Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Good water flux" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of oxidized graphene doped hollow fiber nanofiltration membrane

InactiveCN106890570AHigh mechanical strengthExcellent salt rejectionReverse osmosisHollow fibreFiber

The invention provides a preparation method of an oxidized graphene doped hollow fiber nanofiltration membrane. The preparation method comprises the steps that a plurality of hollow fiber nanofiltration membrane serve as basic membranes to be packaged into a component shell to obtain a membrane component for usage; oxidized graphene, an active monomer and an acid absorbing agent are added into a solvent A for uniform ultrasonic mixing to obtain a solution A; multielementacyl chloride is dissolved in a solvent B to obtain a solution B; the solution A is introduced into the inner cavity of the hollow fiber nanofiltration membrane of the membrane component for full infiltration, the solution A is removed, drying is performed, the solvent B is introduced into the inner cavity of the membrane for interfacial polymerization reaction, then the solution B is removed, drying is performed, andpure-water rinsing and drying are performed to obtain the membrane. The oxidized graphene is added in the membrane preparation process and has the very good effect on the aspects of surface hydrophilicity improvement, membrane flux increase and pollution resistance. The product is good in mechanical strength andcontamination resistance and is higher than an oxidized-graphene-free pure polyamide nanofiltration membraneindesalting rate and water flux.

Owner:ZHEJIANG UNIV OF TECH

Polyvinylidene fluoride anti-pollution membrane and preparation method thereof

ActiveCN107149882AEasy to makeLow preparation equipment requirementsMembranesSemi-permeable membranesPhase conversionUltraviolet

The invention discloses a polyvinylidene fluoride anti-pollution membrane and a preparation method thereof, and belongs to the field of environmental functional membrane materials. The preparation method comprises: (1) self-polymerizing dopamine on the surface of polyvinylidene fluoride powder, and adhering the generated poly dopamine functional layer onto the surface of the polyvinylidene fluoride powder; (2) preparing a poly dopamine modified polyvinylidene fluoride membrane by using a phase conversion method; and (3) depositing a nano-TiO2 functional layer on the membrane prepared in the step (2) through a liquid phase deposition method to prepare the polyvinylidene fluoride anti-pollution membrane. According to the present invention, by combining the strong adhesion and the polyfunctional group of poly dopamine, the ultraviolet resistance and stable chemical performance of polyvinylidene fluoride, and the advantages of hydrophilicity, high photocatalytic activity and the like of nano-TiO2, the polyvinylidene fluoride anti-pollution membrane is developed; and the prepared polyvinylidene fluoride anti-pollution membrane has excellent pollution resistance, and can be used in various membrane separation fields.

Owner:天津鼎芯膜科技有限公司

Method of manufacturing for aromatic polyamide composite membrane

InactiveCN101228214AExcellent salt rejectionGood water fluxPolyamide coatingsDendrimerPolymer substrate

The present invention provides a method of manufacturing an aromatic polyamide composite membrane comprising: coating an aqueous solution containing polyfunctional aromatic amine to a porous polymer substrate; and reacting the coated substrate with an organic solution containing polyfunctional aromatic acyl halide to lead to interfacial condensation polymerization between the polyfunctional aromatic amine and the polyfunctional aromatic acyl halide so that the reaction product resulting from the interfacial condensation polymerization is coated on the surface of the substrate, characterized in that either of the aqueous solution containing polyfunctional aromatic amine or the organic solution containing polyfunctional aromatic acyl halide has dendritic polymer as one of polyfunctional compounds added thereto. The resulting aromatic polyamide composite membrane which includes dendrimer as polyfunctional compound, exhibits high salt rejection rate and water flux.

Owner:KOLON IND INC

Preparation method of high-performance reverse-osmosis anti-pollution film

ActiveCN105561801AGood water fluxGood rejectionMembranesReverse osmosisComposite filmReverse osmosis

The invention belongs to the technical field of reverse osmosis composite films, and particularly relates to a high-performance reverse-osmosis anti-pollution film and a preparation method thereof. The preparation method includes: pre-coating a high molecular water solution soluble in water on a reverse osmosis base film mainly to protect a film surface structure; after drying in the shade, coating a hydrophilic high molecular water solution; post-treating the reverse osmosis film at certain temperature to obtain the high-performance reverse-osmosis anti-pollution film, wherein additive or crosslinking agent soluble in water is contained in water phase of coating solutions. The high-performance reverse-osmosis anti-pollution film and the preparation method have the advantages that through a method of pre-coating and secondary coating, preparation of the high-performance reverse-osmosis anti-pollution film can be realized without changing or increasing preparation processes of conventional composite separation films; compared with the prior art, the high-performance reverse-osmosis anti-pollution film has the advantages that high water flux and rejection rate are maintained, the film has good anti-pollution performance, high reproducibility and low preparation cost.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

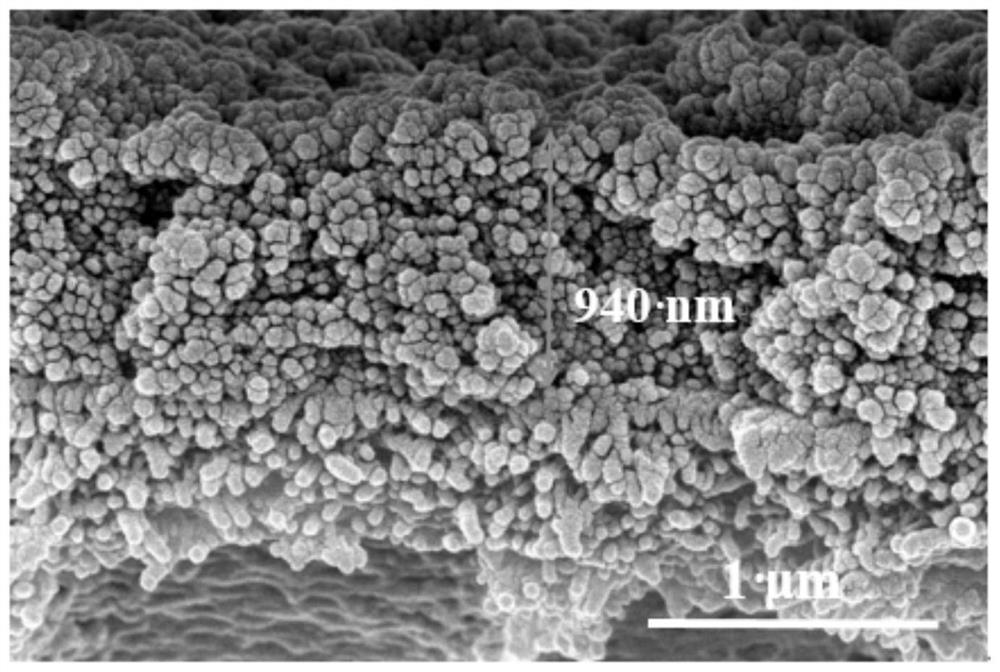

Preparation method and application of nano MFe2O4 supported hollow fiber composite ceramic membrane with catalytic separation function

ActiveCN107174955AHigh removal rateGood water fluxMembranesSemi-permeable membranesMethyl blueWater treatment

The invention relates to a preparation method and application of a nano MFe2O4 supported hollow fiber composite ceramic membrane having catalytic separation function, pollution resistance and low energy consumption, and belongs to the field of application of inorganic ceramic membranes in water treatment. A hollow fiber ceramic membrane is used as a support, stable nitric metal salt of citric acid is used as a catalyst mother liquid, and dipping and temperature calcining process is performed to prepare the nano MFe2O4 supported hollow fiber composite ceramic membrane. In in-situ coupling with the sulfuric free radical advanced oxidation technique, the nano MFe2O4 supported hollow fiber composite ceramic membrane can be applied to the treatment of low-concentration organic wastewater, such as dye wastewater and medicine and personal nursing product wastewater, in order to efficiently remove typical contaminants, such as methyl blue, rhodamine B and ibuprofen drugs, with the removal rate stilling being 91.8% and above in 55-60 min while methyl blue wastewater concentration is < / =25 mg / L and water level is 30 cm (2.94 kPa); similarly, the removal rate of rhodamine B is 90.7%; after 1 h of operation, when ibuprofen wastewater concentration is < / =10 Mu mol / L, the removal rate of ibuprofen is kept to 99.5% and above.

Owner:DALIAN UNIV OF TECH

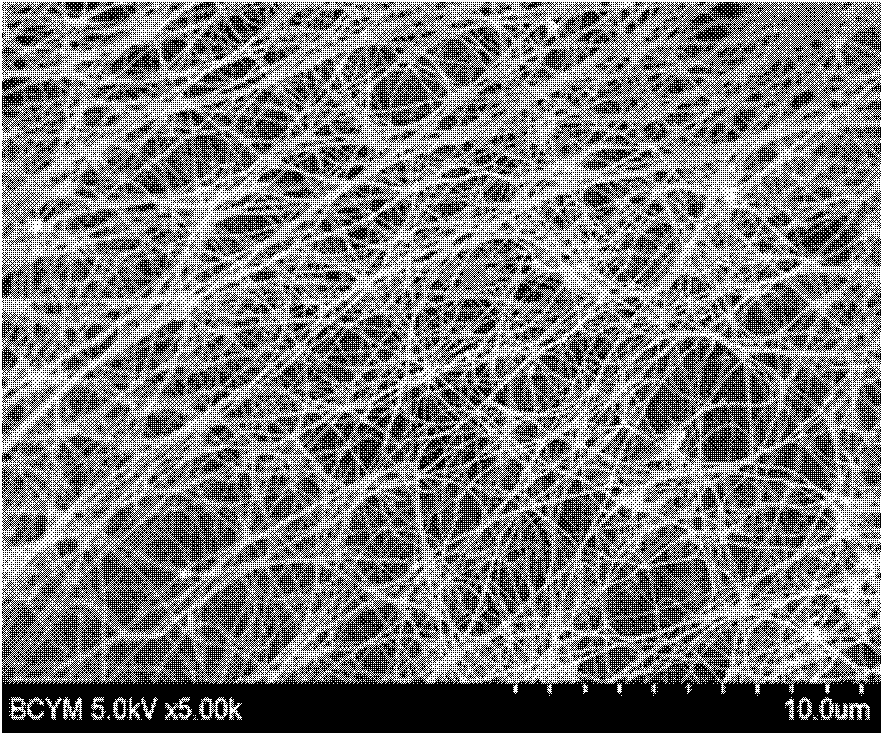

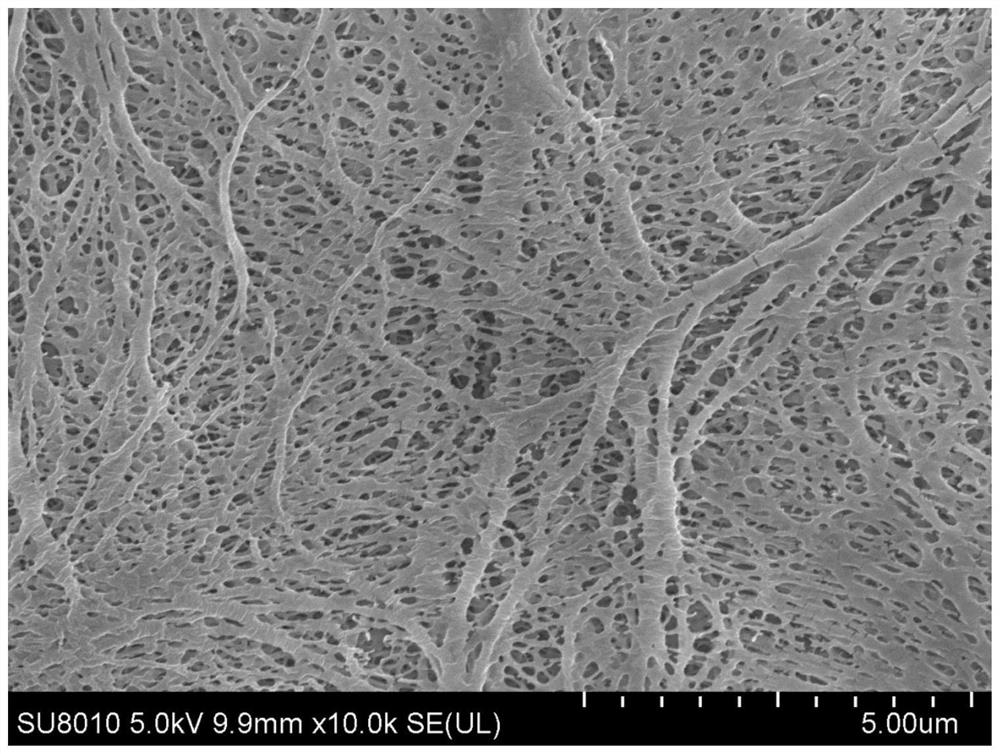

A kind of bacterial cellulose porous foam material and preparation method thereof

