Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Guaranteed break" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

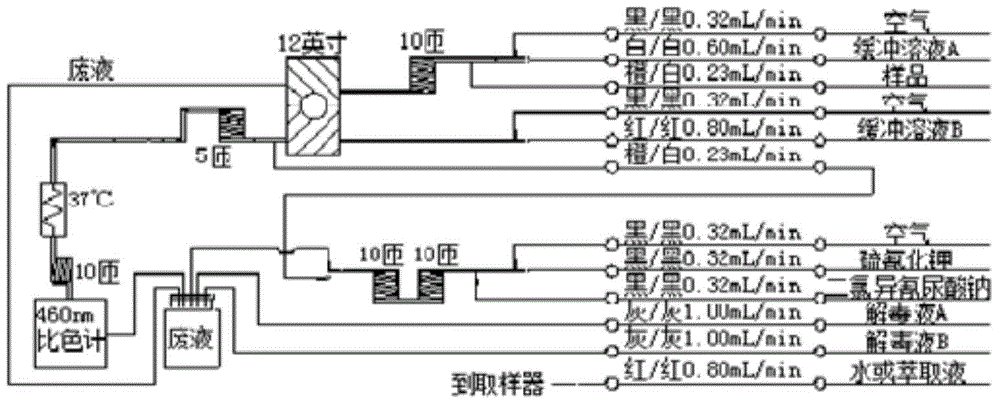

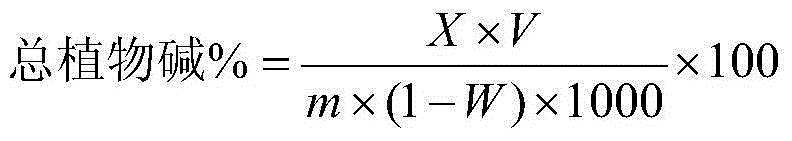

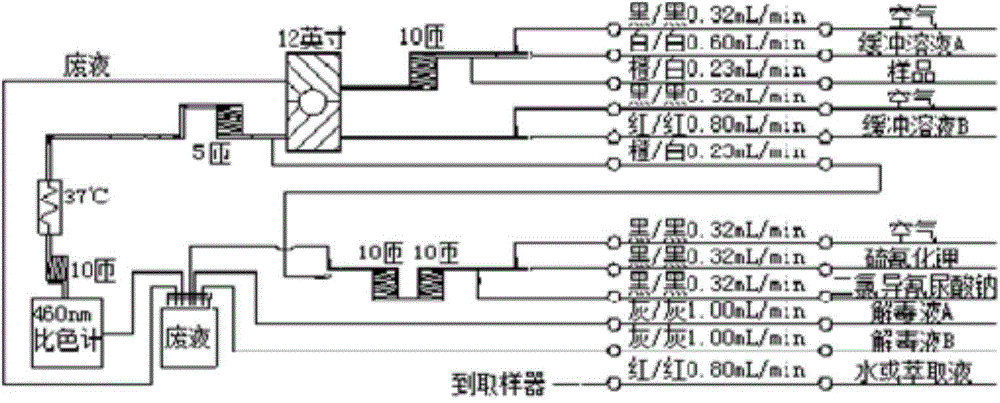

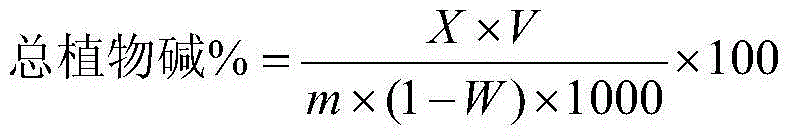

Continuous flow method for measuring total alkaloid in tobacco or tobacco products

ActiveCN104132937AGuaranteed pHWill not be affected by acid and alkali environmentMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationPotassium thiocyanateContinuous flow

The invention provides a continuous flow method for measuring total alkaloid in tobacco or tobacco products. In the method, potassium thiocyanate and sodium dichloro isocyanurate are adopted to carry out reactions to generate cyanogen chloride on line. The cyanogen chloride can carry out reactions with total alkaloid (calculated in the form of nicotine) in tobacco or tobacco products to break off the pyridine rings of nicotine, and then further carries out reactions with p-aminobenzene sulfonic acid. The reaction products are measured by a chromometer at 460 nm. The method uses a buffer system to control the pH value of the reaction system in a range of 6.0 to 7.5, and the buffer system is composed of a buffer solution A and a buffer solution B. The buffer solution A is prepared by the following steps: weighing disodium hydrogen phosphate and trisodium phosphate, placing the weighed substances in a beaker, dissolving the substances with water, transferring the solution to a volumetric flask (1L), and adding water into the volumetric flask until the water reaches the scale. The buffer solution B is prepared by the following steps: weighing p-aminobenzene sulfonic acid, disodium hydrogen phosphate, sodium dihydrogen phosphate, and sodium citrate, placing the weighed substances into a beaker, dissolving the substances with water, transferring the solution to a volumetric flask (1L), and then adding water into the volumetric flask until the water reaches the scale.

Owner:CHINA NAT TOBACCO QUALITY SUPERVISION & TEST CENT

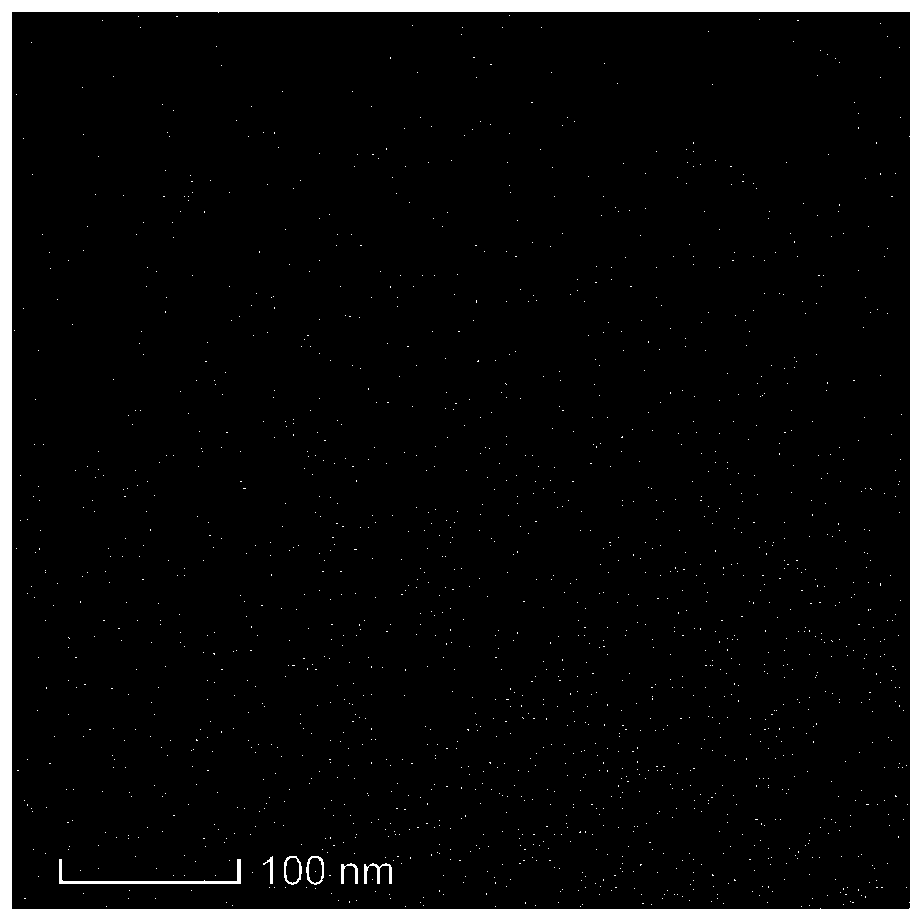

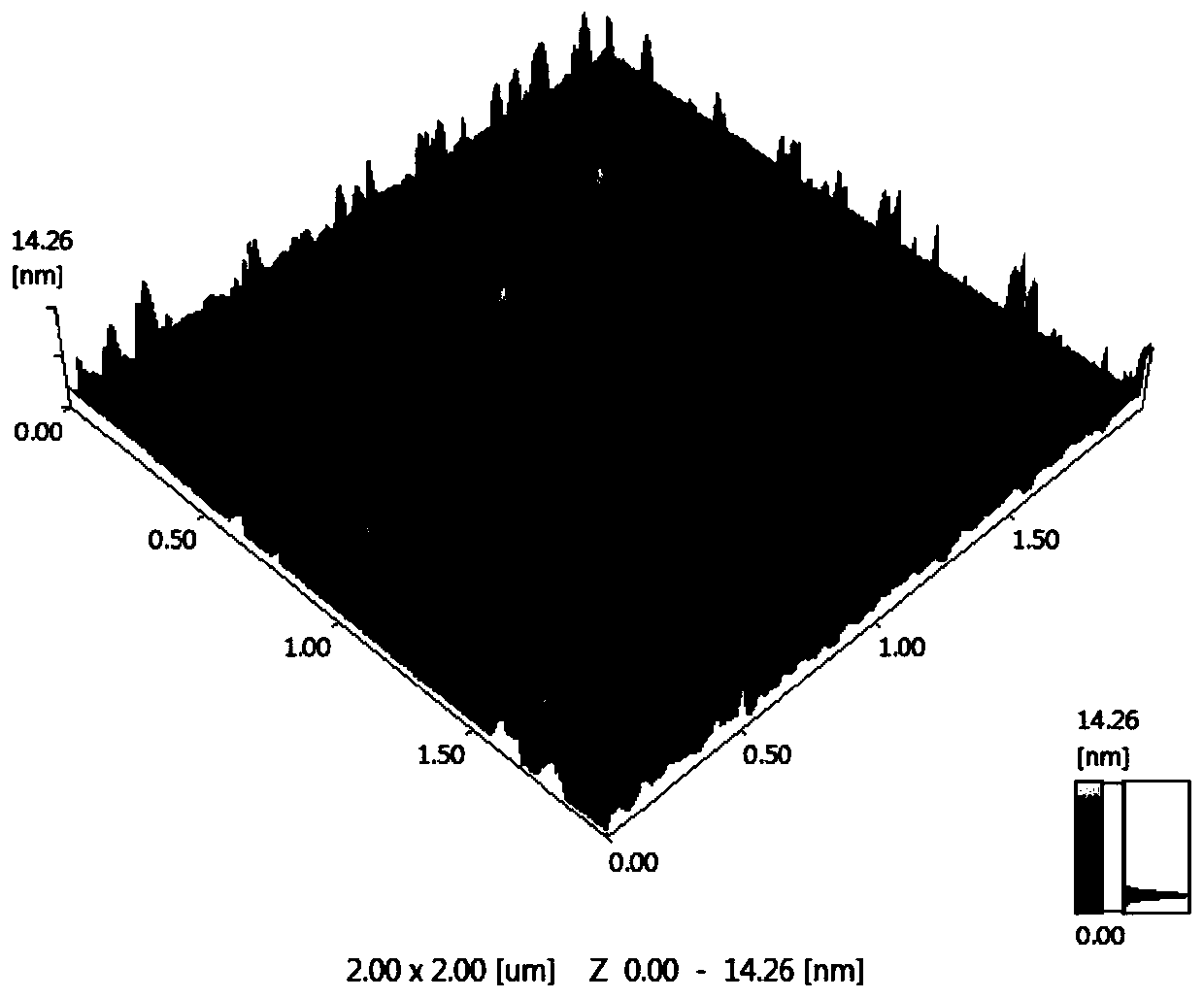

Method for preparing carbon quantum dots from lignin, and product

InactiveCN110054170ATake advantage ofGuaranteed normal breakingNano-carbonLiquid productFreeze-drying

The invention belongs to the field of preparation of carbon quantum dots, and specifically discloses a method for preparing the carbon quantum dots from lignin, and a product. The method includes adding the lignin to water to obtain a lignin solution, and adding an activator for ultrasonic treatment to obtain a micromolecular lignin solution; subjecting the micromolecular lignin solution to hydro-thermal treatment at 150-250 DEG C, and cooling down to room temperature after reaction to obtain a liquid product; ultrasonically treating the liquid product, and preforming filtering and dialyzing to obtain a carbon quantum dot solution; and freeze-drying the carbon quantum dot solution to obtain the carbon quantum dots. The method has the advantages that the lignin can be sufficiently utilizedthrough reduction of reaction activation energy of the lignin, the production cost is reduced while the yield and quality of the carbon quantum dots are improved, and the yield of the finally obtainedcarbon quantum dots can reach 35% through control of reaction conditions.

Owner:HUAZHONG UNIV OF SCI & TECH

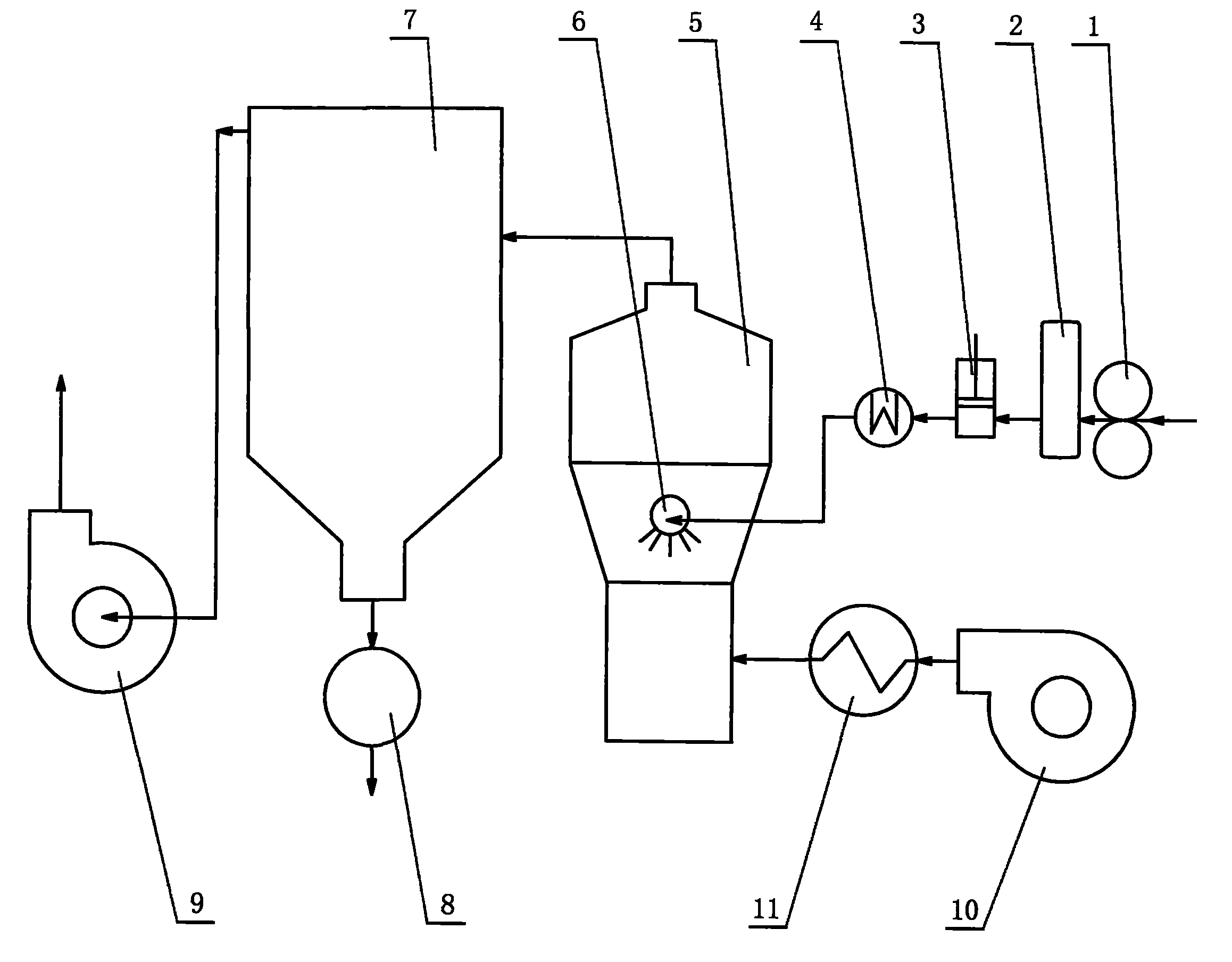

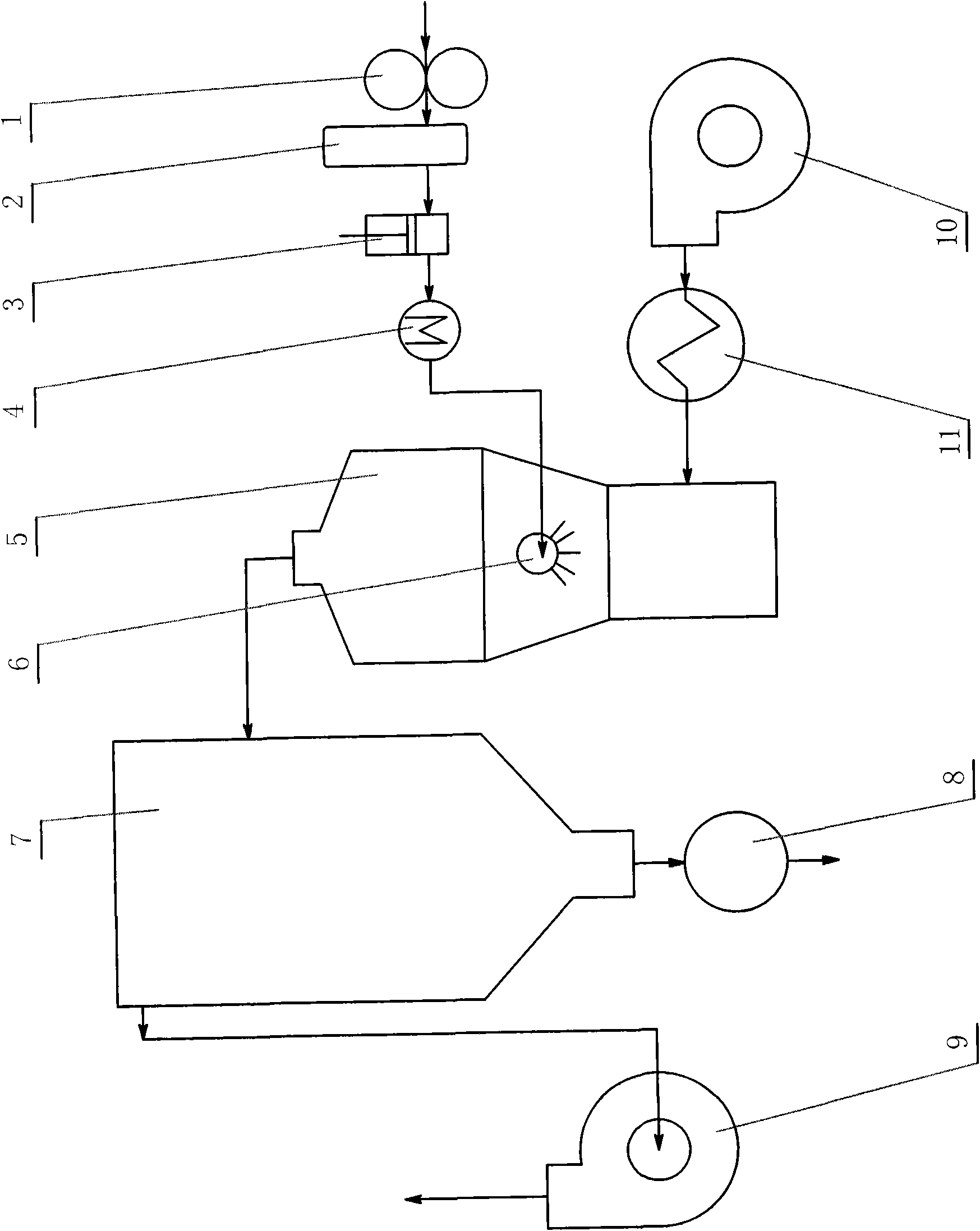

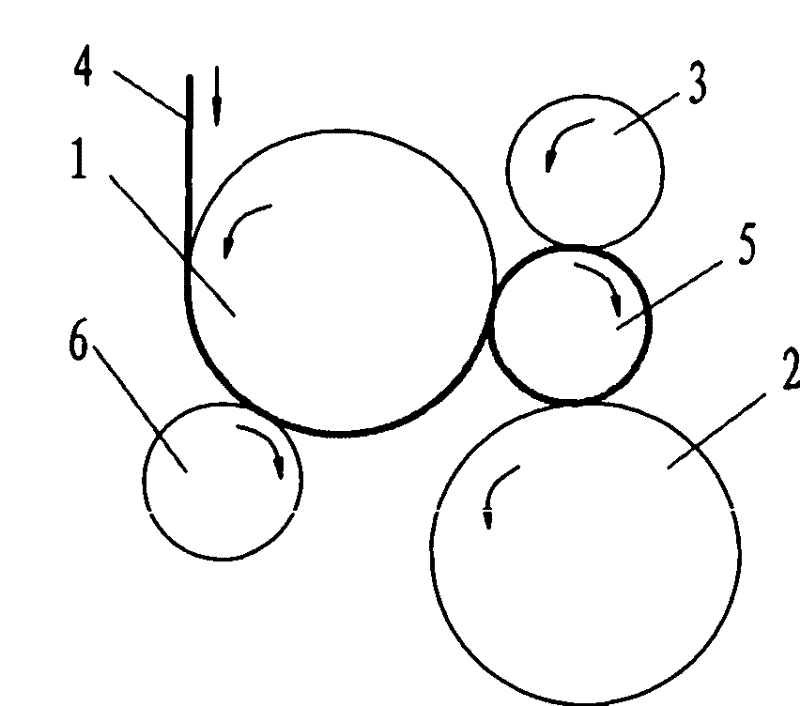

Method for continuously drying sodium aliphatic alcohol sulfate and sodium olefin sulfonate slurry

InactiveCN101811994AAvoid the difficulty of continuous and stable atomizationEfficient dryingOrganic compound preparationTransportation and packagingFluidized bed dryingSulfate

The invention provides a method for continuously drying sodium aliphatic alcohol sulfate and sodium olefin sulfonate slurry with easy continuous processing and low cost. The method comprises the following steps of: inputting airflow at the temperature of between 70 and 180 DEG C into a fluidized bed dryer (5) to ensure that inert particles in the dryer are fluidized; preheating the measured sodium aliphatic alcohol sulfate and sodium olefin sulfonate slurry to the temperature of between 50 and 150 DEG C, and inputting the measured sodium aliphatic alcohol sulfate and sodium olefin sulfonate slurry into the fluidized bed dryer (5) in a pulsating flow mode; allowing the slurry to pass through a mesh distribution screen (6); rupturing the slurry into short columns; ,making the slurry fall into a fluidized bed layer of the dryer; fluidizing the slurry and the inertia particles, and drying the fluidized slurry and the inertia particles to obtain the material; separating the dried material from surfaces of the inert particles to form fine powder; discharging the fine powder from the top of the fluidized bed dryer along with air flow, and allowing the fine powder to enter a bag separator (7); and exhausting tail gas from the top of the bag separator, and outputting the product of fine powder from the lower part of the bag separator. The method is suitable for drying a surface active agent.

