Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

198 results about "SODIUM OLEFIN SULFONATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium Alpha-Olefin Sulfonates (Sodium C12-14 Olefin Sulfonate, Sodium C14-16 Olefin Sulfonate, Sodium C14-18 Olefin Sulfonate, Sodium C16-18 Olefin Sulfonate) are mixtures of long chain sulfonate salts prepared by the sulfonation of alpha olefins.

Laundry sheet

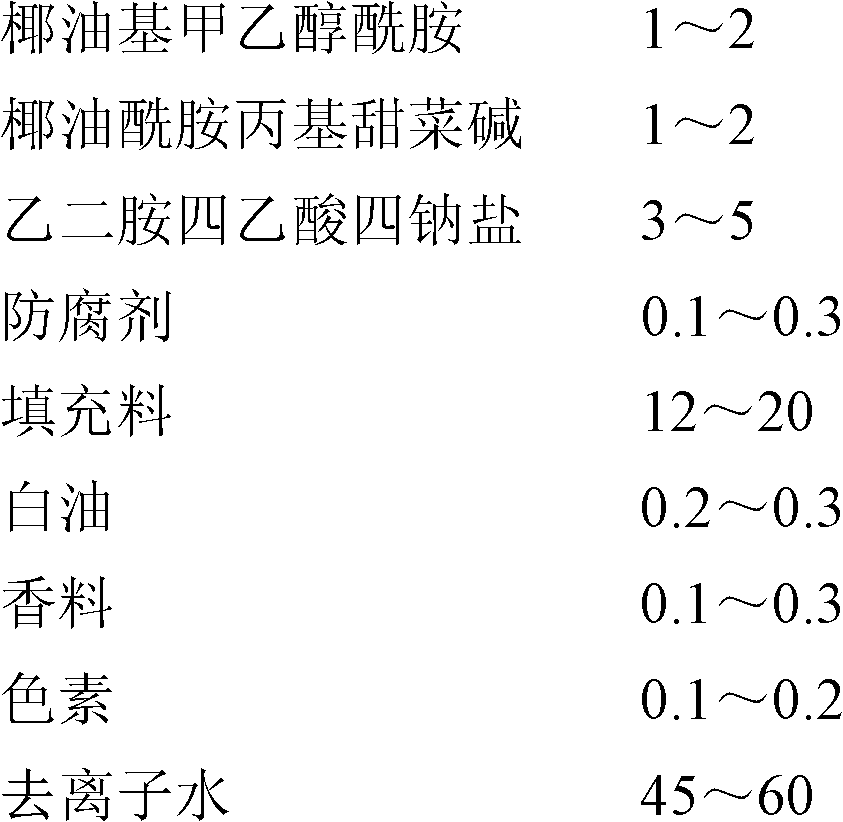

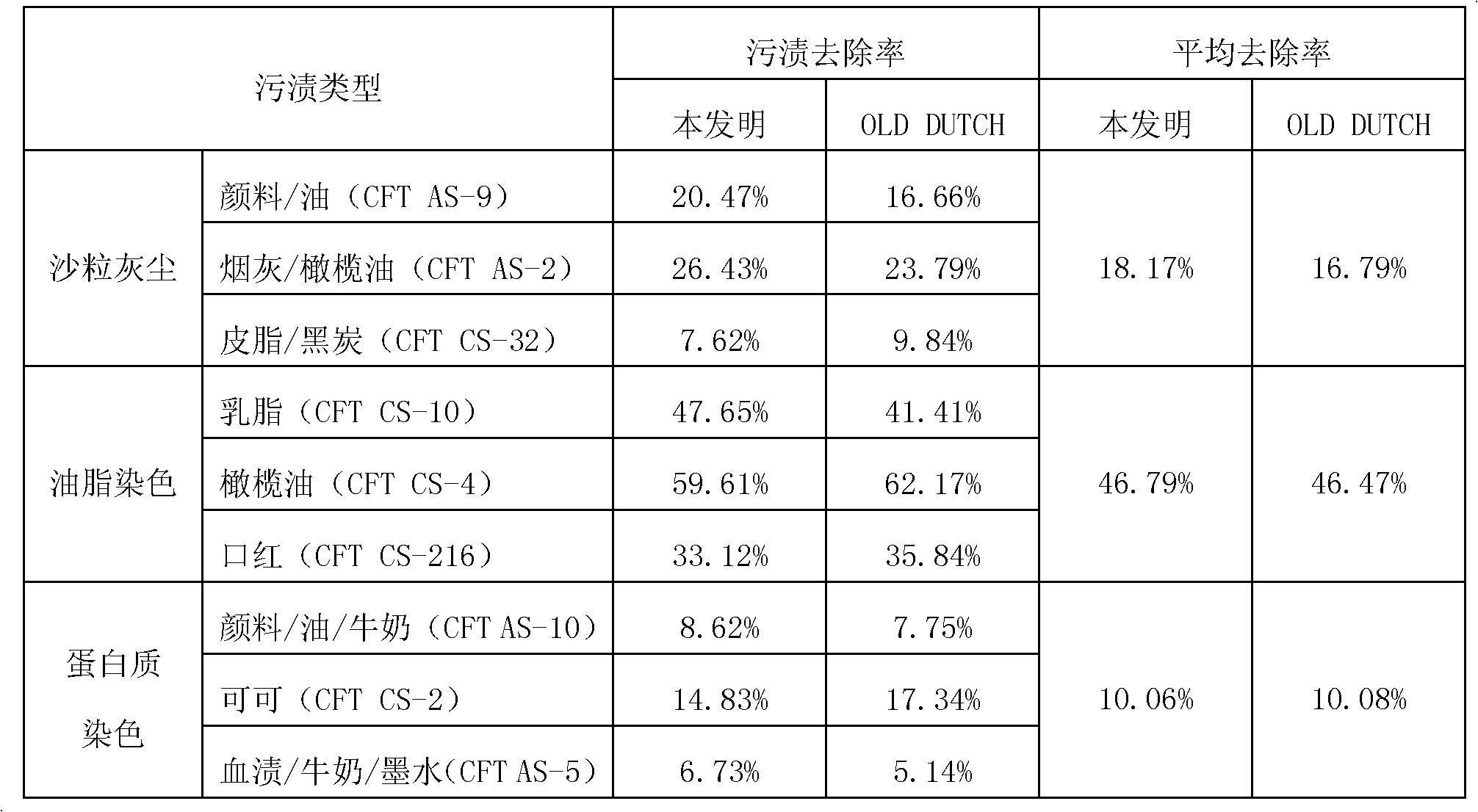

ActiveCN102492573APrevent overflowAvoid messOrganic detergent compounding agentsAmpholytes/electroneutral surface-active compoundsPhysical shapeCocamidopropyl betaine

The invention relates to a laundry sheet which comprises film former, sodium olefinsulfonate, coconut oil base methyl glycollic amide, coconut oil amide propyl lycine, ethylene diamine tetraacetic acid tetrasodium salt, preservative, filling material, white oil, essence, pigment and deionized water. The laundry sheet is prepared by the following steps: evenly mixing the raw materials according tomass parts, carrying out film formation by drying to a obtain paper type laundry sheet, cutting, punching, packaging and the like. The invention implements paper type laundry detergent in the aspect of physical shape, maintains the washing effect of the traditional laundry detergent, has the characteristics of less foam and high efficiency, and can be completely dissolved in water; the laundry sheet is convenient to store and use, and avoids the overflow problem in the common laundry detergent, thereby avoiding mess and difficulty in cleaning due to overflow of the laundry detergent; and the laundry sheet is convenient to, overcomes the defect that the traditional laundry detergent has heavy volume and can not be conveniently carried and stored after being opened, thereby providing convenience for clothes cleaning for people on a journey. The laundry sheet is free of any environment-polluting component, and can be completely degraded naturally, thereby making a contribution to environmental protection.

