Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Good fuel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

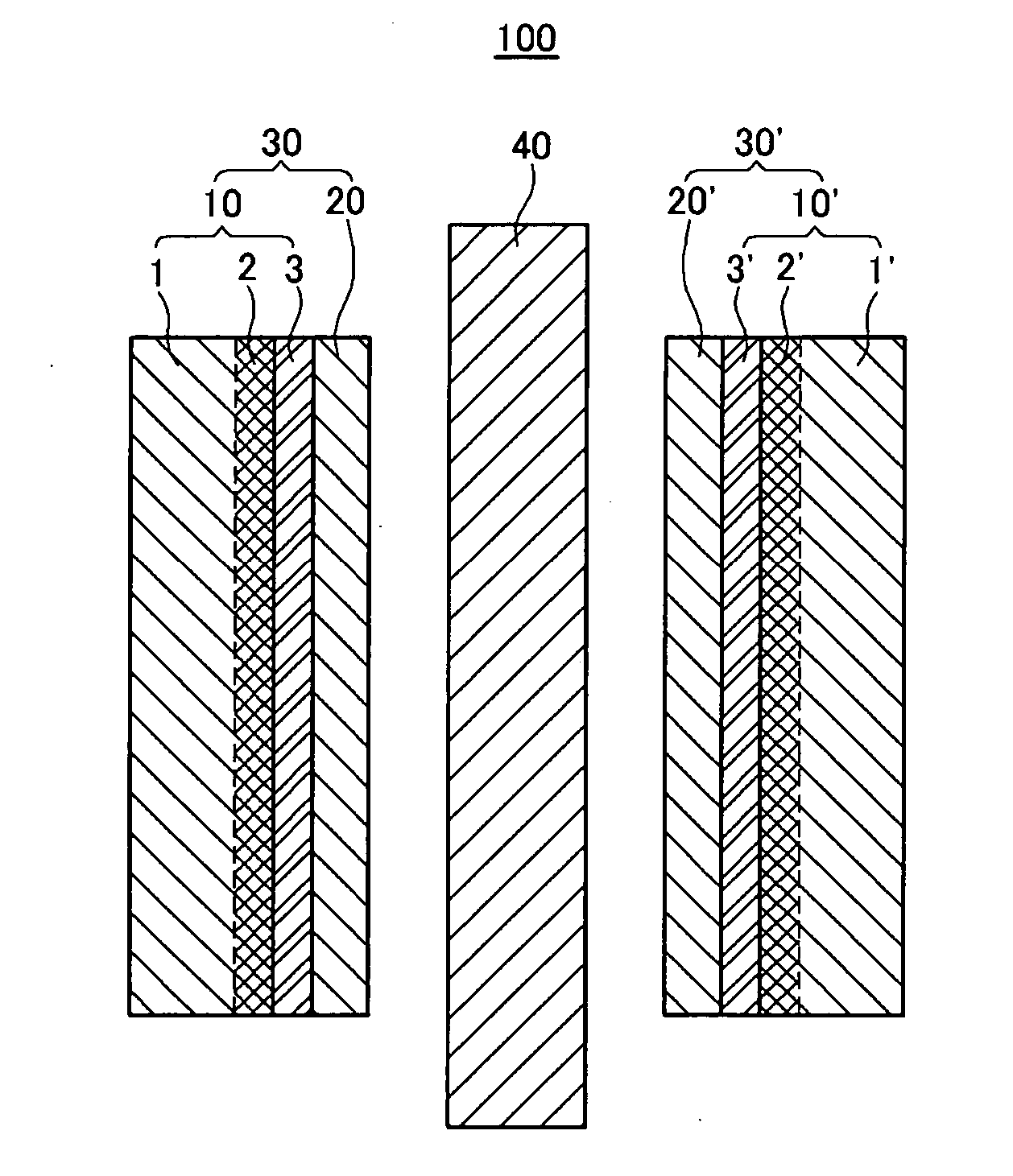

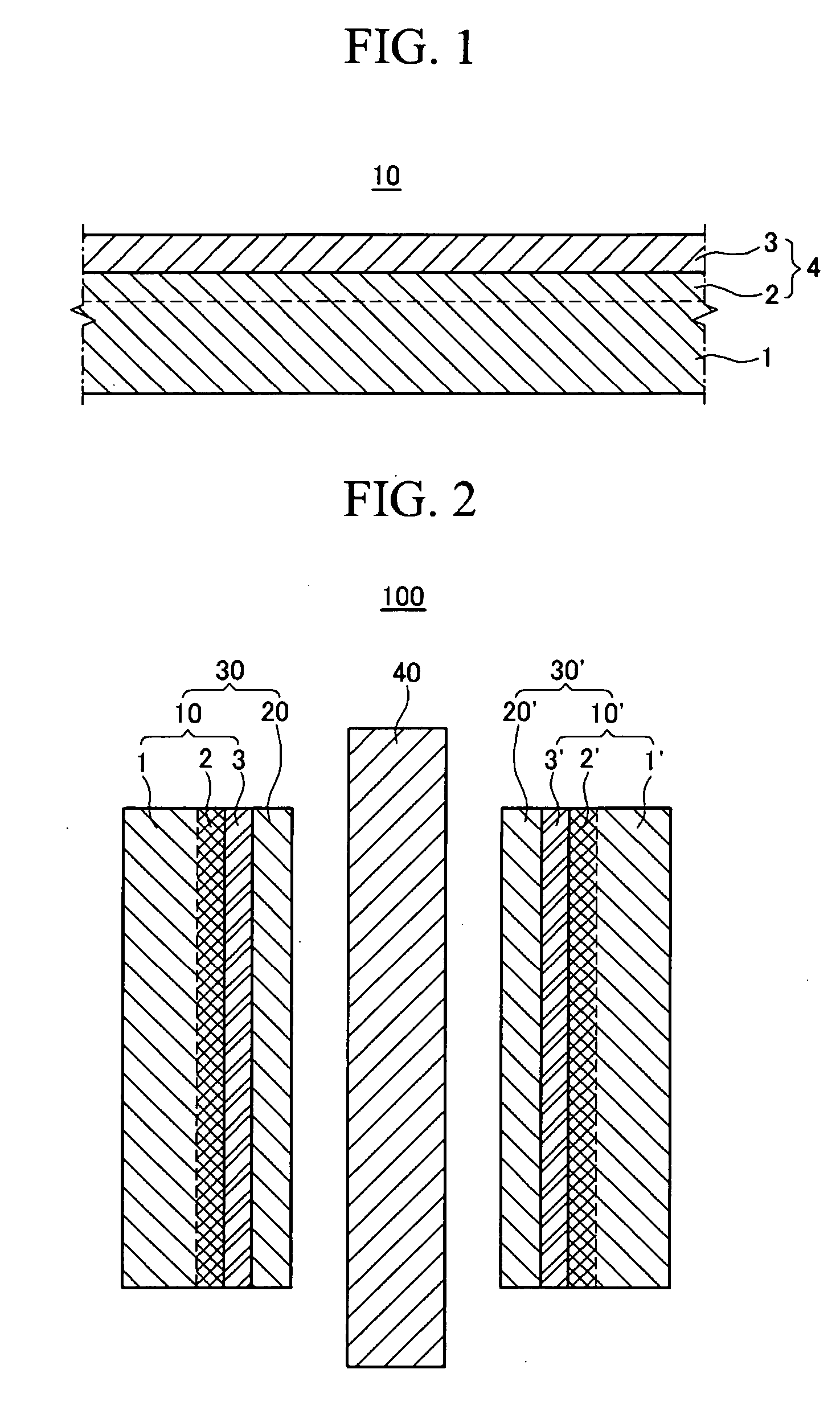

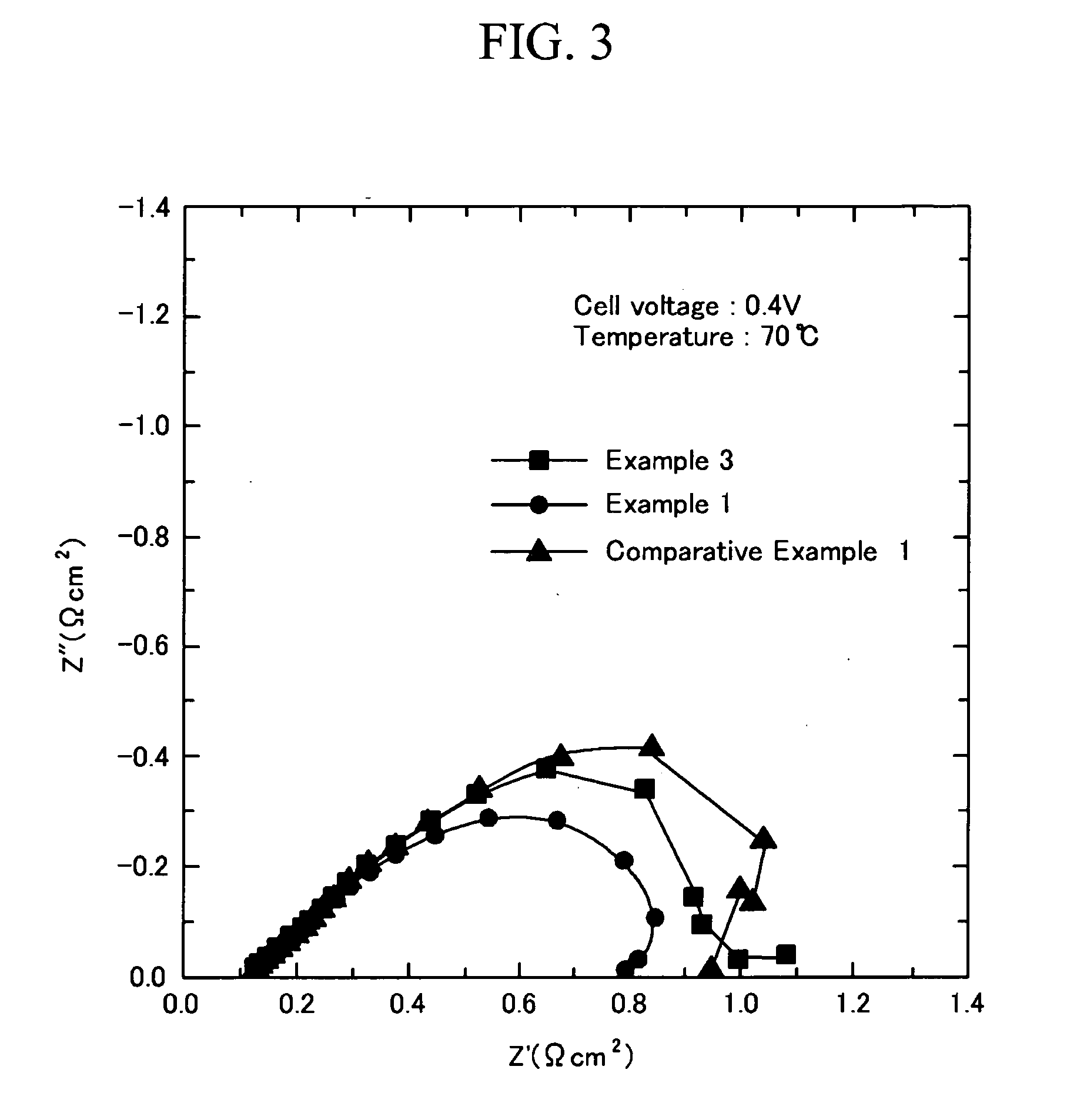

Electrode substrate for a fuel cell, a method for preparing the same, and a membrane-electrode assembly comprising the same

InactiveUS20060257641A1Improved fuelImproved oxidant diffusion performanceMachining electrodesCellsDiffusionFuel cells

An electrode substrate for a fuel cell including a diffusion layer, a first microporous layer that embeds into the diffusion layer, with the first microporous layer having a thickness in the range of 10 to 30 μm, and a second microporous layer that forms a boundary with the diffusion layer on the surface of the first microporous layer. The electrode substrate has improved performance such as increased diffusion properties of a fuel or an oxidant, increased properties of releasing moisture, and enhanced electron conductivity.

