Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Good printing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

3D laser printing method and system

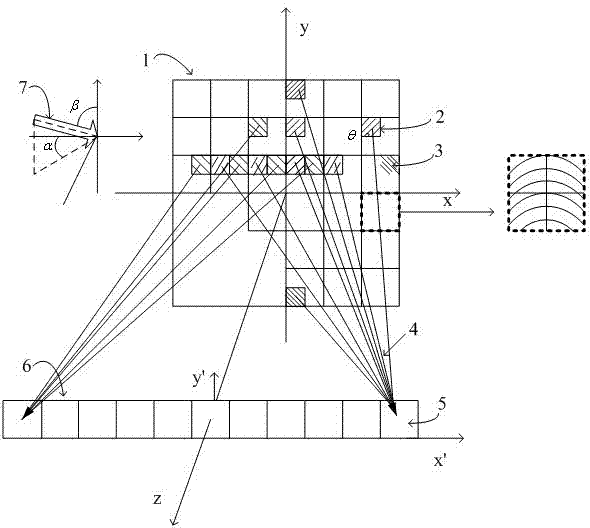

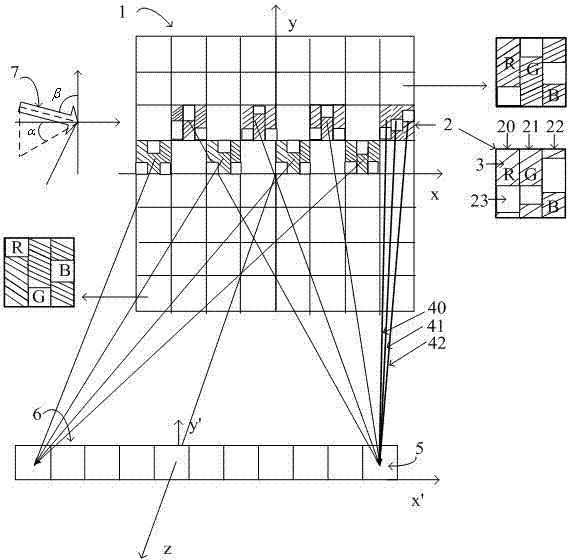

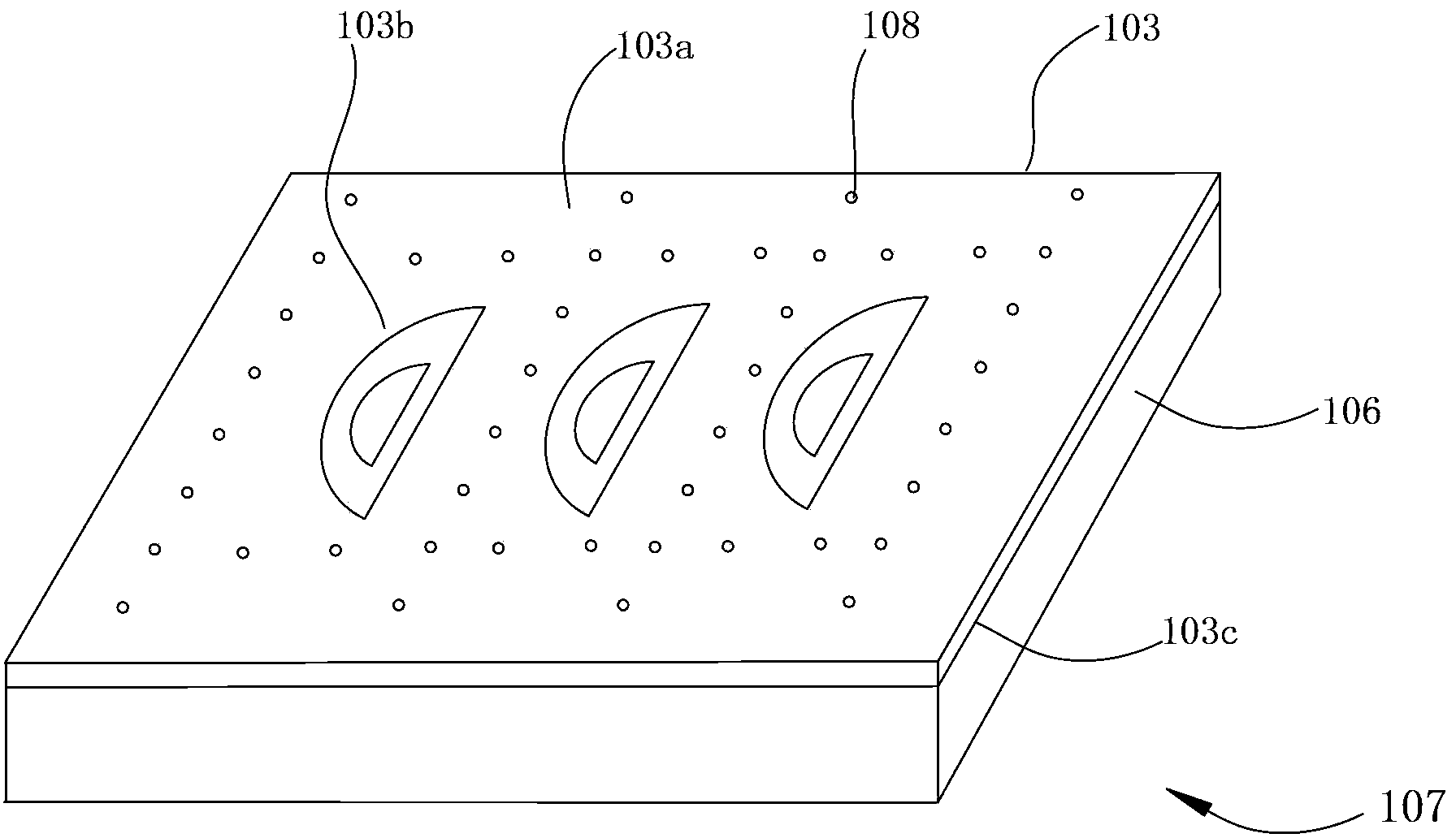

ActiveCN103246195ARealize continuously adjustableStrong three-dimensional senseDiffraction gratingsColor imageMicro nano

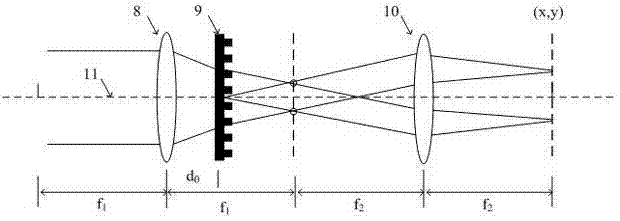

The invention discloses a 3D laser printing method and system. A four-parameter continuous modulation laser printout method is adopted to prepare a 3D image consisting of diffraction pixels arranged according to the position coordinates and provided with both a specific grating space frequency and an angle of orientation; the modulation method of parameters of grating stripes in the diffraction pixels is realized on the basis of a 4F imaging system and a diffraction grating; the 4F imaging system comprises a first Fourier transformation lens or lens group and a second Fourier transformation lens or lens group; the diffraction grating is placed between the first Fourier transformation lens or lens group and the second Fourier transformation lens or lens group; the distance between the diffraction grating and the first Fourier transformation lens or lens group is changed to realize continuous modulation of the space frequency of the grating stripes; and the diffraction grating is rotated to realize continuous modulation of the grating orientation angle of the grating stripes. The 3D laser printing method and system realize continuous adjustment of the space frequency and the orientation of the grating, and encodes on the basis of the four-parameter micro-nano structure with continuously changeable space frequency and orientation of the grating to form a 3D color image.

Owner:SVG TECH GRP CO LTD

High impact resistant mobile phone glass cover-plate and manufacturing technology thereof

InactiveCN106183501AGood printing effectGood curing effectCoatingsGlass tempering apparatusBrightness perceptionMobile phone

The invention relates to the technical field of a mobile phone glass cover-plate, in particular to a high impact resistant mobile phone glass cover-plate and manufacturing technology thereof. The manufacturing technology comprises the following steps of (1) cutting; (2) fine machining; (3) grinding, that is, conducting sanding treatment on the surface of a fine machined plate glass; (4) reinforcing; (5) plane grinding; (6) the first time of cleaning; (7) silk printing, specifically, silk printing comprises the following steps of the first time of mirror-like silver printing, the second time of black printing, the third time of gold printing, the fourth time of gold printing, the fifth time of bluish violet printing, the sixth time of black printing, the seventh time of white printing, and the eighth time of gloss oil printing; and (8) the second time of cleaning, that is, the glass cover-plate is cleaned neatly after being subjected to the silk printing treatment, and then the high impact resistant mobile phone glass cover-plate is obtained. The obtained high impact resistant mobile phone glass cover-plate has the advantages that impact resistance is good; abrasive resistance is high; brightness is good; color stability is high; the effect of environment protection is achieved; and water resistant performance, acid and alkali resistant performance and ageing resistant performance are better.

Owner:DONGGUAN JINGBO PHOTOELECTRIC BIT CO

Preparation method of polyacrylate-polyurethane resin binder for single-fluid general plastic gravure alcohol-soluble and water-soluble composite ink

The invention relates to a resin binder for the plastic gravure composite ink, in particular to a preparation method of a resin binder for the single-fluid general plastic gravure alcohol-soluble and water-soluble composite ink. The invention provides a preparation method of a polyacrylate-polyurethane resin binder for the single-fluid general plastic gravure alcohol-soluble and water-soluble composite ink. The method uses (methyl) acrylate, vinyl acetate, polymerizable polyurethane macromonomer and activated functional monomer as raw materials and is prepared by the radical polymerization of solution. As polyurethane branch chains are introduced, the composite ink has good adhesive force to various plastic film substrates such as BOPP, PET, PA, PVC, PE and PC, good printing adaptability and high combined strength, and can adapt to various laminating adhesives such as fat-soluble laminating adhesives and alcohol-soluble laminating adhesives. The preparation method of the resin binder for the ink is easy, the prepared ink has good printing effect and high adaptability and can be used for printing various plastic substrates; crosslinking component is not needed to use, the resin binder has convenient operation and high combined strength; the resin binder is alcohol-soluble, water-soluble, economical and environmentally friendly, and has wide application prospect in the plastic gravure composite ink field.