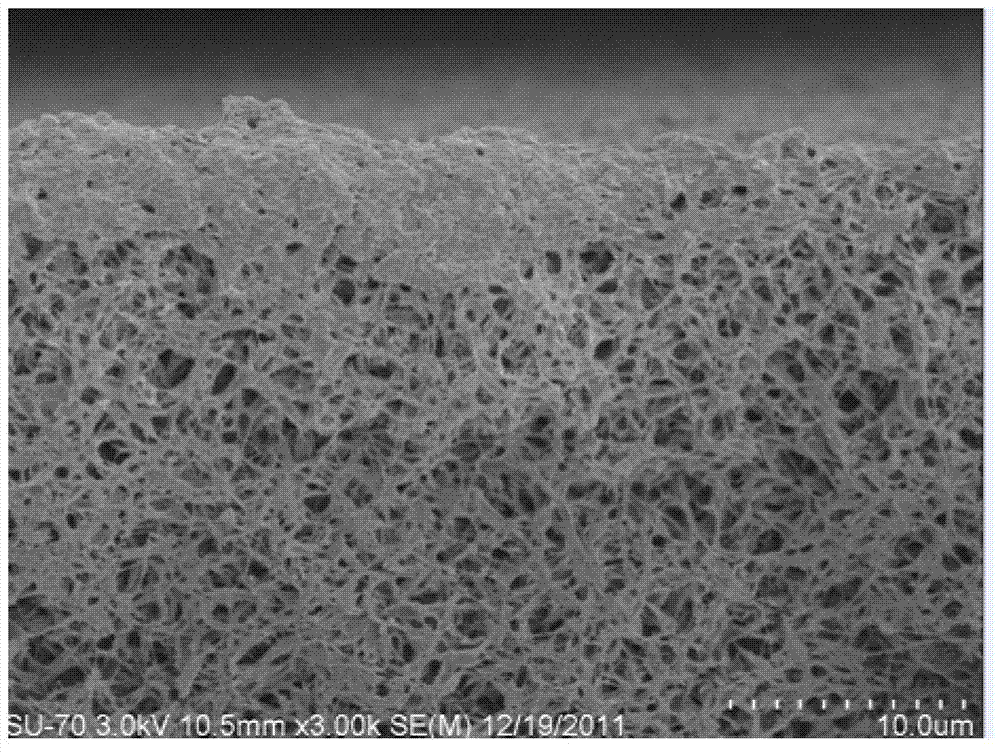

The invention relates to a bacterial cellulose porous foam material and a preparation method thereof, and in particular relates to a foam material used for preparing a moulded bacterial cellulose membrane by utilizing azodicarbonamide (AC foaming agent) and a preparation method thereof. In the bacterial cellulose porous foam material provided by the invention, internal structure of the bacterial cellulose membrane is shown as ellipse holes, the holes are interpenetrated, and hole diameter is 5-10 mu m. The preparation method of the bacterial cellulose porous foam material provided by the invention comprises the following steps of: preparing foaming solution by taking azodicarbonamide as a foaming agent and adding a surfactant and a foam stabilizer, fully soaking the moulded bacterial cellulose membrane into the foaming solution and then heating and foaming so as to prepare the bacterial cellulose porous foam material. In the process, the AC foaming agent is effectively introduced intothe moulded bacterial cellulose membrane, decomposition temperature of the AC foaming agent is appropriate, a technological process is simple, preparation period is short, and the original chemical structure of the bacterial cellulose is not damaged, thus the bacterial cellulose porous foam material can be applied to multiple industrial fields.

Owner:DONGHUA UNIV

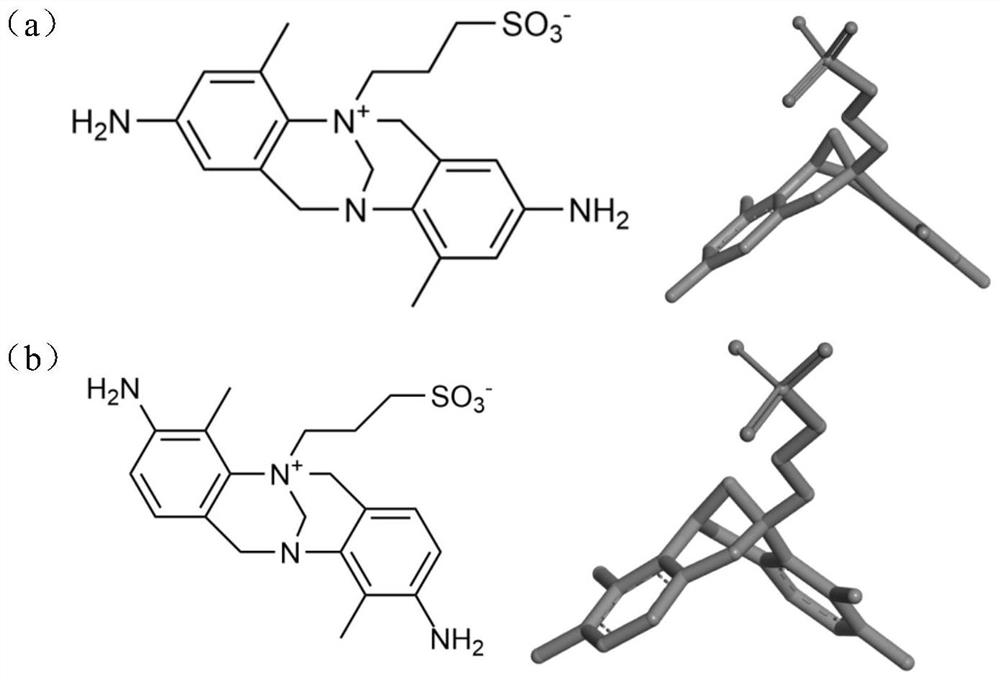

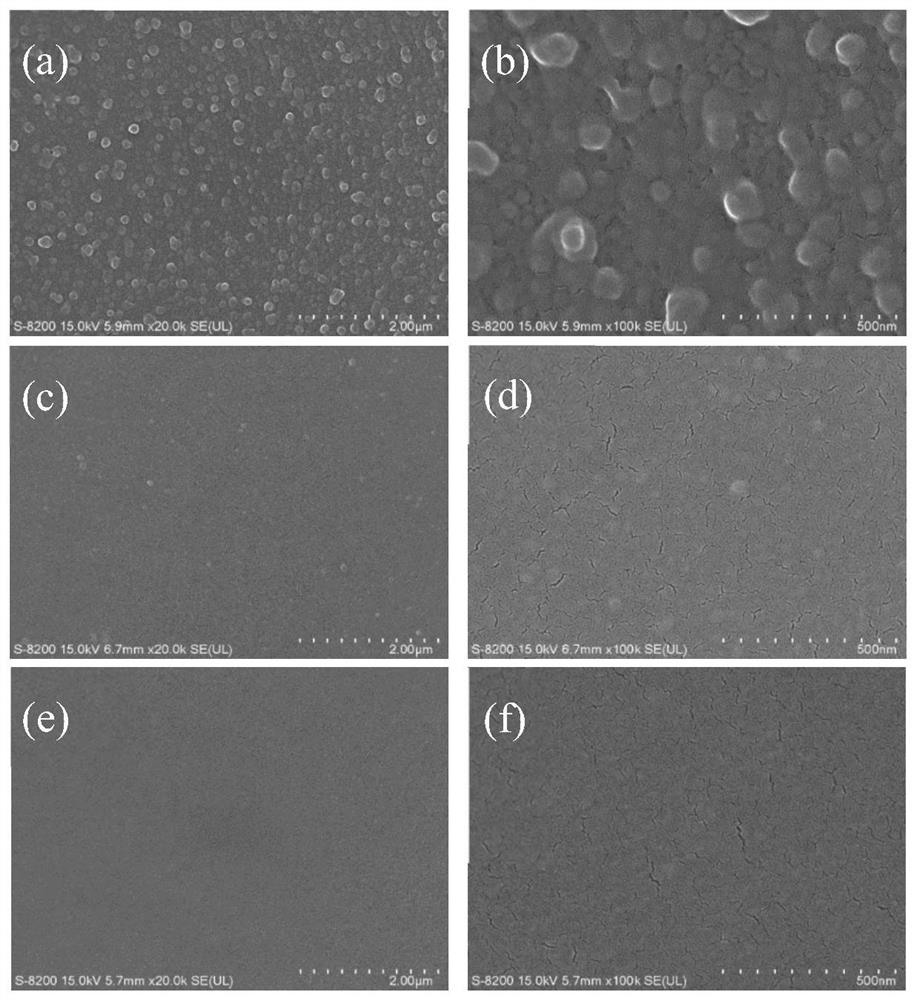

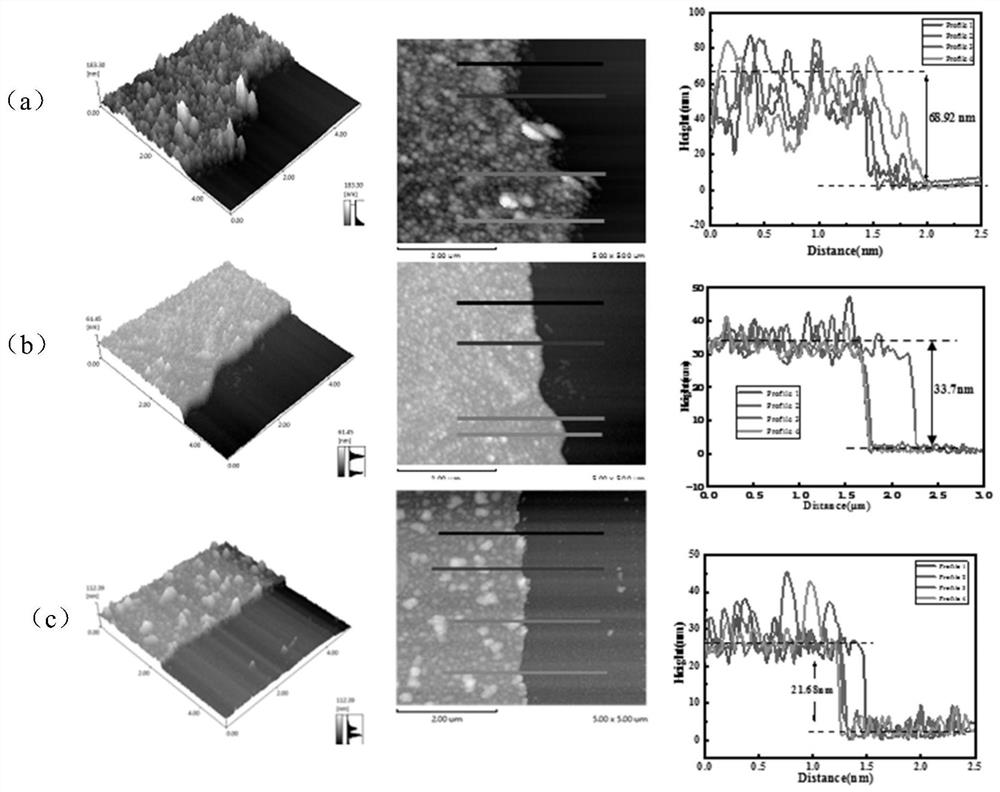

High-selectivity self-microporous polyamide nanofiltration composite membrane and preparation method thereof

ActiveCN113385049AWide pore size distributionMany free poresSemi-permeable membranesGeneral water supply conservationPolyamideNanofiltration

The invention discloses a high-selectivity self-microporous polyamide nanofiltration composite membrane and a preparation method thereof. The composite membrane is formed by compounding an ultrafiltration base membrane and a polyamide separation layer, wherein the polyamide separation layer is formed by polymerizing a water-phase mixed amine solution and an organic acyl chloride solution on the surface of the ultrafiltration base membrane, the water-phase mixed amine solution is a mixed solution of organic amine and an amine monomer which contains a sulfonic acid quaternary ammonium salt group and has a rigid twisted structure; the ultrafiltration base membrane can also adopt a surface hydrophilic modified ultrafiltration base membrane, and the polyamide separation layer is polymerized on the surface of the hydrophilic modified ultrafiltration base membrane in an in-situ support-free interface polymerization mode, so that the ultrathin high-selectivity self-microporous polyamide nanofiltration composite membrane can be obtained. The high-selectivity self-microporous nanofiltration membrane is prepared by introducing a novel amine monomer which contains a sulfonic acid quaternary ammonium salt group and has a rigid twisted structure, and the problems that an existing self-microporous nanofiltration membrane is relatively hydrophobic, so that the flux is low, the selectivity is insufficient, the pollution resistance is poor due to large membrane surface roughness and the like can be solved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