Owner:SINOLIGHT CHEM

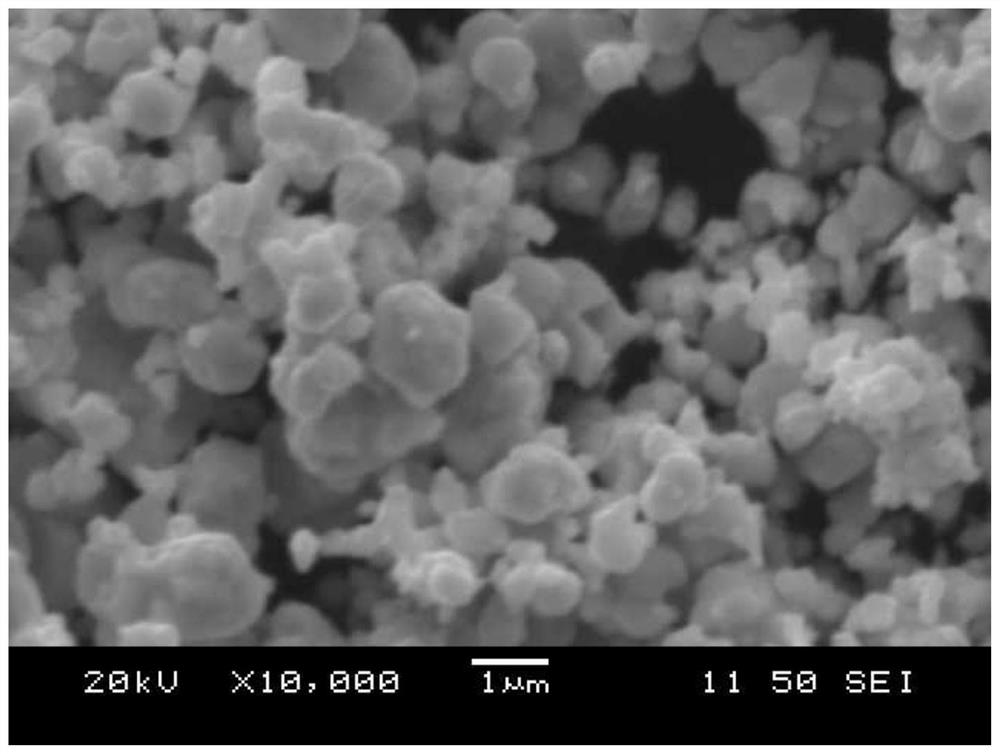

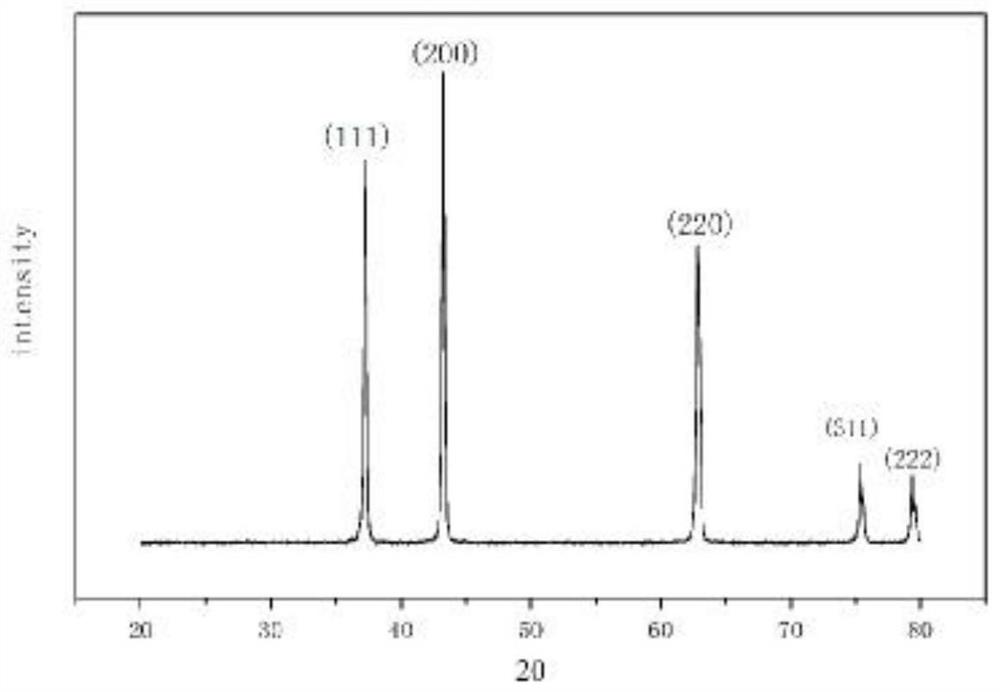

Cold isostatic pressing forming preparation method of nickel oxide-based ceramic target material

InactiveCN112456971AImprove conductivityHigh densityVacuum evaporation coatingSputtering coatingSpray driedMass fraction

The invention relates to a cold isostatic pressing forming preparation method of a nickel oxide-based ceramic target material, wherein the method comprises the following steps: A, preparing raw materials: preparing mixed powder of nickel oxide powder and doped source powder, wherein the total mass fraction of doped source elements in the mixed powder is not more than 10%, wherein the doping sourceelement is selected from one or more of 0-6% of Li, 0-0.3% of Na, 0-1.0% of Mg, 0-0.1% of Al, 0-0.1% of Si, 0-0.15% of K, 0-12% of Zn, 0-1.5% of Zr, 0-1.2% of Mn, 0-10% of Cu, 0-1.2% of Cr, 0-0.3% ofV, 0-10% of W and 0-2.5% of Ti; B, carrying out spray drying; C, compacting by vibration; D, feeding a mold into a cold isostatic pressing chamber for pressing; E, degumming a biscuit; F, sintering;G, cooling after heat preservation is finished; and H, machining or not machining according to needs. The preparation method can be used for preparing the nickel oxide-based ceramic which is good in conductivity, relatively high in purity and fine in grain size.

Owner:北京航大微纳科技有限公司

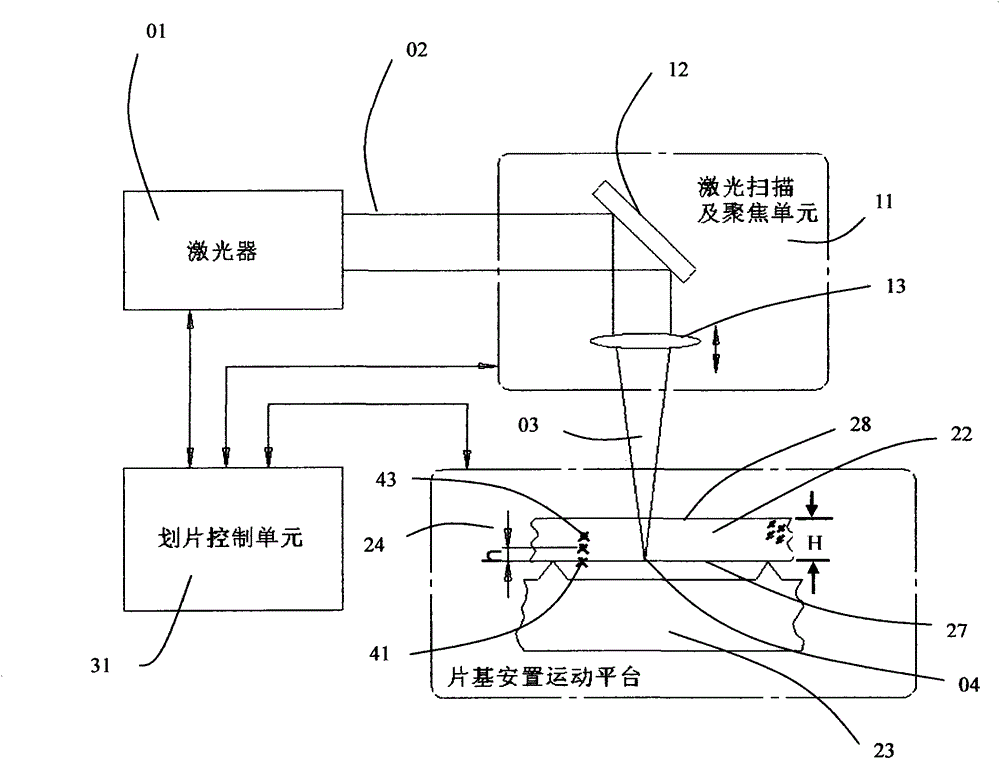

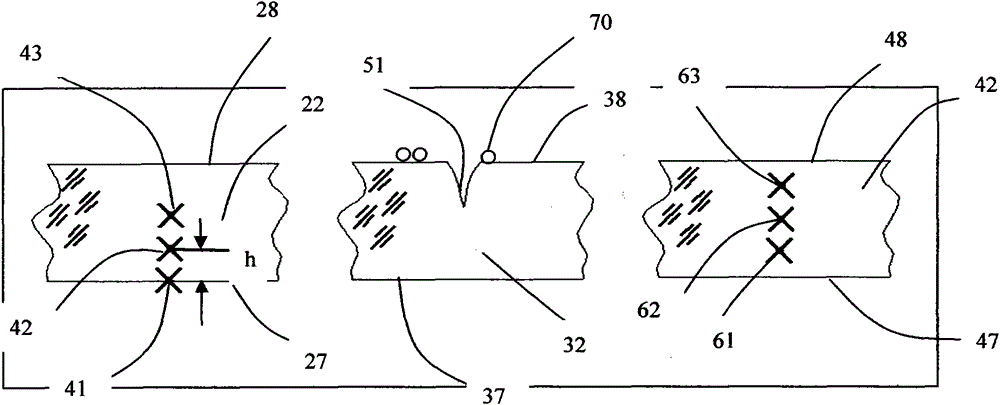

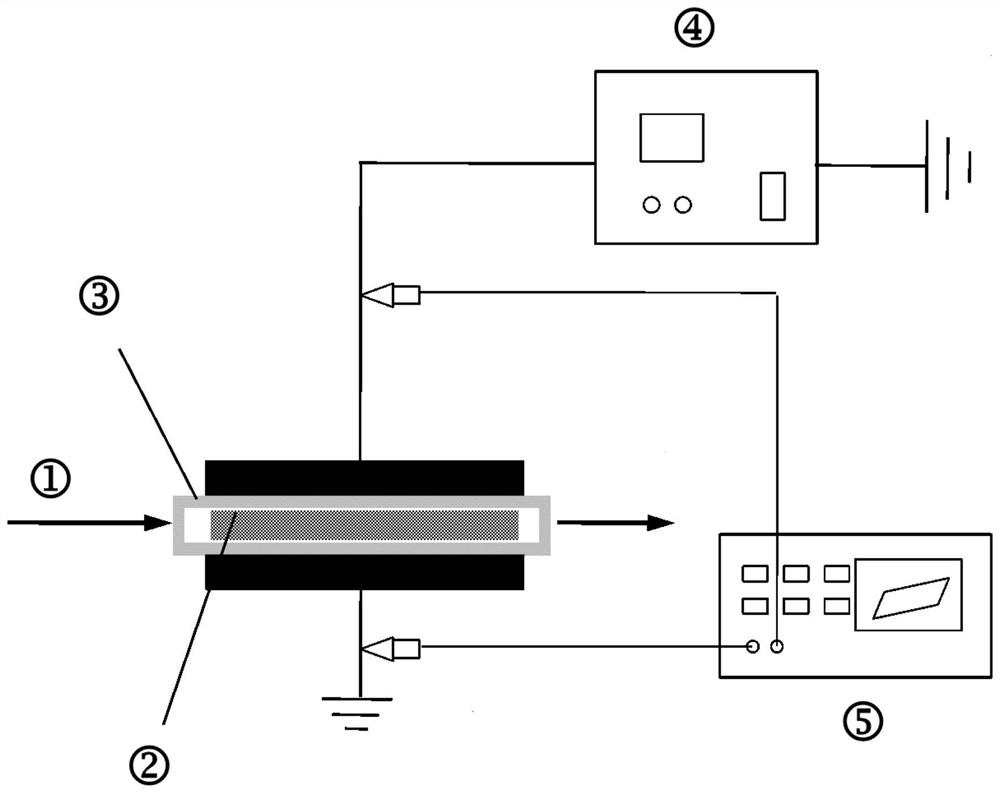

Laser scribing method and system

InactiveCN104646834AAvoid pollutionGuaranteed breakGlass severing apparatusMetal working apparatusLasing wavelengthOptoelectronics

The invention provides a laser scribing method and a laser scribing system for cutting a material substrate transparent relative to laser wavelength. A laser beam is enabled to penetrate through and be focused on the bottom surface of the substrate, the laser beam is scanned according to a required route to cause the material on the bottom face of the substrate to be modified or laser scratch, then repeated scribing is carried out after the laser focusing point is shifted up for a predetermined height. The laser intensity adopted for scribing each time can vary from the height of the focusing points, and scribed lines are in uniform or non-uniform distribution in the thickness direction of the substrate. The scribing can be performed all the time until the laser focusing point is close to the upper surface of the substrate. Then a proper force is applied to the substrate, and the substrate is split along the scribed lines, thus scribing is finished. When pulse laser with the pulse width being smaller than 1ns is adopted, modification of the substrate material can be mainly material breakdown rather than thermally induced corrosion. According to the invention, the laser scribing system has corresponding hardware and control, can precisely focus the laser beam on the bottom face of the substrate, scribe lines according to a predetermined route, and then scribe lines by changing the height of the laser focusing point until finishing scribing.

Owner:北京科涵龙顺激光设备有限公司 +1

Buffer system suitable for continuous flow method for measuring total alkaloid in tobacco and tobacco products

ActiveCN104132895AGuaranteed pHWill not be affected by acid and alkali environmentAnalysis by subjecting material to chemical reactionColor/spectral properties measurementsGramContinuous flow

The invention provides a buffer system suitable for a continuous flow method for measuring total alkaloid in tobacco and tobacco products. The buffer system comprises a buffer solution A and a buffer solution B; wherein the buffer solution A is prepared by the following steps: weighing 60.5 to 83.0 grams of disodium hydrogen phosphate (the preferable amount is 71.6 grams) and 10.1 to 20.2 grams of trisodium phosphate (the preferable amount is 15.2 grams), placing the weighed substances into a beaker, dissolving the mixture with water, then transferring the solution into a volumetric flask, and then filling water into the volumetric flask until the water reaches the scale; and the buffer solution B is prepared by the following steps: weighing 5.5 to 8.0 grams of p-aminobenzene sulfonic acid (the preferable amount is 7.0 grams), 60.5 to 83.0 grams of disodium hydrogen phosphate (the preferable amount is 71.6 grams), 5.0 to 7.0 grams of sodium dihydrogen phosphate (the preferable amount is 6.2 grams), and 10.0 to 12.1 grams of sodium citrate (the preferable amount is 11.8 grams), placing the weighed substances into a beaker, dissolving the mixture with water, transferring the solution into a volumetric flask, and then filling water into the volumetric flask until the water reaches the scale.

Owner:CHINA NAT TOBACCO QUALITY SUPERVISION & TEST CENT

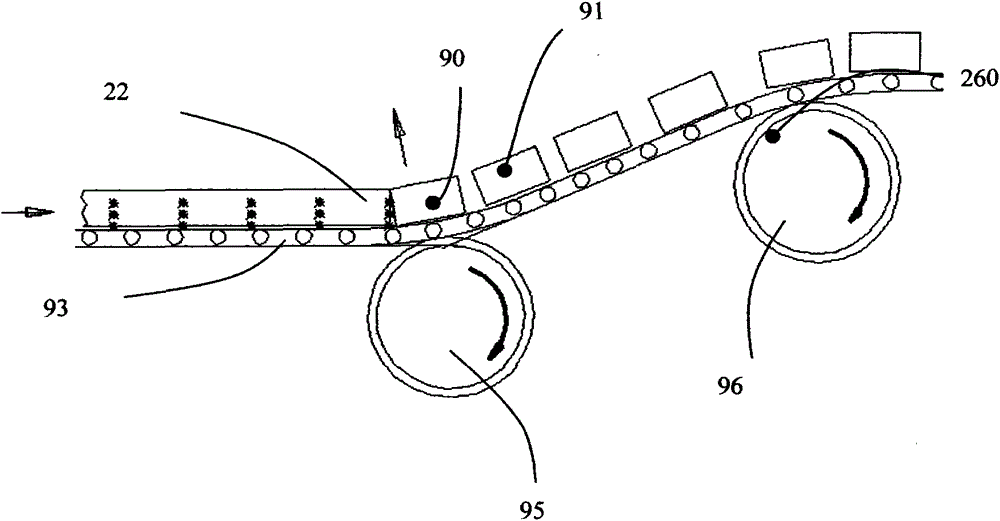

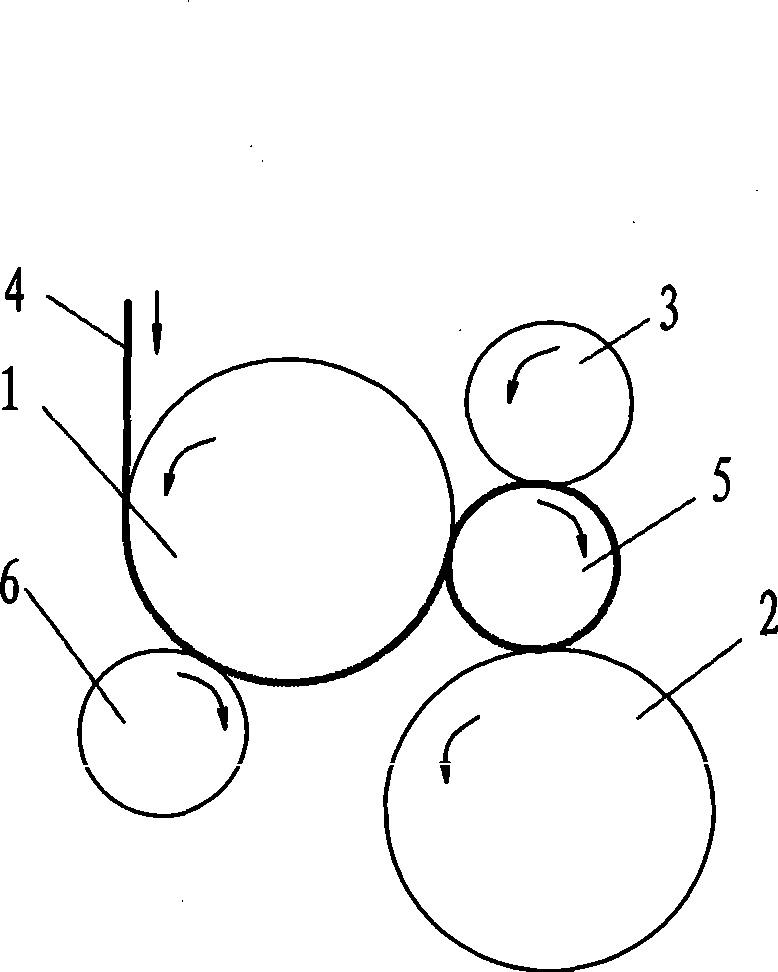

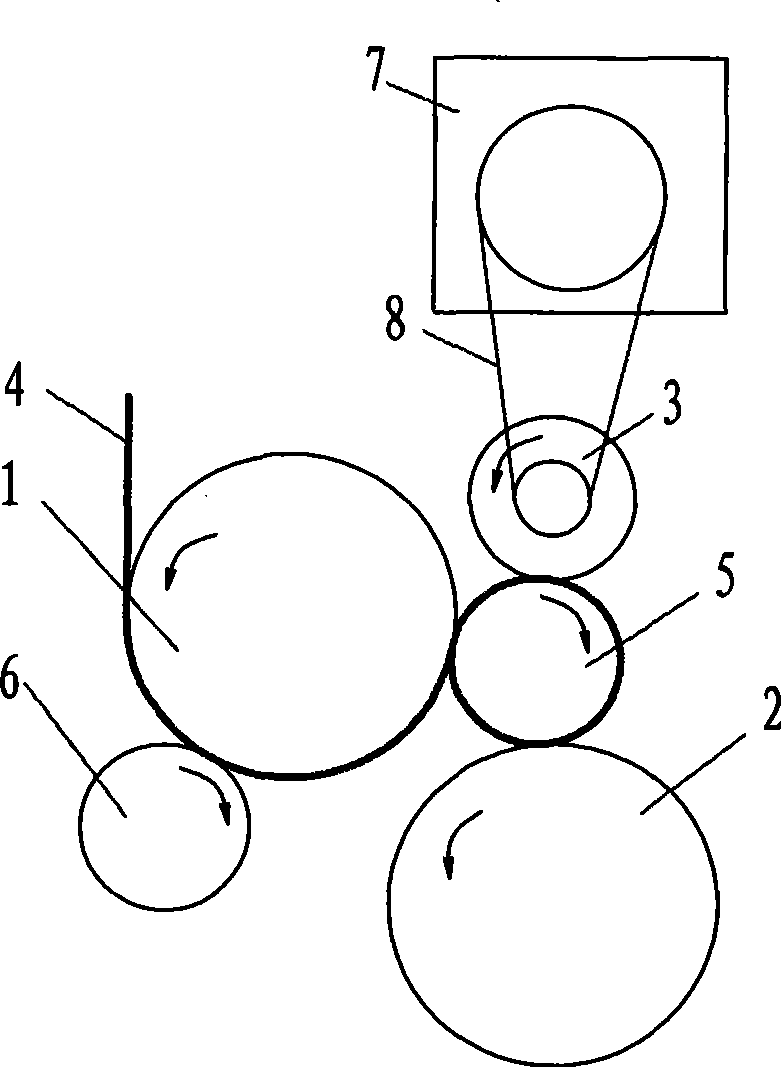

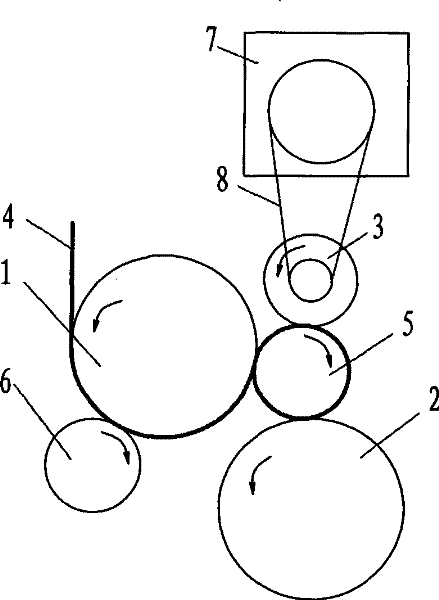

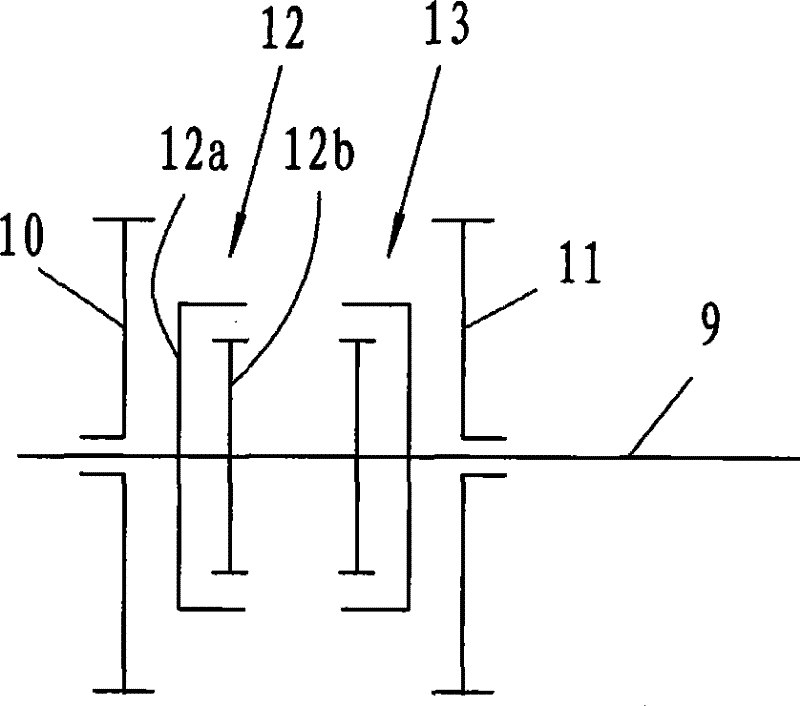

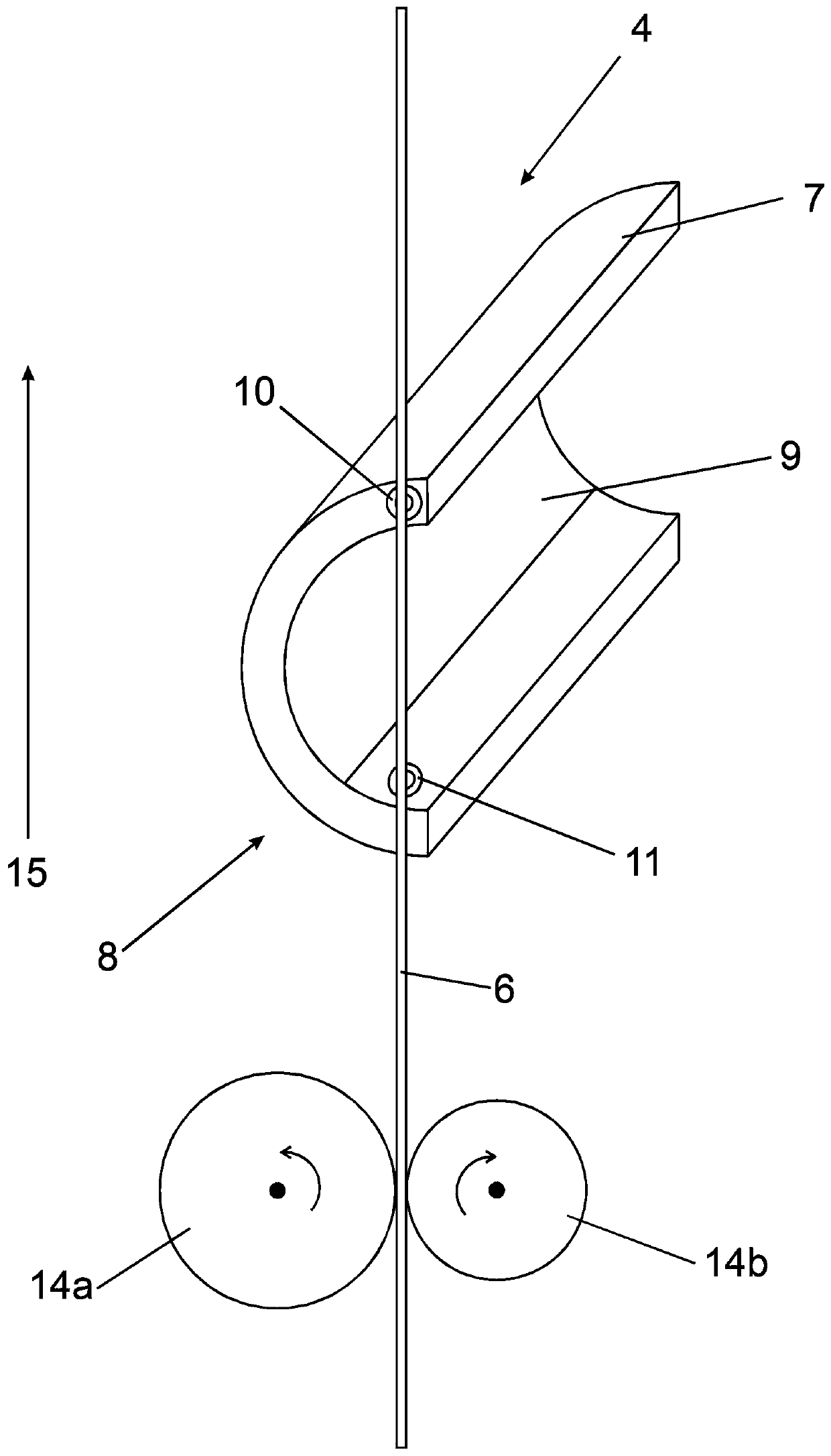

Paper cutting method and mechanism of rewinder

ActiveCN101503154AEliminate trimming processSave paperWebs handlingPaper sheetPulp and paper industry

The invention provides a paper-breaking method and a paper-breaking mechanism for a rewinder. The paper-breaking method is characterized in that the rotating speed of one drive roller of the rewinder is momentarily higher than the rotating speed of the other two drive rollers so that a paper holder fast rolls towards the direction where three drive rollers are separated from one another, and before the paper holder is completely separated from the three drive rollers, paper at the tail part of the paper holder is broken. The paper-breaking mechanism is essentially characterized in that one drive roller of the rewinder is connected with a sudden acceleration speed changer. The invention has the working principle that the rotating speed of the drive rollers is suddenly changed to break the paper so as to prevent a press block from pressing the paper like the prior art in the process of paper breaking and also avoid the strict condition which is needed to be met when the press block is momentarily contacted with the paper. The invention can easily ensure that the paper at the tail part of the paper holder is broken on the same perforatig line.