Owner:CHENGDU XINJIN TUOZHAN PRINTING INK

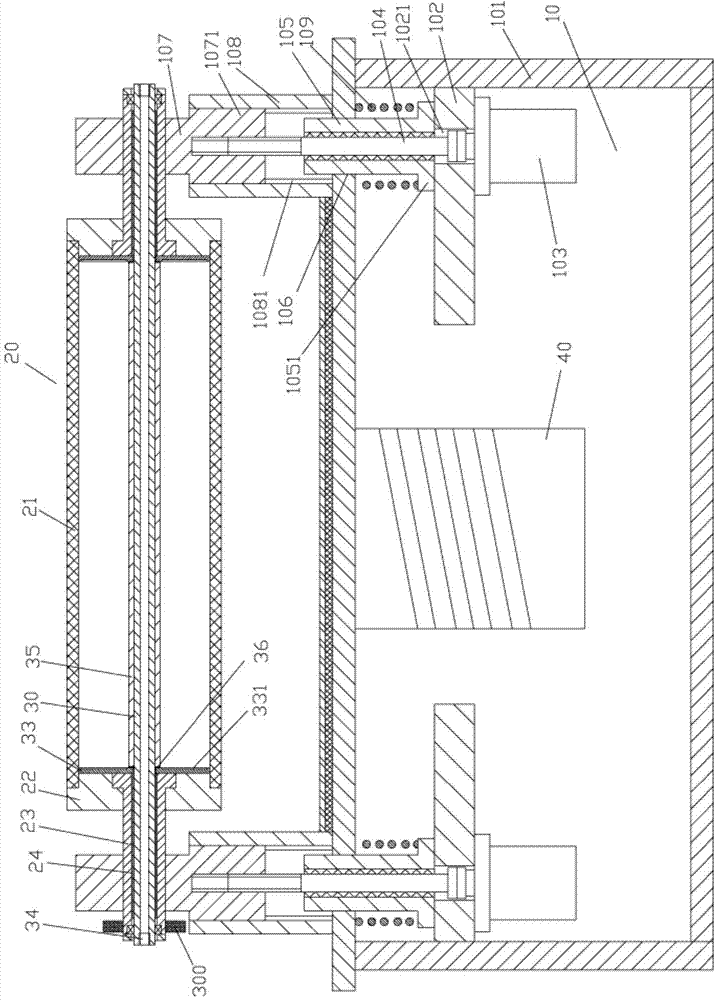

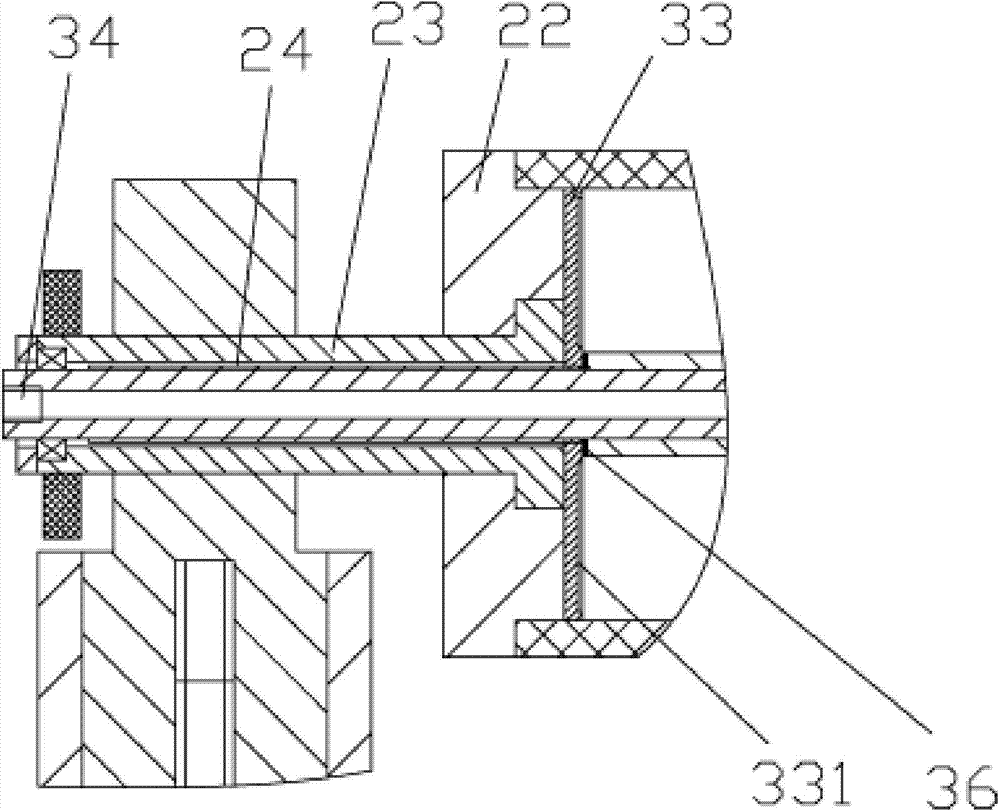

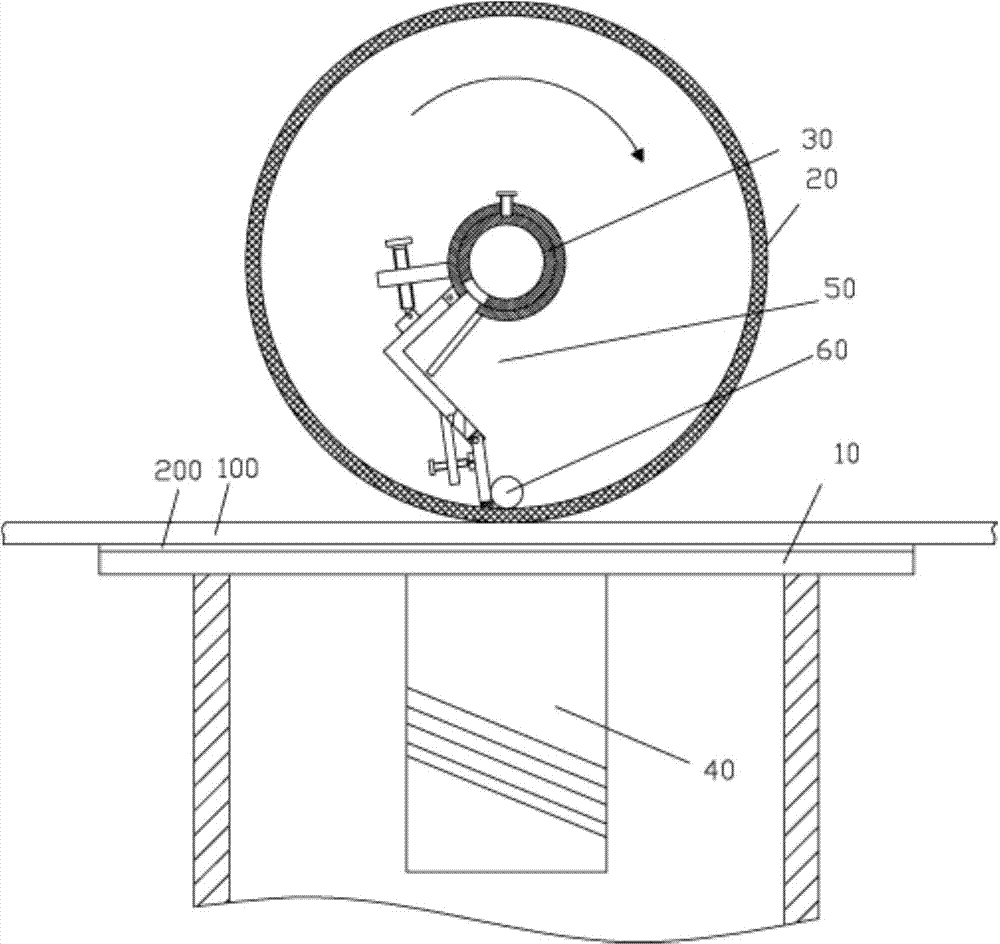

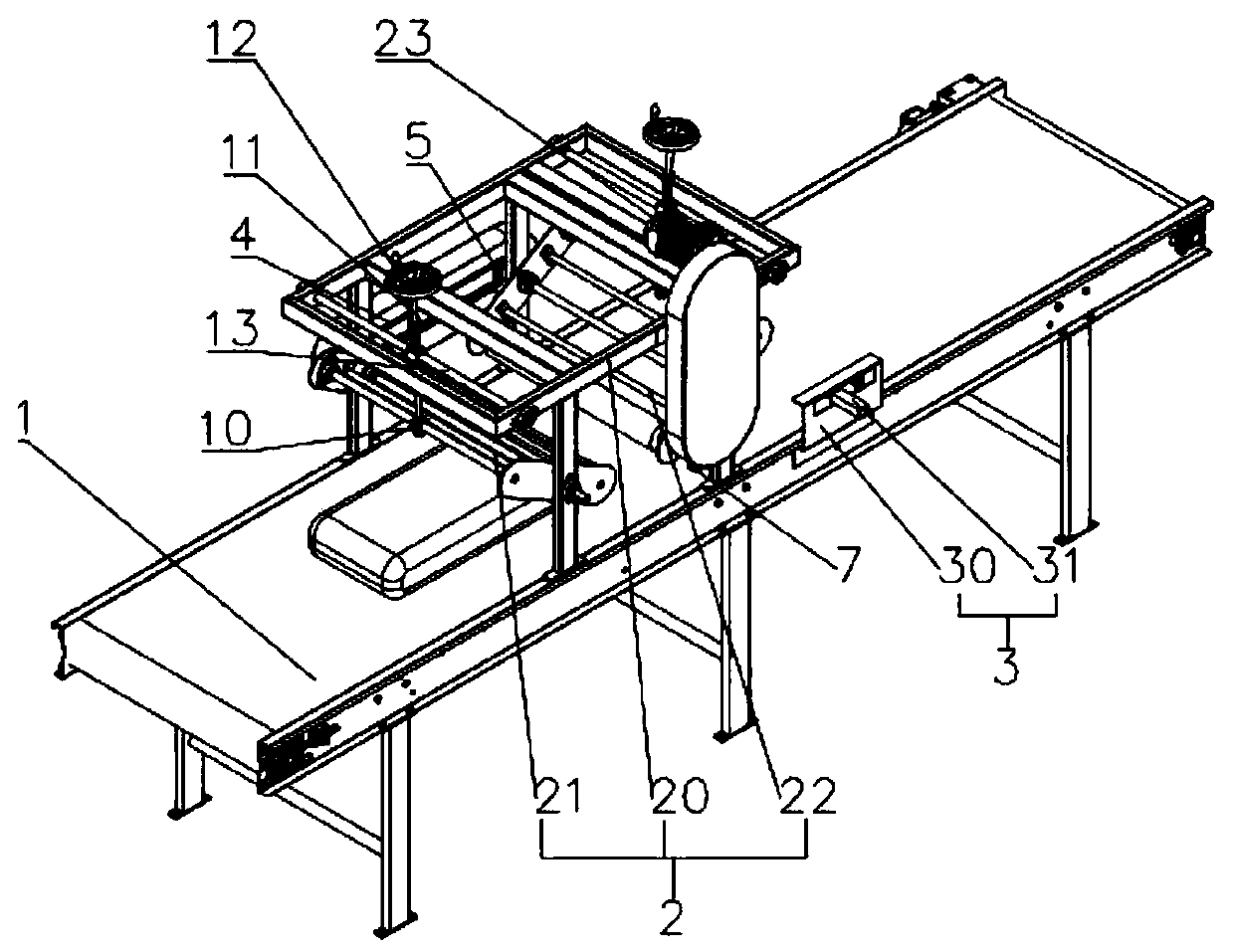

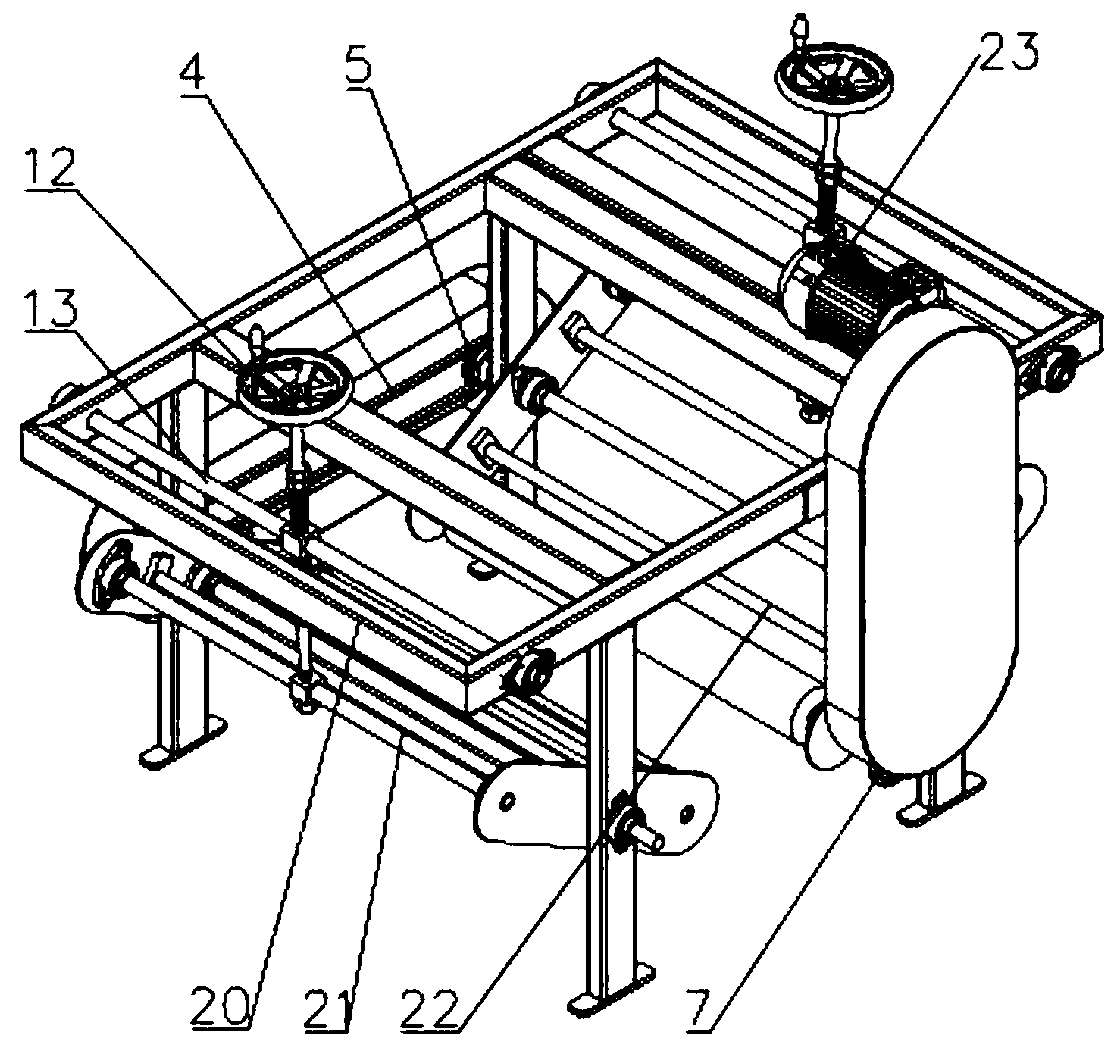

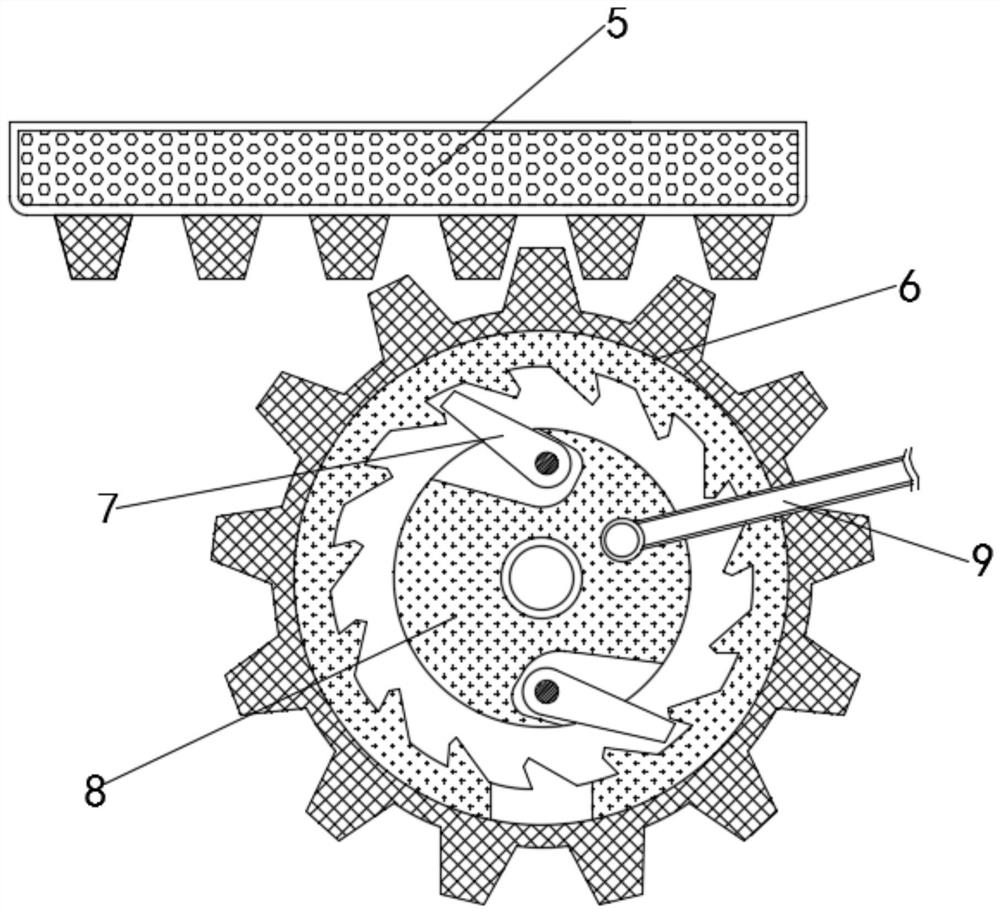

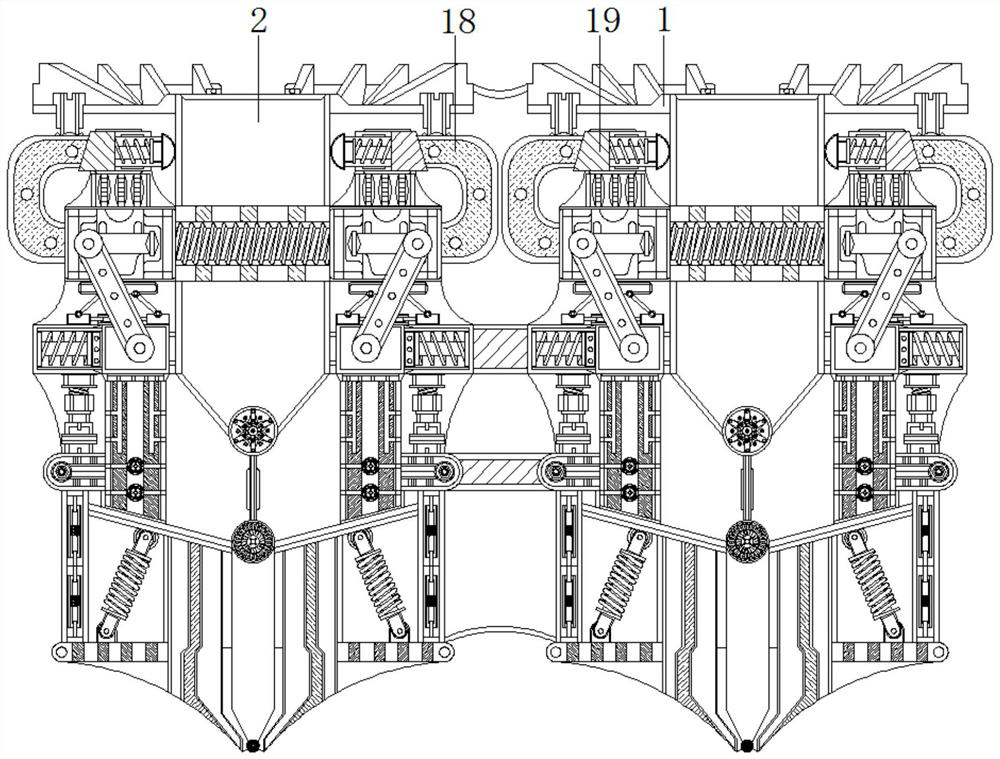

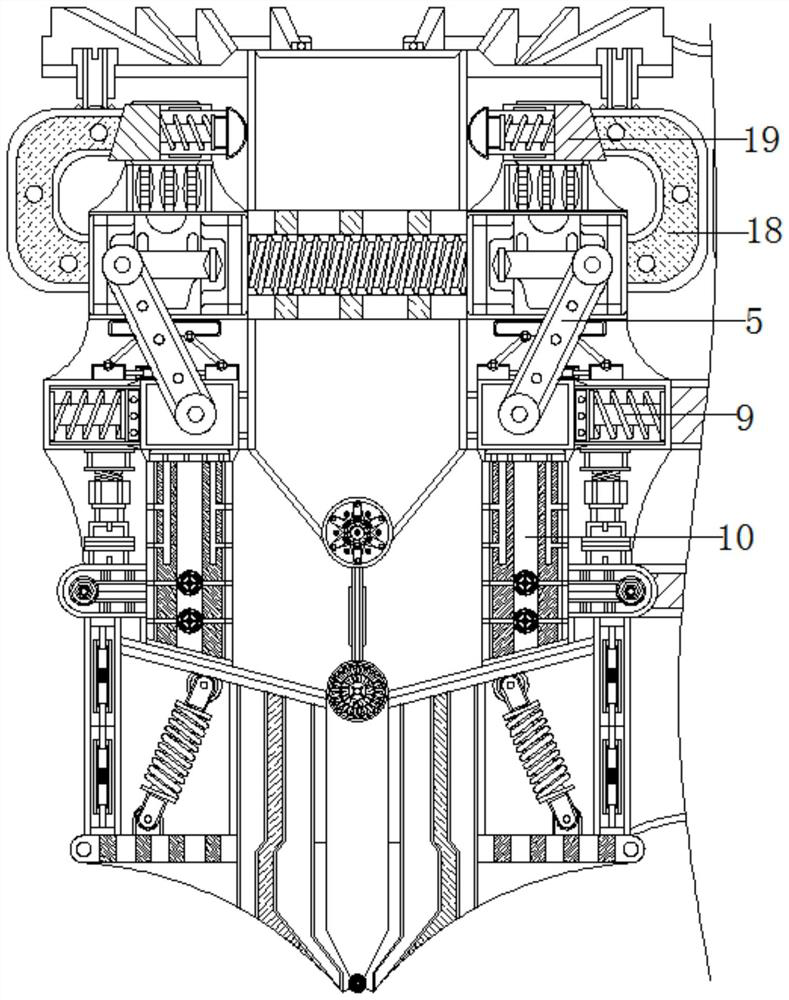

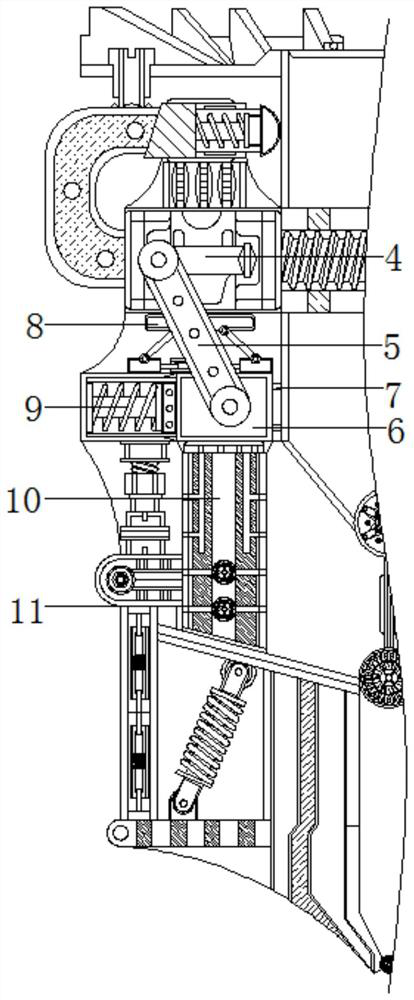

Circular screen printer adjusting mechanism adopting magnetic bar printing mechanism

The invention discloses a circular screen printer adjusting mechanism adopting a magnetic bar printing mechanism. The circular screen printer adjusting mechanism comprises a rack, support plates are fixed on two side plates below the rack, a magnetic table is fixed on the back of a top plate of the rack, driving motors are fixed on the support plates, output shafts of the driving motors are inserted into holes in the support plates and are fixed with vertical adjusting rods via couplers, and the lower ends of the vertical adjusting rods and the couplers are arranged in the holes. The vertical adjusting rods are inserted into adjusting sleeves, the adjusting sleeves are inserted into through holes of the top plate of the rack, the top ends of the vertical adjusting rods extend out of the adjusting sleeves, the top ends of the vertical adjusting rods are connected with connectors in a threaded manner, and two ends of a nickel screen roller are hinged with the connectors correspondingly. The nickel screen roller can be adjusted up and down so as to be pressed against cloth for printing. Meanwhile, paste discharge amount and speed of a pulp delivery roller can be controlled, and printing effect is ensured.

Owner:威海毛纺织集团有限公司

Printing and forming process of environment-friendly APET plastic products

InactiveCN106827598AStable printingBeautiful printPattern printingFlat articlesScreen printingPlastic film

The invention relates to a processing process of APET plastic products, in particular to a printing and forming process of environment-friendly APET plastic products. The printing process comprises the following steps:1) making an APET plastic plate; 2) embossing a leading wire on the APET plastic plate and laminating a film on the APET plastic plate; 3) cutting the APET plastic plate; 4) carrying out silk-screen printing; 5) coating the APET plastic plate with a protective film layer; 6) pressing sides; 7) carrying out die-cutting forming; and 8) carrying out high-frequency splicing. According to the process, the APET plastic is used as an original material of the plastic products so that the environment can be protected, the resources can be recycled, and the processing cost can be reduced; the reasonable printing process is adopted so that the pattern printing and the pattern die-cutting forming of the APET plastic sheet material can be smoothly completed in shortest time and in most convenient operation steps; and the most suitable forming process is adopted, so that the APET sheet material can be stereoscopically formed smoothly, and the APET plastic products which are attractive in printing, stable in quality and energy-saving can be obtained.