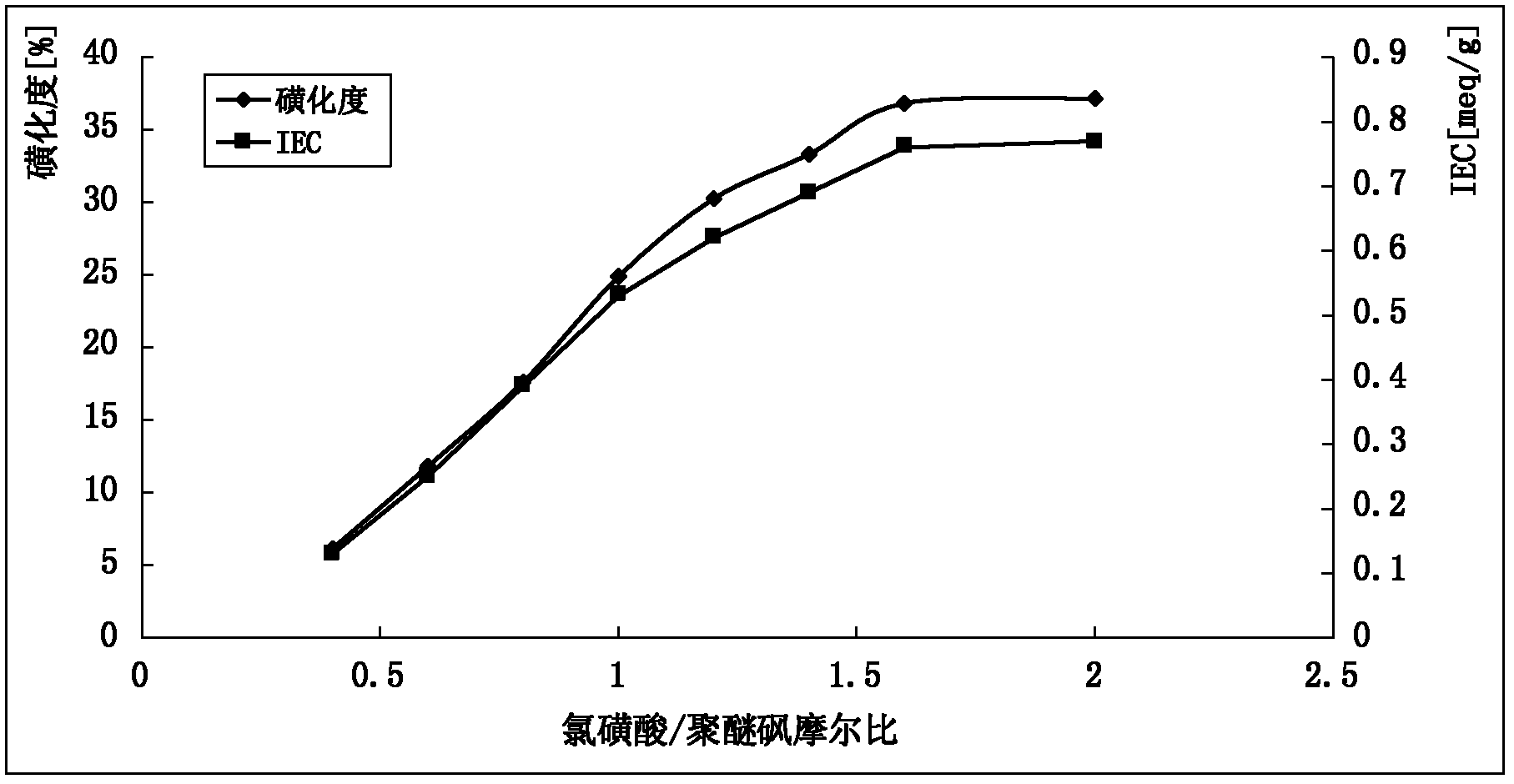

Preparation method of sulfonated polyethersulfone for preparing macromolecule separation films

InactiveCN102504257AEasy to separateGood water fluxSemi-permeable membranesChemical synthesisChlorosulfuric acid

The invention discloses a chemical synthesis method of macromolecule materials and particularly relates to a preparation method of sulfonated polyethersulfone for preparing macromolecule separation films. The preparation method includes steps of drying polyethersulfone, adding the same serving as solute into concentrated sulfuric acid to dissolve, preparing chlorosulfonic acid serving as sulfonating agent and the polyether sulfone according to a certain proportion and mixing the same to react for 2 to 8 hours, transferring materials of the mixture into ice and water mixed liquid and precipitating products from the mixed liquid after reaction is finished, washing the products to be neutral by distilled water after the products are filtered, and finally drying the products to obtain sulfonated polyethersulfone. The preparation method has the advantages that the products uniform in sulfonation degree are obtained, precipitation and the like under the action of solvent is avoided during integral reaction, the macromolecule separation film prepared by the sulfonated polyethersulfone has better separation effect, water flux capability, contamination resistance and more stable performance and the like. The sulfonated polyethersulfone prepared by the preparation method has wide application prospect in film manufacturing field.

Owner:杭州北斗星膜制品有限公司

Inorganic-organic hybrid film based on Cu2O nano wire, and preparation method and application thereof

InactiveCN104772047AImprove stability and mechanical propertiesHigh water flux and retentionUltrafiltrationMechanical properties of carbon nanotubesSurface layer

The invention discloses an inorganic-organic hybrid film based on a Cu2O nano wire, and a preparation method and application thereof. The preparation method comprises the following steps: uniformly dispersing the Cu2O nano wire and inorganic substances in an organic solvent--dimethyl acetamide so as to obtain a film casting solution; and preparing a flat sheet film by using an immersion phase inversion method. According to the invention, through addition of the inorganic particle, the porosity and the average pore size of the hybrid film are increased, the pure water flux of the film is improved, and hybrid film maintains an asymmetric structure composed of an upper compact surface layer and a lower finger-like porous supporting layer. The preparation method is simple, is convenient to operate and can easily realize industrial production; and the prepared hybrid film has high water flux, good stability, good mechanical properties and a high retention rate.

Owner:ZHEJIANG UNIV OF TECH

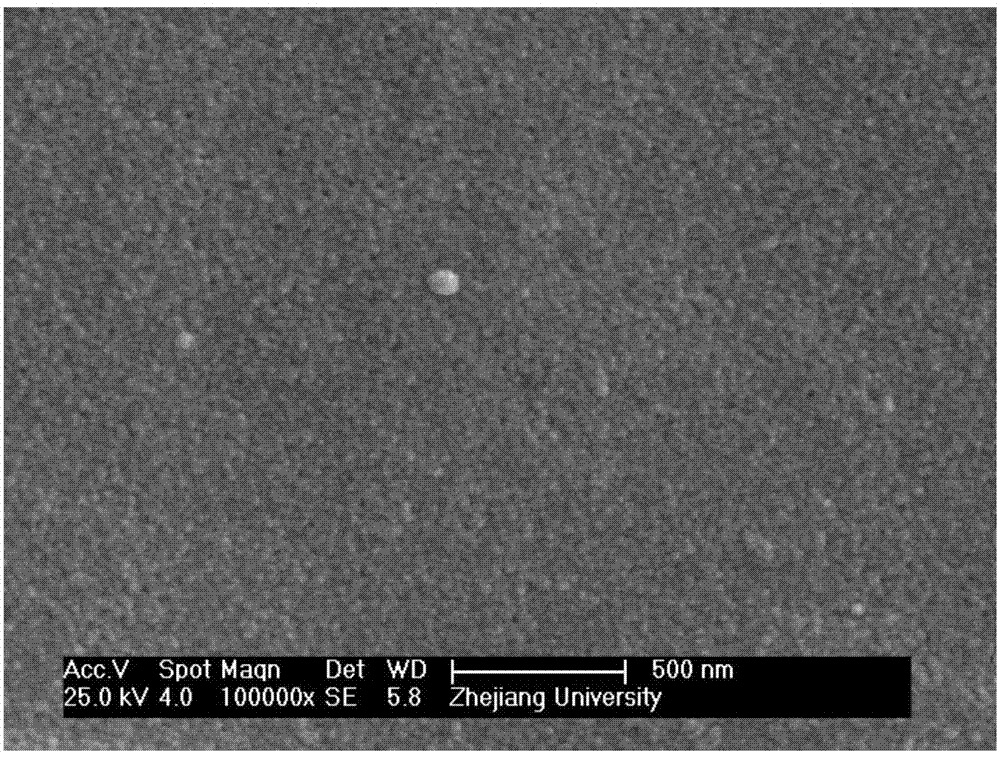

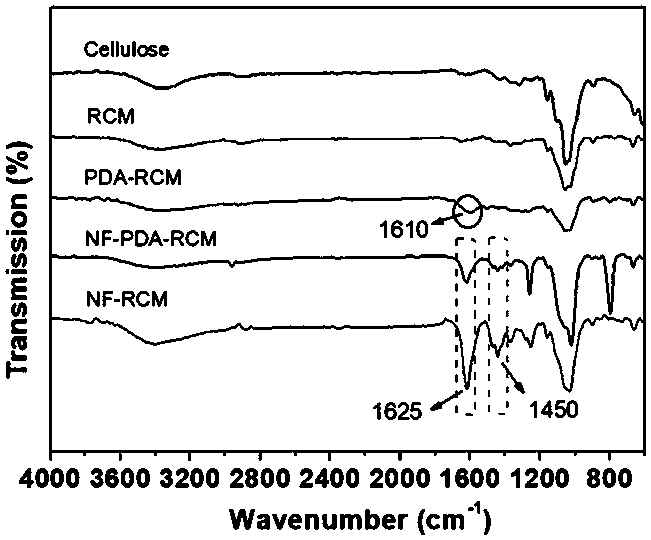

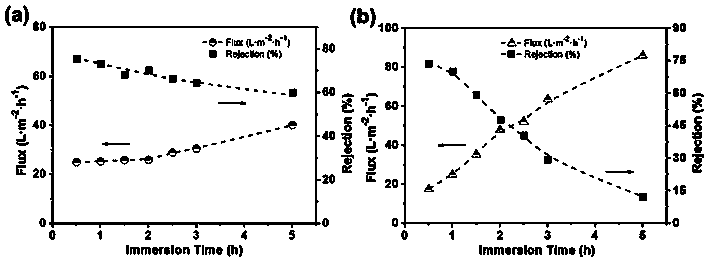

Preparation method of cellulose flat nanofiltration membrane with stable structure

ActiveCN111569661AWide variety of sourcesCheap sourceMembranesSemi-permeable membranesPolymer sciencePolyamide

The invention discloses a preparation method of a cellulose flat nanofiltration membrane with a stable structure. According to the preparation method, a regenerated cellulose membrane, taken as a supporting layer is soaked in a dopamine solution for surface modification, and the regenerated cellulose membrane subjected to surface modification is sequentially put into a piperazine aqueous solutionand an n-hexane solution of trimesoyl chloride for reaction, so that a polyamide active layer is formed on the surface of the membrane. With the use of dopamine, the interaction force between the basemembrane and the polyamide active layer is increased, such that a support layer and the active layer are tightly combined, and the prepared nanofiltration membrane has good stability.

Owner:FUJIAN AGRI & FORESTRY UNIV

Method for preparing polyvinylidene fluoride alloy film

The invention relates to a method for preparing a polyvinylidene fluoride alloy film, which comprises the following steps: 1), uniformly mixing polyvinylidene fluoride, hydrophilic copolymers and caprolactam; 2, heating the mixed polyvinylidene fluoride, hydrophilic copolymers and caprolactam under the protection of nitrogen to a solution temperature, and maintaining for 0.5-2 h at the temperature; 3), after the polyvinylidene fluoride, hydrophilic copolymers and caprolactam are completely solved, stirring for 0.5-1.5 h and then standing to obtain a casting solution, and saving the casting solution at the solution temperature; 4), fabricating the casting solution to a film which is then placed in the air for natural cooling until complete solidification; and 5), finally, extracting caprolactam, actually the polyvinylidene fluoride alloy film, through an extracting agent. The method has the advantages of simple technology, zero contamination and lower cost. The prepared polyvinylidene fluoride alloy film has the advantages of superior chemical stability, high mechanical strength, contamination resistance and easiness in cleaning. The method provided by the invention can provide high-performance alloy film products for the MBR technology in the filed of sewage disposal and water resource recycle, and has an extensive application in the fields of industry, medicine, sewage disposal and the like.

