Graphene oxide-modified fly-ash cementing material, mortar and concrete for buildings and preparation method

A graphene modification, cementitious material technology, applied in cement production and other directions, can solve problems such as large energy consumption, and achieve the effects of solving pollution problems, good durability, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

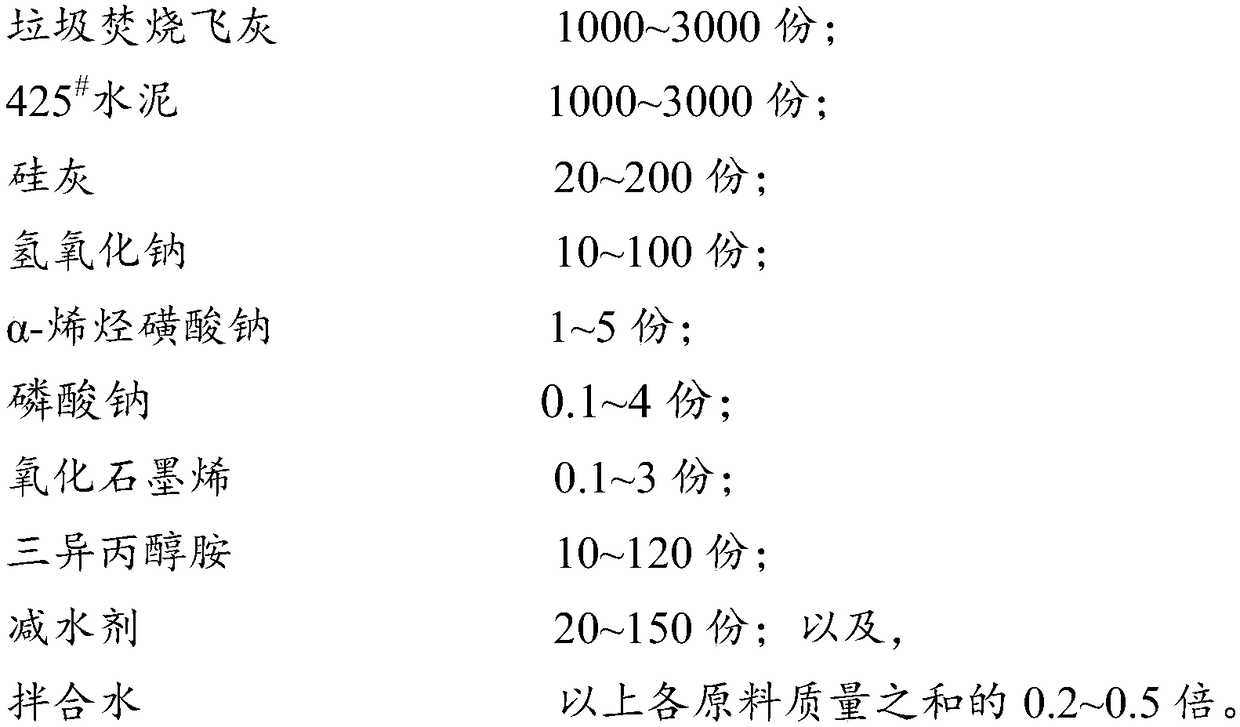

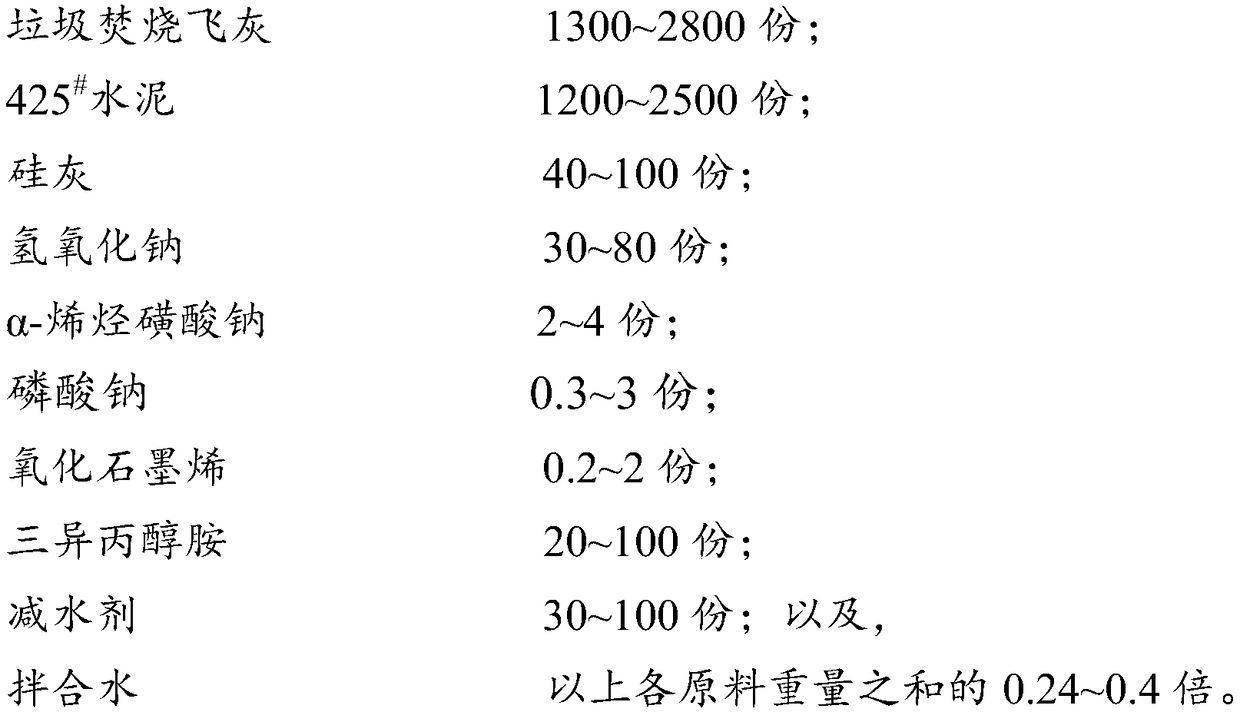

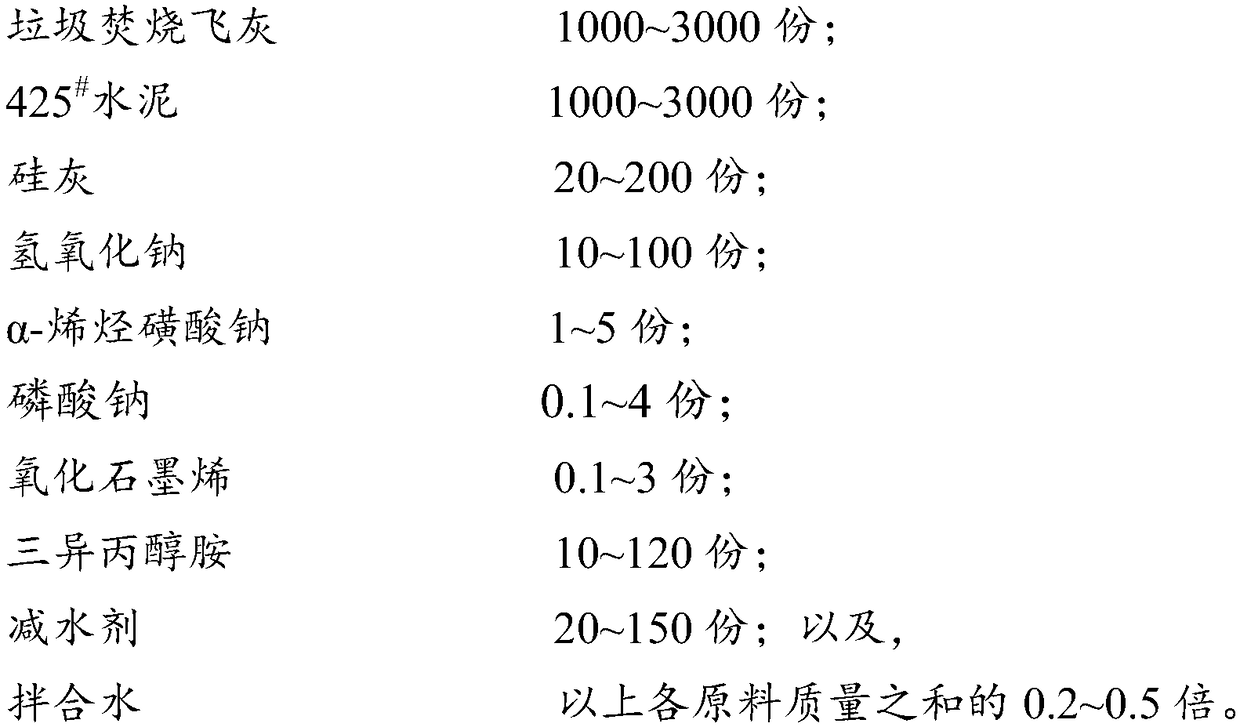

[0035] The present invention further proposes a kind of preparation method of graphene oxide modified fly ash construction cementitious material as above, comprising the following steps:

[0036] Step S10, dissolving graphene oxide in 1 / 3 mixing water to form a first solution;

[0037] Wherein, the dissolution of the graphene oxide in the mixing water can be carried out by means of ultrasonic dispersion, and the graphene oxide can be fully dissolved. Of course, in other embodiments, other conventional dispersion methods can also be used, such as rapid stirring and the like.

[0038] Step S20, dissolving sodium α-olefin sulfonate, triisopropanolamine and water reducer in the remaining 2 / 3 mixing water to form a second solution;

