Offset press with enhanced type drying system

A drying system and enhanced technology, which is applied to printing machines, rotary printing machines, lithographic rotary printing machines, etc., can solve the problems that the drying effect needs to be enhanced, the drying method is single, and the length of the lamp tube is fixed, so as to achieve good drying effect and dry Good effect, good printing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

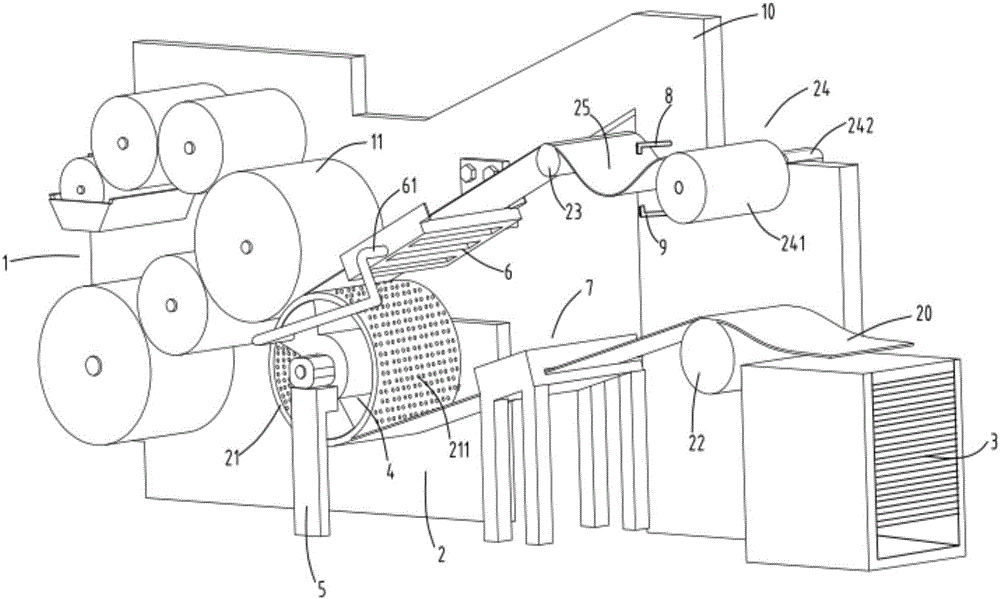

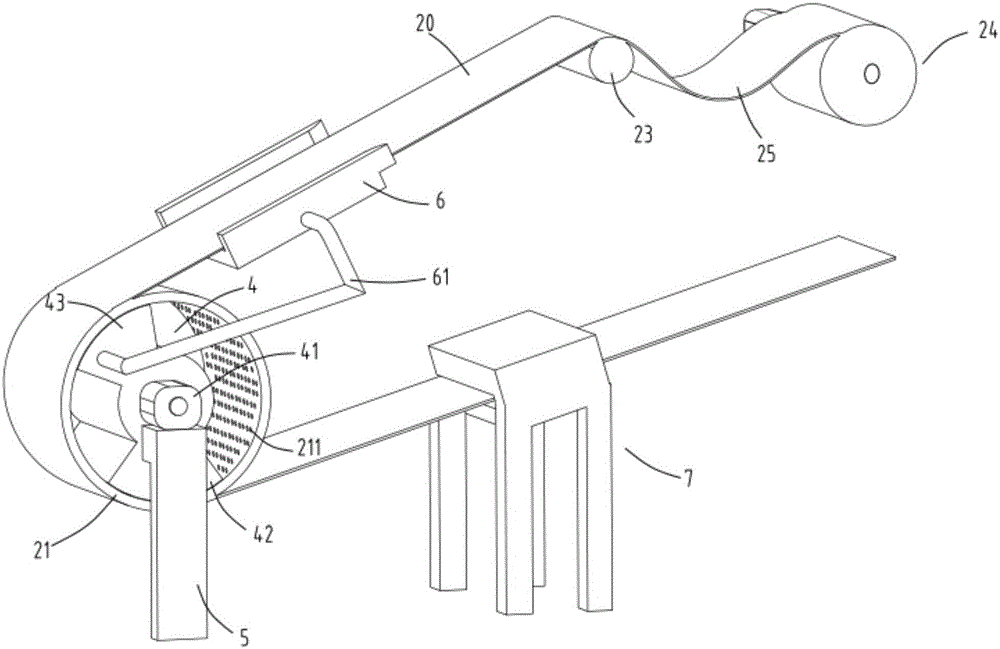

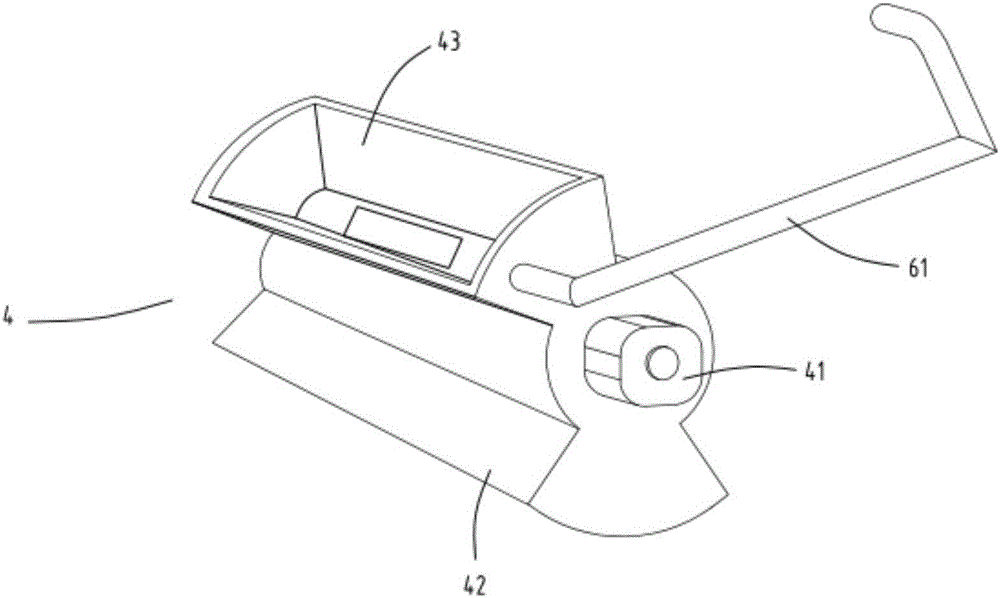

[0026] figure 1 It is a structural schematic diagram of an offset printing machine with an enhanced drying system, figure 2 It is a schematic diagram of the partial structure of the transmission part and the printing part, image 3 It is a schematic diagram of the structure of the suction and blowing device, Figure 4 It is a schematic diagram of the structure of the UV drying device. Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, an offset printing machine with an enhanced drying system includes a printing part 1, a paper conveying part 2 and a delivery table 3; the printing part 1 includes a printing roller rotatably arranged on a frame 10 11. The paper conveying part 2 includes a coating idler roller 21 and a delivery roller 22 which are rotatably arranged on the frame 10, and which rotate counterclockwise with the coating roller 11 under the action of the coating roller 11;

[0027] The curved surface of the printing roller 21 is provided with severa...

Embodiment 2

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that: a UV drying device 7 is provided in the paper output direction of the coating roller 21; the UV drying device 7 includes a support 71 and is evenly arranged on the support 71 Several UVLED lamps 72; UVLED lamps 72 are used for further drying, so that the drying effect is good, and power saving and low cost; in addition, a number of UVLED lamps 72 are set, and the number of UVLED lamps 72 that are turned on can be controlled according to actual drying requirements degree of dryness.

Embodiment 3

[0034] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the parts that are the same as or corresponding to those in the second embodiment are marked with the corresponding reference numerals in the second embodiment. For the sake of simplicity, only the differences from the second embodiment will be described below. The difference between the third embodiment and the second embodiment is that: the sensor a8 fixed on the frame 10 is arranged above the parabolic segment 25; the sensor a8 fixed on the frame 10 is arranged below the parabolic segment 25 b9; the driving roller 24 includes a roller 241 and a servo motor 242; the servo motor 242 is fixed on the frame 10 and is respectively signal-connected with the sensor a8 and the sensor b9; For reasonable control, it is preferable to set the sensor a8 and the sensor b9 here as distance sensors. When the arc of the parabolic segment 25 is large, the paper 20 approaches the sensor b9 below, and the sensor b9 sends a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com