Owner:FOSHAN BAOSUO PAPER MASCH MFG CO LTD

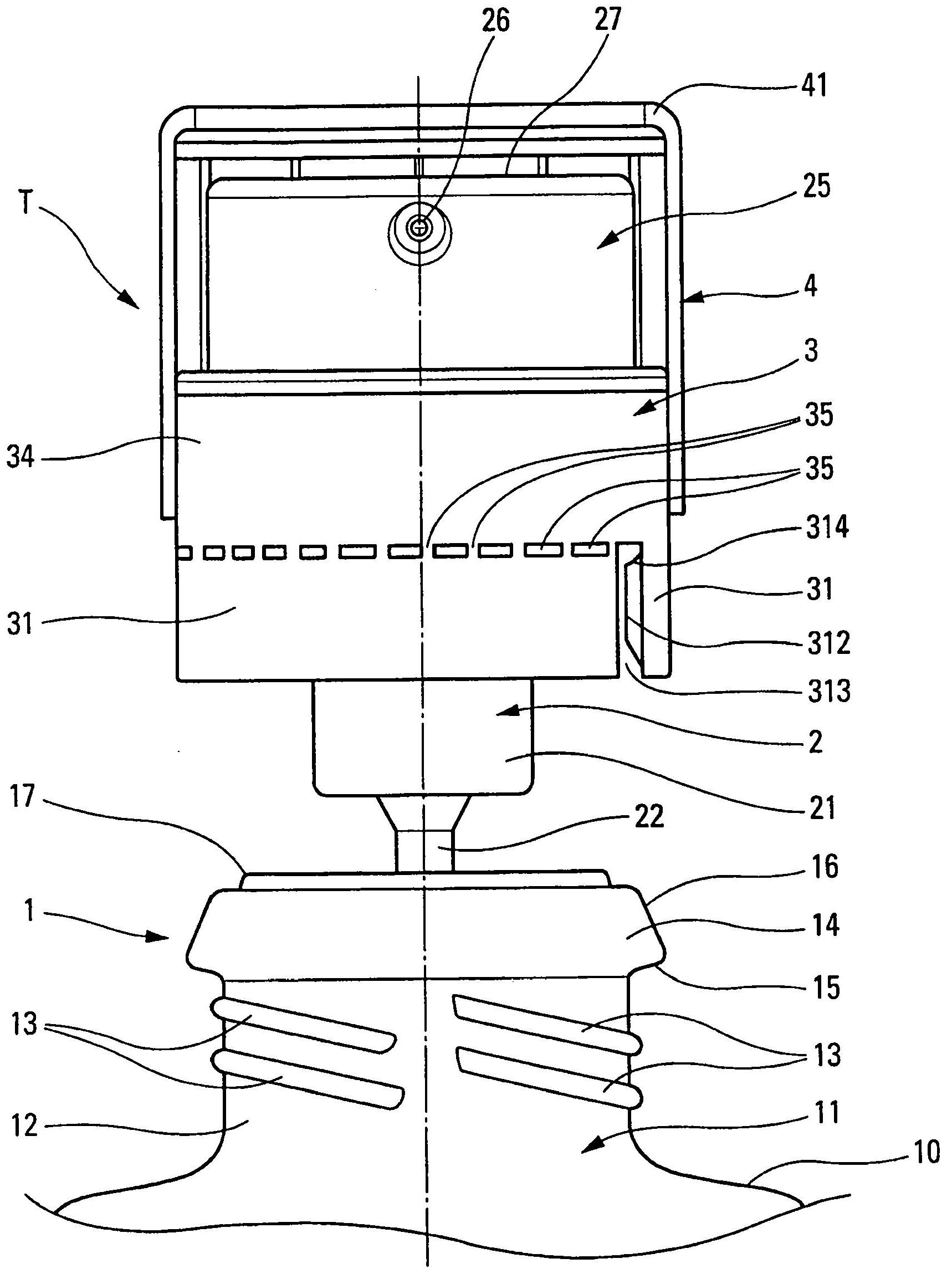

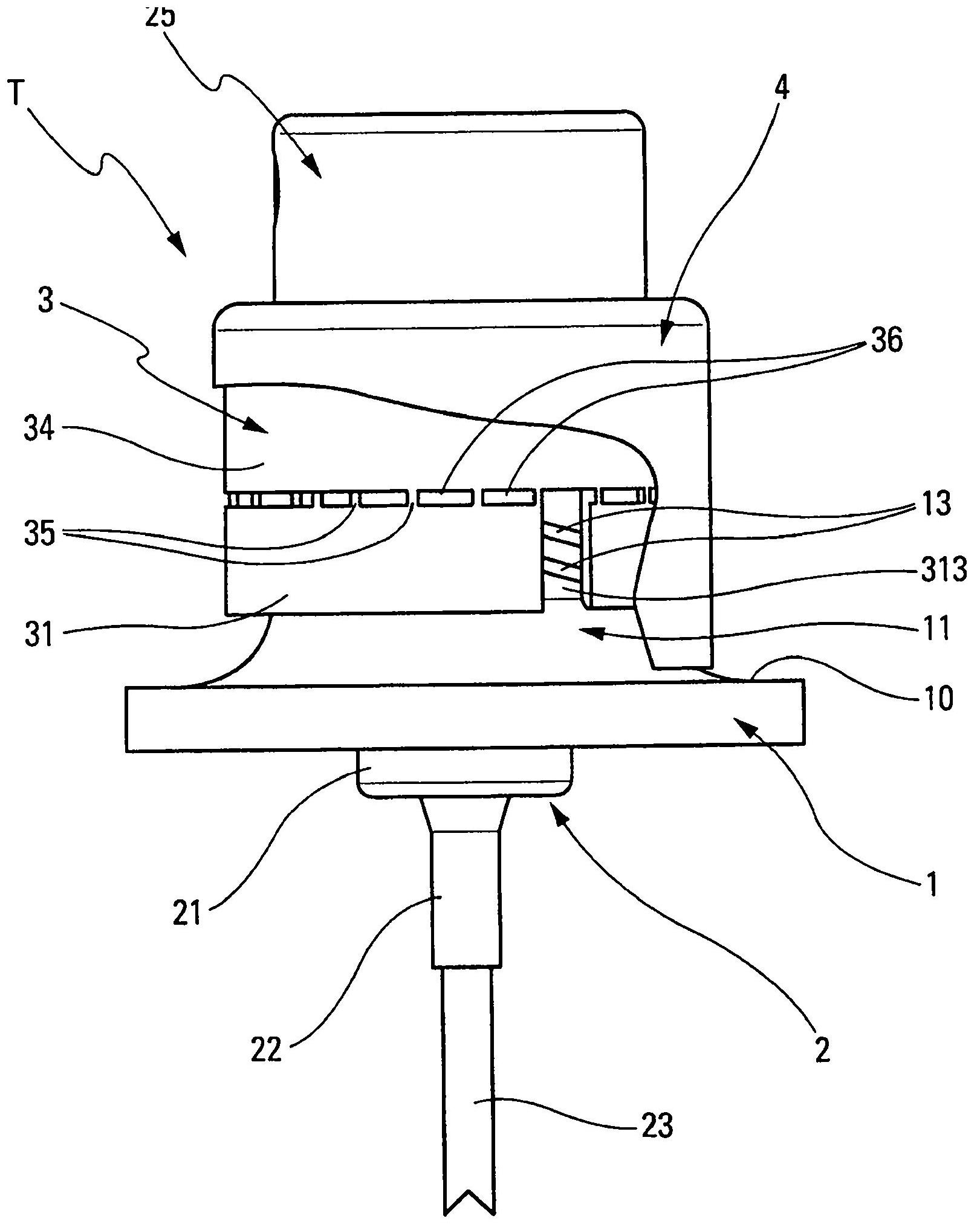

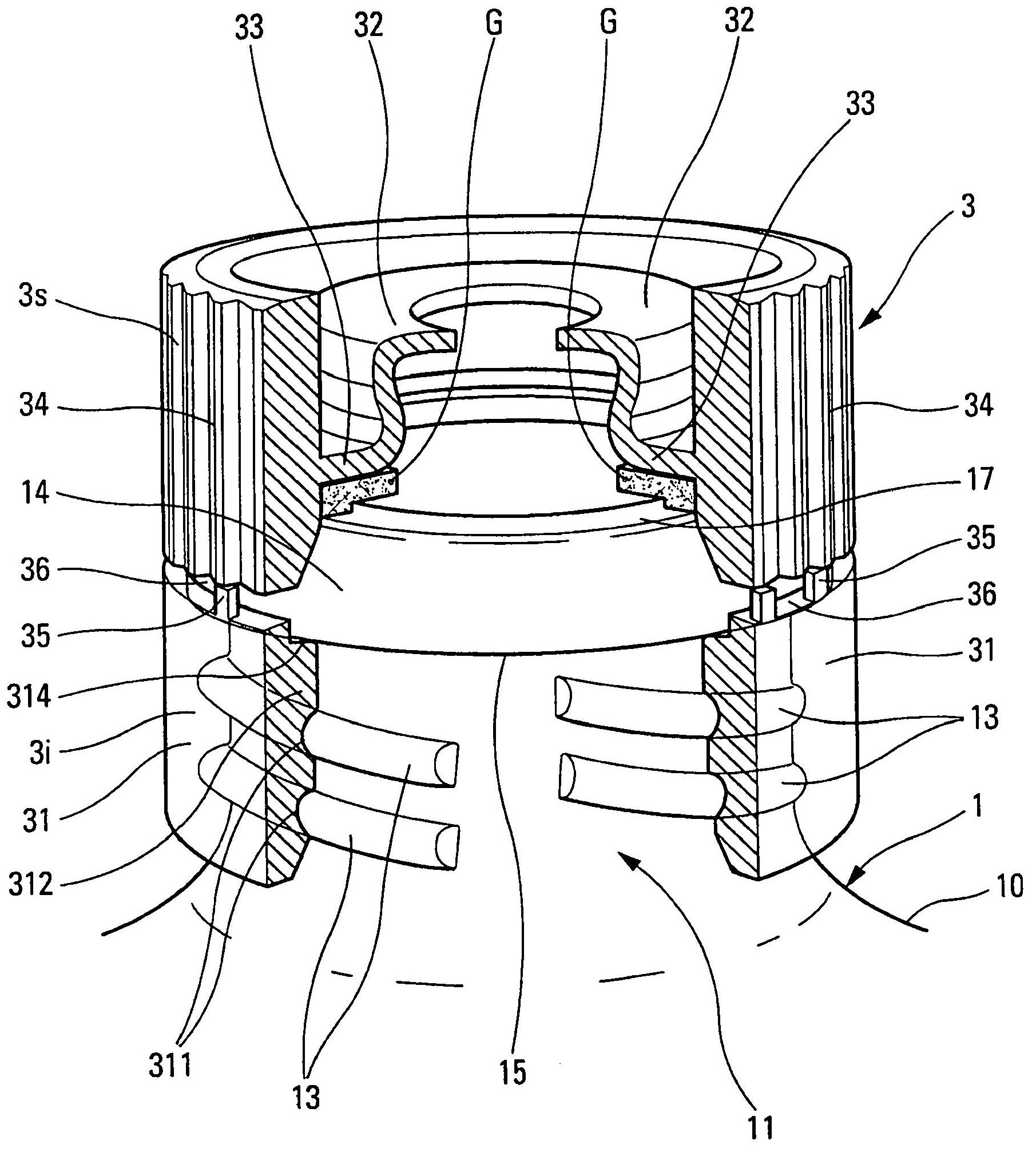

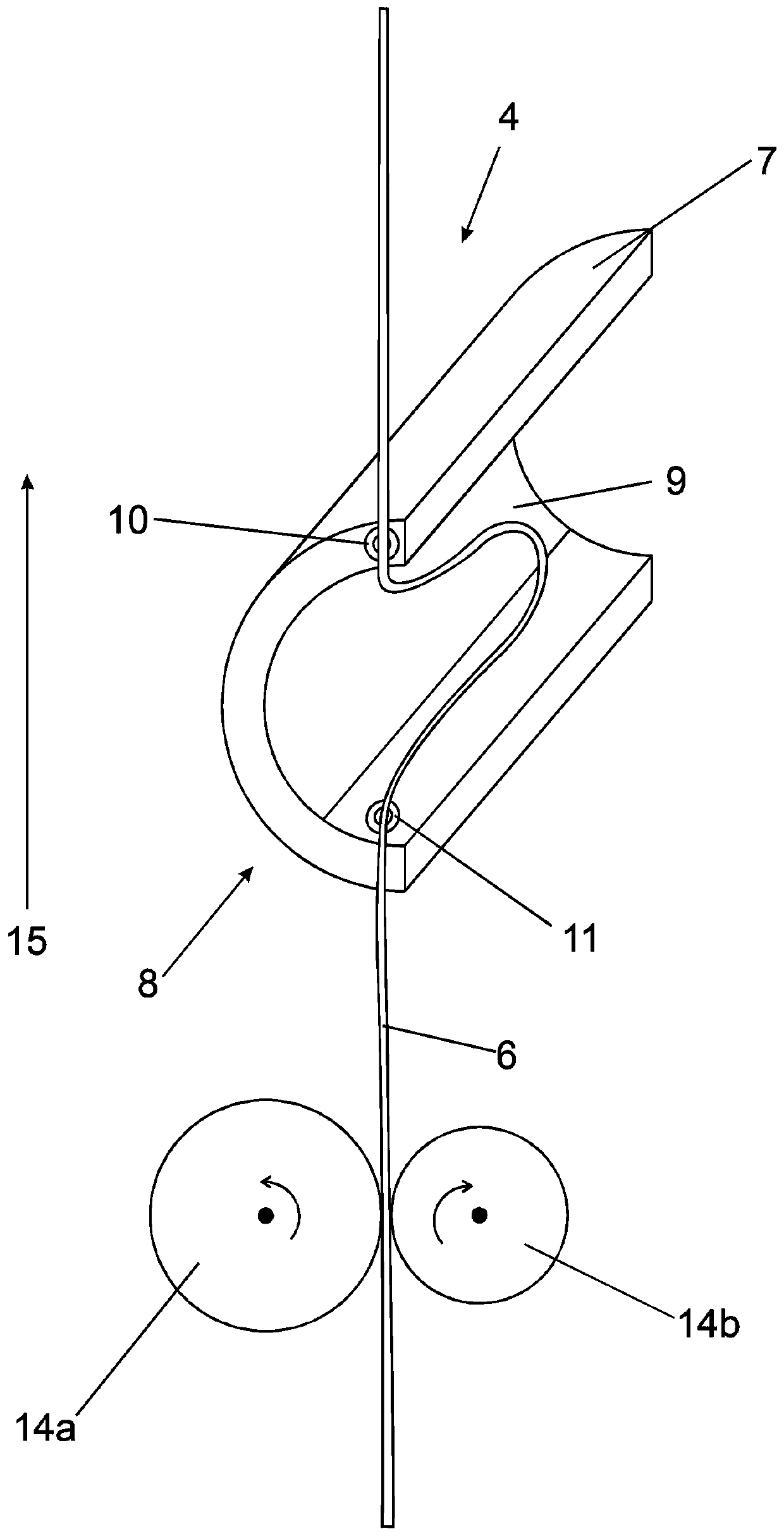

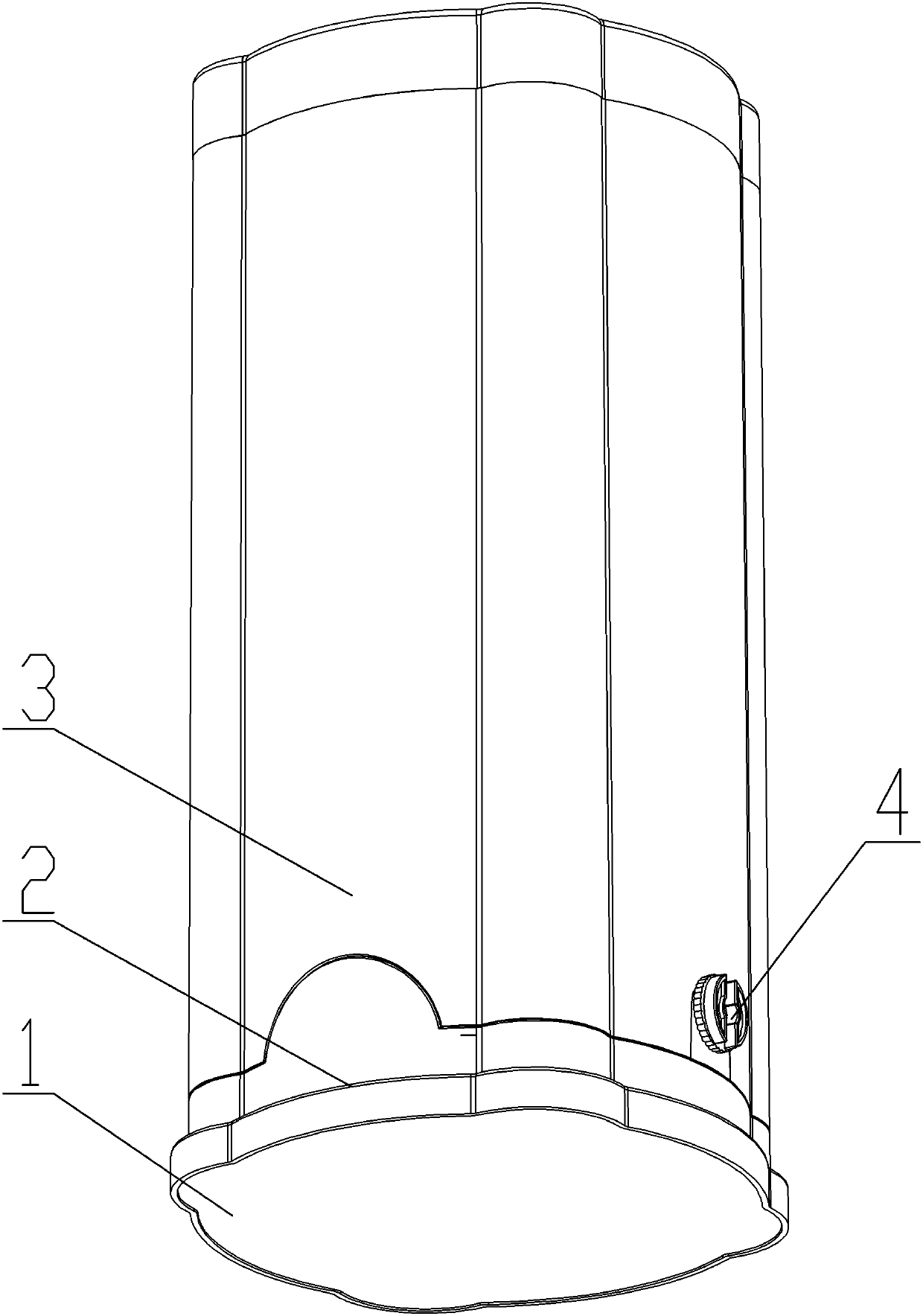

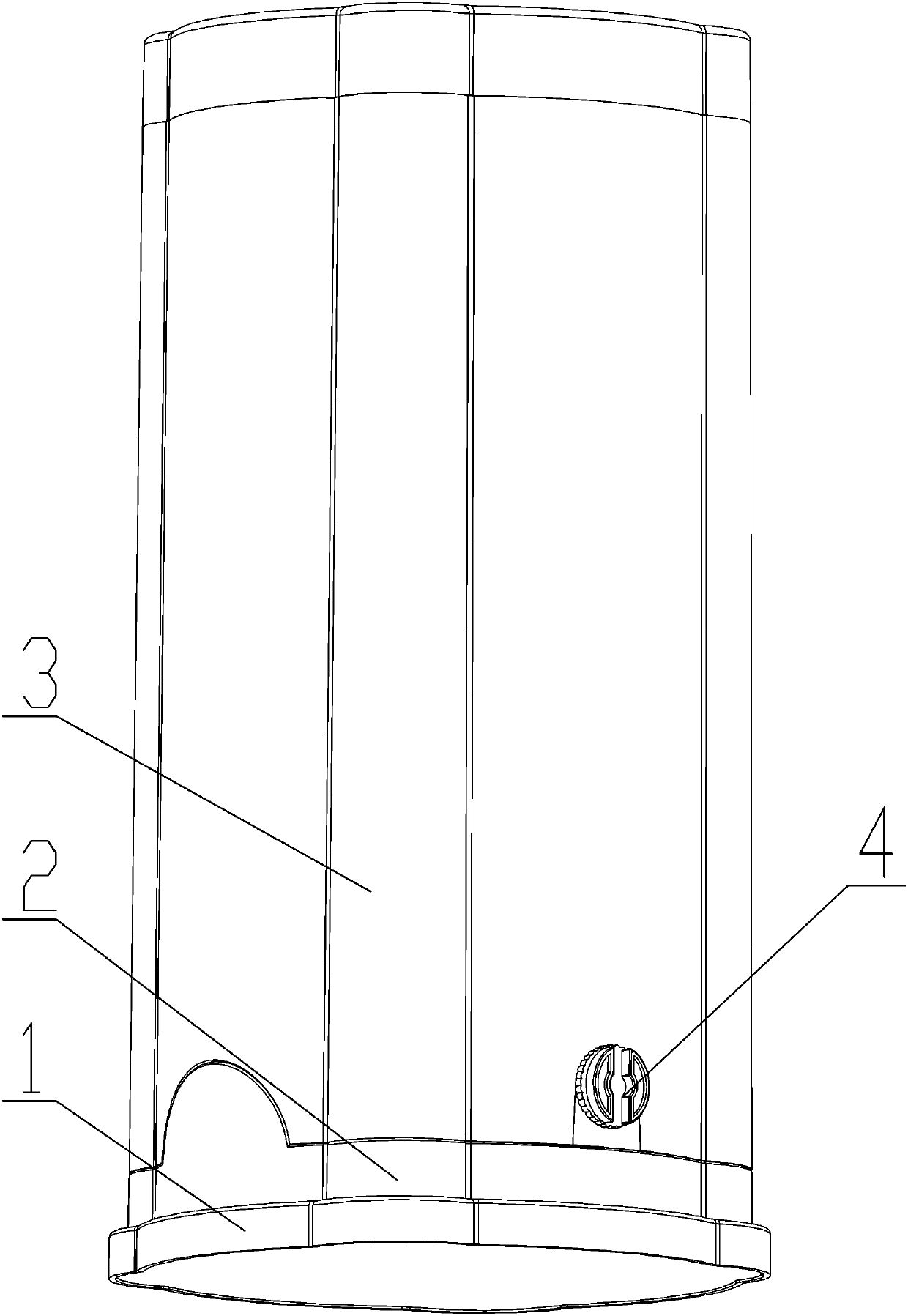

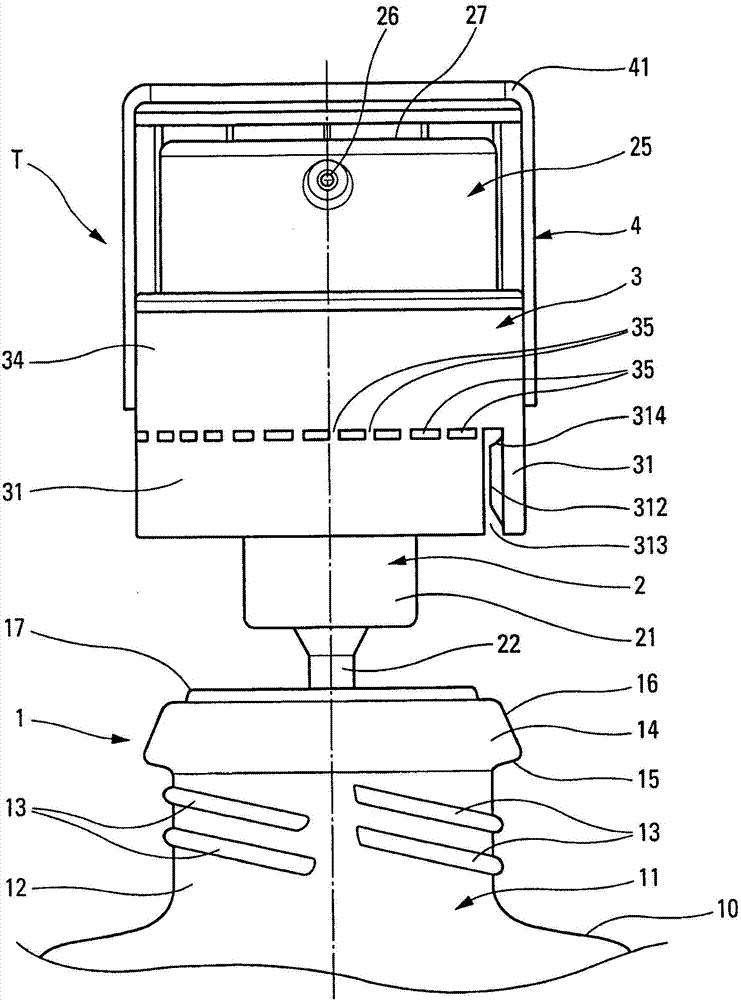

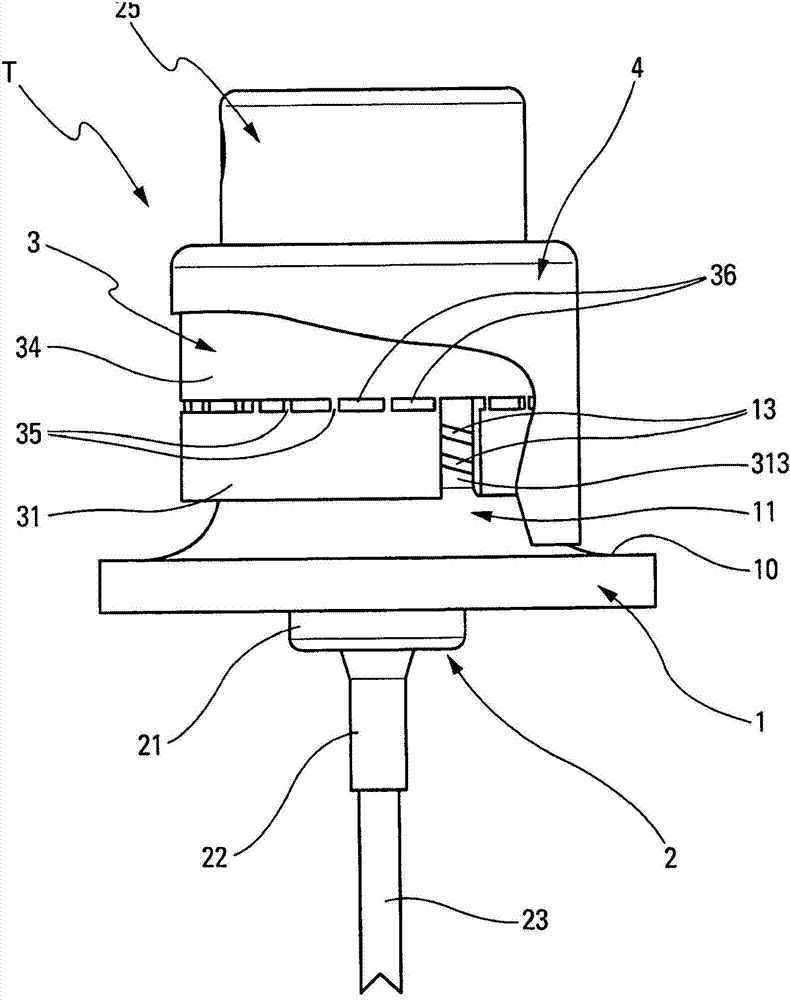

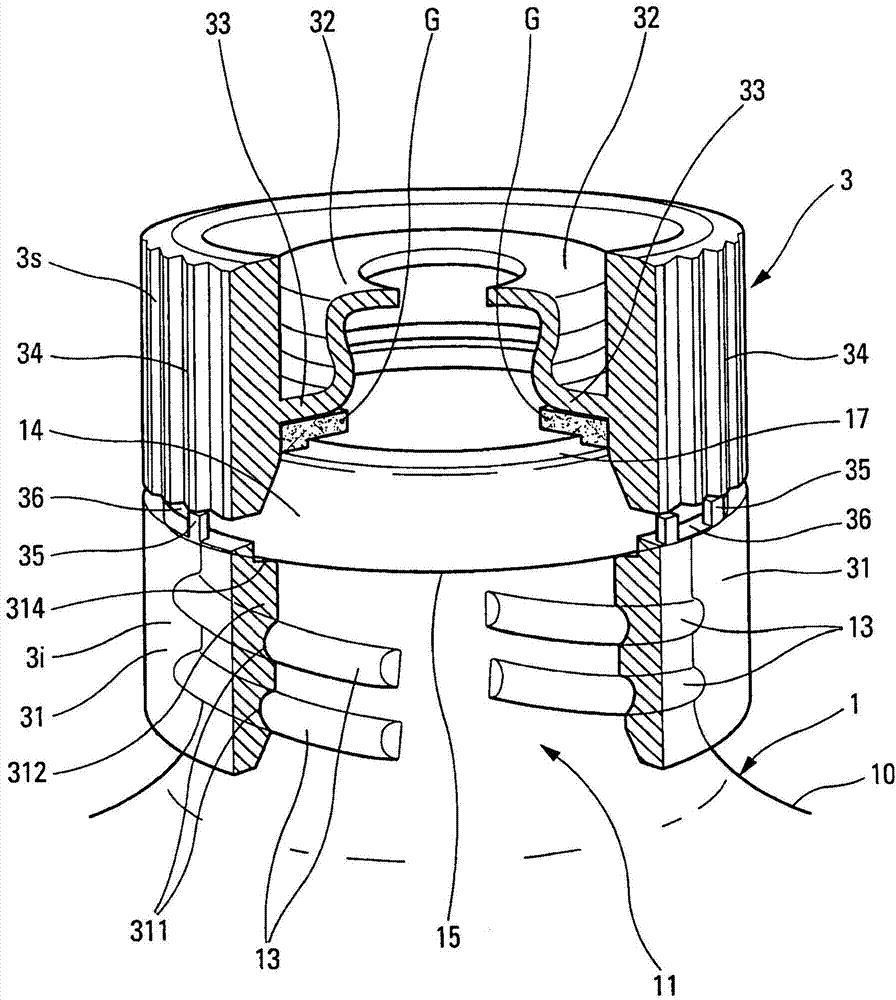

Dispenser of fluid material

InactiveCN102665930AGuaranteed breakAvoid reinstallationDispensing apparatusSingle-unit apparatusBiomedical engineering

The invention relates to a dispenser of fluid material, said dispenser including: a fluid material tank (1) provided with a neck (11) that is threaded on the outside thereof and defines, on the inside thereof, an opening (10) that is in communication with the inside of the tank, the neck (11) forming at least one helical thread (13); and a dispensing head mounted onto the neck (11) by means of an attachment member (3, 4) that meshes, at the same time, with the threaded neck (11) and the dispensing member (2), the attachment member (3, 4) including a ring (3), said ring forming a receiving means (32) for the dispensing member (2), an annular plate (33), and an apron (31) that meshes with the threaded neck (11). Said dispenser is characterized in that the ring (3) includes a breaking means (35, 36), between the plate (33) and the apron (31), for separating the plate from the apron through rotation of the ring (3) on the threaded neck (11) such as to be able to remove the dispensing member (2) from the tank (1).

Owner:APTAR FRANCE SAS

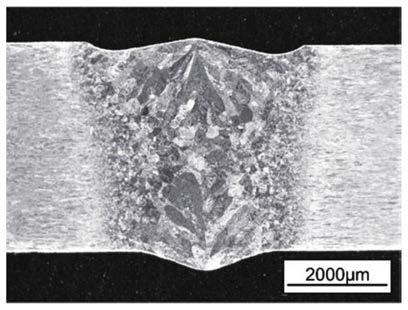

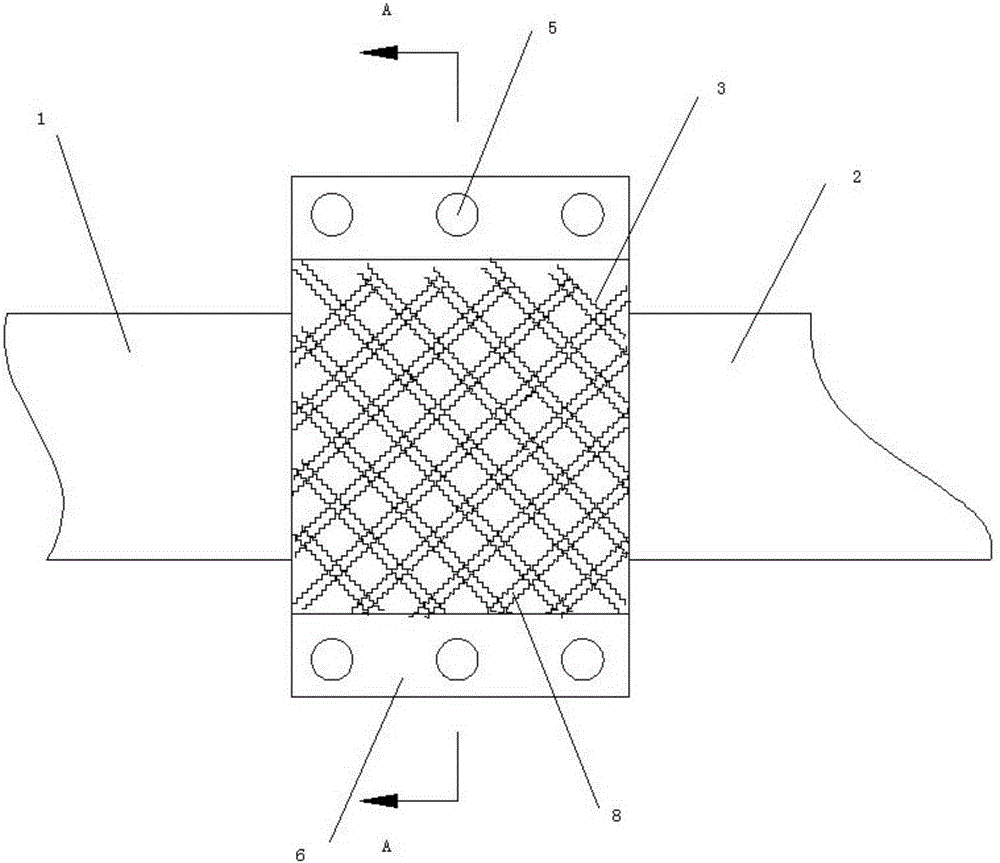

Method for evaluating low-cycle fatigue performance of welded joint

ActiveCN111175157AGuaranteed breakAvoid failureMaterial strength using repeated/pulsating forcesElement analysisTest sample

The invention relates to a method for evaluating low-cycle fatigue performance of a welded joint. Evaluation is carried out by adopting a funnel sample, and a working section of the funnel sample is composed of an arc-shaped section and a parallel section; the center of a micro area of the welded joint to be tested is placed in the middle of the arc-shaped section of the funnel sample so that thefatigue sample is broken in the micro-area to be tested, and then low-cycle fatigue performance of the micro-area of the welded joint is evaluated by adopting the local strain of the plastic area obtained through elastic-plastic finite element analysis in strain concentration. Compared with a traditional smooth test sample, the funnel test sample is adopted for testing fatigue performance of the welded micro-area, the fatigue test sample can be finally broken in the welded joint micro-area needing to be measured, and the tested fatigue performance is the fatigue performance of the welded micro-area instead of fatigue performance of the lowest-strength area in the joint. For low-cycle fatigue, the plastic zone strain is used as local strain to evaluate low-cycle fatigue performance of the funnel sample, which is more reliable than hot spot strain and dangerous section strain evaluation, and the method is simpler and more convenient than a critical distance method for calculation.