Owner:SAMSUNG SDI CO LTD

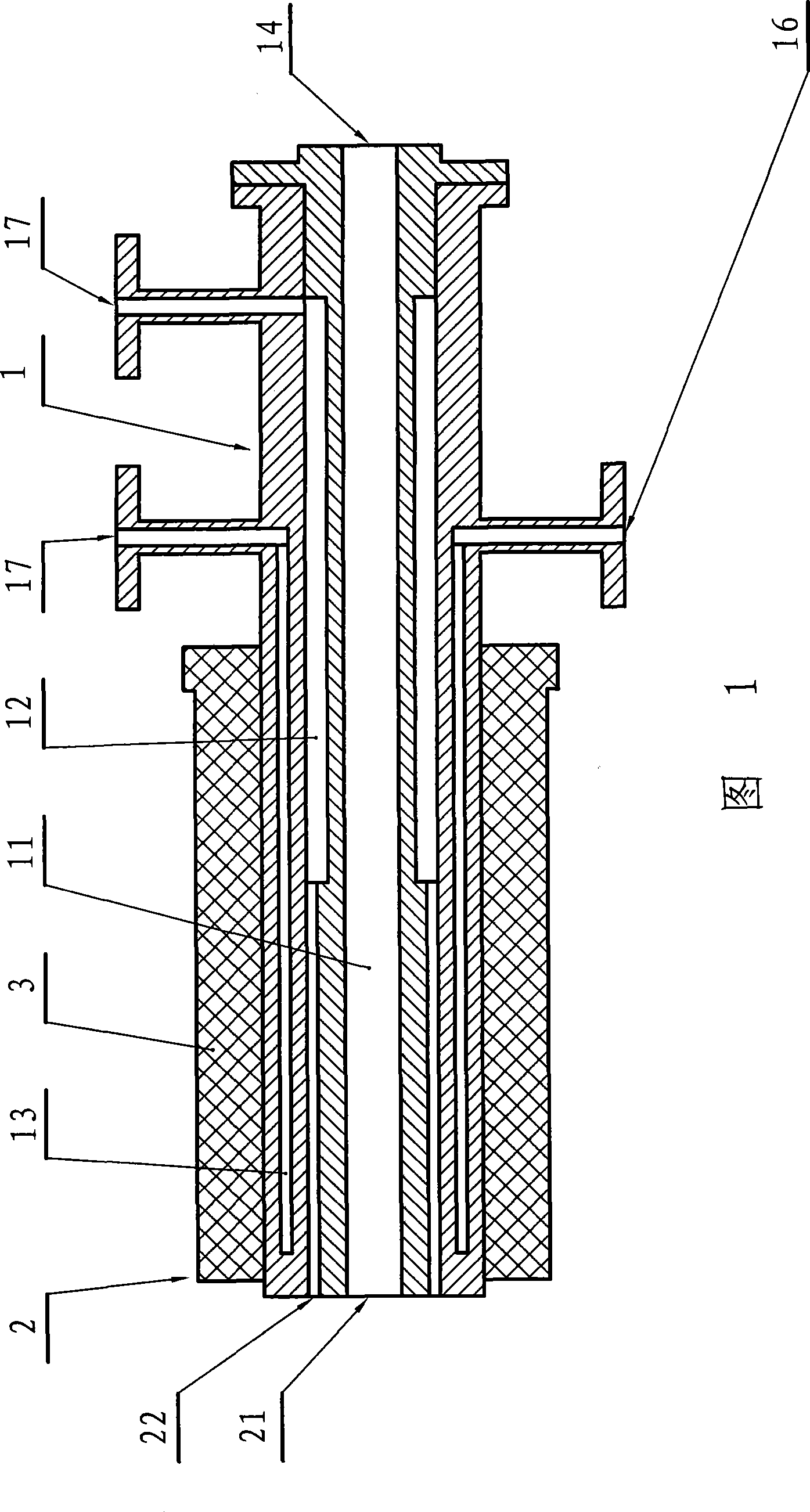

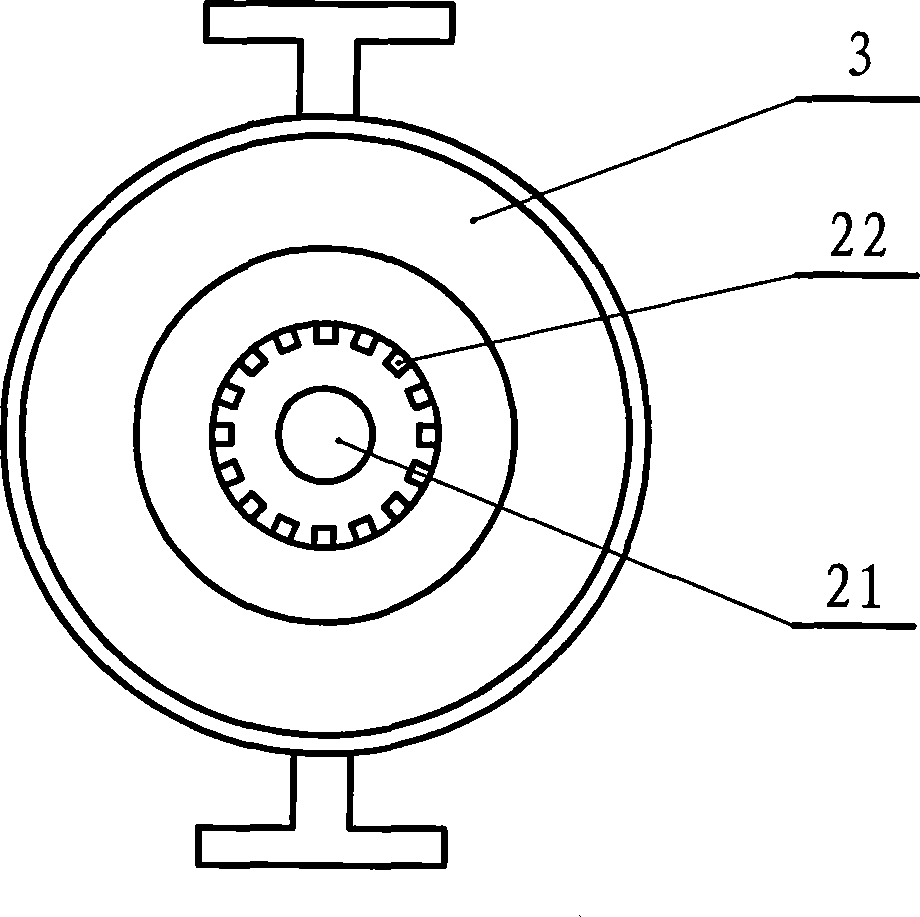

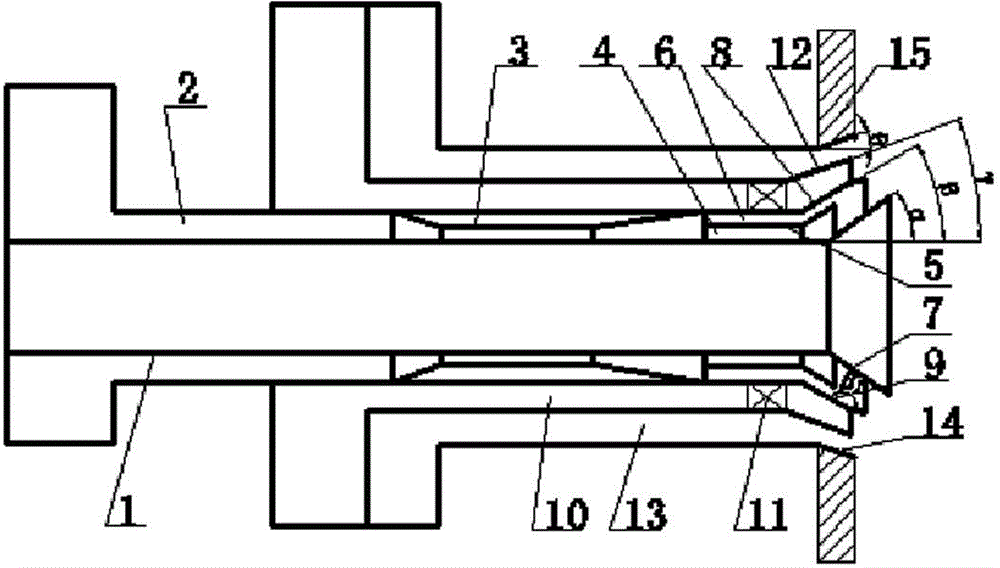

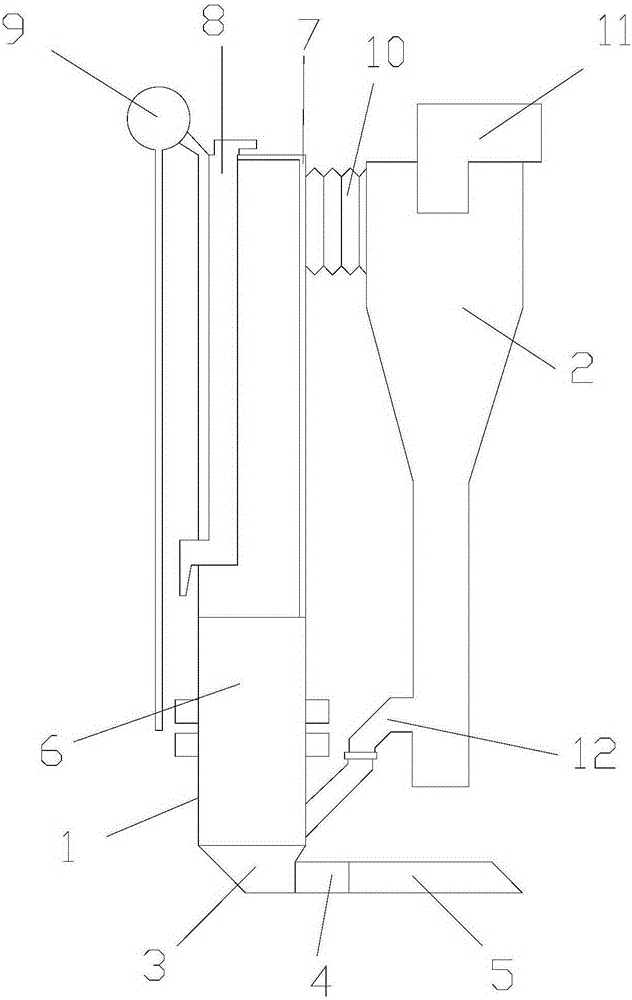

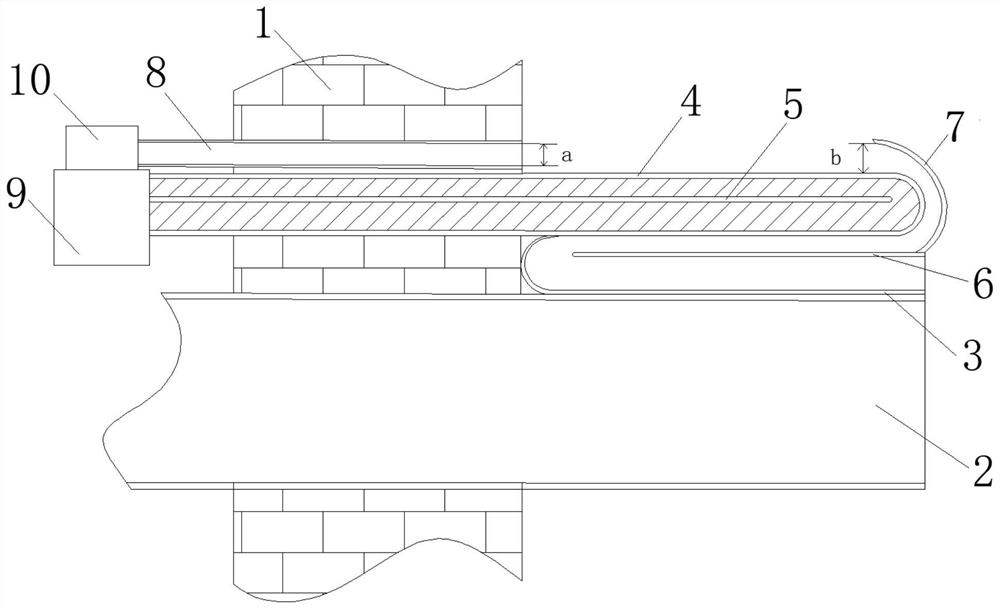