Owner:NINGBO UNIV

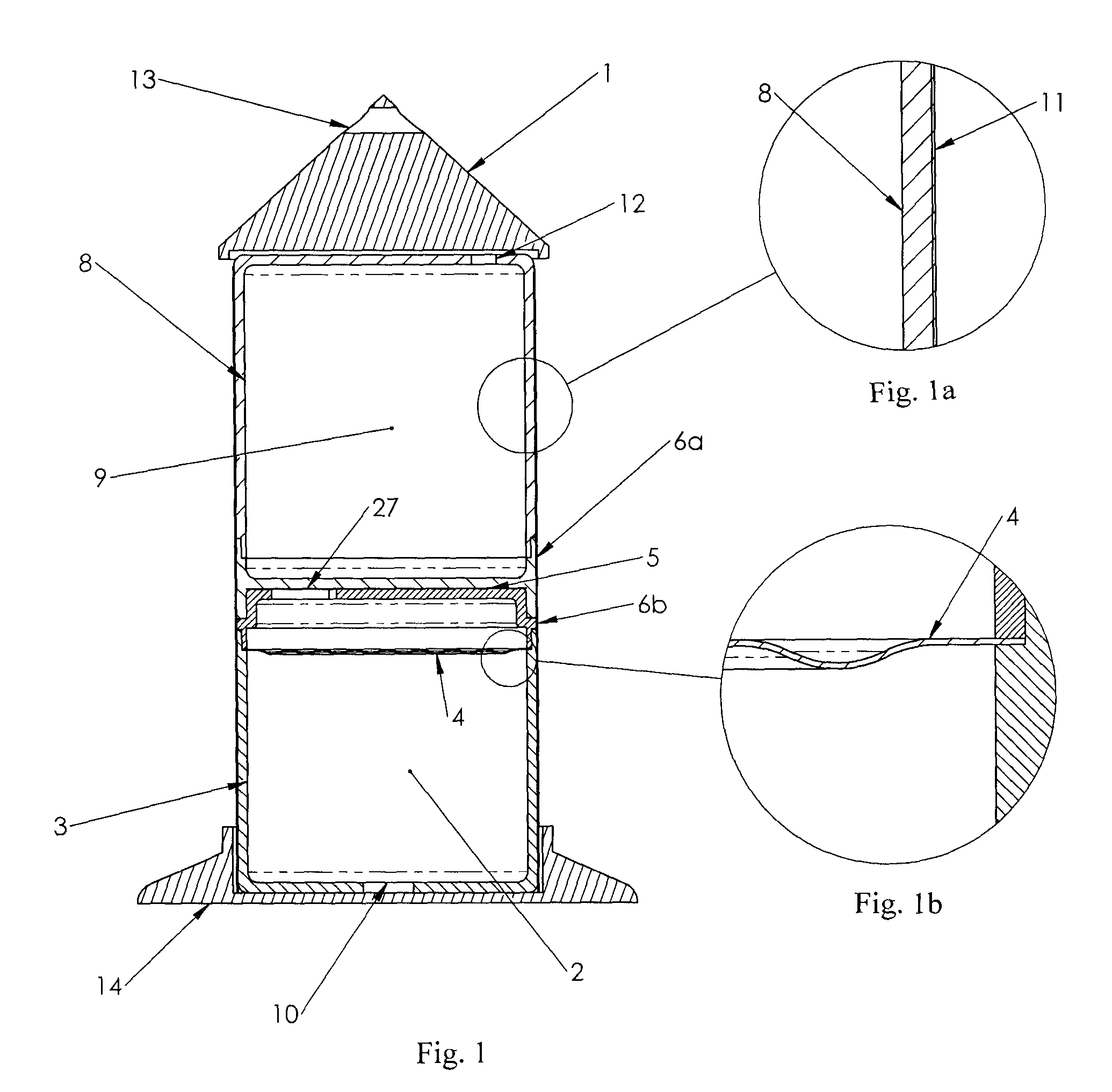

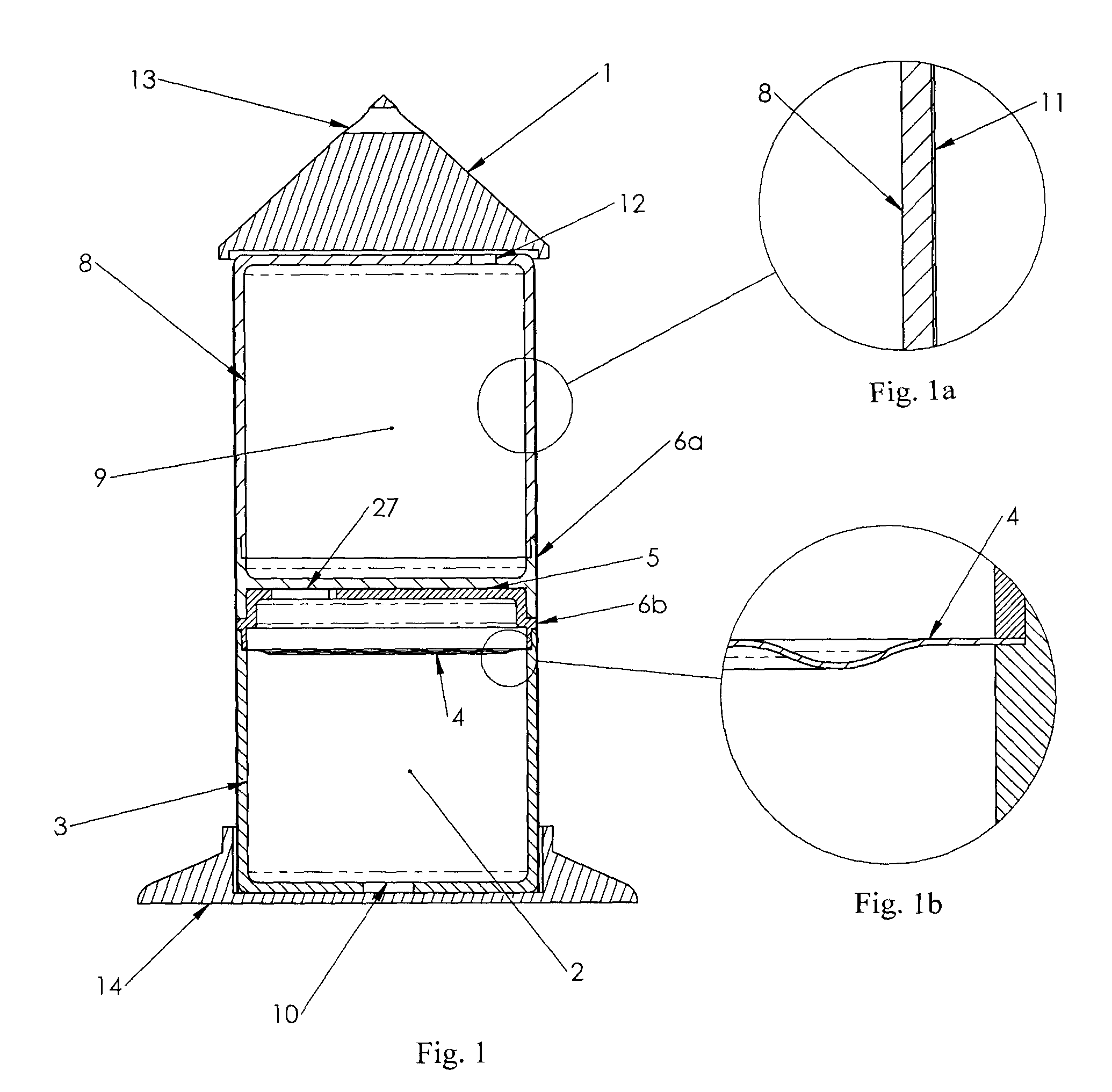

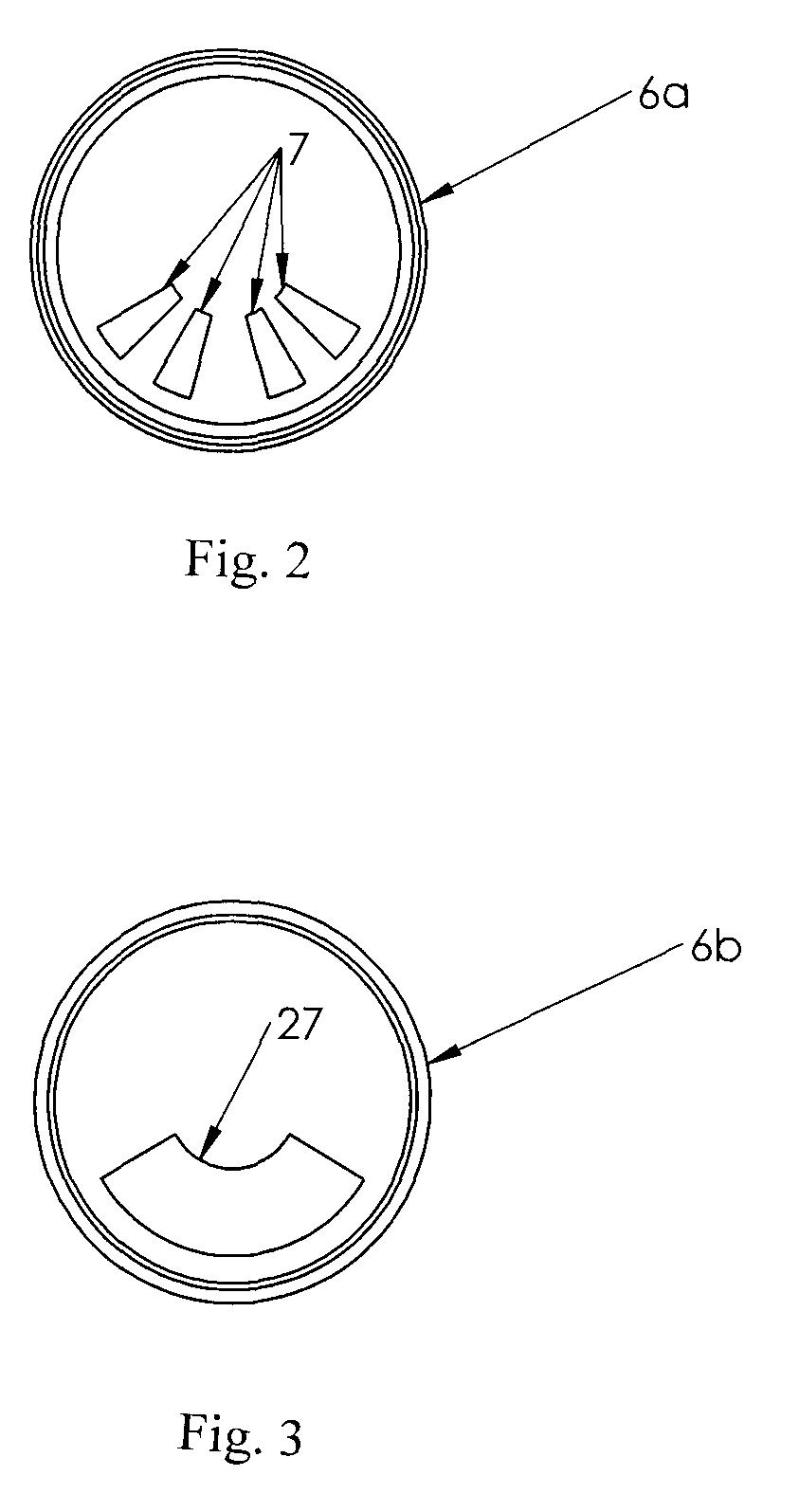

Apparatus and method for delivering beneficial liquids at steady rate

InactiveUS8061280B2Prevent water from spillingPrevent overflowPharmaceutical delivery mechanismDirect liquid fertiliser deliveryEngineeringWater transport

An apparatus for delivering a beneficial agent is disclosed in one embodiment of the invention as including a water collection chamber. A water-transporting membrane is provided to communicate with the water collection chamber. An extraction chamber receives water through the water-transporting membrane, expanding the extraction chamber. A dispensing chamber, containing a beneficial agent, is configured to contract upon expanding the extraction chamber. This causes the dispensing chamber to expel the beneficial agent through a subterranean delivery channel, such as a rigid hollow spike. In certain embodiments, a rate adjustment mechanism may control the rate that water is received through the water-transporting membrane, thereby controlling the rate the beneficial agent is expelled. The water-transporting membrane has features that repel osmagent from passing through to the water collection chamber. The apparatus features steady rate performance without refreshing the water chamber and low temperature sensitivity.

Owner:MICROLIN

MOF-199@PVDF matrix blend membrane having high pollution resistance, and production method thereof

InactiveCN108310985AHigh retention rateStrong anti-pollutionMembranesSemi-permeable membranesChemistryMetal-organic framework

The invention relates to an MOF-199@PVDF matrix blend membrane having high pollution resistance, and a production method thereof. The matrix blend membrane is produced through a phase inversion technology of a membrane casting solution containing PVDF resin, a metal-organic framework material MOF-199 and a pore forming agent. The blend membrane has greatly improved pure water flux, has improved bovine serum albumin (BSA) rejection rate and pollution resistance, and can be applied to the field of membrane filtration.

Owner:TIANJIN POLYTECHNIC UNIV

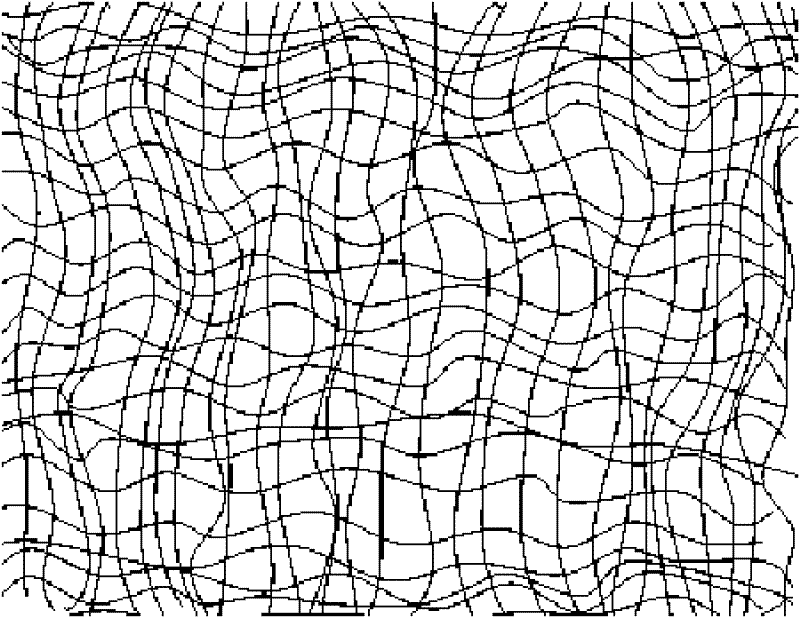

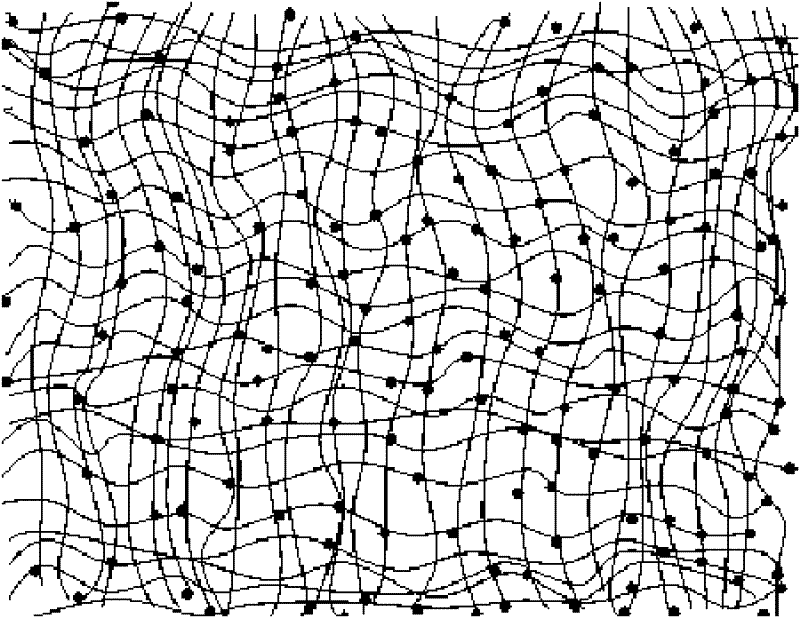

Polymer ultrafiltration membrane applied to polyamide composite membrane support and preparation method thereof

ActiveCN112191114ARegular structureGood water fluxSemi-permeable membranesMolecular sievePolymer science

The invention provides a polymer ultrafiltration membrane applied to polyamide composite membrane support, the polymer ultrafiltration membrane has a two-layer structure, the two-layer structure comprises a small pore structure layer close to a polyamide separation layer and a large pore structure layer adjacent to the small pore structure layer, the pore diameter of the small pore structure layeris about 5-20nm, the pore diameter of the large pore structure layer is about 50-500nm, and the small pore structure layer is doped with an aluminosilicate molecular sieve subjected to dealuminationtreatment. According to the invention, an ultrafiltration support body is improved, so that the spreading of a water-phase monomer on the surface of the membrane is ensured on the basis of ensuring the water flux.