Owner:XI AN JIAOTONG UNIV

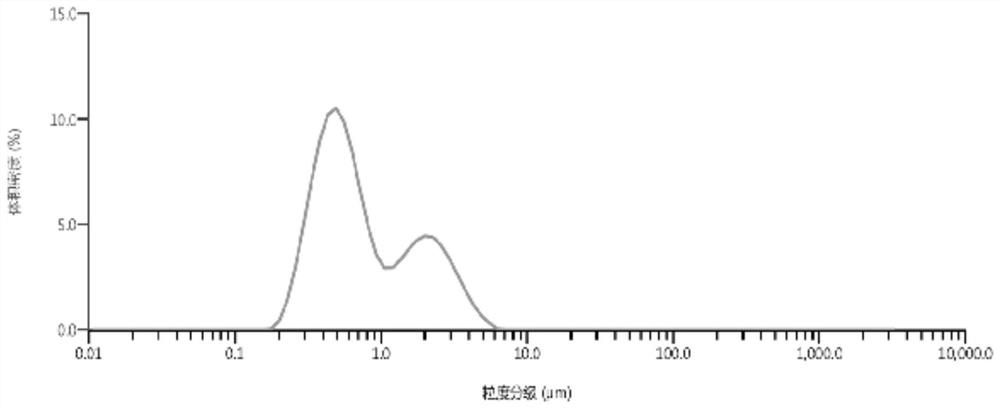

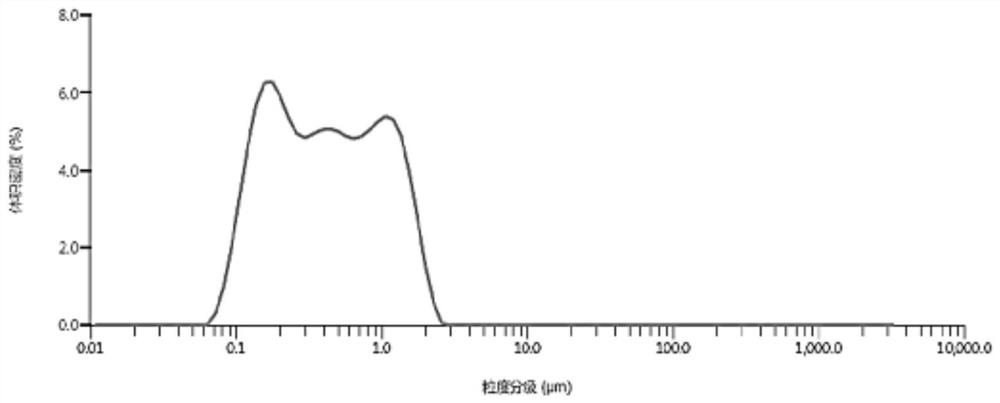

Cold isostatic pressing forming preparation method of tungsten oxide-based ceramic target material

InactiveCN112479707AWide particle size distributionHigh bulk densityVacuum evaporation coatingSputtering coatingHigh densityMetallurgy

The invention relates to a cold isostatic pressing forming preparation method of a tungsten oxide-based ceramic target material, which comprises the following steps of raw material preparation: takingprimary mixed powder containing high-purity tungsten oxide and doping source powder, enabling the doping source to be selected from at least three of Ti, Mo, V, Al, Li and Zr, enabling the purity ofthe mixed powder to be greater than 99.95%, enabling the average particle size to be 500nm to 1800nm, and enabling the D50 particle size to be 200-750nm, wherein the quantitative relation of M1, M2, M3, M4 and M5 conforms to the formula as described in the specification, conducting spray drying, powder filling and compaction, pressing, biscuit degumming and sintering, taking out the sintered blankafter heat preservation, and conducting or not conducting machining according to needs. The cold isostatic pressing forming preparation method can be used for preparing the tungsten oxide-based ceramic target material with good conductivity, higher purity, fine grain size and high density.

Owner:北京航大微纳科技有限公司

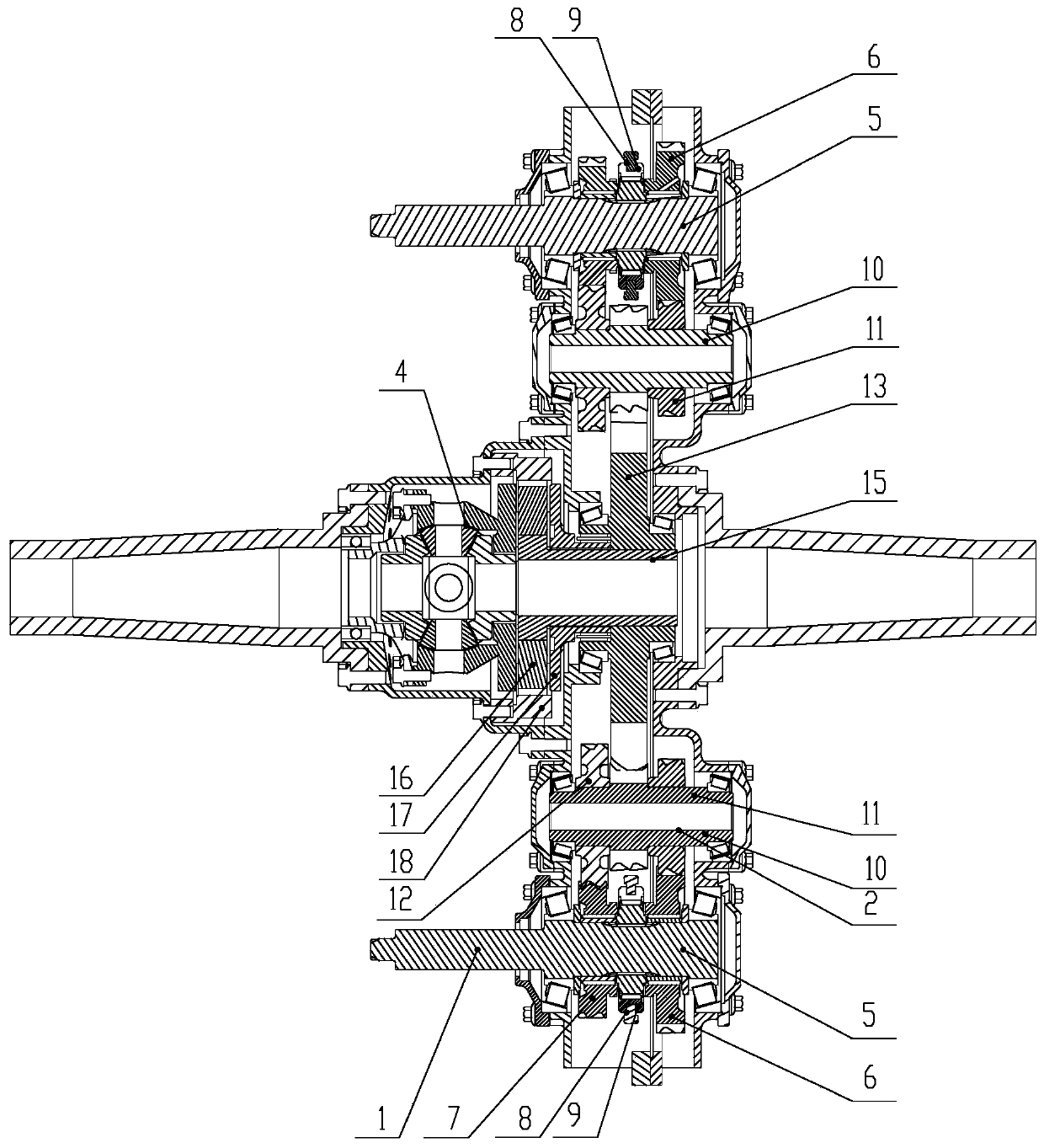

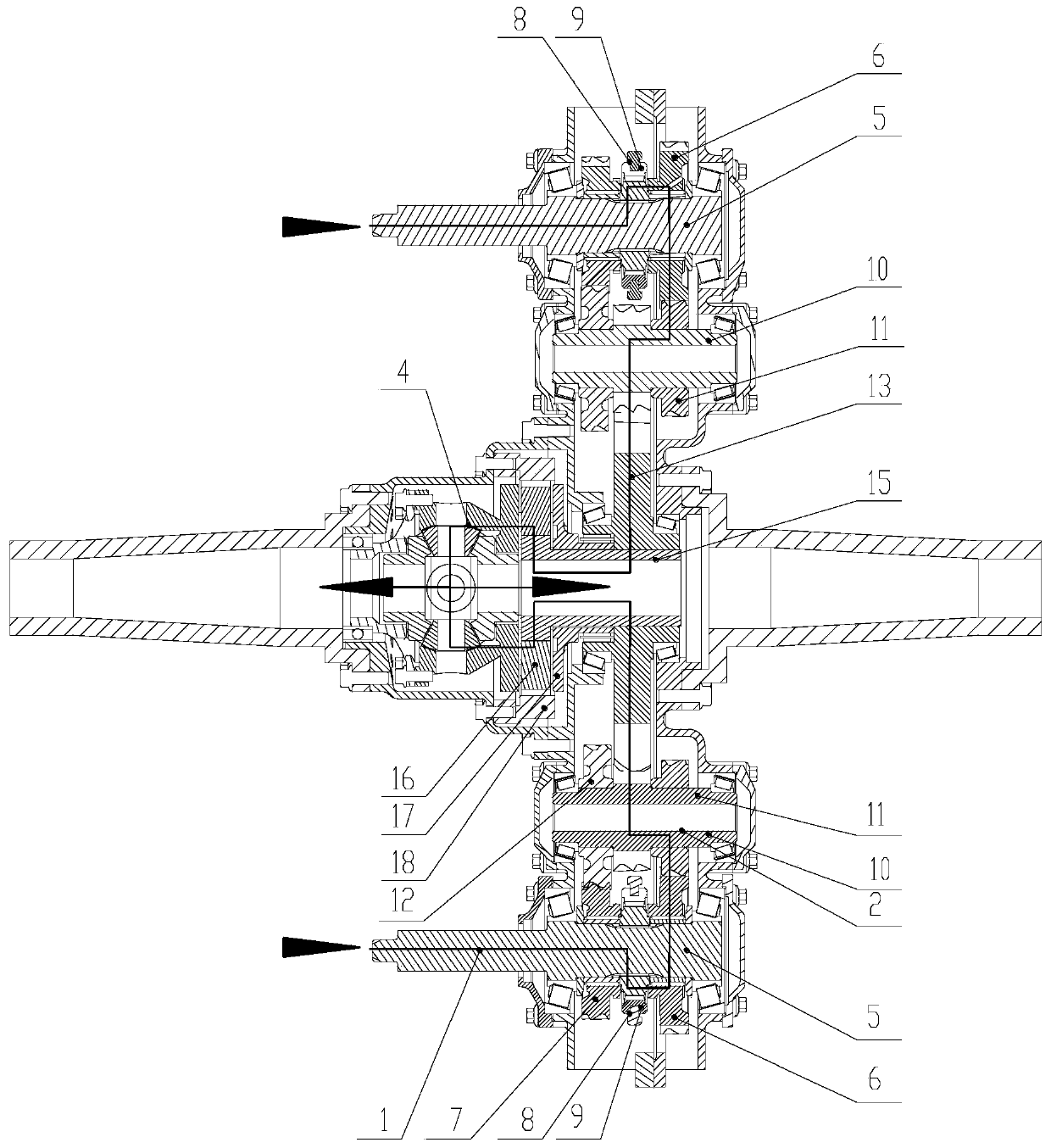

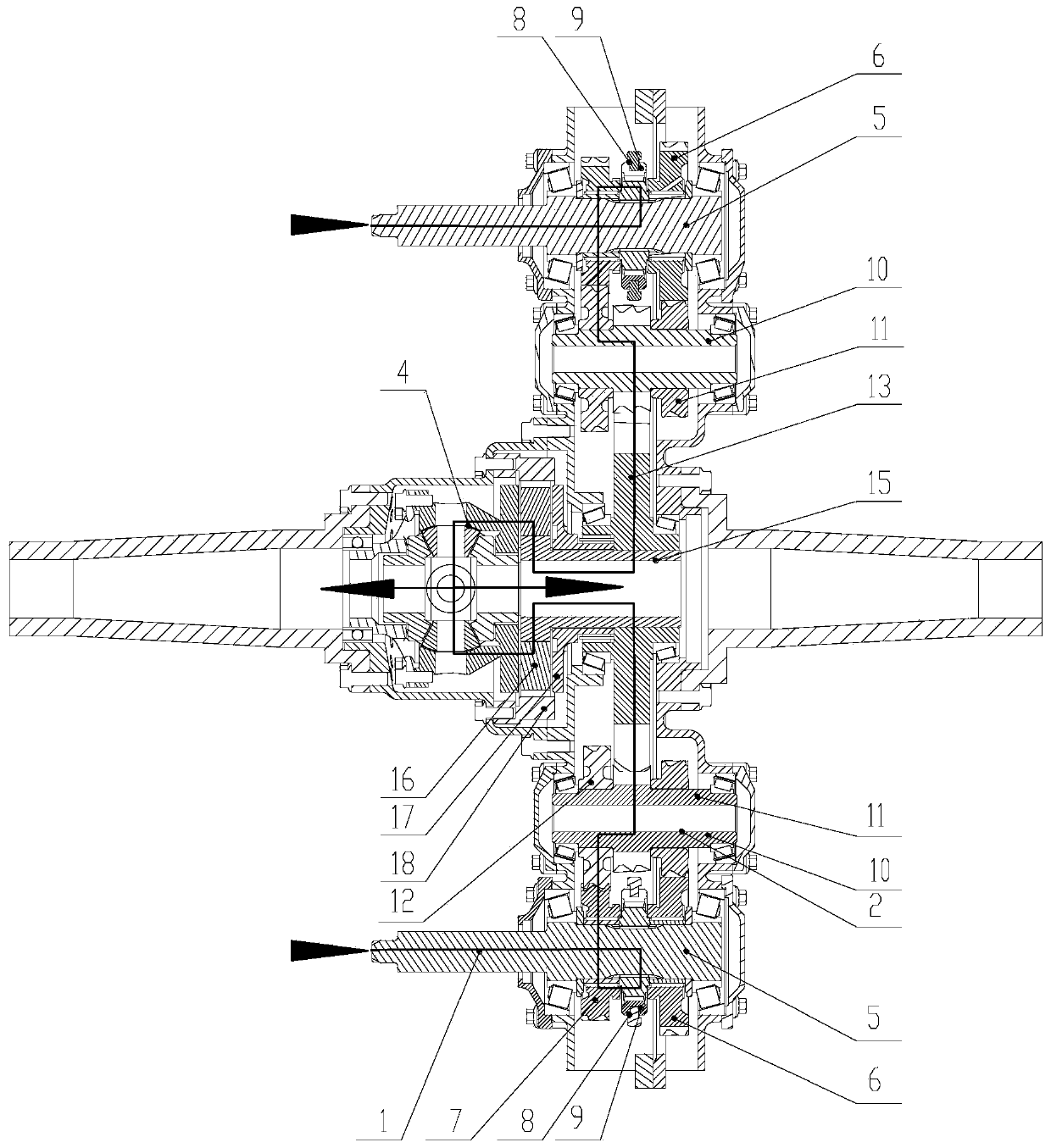

Dual-motor transverse gear-shiftable electric drive axle speed reducer assembly

PendingCN110848346AAchieve shiftSave layout spaceToothed gearingsGearing detailsReduction driveGear wheel

The invention discloses a dual-motor transverse gear-shiftable electric drive axle speed reducer assembly which comprises two motors, two gear-shifting assemblies, a planetary reduction gear assemblyand a differential mechanism assembly. The gear-shifting assemblies include a first shaft assembly and a second shaft assembly. The motors are connected with the first shaft assembly. High-speed and low-speed two-gear speed regulation is realized through a sliding meshing assembly on the first shaft assembly. The second shaft assembly is in transmission with a sun wheel axle of the planetary reduction gear assembly through a long meshing gear set. A planet carrier of the planetary reduction gear assembly is connected with a differential mechanism inner shell of the differential mechanism assembly through a planet pinion shaft. A gear ring is connected with a differential mechanism shell. The dual-motor transverse gear-shiftable electric drive axle speed reducer assembly is compact in structure, high in integrity, low in machining difficulty and light in weight.

