Method for evaluating plastic pipe butt-fusion welding quality

A technology of hot-melt butt joint and plastic pipes, which is applied in the direction of applying stable tension/pressure to test the strength of materials, which can solve the problems of low reliability, large influence of subjective factors, and long evaluation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

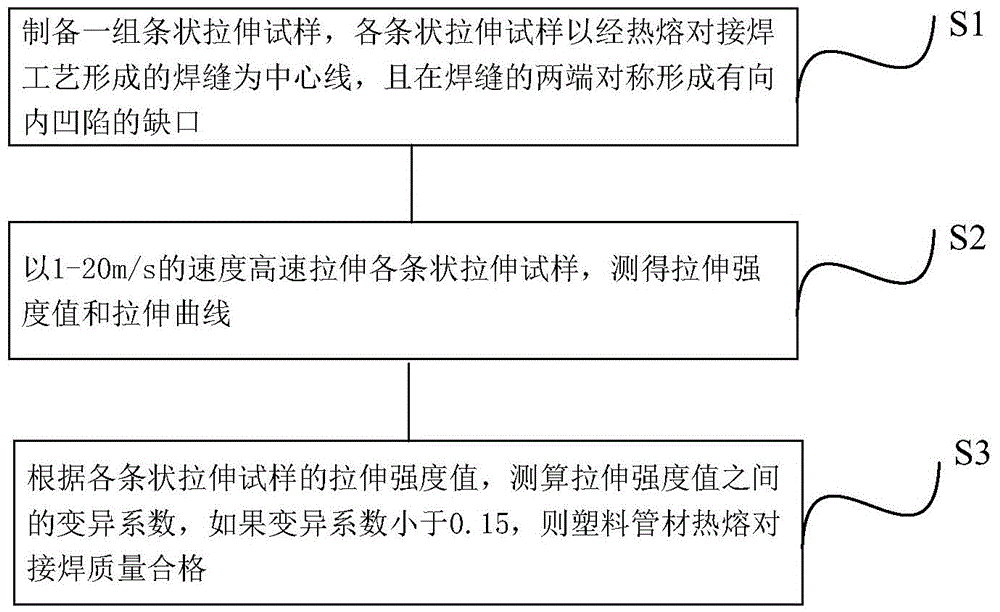

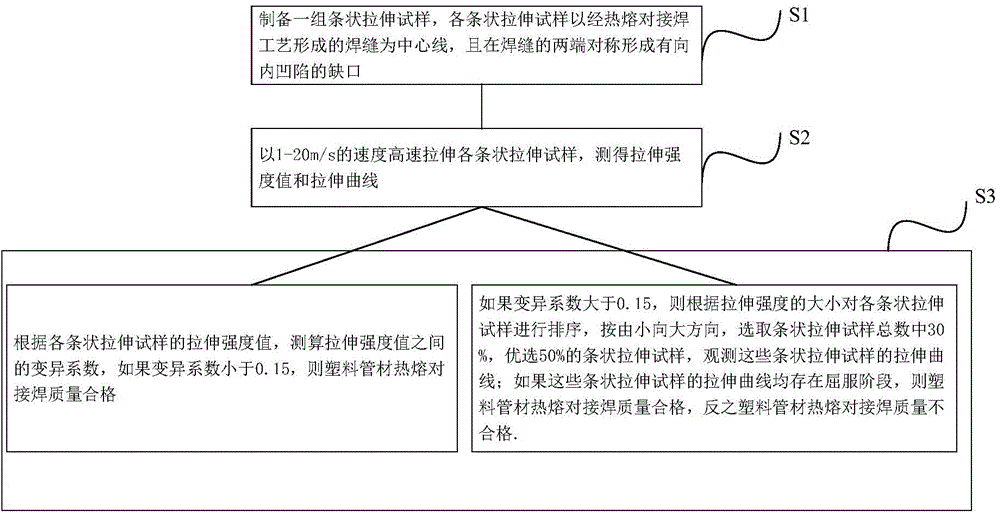

[0082] The methods to evaluate the quality of butt welding of plastic pipes are as follows:

[0083] S1. Take the hot-melt butt-welded pipe 1 prepared above, take 10 tensile specimens uniformly along the radial direction of the pipe, and machine them into a dumbbell-shaped GB / T1040.2-2006 1B, and let the weld be tested The exact center position;

[0084] S2. Use a milling cutter to mill out two symmetrical V-shaped notches (angle of 30°) of the 10 dumbbell-shaped tensile specimens at the two ends of the weld position, and the depth of the notch is 2mm (notch depth and strip The ratio of the length of the welding wire on the tensile specimen is 1:4);