Owner:广州市黄埔南方供水环保工程有限公司

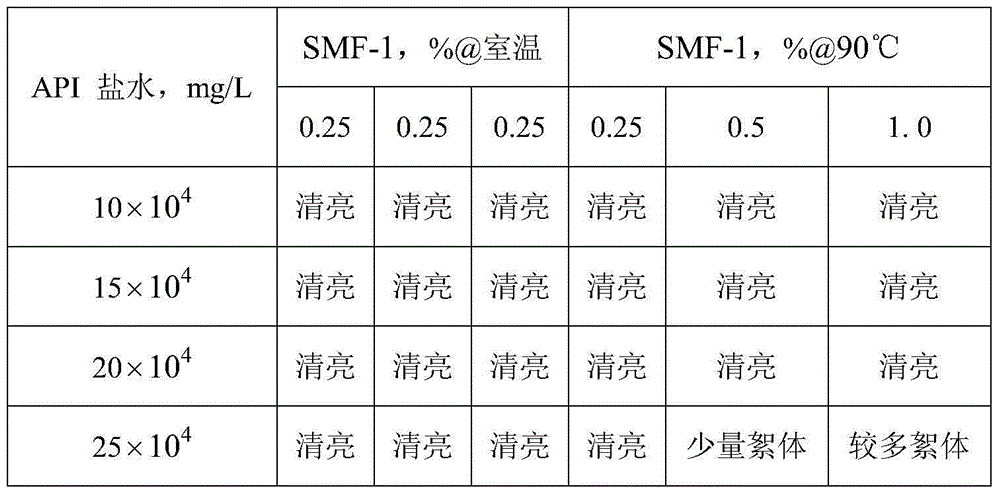

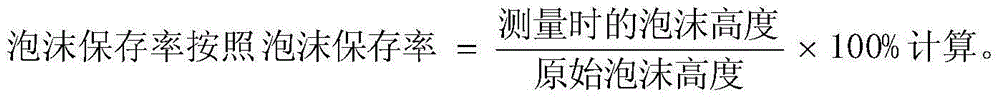

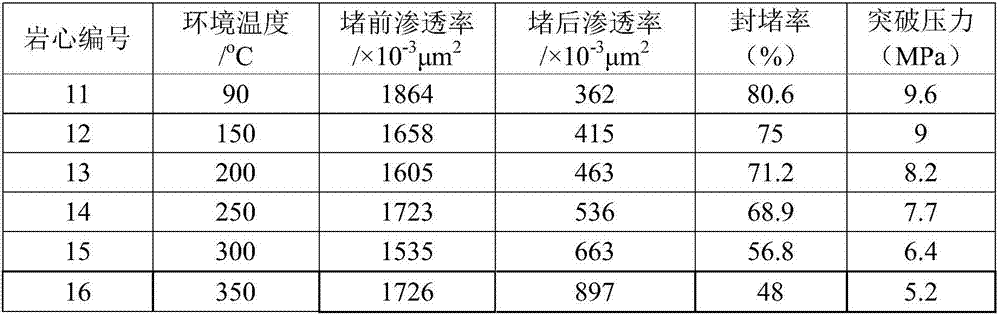

Salt-tolerance temperature-resistance foaming agent

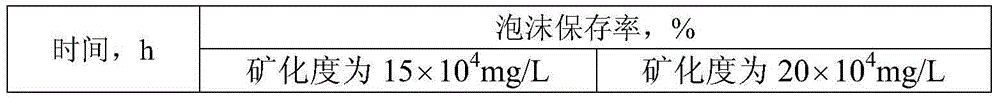

The invention provides a salt-tolerance temperature-resistance foaming agent. The salt-tolerance and temperature-resistance foaming agent is prepared from long-chain alpha-olefin sulfonates, a betaine type surfactant and a hydrophilic coupling agent according to the molar ratio of 1: 1: (0.01-0.24), wherein the long-chain alpha-olefin sulfonates is C14-16 alpha-olefin sulfonates, C14-18 alpha-olefin sulfonates, C16-18 alpha-olefin sulfonates or C20-24 alpha-olefin sulfonates, the betaine type surfactant is coconut fatty amido propyl betaine, hexadecyl betaine or a mixture of the coconut fatty amido propyl betaine and the hexadecyl betaine, and the hydrophilic coupling agent is hexadecyl glucoside, octadecyl glucoside or a mixture of the hexadecyl glucoside and the octadecyl glucoside. The foaming agent is suitable for a foam flooding foaming agent, a foam plugging agent, a foam drilling fluid foaming agent or a foam scrubbing agent used for drainage gas recovery under the oil reservoir conditions that the salinity is lower than 25*10<4>mg / L, and the temperature reaches up to 120 DEG C.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Formulation of surfactant oil displacement system for anionic and nonionic oil displacement

ActiveCN101705083ASignificant precipitation and oil increase effectImprove oil displacement efficiencyDrilling compositionAlkanePhosphate

The invention provides a composition of a surfactant oil displacement system for anionic and nonionic oil displacement. The composition consists of 18% C18 sodium alkyl benzene sulfonate, C16 fatty acid, 25% C2 alkanolamide, 7% C8 alkylphenol polyoxyethylene ether phosphate, 17% ethanol, 3% octanol, 30% water; the alkyl is a hydrocarbyl group with linear chain, branched chain and ring structures in a calibrated carbon atom range, and also can be substituted by one or more halogens, alkyls or alkoxys; the sodium sulfonates are formed by sulfonating different alkanes or arenes by SO3 or chlorosulfonic acid in chloroalkane environment and then neutralizing the sulfonate and sodium hydroxide; and the esterification derivatives are sulfates or phosphates. The formulation has highoil displacement efficiency, strong oil deposit adaptability and good popularization prospect.

Owner:DESHI ENERGY TECH GRP CO LTD

Deodorizing sterilizing foamed liquid for water closet

InactiveCN101239194AReasonable formulaDesign innovationNon-ionic surface-active compoundsDetergent compounding agentsAlpha-olefinFatty alcohol

The present invention provides a deodorization sterilization foam liquid used in washroom which belongs to chemical technical field, and is used for solving problems of large water consumption, poor effects on deodorization and killing venomousness germina. The foam liquid is composed of components by weight part as follows: 12.0-17.5 parts anionic surfactant, 3.5-8.0 parts nonionic surfactant, 3.3-7.5 parts defoamer, 1.2-4.5 parts buffer, 0.8-2.0 parts perfume; anionic surfactant is one or more of alkyl sodium sulfonate, alpha-olefin sulfonates, sodium dodecyl sulfate, polyoxyethylene fatty alcohol sodium sulfate, nonionic surfactant is one of fatty acid alkanolamide and amine oxide, defoamer is one of isopropanol and ethanol, buffer is one of citric acid and disodium hydrogen phosphate. Or fungicidal preservative, cationic alkyl glycoside are added. The foam liquid has reasonable prescription, gathers in integral whole of sterilization, deodorization, clean, contaminant separation and froth, and is suitable for various washroom, especially for various environmental protection water saving type washroom.

Owner:张博

Sulfur-fixing combustion-supporting high-temperature profile control agent, and preparation method and application thereof

ActiveCN106833588AImprove temperature resistanceImprove seal strengthDrilling compositionFiberCellulose

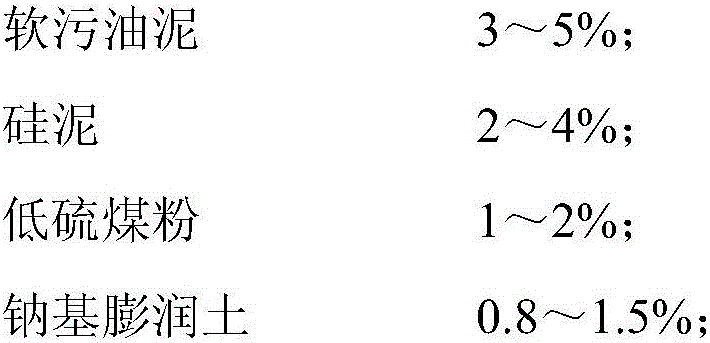

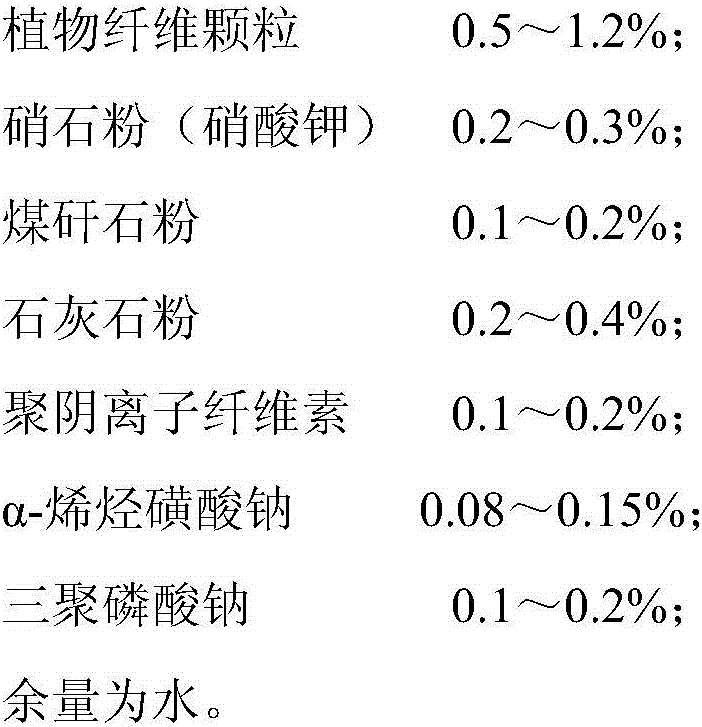

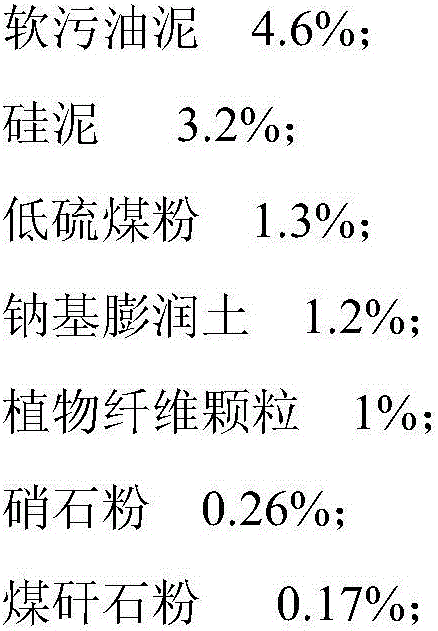

The invention provides a sulfur-fixing combustion-supporting high-temperature profile control agent, and a preparation method and application thereof. By taking the total weight of the sulfur-fixing combustion-supporting high-temperature profile control agent as 100%, the profile control agent is prepared from the following raw materials in percentage by weight: 3-5% of soft oil sludge, 2-4% of silicon sludge, 1-2% of low sulfur coal powder, 0.8-1.5% of sodium bentonite, 0.5-1.2% of plant fiber particle, 0.2-0.3% of saltpetre powder, 0.1-0.2% of coal gangue powder, 0.2-0.4% of limestone powder, 0.1-0.2% of polyanionic cellulose, 0.08-0.15% of alpha-sodium olefinsulfonate, 0.1-0.2% of sodium tripolyphosphate and the balance of water. The profile control agent has favorable stratum compatibility, causes no damage to the oil reservoir, does not pollute the stratum, and has favorable temperature tolerance; and meanwhile, the profile control agent has sulfur-fixing and combustion-supporting functions, thereby being completely applicable to a profile control technology for a thick oil fireflood chemical profile control gas injection well.

Owner:PETROCHINA CO LTD

High-efficient foam compound flooding agent for tertiary oil recovery and preparation method thereof

The invention relates to a high-efficient foam compound flooding agent for tertiary oil recovery and a preparation method thereof, belonging to the technical field of chemical flooding capable of improving the recovery ratio of crude oil from an oilfield. Surfactants used by the high-efficient foam compound flooding agent take sodium alpha-olefin sulfonate as a main surfactant, and the high-efficient foam compound flooding agent is prepared by compounding the surfactant with other anionic surfactants, amphoteric surfactants and anionic-nonionic surfactants. Compared with the prior art, the high-efficient compound flooding agent has the characteristics of good capability of reducing tension of an oil-water interface, good compatibility with high-salinity water, no influence of the salinity on the tension of the oil-water interface, small using quantity and the like. A compound flooding system can improve the recovery rate of the crude oil by above 17%.

