Method for preparing polyvinyl composite nanofiltration membrane through reversed-phase interfacial polymerization

A composite nanofiltration membrane, polyethylene-based technology, applied in the field of nanofiltration membranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

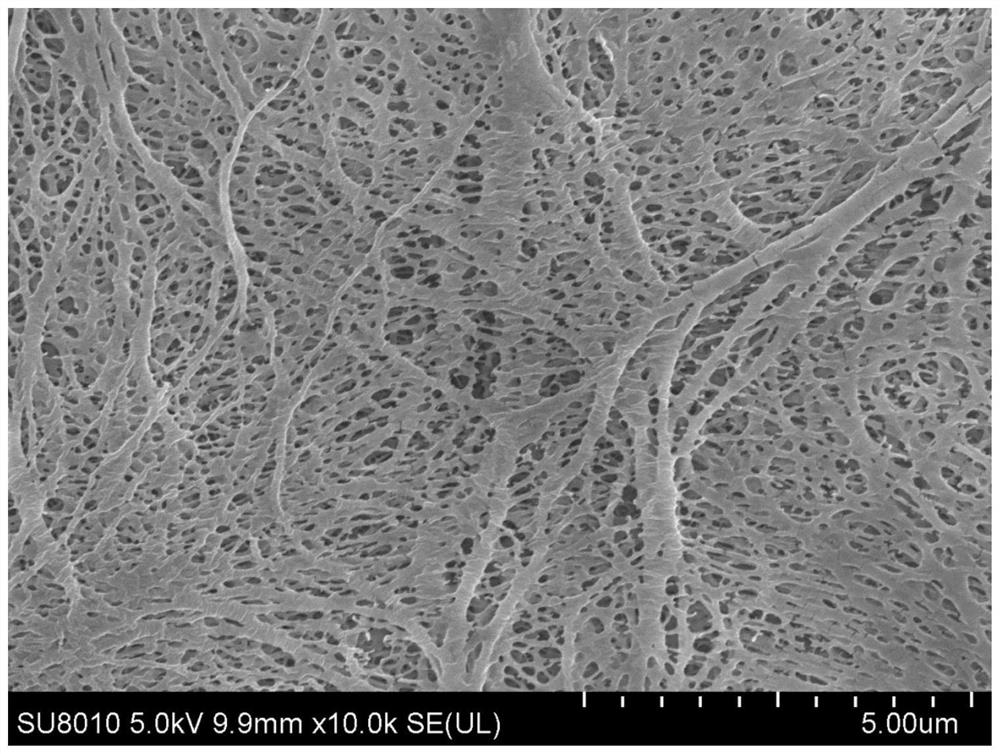

Image

Examples

Embodiment 1

[0027] (1) Take a polyethylene porous membrane with a thickness of 9 μm as the support layer, weigh 0.075 g of trimesoyl chloride and dissolve it in 100 mL of n-hexane, contact the polyethylene porous membrane with the trimesoyl chloride solution for 4 minutes, and then dry it.

[0028] (2) Weigh 0.2g of piperazine and dissolve it in 100mL of deionized water, contact the side of the film obtained in step (1) that has been in contact with the organic phase monomer with the water phase monomer for 1min, and then bake in an oven at 60°C for 15min .

[0029] (3) Weigh 200 mL of isopropanol with a purity of 99.7%, soak the film obtained in step (2) in the solution for 5 minutes, and then take it out for testing.

[0030] The thickness of a polyethylene-based nanofiltration membrane prepared in Example 1 is 10±3um. The nanofiltration membrane prepared in this example was put into a performance evaluation device, and the experimental conditions were: 0.6Mpa, pre-compressed for 1 hou...

Embodiment 2

[0032] (1) Take a polyethylene porous membrane with a thickness of 16 μm as the support layer, weigh 0.075 g of trimesoyl chloride and dissolve it in 100 mL of n-hexane, contact the polyethylene porous membrane with the trimesoyl chloride solution for 4 minutes on one side and then dry it.

[0033] (2) Weigh 0.1g of piperazine and dissolve it in 100mL of deionized water, contact the side of the film obtained in step (1) that has been in contact with the organic phase monomer with the water phase monomer for 1 min, and bake in an oven at 60°C for 15 min .

[0034] (3) Weigh 200 mL of isopropanol with a purity of 99.7%, soak the film obtained in step (2) in the solution for 5 hours, and then take it out for testing.

[0035] The thickness of a polyethylene-based nanofiltration membrane prepared in Example 2 is 17±3um. The nanofiltration membrane prepared in this example was put into a performance evaluation device, and the experimental conditions were: 0.6Mpa, pre-compressed fo...

Embodiment 3

[0037] (1) Take a polyethylene porous membrane with a thickness of 16 μm as the support layer, weigh 0.075 g of trimesoyl chloride and dissolve it in 100 mL of n-hexane, contact the polyethylene porous membrane with the trimesoyl chloride solution for 4 minutes on one side and then dry it.

[0038] (2) Weigh 0.2g of piperazine and dissolve it in 100mL of deionized water, contact the side of the film obtained in step (1) that has been in contact with the organic phase monomer with the water phase monomer for 1min, and then bake in an oven at 60°C for 15min .

[0039] (3) Weigh 200 mL of isopropanol with a purity of 99.7%, soak the film obtained in step (2) in the solution for 5 hours, and then take it out for testing.

[0040] The thickness of a polyethylene-based nanofiltration membrane prepared in Example 3 is 17±3um. The nanofiltration membrane prepared in this example was put into a performance evaluation device, and the experimental conditions were: 0.6Mpa, pre-compressed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com