Modified rice hull ash-silicone rubber composite material and preparation method thereof

A composite material and technology of rice husk ash, applied in the field of modified rice husk ash-silicon rubber composite material and its preparation, can solve the problem of not finding a suitable development and utilization way, achieve good self-leveling, reduce carbon element content, The effect of improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

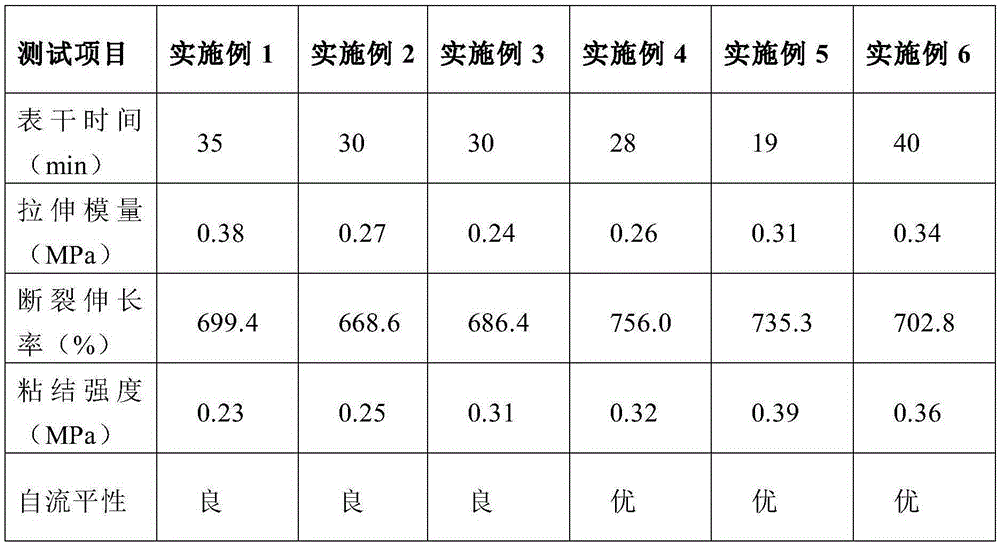

Examples

Embodiment 1

[0031] Embodiment 1: A kind of modified rice husk ash-silicone rubber composite material

[0032] According to 107 base rubber: crosslinking agent: chain extender: tackifier: plasticizer: modified rice husk ash: catalyst is composed in a ratio of 100:5:0.2:1:20:15:0.3 by weight.

[0033] Among them, the crosslinking agent is methyl tributyl ketoxime silane, the chain extender is methyl vinyl amido silane, the catalyst is octyl tin maleate, the plasticizer is non-reactive dimethyl silicone oil, and the tackifier for the KH550.

Embodiment 2

[0034] Embodiment 2: A kind of modified rice husk ash-silicone rubber composite material

[0035] According to 107 base rubber: crosslinking agent: chain extender: tackifier: plasticizer: modified rice husk ash: catalyst is composed in a ratio of 100:1:0.2:1:20:30:0.3 by weight.

[0036] Among them, the cross-linking agent is vinyl tributyl ketoxime silane, the chain extender is dimethyl hydroxylamino silane, the catalyst is dibutyl tin laurate, the plasticizer is MDT type silicone oil, and the tackifier is KH560.

Embodiment 3

[0037] Embodiment 3: A kind of modified rice husk ash-silicone rubber composite material

[0038] According to 107 base glue: crosslinking agent: chain extender: tackifier: plasticizer: modified rice husk ash: catalyst is composed in the ratio of 100:5:0.3:3:50:20:0.3 by weight.

[0039] Among them, the cross-linking agent is methyl tributylketoxime silane; the chain extender is methyl vinyl amido silane and dimethyl hydroxylamino silane, the ratio of the two is 1:1; the catalyst is octyltin maleate; The plasticizer is non-reactive simethicone, and the tackifier is KH570.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com