Owner:SHANGHAI UNIV

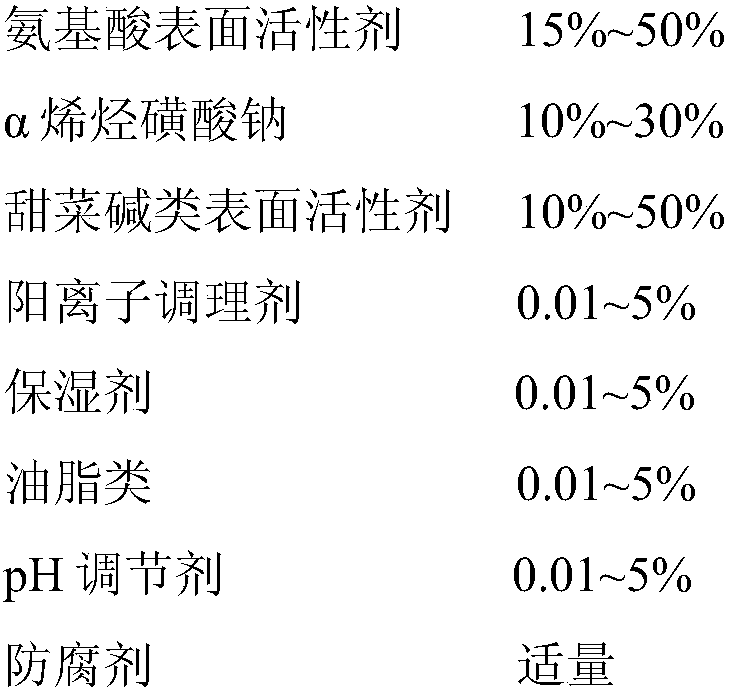

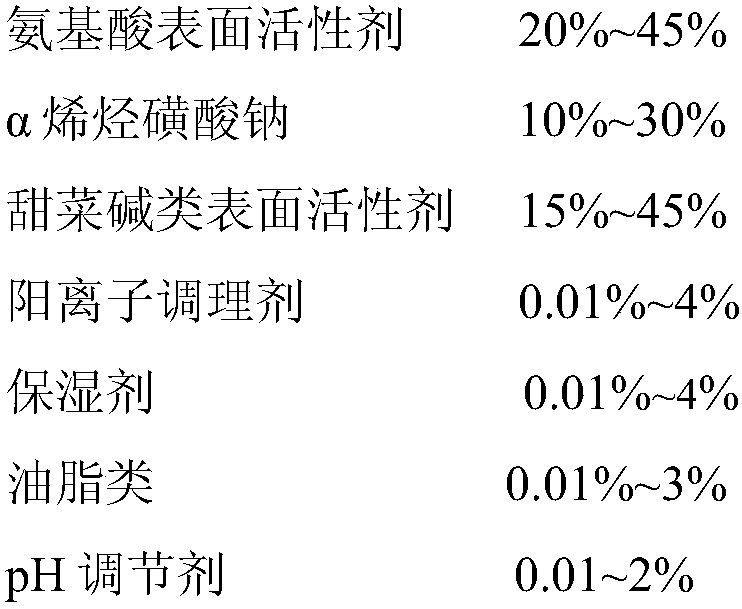

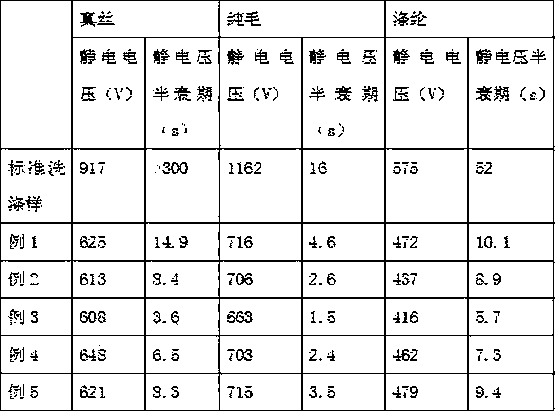

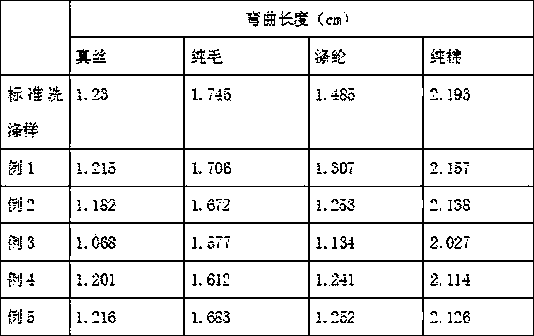

Amino acid shampoo composition and preparation method thereof

ActiveCN107898654AStrong thickeningImprove stabilityCosmetic preparationsHair cosmeticsSulfonateBetaine

The invention relates to a cleaning composition and a preparation method thereof, belonging to the technical field of cosmetics. The composition comprises, by weight, 15 to 50% of an amino acid surfactant, 10 to 30% of sodium alpha-olefinsulfonate and 15 to 50% of a betaine surfactant. The composition provided by the invention effectively overcomes the problem of difficulty in thickening of conventional products with the amino acid surfactant as a main surfactant, realizes thickening mainly through complex formulation of an anionic surfactant and an ampholytic surfactant, and constructs a micelle from sodium C14-16 olefin sulfonate and the betaine surfactant in a proper ratio so as to realize system thickening; other thickening agent is not needed; cold preparation can be realized, so production time is substantially reduced; and the prepared cleaning composition has abundant and fine foam, is greatly saved in cost and overcomes the problem of difficulty in thickening of the amino acidsurfactant and the problem of low foam of the amino acid surfactant.

Owner:GUANGZHOU KENENG COSMETICS RES CO LTD +1

Essential oil condensation beads for washing clothes and preparing method thereof

InactiveCN105039014AEasy to useGood effectAmpholytes/electroneutral surface-active compoundsDetergent compounding agentsBiotechnologyTriclosan

The invention provides essential oil condensation beads for washing clothes. The essential oil condensation beads comprise, by weight, 20-25% of sodium C14-16 olefin sulfonate, 15-20% of fatty alcohol polyoxyethylene ether (9EO), 10-12% of sodium alcohol ether sulphate, 8-10% of lauryl alcohol sulphate triethanolamine, 2-4% of polyethylene glycol, 1-3% of cationic alkyl polysaccharide, 1-2% of D-panthenol, 0.3-0.7% of phenoxyethanol, 0.05-0.01% of disodium ethylenediamine tetraacetate, 0.5-1% of jasminum essential oil, 0.05-0.1% of triclosan, 0.1-0.2% of protease, 0.002-0.005% of red-33 pigment and the balance deionized water. The invention further provides a preparing method for the essential oil condensation beads. The essential oil condensation beads have the multiple effects of washing, caring, sterilizing, deodorizing and physical and mental delighting, and are convenient to use.

Owner:GUANGZHOU BAILICHEN COSMETICS CO LTD

Efficient laundry detergent

InactiveCN103881855AEfficient decontaminationEfficient sterilizationSurface-active non-soap compounds and soap mixture detergentsSoftened waterSolvent

The invention provides an efficient laundry detergent. The laundry detergent is prepared from following components in parts by weight: 20-60 parts of cation alkyl polyglucoside, 5-12 parts of fatty acid polyoxyethylene ester, 0.5-5 parts of alpha olefin sodium sulfonate, 5-30 parts of fatty alcohol-polyoxyethylene ether sodium sulfate, 4-12 parts of alkanolamide, 5-10 parts of natural soap powder, 0.01-6 parts of bio-enzyme, 2-12 parts of enzyme stabilizer, 2-10 parts of cosolvent, 0.01-2.5 parts of preservative, 4-8 parts of herbal extract solution, 0.1-2 parts of aromatic, 5-50 parts of softened water, and proper amount of citric acid. The laundry detergent has the beneficial effects of having efficient decontamination, degerming and anti-static capacities, well protecting hands and hardly hurting the hands in washing by hands due to the herbal extract solution, and having pleasant smell due to the aromatic.

Owner:李新琴

Modified composite type surface active agent

InactiveCN106693829AImprove performanceWeather resistantTransportation and packagingMixingBetaineAlpha-olefin

The invention discloses a modified composite type surface active agent. The raw materials is prepared from modified organosilicone surface active agent, polyether polyamine organosilicone surface active agent, fluorine silicon surface active agent, triethanolamine, ethylene diamine tetraacetic acid, sodium dodecyl benzene sulfonate, sodium oxalate, sodium dodecyl sulfate, cetyl trimethyl ammonium bromide, sodium di(2-ethyl-hexyl)sulfosuccinate, Tween 40, polysorbate 40, sodium alpha-olefin sulfonate, dodecyloxy hydroxypropyl betaine, dodecylbenzene sulfonic acid triethanolamine salt, tetraalkyl ammonium chloride and ethyl alcohol. The prepared modified composite type surface active agent has excellent high and low temperature resistance, corrosion resistance and weather resistance, and has excellent chemical stability and waterproof oil repellency at the same time.

Owner:柏青龙

Laundry detergent for removing oil contamination

InactiveCN105238573AWash thoroughlyInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsSulfonateActive agent

The invention discloses a laundry detergent for removing oil contamination. By combining a specific sodium sulfonate surfactant and internal-olefins sodium sulfonate, during the process for washing the oil contamination dipped in a fabric, thoroughness in washing can be realized, and the fabric is soft.

Owner:华玉叶

Cleansing and Anti-acne composition

InactiveUS20130323228A1Avoid significant dripping or poolingCosmetic preparationsToilet preparationsBenzoyl peroxideCleansing Agents

Disclosed is a cleansing composition and methods for its use capable of treating acne comprising an anti-acne agent comprising benzoyl peroxide, a combination of cleansing agents comprising disodium laureth sulfosuccinate and sodium C14-16 olefin sulfonate, and a combination of skin active ingredients comprising Cucurbita pepo fruit extract, niacinamide, epilobium angustifolium extract, Silybum marianum fruit extract, and Lactobacillus / ganoderma lucidum extract / Lentinus edodes extract ferment filtrate.

Owner:WIRELESS TECH SOLUTIONS +1

High-temperature foaming agent and preparation method thereof

ActiveCN102676145AImprove solubilityPromote degradationFluid removalDrilling compositionArylFoaming agent

The invention relates to a high-temperature foaming agent and a preparation method thereof, wherein the high-temperature foaming agent is prepared from the following materials in percentage by weight: 40-50% of alpha-olefin sulfonate, 25-35% of aryl alkyl sulfonate, 1-5% of high-temperature foam stabilizer and the balance of water. The preparation method of the high-temperature foaming agent comprises the following steps of: placing alpha-olefin sulfonate and aryl alkyl sulfonate in a mixed kettle, stirring, heating to 45-50 DEG C, adding the high-temperature foam stabilizer and water slowly, stirring continuously for 45-60 minutes, reducing temperature and discharging, thereby obtaining the high-temperature foaming agent. The high-temperature foaming agent provided by the invention has good thermal stability and high foaming and sealing performances under high temperature, and has wide application prospect in thickened oil deposit steam injection heat collecting and steam channeling.