Owner:东莞市巨泓彩色印刷有限公司

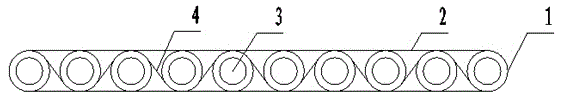

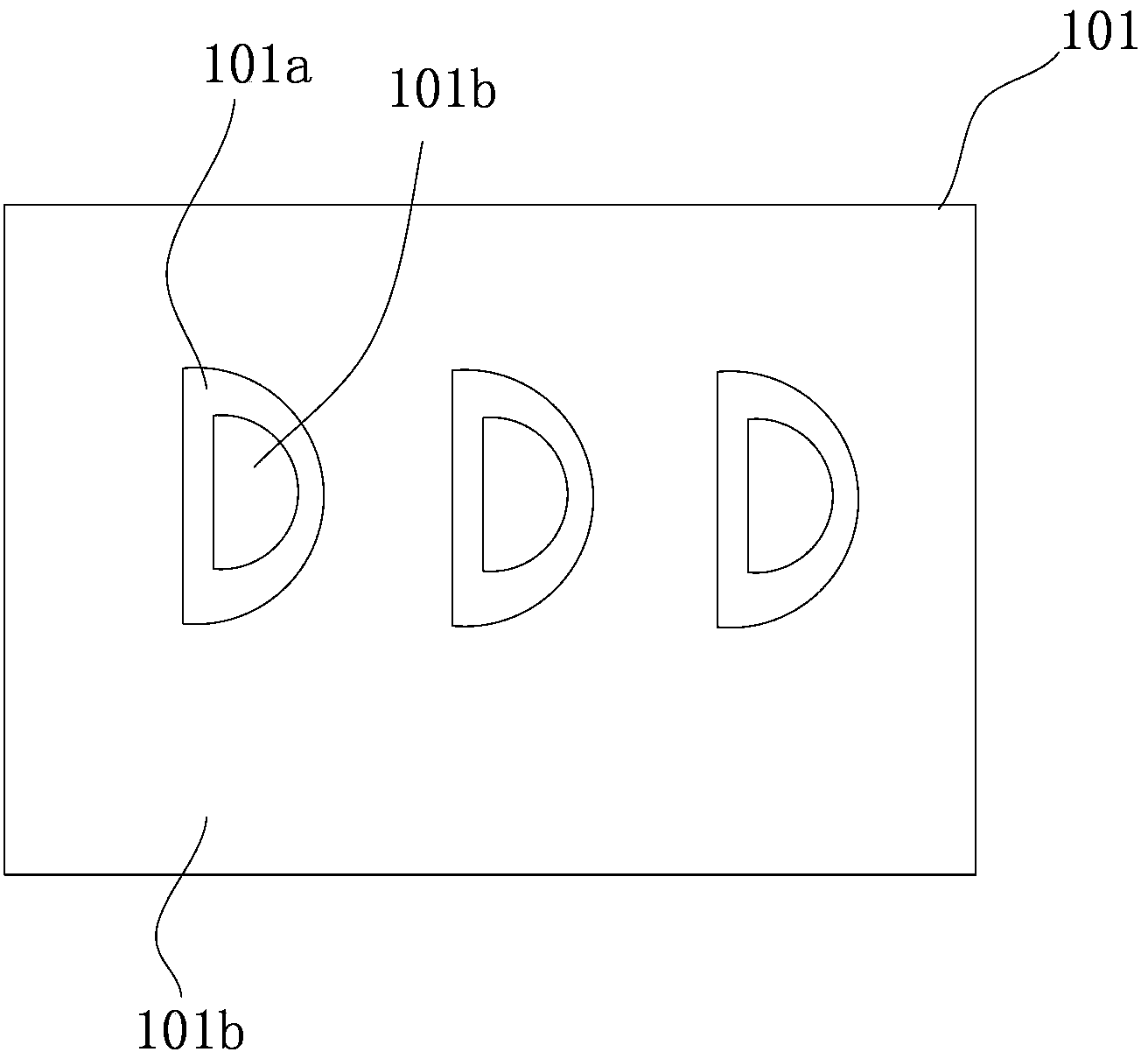

Nylon coating trademark cloth for bar code printing and preparation method

ActiveCN104480694AGood printing effectStable structureBiochemical fibre treatmentFibre typesPolyamidePolyester

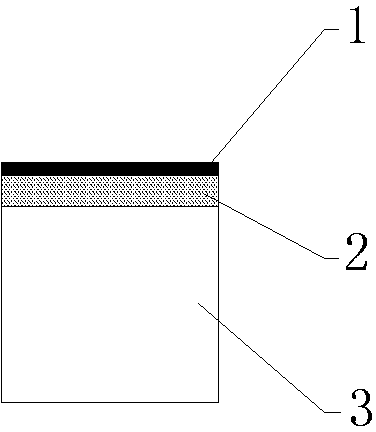

The invention discloses nylon coating trademark cloth for bar code printing. The cloth comprises a piece of nylon base cloth (1), wherein a polymer coating (2) is arranged on the surface of the nylon base cloth (1); the nylon base cloth (1) comprises warp yarns (3) and weft yarns (4) which are vertically interlaced with the warp yarns; the wrap density of the nylon base cloth (1) is 75-80 pieces / cm while the weft density of the nylon base cloth (1) is 35-50 pieces / cm; the warp yarns (3) are 30D or 70D monofilaments, and the weft yarns (4) are 70D polyester / polyamide compound fibers. The manufacturing method of the nylon coating trademark cloth for bar code printing comprises the step that a finished product is prepared by sequentially weaving, desizing, sizing, scrap-coating and baking sizing. The nylon coating trademark cloth has the advantages of stable structure and god printing effect, and is suitable for bar code printing.

Owner:HUZHOU HENGXIN TRADEMARK MAKING BRINGING

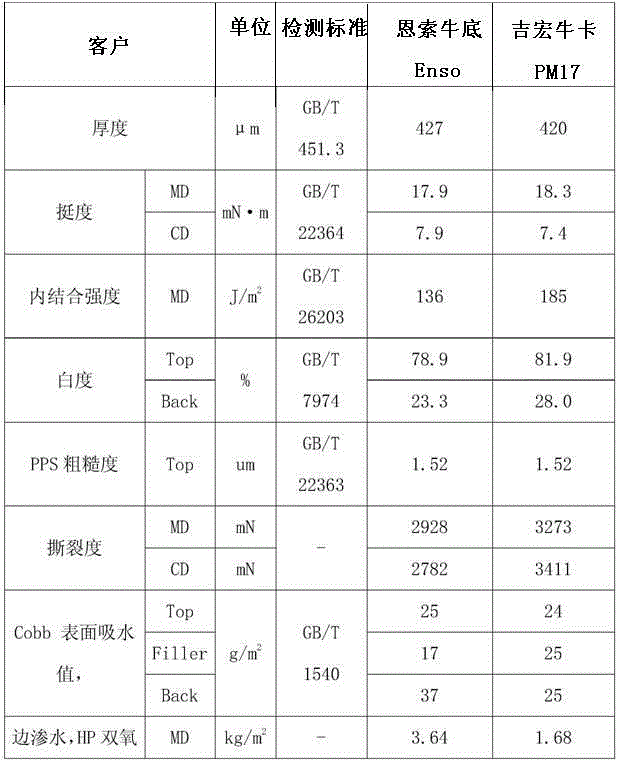

Coated kraft paper and production technology thereof

InactiveCN104928968AReasonable ratio of long and short fibersReasonable proportionSpecial paperPaper-making machinesFiberKraft paper

The invention discloses coated kraft paper and a production technology thereof. The coated kraft paper comprises a coated layer, a surface layer, a core layer, a bottom layer and a starch gluing layer, wherein the coated layer, the surface layer, the core layer, the bottom layer and the starch gluing layer are sequentially stacked together; the surface layer is bleached chemical wood pulp; the bleached chemical wood pulp comprises the following ingredients in percentage by weight: 20%-80% of bleached chemical hardwood pulp and 20%-80% of bleached chemical needle pulp; the core layer is mixed pulp; the mixed pulp comprises the following ingredients in percentage by weight: 30%-70% of ecru pulp and 30%-70% of mechanical pulp; and the bottom layer is 100% of ecru pulp. Because the coated kraft paper is manufactured by a three-layered net, 100% of native wood pulp is used, a front surface of the coated draft paper is a coating layer, the back surface of the coated draft paper is the starch gluing layer, the proportion of long fibers and short fibers of the pulp is reasonable, an efficient technological control means is adopted, and the strength of paper and the tenderness of paper surfaces can be guaranteed simultaneously.