[0039] Step S30, waste incineration fly ash, 425 # Cement, silica fume, sodium hydroxide and sodium phosphate are mixed by dry mixing to form a powder, then the second solution is added to the powder, the first stirring is carried out, and the first ...

Embodiment 1

[0048] Embodiment 1 Preparation of graphene oxide modified fly ash cementitious material for construction

[0049] (1) Raw material preparation: correspondingly weigh 2000Kg of waste incineration fly ash, 425 # Cement 1500Kg, silica fume 60Kg, sodium hydroxide 40Kg, sodium α-olefin sulfonate 3Kg, sodium phosphate 0.6Kg, graphene oxide 0.7Kg, triisopropanolamine 40Kg, TJ-1 series polycarboxylate high-performance water reducer 40Kg and 1200Kg of mixing water, set aside.

[0050] (2) Preparation of gelling material:

[0051] Add graphene oxide into 400Kg mixing water, and ultrasonically disperse until graphene oxide is fully dissolved to form the first solution;

[0052] Add α-olefin sulfonate sodium, triisopropanolamine and water reducer to 800Kg of mixing water, stir until α-olefin sulfonate sodium, triisopropanolamine and water reducer are fully dissolved to form a second solution;

[0053] Waste incineration fly ash, 425 # Dry mix cement, silica fume, sodium hydroxide and...

Embodiment 2

[0054] Example 2 Preparation of Graphene Oxide Modified Fly Ash Construction Cementitious Material

[0055] (1) Raw material preparation: correspondingly weigh 2000Kg of waste incineration fly ash, 425 # Cement 1000Kg, silica fume 60Kg, sodium hydroxide 45Kg, α-olefin sulfonate sodium 2.5Kg, sodium phosphate 0.5Kg, graphene oxide 0.75Kg, triisopropanolamine 40Kg, TJ-1 series polycarboxylic acid high-performance water reducing 30Kg of agent and 1050Kg of mixing water are set aside.

[0056] (2) Preparation of gelling material:

[0057] Add graphene oxide into 350Kg mixing water, and ultrasonically disperse until graphene oxide is fully dissolved to form the first solution;

[0058] Add sodium α-olefin sulfonate, triisopropanolamine and water reducer to 700Kg of mixing water, stir until sodium α-olefin sulfonate, triisopropanolamine and water reducer are fully dissolved to form a second solution;

[0059] Waste incineration fly ash, 425 # Dry mix cement, silica fume, sodium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com