Owner:PETROCHINA CO LTD

Liquid laundry detergent capable of removing grease dirt

InactiveCN105273859AWash thoroughlyThoroughly oiledCosmetic preparationsNon-ionic surface-active compoundsLiquid laundry detergentSODIUM OLEFIN SULFONATE

The invention discloses liquid laundry detergent capable of removing grease dirt. According to the liquid laundry detergent, a specific combination of sodium sulfonate surfactants and internal olefin sulphonates is adopted, and in the process of removing the grease dirt immersed in a fabric, washing is thorough and the fabric is soft and smooth.

Owner:华玉叶

Phosphate ore reverse flotation collecting agent for efficiently removing calcite

The invention relates to a phosphate ore reverse flotation collecting agent for efficiently removing calcite. The phosphate ore reverse flotation collecting agent is composed of, by mass, 80%-90% of modified fatty acid and 10%-20% of composite surfactants in a compound mode. The modified fatty acid is composed of 50% of Turkey red oil and 50% of triethanolamine oleic soap in a compound mode. The composite surfactants are composed of 20% of sulfonated oil, 30% of fatty alcohol polyoxyethylene ether AEO-3, 20% of palmitic acid methyl ester sodium sulfonate and 30% of alpha-olefin sodium sulfonate in a compound mode. The phosphate ore reverse flotation collecting agent is suitable for a reverse flotation process for removing calcite from phosphate rock and has the characteristics of being excellent in selectivity and high in concentrate recovery rate.

Owner:HUBEI FORBON TECH

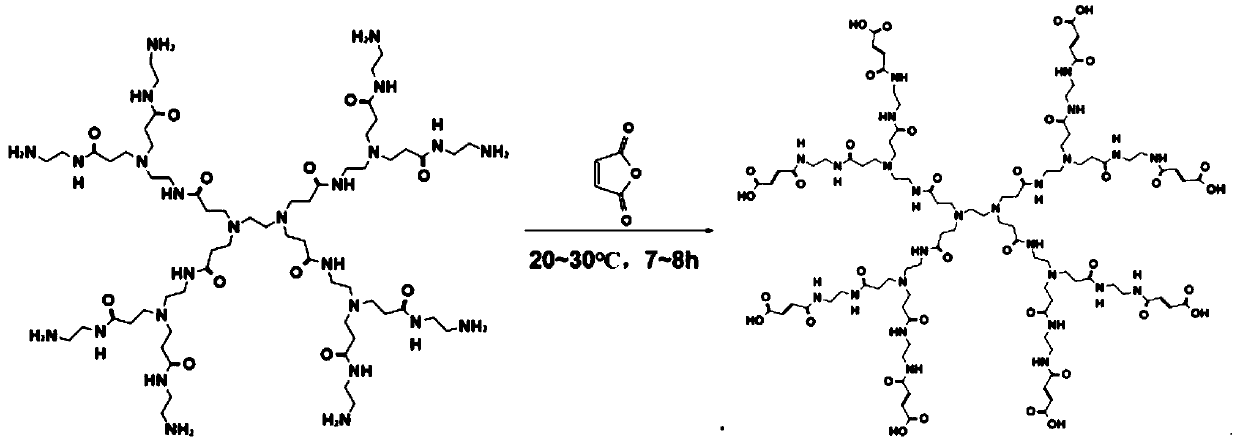

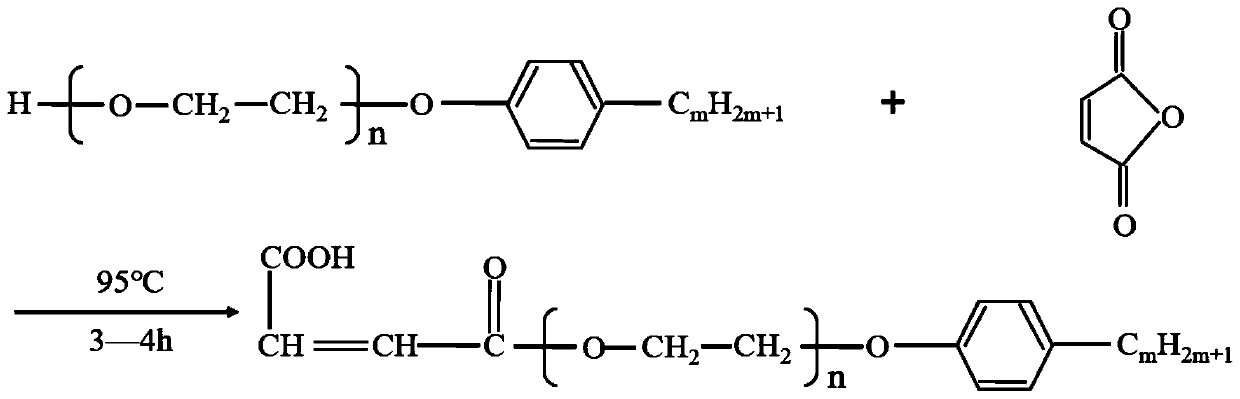

Water-soluble hyperbranched polymer thick oil viscosity reducing agent and preparation method thereof

The invention discloses a water-soluble hyperbranched polymer thick oil viscosity reducing agent and a preparation method thereof. The viscosity reducing agent is prepared by carrying out a free radical polymerization reaction on 0.1-0.5% of a functional framework monomer, 10-20% of acrylamide, 35-45% of modified nonionic polyoxyethylene ether and 40-50% of anionic monomer sodium olefinsulfonate in an aqueous solution at a temperature of 45-60 DEG C. The polymer thick oil viscosity reducing agent can be quickly dissolved in water, has high temperature resistance and salt resistance, and has good mixing and emulsifying performance with crude oil; the viscosity reducing rate of thick oil with medium and low viscosity is 85% or above; and an emulsion is broken easily. Meanwhile, raw materialsfor preparing the polymer thick oil viscosity reducing agent are wide in source, and the preparation process of the viscosity reducing agent is simple and convenient.

Owner:CNOOC TIANJIN BRANCH +1

Cleaning agent for automotive body and preparation method of cleaning agent

InactiveCN105950309AProtect from being scratchedEfficient removalInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsCocamidopropyl dimethylamineCleansing Agents

The invention relates to a cleaning agent for an automotive body and a preparation method of the cleaning agent. The cleaning agent aims to solve the technical problems to improve the cleaning effect, reduce water consumption, improve a sunlight exposure preventing effect and the like. The cleaning agent is prepared from at least the following components in percentage by weight: 0.5%-50% of a surfactant, 0.85%-10% of a brightening agent, 0.5%-8.0% of a pH conditioning agent and the balance of water through mixing, wherein the surfactant comprises at least five substances as follows: nonylphenol polyoxyethylene ether, sodium dodecylbenzene sulfonate, alpha-sodium olefinsulfonate, dimethyl dodecyl amine oxide and cocamidopropyl dimethylamine oxide. The preparation method comprises steps as follows: all the surfactants are dissolved in part of water firstly at the room temperature under normal pressure, the brightening agent is added, the mixture is stirred uniformly, the pH value of the mixture is adjusted to range from 8.0 to 8.5 with a 20% sodium hydroxide aqueous solution, the balance of water is added, the mixture is mixed uniformly, and the cleaning agent is obtained.

Owner:宁波市乾东网络科技有限公司

Foam foaming agent for cement and preparation method of foam foaming agent

The invention provides a foam foaming agent for cement and a preparation method of the foam foaming agent. The foaming agent is prepared from a foaming main material, a surface active agent, a foam stabilizer, a chelating agent, an organic solvent and water, wherein the foaming main material is lauryl sodium sulfate; the surface active agent is selected from one or more of alpha-sodium olefinsulfonate, laurinol polyoxyethylene ether sodium sulfate or lauramidopropylamine oxide; the foam stabilizer is silicon resin polyether. The foaming agent solves the problem that a traditional foaming agentis poor in performance and instable.

Owner:上海市地江建筑科技有限公司

Composite surfactant with excellent surface activity and spumescence

InactiveCN106669538AImprove surface activityGood foaming performanceTransportation and packagingMixingBetainePhenyl Ethers

The invention discloses a composite surfactant with excellent surface activity and spumescence, and the composite surfactant is prepared from the following materials of modified polymer surfactant, modified fluorosilicone surfactant, triethanolamine, EDTA (ethylene diamine tetraacetic acid) disodium, polyethyleneglycol monooleate, sodium alkyl phenyl ether disulfonate, sodium oxalate, lauryl sodium sulfate, sodium alpha-olefin sulfonate, CTAB (cetyl trimethyl ammonium bromide), lauramidopropylamine oxide, octadecyl trimethyl ammonium chloride, sodium di(2-ethyl-hexyl)sulfosuccinate, Tween 40, polysorbate 40, sodium alpha-olefin sulfonate, dodecyloxy hydroxypropyl betaine, triethanolamine dodecylbenzenesulfonate, tetralkyl ammonium chloride and ethyl alcohol. The composite surfactant disclosed by the invention has excellent surface activity and spumescence.

Owner:安徽艾蒂贝生物股份有限公司

Addition agent having synergistic effect on cement and preparing method

InactiveCN105693131AImprove physical and mechanical propertiesWide variety of sourcesSodium phosphatesNitrilotriacetic acid

The invention discloses an addition agent having a synergistic effect on cement.The addition agent is prepared from, by weight, 5.4-5.8 parts of nitrilotriacetic acid, 1.8-2.4 parts of ethylene diamine tetra (methylene phosphonic acid) sodium, 2.4-2.7 parts of triisopropanolamine, 3.7-4.3 parts of acrylamide, 3.2-3.5 parts of alpha-sodium-olefinsulfonate, 3.3-3.6 parts of useless lubricating oil, 3.9-4.4 parts of lauryl sodium sulfate, 4.9-5.7 parts of urea, 2.2-2.5 parts of calcium lignosulfonate, 0.6-0.8 parts of molasses, 2.6-3.0 parts of sodium thiosulfate, 2.1-2.5 parts of a silicone lubricating agent, 1.5-1.9 parts of a fluorine-containing lubricating agent, 2.1-2.5 parts of polysorbate-80 and 2.3-2.7 parts of sorbitol.The construction efficiency can be improved effectively, price is low, the enhancing effect is remarkable, fallen dust is reduced, resources are saved, the raw materials are wide in source, and the manufacturing technology is simple.

