Preparing method for self-healing polysaccharide hydrogel

A hydrogel and self-healing technology, which is applied in the field of preparation of self-healing polysaccharide hydrogel, can solve the problems of poor controllability, too fast oxidation rate, and uneven oxidation degree of products, and achieve easy biodegradation, reaction The effect of simple process and abundant raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) 1-allyl-3-methylimidazolium chloride salt ionic liquid dissolves cellulose

[0031] Weigh 38.0g of ionic liquid into a 100mL three-necked bottle, cut the wood pulp cellulose into pieces, dry it in vacuum at 60°C for 24 hours, weigh 2.0g of dried wood pulp cellulose, add it to a three-necked bottle, and heat at 95°C until the cellulose Dissolve completely (about 2h), stop heating and cool to room temperature.

[0032] 2) Preparation of cellulose acetoacetate

[0033] Heat the cellulose ionic liquid solution dissolved in step 1) to 110°C, protect it with nitrogen, weigh 19.5g of tert-butyl acetoacetate and add it dropwise into a three-necked flask. After reaching room temperature, the reaction mixture was added dropwise into a large amount of methanol solvent to precipitate a precipitate. The product was washed with methanol solvent in a Soxhlet extractor for 24 hours, filtered with suction, and dried in vacuum at 60° C. for 12 hours to obtain cellulose acetoacetate p...

Embodiment 2

[0037] 1) 1-allyl-3-methylimidazolium chloride salt ionic liquid dissolves cellulose with embodiment 1

[0038] 2) prepare cellulose acetoacetate with embodiment 1

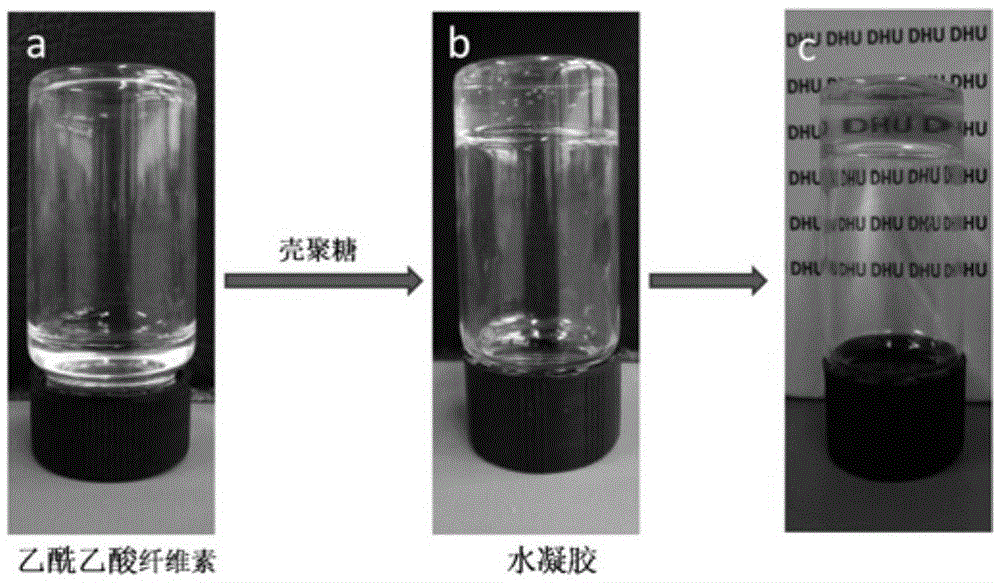

[0039] 3) A cellulose acetoacetate solution with a concentration of 1 wt% was prepared with deionized water, and a chitosan solution with a concentration of 1 wt% was prepared with a 1 wt% acetic acid solution. At room temperature, 1.2g of 1wt% chitosan solution was added to 1.2g of 1wt% cellulose acetoacetate solution, mixed on a vortex shaker, and a gel phenomenon appeared within 150s.

Embodiment 3

[0041] 1) 1-allyl-3-methylimidazolium chloride salt ionic liquid dissolves cellulose with embodiment 1

[0042] 2) prepare cellulose acetoacetate with embodiment 1

[0043] 3) A cellulose acetoacetate solution with a concentration of 0.5 wt% was prepared with deionized water, and a chitosan solution with a concentration of 0.5 wt% was prepared with a 1 wt% acetic acid solution. At room temperature, 1.2g of 0.5wt% chitosan solution was added to 1.2g of 0.5wt% cellulose acetoacetate solution, mixed on a vortex shaker, and a gel phenomenon appeared within 6min.

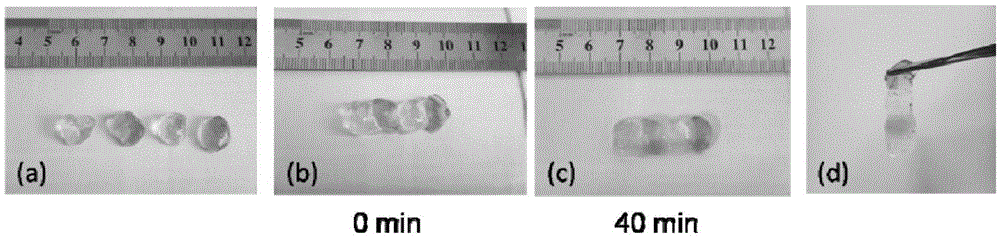

[0044] See figure 2 , the hydrogel that embodiment 2 makes is cut into 4 fritters, wherein two fritters are stained with rhodamine B ( figure 2 a), put together ( figure 2 b), After standing at 25°C for 40 minutes, the border between the stained gel and the unstained gel became blurred ( figure 2 c), while the four gels are connected as a whole ( figure 2 d).

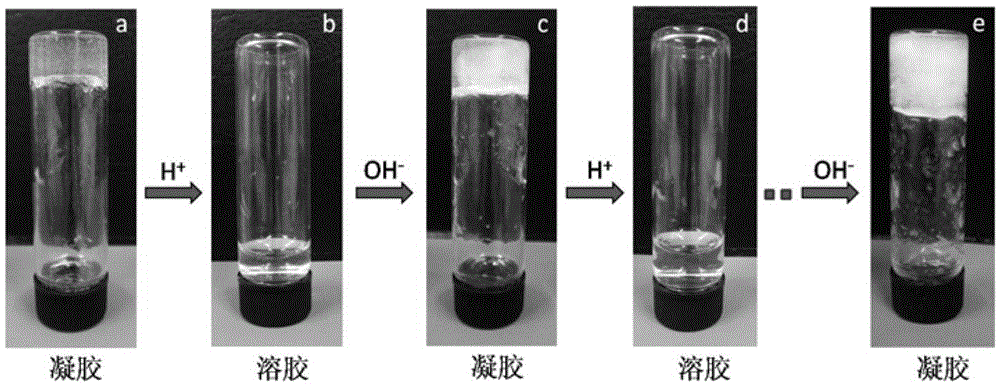

[0045] See image 3 , the hydrogel ( image 3 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com