Light emitting element, light emitting element array and light emitting device thereof

A technology of light-emitting elements and light-emitting devices, which is applied in the direction of electrical components, electric solid-state devices, semiconductor devices, etc., can solve problems such as poor product yield and line damage, and achieve the effects of improving production efficiency, reducing residues, and shortening process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

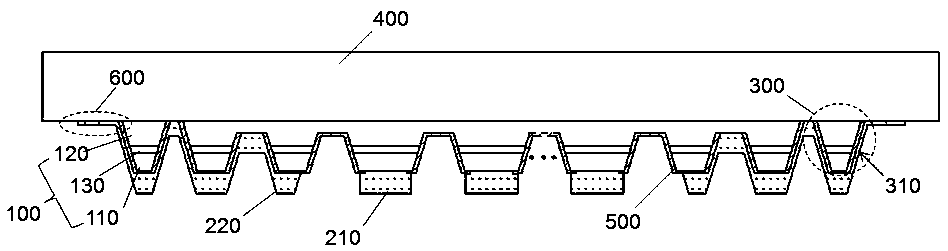

Image

Examples

Embodiment Construction

[0052] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and examples, so as to fully understand and implement the process of how to apply technical means to solve technical problems and achieve technical effects in the present invention. It should be noted that, as long as there is no conflict, each embodiment and each feature in each embodiment of the present invention can be combined with each other, and the formed technical solutions are all within the protection scope of the present invention.

[0053] It should be understood that the terminology used in the present invention is only for the purpose of describing specific embodiments, rather than limiting the present invention. It is further understood that when the terms "comprising" and "comprising" are used in the present invention, they are used to indicate the existence of stated features, integers, steps, elements, and / or, without excluding one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com