Owner:泰州禾益新材料科技有限公司

Apparatus and method for delivering beneficial liquids at steady rate

InactiveUS20100022993A1Prevent water from spillingPrevent overflowPharmaceutical delivery mechanismPressure infusionWater transportEngineering

An apparatus for delivering a beneficial agent is disclosed in one embodiment of the invention as including a water collection chamber. A water-transporting membrane is provided to communicate with the water collection chamber. An extraction chamber receives water through the water-transporting membrane, expanding the extraction chamber. A dispensing chamber, containing a beneficial agent, is configured to contract upon expanding the extraction chamber. This causes the dispensing chamber to expel the beneficial agent through a subterranean delivery channel, such as a rigid hollow spike. In certain embodiments, a rate adjustment mechanism may control the rate that water is received through the water-transporting membrane, thereby controlling the rate the beneficial agent is expelled. The water-transporting membrane has features that repel osmagent from passing through to the water collection chamber. The apparatus features steady rate performance without refreshing the water chamber and low temperature sensitivity.

Owner:MICROLIN

Method for delivering beneficial liquids at steady rate

InactiveUS20120037658A1Prevent water from spillingPrevent overflowOpening closed containersBottle/container closureEngineeringWater transport

A method for delivering a beneficial agent is disclosed in one embodiment of the invention as including a water collection chamber. A water-transporting membrane is provided to communicate with the water collection chamber. An extraction chamber receives water through the water-transporting membrane, expanding the extraction chamber. A dispensing chamber, containing a beneficial agent, is configured to contract upon expanding the extraction chamber. This causes the dispensing chamber to expel the beneficial agent through a subterranean delivery channel, such as a rigid hollow spike. In certain embodiments, a rate adjustment mechanism may control the rate that water is received through the water-transporting membrane, thereby controlling the rate the beneficial agent is expelled. The water-transporting membrane has features that repel osmagent from passing through to the water collection chamber. The method features steady rate performance without refreshing the water chamber and low temperature sensitivity.

Owner:MICROLIN

Preparation method of blended polyamide composite nanofiltration membrane

The invention discloses a preparation method of a blended polyamide composite nanofiltration membrane. A water phase monomer is prepared by blending two monomers with different structures according toa certain ratio. The preparation method comprises following steps: preparing a water phase solution and an oil phase solution; painting the water phase solution on an ultrafiltration base membrane atfirst; after a while, removing the water phase solution on the ultrafiltration base membrane, drying the ultrafiltration base membrane in the shade; then painting the ultrafiltration base membrane bythe oil phase solution; and finally carrying out a heat treatment at a temperature of 50 to 120 DEG C to obtain a nanofiltration composite membrane that is resistant to chlorine. Compared with a nanofiltration membrane, which is prepared by interfacial polymerization between a water phase monomer and an oil phase monomer, the provided nanofiltration membrane has a better performance and a betterchlorine resistant performance. The membrane forming process is simple. The price of used medicaments is low. The commercial feasibility is higher.

Owner:蓝星(杭州)膜工业有限公司

Polyvinylidene fluoride lyophobic separation membrane and preparation method thereof

InactiveCN106582303AImprove hydrophobicityHigh retention rateMembranesSemi-permeable membranesLithium chloridePolyethylene glycol

The invention relates to a polyvinylidene fluoride lyophobic separation membrane and a preparation method thereof, and belongs to the technical field of lyophobic separation membranes. The polyvinylidene fluoride lyophobic separation membrane comprises the following raw materials in parts by weight: 15-20 parts of polyvinylidene fluoride, 75-85 parts of N,N-dimethyl formamide, 3-5 parts of n-butyl alcohol, 3-5 parts of butyl acetate, 3-5 parts of tributyl phosphate, 5-10 parts of polyethylene glycol PEG-1000, 3-5 parts of anhydrous lithium chloride, 3-5 parts of sodium chloride, 300-500 parts of deionized water, 5-10 parts of alcohol, 5-10 parts of isopropyl alcohol and 2-5 parts of a lyophobic coating. The polyvinylidene fluoride lyophobic separation membrane provided by the invention has hydrophobicity and is capable of preventing contamination.

Owner:廖正康

Composite nanofiltration membrane and preparation method thereof

InactiveCN112058105ASimple manufacturing methodImprove production efficiencyMembranesReverse osmosisNanofiltrationOrganic chemistry

The invention discloses a preparation method of a composite nanofiltration membrane, which is characterized by comprising the following steps: S1, modifying amino-modified fullerene with quaternary ammonium salt 15; S2, preparing a primary product of the composite nanofiltration membrane; and S3, preparing a composite nanofiltration membrane finished product. The invention also provides the composite nanofiltration membrane prepared according to the preparation method of the composite nanofiltration membrane. The composite nanofiltration membrane disclosed by the invention is excellent in rejection rate, water flux and pollution resistance, good in mechanical property and performance stability and wide in application range.

Owner:CHENGDU ZHIA TECH CO LTD

PSF (polysulfone)-TPE (thermoplastic elastomer)-OMMT (organic montmorillonite) blended hollow fiber membrane and preparation method thereof

ActiveCN106000133AImprove toughnessPromote mutual solubilityMembranesSemi-permeable membranesElastomerPolymer science

The invention discloses a PSF (polysulfone)-TPE (thermoplastic elastomer)-OMMT (organic montmorillonite) blended hollow fiber membrane and a preparation method thereof. Aiming at problems of performance of a PSF hollow fiber membrane and combining respective advantages of the TPE and the OMMT, the novel PSF / TPE / OMMT blended hollow fiber membrane is prepared with a phase inversion method. According to the invention, the toughness of the PSF hollow fiber membrane is improved, and the application range of the PSF hollow fiber membrane is extended; furthermore, on the premise that the better water flux and higher rejection rate of the PSF hollow fiber membrane are kept, the synthesized mechanical properties and the antifouling property of the PSF hollow fiber membrane can be improved; the overall performance of the polymer membrane can be improved, the OMMT further plays a role of a bulking agent for a PSF / TPE composite material, intersolubility of PST / TPE is improved, and a PSF / TPE / OMMT composite material with more stable performance is formed.

Owner:贵州省材料技术创新基地

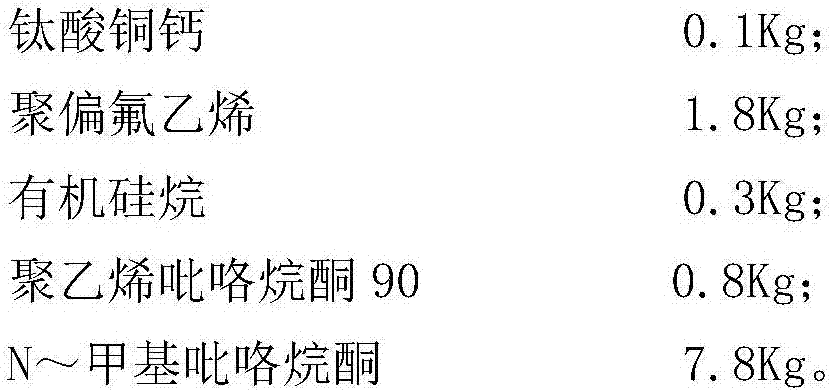

High dielectric constant nano-filtration composite film and preparation method thereof

InactiveCN107096401AHigh dielectric constantReduce electric field lossSemi-permeable membranesPolyesterDielectric

The present invention relates to a high dielectric constant nano-filtration composite film, which comprises a porous base film and a polyester amine active layer attached onto the porous base film, wherein the porous base film contains a high dielectric constant modifier and a film material, a weight ratio of the high dielectric constant modifier to the film material is 1-25%, and the polyester amine active layer comprises a polyamine monomer. The preparation method of the high dielectric constant nano-filtration composite film comprises: 1) modifier preparation; 2) film casting liquid preparation; 3) film formation; 4) curing; and 5) nano-filtration composite film forming. According to the present invention, by adding the high dielectric constant modifier, the dielectric constant of the nano-filtration composite film can be well improved; by combining the high dielectric constant nano-filtration composite film and the unique DEP power supply of our company, the pollution resistance of the nano-filtration composite film can be significantly improved; and under the action of dielectric electrophoresis, the pollutants can be enriched around the electric field and cannot be adsorbed onto the surface of the nano-filtration composite film, such that the flux of the nano-filtration composite film, the quality of the produced water and the like can be substantially improved.

Owner:INNER MONGOLIA TIANYI ENVIRONMENTAL TECH

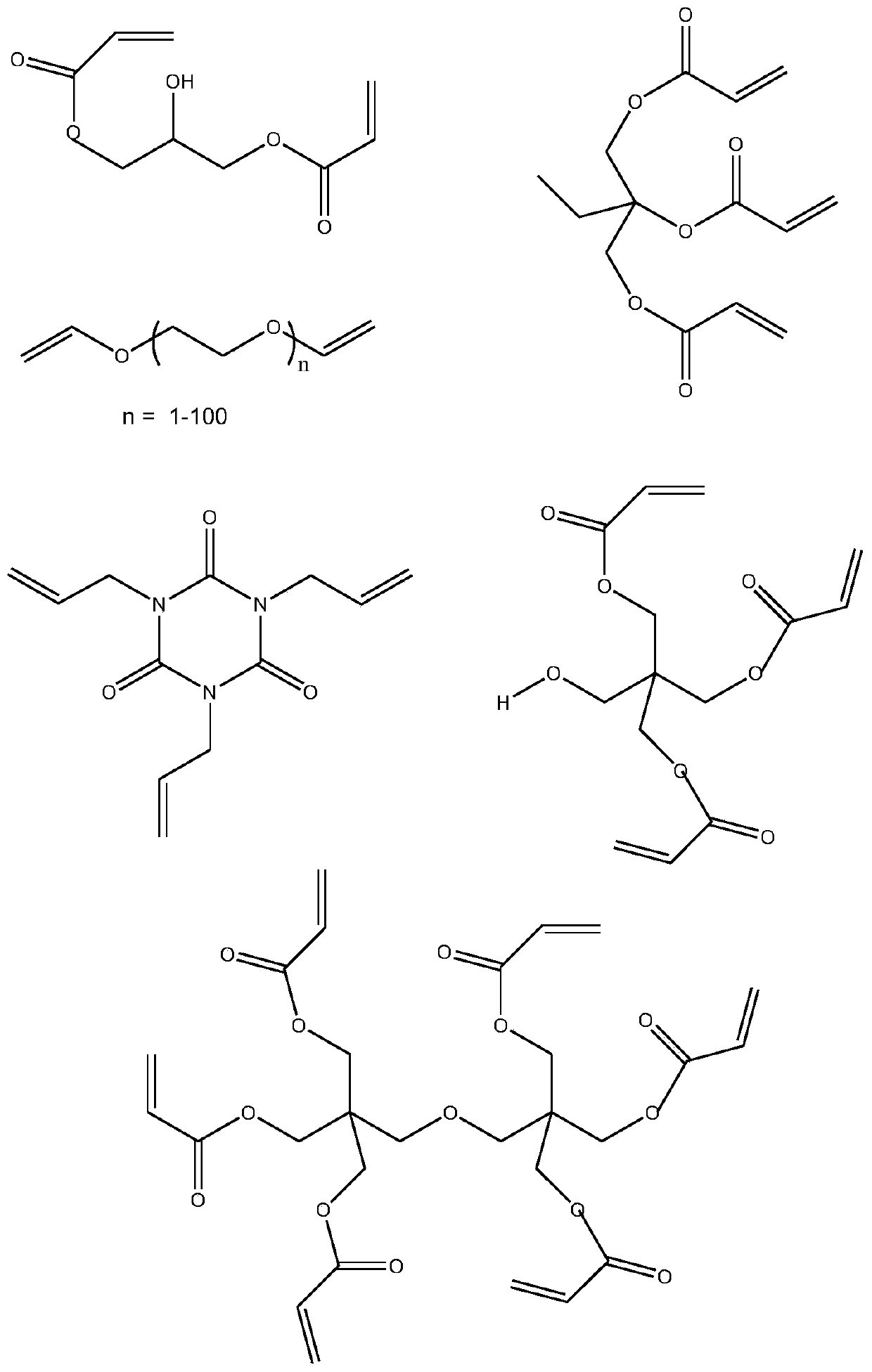

Multilayer reverse osmosis composite membrane

InactiveCN111203106AExcellent salt rejectionGood water fluxGeneral water supply conservationReverse osmosisChemical physicsReverse osmosis

The invention discloses a multilayer reverse osmosis composite membrane which is provided with a photo-initiation polymer protective layer, and comprises a base layer playing a supporting role, a transition layer, a separation layer and a protection layer; the transition layer is located on the base layer, the separation layer is located on the transition layer, the protection layer is located onthe separation layer, and the protection layer is of a three-dimensional network structure formed by a photo-induced polymerization reaction. According to the multilayer reverse osmosis composite membrane, the protective layer with the three-dimensional network structure is formed on the surface of a composite membrane through photo-induced polymerization reaction, and under the condition that requirements on the desalination rate and flux of the multilayer reverse osmosis composite membrane are met, the composite membrane separation layer can be effectively prevented from being damaged and abraded by the outside, the service life of the composite membrane is greatly prolonged, and the anti-pollution performance of the composite membrane can be effectively improved.