Owner:XIAMEN JIHONG TECH CO LTD +1

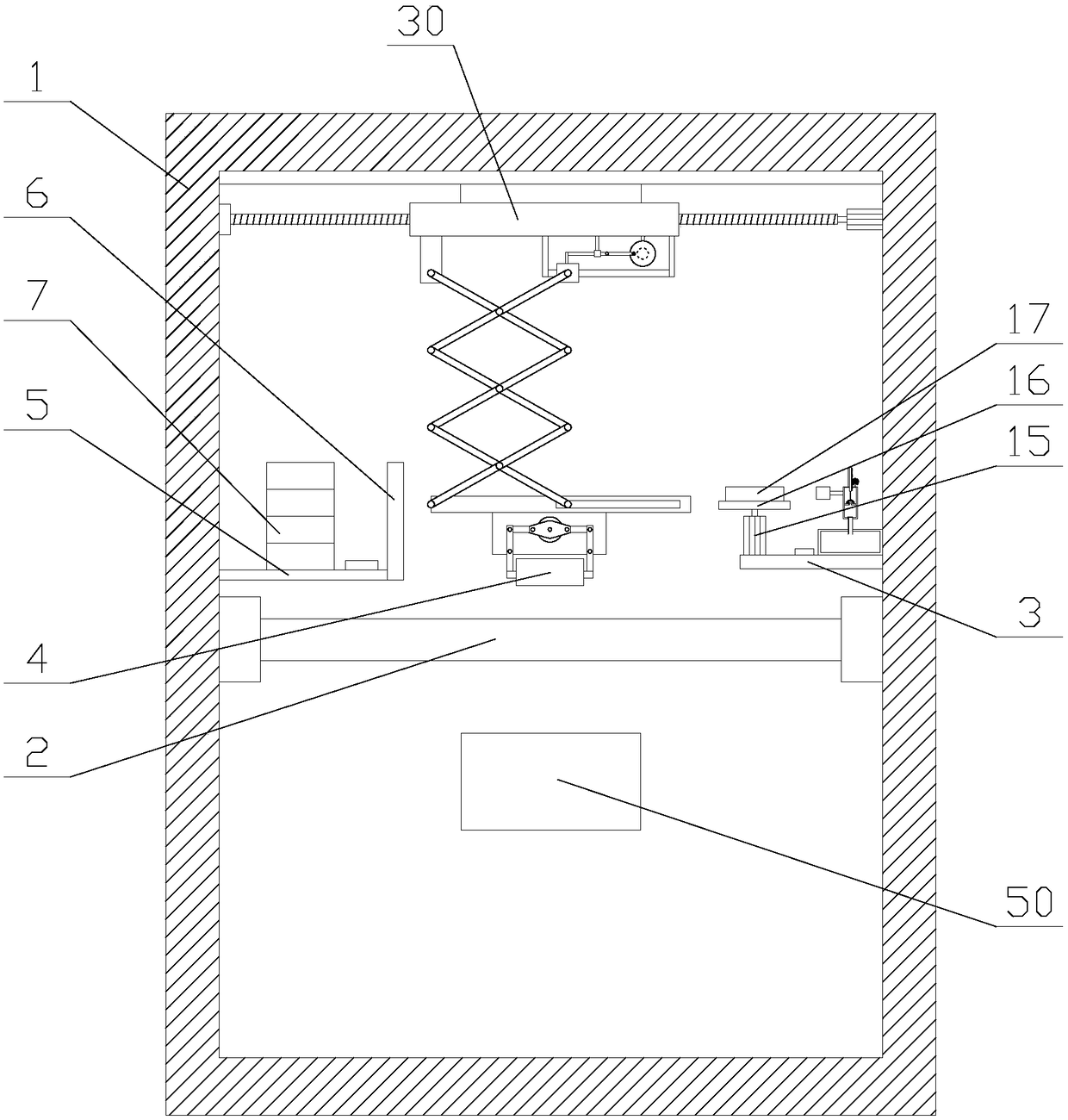

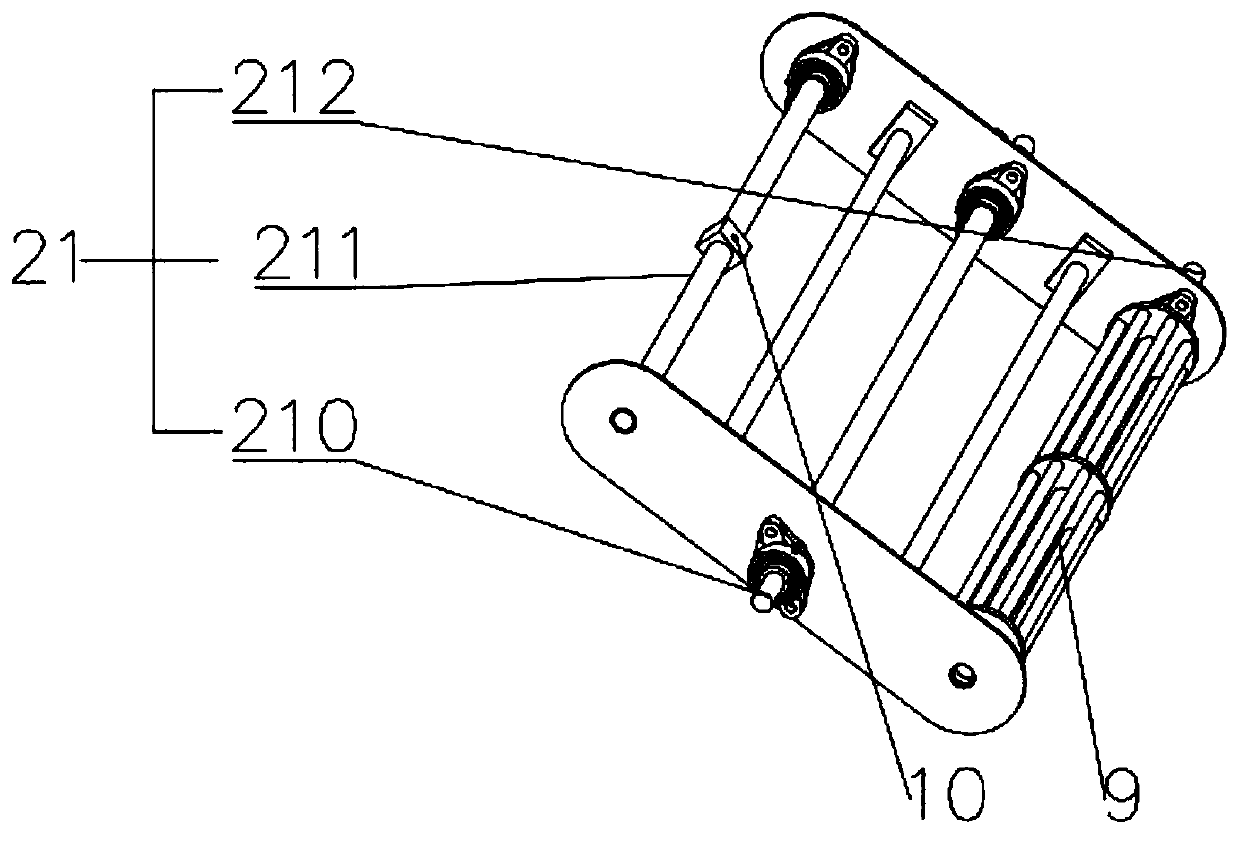

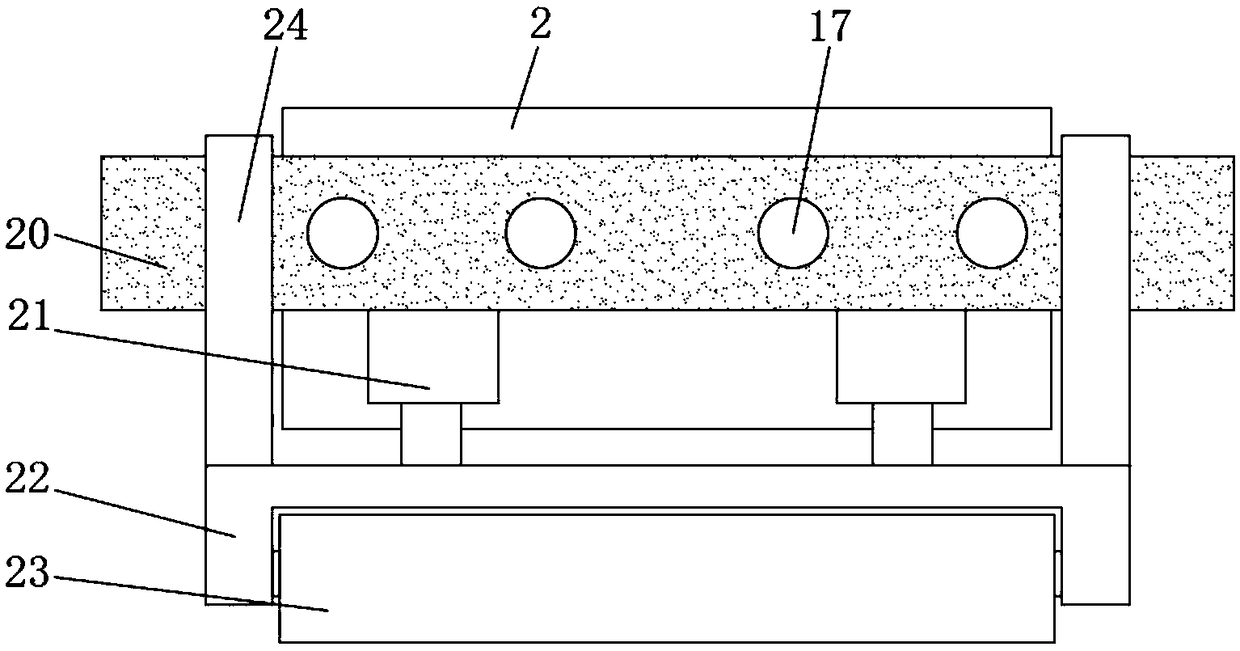

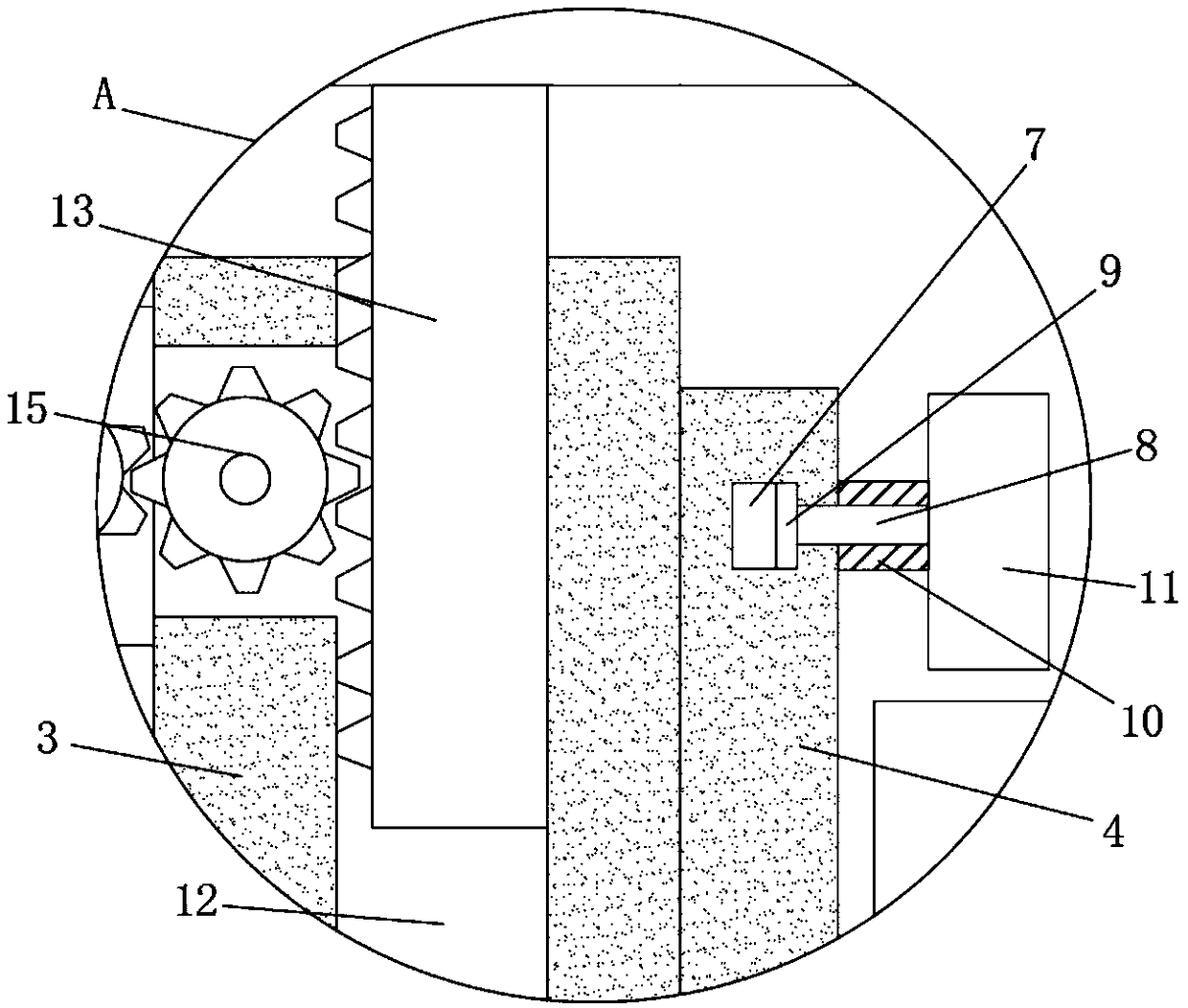

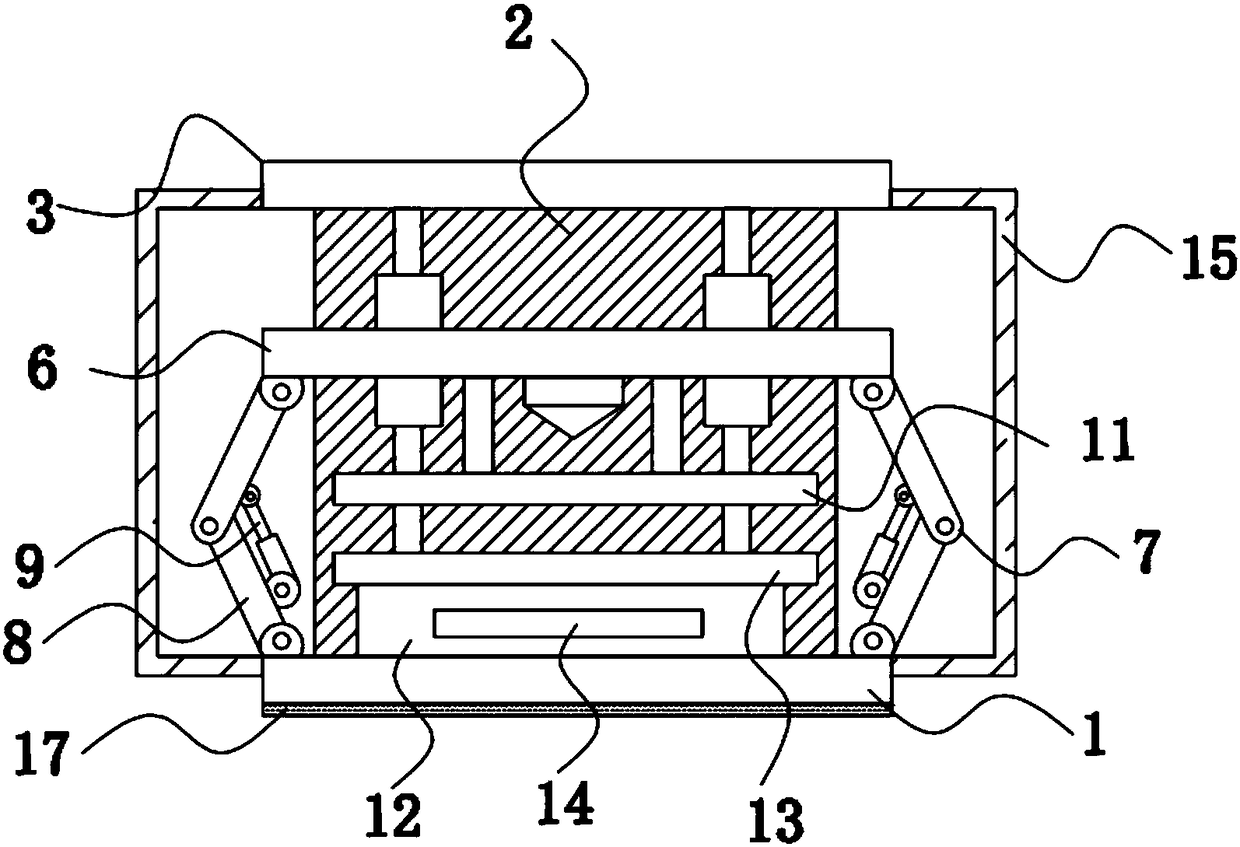

Cleaning type Printronix barcode printer achieving automatic replacement of print head

InactiveCN108177445AGood printing effectImprove securityTypewritersOther printing apparatusElectric machineryDistance sensors

The invention relates to a cleaning type Printronix barcode printer achieving automatic replacement of a print head. The cleaning type Printronix barcode printer achieving automatic replacement of theprint head comprises a shell and a color sensor. A rolling shaft, a supporting plate, a main print head, a moving mechanism, a telescopic mechanism, a grabbing mechanism, a washing mechanism, a firstpartition plate, a second partition plate and at least two standby print heads are arranged in the shell. The grabbing mechanism comprises a fixing plate, a first motor, a crank and two grabbing assemblies. A grabbing assembly comprises a drive rod, a driven rod, a supporting rod and a clamping block. The washing mechanism comprises a water spraying assembly and a rotating assembly. According tothe cleaning type Printronix barcode printer achieving automatic replacement of the print head, after the main moving head is moved to the position above a distance sensor on the supporting plate through the moving mechanism and the telescopic mechanism, the main print head is washed through the washing mechanism, residual accumulated thermal transfer ribbons in the main print head are removed, sothat the main print head is kept clean, and therefore the print effect of the Printronix barcode printer is better.

Owner:SHENZHEN ANSIKE ELECTRONICS TECH CO LTD

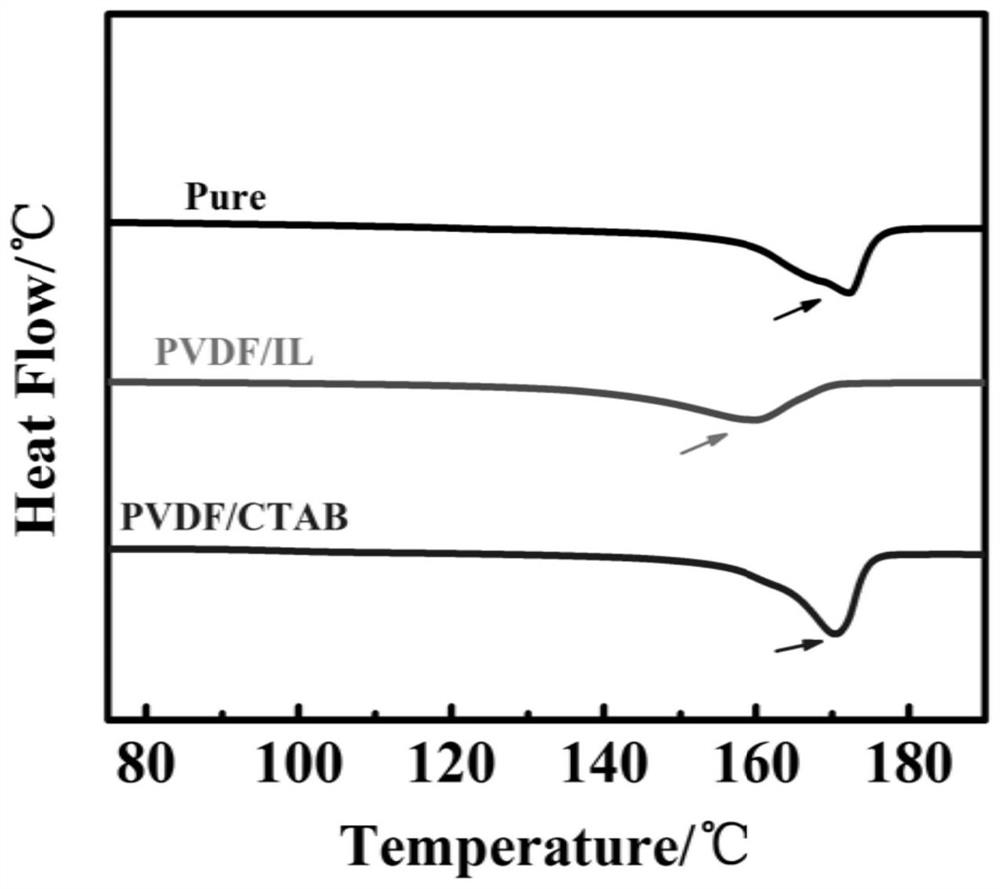

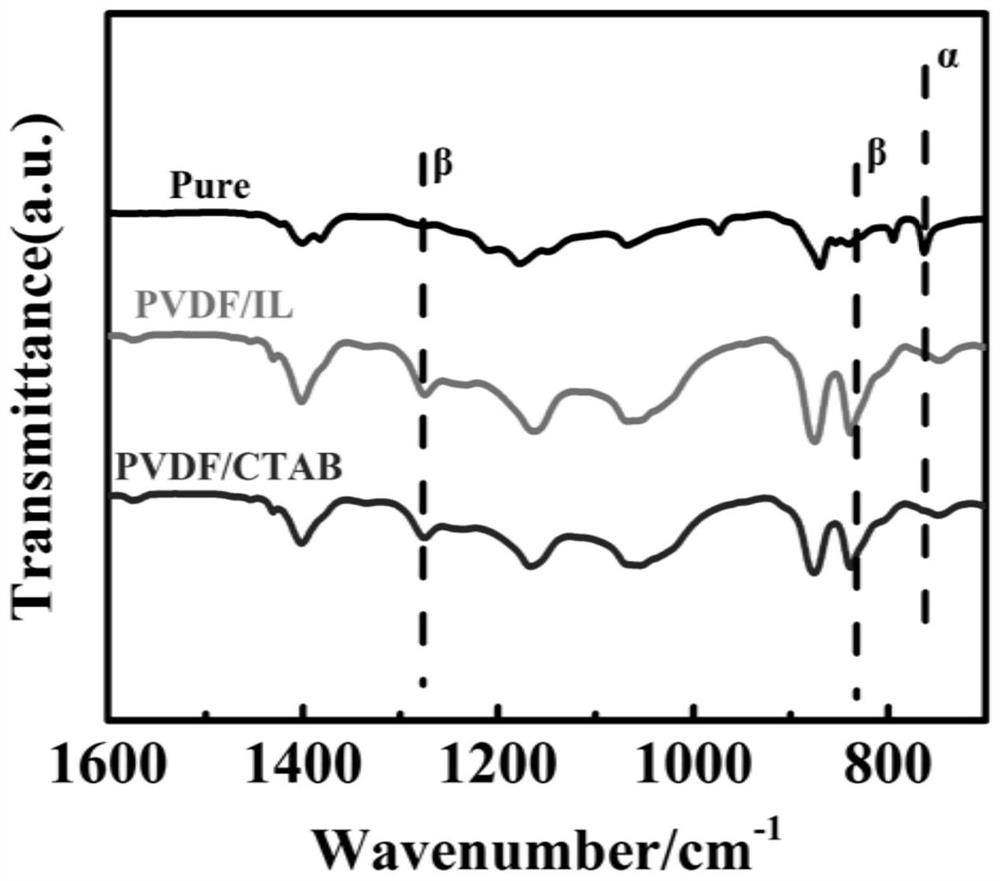

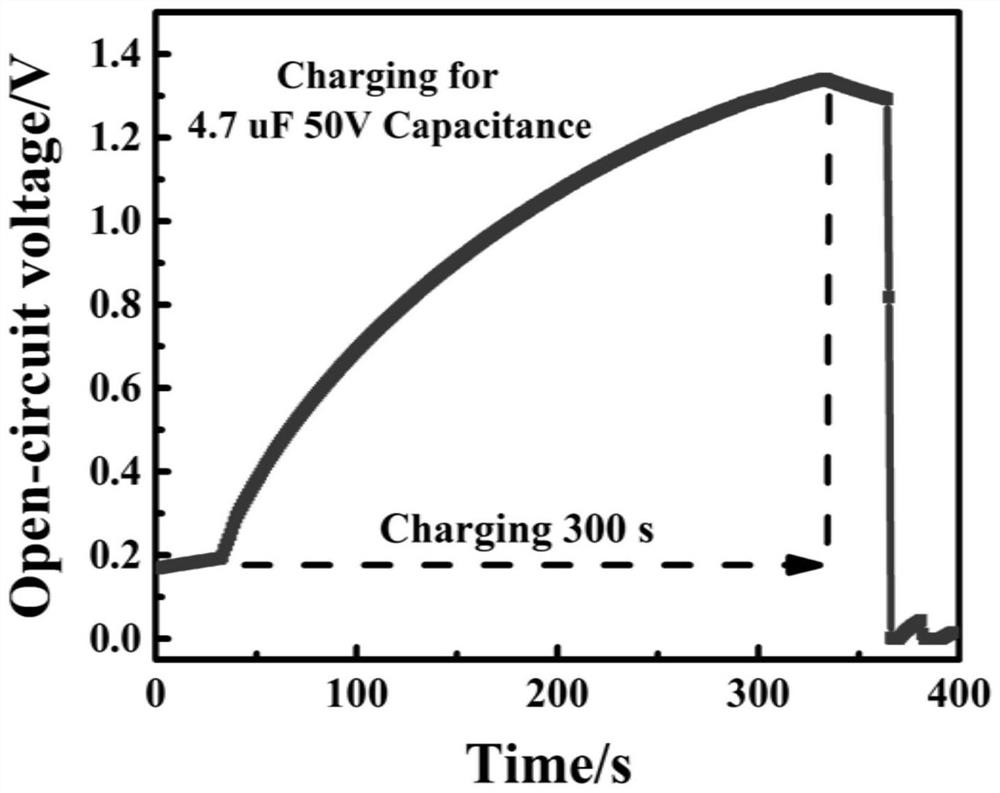

Fused deposition modeling 3D printing method of PVDF with high beta crystal content

ActiveCN112045992AIncrease β-crystal contentStrong ion-dipole interactions3D object support structuresManufacturing data aquisition/processingComputer printingNew energy

The invention discloses a fused deposition modeling 3D printing method of PVDF with high beta crystal content. The method comprises the following steps that firstly, PVDF and a modifier are uniformlymixed, then granulating is carried out, melt extrusion is carried out to form filaments, and the filaments are placed in an FDM 3D printer to obtain the product. According to the method, the modifiersuitable for the high-temperature melting condition is selected, the melting processing performance of the PVDF raw material and beta crystals in the PVDF are improved, and the PVDF material is endowed with excellent piezoelectric conversion performance; and the product prepared through the method can serve as a mechanical energy collecting device, a sensor, a driver and the like to be used in thefields of new energy harvesting, sensing, artificial intelligence and the like.

Owner:SICHUAN UNIV +1

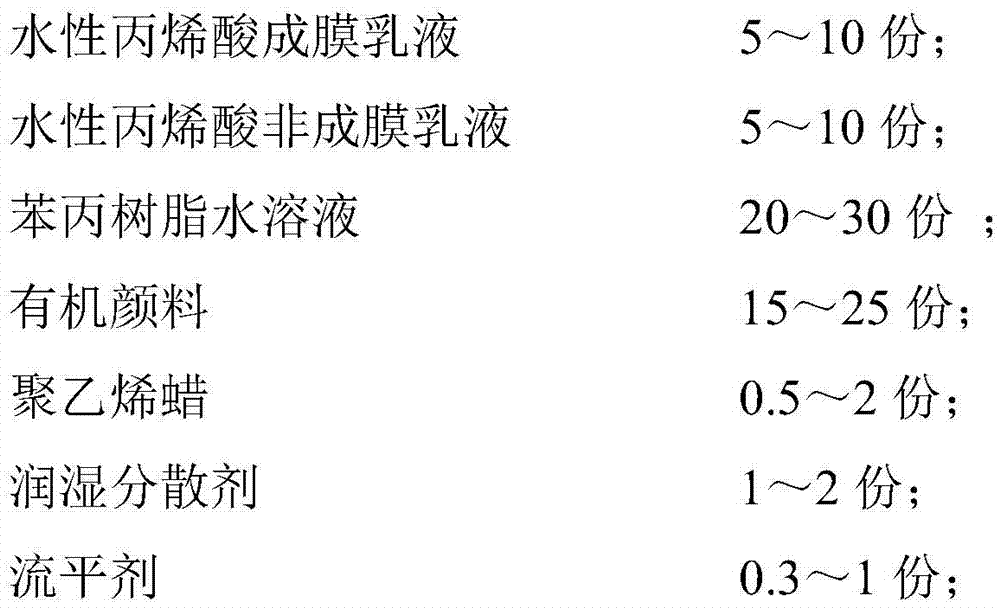

Gravure water-based ink for ivory board and printing method

The invention discloses gravure water-based ink for an ivory board and a printing method, and belongs to the field of water-based ink production. The ink is prepared by mixing water-based acrylic film-forming emulsion, water-based acrylic non-film-forming emulsion, a styrene-acrylic resin aqueous solution, organic pigments, polyethylene wax, a wetting dispersant, a levelling agent, a PH value regulating agent, a defoaming agent and water and has the advantages of being good in stability and the like. In the printing process, ultraviolet irradiation is performed in a matched mode, therefore, the performance indexes of a printed product on the aspects such as the glossiness and the levelling property are all obviously improved, and the very good application and popularization value is achieved.

