Label rolling mechanism

A technology of rolling labels and driving motors, applied in labeling machines, labels, packaging, etc., can solve the problems of wasting human resources, labels cannot be flattened, and affect the quality of product shipments, and achieve the effect of improving the quality of shipments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] This embodiment provides a rolling labeling mechanism for rolling labeling after the labeling of circular surface products;

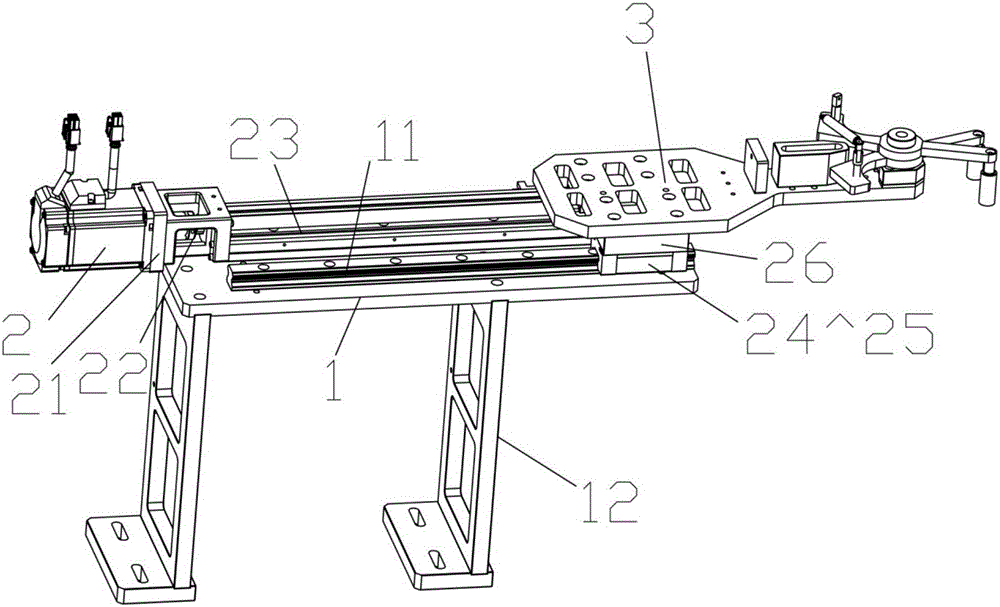

[0028] Please refer to figure 1 , which shows a rolling label mechanism, including a driving assembly (not shown in the figure), and a rolling label assembly 3 connected to the driving assembly (not shown in the figure);

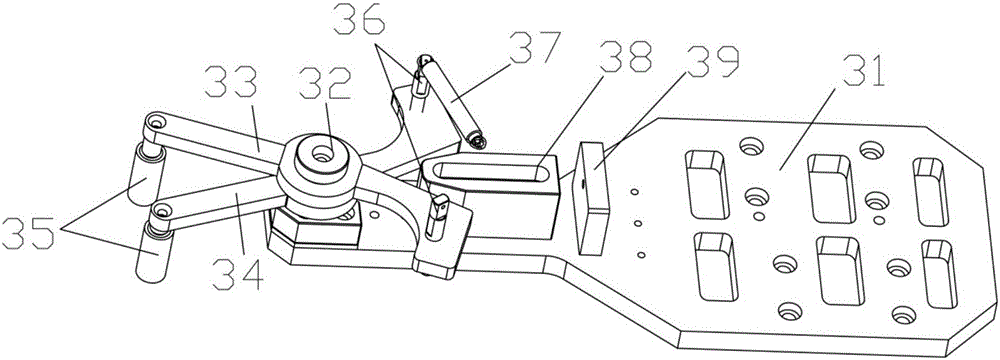

[0029] Please refer to figure 2 , which shows the roller label assembly 3, including a base plate 31 whose head end is connected to the drive assembly (not shown in the figure), a rotating shaft 32 arranged at the end of the base plate 31, a middle crossing arranged on the rotating shaft 32 and used in conjunction with The left drive rod 33 and the right drive rod 34, the marking wheel 35 that is respectively arranged at the ends of the left drive rod 33 and the right drive rod 34, the resetting pillar 36 that is respectively arranged at the head end of the left drive rod 33 and the right drive rod 34, and The two ends are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com