Metal powder laser 3D printing nozzle

A metal powder, 3D printing technology, applied in the direction of improvement of process efficiency, additive manufacturing, additive processing, etc., can solve the problem of not seeing the patent documents and so on, and achieve the effect of simple structure and good printing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

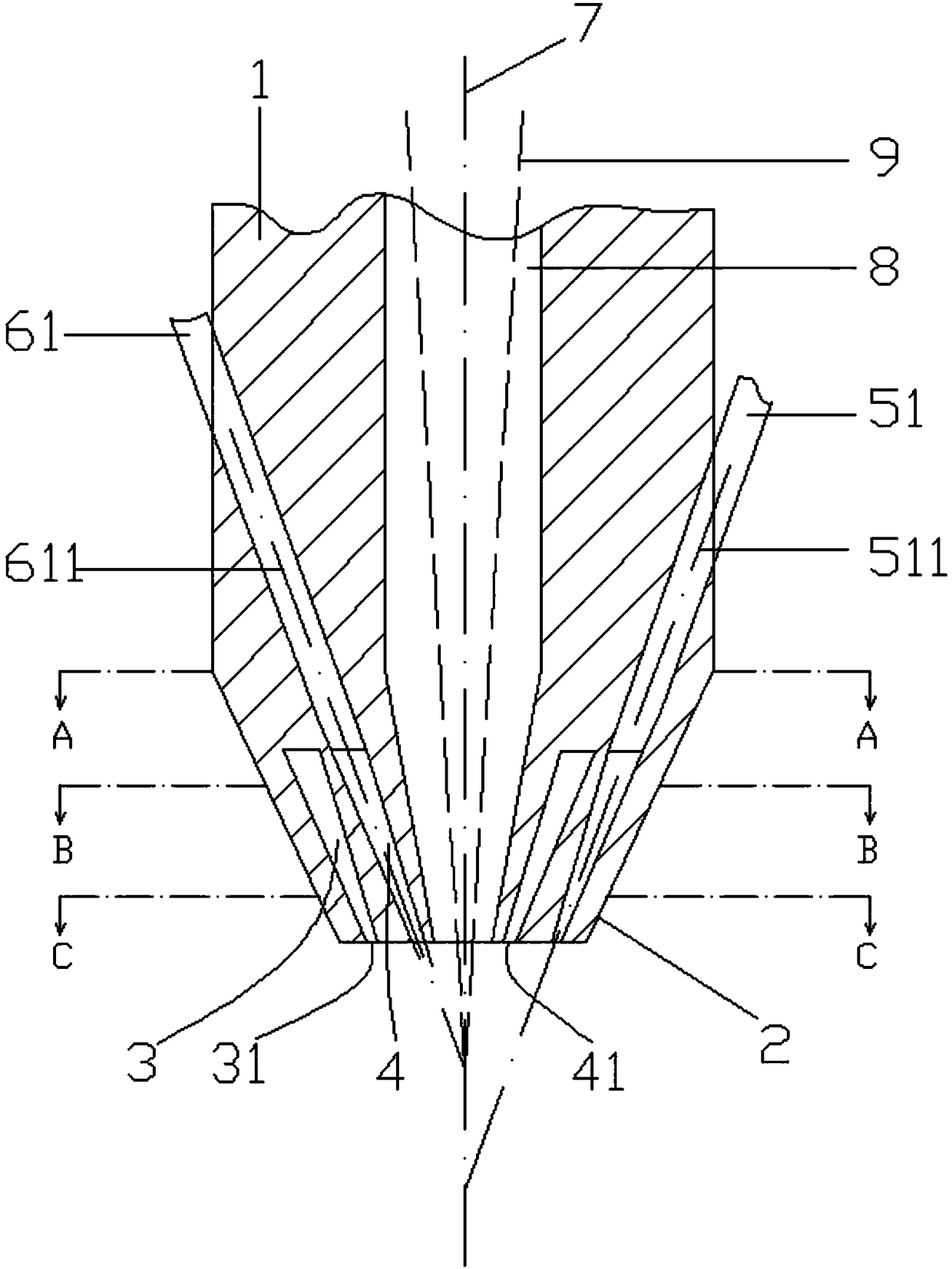

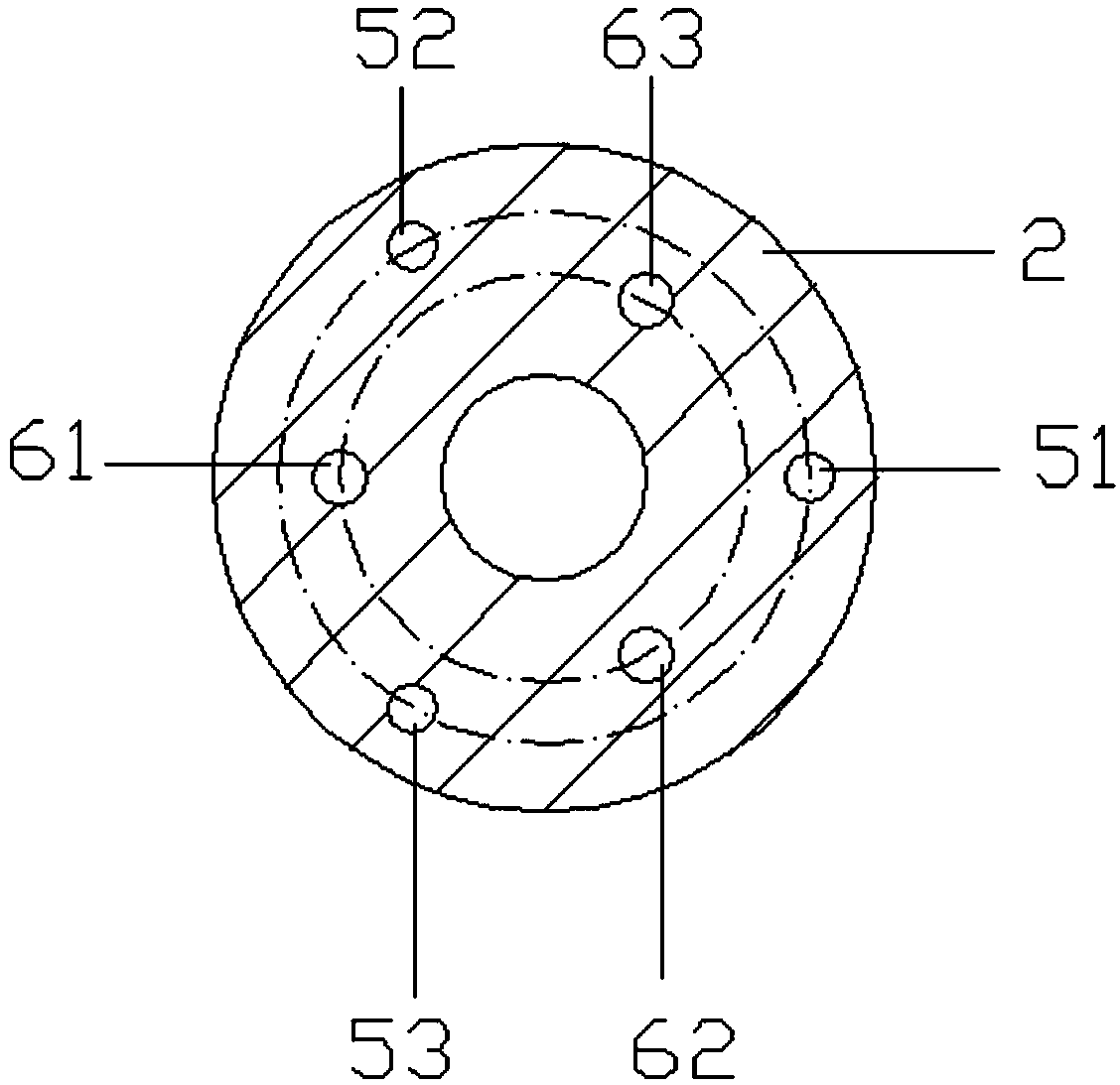

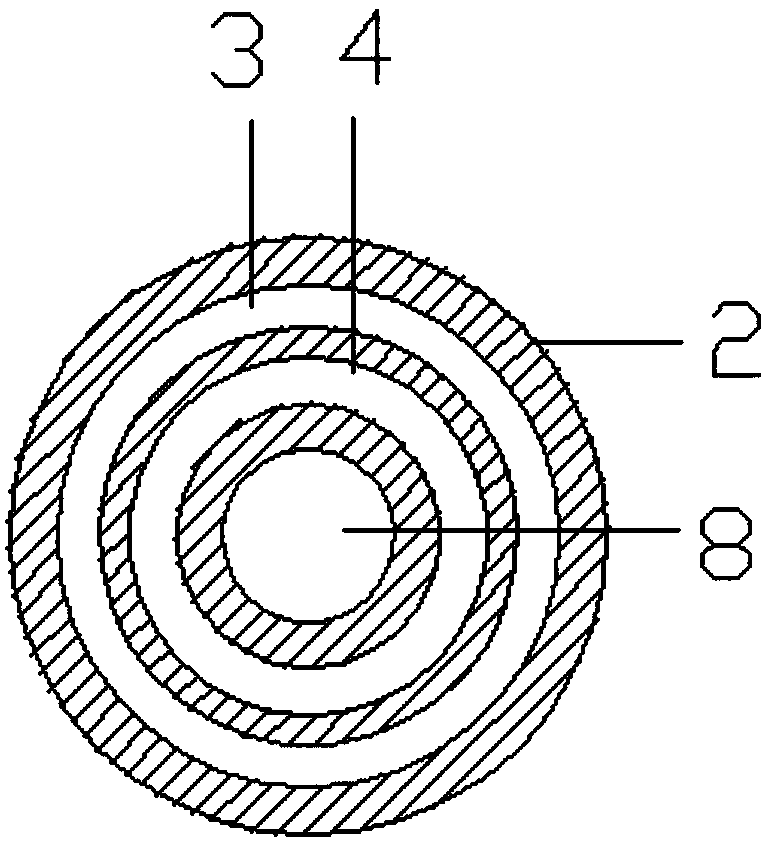

[0017] Example: see Figures 1 to 4 As shown, a metal powder laser 3D printing nozzle has a truncated cone-shaped nozzle head 2 formed on the lower part of the entity 1, and a first annular cavity 3 and a second annular cavity 4 are formed on the nozzle head 2. The second annular cavity The cavity 4 is located inside the first annular cavity 3, the first annular cavity 3 forms a first annular cavity opening 31 at the lower part of the nozzle head 2, and the second annular cavity 4 forms a second annular cavity at the lower part of the nozzle head 2 cavity opening 41;

[0018] The first shielding gas conveying pipe 51, the second shielding gas conveying pipe 52 and the third shielding gas conveying pipe 53 are all in communication with the first annular cavity 3, the first metal powder conveying pipe 61, the second metal powder conveying pipe 62 and The third metal powder conveying pipe 63 is all communicated with the second annular cavity 4, the first annular cavity 3 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com