Owner:DONGFENG COMML VEHICLE CO LTD

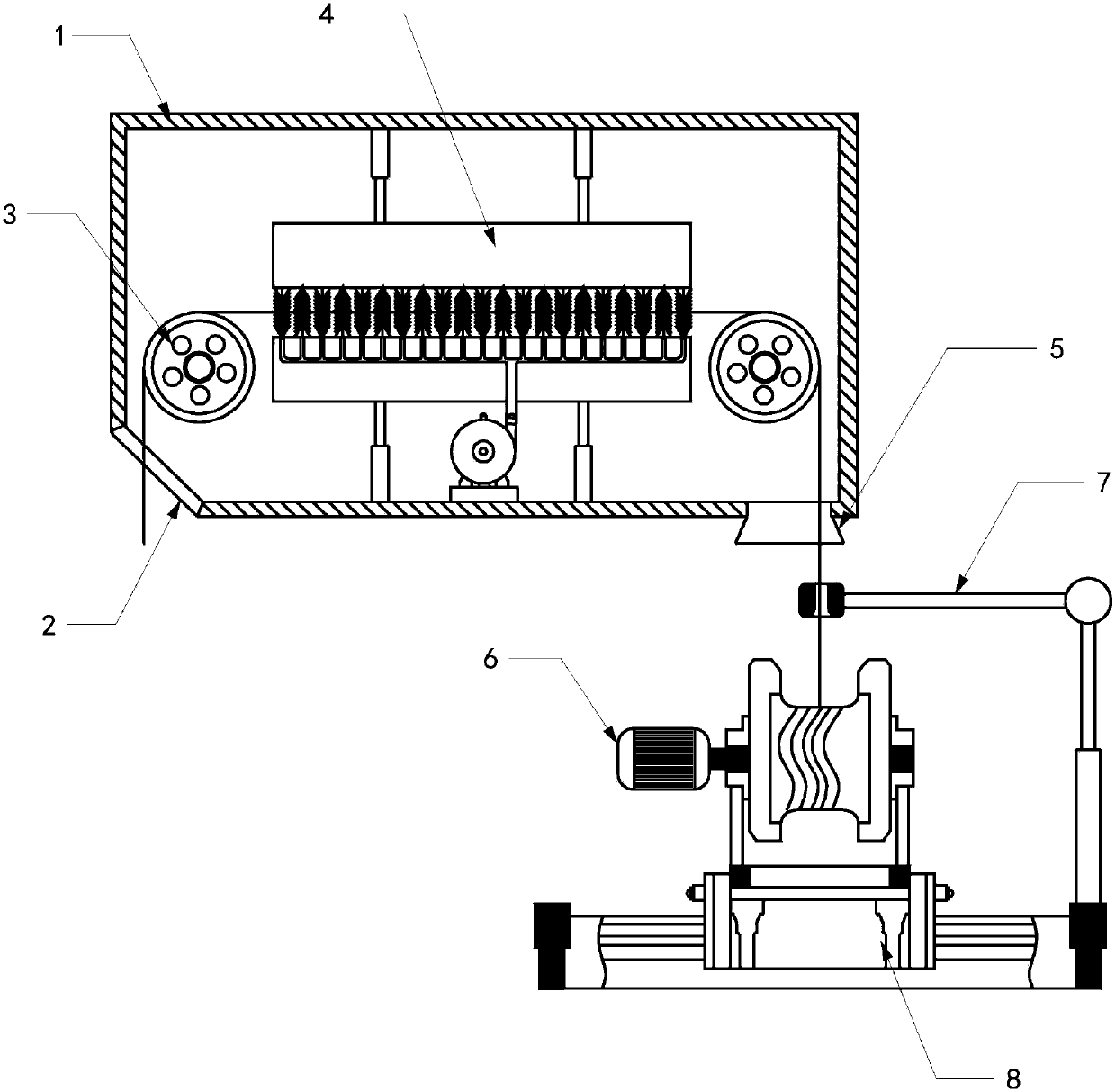

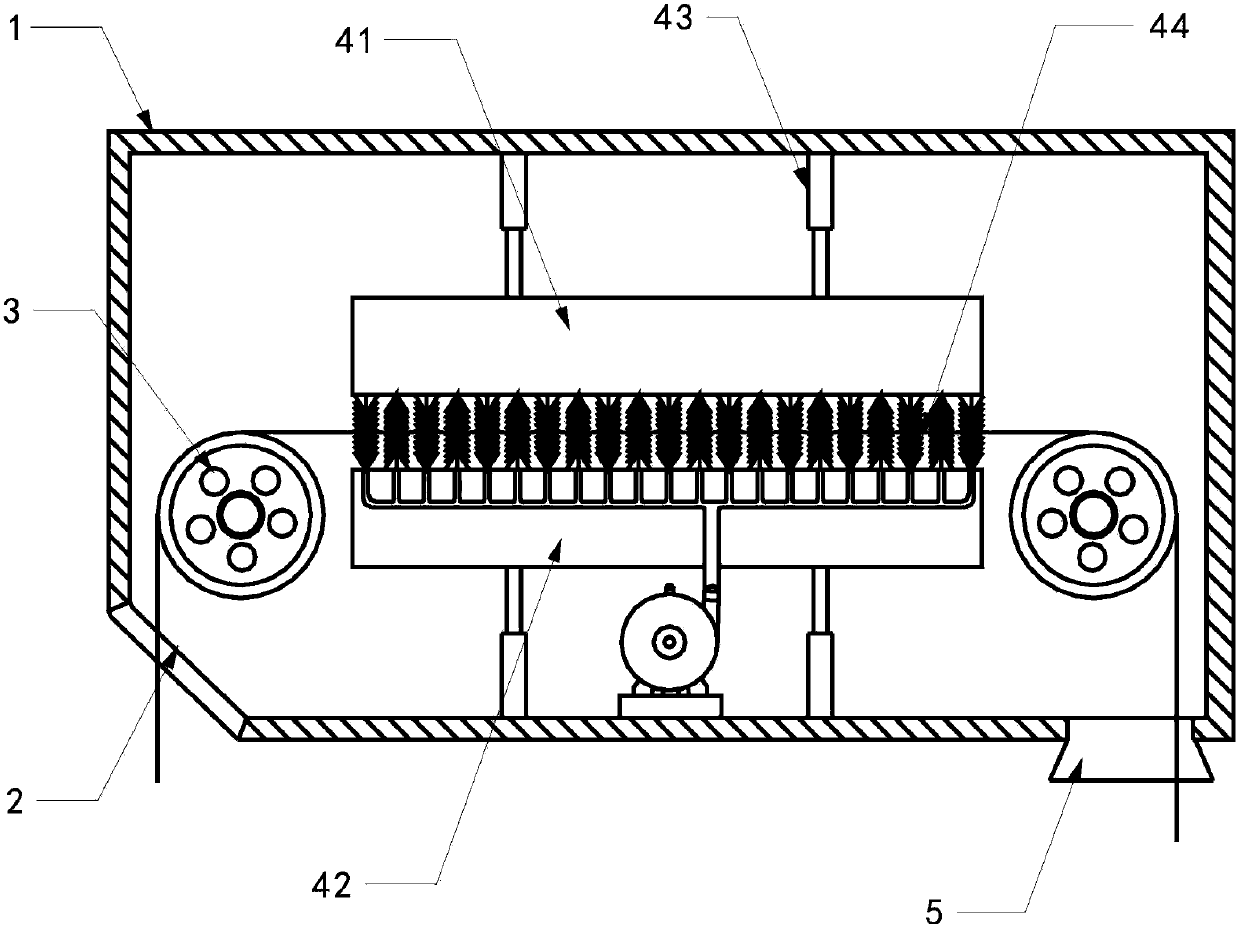

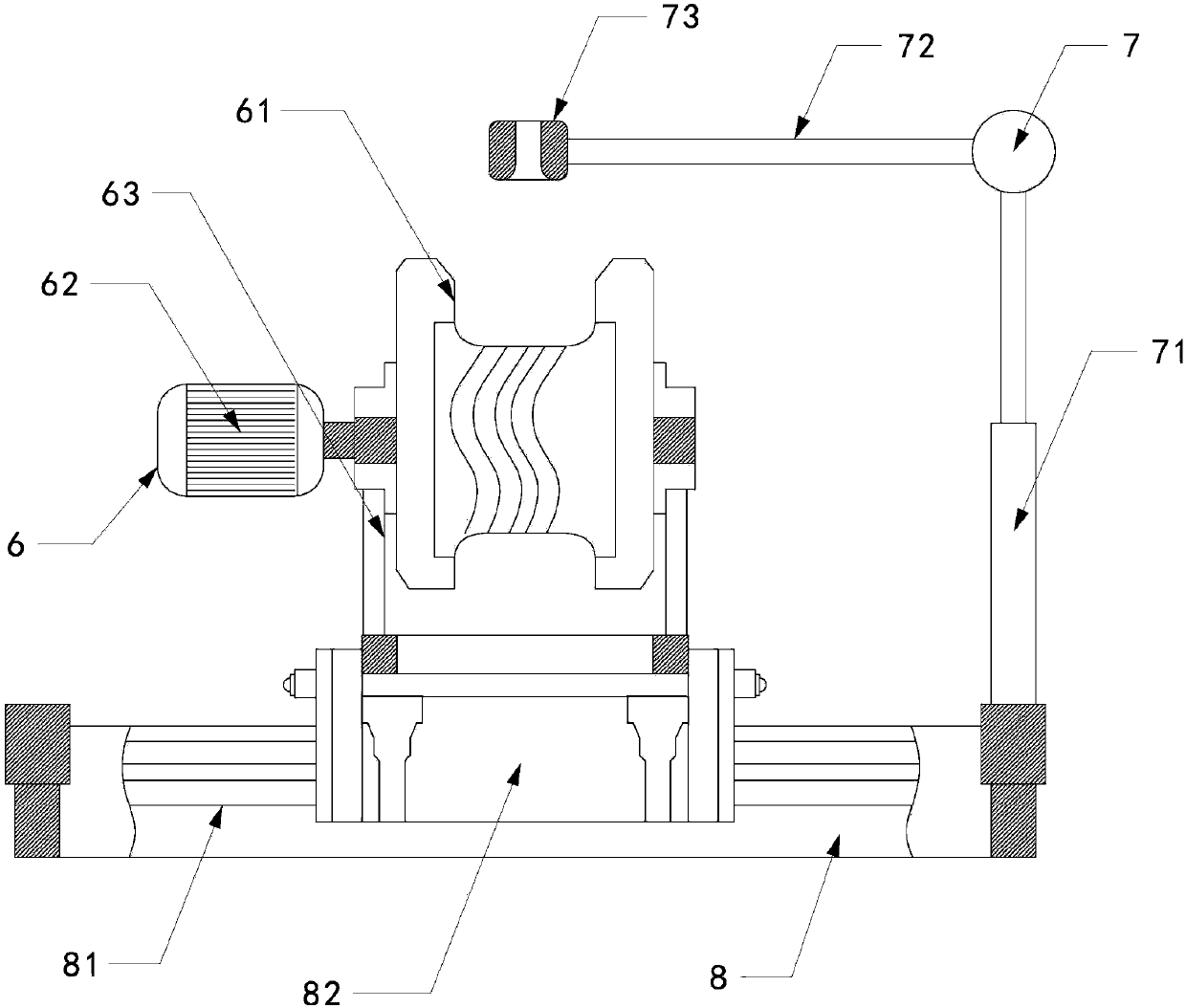

Anti-fracture water-cooling automatic water-removing wire-winding metal drawing machine equipment

InactiveCN107755459APrevent rustKeep dryDrying solid materials without heatDrying machines with progressive movementsEngineeringWater cooling

The invention discloses anti-fracture water-cooling automatic water-removing wire-winding metal drawing machine equipment and relates to the technical field of drawing machine equipment. The drawing machine equipment disclosed by the invention comprises a shell, wherein a through hole through which metal wires are introduced is formed in the lower end of the shell. The drawing machine equipment further comprises a guide runner, a drying mechanism and a wire outlet which are sequentially arranged inside the shell, as well as a rolling mechanism, a limiting mechanism and a displacement mechanism, wherein the drying mechanism is used for cleaning moisture on the metal wire surface and is connected with upper and lower walls of the shell; the wire outlet is formed in the tail of the shell; therolling mechanism is used for collecting metal wires; the limiting mechanism is used for limiting a swing amplitude of the metal wire; the displacement mechanism is used for controlling a horizontalmovement of the rolling mechanism; the rolling mechanism is arranged below the wire outlet and fixed on the displacement mechanism; and the limiting mechanism is fixed just above the rolling mechanism. According to the drawing machine equipment disclosed by the invention, the metal wires can be automatically dried, wire fracture is avoided, and the quality of the metal wire products is improved.

Owner:CHENGDU KECHUANGGU TECH CO LTD

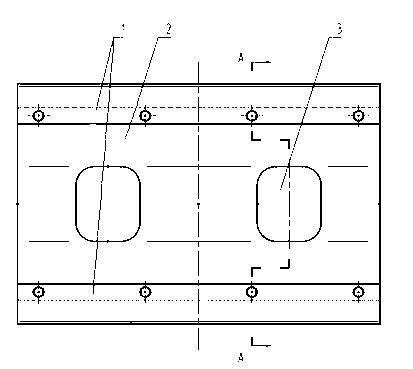

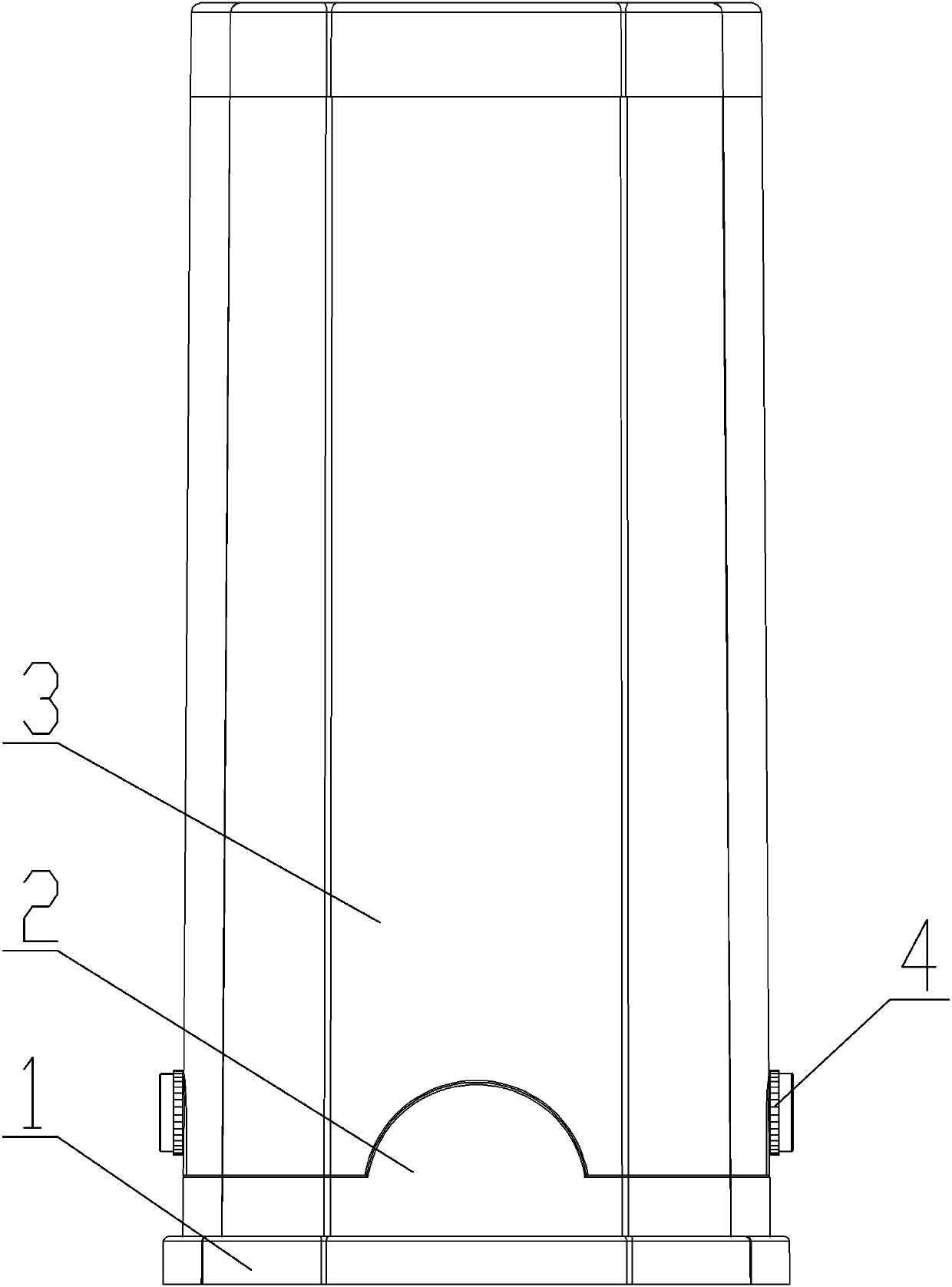

Jaw crusher toggle plate

The invention provides a jaw crusher toggle plate. The jaw crusher toggle plate comprises a toggle plate body (2) and wear-resisting bodies (1) at the two sides of the toggle plate body (2), wherein the two sides of the toggle plate body (2) are provided with steps, and the wear-resisting bodies (1) are provided with steps (5) matched with the toggle plate body steps (7). The jaw crusher toggle plate disclosed by the invention has the technical effects that firstly, the two ends of the toggle plate body are provided with the wear-resisting bodies, so that the abrasion between the toggle plate body and a toggle plate cushion is alleviated, the service life of the toggle plate is prolonged for 7-8 times and the utilization rate of materials is greatly improved; secondly, the toggle plate body adopts a casting to guarantee that a jaw crusher cracks when non-crushed materials fall into a machine or a machine is seriously overloaded so as to protect a movable jaw and a rack and achieve a safety effect, and the toggle plate body is convenient to replace; and thirdly, one ends of the wear-resisting bodies are circular-arc-shaped, and good rolling abrasion can be formed between the toggle plate and the toggle plate cushion to alleviate the impact on the toggle plate, so that the equipment can be reliably operated for a long period and the use and maintenance costs of the equipment are reduced.

Owner:HAIAN TIANPENG MACHINERY MFG

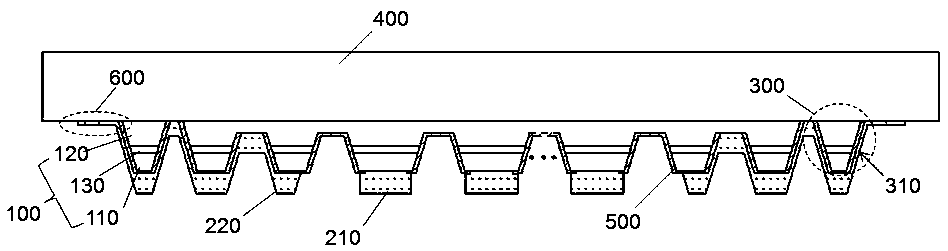

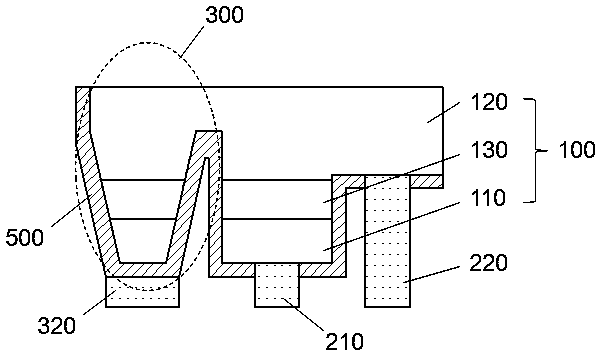

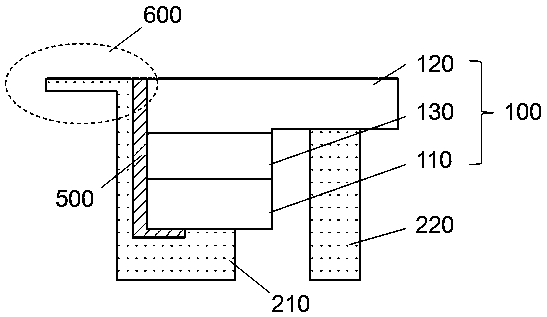

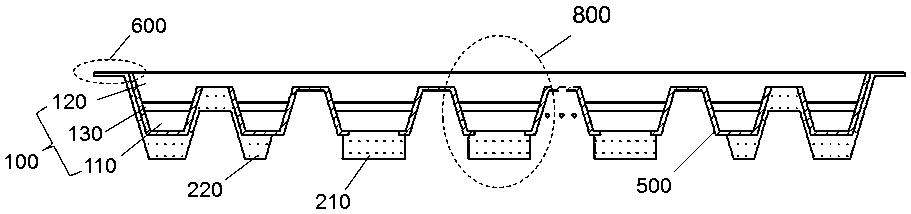

Light emitting element, light emitting element array and light emitting device thereof

ActiveCN110088919AAvoid damageReduce processing timeSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringControl circuit

The invention provides a light emitting device. The light emitting device is provided with a substrate which includes a control circuit. The light emitting device comprises a light emitting element with a semiconductor layer sequence. The semiconductor layer sequence comprises a first-type semiconductor layer, a second-type semiconductor layer and an active light emitting layer between the first-type semiconductor layer and the second-type semiconductor layer. The light emitting device has shielding layers which are distributed at periphery of the light emitting element. The light emitting element is connected with the control circuit of the substrate. The light emitting element utilizes or is going to utilize a substrate stripping process by laser. The shielding layers prevent working abnormities of the light emitting device cased by control circuit damage by the laser in substrate stripping.