Owner:王金奎

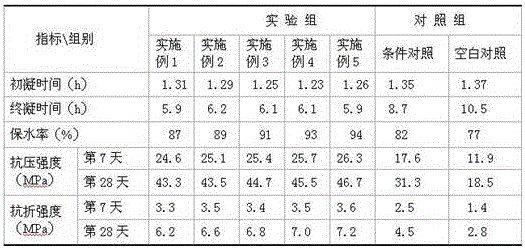

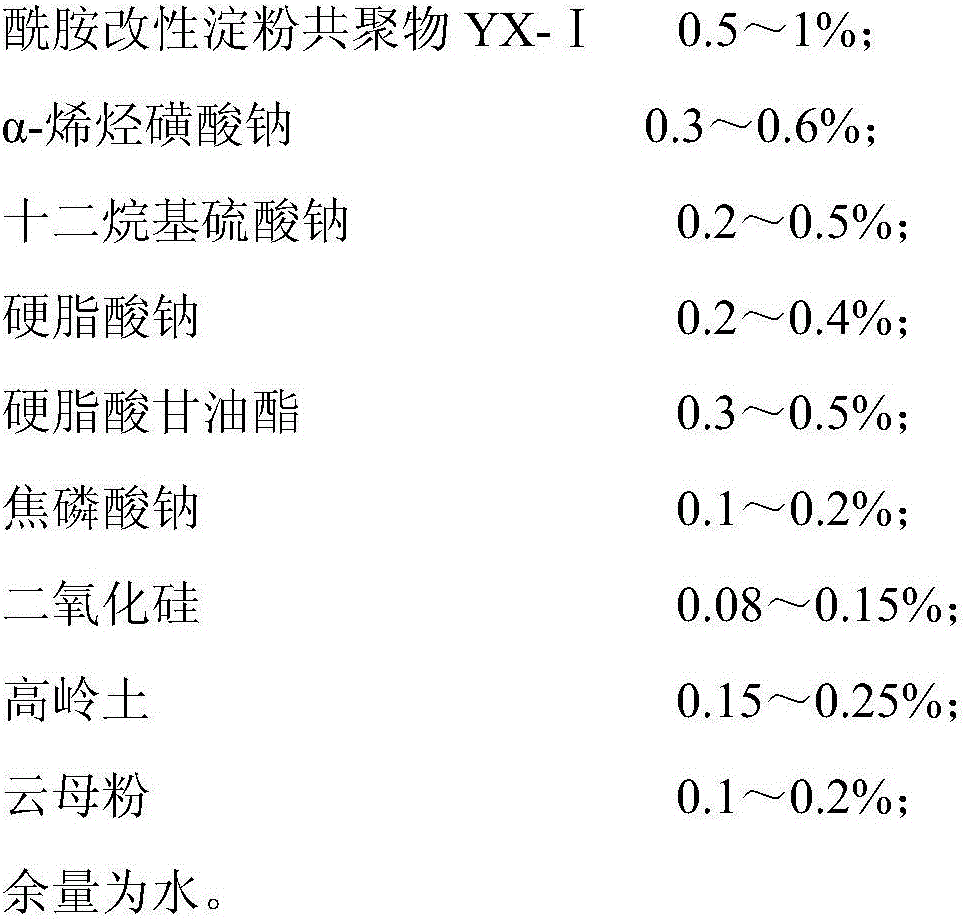

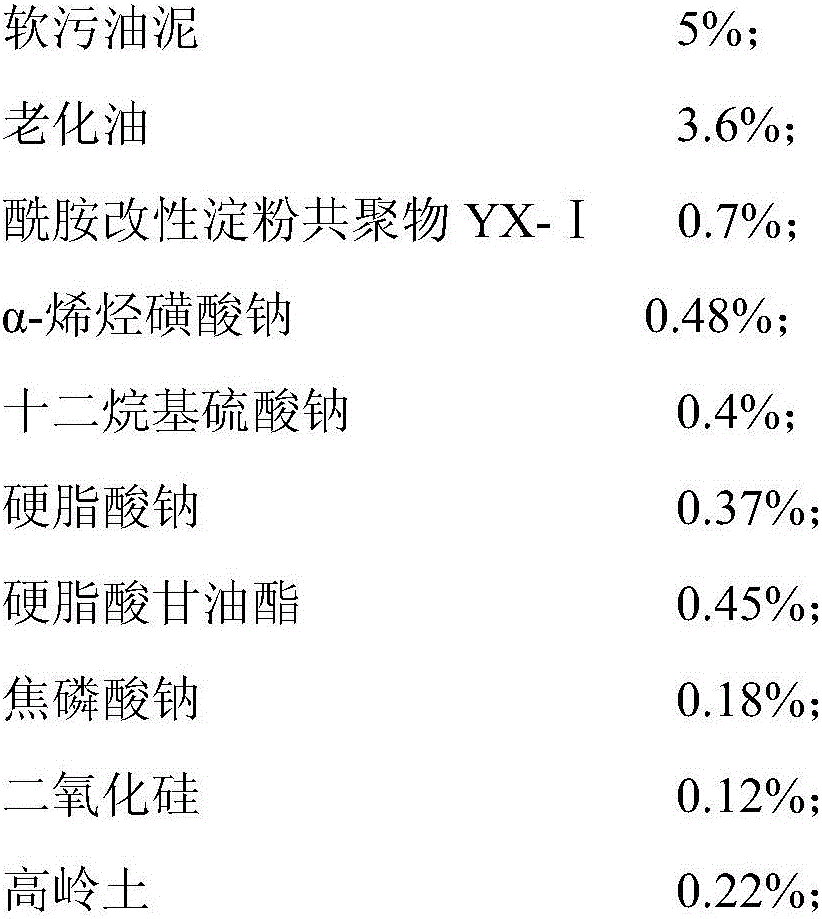

Selective water plugging agent of thin oil well as well as preparation method and application of selective water plugging agent

ActiveCN106753299AGood emulsifying effectGood thickening effectDrilling compositionSealing/packingSodium stearatePyrophosphate

The invention provides a selective water plugging agent of thin oil well as well as a preparation method and application of the selective water plugging agent. By taking the total weight of the selective water plugging agent as 100 percent, the selective water plugging agent is prepared from the following raw materials through the following dosage: 3 percent to 6 percent of soft oil sludge, 2 percent to 4 percent of ageing oil, 0.5 percent 1 percent of an amide modified starch copolymer YX-I, 0.3 percent to 0.6 percent of sodium alpha-olefinsulfonate, 0.2 percent to 0.5 percent of sodium dodecyl sulfate, 0.2 percent to 0.4 percent of sodium stearate, 0.3 to 0.5 part of glyceryl stearate, 0.1 percent to 0.2 percent of sodium pyrophosphate, 0.08 percent to 0.15 percent of silicon dioxide, 0.15 percent to 0.25 percent of kaolin, 0.1 percent to 0.2 percent of mica powder and the balance of water. The selective water plugging agent has good compatibility with a stratum; the plugging strength is great and deep water plugging can be realized; the selective water plugging capability is high; the selective water plugging agent has no damages to an oil layer and does not pollute the stratum, so that the selective water plugging agent is completely suitable for an oil well plugging technology of a thin-oil oil reservoir.