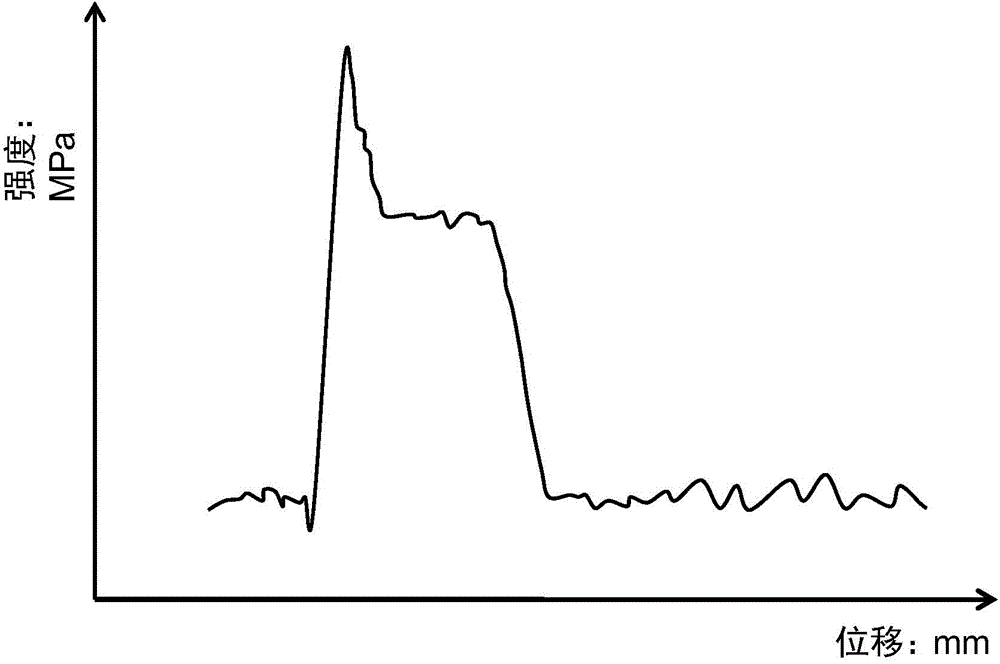

[0085] S3. The dumbbell-shaped tensile specimen with V-notch obtained in step S2 was stretched with a high-speed tensile testing machine at a speed of 9 m / s, and the tensile strength of the specimen was measured as shown in Table 4. Among them, the coefficient of variation between the tensile strength values is calculated to be 0.01...

Embodiment 2

[0087] The methods to evaluate the quality of butt welding of plastic pipes are as follows:

[0088] S1. Take the hot-melt butt-welded pipe 2 prepared above, obtain 10 tensile specimens uniformly along the radial direction of the pipe, and machine them into a dumbbell-shaped GB / T1040.2-2006 1B, and let the weld be tested The exact center position;

[0089] S2. Use a milling cutter to mill out two symmetrical V-shaped notches (angle of 150°) of the 10 dumbbell-shaped tensile specimens at the two ends of the weld, and the depth of the notch is 2mm (the depth of the notch is the same as that of the strip The ratio of the length of the welding wire on the extension sample is 1:6);

[0090] S3. The dumbbell-shaped tensile specimen with V-notch obtained in step S2 is stretched with a high-speed tensile testing machine at a speed of 9m / s, and the tensile strength of the specimen is measured as shown in Table 4. Among them, the coefficient of variation between the tensile strength values ...

Embodiment 3

[0093] The methods to evaluate the quality of butt welding of plastic pipes are as follows:

[0094] S1. Take the hot-melt butt-welded pipe 3 prepared above, obtain 10 tensile specimens uniformly along the radial direction of the pipe, and machine them into a dumbbell-shaped GB / T1040.2-2006 1B, and let the weld be tested The exact center position;

[0095] S2. Use a milling cutter to mill out two symmetrical V-shaped notches (with an angle of 90°) of the 10 dumbbell-shaped tensile specimens at the two ends of the weld, and the depth of the notch is 2mm (notch depth and strip The ratio of the length of the welding wire on the tensile specimen is 1:3);

[0096] S3. The dumbbell-shaped tensile specimen with V-notch obtained in step S2 is stretched with a high-speed tensile testing machine at a speed of 9m / s, and the tensile strength of the specimen is measured as shown in Table 4. Among them, the coefficient of variation between the tensile strength values is 0.235.

[0097] Since th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com