Owner:JINAN QUANYONG PRINTING

3D printer

ActiveCN112959657ASolve precise controlHigh movement accuracyManufacturing heating elements3D object support structuresThermal dilatationComputer printing

The invention relates to the technical field of printing equipment, in particular to a 3D printer which comprises a bottom frame. Multiple sets of vertical frames are arranged at the top of the bottom frame, a top frame is arranged between any two vertical frames, a cross beam is arranged between the top frames through a Y-axis controller, and an X-axis controller on the outer surface of the cross beam is slidably connected with a printing device; and a bottom plate is arranged at one side of each top frame through a Z-axis controller, the printing device comprises a booster, a raw material pipe is slidably connected into the booster, a heating cavity is formed in the bottom of the booster, the bottom of the heating cavity communicates with a flowing cavity, and a temperature sensor is arranged in the flowing cavity and used for detecting the internal temperature of the flowing cavity. According to the 3D printer, the current value of an electromagnet is controlled to change a gap between a heat-resistant magnetic ball and a spray head and change the volume of a molten material flowing out of the spray head, the material thermal expansion principle is combined, the material volume is increased when the temperature rises, the needed shape and volume are obtained after cooling, the printing effect is good, and the printing precision is high.

Owner:深圳市俩棵树科技有限公司

Essence for dispelling acne traces

InactiveCN111329828AInhibition formationInhibition of value addedCosmetic preparationsToilet preparationsCentella asiatica extractGlycyrrhiza inflata root extract

The invention discloses essence for dispelling acne traces, and relates to the technical field of cosmetics. The essence comprises the following components of water, butanediol, a PEG / PPG-17 / 6 copolymer, nicotinamide, a centella asiatica extract, PEG / PPG / polytetramethylene glycol polytetramethylene glycol-8 / 5 / 3 glycerine, a radix sophorae yellowish sophora extract, a glycyrrhiza inflata root extract, a scutellariae extract, glycerine, a harba dendrolii nobilis stem extract, an aloe vera leaf extract, a lycium barbarum l. fruit extract, a purple echinacea Echinacea purpurea extract, 1,2-hexanediol,hydroxyacetophenone, phenoxyethanol, carbomer, triethanolamine, sodium hyaluronate, PEG-40 hydrogenated castor oil and cananga odorata flower oil. The nicotinamide in the raw materials has the efficacy of resisting inflammation and dispelling melanin, and can lighten acne traces, besides, components of the centella asiatica extract and the like are added, so that wound healing can be promoted,and the regeneration capacity of skin can be strengthened. Through effective combination of restraining melanin and repairing regenerated skin and muscle, the purpose of dispelling acne traces can beachieved, and the effect of dispelling acne traces is good.

Owner:南京苗邦美业企业管理有限公司

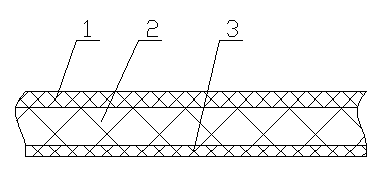

Novel spray-painted advertisement lamp box fabric

ActiveCN102794957AGood printing effectEnvironmentally friendlySynthetic resin layered productsHigh-density polyethyleneWoven fabric

The invention relates to novel spray-painted advertisement lamp box fabric. The novel spray-painted advertisement lamp box fabric comprises a blended modified plastic laminated film layer (1), low-pressure high-density polyethylene woven fabric (2) and a high-pressure low-density polyethylene laminated film layer (3), wherein the blended modified plastic laminated film layer (1) is arranged on the front surface of the low-pressure high-density polyethylene woven fabric (2), and the high-pressure low-density polyethylene laminated film layer (3) is arranged on the reverse surface. The novel spray-painted advertisement lamp box fabric disclosed by the invention has the advantages of good environment-friendly performance, low temperature resistance and printing effect, can be compatible with four types of ink printing, namely solvent type, weak solvent type, UV (ultraviolet) curing type and Latex type, and can withstand the expose to sun and rain.

Owner:江苏耐斯数码科技股份有限公司

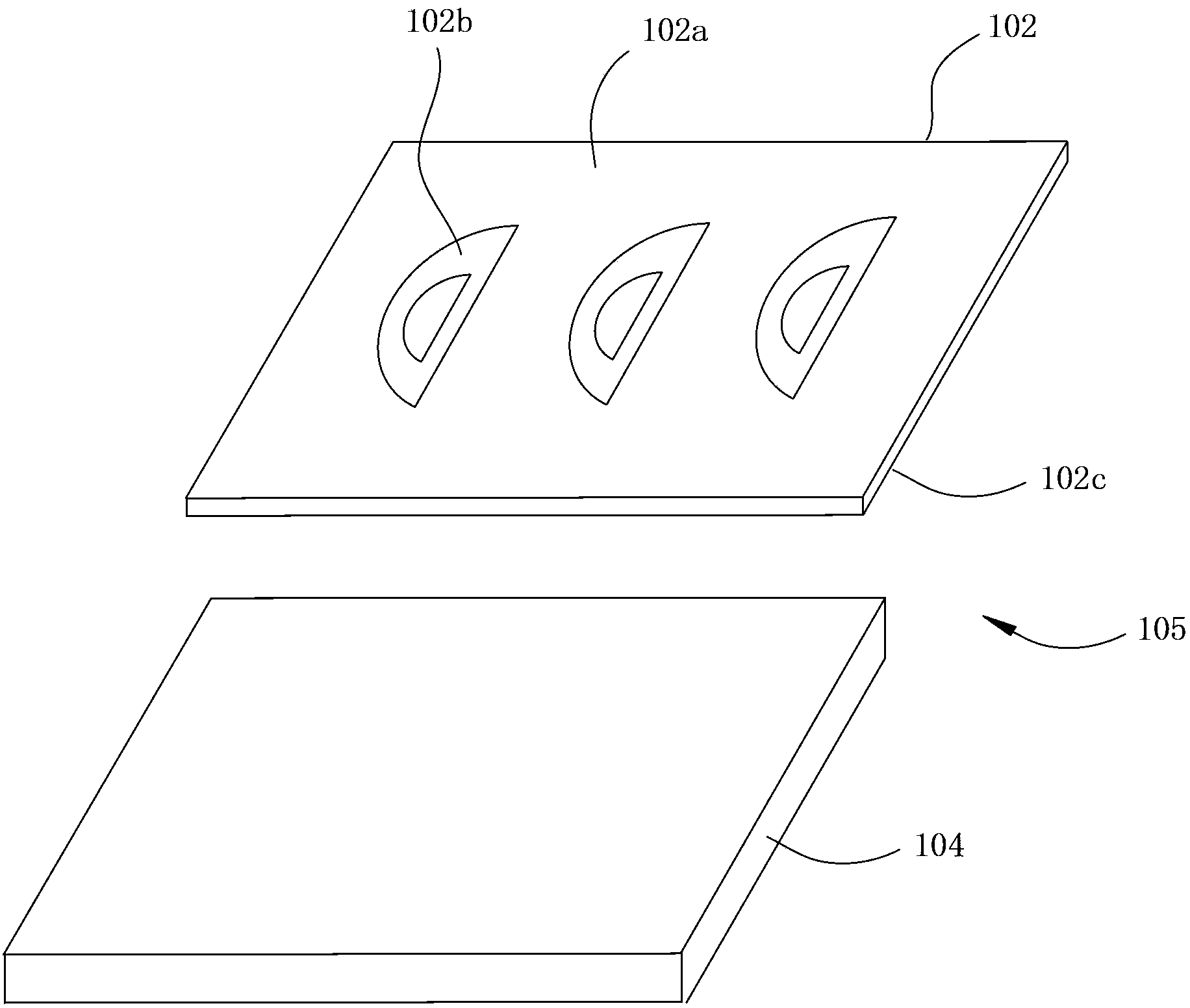

Three-dimensional concave-convex grain printing process

ActiveCN104044375AGood printing effectImprove appearance qualityPattern printingOther printing apparatusEngineeringTransfer printing

The invention relates to a three-dimensional concave-convex grain printing process, which comprises the following steps that S1, according to requirements, a three-dimensional concave-convex grain drawing file is designed; S2, a first flexographic plate and a second flexographic plate corresponding to the three-dimensional concave-convex grain drawing file are output through automatic plate discharging equipment; S3, the first flexographic plate is pasted on a first hard plate for forming a production mother plate; S4, the second flexographic plate is pasted on a second hard plate for forming a production bottom plate; S5, three-dimensional concave-convex grain semi-finished products are produced by utilizing the production mother plate through a UV (ultraviolet) transfer printing process; S6, the three-dimensional concave-convex grain semi-finished products are pasted and fixed with the production bottom plate, and colors are printed on the three-dimensional concave-convex grain semi-finished products; S7, processing forming is carried out, and finished products are formed. The three-dimensional concave-convex grain printing process has the advantages that a better printing effect can be achieved, and the appearance quality of the three-dimensional concave-convex grains is improved.

Owner:CYMMETRIK SHENZHEN PRINTING

Chromo board paint special for electrostatic printing and application thereof

InactiveCN106120444AImprove resistance performanceGood printing effectDefoamers additionCoatings with pigmentsColor saturationDefoaming Agents

The invention discloses a special coating for electrostatic printing copper plates, which is composed of the following components by mass: 100 parts of pigment; 10-15 parts of latex; 0.01-2 parts of defoaming agent; 0.01-2 parts of rheological agent; 0.01-2 parts; paper resistance regulator 1-5 parts; whitening agent 0.5-3 parts; fungicide 0.01-2 parts; pH regulator 0.01-3 parts. The present invention forms a high-resistance coating on the surface of the copperplate card through the action of the paper surface resistance regulator in the coating, which not only ensures the original printing properties of the copperplate card, but also improves the resistance performance of the paper coating, so that the paper is in the process of electrostatic printing. The printing effect is good, the color saturation is good, the dots are clear, and the copper cardboard has better quality as a printing cover.

Owner:GOLD HUASHENG PAPER SUZHOU IND PARK

Vacuum aluminized paper

InactiveCN103397573AModerate increaseHigh strengthFlexible coversWrappersEpoxyPulp and paper industry

The invention discloses a vacuum aluminized paper and relates to the package material field. The vacuum aluminized paper comprises a base layer and an aluminized layer. The vacuum aluminized paper is characterized in that the thickness of the aluminized layer is 0.05-0.075 micron; a pull-resisting layer is arranged between the base layer and the aluminized layer; the pull-resisting layer is made of composite materials of epoxy resins and phenyl ether. The vacuum aluminized paper can be applied in the food and medicine packaging fields, and has good flexibility and pull resistance. The intensity of the paper can be ensured and damage can be prevented. The vacuum aluminized paper is an environmental protection material with air blocking performances of aluminum foil composite papers.

Owner:KUNSHAN RONGAO WEIJIE TRADE

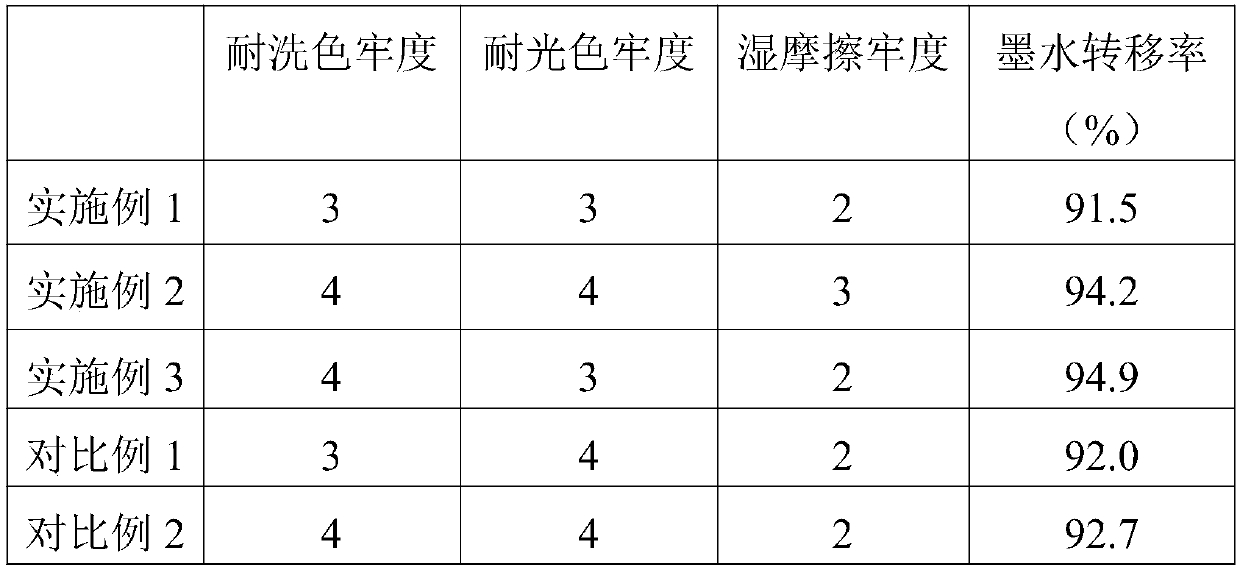

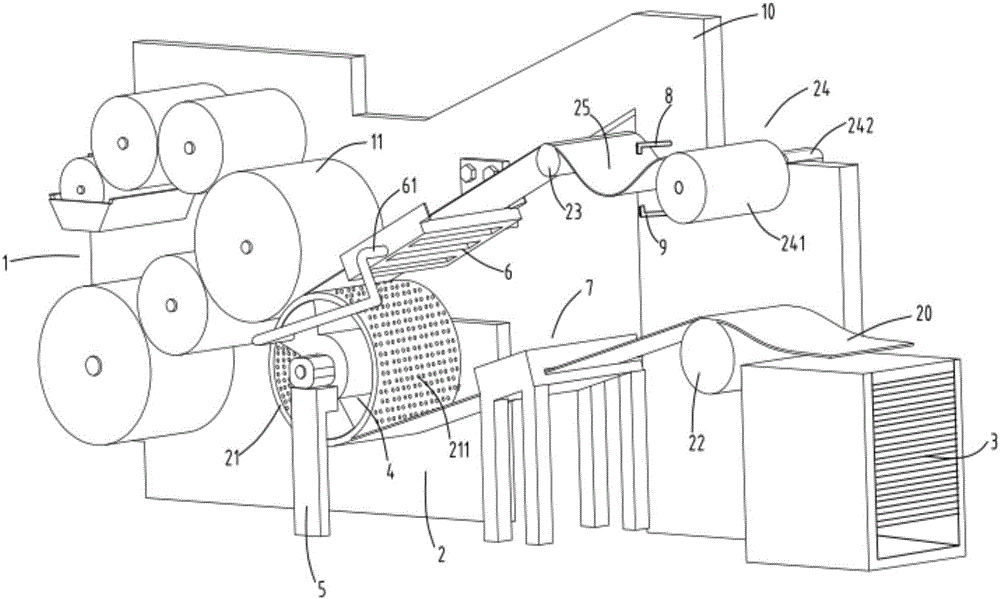

High-efficiency digital transfer process for fabrics

ActiveCN107630371AGood printing effectGood dispersionTransfer printing processDyeing processPrinting inkEngineering

The invention discloses a high-efficiency digital transfer process for fabrics. The high-efficiency digital transfer process comprises the following steps: (S1) carrying out jet-printing, namely jet-printing ink on transfer paper; (S2) transferring: (S3) ageing; and (S4) cooling. The high-efficiency digital transfer process disclosed by the invention has the advantages that firstly, proper dispersing agent and color fixing agent are selected to prepare ink with high dispersion and high stability, the influences of the type and the use amount of the dispersing agent and the color fixing agent on the fabric dyeing and printing properties are explored, clean production and anhydrous production of the fabric dyeing and printing procedures can be realized, so that the emission of industrial sewage is nearly zero, the printing effect is good and all properties meet the requirements.

Owner:SHANGHAI YONGZI FASHION

Double-layer printing technology

InactiveCN107458105AImprove permeabilityGood printing effectPattern printingOther printing apparatusPrinting inkDyeing

The invention discloses a double-layer printing technology. The double-layer printing technology comprises the following steps that printing ink I and printing ink II are correspondingly heated to 40-60 DEG C and then are maintained 3-4 hours, and mixing of the printing ink is conducted, specifically, 30 parts by weight of the printing ink I and 40 parts by weight of the printing ink II are dissolved in 20 parts by weight of activator. The double-layer printing technology has the beneficial effects that according to the double-layer printing technology, existing single printing is changed into double circulating, surface printing is conducted twice to achieve printing surface stereo effect, a decorative film printed is more beautiful, and the permeability on the decorative film of printing ink on the decorative film is high, so that the dyeing and printing effects on the decorative film of the printing ink is better.

