Preheater cyclone internal cylinder with steel strips made of super-strong heat resistant steel

A heat-resistant steel, super-strong technology, applied in the field of the preheater cyclone inner tube and ceramic coupons, can solve the problems of affecting quality and service life, difficult processing of assembled parts, and insufficient heat resistance. Convenience, connection and installation are convenient and simple, and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention is illustrated in conjunction with the accompanying drawings.

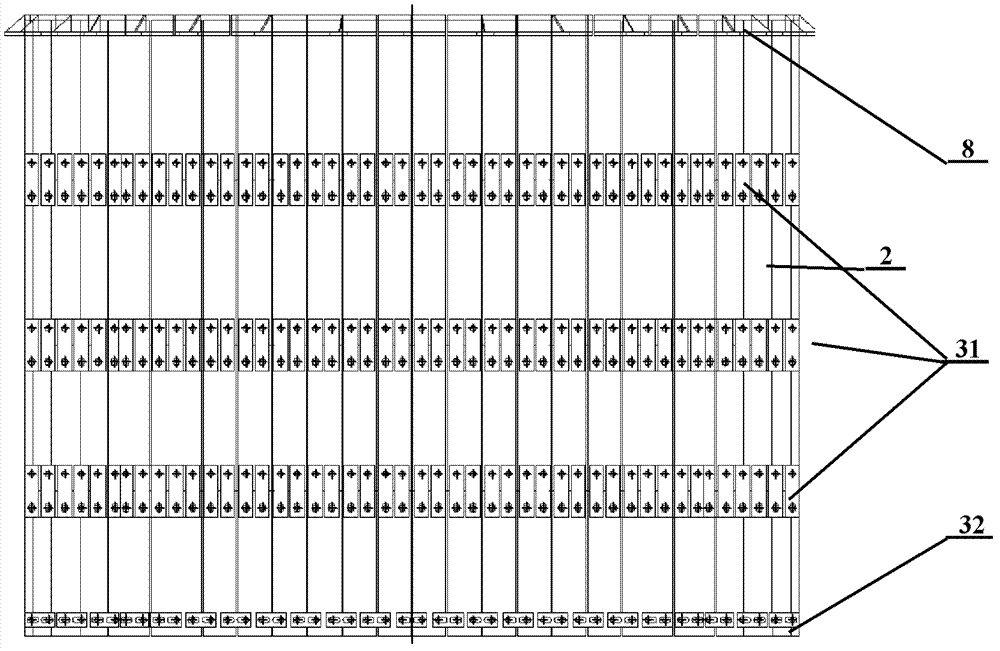

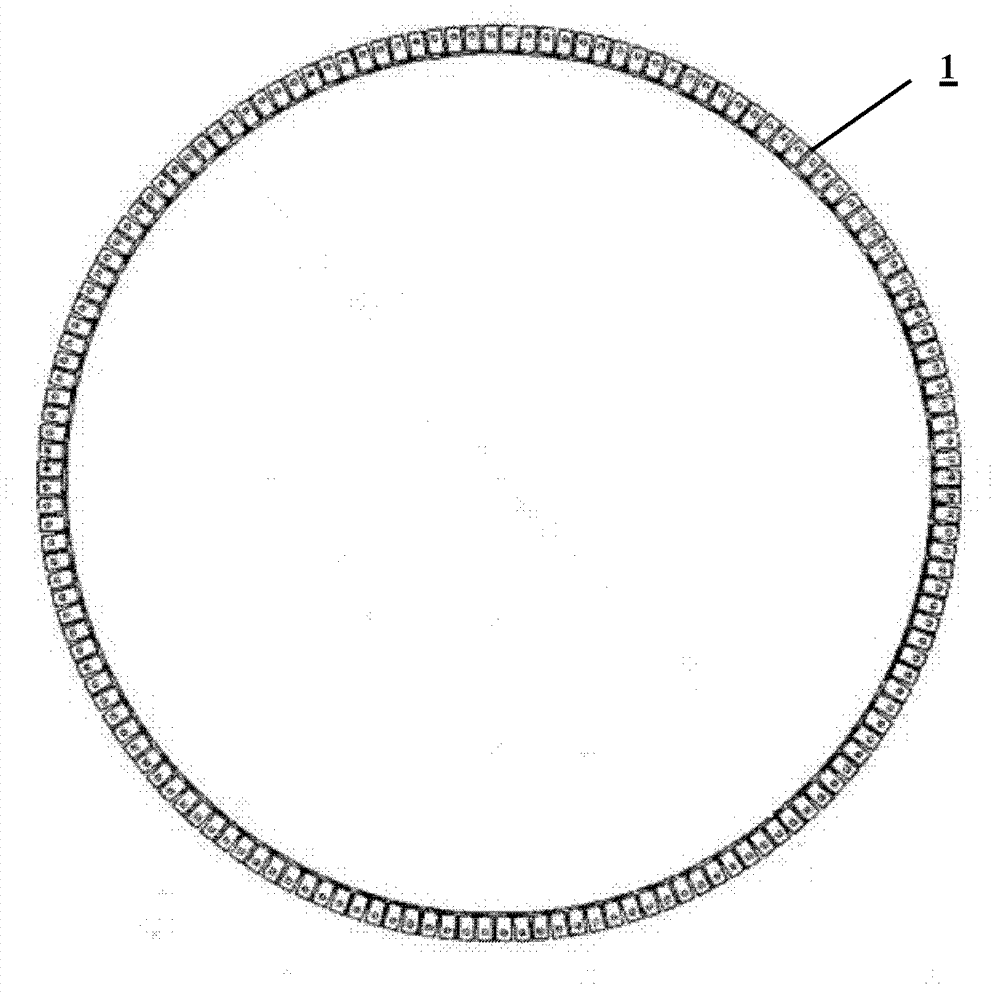

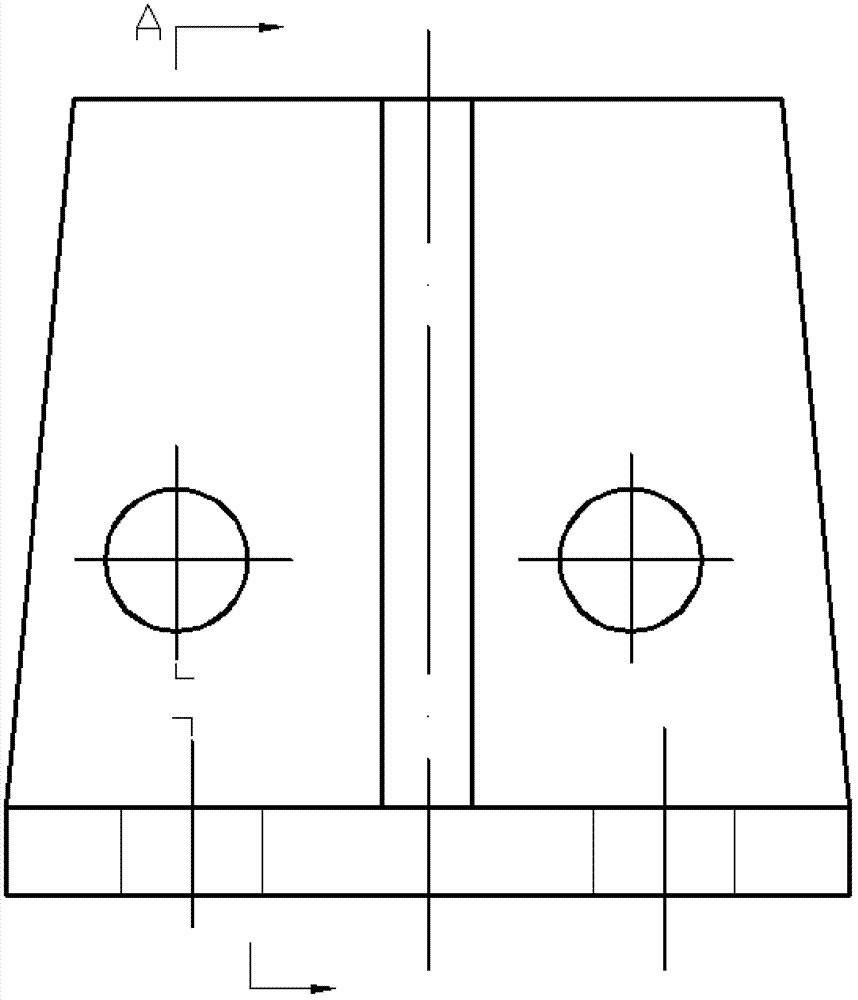

[0052] figure 1 , figure 2 It is a side view and a top view of the inner cylinder of the preheater cyclone of the present invention, Figure 3a and Figure 3b It is the front view and AA sectional view of the fixing seat of the inner cylinder of the preheater cyclone from figure 1 and figure 2 Visible, from figure 1 and figure 2 It can be seen that the inner cylinder body 1 connected with the cyclone fixing seat 8 is included, and the inner cylinder body 1 is composed of a plurality of ceramic hanging pieces 2 and ceramic connecting plates matched and connected with each other. The ceramic connecting plate includes an intermediate connecting plate 31 and a lower connecting plate 32; the ceramic hanging pieces 2 are closely arranged in the circumferential direction to form a cylindrical body, and the upper and lower ceramic hanging pieces 2 are fixedly connected longitudinally ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com