Owner:XIAMEN SANAN OPTOELECTRONICS CO LTD

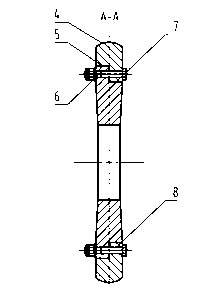

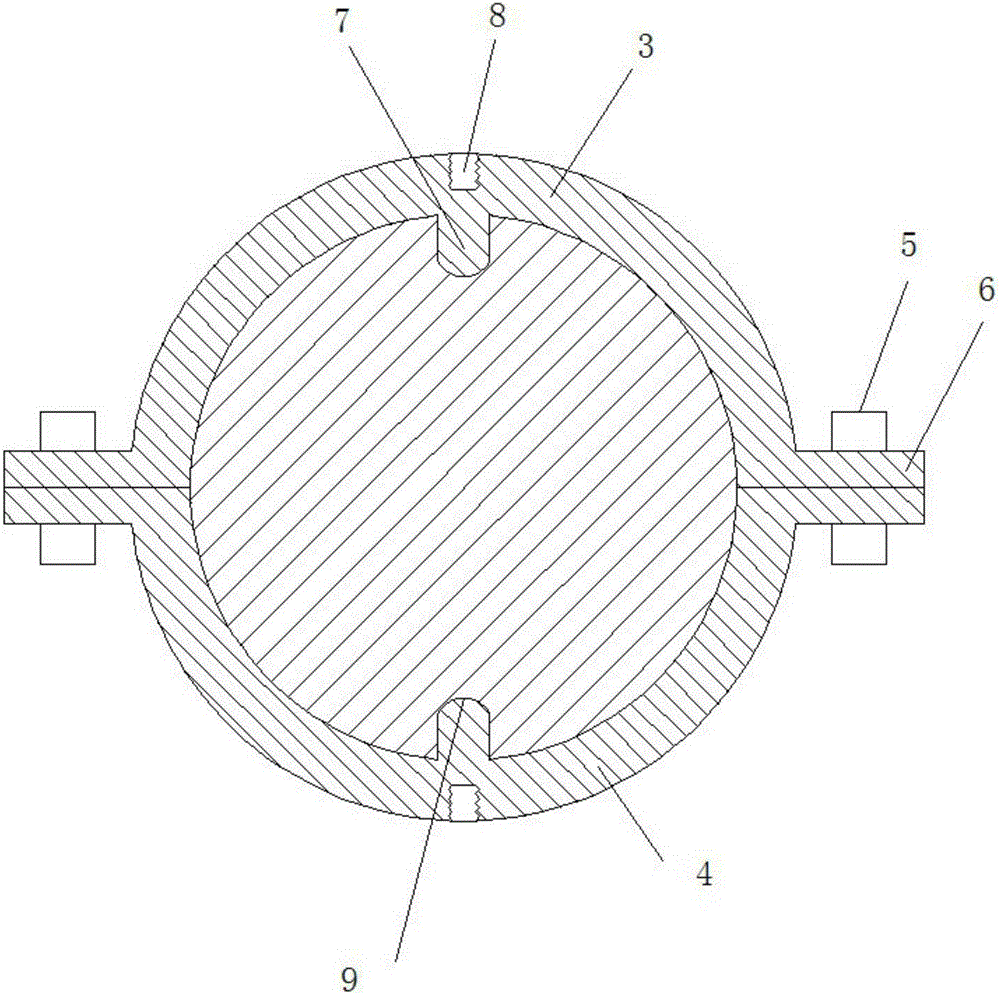

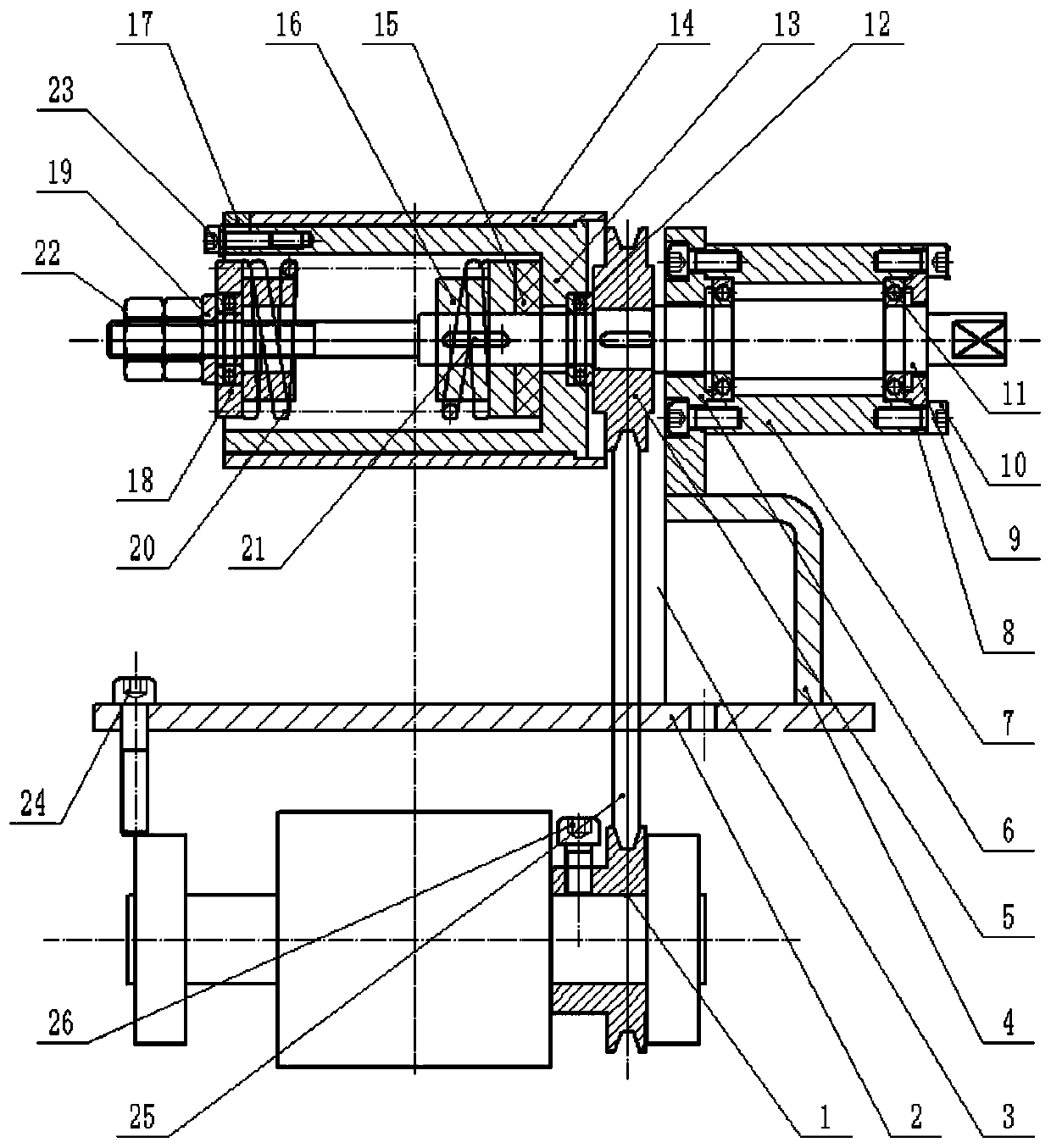

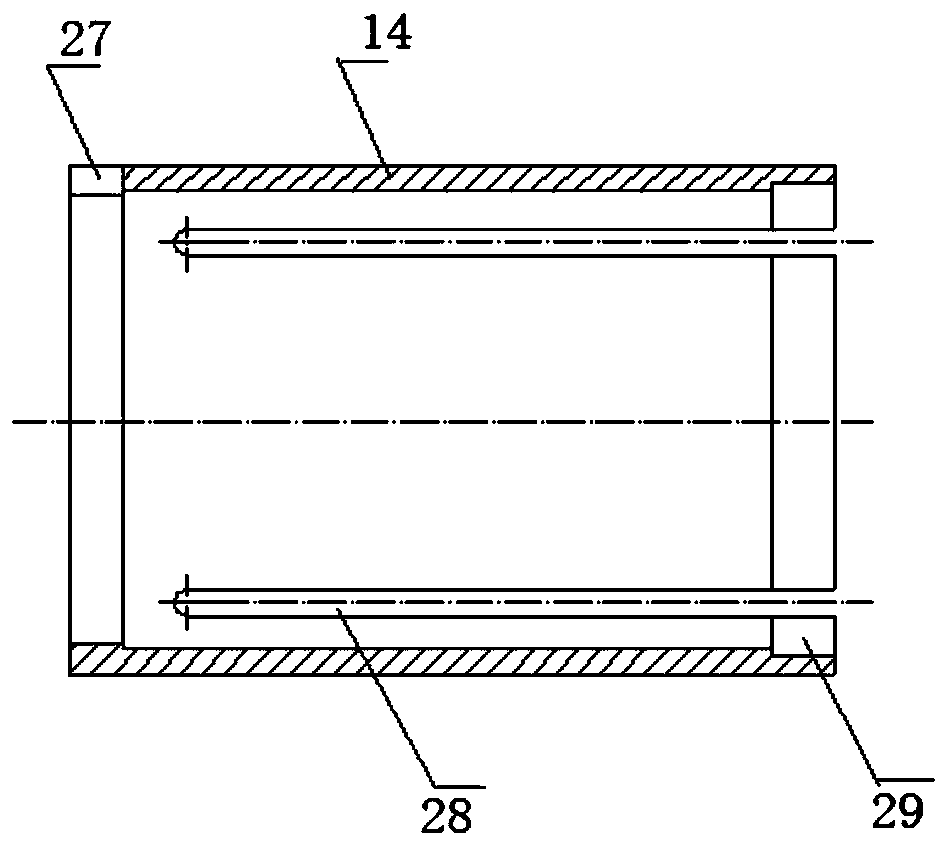

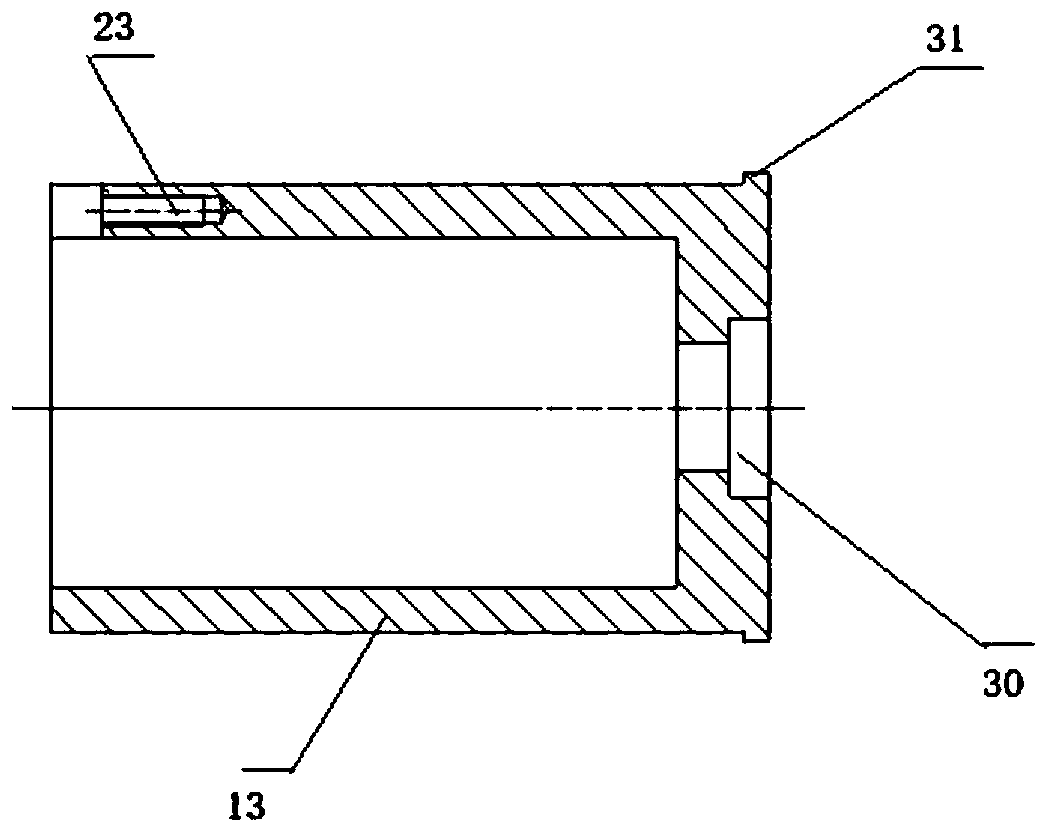

Coupler mechanism

InactiveCN105221592AReliable deliveryGuaranteed breakCouplings with disconnecting safety membersCouplingDrive shaft

The invention relates to a coupler mechanism used for connecting a drive shaft and a driven shaft. The coupler mechanism comprises an upper arc clamping piece, a lower arc clamping piece corresponding to the upper arc clamping piece and fastening pieces. Flanges are externally connected to the two sides of the upper arc clamping piece and the two sides of the lower arc clamping piece respectively. The fastening pieces are installed on the flanges, and the upper arc clamping piece and the lower arc clamping piece are fixedly connected. Fracture cracks fracturing immediately are arranged on the upper arc clamping piece and the lower arc clamping piece respectively. The coupler mechanism is wide in application range and reliable in transmission, and immediate fracturing under accidental situations can be guaranteed.

Owner:GUILIN WEIMEIYUAN RESTAURANT MANAGEMENT

Automatic bagging and packaging equipment for paper cup production

ActiveCN114132578AAchieving package-by-package useAchieve clamping and settingBio-packagingWrapper twisting/gatheringPaper cupIndustrial engineering

Automatic bagging and packaging equipment for paper cup production comprises a processing cylinder, the processing cylinder comprises an upper cylinder body, an edge sealing box and a lower cylinder body which are sequentially arranged from top to bottom, an inner clamping plate is used for attaching and pressing a film covering belt to the inner wall of the upper cylinder body, and the film covering belt comprises side edge strips and a packaging bag body; a plurality of packaging bag bodies are arranged in the area between the two side edge strips in a linear array mode, each packaging bag body comprises a main film body, and the two side edge areas of each main film body are heat sealing edges. The main film body entering the upper barrel body is adjusted to be U-shaped by the inner clamping plate; the U-shaped packaging bag main body comprises a first side part surface, a bottom surface and a second side part surface; according to the paper cup packaging machine, side edge heat sealing and opening heat sealing can be achieved through the first heat sealing assembly and the second heat sealing assembly, in this way, comprehensive packaging of stacked paper cups is achieved, and after packaging is completed, the discharging assembly can discharge the packaged paper cups; therefore, the production process is optimized, packaging can be realized in the stacking process, and the processing efficiency is higher.

Owner:安徽创欣环保科技有限公司

Uncoiled aluminum plate synchronous film rolling machine

The invention discloses an uncoiled aluminum plate synchronous film rolling machine. A driving wheel and a fixing base plate are included. A connecting piece is fixed to the right end of the upper surface of the fixing base plate. The side face of the connecting piece is connected with the fixing base plate through a rib plate. A bearing block fixing plate is fixed to the upper end face of the connecting piece. A bearing block is fixed to the right side ring face of the bearing block fixing plate. A deep groove ball bearing is arranged in a shaft hole in the middle portion of the bearing block. A core shaft in the horizontal direction is arranged in a shaft hole of the deep groove ball bearing. A driven wheel is fixed to the middle portion of the core shaft, and the driven wheel is connected with the driving wheel through a triangular belt. The uncoiled aluminum plate synchronous film rolling machine is simple in structure and can be used in cooperation with a metal forming machine, the efficiency is greatly improved, laminated film removal is convenient and fast, influences from the uncoiling rotation speed are avoided, the uncoiled aluminum plate synchronous film rolling machinecan be constantly kept to synchronously rotate with an uncoiled aluminum plate, film rolling is accurate, manpower is reduced, one person can conduct operation, cost is saved, and control and usage are convenient.

Owner:ANHUI KAILE SPECIAL VEHICLES

High-activity mercury removal adsorbent and preparation method thereof

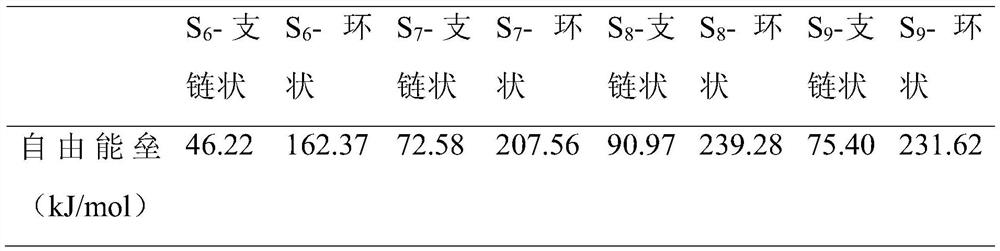

ActiveCN112588254AIncrease reaction rateEasy to prepareGas treatmentOther chemical processesPollutantSulfur containing

The invention belongs to the field of coal-fired pollutant control, and particularly discloses a high-activity sulfur-loaded mercury removal adsorbent and a preparation method thereof. The method specifically comprises the steps: activating sulfur-containing steam by utilizing plasmas to generate high-energy active particles, and breaking S-S bonds in gaseous elemental sulfur molecules by virtue of the active particles, so as to prepare the high-activity mercury removal adsorbent. The problems of low elemental sulfur utilization rate and low mercury removal efficiency due to the fact that themain component in common sulfur is cyclic S8 molecules and the reaction free energy barrier between the cyclic S8 molecules and Hg<0> is relatively high are considered. Therefore, according to the invention, the sulfur-containing steam is activated by adopting the plasmas, so that the S-S bonds in the gaseous S8 molecules are broken, S6, S7 and S9 molecules with relatively low chemical reaction energy barriers and branched S8 molecules are generated, the rate of reaction with Hg<0> is effectively increased, and the high-activity mercury removal adsorbent is prepared. The method has the advantages of simple preparation process and mild conditions, and can effectively reduce the preparation cost.