Owner:PETROCHINA CO LTD

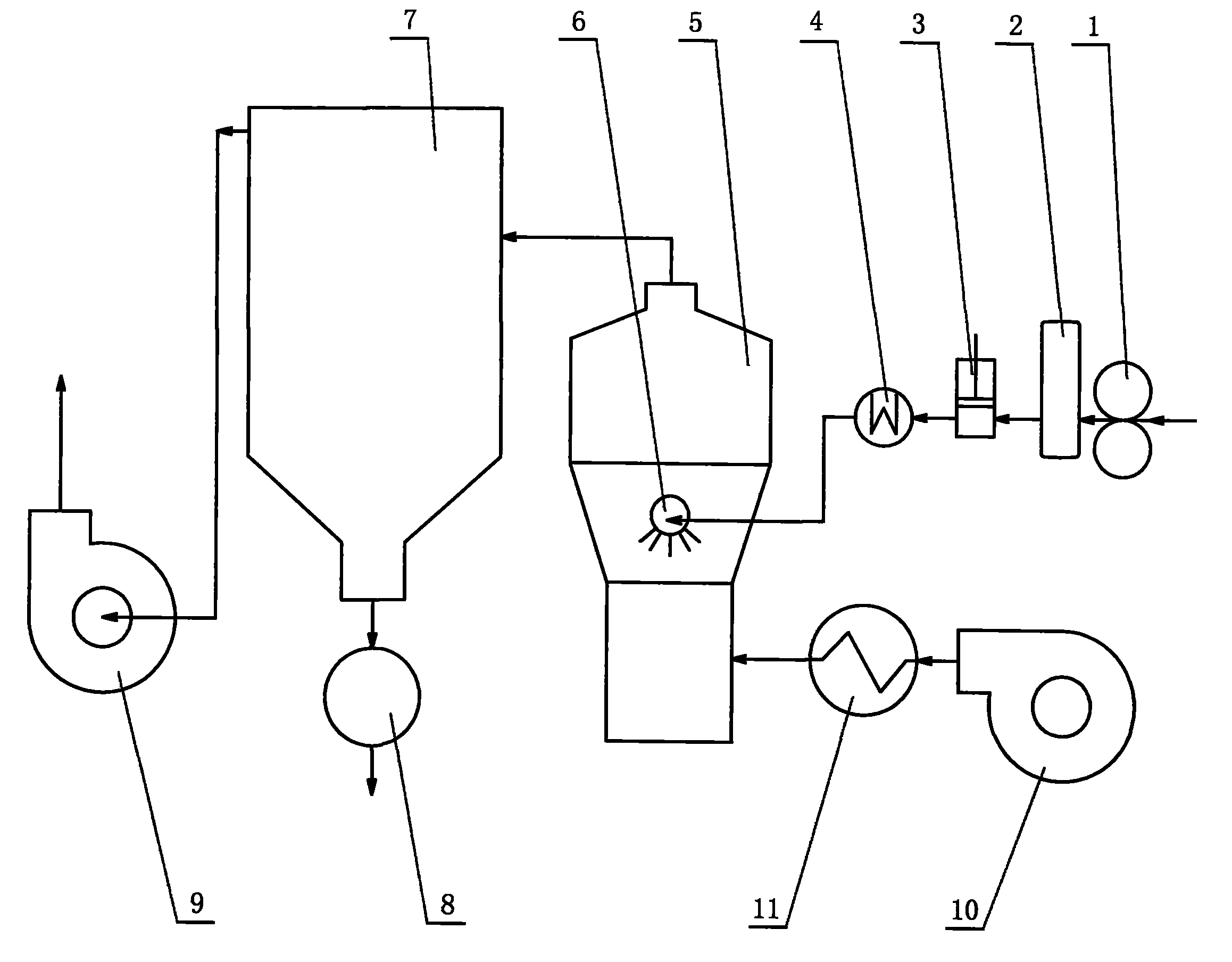

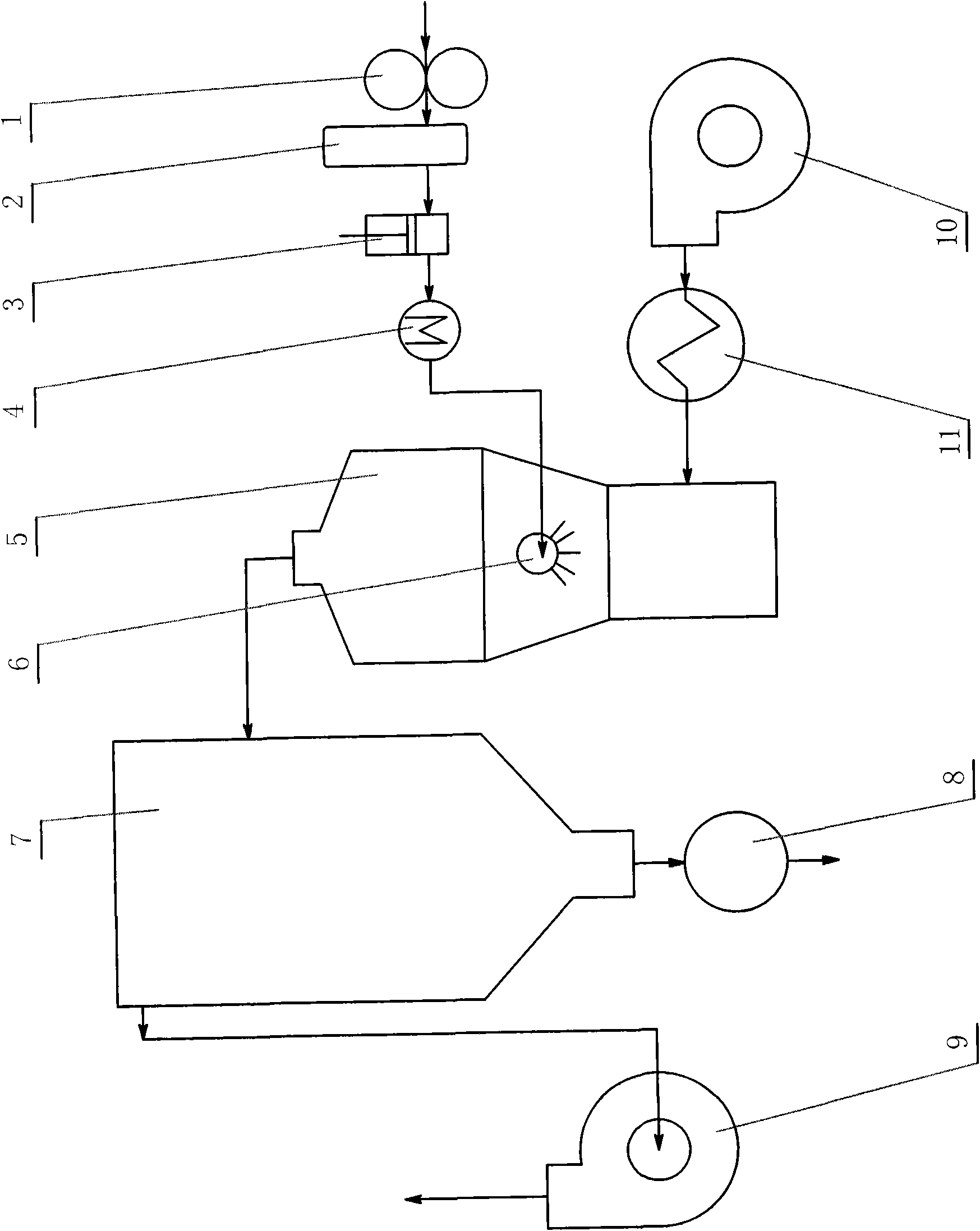

Method for continuously drying sodium aliphatic alcohol sulfate and sodium olefin sulfonate slurry

InactiveCN101811994AAvoid the difficulty of continuous and stable atomizationEfficient dryingOrganic compound preparationTransportation and packagingFluidized bed dryingSulfate

The invention provides a method for continuously drying sodium aliphatic alcohol sulfate and sodium olefin sulfonate slurry with easy continuous processing and low cost. The method comprises the following steps of: inputting airflow at the temperature of between 70 and 180 DEG C into a fluidized bed dryer (5) to ensure that inert particles in the dryer are fluidized; preheating the measured sodium aliphatic alcohol sulfate and sodium olefin sulfonate slurry to the temperature of between 50 and 150 DEG C, and inputting the measured sodium aliphatic alcohol sulfate and sodium olefin sulfonate slurry into the fluidized bed dryer (5) in a pulsating flow mode; allowing the slurry to pass through a mesh distribution screen (6); rupturing the slurry into short columns; ,making the slurry fall into a fluidized bed layer of the dryer; fluidizing the slurry and the inertia particles, and drying the fluidized slurry and the inertia particles to obtain the material; separating the dried material from surfaces of the inert particles to form fine powder; discharging the fine powder from the top of the fluidized bed dryer along with air flow, and allowing the fine powder to enter a bag separator (7); and exhausting tail gas from the top of the bag separator, and outputting the product of fine powder from the lower part of the bag separator. The method is suitable for drying a surface active agent.

Owner:SINOLIGHT CHEM

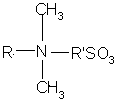

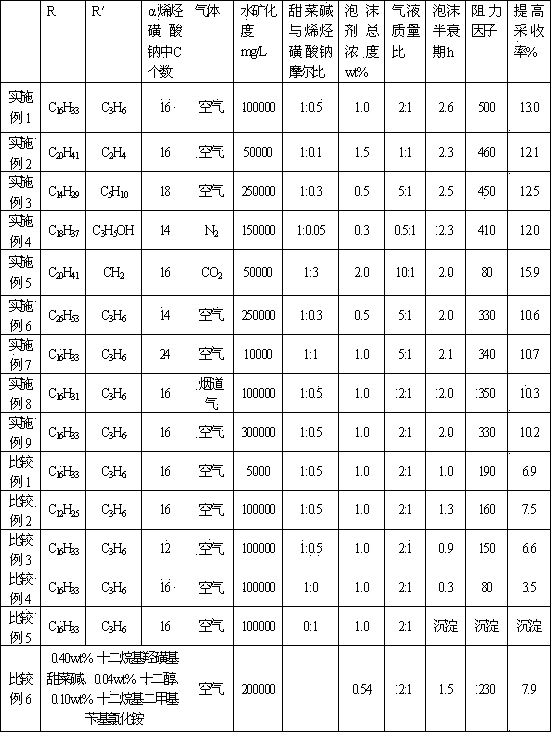

Reinforced foam flooding composition for high salinity reservoirs, and preparation method thereof

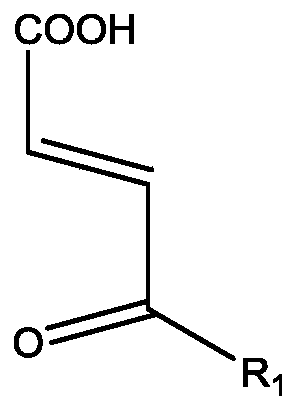

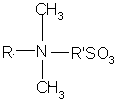

The invention relates to a reinforced foam flooding composition for high salinity reservoirs, and a preparation method thereof. The problems of bad form stability after meeting a salinity precipitate and poor plugging performance of foaming agents in a high salinity reservoir foam flooding oil extraction process are mainly solved. The foam composition comprises long chain betaine, sodium alpha-olefin sulfonate, mineralized water and a gas, and long chain betaine and sodium alpha-olefin sulfonate are dissolved in the mineralized water, the obtained solution is mixed with the gas to form foams, the long chain betaine is sulfonate, and the molecular general formula of the long chain betaine is shown in the specification. The composition well solves the problems, and can be used in the reinforced foam flooding process of the high salinity reservoirs.

Owner:CHINA PETROLEUM & CHEM CORP +1

Multifunctional water-based cleaning agent

InactiveCN105925991AGood effectImprove cleaning efficiencyDiethylene glycol monobutyl etherWater based

The invention relates to a cleaning agent, in particular to a KB-001 multifunctional water-based cleaning agent, and belongs to the technical field of cleaning agents. The multifunctional water-based cleaning agent comprises the following components by weight percent: 70 to 85% of water, 2.1 to 2.4% of diethylene glycol monobutyl ether, 1.0 to 1.2% of alpha-olefin aulfonate surfactant, 1.2 to 1.4% of cocamidopropyl dimethylamine oxide, 0.8 to 1.0% of organic amine ester, 7.3 to 7.5% of sodium citrate, 6.4 to 6.6% of sodium gluconate and 1.0 to 1.5% of methenamine. According to the multifunctional water-based cleaning agent, water is adopted as the main material, phosphorus-containing substances and nonyl phenol substances are contained, the cleaning agent is environment-friendly and can clean oil stains and rust on a metal surface, the effect is remarkable, the cleaning efficiency is far higher than that of the same type of water-based cleaning agents of which the evaluation is relatively good abroad, the cleaning speed is improved by 46%, the cleaning effect can be achieved under the condition of 40 DEG C water bath soaking, and running water flushing and ultrasonic vibration are not required.

