A kind of bacterial cellulose porous foam material and preparation method thereof

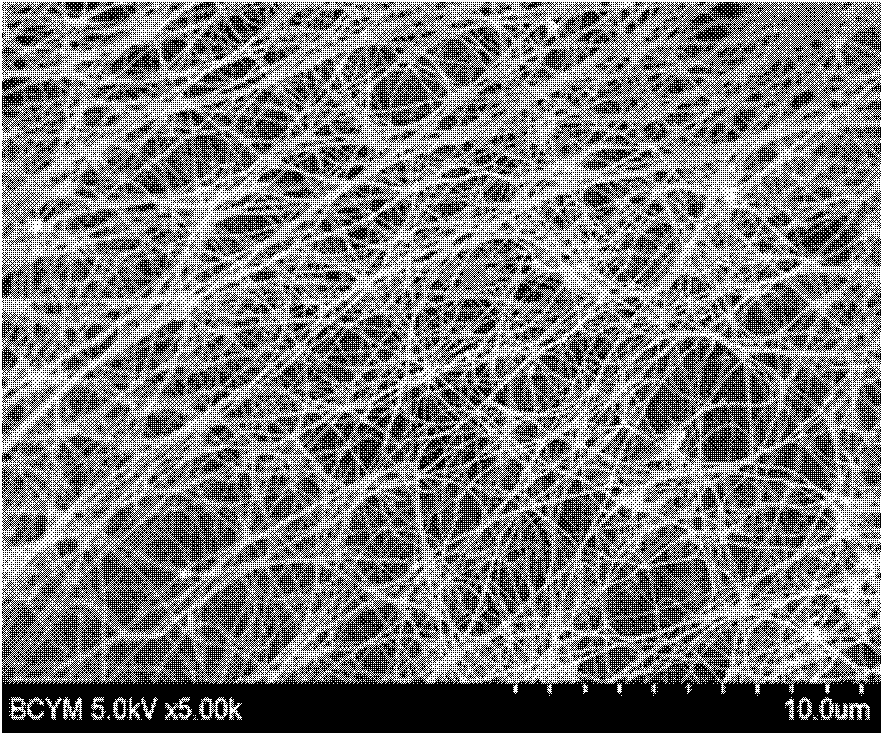

A technology of porous foam material and bacterial cellulose, which is applied in the field of bacterial cellulose porous foam material and its preparation, to achieve regular and uniform arrangement, regular holes and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Pretreatment: first wash the bacterial cellulose membrane several times with deionized water until the pH value of the bacterial cellulose membrane is neutral, and then soak the bacterial cellulose membrane in a NaOH alkaline solution with a mass concentration of 1%. Middle 24h, take out the bacterial cellulose membrane and set aside;

[0031] (2) Preparation of foaming solution: add AC foaming agent, NaOH and deionized water into the reaction vessel, the mass ratio is 3:1:100, stir and dissolve until it becomes a transparent yellow solution, that is, it is prepared into a foaming solution solution;

[0032] (3) Soak the pretreatment membrane: soak the bacterial cellulose membrane treated in step (1) in the foaming solution, and keep stirring for 3 hours;

[0033] (4) Preparation of polyvinyl alcohol solution: Weigh a certain mass of polyvinyl alcohol solid, and its mass ratio to AC foaming agent is 2:1, place it in deionized water and heat it to 80°C until it is com...

Embodiment 2

[0037] (1) Pretreatment: first wash the bacterial cellulose membrane several times with deionized water until the pH value of the bacterial cellulose membrane is neutral, and then soak the bacterial cellulose membrane in a NaOH alkaline solution with a mass concentration of 1%. Middle 24h, take out the bacterial cellulose membrane and set aside;

[0038] (2) prepare foaming solution: add AC foaming agent, NaOH and deionized water in reaction vessel, its mass ratio is 3: 1: 100, add surfactant Tween-80 simultaneously, it and AC foaming agent The mass ratio of the solution is 1:10, stir and dissolve until it turns into a transparent yellow solution, that is, it is prepared into a foaming solution;

[0039] (3) Soak the pretreatment membrane: soak the bacterial cellulose membrane treated in step (1) in the foaming solution, and keep stirring for 3 hours;

[0040] (4) Preparation of polyvinyl alcohol solution: Weigh a certain mass of polyvinyl alcohol solid, and its mass ratio to...

Embodiment 3

[0044] (1) Pretreatment: first wash the bacterial cellulose membrane several times with deionized water until the pH value of the bacterial cellulose membrane is neutral, and then soak the bacterial cellulose membrane in a NaOH alkaline solution with a mass concentration of 1%. Middle 24h, take out the bacterial cellulose membrane and set aside;

[0045] (2) Prepare foaming solution: add AC foaming agent, NaOH and deionized water in the reaction vessel, its mass ratio is 3: 1: 100, add surfactant Span-80 simultaneously, it and AC foaming agent The mass ratio of the solution is 1:10, stir and dissolve until it turns into a transparent yellow solution, that is, it is prepared into a foaming solution;

[0046] (3) Soak the pretreatment membrane: soak the bacterial cellulose membrane treated in step (1) in the foaming solution, and keep stirring for 3 hours;

[0047] (4) Preparation of polyvinyl alcohol solution: Weigh a certain mass of polyvinyl alcohol solid, and its mass ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com