Owner:山东尚品家居配饰制造有限公司

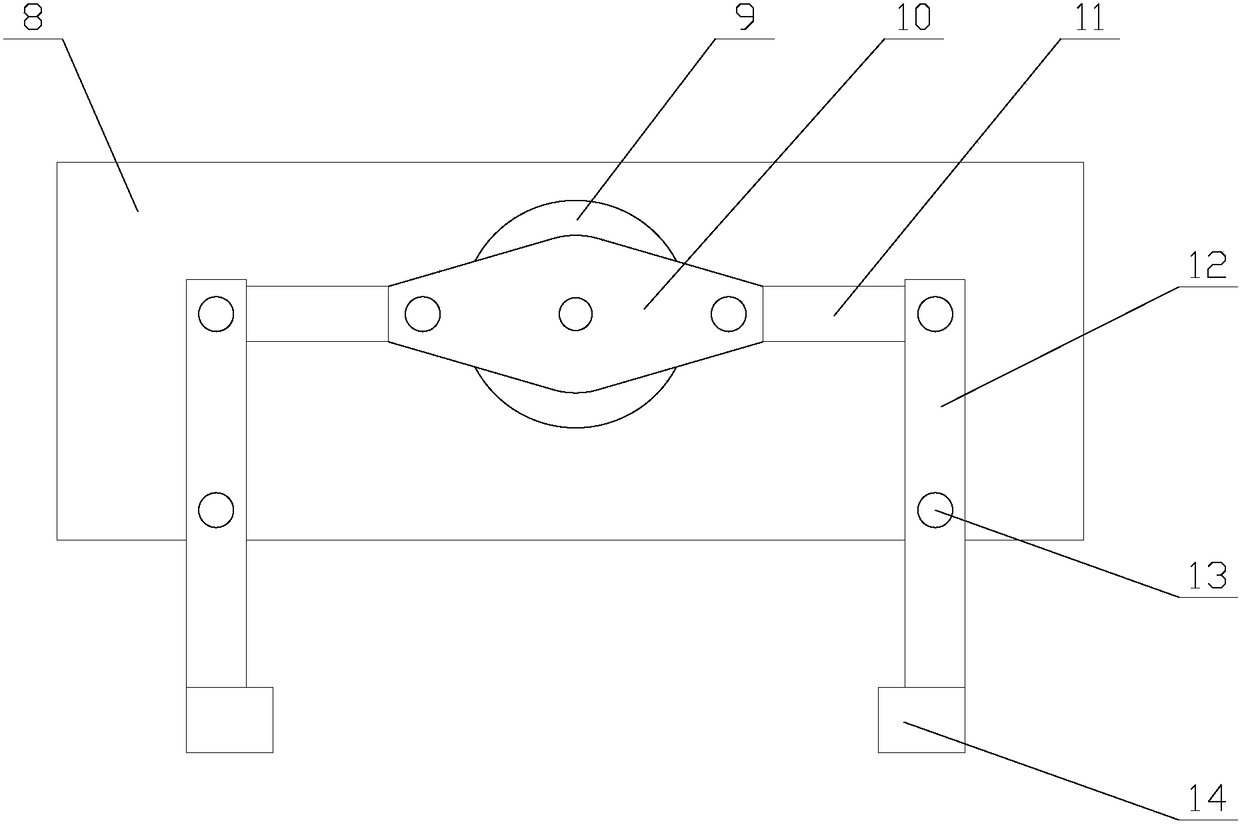

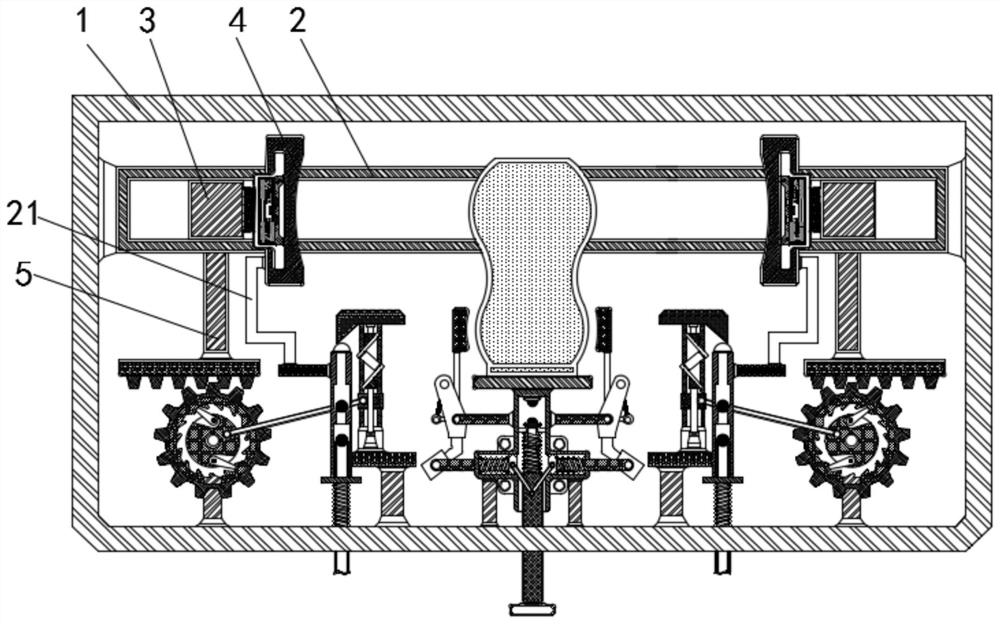

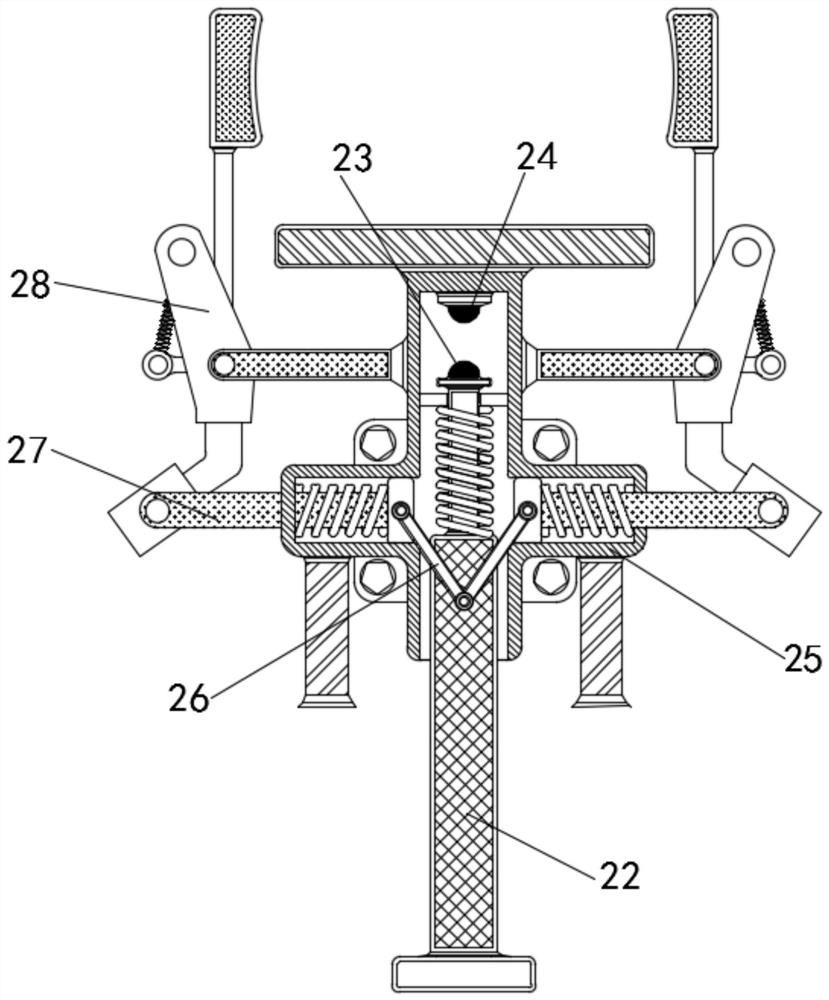

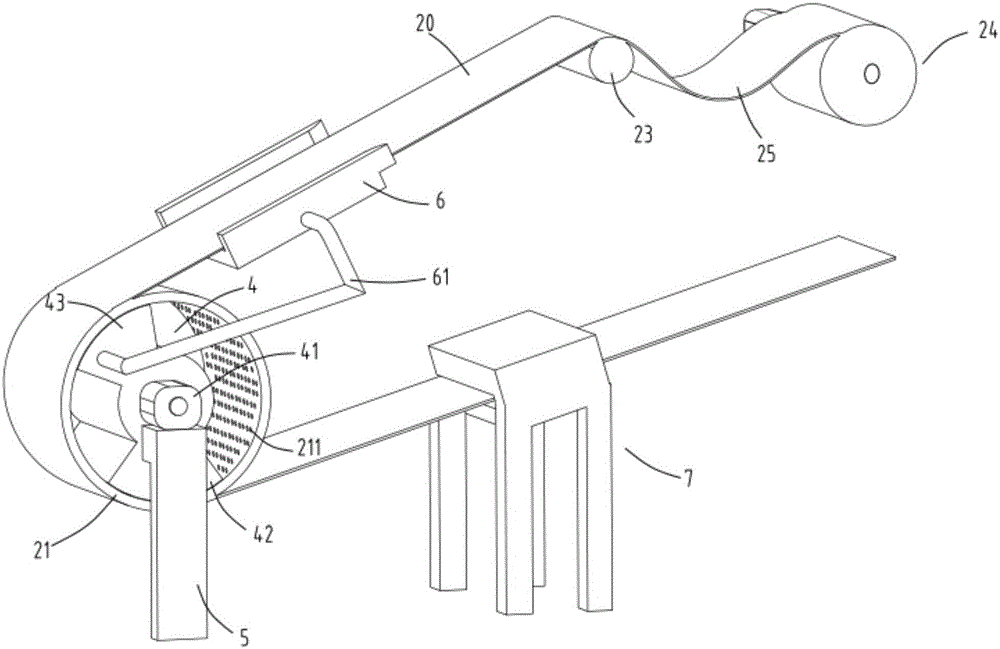

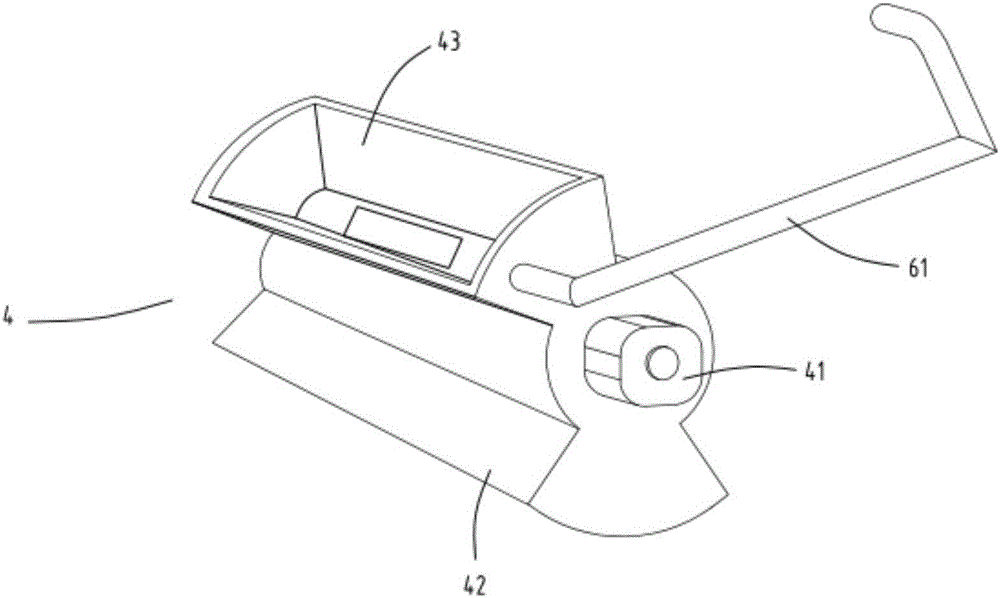

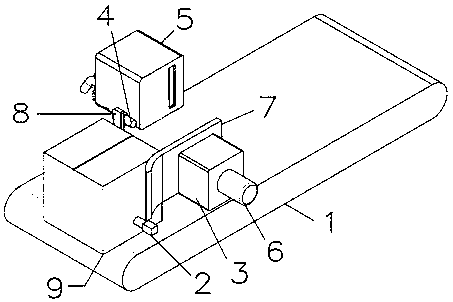

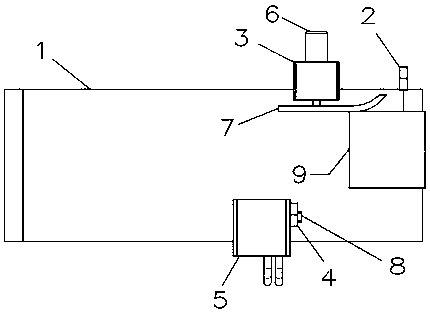

Shape flattening and information visual detection machine for bagged products

InactiveCN110252684AReduce error rateGood printing effectTypewritersOther printing apparatusDrive motorVisual perception

The invention provides a shape flattening and information visual detection machine for bagged products. The shape flattening and information visual detection machine comprises a worktable, wherein the worktable is also provided with a flattening mechanism and a detection module; the flattening mechanism comprises a supporting frame, a first flattening part, a second flattening part and a driving motor; the supporting frame is fixedly connected to the worktable; the driving motor is fixedly arranged at the top of the supporting frame; the first flattening part is movably connected to the supporting frame; in addition, the second flattening part is also movably connected to the supporting frame; a first synchronous belt is arranged on one side of the first flattening part; a first synchronous pulley matched with the first synchronous belt is also fixedly connected to one side of the second flattening part; the first flattening part is movably connected with one side of the second flattening part through the first synchronous pulley and the first synchronous belt. According to the shape flattening and information visual detection machine provided by the invention, though automatic detection of the detection module, the working efficiency of detection is improved and the error rate of traditional artificial naked-eye detection is reduced.

Owner:武汉楚锐视觉检测科技有限公司

Embossing machine for plate processing

The invention discloses an embossing machine for plate processing, and relates to the technical field of plate processing. The embossing machine comprises a base and a mounting frame; two sides of thetop end of the base are fixedly connected with fixed columns; the inner sides of the fixed columns are fixedly connected with fixed parts; the lower ends of one sides of the fixed parts are fixedly connected with checkered plates; first grooves are formed in the upper ends of one sides of the fixed parts; expansion links are arranged in the first grooves; one ends of the expansion links are fixedly connected with spacing blocks; the other ends of the expansion links penetrate through the fixed parts and are fixedly connected with stop dogs; the expansion links are circumferentially provided with springs; second grooves are formed in the upper ends of the fixed columns; adjustment rods are arranged in the second grooves; and the upper ends of the adjustment rods penetrate through the fixedcolumns and are fixedly connected with fixed plates. According to the embossing machine for plate processing, different patterns can be changed through setting the fixed parts and the checkered plates, so that the diversity of the embossing machine is increased; and through setting the adjustment rods and the fixed plates, the clamping height and force are decided according to the thicknesses ofplates, so that the aim of being multifunctional is realized.

Owner:湖州亚信科技孵化有限公司

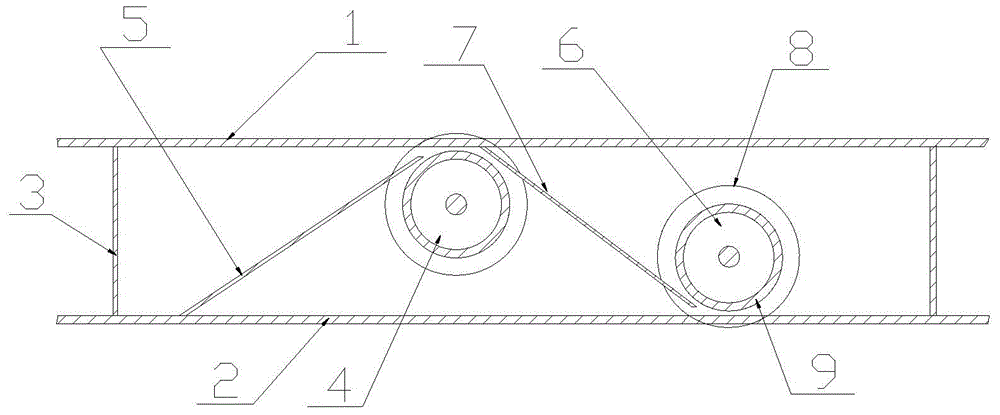

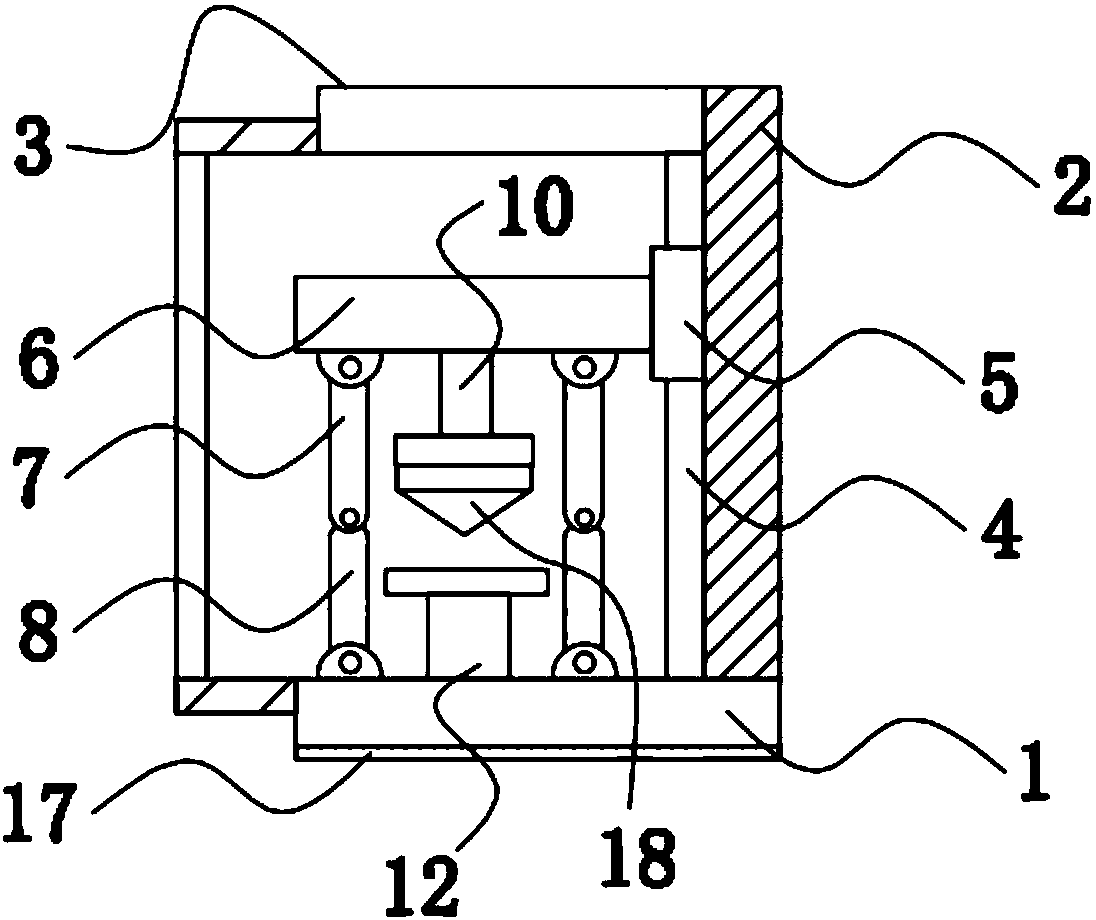

Paper leveling device of printer

InactiveCN104309330AGood printing effectSimple structureOther printing apparatusLeveling mechanismPulp and paper industry

The invention discloses a paper leveling device of a printer. The paper leveling device of the printer mainly comprises an upper plate, a lower plate and a connecting rod, wherein the upper plate and the lower plate are fixedly connected through the connecting rod. A leveling mechanism is arranged between the upper plate and the lower plate and comprises a first roller, a first inclined plate, a second roller and a second inclined plate. The first inclined plate is arranged on the lower plate and the inclined direction of the first inclined plate is identical to the paper feeding direction. One end of the first inclined plate is fixedly connected with the lower plate. The first roller is arranged behind the first inclined plate and tangential to the upper plate. The second inclined plate is arranged behind the first roller and the inclined direction of the second inclined plate is identical to the paper feeding direction. One end of the second inclined plate is fixedly connected with the upper plate. The second roller is arranged behind the second inclined plate and tangential to the lower plate. The paper leveling device of the printer can level paper before printing and is simple in structure, easy to use and good in leveling effect.

