Washing and conditioning integrated laundry detergent enabling rinsing to be easy

A laundry liquid and easy-rinsing technology, which is applied in the direction of detergent compounding agent, detergent composition, organic washing composition, etc., can solve the problems of poor softness effect, unfavorable environmental protection, unfavorable washing, etc., and achieve good softness of clothes , Excellent compound performance, good decontamination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Take each raw material according to the ratio of raw materials in Table 1;

[0054] raw material example 1 Example 2 Example 3 cationic alkyl polyglycoside 2.2 3.5 2.3 Sodium Fatty Alcohol Polyoxyethylene Ether Sulfate 10.5 12 10.6 Sodium alpha olefin sulfonate 1 3 1.4 Alkyl glycoside 1 3 2 Fatty alcohol polyoxyethylene ether 2.1 4 2.2 Cocoyl Diethanolamine 2.1 2.8 2.3 Polyacrylate 0.12 2.8 0.18 liquid protease 16XL 0.2 0.4 0.3 4-Formylphenylboronic acid 0.55 4.8 2.6 2-Methylisothiazol-3(2H)-one (MIT) 0.3 0.5 0.4 Sodium chloride 1.2 3.4 1.8 Simethicone 0.55 1.45 1.2 Deionized water 77.98 58.35 72.72

Embodiment 2

[0056] The fabric softener prepared by the present invention is tested according to national standards and industry standards such as "Test of Antistatic Performance of Fabric Conditioner" (GB / T 16801-1997).

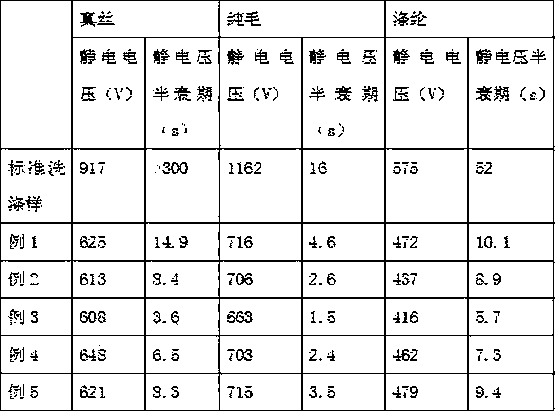

[0057] 1. Antistatic performance test

[0058]

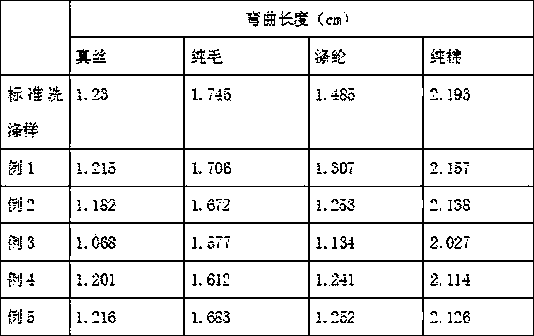

[0059] 2. Bending soft performance test

[0060]

Embodiment 3

[0062] Antibacterial test

[0063] 1. Preparation of culture medium

[0064] Nutrient agar: Weigh 3.2g of agar, add 100ml of water, stir, heat to boil, sterilize under high pressure at 121℃ for 15min, dispense into 9cm diameter Petri dishes, 15-20ml / piece, make plates for later use.

[0065] MH broth (single ingredient): Weigh 2.7g of this product, add 100ml of distilled water into a conical flask (250ml), stir and boil to dissolve, autoclave at 121°C for 15min for later use.

[0066] MH broth (double ingredients): Weigh 5.4g of this product, add 100ml of distilled water, stir, heat to boil, and autoclave at 121°C for 15 minutes for later use.

[0067]Nutrient Broth (NB): Weigh 1.8g of this product, add 100ml of distilled water into a conical flask (250ml), stir and boil to dissolve, and autoclave at 121°C for 15 minutes for later use.

[0068] Physiological saline: Weigh 0.9g, add 100ml distilled water, stir and boil to dissolve, then autoclave.

[0069] 2. Bacterial solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com