Owner:科谱研发技术中心(青岛)有限公司

Modified concrete foaming agent

The invention discloses a modified concrete foaming agent. The modified concrete foaming agent is prepared from the following components: sodium dodecyl sulfate, triethanolamine, methyl cellulose, sodium alpha-olefinsulfonate, polyallylamine, propane diacid and water. The foaming agent provided by the invention has strong foaming capability and large foam yield per unit volume and allows produced foam to be maintained for a long time; methyl cellulose and triethanolamine are doped, methyl cellulose can guarantee the foaming rate of the foaming agent, triethanolamine can greatly improve foam stability, and mixed modification of the foaming agent by methyl cellulose and triethanolamine enables the foaming agent to have ideal effect and stability of foaming of the mother liquor of the foaming agent to be improved; and the modified concrete foaming agent uses widely available raw materials, has low cost, is simple to prepare, produces fine foam which has good compatibility with a used medium and overcomes the problems of poor foamability and foam stabilization performance, high cost, complex preparation technology and the like in the prior art.

Owner:宣城市聚源精细化工有限公司

Full liquid phase airflow diversion agent for deep oil reservoir and preparation method of full liquid phase airflow diversion agent

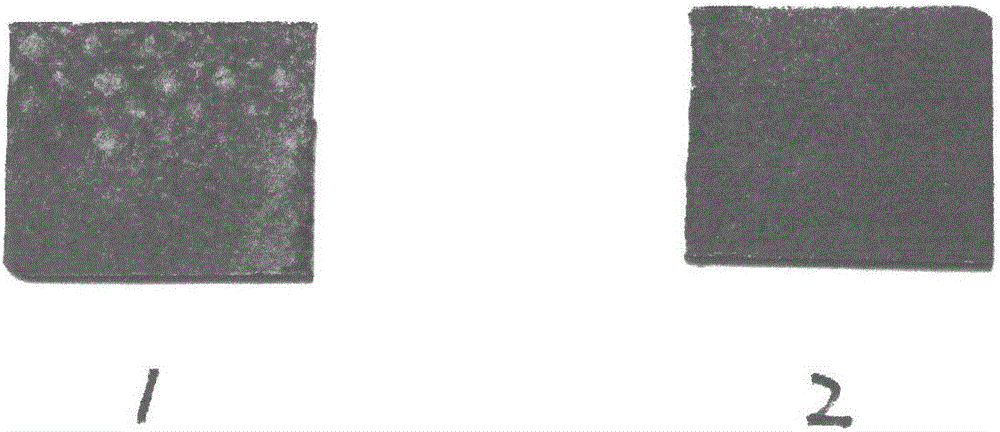

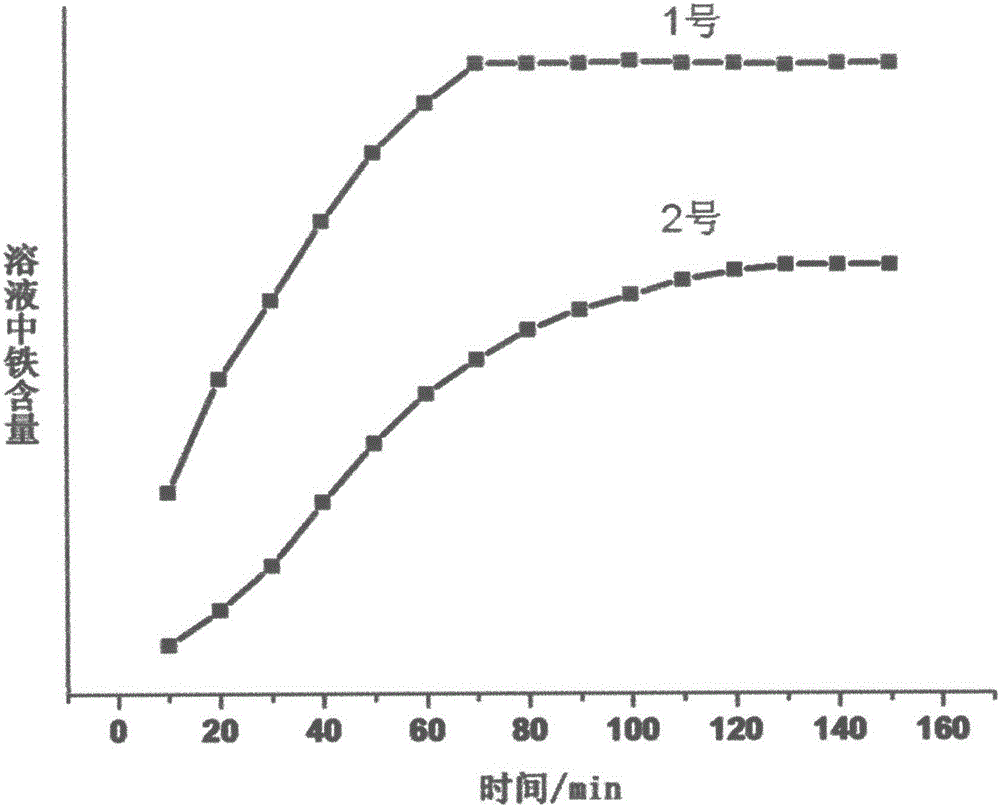

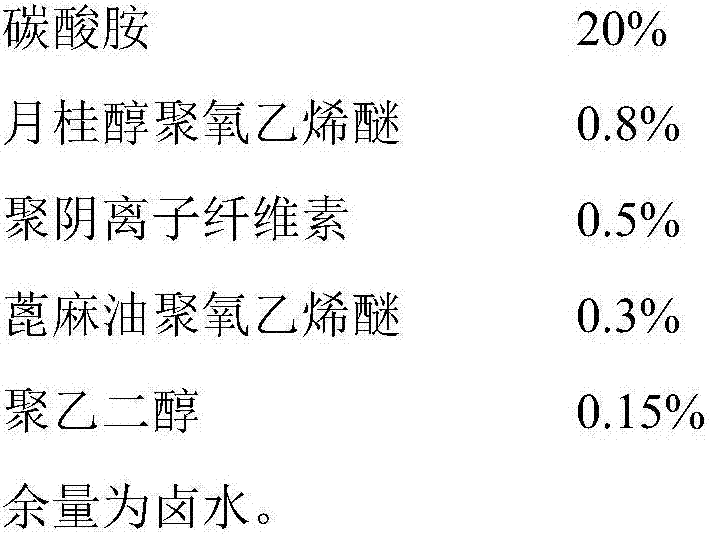

The invention provides a full liquid phase airflow diversion agent for a deep oil reservoir and a preparation method of the full liquid phase airflow diversion agent. The diversion agent is prepared from a slug I, insulating liquid and a slug II, wherein the volume ratio of the slug I to the insulating liquid to the slug II is (15 to 30) to (45 to 73) to (12 to 25); the slug I is prepared from thefollowing raw materials: a water glass solution, ammonium oxalate, glycerol polyoxyethylene ether, methoxy polyethylene glycol, ammonium chloride and the balance of water; the insulating liquid is prepared from the following raw materials: alpha-sodium olefinsulfonate, iso-tridecanol polyoxyethylene ether and the balance of water; the slug II is prepared from the following raw materials: ammoniumcarbonate, lauryl alcohol polyoxyethylene, polyanionic cellulose, castor oil polyoxyethylene ether, polyethylene glycol and the balance of brine. The invention also provides the preparation method ofthe diversion agent. The diversion agent disclosed by the invention has good temperature resistance; in addition, the plugging strength can be controlled, the construction is safe and convenient, andblockage of a tubular column is avoided.

Owner:PETROCHINA CO LTD

Washing and conditioning integrated laundry detergent enabling rinsing to be easy

InactiveCN104140897AEasily biodegradableGood recombinationInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSurface-active agentsAlpha-olefin

The invention discloses a washing and conditioning integrated laundry detergent enabling rinsing to be easy. The laundry detergent is characterized by comprising, by mass, 2-5% of cationic alkyl polyglucoside, 8-12% of sodium alcohol ether sulphate, 1-5% of alpha-olefin sulfonates, 1-5% of alkyl glycoside, 1-3% of fatty alcohol-polyoxyethylene ether, 1-3% of coconut diethanolamide, 0.1-0.5% of polyacrylate, 0.1-0.6% of liquid protease16XL, 0.5-8% of 4-formylbenzeneboronic acid, 1-4.5% of sodium chloride, 0.5-2% of dimethicone and the balance being deionized water. According to the washing and conditioning integrated laundry detergent, the novel cationic surface active agent (alkyl polyglucoside) is adopted, in this way, the laundry detergent has the advantages of being environmentally friendly, natural and low in toxicity and irritation and has various cationic characteristics of quaternary ammonium salt, and biological degradation is easy.

Owner:SHANGHAI SOAP GRP RUGAO

Composite modified organosilicon surfactant

InactiveCN106669539AImprove surface activityStable chemical propertiesTransportation and packagingMixingAlkaneFatty alcohol

The invention discloses a composite modified organosilicon surfactant which is prepared from a terminal-group polyether-modified organosilicon surfactant, a modified high-molecular surfactant, sodium petroleum sulfonate, fatty alcohol polyoxyethylene sodium sulfate, alkyl benzene ether sodium disulfonate, polyoxyethylene oleate, dialkyl benzene polyoxyethylene alkane sulfonate, sodium dodecyl benzene sulfonate, lauryl sodium sulfate, alpha-sodium olefinsulfonate, sodium dodecyl glycinate, sodium dodecyl sarcosine, lauramidopropyl amine oxide, cocamidopropyl amine oxide, octadecyltrimethylammonium chloride, cetyl trimethylammonium bromide, nonylphenol polyoxyethylene ether, lauroyl diethanolamide, isopropanol and ethanol. The composite modified organosilicon surfactant has the advantages of excellent surface activity, stable chemical properties and excellent defoaming property.