Owner:XIAMEN JIANGTIAN MEMBRANE BIOTECH LTD

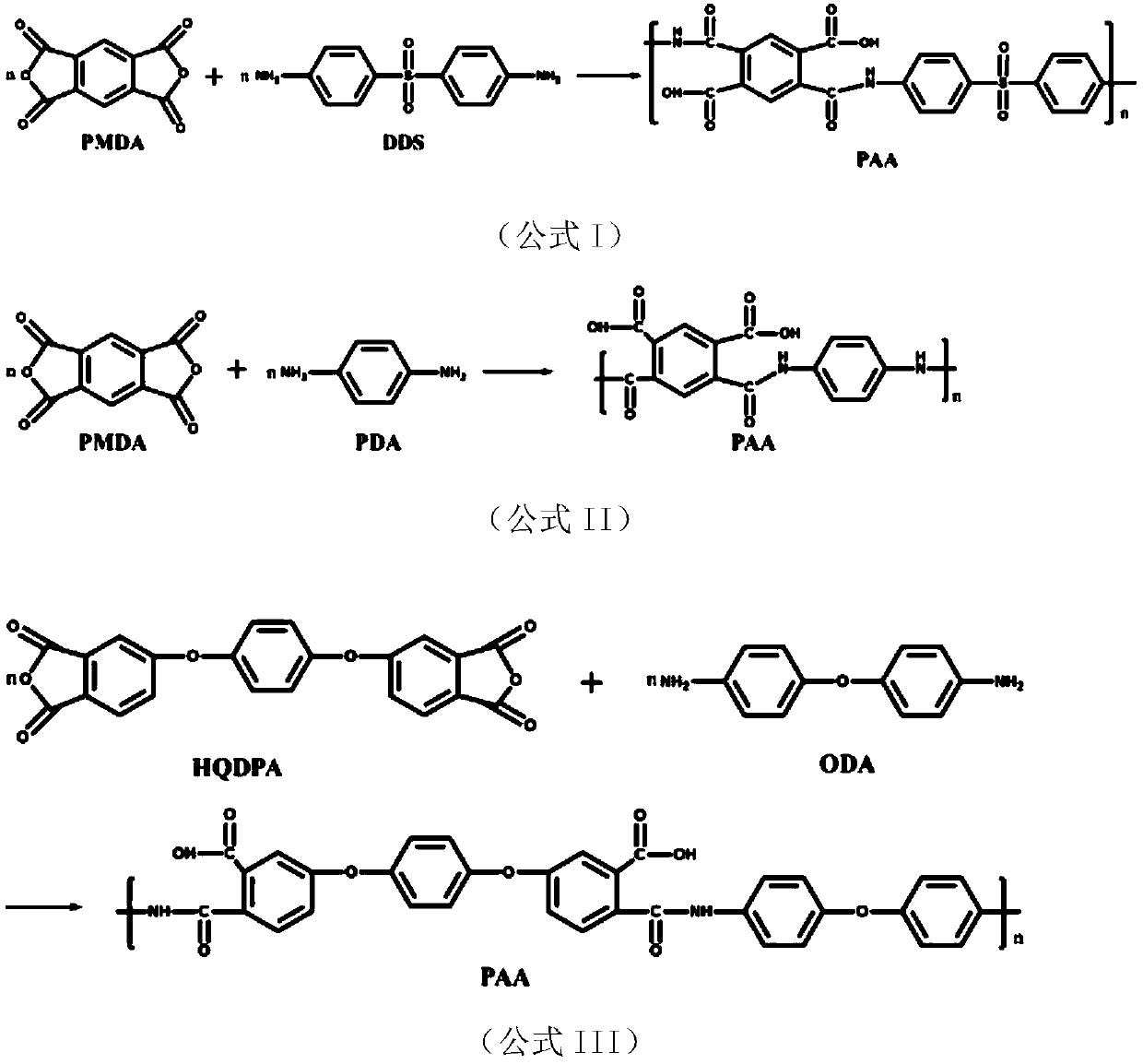

Low-pressure high-flux hydrophilic ultrafiltration membrane and preparation method thereof

InactiveCN111249925AImprove hydrophilicityGood compatibilityMembranesSemi-permeable membranesPolymer scienceOrganic solvent

The invention discloses a low-pressure high-flux hydrophilic ultrafiltration membrane and a preparation method thereof. The low-pressure high-flux hydrophilic ultrafiltration membrane comprises a basemembrane material, an organic solvent, a monomer A and a monomer B; and the method comprises the following steps: dissolving the base membrane material in an organic solvent, mechanically heating andstirring, and fully and uniformly mixing to obtain a primary membrane casting solution; adding the monomer A into the preliminary membrane casting solution, then carrying out mechanical stirring to fully and uniformly mix, then adding the monomer B, carrying out mechanical stirring to enable the monomer A and the monomer B to react in the preliminary membrane casting solution, then performing standing in vacuum to be defoamed to obtain a clear and transparent solution, and then putting the clear and transparent solution on a glass plate or non-woven fabric to carry out membrane scraping. Themonomer A and the monomer B are subjected to condensation polymerization in the preliminary membrane casting solution to generate gel-state polyamic acid, and the ultrafiltration membrane is preparedthrough membrane scraping and has good hydrophilicity, temperature resistance and toughness, the membrane performance is stable, and hydrophilic substances are not prone to loss.