Owner:CHENGDU AIWEI KECHUANG TECH

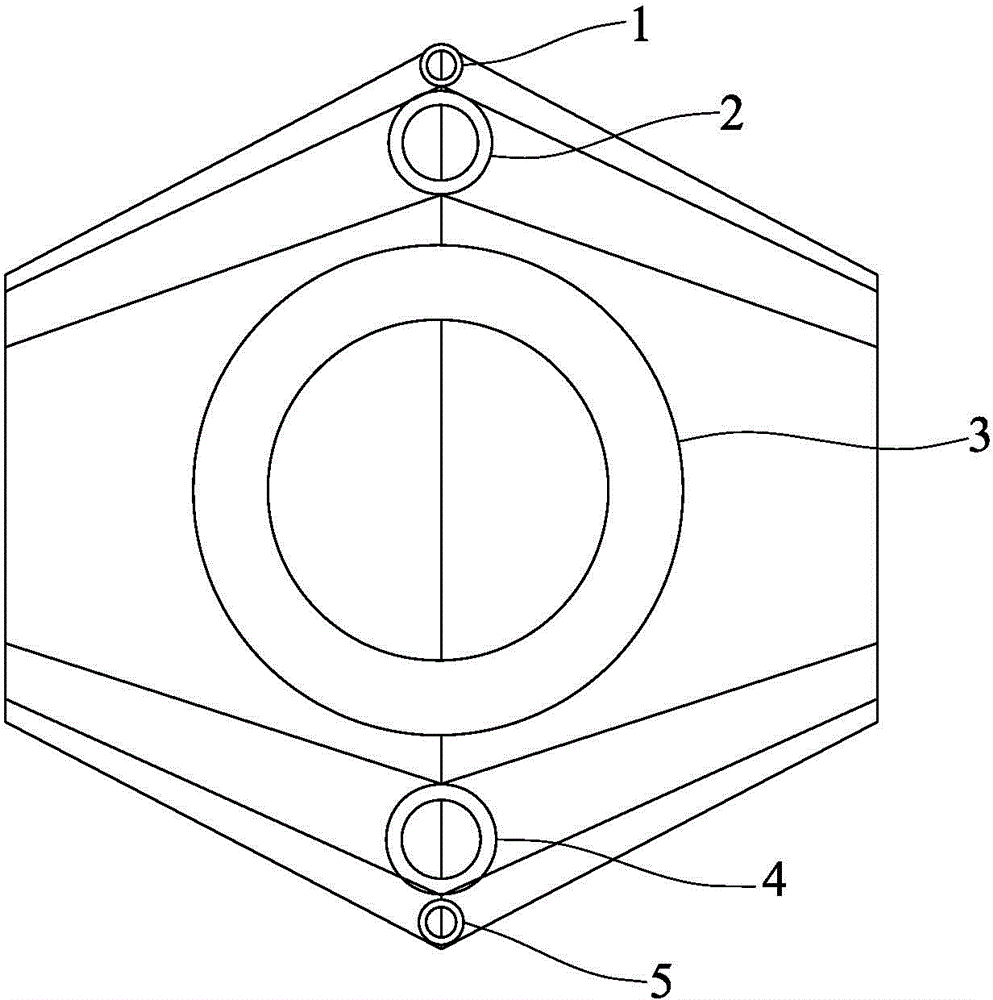

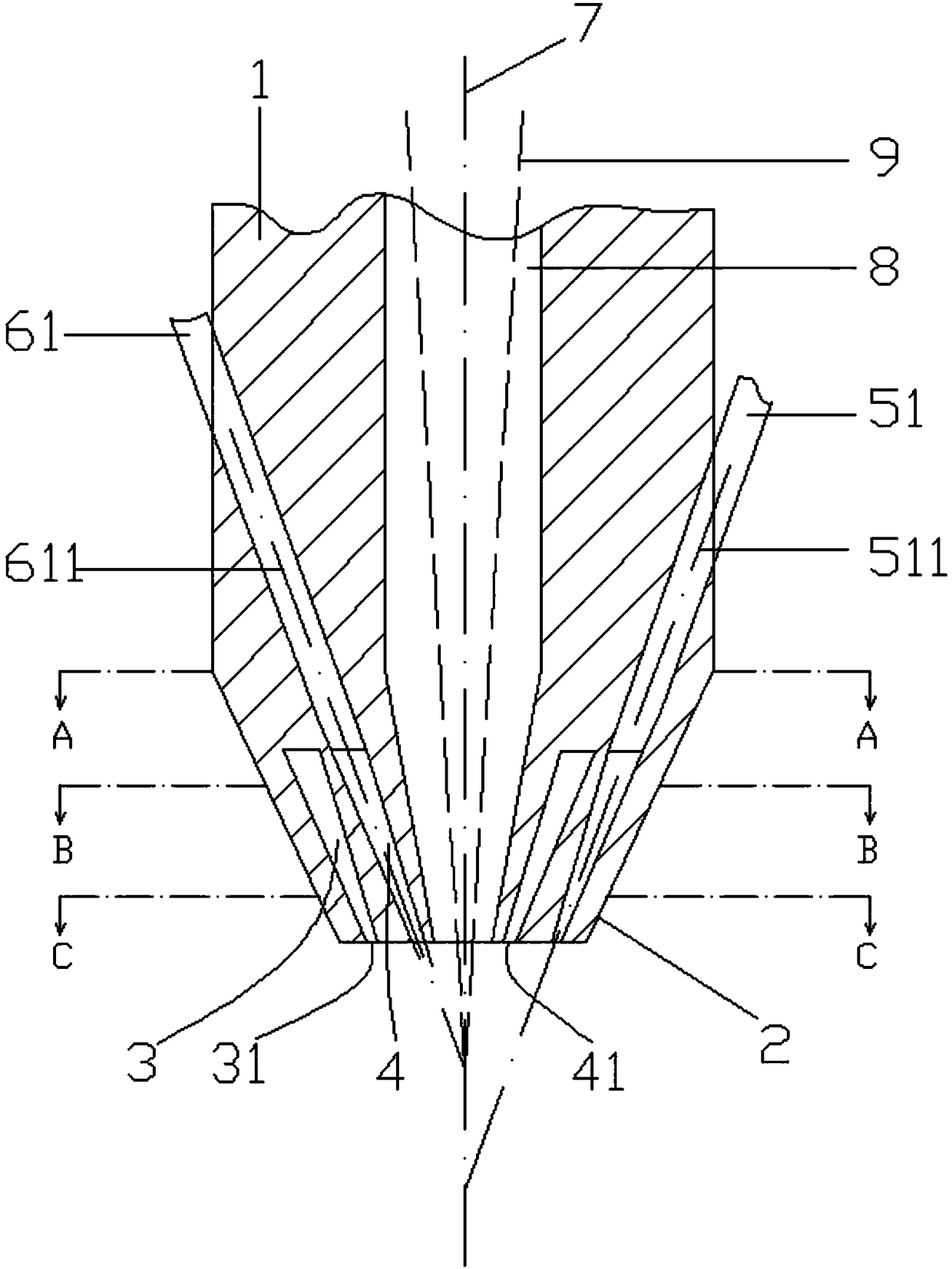

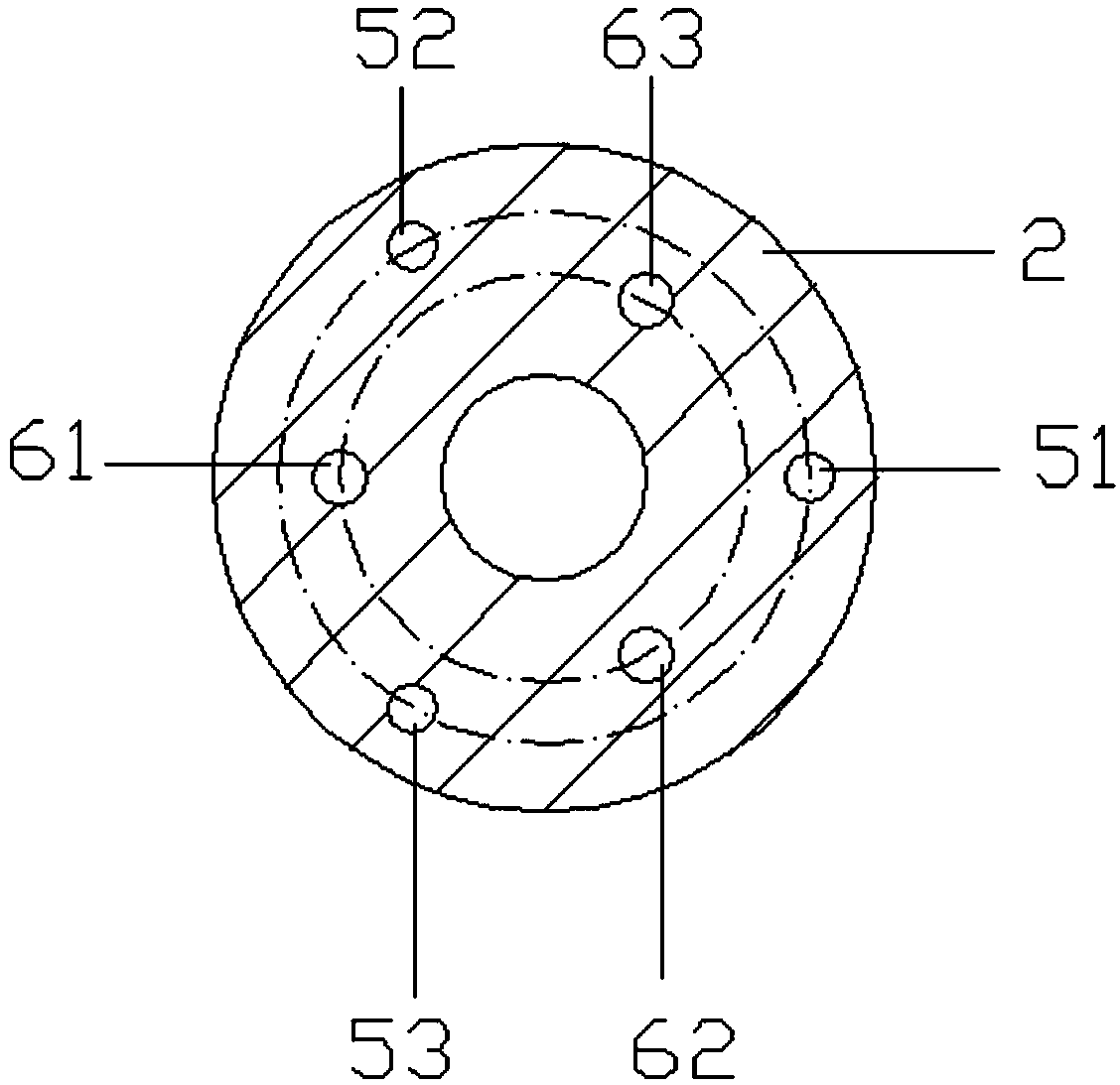

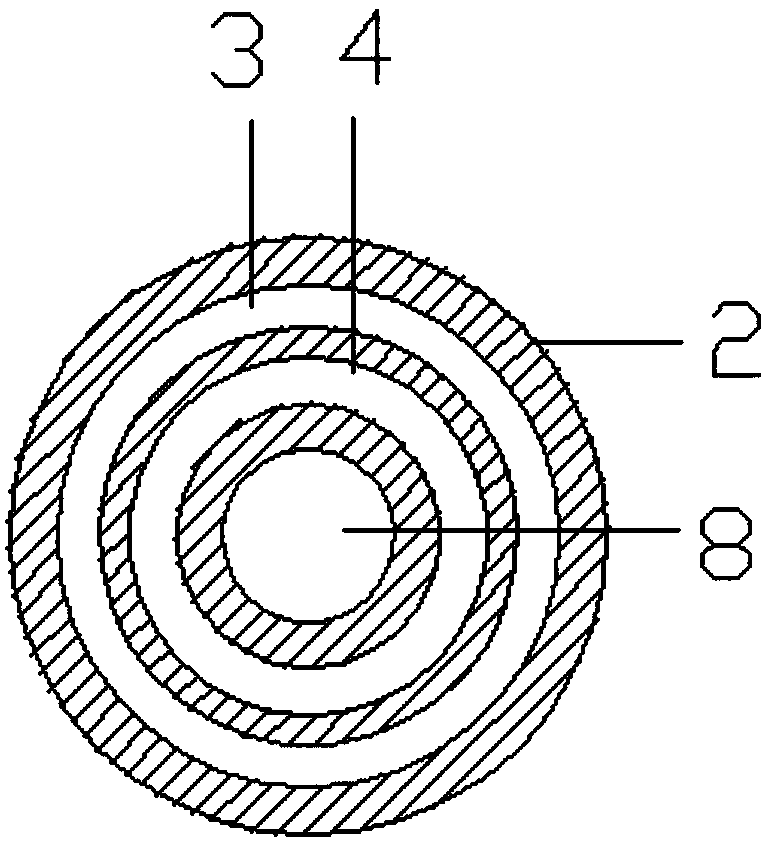

Metal powder laser 3D printing nozzle

PendingCN108127118ASimple structureGood printing effectAdditive manufacturing apparatusIncreasing energy efficiencyLaser beamsLight beam

The invention discloses a metal powder laser 3D printing nozzle. A first annular cavity and a second annular cavity are formed in a nozzle head, the second annular cavity is located on the inner sideof the first annular cavity, and the first annular cavity forms a first annular cavity opening in the lower portion of the nozzle head; the second annular cavity forms a second annular cavity openingin the lower portion of the nozzle head; a laser beam is focused on a dot; and a first metal powder conveying pipe, a second metal powder conveying pipe and a third metal powder conveying pipe are distributed on the nozzle head in an annular array by taking the circle center of the cone-shaped nozzle head as a center, and an included angle between every protective gas conveying pipe and the metalpowder conveying pipe correspondingly adjacent to the protective gas conveying pipe is 60 degrees. A laser is used for carrying out hot melting on the metal powder so as to realize 3D printing and curing, the hot-melt metal powder is prevented from being oxidized under the protection of inert gases, the structure is simple, and the printing effect is good during actual application.