Owner:HUAZHONG UNIV OF SCI & TECH

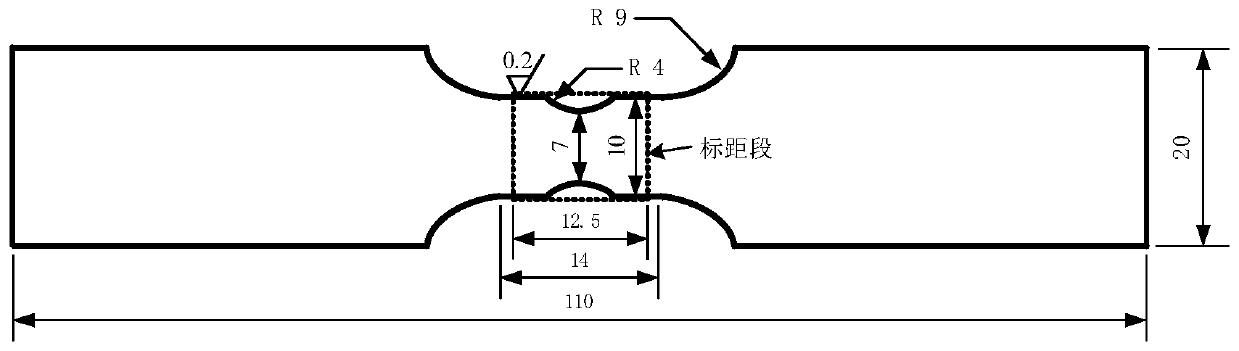

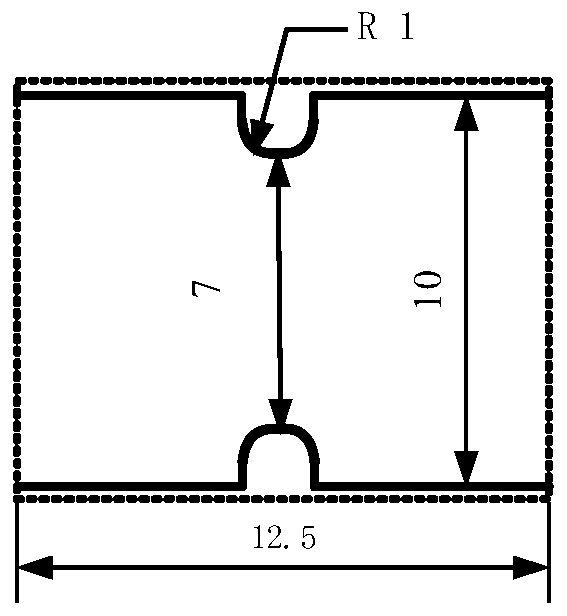

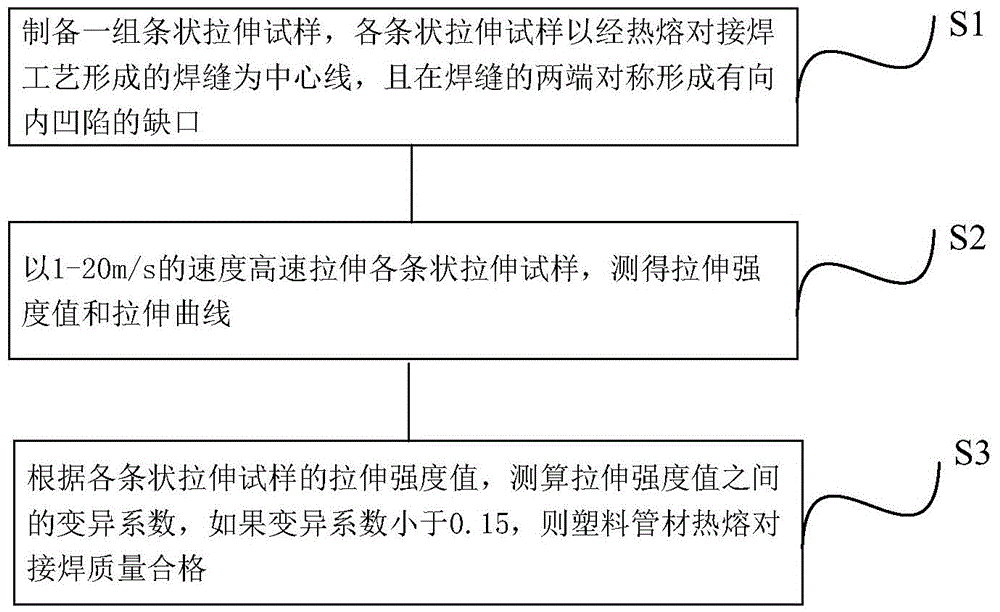

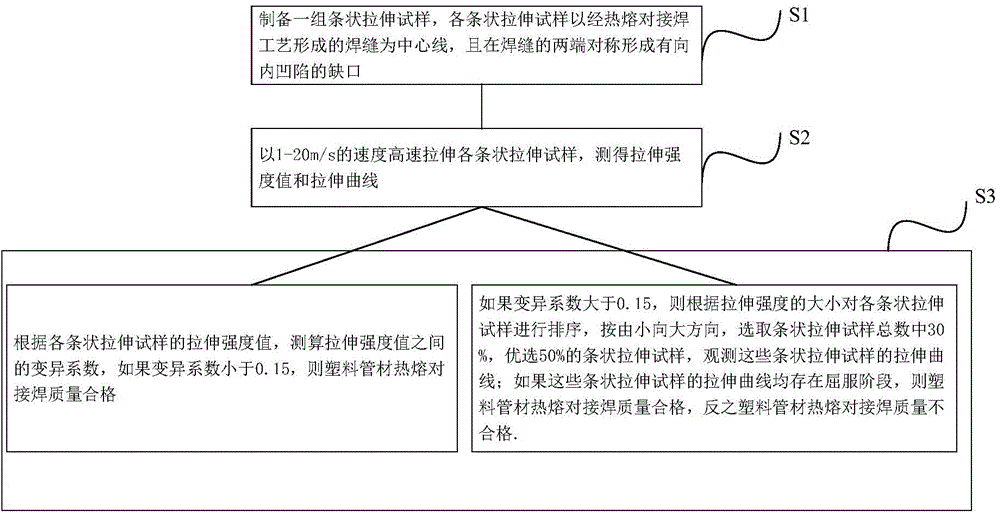

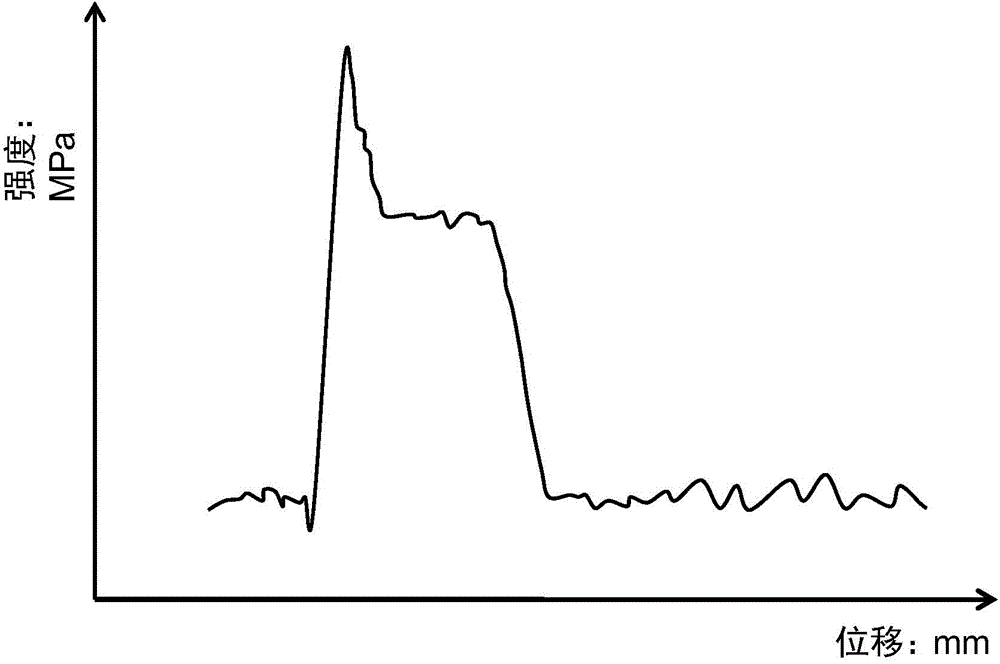

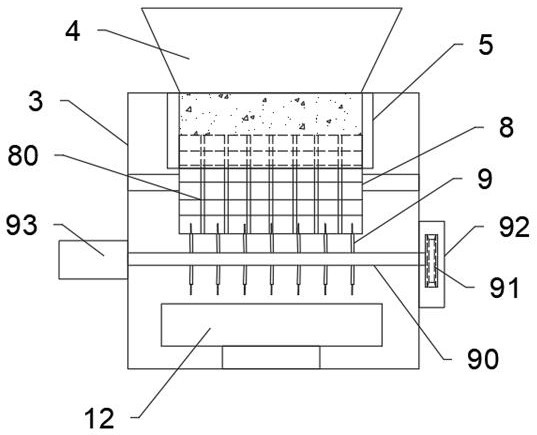

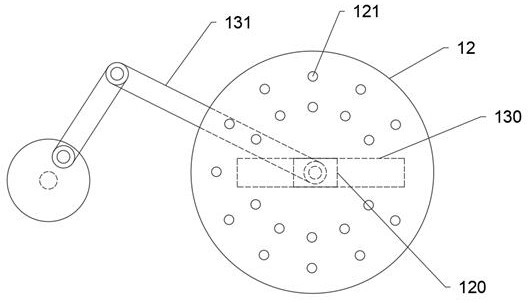

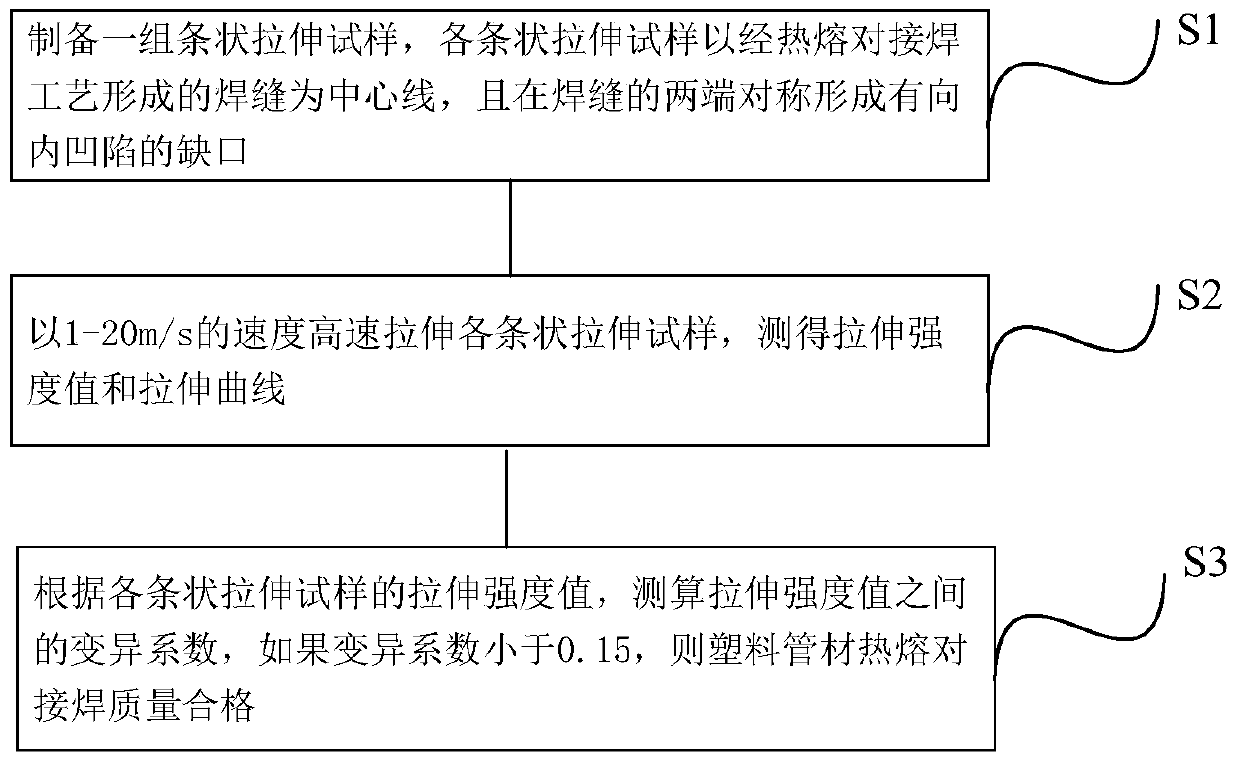

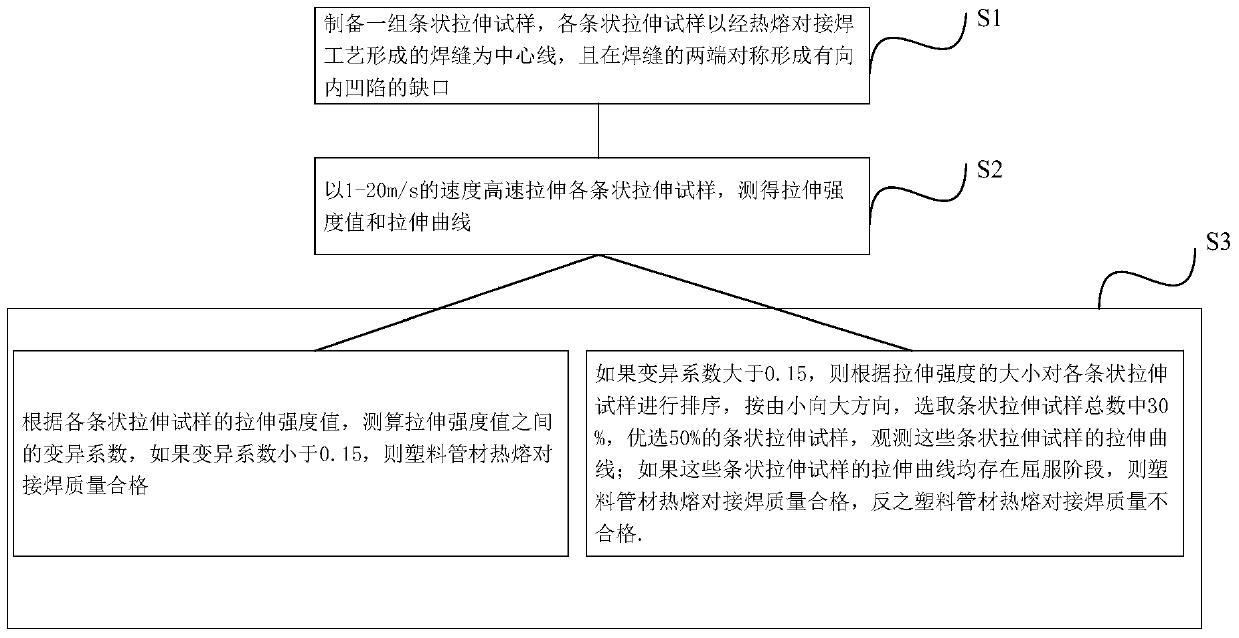

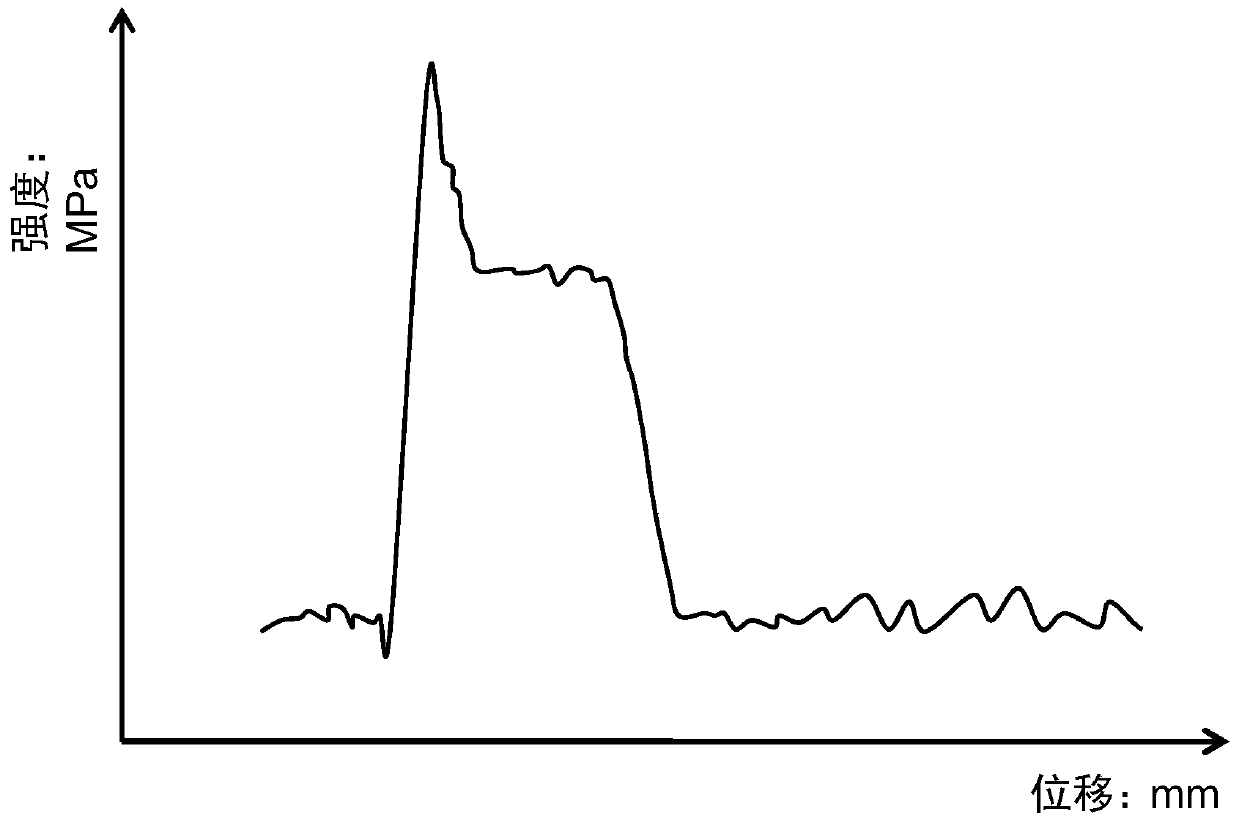

Method for evaluating plastic pipe butt-fusion welding quality

ActiveCN105527163AGuaranteed breakShorten test timeMaterial strength using tensile/compressive forcesHigh rateHot melt

The invention discloses a method for evaluating plastic pipe butt-fusion welding quality. The method comprises S1, preparing a group of strip-shaped tensile samples, wherein the strip-shaped tensile sample has a butt-fusion welding line as a center line and forms symmetrical concave gaps at two sides of the center line, S2, drawing the strip-shaped tensile samples at a high rate of 1-20m / s and detecting tensile strength values and curves and S3, according to the tensile strength values of the strip-shaped tensile samples, calculating a variable coefficient of the tensile strength values, wherein if the variable coefficient is less than 0.15, the plastic pipe butt-fusion welding quality is eligible. Through a high-speed drawing technology, the method shortens test time. Through the variable coefficient of the tensile strength values, plastic pipe butt-fusion welding quality is determined. The method can produce an objective determination result, reduce subjective factor-caused influence and improve determination reliability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Light-emitting element, light-emitting element array and light-emitting device thereof

ActiveCN108878605AShorten process timeImprove production efficiencySolid-state devicesSemiconductor devicesEngineeringSemiconductor

The invention provides a light-emitting device, having a substrate including a control circuit, wherein the light-emitting device includes a light-emitting element, and the light-emitting element hasa semiconductor layer sequence that includes a first type semiconductor layer, a second type semiconductor layer and an active light-emitting layer between the first type semiconductor layer and the second type semiconductor layer; the light-emitting device has a sacrificial structure, the light-emitting element is connected to the control circuit of the substrate, the light-emitting element has adopted or will adopt a process of laser stripping substrate, and the sacrificial structure prevents the light-emitting element from being damaged caused by too large peeling impact force when the substrate is being peeled off.

Owner:XIAMEN SANAN OPTOELECTRONICS CO LTD

Paper breaking method and paper breaking mechanism of rewinder

ActiveCN101503154BGuaranteed breakReduce manufacturing costWebs handlingPunchingIndustrial engineering

The present invention provides a paper-breaking method and a paper-breaking mechanism for the rewinder. The paper-breaking method is characterized in that the speed of one drive roller of the rewinder is instantly higher than the speed of the other two drive rollers when the paper is broken. Make the paper roll quickly roll towards the direction away from the three driving rollers, and before the paper roll completely breaks away from the three driving rollers, the paper at the end of the paper roll has been pulled off. The main feature of the paper breaking mechanism is that a sudden acceleration transmission is connected to a drive roller of the rewinder. The working principle of the present invention is to use the sudden change in the rotational speed of the driving roller to break the paper. During the paper breaking process, there is no need to temporarily press the paper with a briquetting block as in the prior art, thus avoiding the need for the momentary contact between the briquetting block and the paper. Strict conditions are met. Therefore, the present invention can easily ensure that the paper at the end of the paper roll is broken on the same punching line.

Owner:FOSHAN BAOSUO PAPER MASCH MFG CO LTD

Wafer thinning grinding wheel and preparation method thereof

ActiveCN108942709BReduce hardnessReduce thicknessAbrasion apparatusGrinding devicesPolymer scienceHexagonal boron nitride

The invention belongs to the technical field of wafer processing, and particularly relates to a wafer thinning grinding wheel and a preparation method thereof. The thinning grinding wheel comprises, by volume part, 12-18 parts of diamond, 3-7 parts of silicon carbide, 2-5 parts of hexagonal boron nitride, 6-10 parts of foaming agent, 35-45 parts of polyimide resin and 2-5 parts of coupling agent.The low-density thinning grinding wheel is prepared, at certain strength, the overall grinding material layer hardness is reduced, pressure stress in the grinding process is reduced, and therefore thedamage layer thickness is reduced, and the wafer thinning grinding wheel is especially suitable for wafer thinning and old operation equipment in the 3D packaging technology of thin wafers. The prepared grinding wheel can effectively reduce a wafer damage layer and cracks, and the yield is guaranteed.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

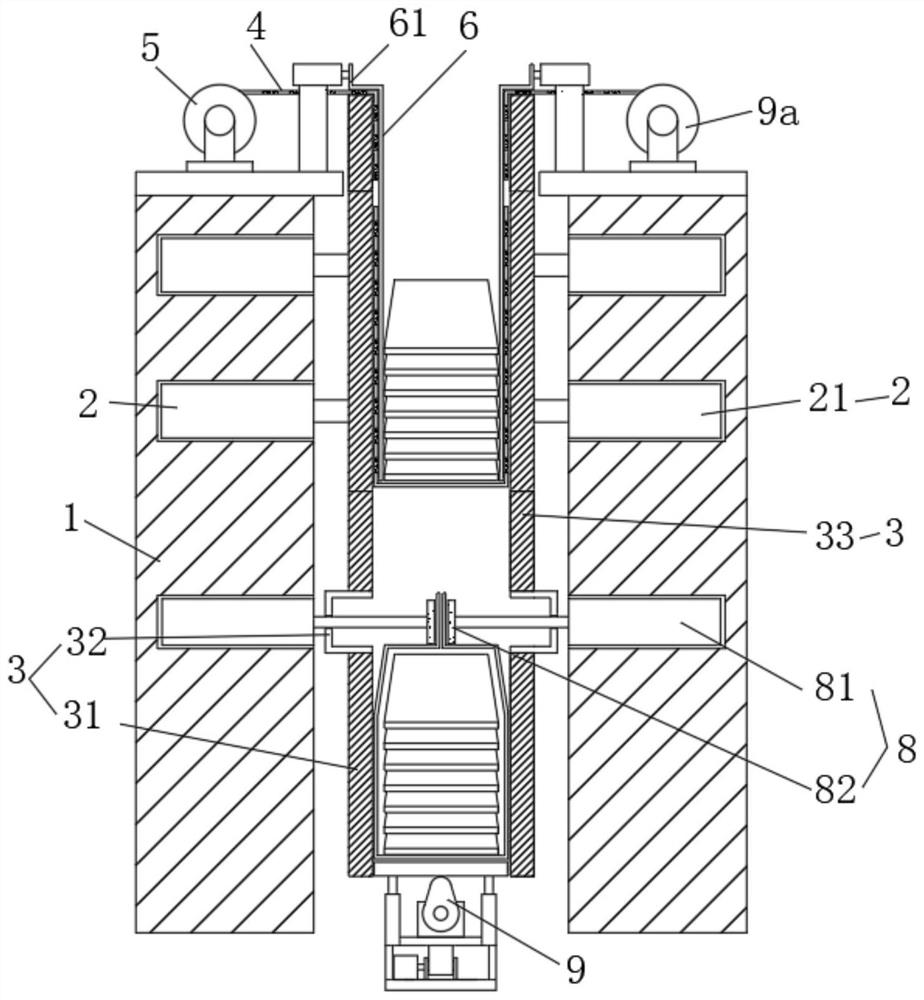

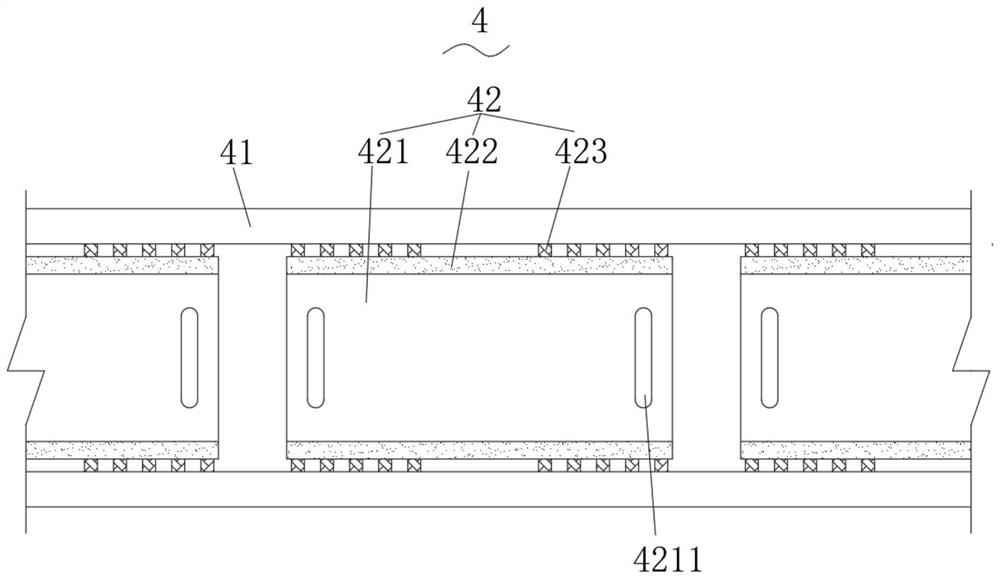

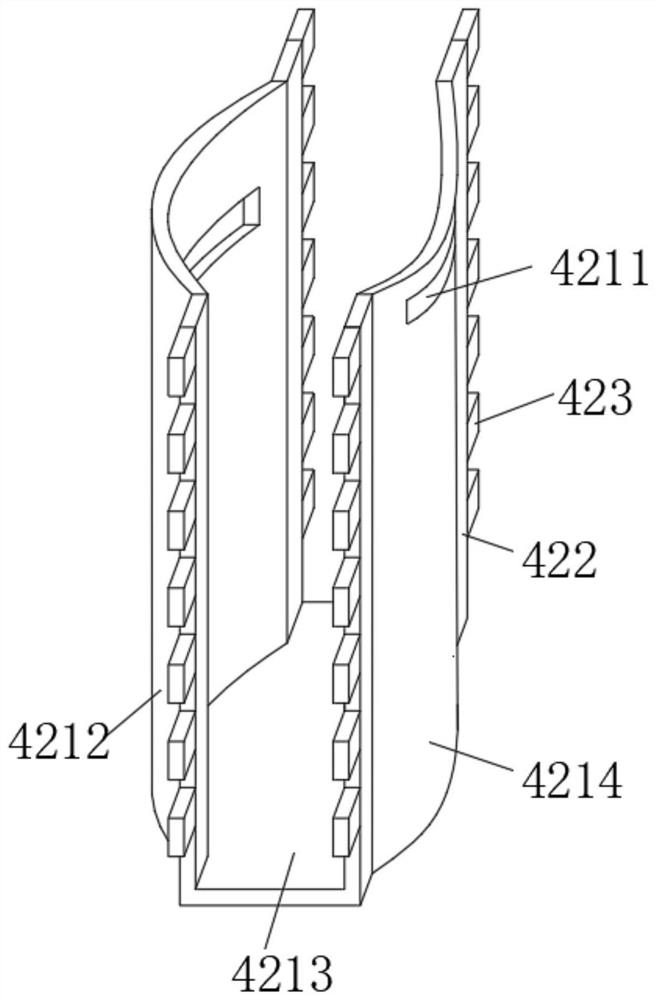

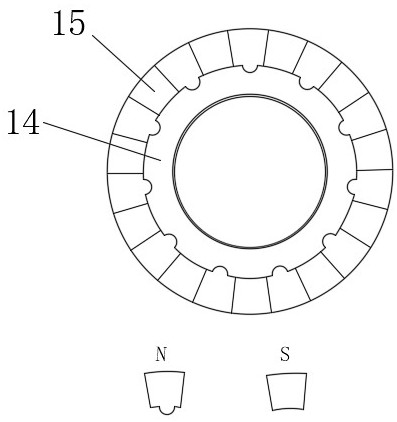

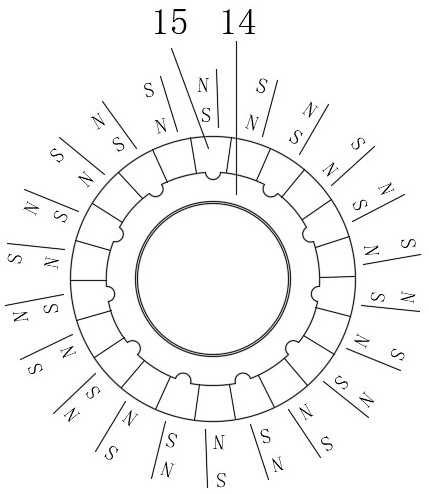

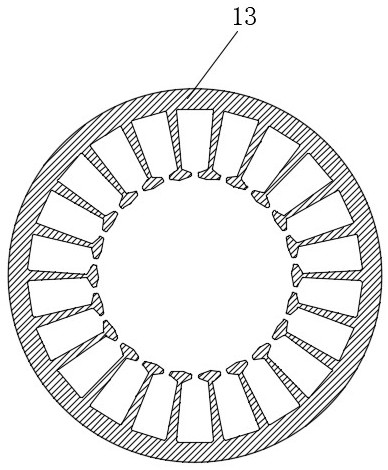

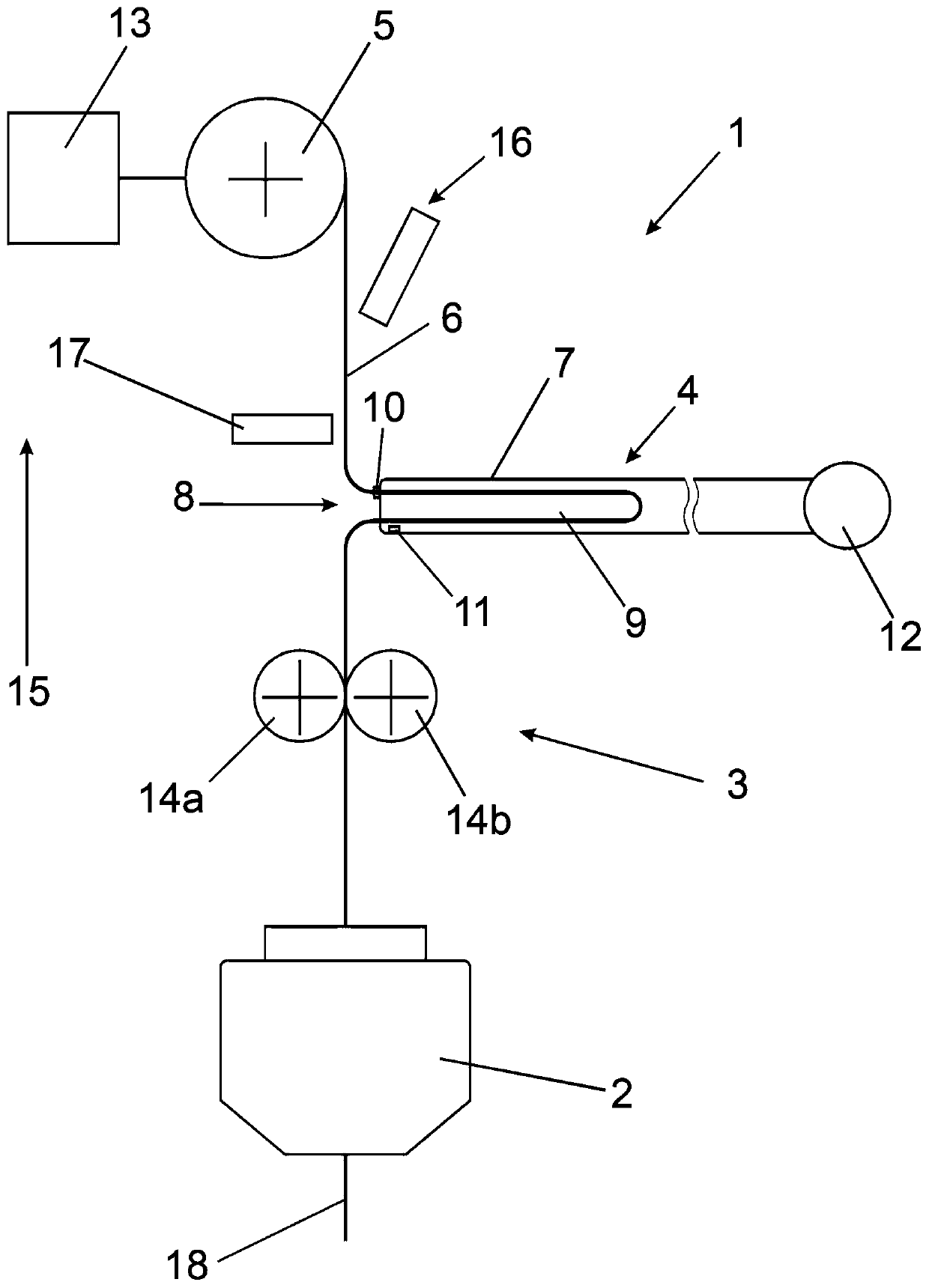

Submersible screw pump based on ultra-low speed multi-rotor permanent magnet submersible motor

ActiveCN113612348BHigh strengthImprove toughnessMagnetic circuit stationary partsRotary/oscillating piston combinationsFrequency changerElectric machine

The invention provides a submersible screw pump based on an ultra-low-speed multi-rotor permanent magnet submersible motor, and relates to the technical field of oil well mechanical oil extraction equipment. The submersible screw pump includes a permanent magnet submersible motor, a protector joint and a conversion joint. One end of the spline shaft is provided with a main shaft, the outside of the spline shaft is fixedly connected with a boss, and the inside of the joint An installation groove is provided, and balls are arranged in the middle side wall and the upper and lower side walls of the installation groove, and the outer side of the ball is connected to the outer side of the boss. The permanent magnet submersible motor includes a motor joint assembly, a motor rotor, a central Bearings and motor stators, permanent magnets have a total of 22 poles, with fan-shaped opening slots, the downhole sensor is connected to a frequency converter, and one end of the thrust plate is provided with a thrust bearing to reduce the load on the central bearing. The system does not need to use a reducer, which improves the reliability of the system Higher starting torque, lower system current and unit heat generation.