Owner:ZHEJIANG UNIV OF TECH

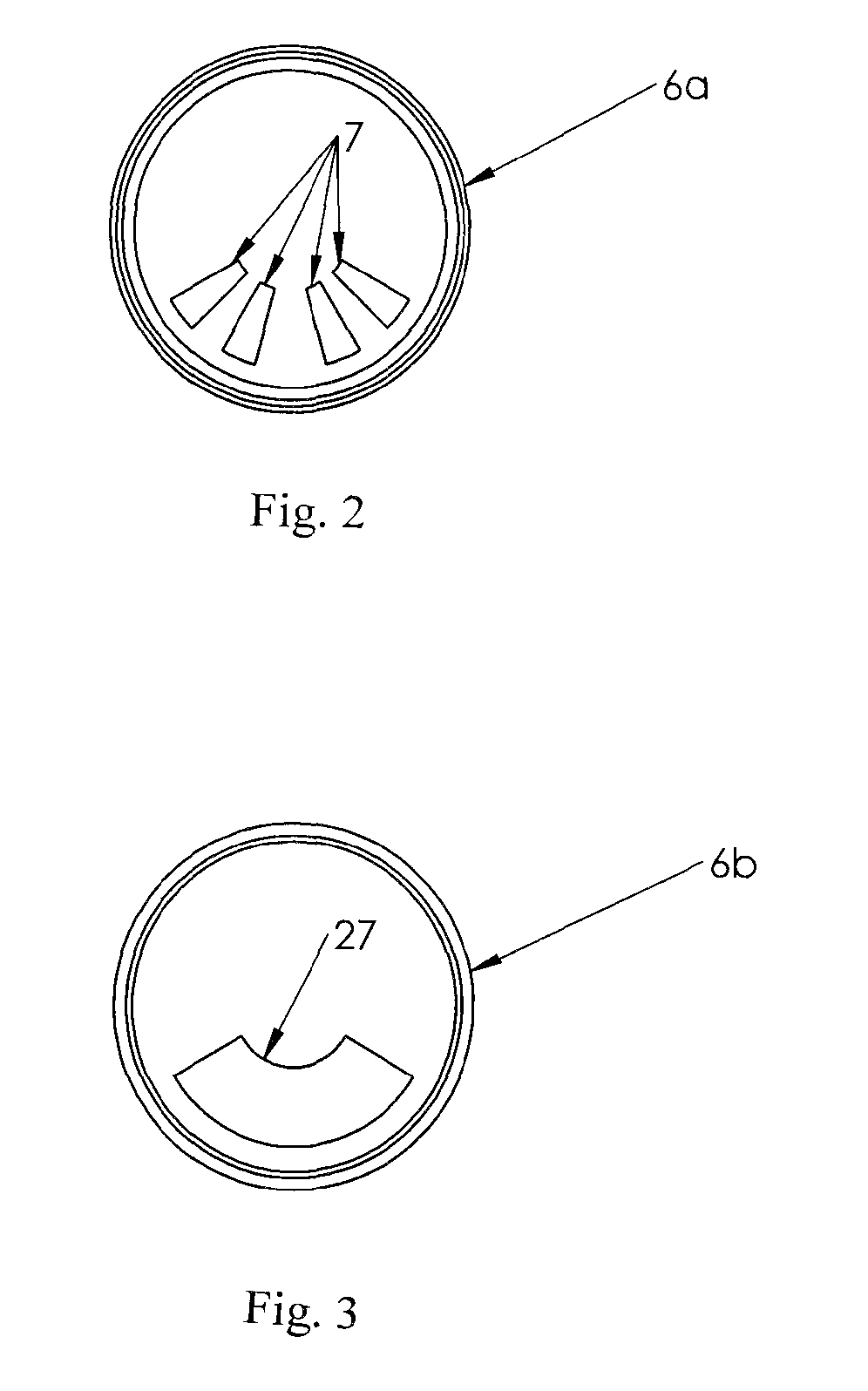

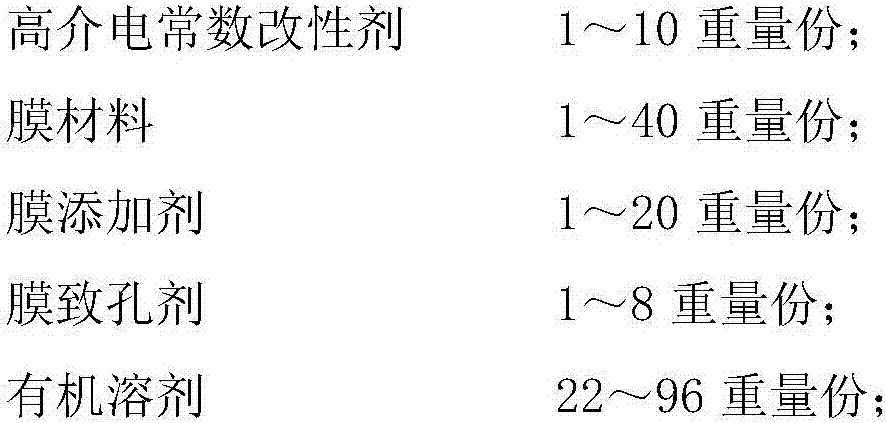

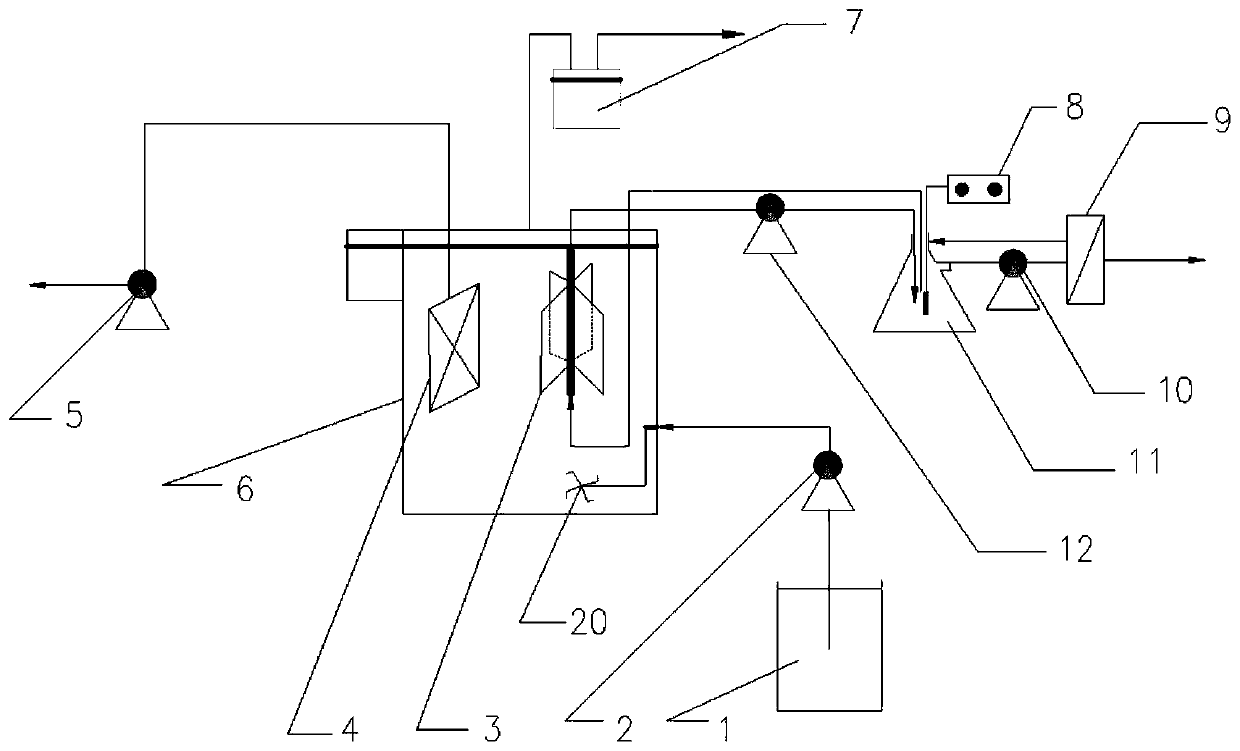

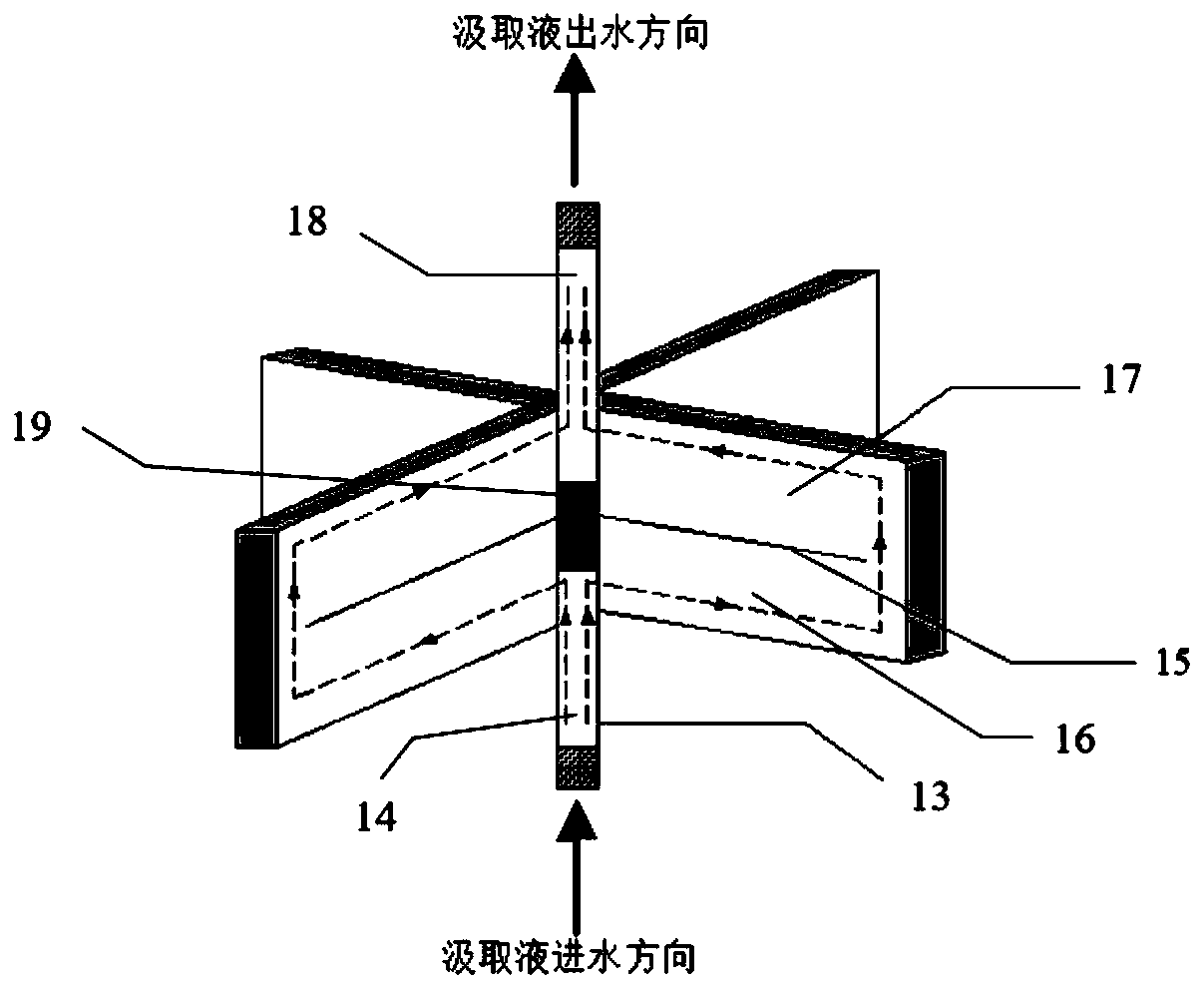

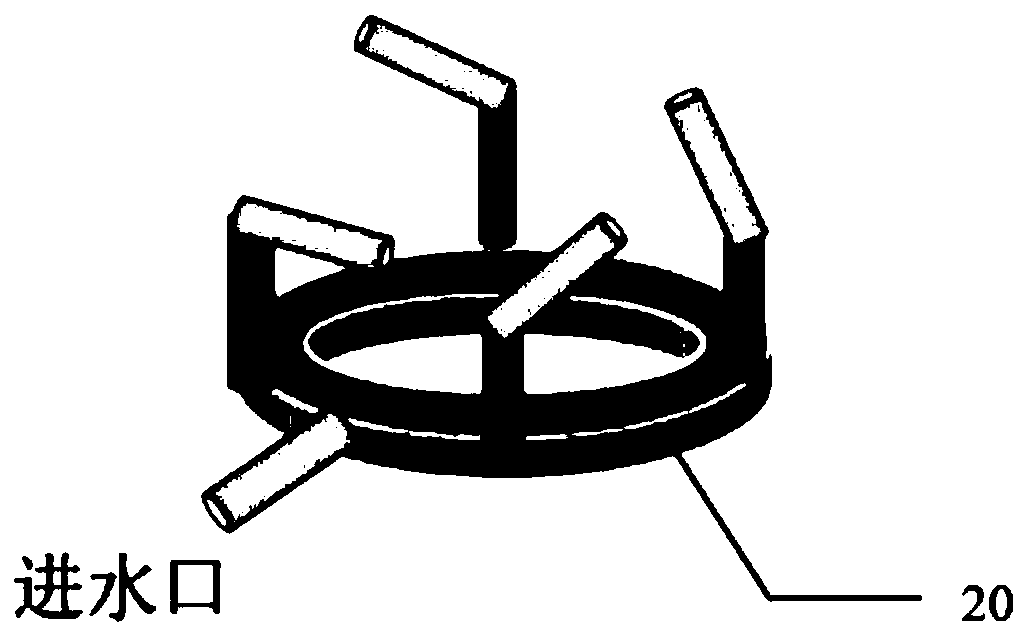

Autogiration-type anaerobic positive penetration membrane penetration membrane bioreactor, and applications thereof

ActiveCN110395853AImprove throughputReduce pollutionWater treatment parameter controlSpecific water treatment objectivesPollutionChemistry

The invention discloses an autogiration-type anaerobic positive penetration membrane penetration membrane bioreactor, and applications thereof, and belongs to the technical field of sewage processing.A processing method comprises following steps: raw water is introduced into an anaerobic reaction zone through a water inlet pump, generated biogas is subjected to water sealing and collecting recycling; a part of sewage is subjected to separation purifying under the effect of a FO membrane, and is subjected to processing recycling using a RO membrane; the other part of sewage is delivered through a MF membrane for separation purifying. According to the autogiration-type anaerobic positive penetration membrane penetration membrane bioreactor, a blade type FO membrane assembly is fixedly arranged on a rotating shaft, and is pushed to perform rotation motion under the effect of inlet water flow, so that transmission effect is improved, FO membrane pollution is alleviated, and reactor operation time is prolonged; the MF membrane is adopted to control salinity accumulation; reactor occupied space is small; organic matters in sewage are recycled in the form of biogas; and automatic controlof the whole system is realized.

Owner:JIANGNAN UNIV

Two-dimensional layered zeolite molecular sieve membrane with high separation stability as well as preparation method and application thereof

ActiveCN112279264AHigh film stabilityEasy to operateSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisMolecular sieveZeolite

The invention relates to a two-dimensional layered zeolite molecular sieve membrane with high separation stability, which is prepared by vacuum filtration of stripped two-dimensional zeolite suspension onto a support body, and is prepared by creatively diluting the two-dimensional zeolite suspension, loading the diluted two-dimensional zeolite suspension onto the support body through vacuum filtration, and drying the loaded two-dimensional zeolite suspension to obtain the two-dimensional layered zeolite molecular sieve membrane with high separation stability. The two-dimensional layered zeolite molecular sieve membrane with high separation stability is simple to operate and good in performance, can realize accurate screening of nano-molecules, has membrane stability, good water flux and good separation selectivity for molecular pollutants of 2 nm or above, is high in membrane stability, and is simple and convenient to prepare, And a new possibility is provided for the application of zeolite in water treatment.

