Submersible screw pump based on ultra-low speed multi-rotor permanent magnet submersible motor

A technology of submersible motor and submersible screw, which is used in rotary piston/oscillating piston pump components, rotary piston/oscillating piston pump combinations, pumps, etc., can solve the problem of rodless direct-drive submersible screw pumps. The practicability of oil production is not strong, and the reducer cannot work reliably for a long time, so as to achieve the effect of high starting torque, reducing load and improving system efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

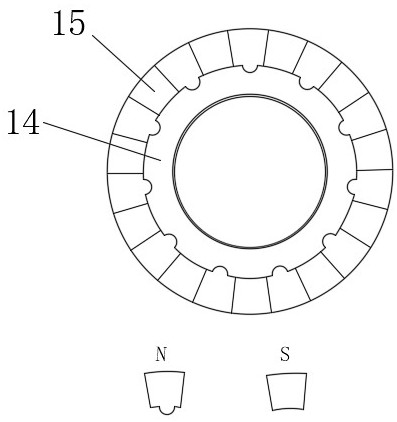

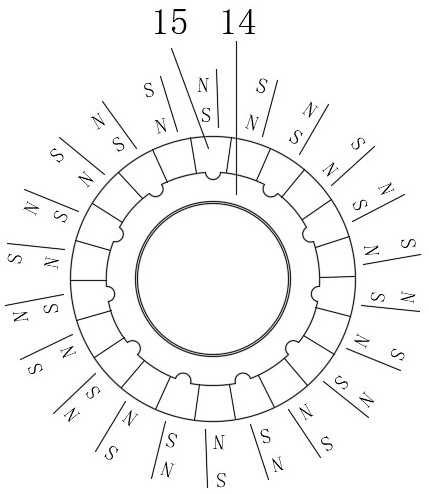

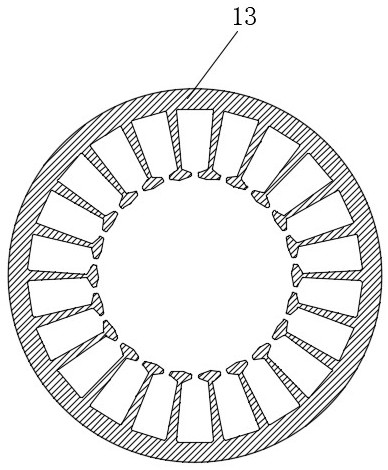

[0028] Such as Figure 1-8 As shown, the embodiment of the present invention provides a submersible screw pump based on an ultra-low-speed multi-rotor permanent magnet submersible motor, including a permanent magnet submersible motor, a protector joint 16 and a conversion joint 21, and one end of the protector joint 16 passes through a connector 17 Fixedly connected to one end of the conversion joint 21, the interior of the conversion joint 21 is provided with a flexible shaft 22, one end of the flexible shaft 22 is fixedly connected to a spline shaft 20, and one end of the spline shaft 20 is provided with a main shaft 24, and the screw pump passes through the flexible shaft 22 Connect the spline shaft 20, and then connect the output end motor rotor 9 of the permanent magnet submersible motor through the main shaft 24, the outer side of the spline shaft 20 is fixedly connected with the boss 18, and the inner side of the connector 17 is provided with a mounting groove 23, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com