Owner:东营市丰润通科技发展有限公司

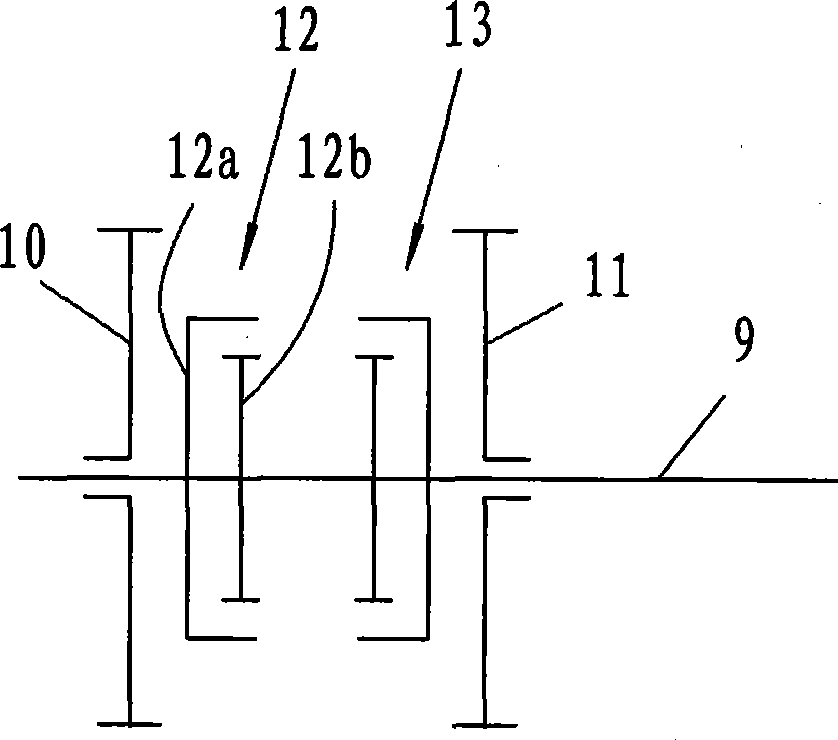

Yarn storage tube for work station of textile machine and work station of textile machine

The invention relates to a thread storage tube for a textile machine station and the textile machine station. The station is provided with a thread storage device used for temporarily storing part ofthreads and a thread winding device arranged behind the thread storage device. The aim of the invention is to provide a thread storage tube for a textile machine station having a thread winding device, and a textile machine station. The station allows reliable monitoring of the thread travel path and a compact design of the station, provision is made for the thread storage tube to integrate a first thread sensor arranged in the region of the thread inlet in such a way that it monitors the thread travel path in the region in front of the thread inlet. Specification for a station, according to the invention, the thread accumulator has a thread accumulator tube which is arranged with a thread inlet in a thread travel path region and which bears the effect of an air flow directed from the thread inlet into the thread accumulator tube, in which a first thread sensor is integrated on the thread accumulator tube in the thread inlet region in such a way that it monitors the thread travel pathin the region in front of the thread inlet.

Owner:SAURER SPINNING SOLUTIONS GMBH & CO KG

Anti-fake white spirit box and assembling and using method

PendingCN111038847AReduce thicknessLow costAnti-theftDamagable goods packagingEngineeringStructural engineering

The invention provides an anti-fake white spirit box and an assembling and using method. The anti-fake white spirit box comprises a base, wherein a bottom cover is fixed to the bottom of the base; anouter box body is mounted on the top of the base; and the outer box body and the base are fixedly connected through an anti-fake rotary knob. According to the anti-fake white spirit box, an anti-faketooth structure is machined and arranged on an opening rotary knob, in the abovementioned way, the thickness of the outer wine box is effectively reduced, then materials are reduced, and the cost of the whole box body is reduced.

Owner:宜昌崟锦包装有限责任公司

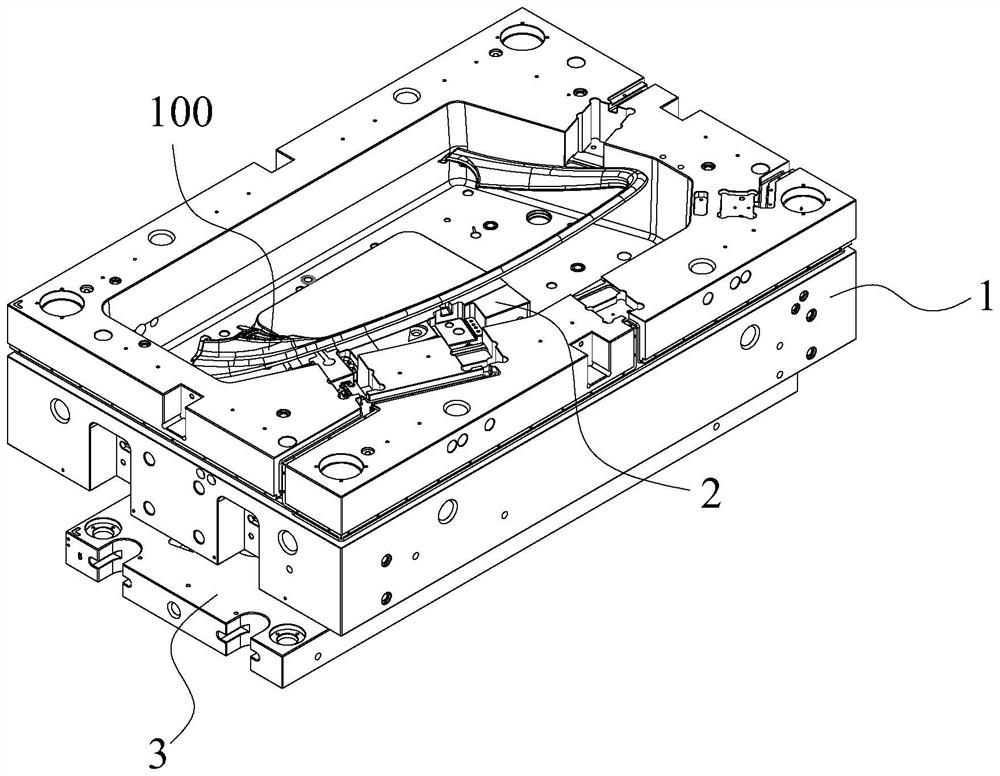

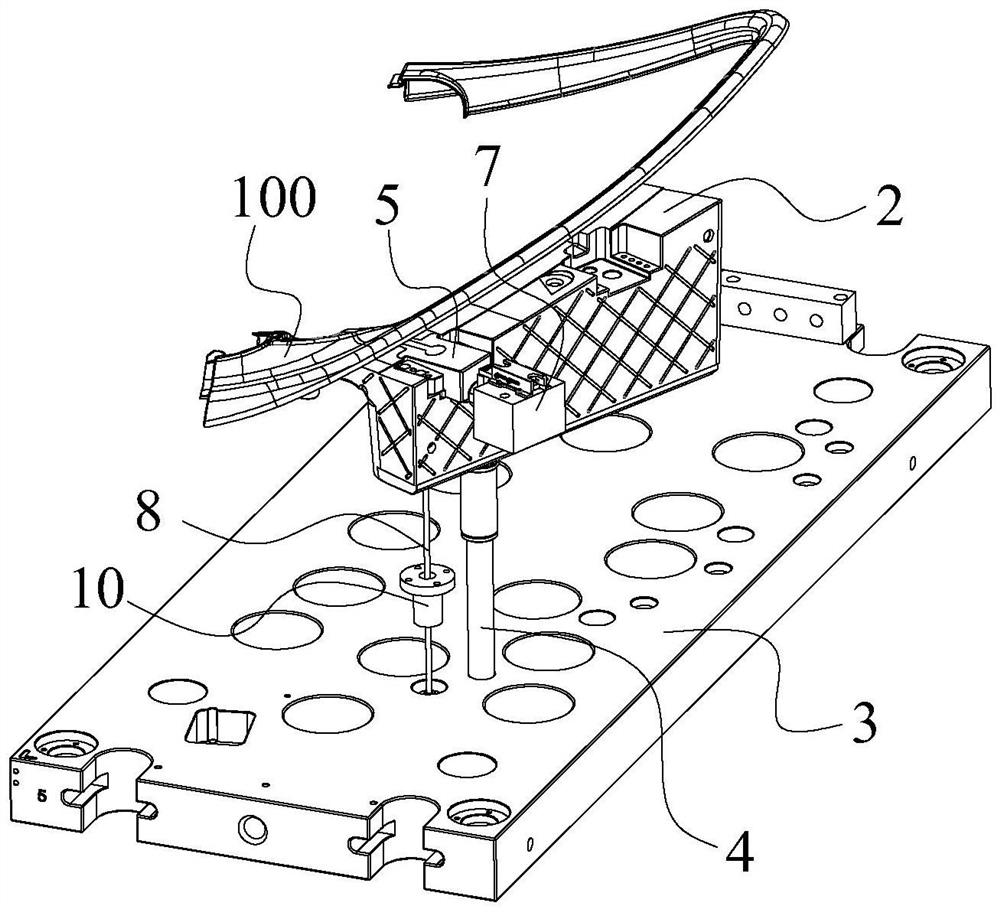

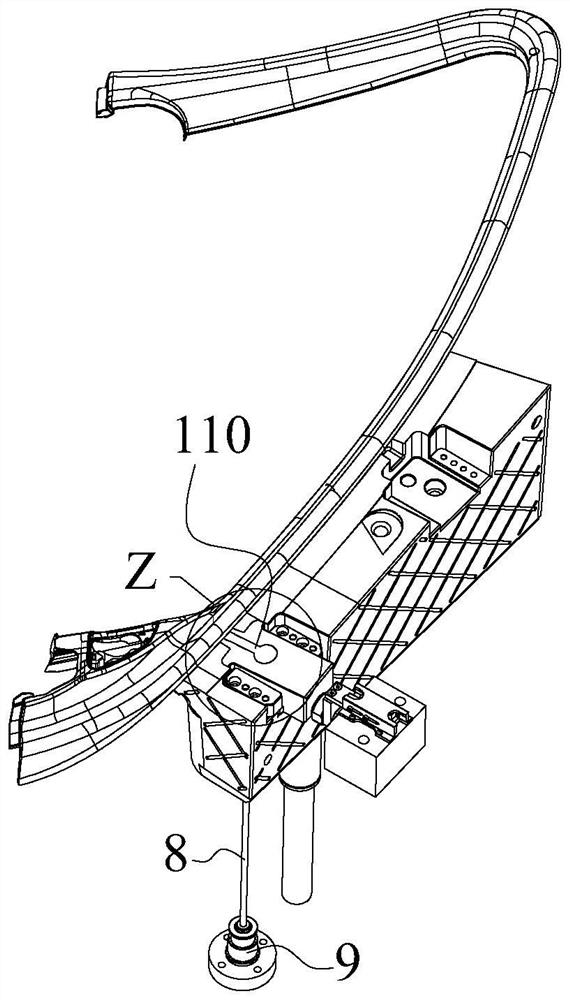

Material cutting mechanism of injection mold

The invention provides an injection mold material cutting mechanism which comprises a fixed mold block, a large sliding block is arranged on the fixed mold block in a sliding mode, an ejector plate is arranged below the fixed mold block, an ejector rod used for driving the large sliding block to slide is arranged on the ejector plate, a small sliding block is arranged on the large sliding block in a sliding mode, and a feeding runner communicated to a mold cavity is arranged on the small sliding block. A driving cylinder used for driving the small sliding block to be separated from the large sliding block is arranged on the fixed mold block, so that material cutting of a material head in the feeding runner and a product in the mold cavity is achieved; the ejector plate is further provided with an ejector rod and a driving assembly in a sliding mode, wherein the driving assembly is used for driving the ejector rod to eject and drive the stub bar to be separated from the feeding runner. According to the material cutting mechanism of the injection mold, rapid separation of an injection product and a material head can be achieved, the separated material head can be effectively separated from the runner, and the demolding efficiency is improved.

Owner:NINGBO FANGZHENG TOOL

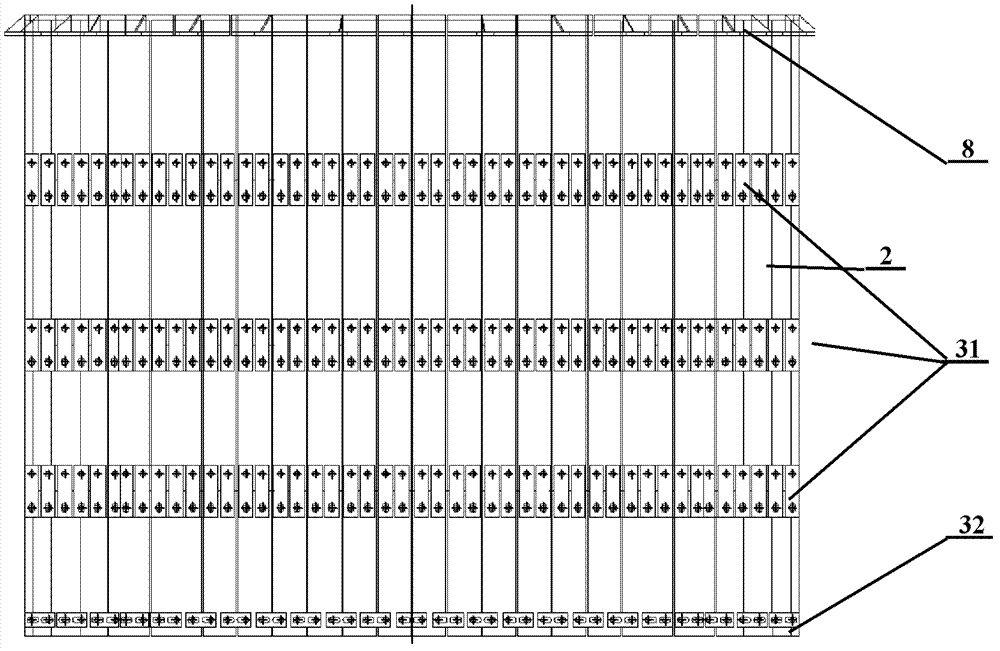

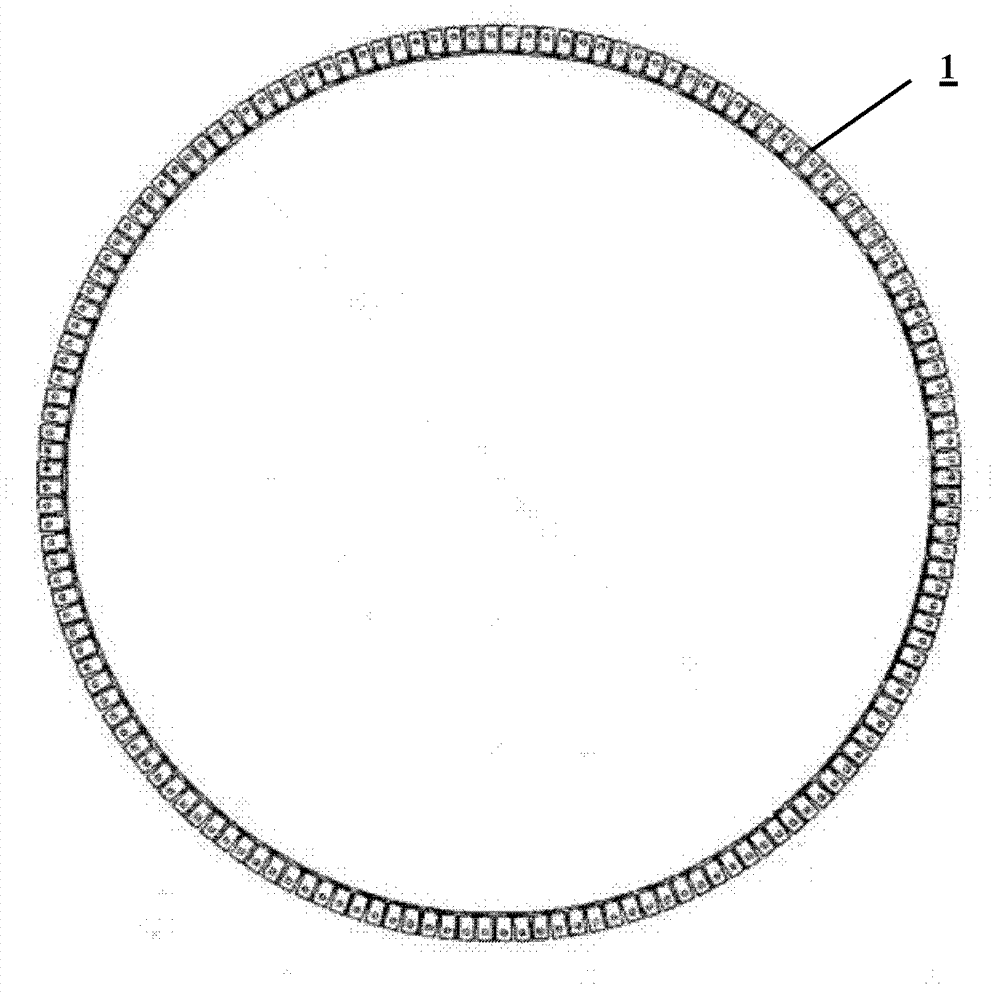

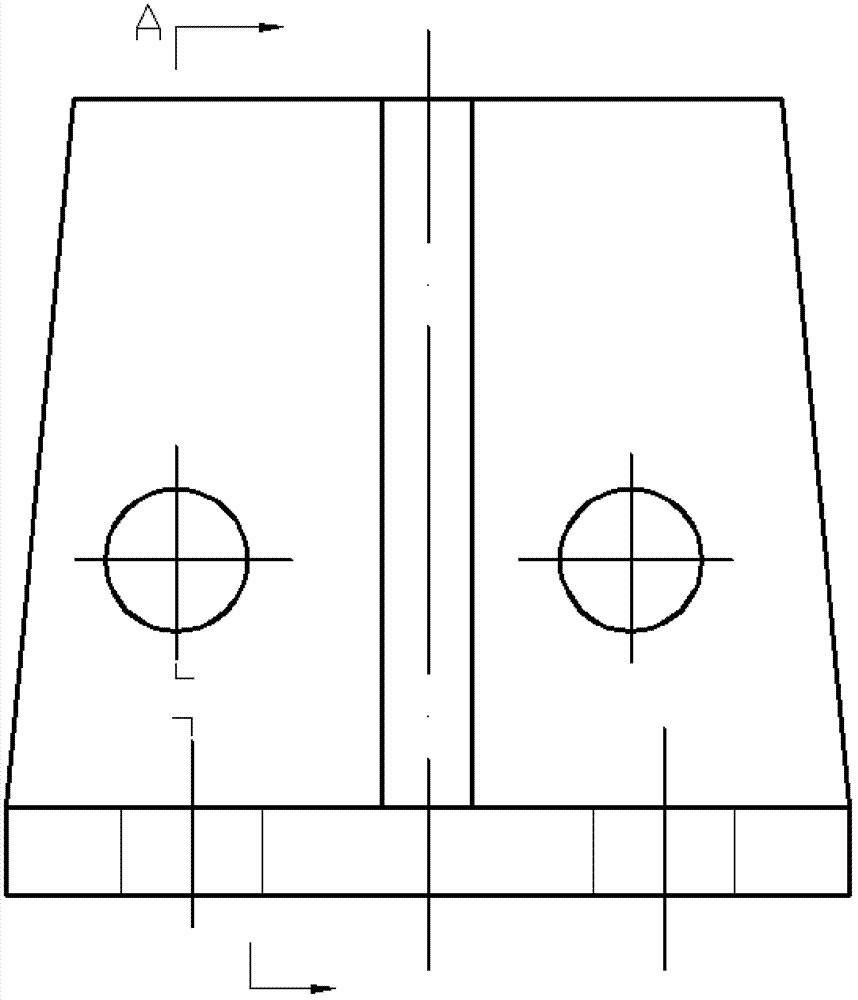

Preheater cyclone internal cylinder with steel strips made of super-strong heat resistant steel

InactiveCN102278891BEasy to manufactureEasy to install and connectPreheating chargesCycloneBoard structure

A preheater cyclone inner tube having a ultrastrong-type heat-resistant steel-belt comprises an inner tube body (1) connected to a cyclone fixing seat (8). The inner tube body (1) is formed by a plurality of ceramic hanging pieces (2) and a ceramic connecting plate (3) matching with and connected to each other. Each ceramic hanging piece (2) has a rectangular board structure, at whose left side and right side are disposed with insertion steps (22) in reverse symmetry, respectively. Every two ceramic hanging pieces (2) are inserted side by side and are tightly arranged circumferentially into a tubular body. The upper end of each ceramic hanging piece (2) at the upper part of the tubular body is connected to the fixing seat (8). The vertically or horizontally adjacent ceramic hanging pieces (2) are fixedly connected through the ceramic connecting plate (3). The ceramic hanging piece (2) has a hollow cavity and an ultrastrong-type heat-resistant steel-belt (10) is disposed inside the hollow cavity. The preheater cyclone inner tube has a low processing difficulty, a simple structure, and a low cost, as well as high corrosion resistance against acids and alkalis, a long service life, and a high use safety.

Owner:JIANGSU HUAXINDA SPECIAL STEEL TECH

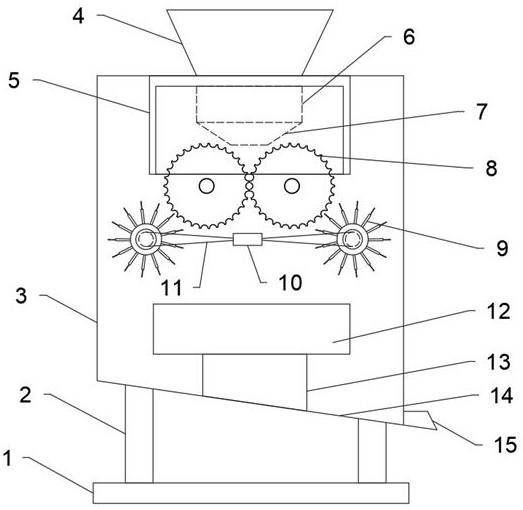

Feed granulator suitable for suckling pigs to eat

InactiveCN114288943AEasy to disconnectSmall particle sizeSievingFeeding-stuffBiotechnologyAnimal science

The invention discloses a feed granulator suitable for suckling pigs to eat, relates to the technical field of feed production, and mainly solves the problems that existing feed granules are large and are not suitable for suckling pig cubs to eat. The device comprises a base, a supporting column is arranged on the base, the supporting column is connected with a granulation box body, a feeding hopper is arranged at the top of the granulation box body, a matching box is arranged at the position, at the bottom of the feeding hopper, of the granulation box body, a middle bin is arranged in the matching box and connected with a discharging port, and the discharging port is connected with a feeding hopper. A feed opening is formed in the bottom of the granulating box body, a granulating roller is arranged in the granulating box body, the feed opening is over against the central position of the granulating roller, a cleaning mechanism is arranged at the bottom of the granulating roller, a vibrating mechanism is arranged at the bottom of the granulating box body, the vibrating mechanism is connected with a driving mechanism, and a discharge opening is formed in the edge of the bottom of the granulating roller; by means of the structure, feed granulation operation is achieved, and suckling pigs can eat the feed conveniently.

Owner:ANHUI ZHENGDAYUAN FEED GRP CO LTD

A method for evaluating the quality of butt welding of plastic pipes

ActiveCN105527163BGuaranteed breakShorten test timeMaterial strength using tensile/compressive forcesHigh rateButt welding

The invention discloses a method for evaluating plastic pipe butt-fusion welding quality. The method comprises S1, preparing a group of strip-shaped tensile samples, wherein the strip-shaped tensile sample has a butt-fusion welding line as a center line and forms symmetrical concave gaps at two sides of the center line, S2, drawing the strip-shaped tensile samples at a high rate of 1-20m / s and detecting tensile strength values and curves and S3, according to the tensile strength values of the strip-shaped tensile samples, calculating a variable coefficient of the tensile strength values, wherein if the variable coefficient is less than 0.15, the plastic pipe butt-fusion welding quality is eligible. Through a high-speed drawing technology, the method shortens test time. Through the variable coefficient of the tensile strength values, plastic pipe butt-fusion welding quality is determined. The method can produce an objective determination result, reduce subjective factor-caused influence and improve determination reliability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fluid product dispenser

InactiveCN102665930BGuaranteed breakAvoid reinstallationDispensing apparatusSingle-unit apparatusEngineeringScrew thread

A fluid dispenser including, a fluid reservoir with a neck externally threaded and that internally defines an opening that communicates with the inside of the reservoir, the neck forming at least one helical thread; and a dispenser head that is mounted on the neck by a fastener member in engagement both with the threaded neck and with the dispenser member. The fastener member includes a ring, the ring forming: a reception mechanism for receiving the dispenser member; an annular ledge; and a skirt that is in engagement with the threaded neck. The ring includes a rupture mechanism between the ledge and the skirt so as to separate the ledge from the skirt by turning the ring on the threaded neck, in such a manner as to remove the dispenser member from the reservoir.

Owner:APTAR FRANCE SAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com