Salt-tolerance temperature-resistance foaming agent

A foaming agent, temperature-resistant technology, applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as poor foaming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] 1. Preparation of SMF-1

[0014] use C 14-16 Sodium α-olefin sulfonate, cocamidopropyl betaine and cetyl glucoside construct a foaming agent suitable for salt and temperature resistance. Choose C 14-16 α - The effective concentration of sodium olefin sulfonate is 48%, the effective concentration of cocamidopropyl betaine is 60% and the effective concentration of cetyl glucoside is 90%, according to the molar ratio of 1:1:0.02 , weighed 5.69g C 14-16 α -Sodium olefin sulfonate, 8.00g cocamidopropyl betaine and 0.12g cetyl glucoside were added successively in a three-necked flask filled with 60mL distilled water, and stirred vigorously for 2.5 hours at a temperature of 60°C, and then in Dehydrate under vacuum conditions to obtain a salt-resistant and temperature-resistant foaming agent (SMF-1).

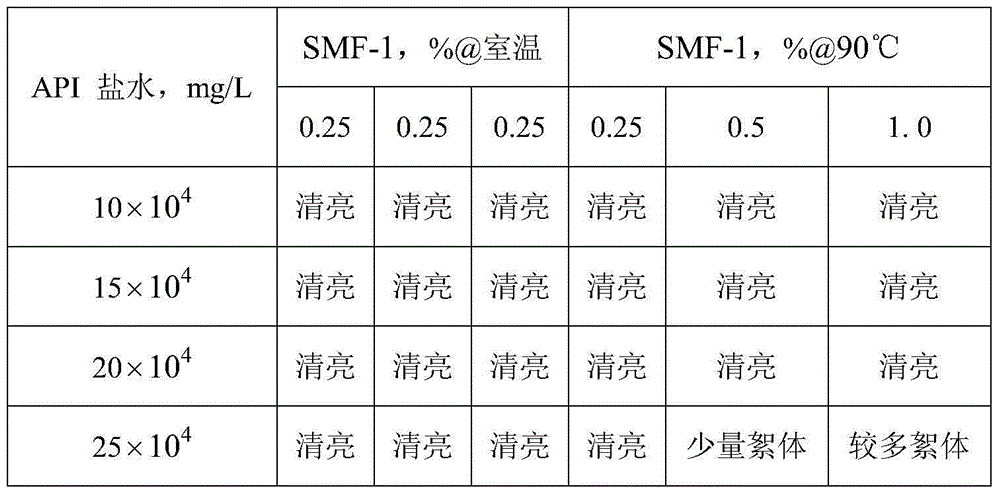

[0015] 2. Investigation of the salt tolerance of SMF-1

[0016] Prepared according to API standard 10×10 4 mg / L, 15×10 4 mg / L, 20×10 4 mg / L and 25×10 4 mg / L of brine (...

Embodiment 2

[0028] 1. Preparation of SMF-2

[0029] use C 14-16 Sodium α-olefin sulfonate, cocamidopropyl betaine and cetyl glucoside construct a foaming agent suitable for salt and temperature resistance. Choose C 14-16 α - The effective concentration of sodium olefin sulfonate is 48%, the effective concentration of cocamidopropyl betaine is 60% and the effective concentration of cetyl glucoside is 90%. According to the molar ratio of 1:1:0.24, weigh 5.69g C 14-16 α -Sodium olefin sulfonate, 8.00g cocamidopropyl betaine and 1.44g cetyl glucoside were added successively in a three-necked flask filled with 60mL distilled water, and stirred vigorously for 2.5 hours at a temperature of 70°C, and then in Dehydration under vacuum conditions to obtain a supramolecular foaming agent (SMF-2) resistant to salt and temperature.

[0030] 2. Investigation of the salt tolerance of SMF-2

[0031] Prepared according to API standard 10×10 4 mg / L, 15×10 4 mg / L, 20×10 4 mg / L and 25×10 4 mg / L of ...

Embodiment 3

[0041] 1. Preparation of SMF-3

[0042] use C 14-16 Sodium α-olefin sulfonate, cocamidopropyl betaine, cetyl betaine and stearyl glucoside build a foaming agent resistant to salt and temperature. Choose C 14-16 α - The effective concentration of sodium olefin sulfonate is 48%, the effective concentration of cocamidopropyl betaine is 60%, the effective concentration of cetyl betaine is 68% and the effective concentration of stearyl glucoside is 86% %. According to the molar ratio of 1:0.5:0.5:0.02, weigh 5.69g C 14-16 Sodium α-olefin sulfonate, 4.00g cocamidopropyl betaine, 4.96g cetyl betaine and 0.13g octadecyl glucoside were successively added to a three-necked flask filled with 60mL distilled water, and the Stir vigorously at high temperature for 2.5 hours, and then dehydrate under vacuum to obtain a salt-resistant and temperature-resistant blowing agent (SMF-3).

[0043] 2. Investigation on the foaming performance of SMF-3 at room temperature

[0044] Use 15×10 4 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com