Water-saving non-return valve

A technology of check valve and spool, which is applied in the direction of lift valve, valve detail, control valve, etc., can solve the problems of increasing the complexity of the spool structure, increasing the space occupied by the check valve, and the long axial length of the spool, to achieve Good water-saving effect, shortened axial length, and reduced material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

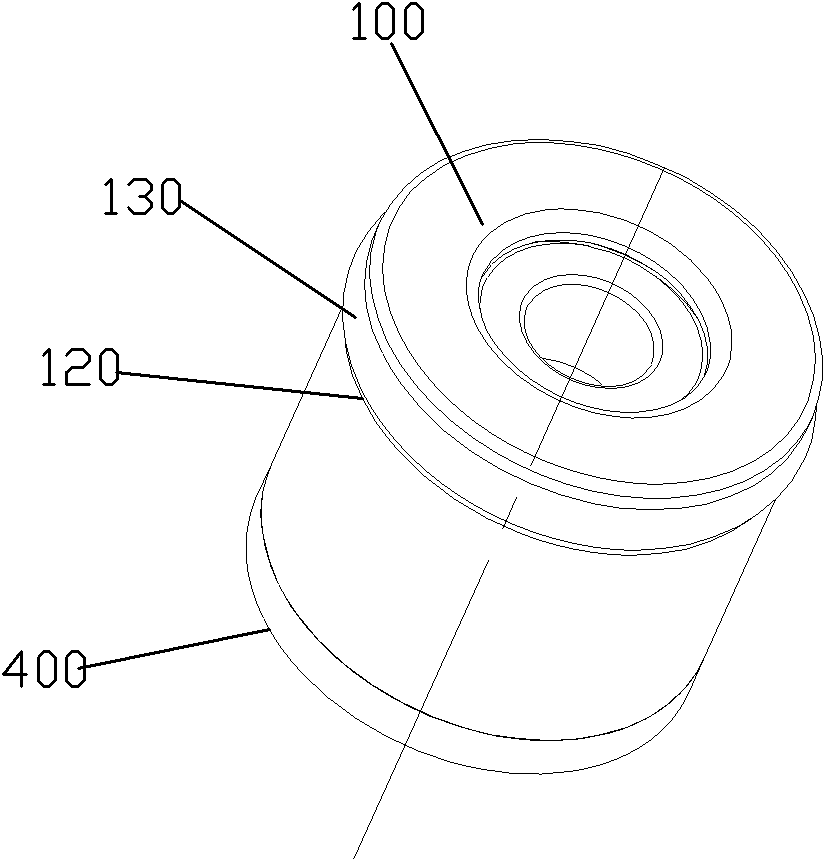

[0042] Please check Figure 1 to Figure 12 , A water-saving check valve, which includes a valve body 100, a valve core 200, a spring 300 and a valve seat 400.

[0043] The valve body 100 is provided with a water passage 110 penetrating through the top and bottom, and an annular assembly groove 120 outside the assembly groove 120, and a sealing ring 130 is sleeved at the assembly groove 120. The inner hole surface of the waterway 110 at least includes a sealing section 111, a water-saving section 112 and a fixed connection section 114 arranged in the forward direction of the water flow of the waterway 110. In this embodiment, the sealing section 111 is set as a conical surface section, and the inner diameter of the conical surface section increases continuously in the forward direction of the water flow, but it is not limited to this. According to needs, the sealing section 111 may also Set as a stepped hole (the sealing ring is connected to the stepped surface of the stepped hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com