triangular shape; each connecting lug is provided with a wiring hole (5); a wire (6) is inserted into each wiring hole, and the wires and the wiring holes are welded after being pressure-welded; and the other end of the wire connected with each electrified ring penetrates out of a wire penetrating hole (8) of a corresponding fan-shaped insulating plate (7) and then is led out of the top of the outer pipe. A plurality of fan-shaped insulating platesare spliced into a cylinder structure, so that the machinability, the mounting operability and the reliability of a product are improved; key positions such as a joint are filled with insulating glue, so that the insulativity is further improved; the outer pipe is connected with an upper body through hanging nails, the wall thickness of the outer pipe can be greatly reduced, and enough space is reserved for the fan-shaped insulating plates.

Owner:贵州航天凯山石油仪器有限公司

A truss support structure member pipe and its overlapping method

ActiveCN106523795BGuaranteed seal strengthGuaranteed connection strengthPipe supportsFlanged jointsMultiple formsLap joint

The invention discloses a structural member pipeline for a truss support body and an overlapping method of the pipeline. The pipeline is characterized by comprising communicating member pipelines having a bearing function for stress transfer of a structural member for the truss support body and gas and liquid delivery functions of a common pipeline as well as connecting member pipelines; the communicating member pipelines comprise various forms of communicating pipeline connecting rods; one or more than two communicating pipeline connecting rods are connected mutually to form a pipeline having the gas and liquid delivery functions; the connecting member pipelines comprise connecting pipeline rod bodies (19), connecting pipeline outer joints (26), connecting member connecting heads and pipeline connecting pieces (34); a plurality of the connecting pipeline rod bodies (19) communicate with one another to form a pipeline having the gas and liquid delivery functions; a plurality of the communicating member pipelines and a plurality of the connecting member pipelines are connected mutually to form the truss support body with a plurality of structural layers and the stable multi-dimensional structure.

Owner:周鼎铭

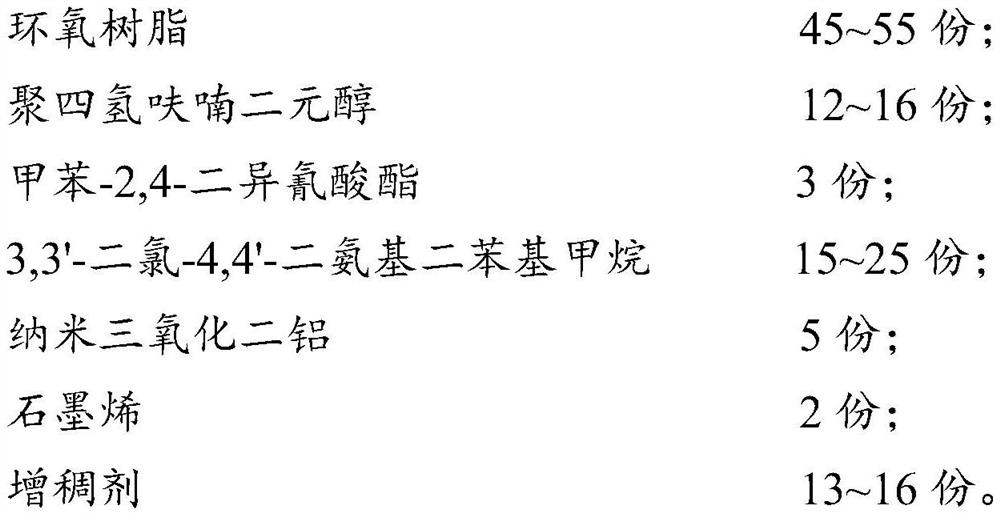

Polyurethane modified epoxy resin adhesive material as well as preparation method and application thereof

ActiveCN114163961AImprove toughnessImprove low temperature resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesElastomerPolymer science

The invention provides a polyurethane modified epoxy resin adhesive material as well as a preparation method and application thereof, and belongs to the technical field of adhesive materials. According to the invention, polyurethane is used for toughening modification of epoxy resin, polytetrahydrofuran diol and toluene-2, 4-diisocyanate are used as raw materials for synthesis of a polyurethane prepolymer, and isocyanate groups in the polyurethane prepolymer can react with hydroxyl groups in the epoxy resin, so that the epoxy resin is subjected to a reaction with hydroxyl groups in the epoxy resin; when the epoxy resin is subjected to toughening modification, no great negative influence is generated on the strength, and the polyurethane has high polarity and high bonding strength on a cable heat shrink tube. The 3, 3 '-dichloro-4, 4'-diaminodiphenyl methane is used as the curing agent, the fluidity of the adhesive material is adjusted by using the nano aluminum oxide, the graphene and the thickening agent, and the obtained adhesive material is in an elastomer form, and can be changed into a flowable liquid state to fill a sealing gap without dripping during thermocuring; therefore, effective bonding and sealing of gaps are realized.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com