Owner:ZHEJIANG WANFENG TECH DEV CO LTD

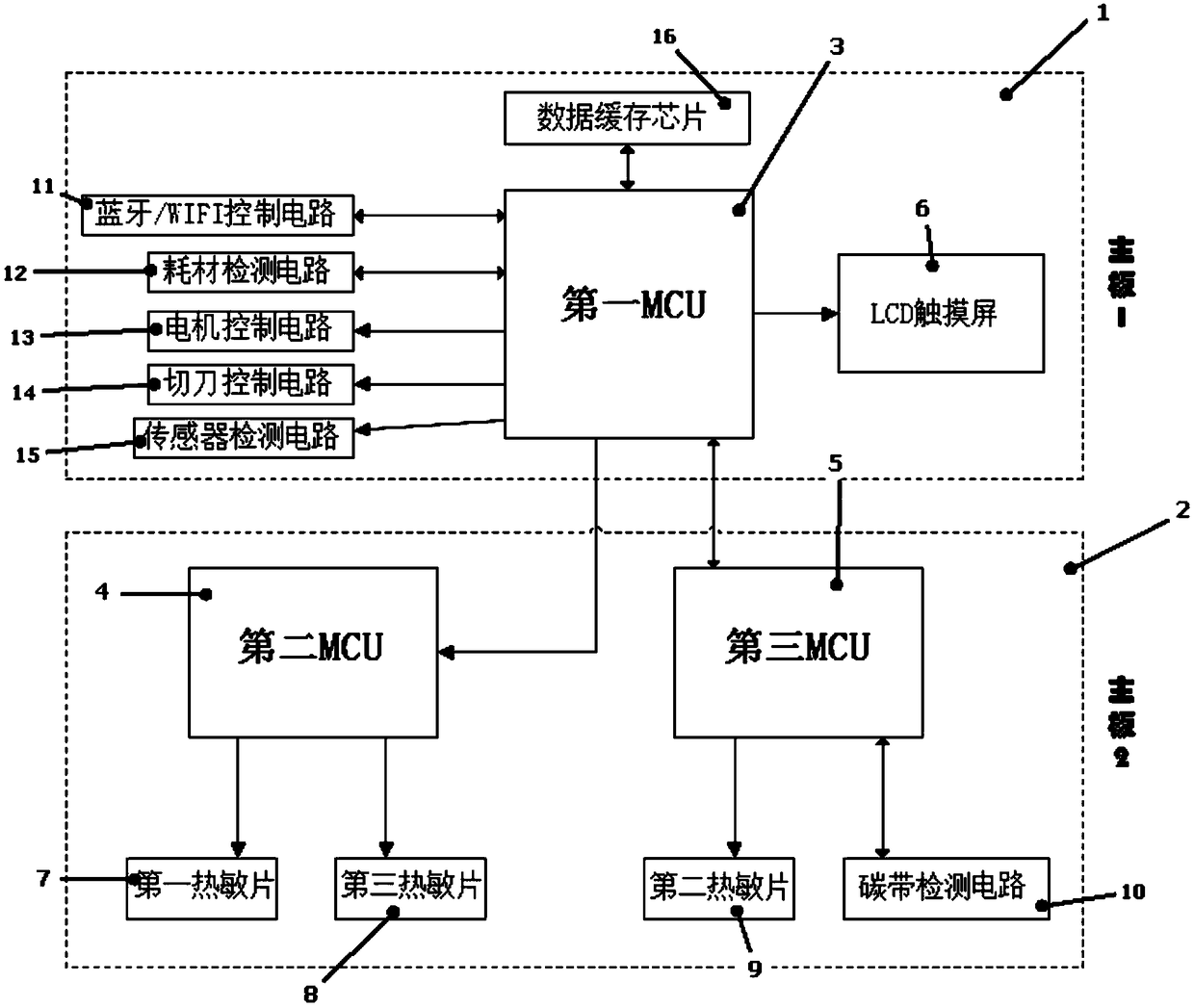

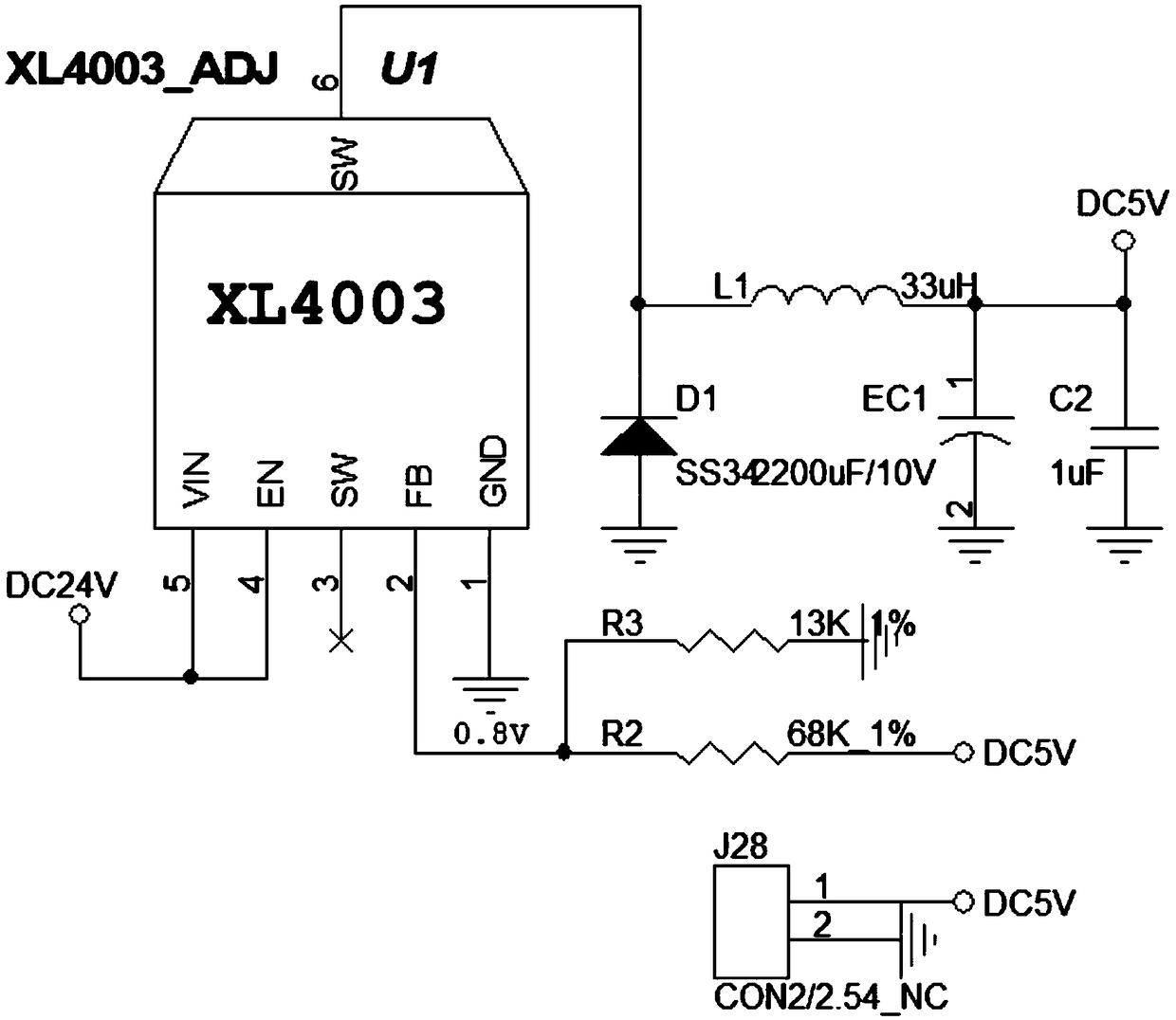

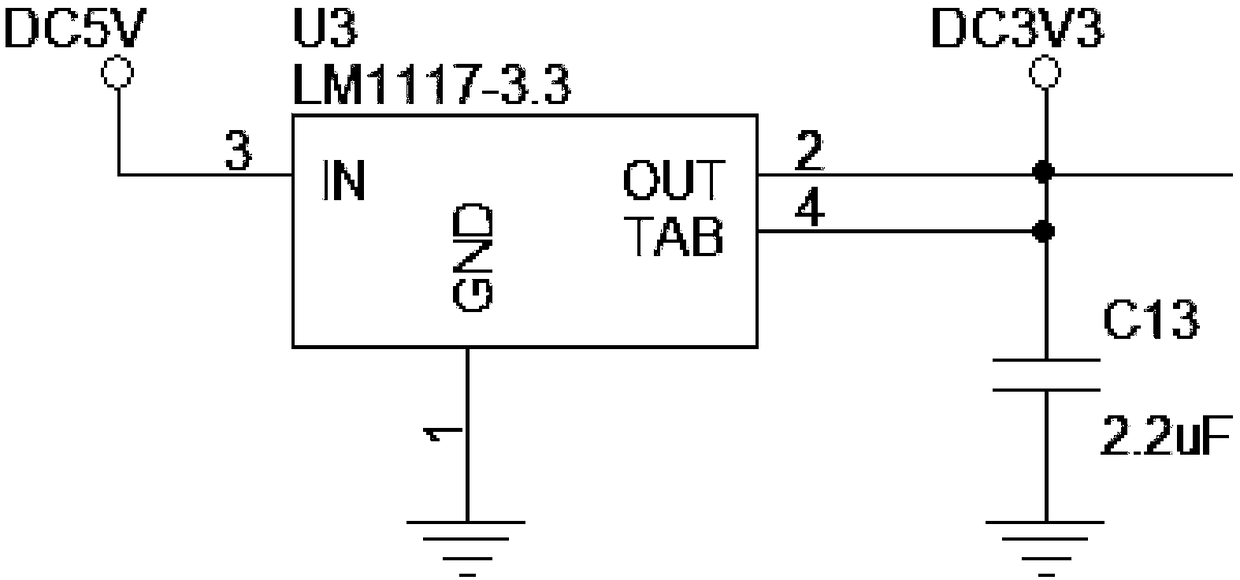

Hardware system of printer

PendingCN109484038AGood printing effectImprove printing effectOther printing apparatusElectricityControl circuit

The invention discloses a hardware system of a printer. The hardware system of the printer comprises a first MCU, a second MCU, a third MCU, a data cache chip, a wireless control circuit, a consumabledetection circuit, a motor control circuit, a cutter control circuit, a sensor detection circuit, a touch screen, a first thermosensitive chip, a second thermosensitive chip, a third thermosensitivechip and a thermal transfer ribbon detection circuit; the first MCU is electrically connected with the second MCU, the third MCU, the data cache chip, the wireless control circuit, the consumable detection circuit, the motor control circuit, the cutter control circuit, the sensor detection circuit and the touch screen; the second MCU is electrically connected with the first thermosensitive chip and the third thermosensitive chip; and the third MCU is electrically connected with the second thermosensitive chip and the thermal transfer ribbon detection circuit. According to the printer, large-format printing can be achieved, a printed nameplate can be kept for a long term, and the printing effect is good.

Owner:深圳市美松智能设备有限公司

Toy printing device capable of automatically supplying ink and stably printing

InactiveCN112918087AStable printingReduce manpower consumptionRotary pressesOther printing apparatusTextile printerProcess engineering

The invention relates to the technical field of printing, and discloses a toy printing device capable of automatically supplying ink and stably printing. The device comprises a machine body, wherein a first rail is connected to the inner side of the machine body, a first driving block is slidably connected to the inner side of the first rail, a printing head is connected to the right side of the first driving block, a first pipeline is arranged on the lower left side of a cam, a first metal ball is arranged on the inner side of the first pipeline, a second pipeline is connected to the inner side of the first pipeline below the first metal ball, a second metal ball is arranged on the upper side of the second pipeline, a third pipeline is connected to the left side of the first pipeline, and a hose is connected to the upper side of the third pipeline. According to the toy printing device capable of automatically supplying the ink and stably printing, the first metal ball is driven to move upwards while the first pipeline moves downwards under the action of pressure, the ink on the lower side flows into the printing head from the third pipeline and the hose, and by means of the structure, the purposes of reducing manpower consumption, automatically adding the ink and being high in printing efficiency are achieved.

Owner:徐美云

Auxiliary device with more obvious printing ink-jet uniform printing effect for mobile phone shell

The invention relates to the technical field of mobile phone accessory printing, and discloses an auxiliary device with a more obvious printing ink-jet uniform printing effect for a mobile phone shell. The auxiliary device comprises a connecting frame, wherein an ink inlet groove is formed in the middle of the connecting frame, a filtering frame is movably connected to the interior of the ink inlet groove, a connecting base is movably connected to the left side of the filtering frame, a telescopic base is movably connected to the bottom of the connecting base, a pull rod is movably connected to the outer part of the connecting base, and a sliding block is movably connected to the bottom of the pull rod. According to the auxiliary device, ink enters the ink inlet groove from the connectingframe, when ink-jet is carried out, the ink can apply a downward pressure to the filtering frame, the pressure is transmitted to the pull rod through the connecting base, then the ink forms a negativepressure in an ink storage groove at the moment of being sprayed out, the ink in a box is stirred to prevent the ink from precipitating and prevent excessive ink from being adsorbed on a gun head, and then the effects of automatically stirring the ink box to prevent the ink from precipitating and preventing the excessive ink from being adsorbed on the ink-jet gun head in the ink-jet process are achieved.

Owner:南京封宝宝电子商务有限公司

Preparation method for easily-printed wool yarn

The invention discloses a preparation method for an easily-printed wool yarn. The preparation method comprises the following steps of: 1, performing pinecone processing to the surface of the yarn by pinecone equipment; 2, performing scale-stripping processing to the surface of the yarn by sodium hypochlorite; 3, secondarily cleaning the yarn which is performed with the scale-stripping processing, and washing a chemical agent on the surface of the yarn; 4, performing softening processing to the yarn by a softening agent; and 5, drying and winding the yarn which is performed with the softening processing. By the preparation method for the easily-printed wool yarn, the scale-stripping processing is performed to the wool fibers, sodium hypochlorite is used as a scale-stripping agent, and after sodium hypochlorite is dissolved in water, hypochlorite reacts with the scales on the surface of the wool to enable the scales of the wool to be stripped and dissolved in water, so that a scale-stripping effect is realized, and when the printing is performed to the yarn, dye is easily penetrated into the yarn, and a dying effect is great.

Owner:ZHEJIANG XINAO

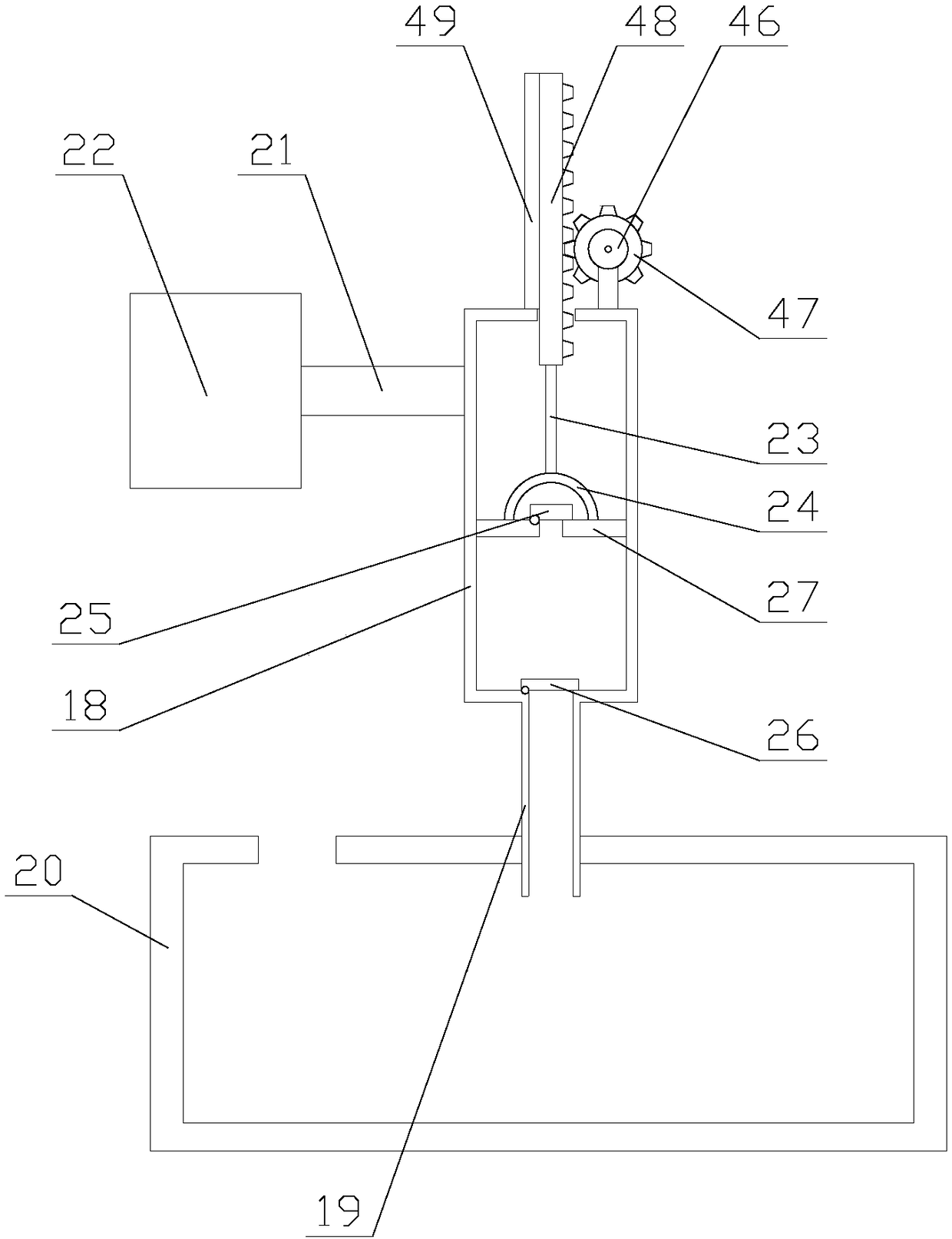

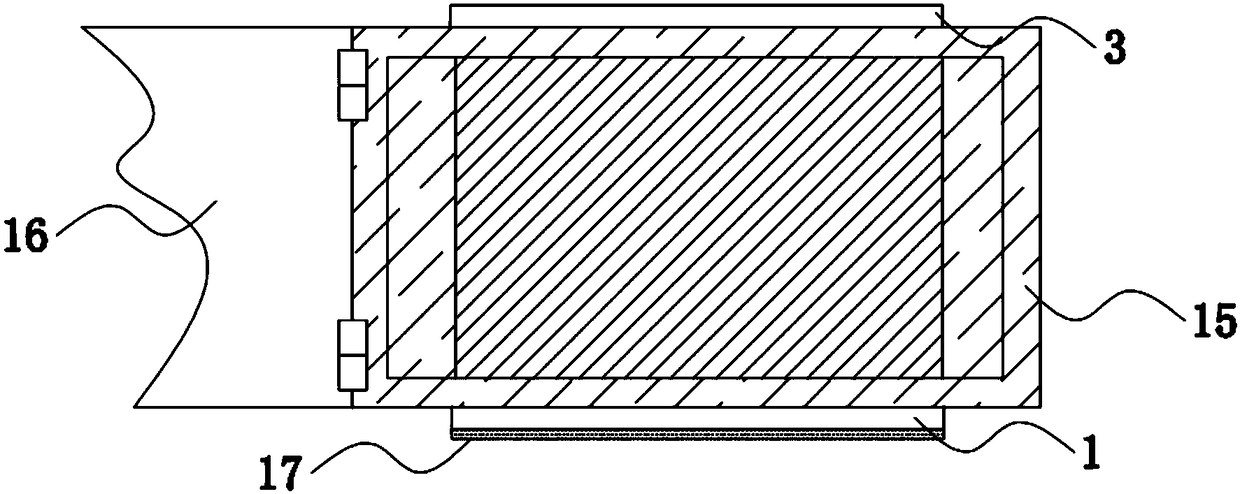

Roll type lifting mechanism for thin film digital printing

InactiveCN108583031AEven by forceGood printing effectPower drive mechanismsOther printing apparatusDigital printingMechanical engineering

The invention discloses a roll type lifting mechanism for thin film digital printing. The roll type lifting mechanism comprises a base. A vertical plate is vertically connected to the rear end of theupper portion of the base. A top plate is vertically connected to the upper end of the front side face of the vertical plate. Square sliding rods are connected to the left side and the right side of the front end face of the vertical plate. Sliding grooves arranged in a U shape are in sliding connection to the square sliding rods, and a lifting plate is connected between the two sliding sleeves. The left end and the right end of the bottom of the lifting plate are rotationally connected with first connecting rods pairwise through pin shafts. According to the roll type lifting mechanism, the first connecting rods and second connecting rods are driven by synchronously-operating hydraulic cylinders to be bent and get close, and therefore the lifting plate operates downwards; supporting rods,the lifting plate and a printing plate are integrally formed, and then a printing spray head at the bottom of the printing plate carries out ink jet printing on printing paper on the upper portion ofa workbench; and in the whole process, stress of the printing plate can be uniform through the four hydraulic cylinders and the paired supporting rods, and the printing effect is good.

Owner:合肥汉闻数字印刷设备有限公司

Offset press with enhanced type drying system

ActiveCN106671567AFit flatGood printing effectRotary lithographic machinesPrinting press partsPaper sheetEngineering

The invention discloses an offset press with an enhanced type drying system. The offset press comprises a coating-printing part, a sheet transmission part and a sheet collecting table, wherein the sheet transmission part comprises a coating-printing supporting roller and a sheet collecting roller, which can be rotatably arranged on the rack, and reversely rotate along with a coating-printing pressure roller under action of the coating-printing pressure roller; a plurality of through holes are formed in a curved surface of the coating-printing supporting roller; an absorbing-blowing device is arranged inside the coating-printing supporting roller; the absorbing-blowing device comprises a blowing-absorbing fan, an air-blowing cover which communicates with an air outlet of the blowing-absorbing fan, and an air absorbing cover which communicates with an air suction hole of the blowing-absorbing fan; an opening of the air-blowing cover faces towards a position where a sheet is to be transmitted away from the coating-printing supporting roller; an opening of the air-absorbing cover faces towards a position where the sheet is to be transmitted to enter the coating-printing pressure roller and the coating-printing supporting roller; a sheet intake direction of the coating-printing supporting roller is equipped with an air-absorbing correcting device; and the air-absorbing correcting device communicates with the air-absorbing cover through a pipeline. The offset press overcomes the problems that an offset press in the prior art is poor in drying effect, is high in energy consumption and is inaccurate in coating-printing.

Owner:CHANGXING HAIPU MACHINERY TECH CO LTD

Inductive positioning code-spurting device

PendingCN109454993AIdeal printing positionAccurate real-time feedbackTypewritersOther printing apparatusUltrasonic sensorEngineering

The invention discloses an inductive positioning code-spurting device. A position sensor, a limit assembly, a first ultrasonic sensor and an ink-jet printer are arranged on the device in sequence. Thelimit assembly comprises a servo motor and a flow guide plate. The servo motor pushes the flow guide plate to move according to the fed-back position of a to-be-code-spurted object, and accordingly,the to-be-code-spurted object is adjusted to the optimal code spurting position. The position sensor is used for detecting whether the to-be-code-spurted object moves close to the inductive positioning code-spurting device, and feeding back the position of the to-be-code-spurted object preliminarily. The first ultrasonic sensor is used for precisely feeding back the position of the to-be-code-spurted object. According to the inductive positioning code-spurting device, by mans of the servo motor and the ultrasonic sensor, the mode that only manual tagging can be adopted for packages of different sizes is changed, the efficiency is improved, in addition, the tagging precision can be greatly improved, and the probability of tagging errors is lowered.

Owner:广州市贝云科技有限公司

Flocking fabric printing technology

InactiveCN109281210AGood printing effectUniform and stable patternTransfer printing processDyeing processParameter controlEngineering

The invention relates to the technical field of printing, in particular to a flocking fabric printing technology which comprises glue loading, glue scraping, curing and transferring; wherein a glue material is sprayed on the upper surface of a flocking fabric by a spraying process in the glue loading process; the glue material on the surface of the flocking fabric is scraped into a uniform thickness of 1-2 mm by a scraping plate; the flocking fabric subjected to the glue scraping is conveyed into a curing box for curing, a double-layer heat source is arranged in the curing box for heating, theflocking fabric penetrates through the double-layer heat source, the curing temperature in the curing box is controlled to be 50-70 DEG C, and the curing time is 30-50 seconds; and the flocking fabric after the curing is printed by a transfer printing film and a hot pressing roller, the temperature of the hot pressing roller for printing is 50-70 DEG C, and the pressure is one atmospheric pressure. According to the flocking fabric printing fabric technology disclosed by the invention, reasonable process design and parameter control are adopted, the flocking fabric can be printed, the printingeffect is good, and the pattern is uniform and stable.

Owner:桐乡市欣旺纺织整理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com