Preparation method of cellulose flat nanofiltration membrane with stable structure

A technology with stable structure and regenerated cellulose membrane, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve the problems of short service life and reduced separation performance of nanofiltration membranes, and achieve reduced production costs, good retention rate, Water flux and strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] 1) The bamboo pulp is pulverized and dissolved in 80wt% NMMO aqueous solution, and 3 wt‰ n-propyl gallate is added, and the reaction is stirred at 100 ℃ for 3 hours, then the heating is stopped, and the stirrer is turned off after the temperature drops to 90 ℃. Vacuum or let stand for 3 hours to defoam to obtain 6 wt% cellulose casting liquid. Pour the obtained cellulose casting liquid on a glass plate, scrape it with a coater to form a film, and then quickly immerse it in deionized water. Membrane, produced regenerated cellulose membrane (RCM);

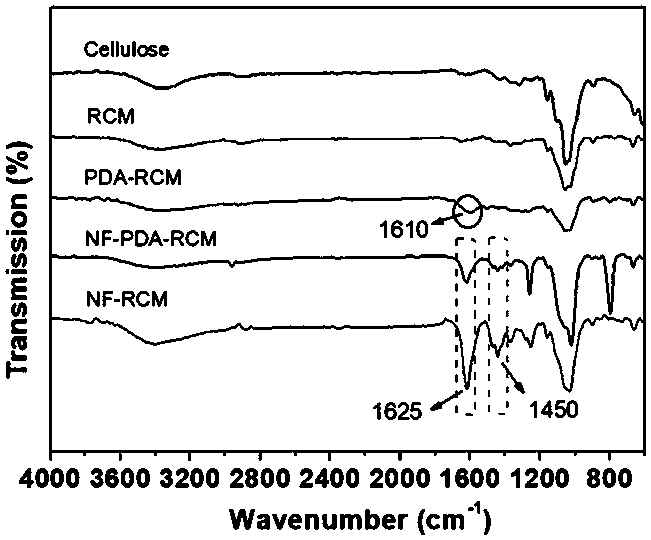

[0027] 2) Prepare a 2 g / L dopamine solution with Tris-HCl buffer (50 mM, pH=7-9), then cut the resulting regenerated cellulose membrane into a circular sheet with a diameter of 5 cm and place it in the resulting In the dopamine solution, vibrate at a constant temperature for 4 hours to cause the dopamine to undergo self-polymerization, and then fully wash with deionized water to obtain a surface-modified regenerated cellulose mem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com