Owner:定远县新海岸生态农业发展有限公司

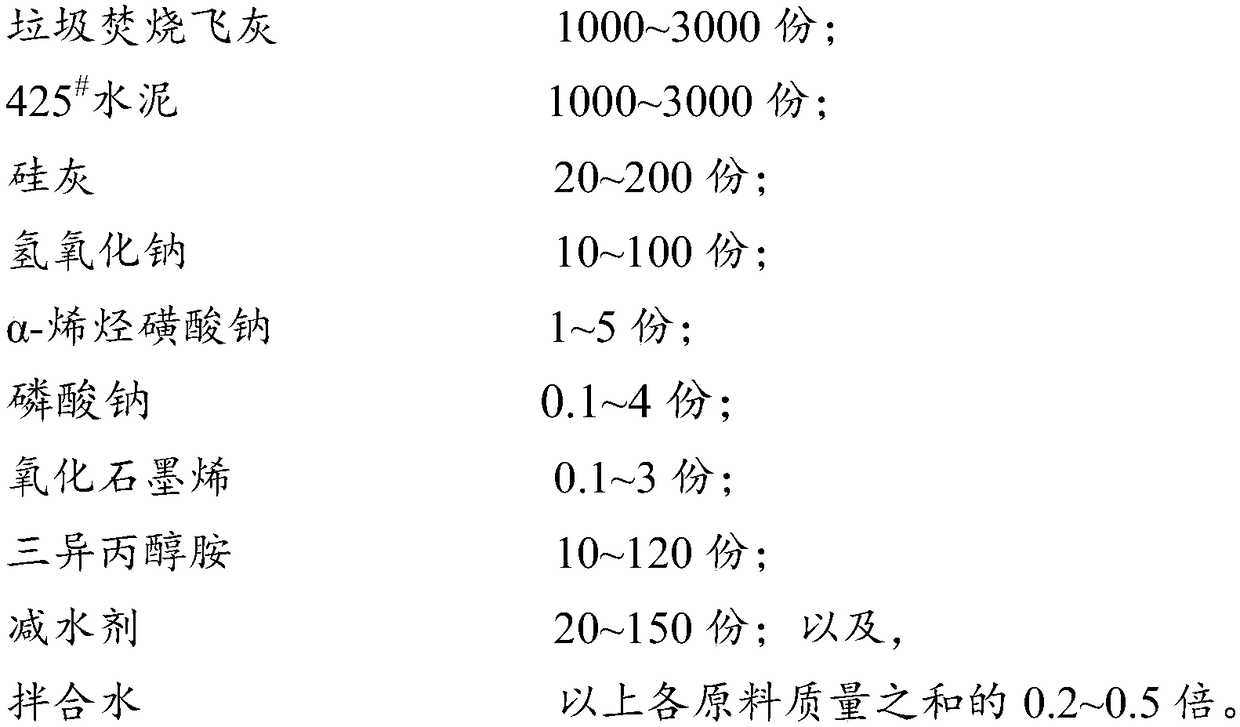

Graphene oxide-modified fly-ash cementing material, mortar and concrete for buildings and preparation method

InactiveCN108358479ASolve pollutionIncreased durabilityCement productionSodium phosphatesSODIUM OLEFIN SULFONATE

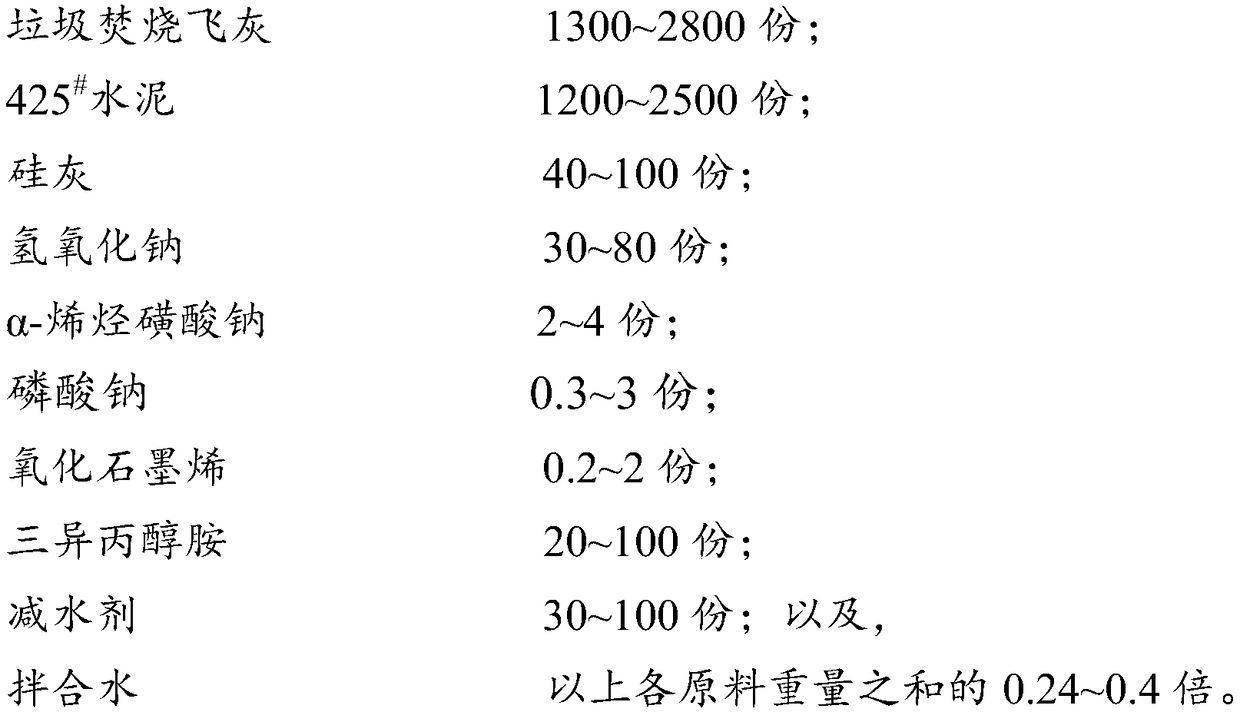

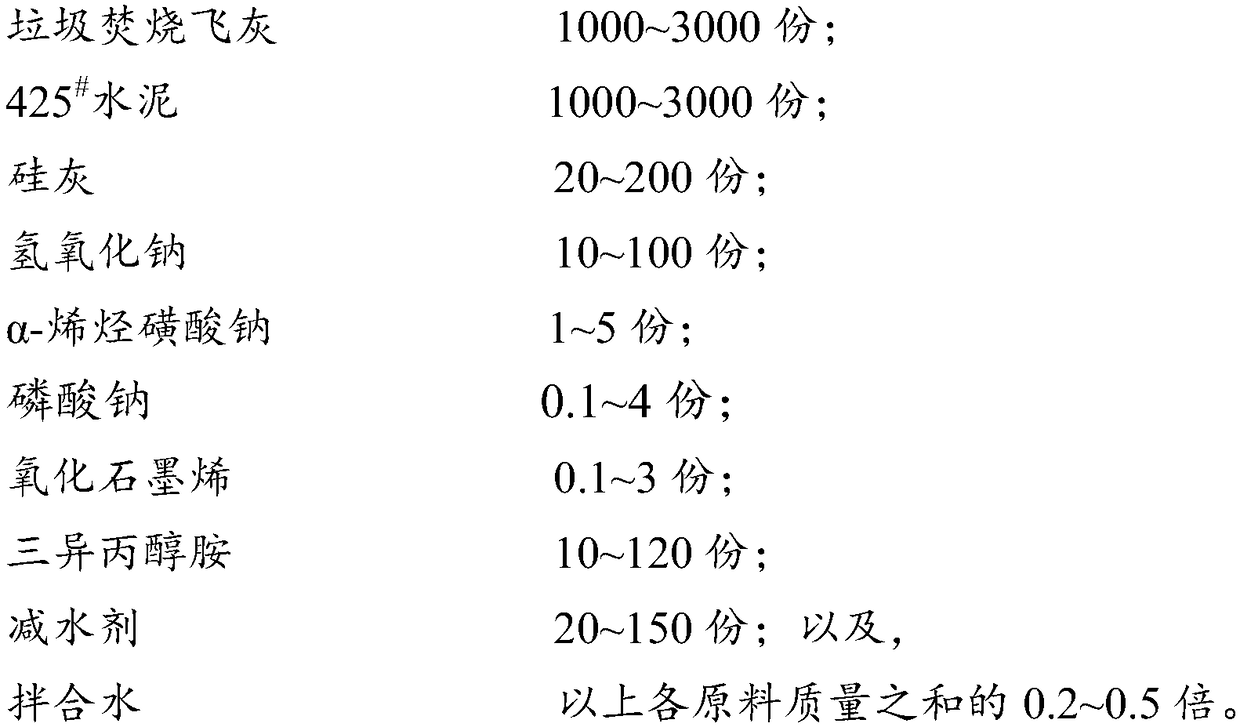

The invention discloses a graphene oxide-modified fly-ash cementing material, mortar and concrete for buildings and a preparation method. The graphene oxide-modified fly-ash cementing material is prepared from the following components in parts by mass: 1000 to 3000 parts of waste incineration fly ash, 1000 to 3000 parts of number-425 cement, 20 to 200 parts of silica fume, 10 to 100 parts of sodium hydroxide, 1 to 5 parts of alpha-sodium olefinsulfonate, 0.1 to 4 parts of sodium phosphate, 0.1 to 3 parts of graphene oxide, 10 to 120 parts of triisopropanolamine, 20 to 150 parts of water reduction agent and mixed water, wherein a water-to-solid ratio is 0.2 to 0.5. By adopting the technical scheme provided by the invention, the waste incineration fly ash can be effectively used, the obtained mortar and concrete are good in performance, and the pollution problem of the fly ash can be effectively solved.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Concrete foaming agent

The invention discloses a concrete foaming agent. The concrete foaming agent is prepared from the following components: sodium dodecyl sulfate, triethanolamine, methyl cellulose, sodium alpha-olefinsulfonate, polyallylamine, propane diacid, modified bentonite and water. According to the invention, through modification of bentonite, foam is allowed to be more uniform and finer, and foam concrete prepared from the concrete foaming agent has higher strength and better heat insulation performance; methyl cellulose and triethanolamine are doped, methyl cellulose can guarantee the foaming rate of the foaming agent, triethanolamine can greatly improve foam stability, and mixed modification of the foaming agent by methyl cellulose and triethanolamine enables the foaming agent to have ideal effect and stability of foaming of the mother liquor of the foaming agent to be improved; and the concrete foaming agent uses widely available raw materials, has low cost, is simple to prepare, and overcomes the problems of poor foamability and foam stabilization performance, high cost, complex preparation technology and the like in the prior art.

Owner:宣城市聚源精细化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com