Owner:SHANDONG UNIV

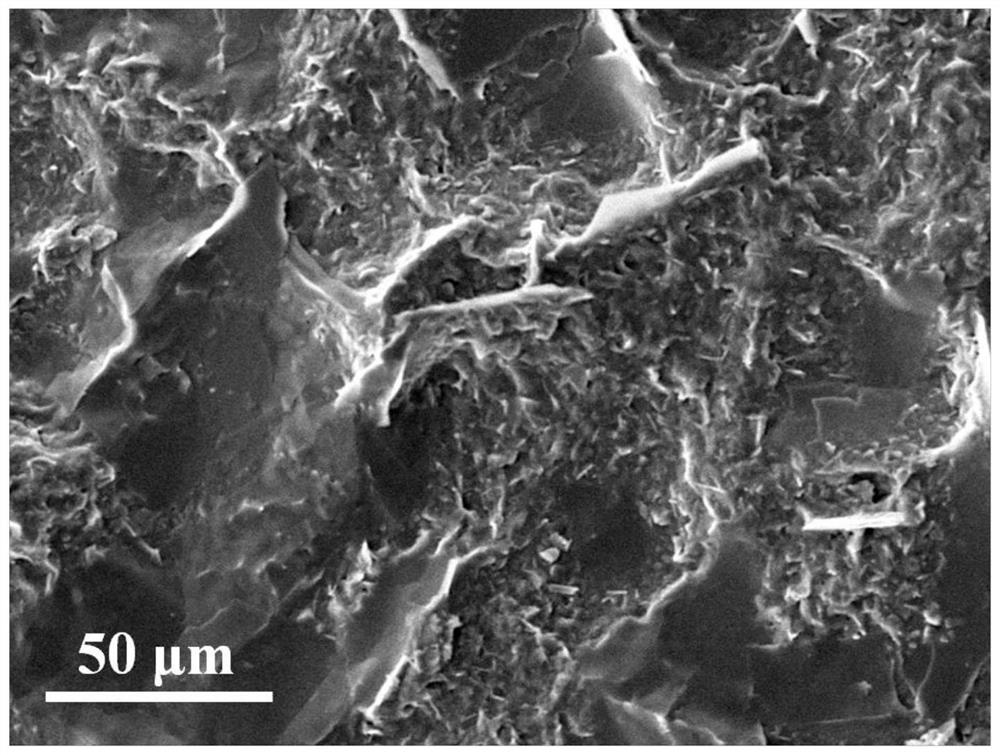

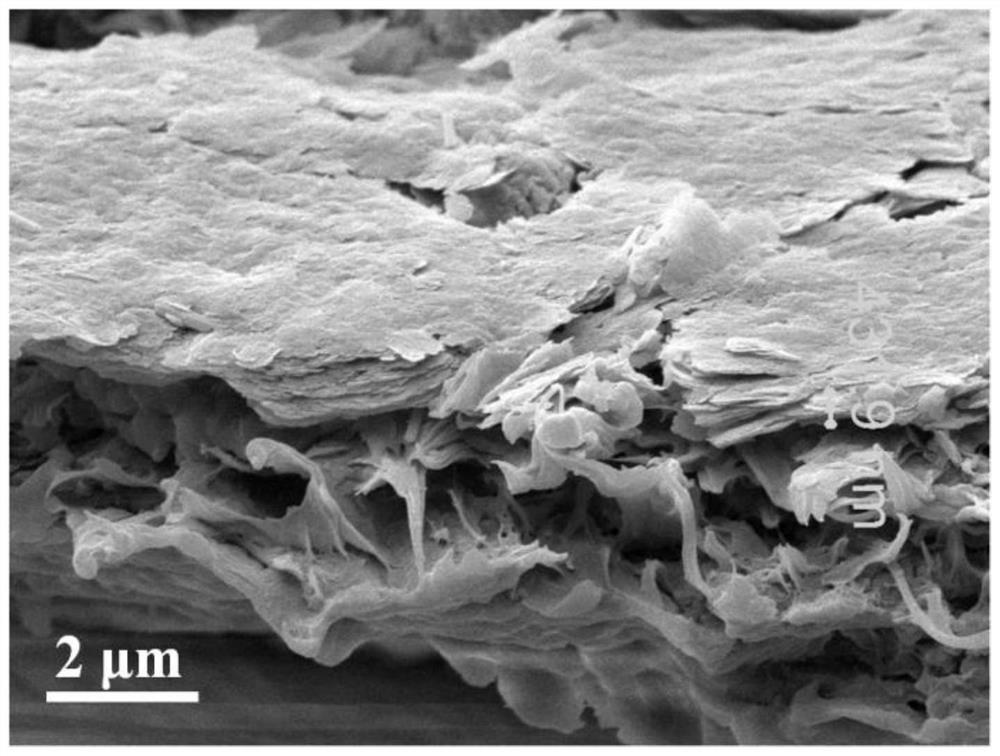

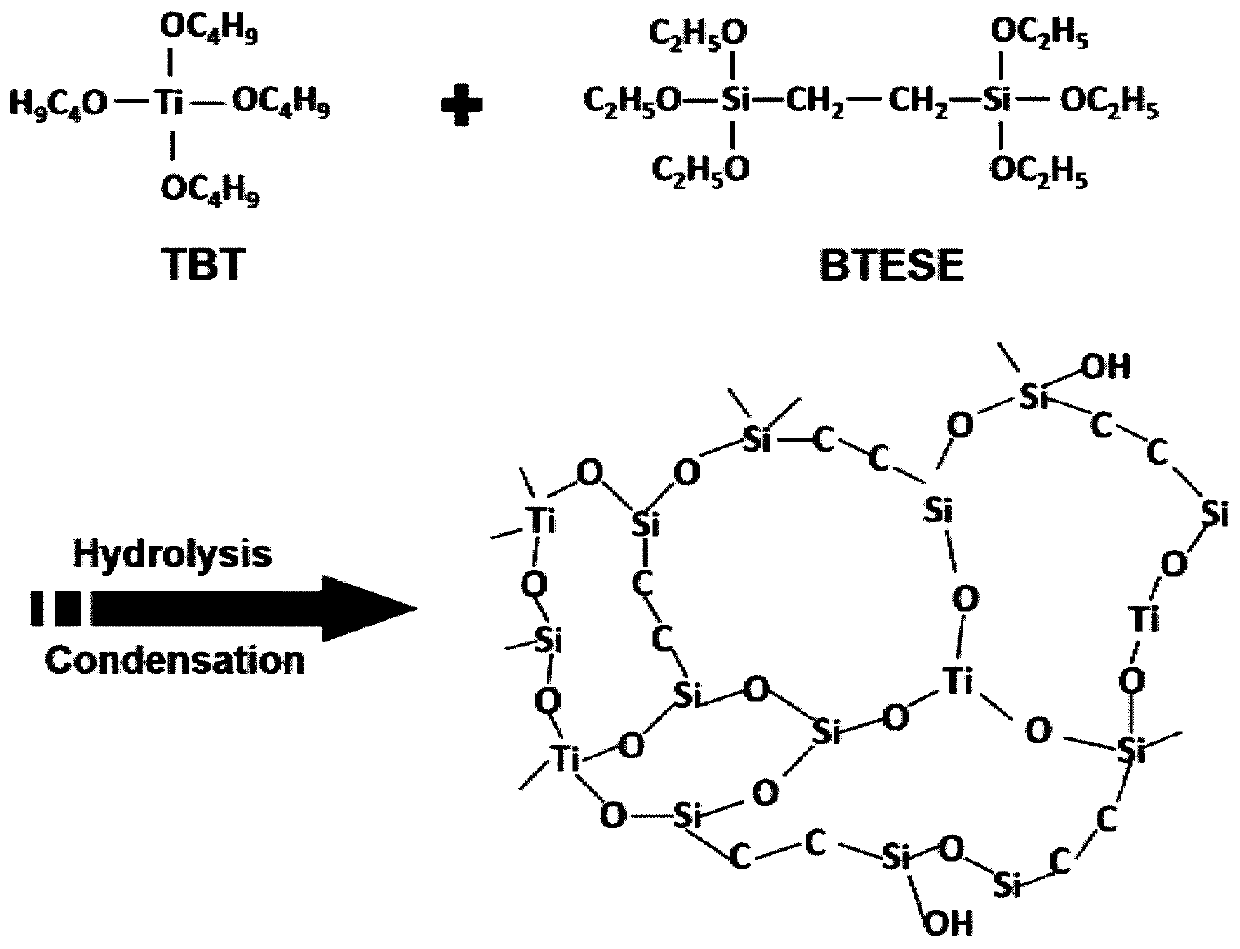

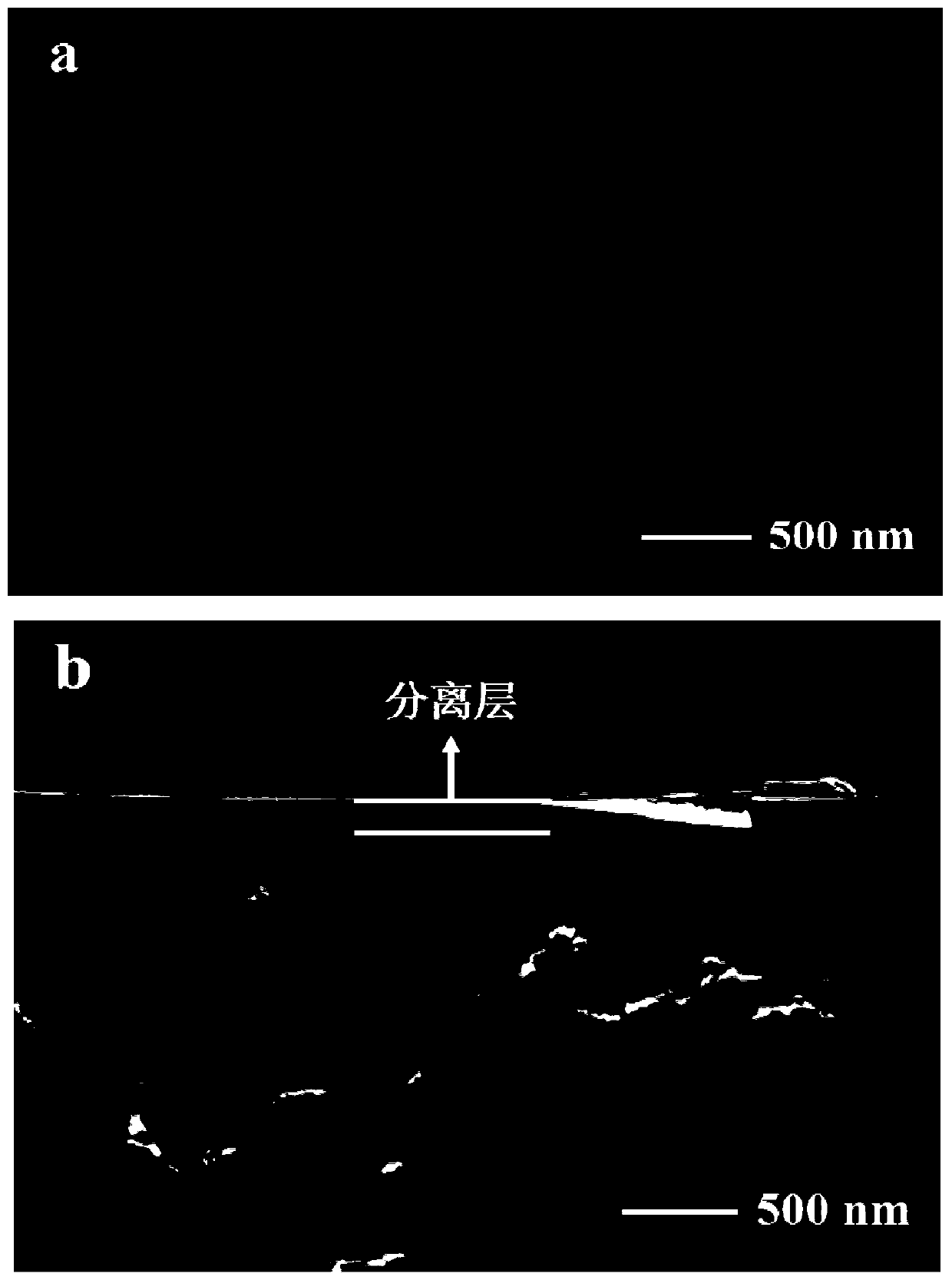

Preparation method and application of anti-pollution silicon-titanium copolymerized composite membrane

ActiveCN109821429ALess copolymerizationEvenly dispersedSemi-permeable membranesNetwork structureSilicon oxide

The invention belongs to the field of separating membranes, and particularly relates to a preparation method and application of an anti-pollution silicon-titanium copolymerized composite membrane. Thepreparation method includes: allowing titanium source precursor and silicon source precursor to be in in-situ copolymerization to form silicon-titanium polymerized sol, and performing high-temperature calcining to form the silicon-titanium copolymerized composite membrane on the surface of a porous inorganic supporting body. In-situ copolymerization enables titanium oxide and silicon oxide to form a uniform and stable Ti-O-Si hybrid network structure, and the problem that TiO2 is nonuniform in dispersion in a matrix during general doping modification is solved. The silicon-titanium compositemembrane formed by in-situ copolymerization presents good anti-pollution performance and separation performance in water treatment like desalting.

Owner:CHANGZHOU UNIV

Method for preparing polyvinyl composite nanofiltration membrane through reversed-phase interfacial polymerization

The invention discloses a method for preparing a polyvinyl composite nanofiltration membrane through reversed-phase interfacial polymerization. The method comprises the following steps: performing single-sided contact on a polyethylene porous membrane and an organic phase monomer solution for 0.1-15 minutes; airing the liquid, enabling one surface, which is in contact with the organic phase monomer solution, of the obtained membrane to be in contact with the water phase monomer solution for 0.1-15 minutes; then drying the solution, and soaking the membrane in a solution containing a surfactant for 5 seconds to 48 hours; and then taking out to obtain the polyvinyl composite nanofiltration membrane. Herein, the polyamide layer is attached to the polyethylene porous membrane through a reversed-phase interfacial polymerization method, the single-layer polyethylene porous membrane is used for replacing a traditional polyester non-woven fabric and polysulfone ultrafiltration layer two-layer structure to serve as a supporting layer, and the thickness and the preparation cost of the membrane can be greatly reduced; besides, the prepared polyamide nanofiltration membrane attached to the polyethylene porous membrane is activated and wetted by a surfactant, is subjected to nanofiltration separation in a water phase system, and has high salt rejection rate and good water flux.

Owner:ZHEJIANG UNIV OF TECH

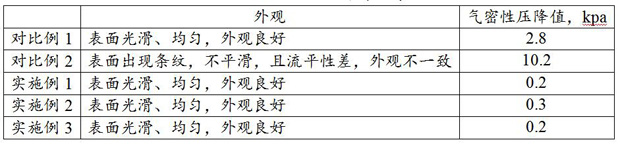

Post-treatment method for improving stability of reverse osmosis membrane and reverse osmosis membrane product

ActiveCN114247298ASolve the problem of air leakageTroubleshoot performance issuesGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisCelluloseActive agent

The invention provides a post-treatment method for improving the stability of a reverse osmosis membrane and a reverse osmosis membrane product. The post-treatment method provided by the invention comprises the following steps: a) impregnating a nascent reverse osmosis membrane with a PVA solution, and removing excess solution on the surface of the nascent reverse osmosis membrane; b) drying the reverse osmosis membrane obtained in the step a) to obtain a post-treated reverse osmosis membrane product; wherein the PVA solution is prepared from the following components in parts by mass: 0.5 to 3 parts of PVA particles, 0.02 to 1.0 part of a surfactant, 0.05 to 5.0 parts of an additive and 91 to 99 parts of water; the additive is selected from one or more of polyacrylic acid, acrylic acid derivatives, cellulose ether and silicone oil. The PVA particles, the surfactant, the specific additive and the water are matched according to a certain proportion to prepare the PVA solution, so that the problems of diaphragm air leakage, poor storage stability and non-uniform coating which are respectively caused when glycerol is added or not added into the conventional PVA solution are solved.

Owner:HUNAN KEENSEN TECH CO LTD

Bacterial cellulose porous foam material and preparation method thereof

The invention relates to a bacterial cellulose porous foam material and a preparation method thereof, and in particular relates to a foam material used for preparing a moulded bacterial cellulose membrane by utilizing azodicarbonamide (AC foaming agent) and a preparation method thereof. In the bacterial cellulose porous foam material provided by the invention, internal structure of the bacterial cellulose membrane is shown as ellipse holes, the holes are interpenetrated, and hole diameter is 5-10 mu m. The preparation method of the bacterial cellulose porous foam material provided by the invention comprises the following steps of: preparing foaming solution by taking azodicarbonamide as a foaming agent and adding a surfactant and a foam stabilizer, fully soaking the moulded bacterial cellulose membrane into the foaming solution and then heating and foaming so as to prepare the bacterial cellulose porous foam material. In the process, the AC foaming agent is effectively introduced intothe moulded bacterial cellulose membrane, decomposition temperature of the AC foaming agent is appropriate, a technological process is simple, preparation period is short, and the original chemical structure of the bacterial cellulose is not damaged, thus the bacterial cellulose porous foam material can be applied to multiple industrial fields.

Owner:DONGHUA UNIV

Preparation method of gradient cross-linked zwitterion-modified multilayer composite nanofiltration membrane and application of composite nanofiltration membrane

ActiveCN111135734BSimple and fast operationEasy to implementSemi-permeable membranesMembranesAcrylonitrileEngineering

The invention provides a preparation method of a gradient cross-linked zwitterion-modified multilayer composite nanofiltration membrane. The preparation method includes obtaining a hydrolyzed polyacrylonitrile ultrafiltration membrane with a polyacrylonitrile ultrafiltration membrane, and placing the ultrafiltration membrane in an ultrafiltration cup. The membrane is soaked with a mixed solution of glutaraldehyde and sodium lauryl sulfate, and an amphoteric polyethyleneimine solution in turn, and then the membrane is stirred and coated with the prepared tannic acid solution, and then the membrane is compressed by pressure filtration to obtain a gradient Cross-linked zwitterion-modified multilayer composite nanofiltration membranes. The present invention also provides the application of using the obtained composite nanofiltration membrane as a salt and dye separation membrane. The preparation method of the invention is simple and convenient, the membrane surface has a hydrophilic, loose and cross-linked separation layer, and the prepared membrane material is used for the separation of salt and dye, and has better water flux, dye retention rate and salt transmittance.

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com