Method for evaluating low-cycle fatigue performance of welded joint

A technology for low cycle fatigue and welded joints, applied in the field of low cycle fatigue performance evaluation of welded joints, can solve the problems of small joint micro-zone size, difficult to determine the fracture position, uncertain fracture position of welded joint fatigue test, etc., to achieve reliable evaluation , the effect of simple calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

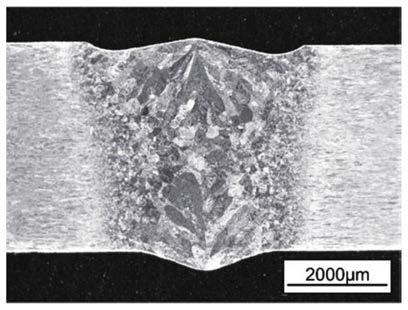

[0056] This embodiment evaluates the low-cycle fatigue performance of the plate-shaped funnel sample at the fusion line of the 4mm thick TC4 titanium alloy laser welding joint. Titanium alloy laser welding parameters are laser power 4000W, defocus distance 6mm, welding speed 1.5m / min, the macroscopic appearance of the weld cross section after welding is shown in figure 2 . The strain concentration of the funnel sample was calculated by elastic-plastic finite element method, and the local strain in the plastic zone of the funnel sample was used to evaluate the low cycle fatigue performance at the fusion line. The specific operation steps are as follows:

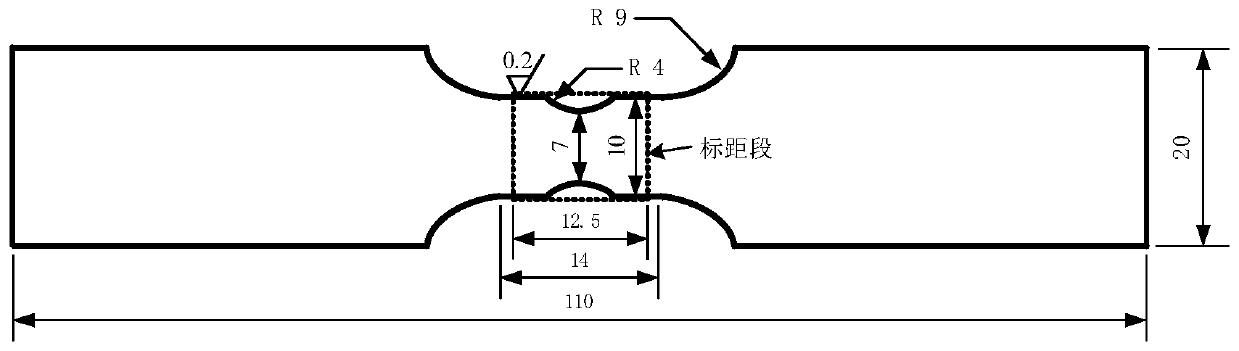

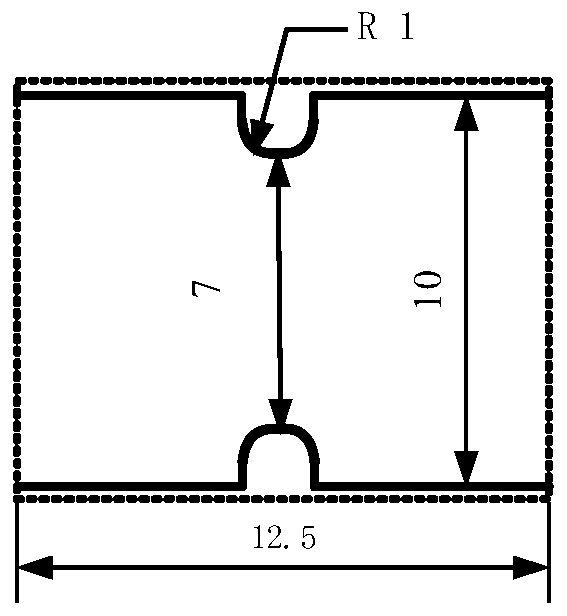

[0057] (1) using such as Figure 1a The funnel specimen shown was subjected to low cycle fatigue testing with the root of the funnel in the region of the fusion line. The loading waveform of the low cycle fatigue test is a triangular wave, and the strain rate is 0.004s -1 , the strain ratio is -1, and the strain amplitude ...

Embodiment 2

[0065] In this embodiment, the low cycle fatigue performance of the 4mm thick TC4 titanium alloy base material funnel sample and the traditional sample are compared. The funnel sample size of the titanium alloy base material is the same as that of the welded joint, and the fatigue sample size of the traditional sample is shown in Figure 7 . The strain concentration of the funnel sample of the base metal was obtained by elastoplastic finite element calculation, and the global strain and local strain of the funnel sample were used to evaluate the low-cycle fatigue performance of the titanium alloy base material, and the titanium alloy obtained by testing with the traditional sample The low cycle fatigue properties of the base metal were compared. The specific operation steps are as follows:

[0066] (1) Low-cycle fatigue tests were performed on the funnel sample and the traditional sample of the titanium alloy base material, and the fatigue life under different global strain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com