Preparation method of gradient cross-linked zwitterion-modified multilayer composite nanofiltration membrane and application of composite nanofiltration membrane

A zwitterion, multi-layer composite technology, applied in the field of composite membranes, can solve the problems of environmental pollution, waste of resources, dye wastewater cannot be directly reused, etc., to improve the retention rate, easy operation, improve water flux and salt permeation. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] On the overall design, the preparation method of this embodiment includes the following steps:

[0036] Step a. Put the polyacrylonitrile ultrafiltration membrane into the sodium hydroxide solution, heat treatment at 50 ° C, rinse the membrane surface with distilled water after heat treatment to obtain a hydrolyzed polyacrylonitrile ultrafiltration membrane, and heat the hydrolyzed polyacrylonitrile ultrafiltration membrane. The filter membrane is fixed in the ultrafiltration cup;

[0037] Step b. Add glutaraldehyde and sodium dodecyl sulfate into water to prepare a mixed solution at room temperature, and soak the surface of the hydrolyzed polyacrylonitrile ultrafiltration membrane fixed in step a with the prepared mixed solution, and after the soaking is completed Pour out the mixed solution, and dry the membrane soaked in the mixed solution;

[0038] Step c. Prepare an amphoteric polyethyleneimine solution at room temperature, soak the film after drying in step b wit...

example 1

[0050] In the preparation process of this example, the polyacrylonitrile ultrafiltration membrane was first put into 1 mol / L sodium hydroxide solution, and the temperature was controlled to be 50 °C for heat treatment for 1 h, and then the surface of the membrane was washed with distilled water to obtain a hydrolyzed polyacrylonitrile ultrafiltration membrane. And fix the membrane on the ultrafiltration cup. Next, at room temperature, the crosslinking agent glutaraldehyde and the active agent sodium dodecyl sulfate are added to water to prepare a mixed solution. The mass concentration of glutaraldehyde in the mixed solution is 0.52%, and the mass concentration of sodium dodecyl sulfate is 0.15%, and poured the prepared mixed solution on the surface of the fixed hydrolyzed polyacrylonitrile ultrafiltration membrane, soaked for 10 min, poured out the solution, and dried the membrane.

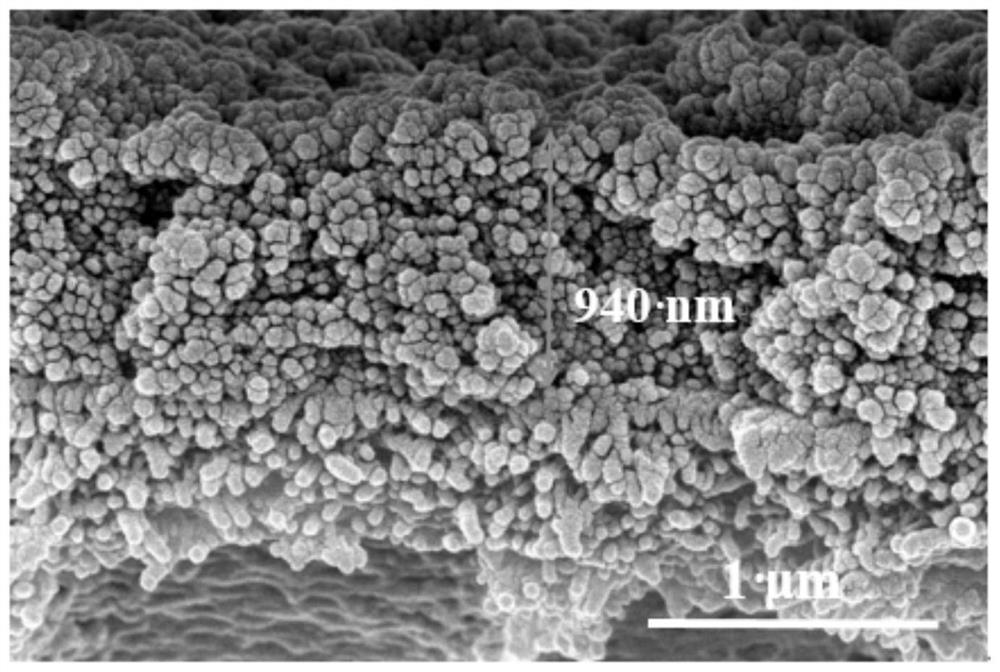

[0051] Then, 2 g of polyethyleneimine and 4 g of zwitterion methacryloylethyl sulfobetaine wer...

example 2

[0057] In the preparation process of this example, the concrete steps are basically the same as Example 1, the difference is only that in the mixed solution of the prepared cross-linking agent glutaraldehyde and the active agent sodium dodecyl sulfate, the mass concentration of glutaraldehyde is 0 %, that is, the mixed solution with the crosslinking agent glutaraldehyde and the active agent sodium lauryl sulfate is not used in this example, the soaking time of the amphoteric polyethyleneimine solution is 20min, and the stirring coating of the tannic acid solution is used. The time is 0 min, that is, the stirring coating of the tannic acid solution is not carried out in this example.

[0058] figure 2 The surface infrared characterization diagram of the composite nanofiltration membrane obtained in this example is shown by figure 2 Can be seen at 1036cm -1 The vibrational absorption peaks of the grafted zwitterionic sulfonate on PEI appeared at , which indicated that the zw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com