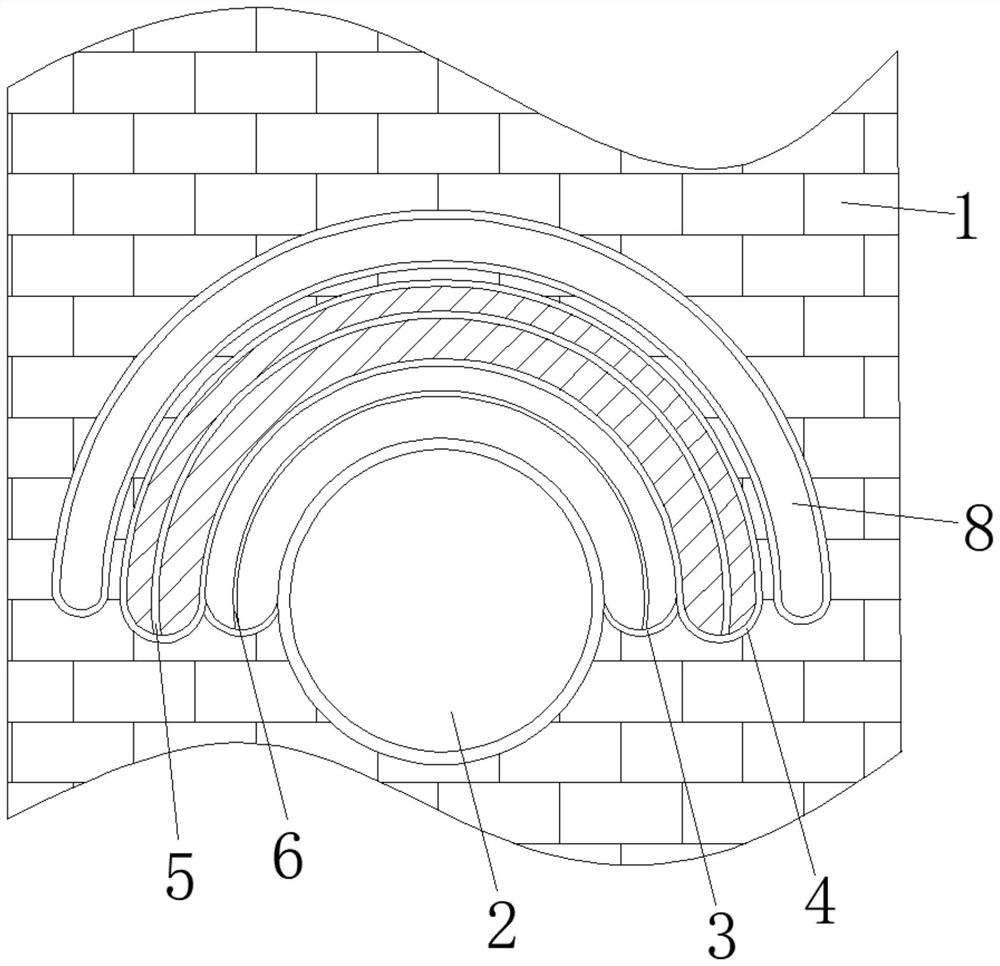

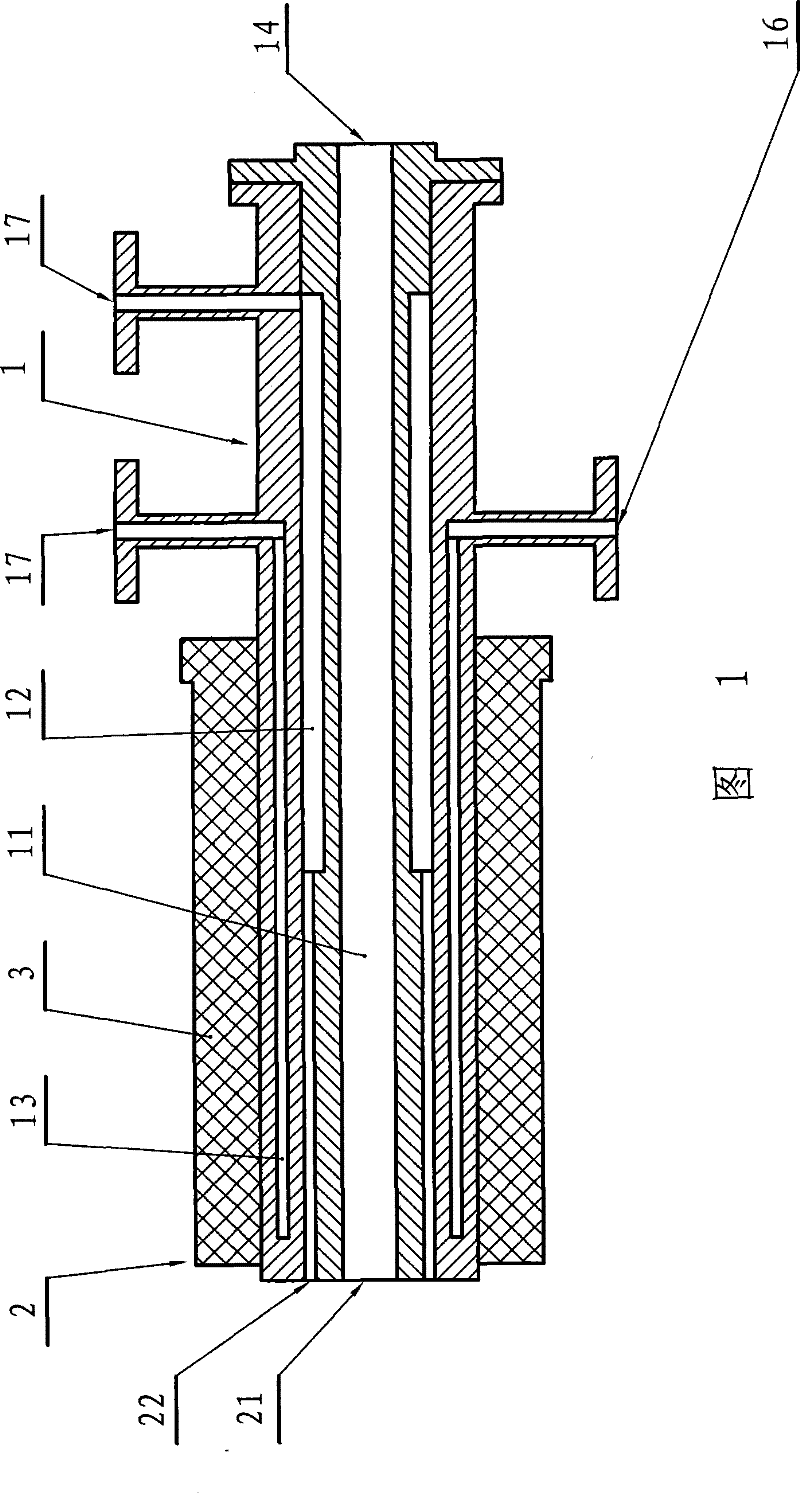

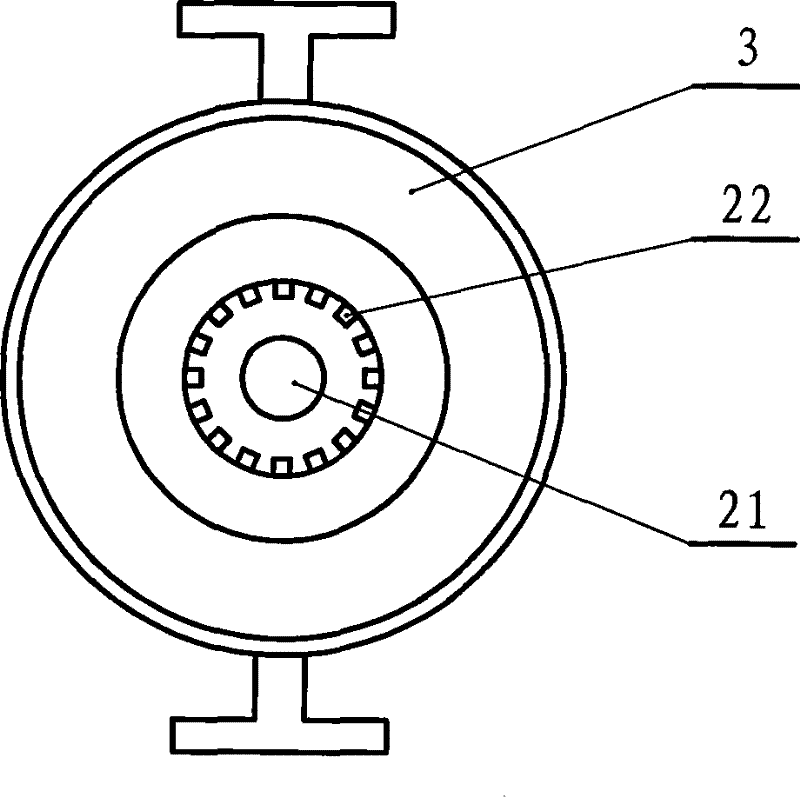

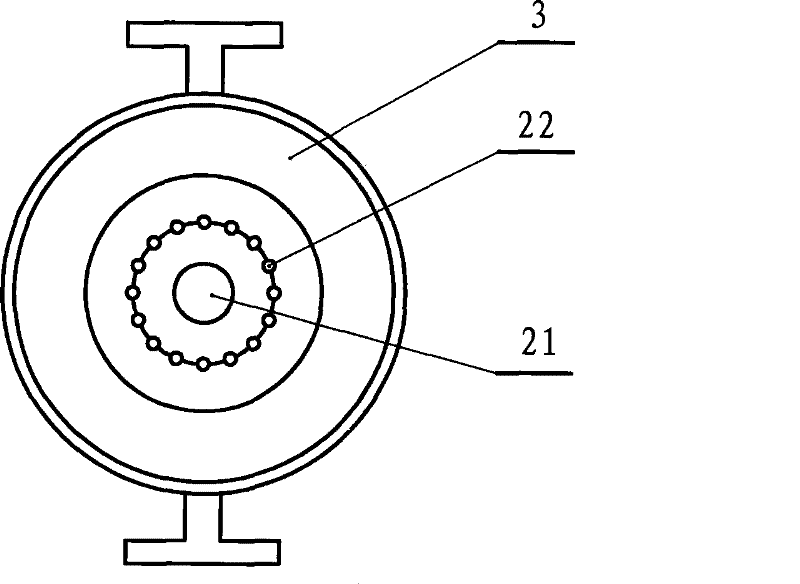

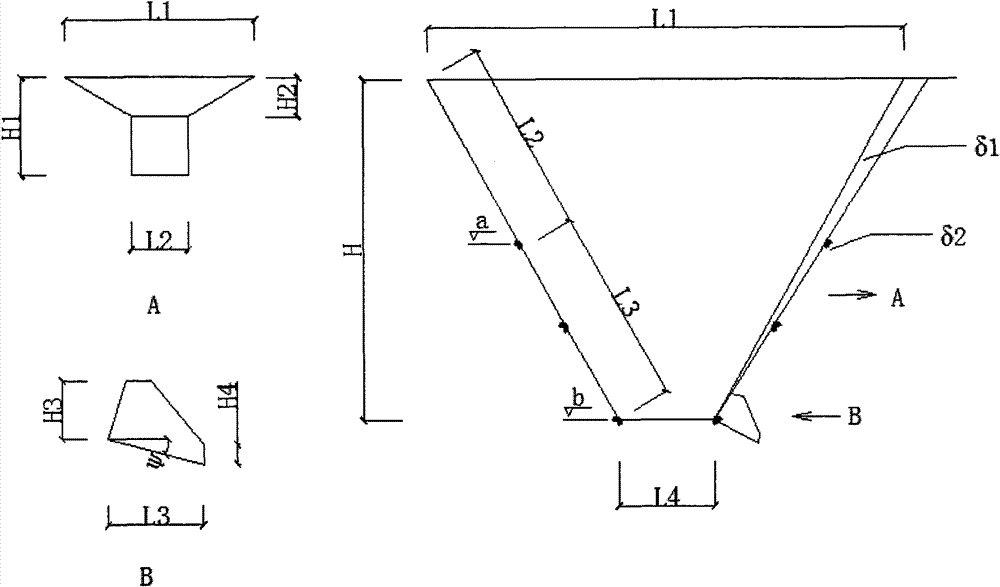

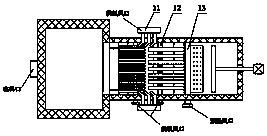

Spray gun of side-blown converter for smelting non-ferrous metal

ActiveCN101382387AImprove combustion performanceSpeed up redox reactionsCharge manipulationCombustionNonferrous metal

The invention discloses a novel side-converter spray gun for smelting nonferrous metals, comprising a spray gun body with a sleeve structure and a spray gun head at the front end of the spray gun body; a central pipeline of the sleeve structure is provided with a connecting interface connected with a fuel conveyor; a sandwich ring channel of the sleeve structure is provided with a connecting interface connected with combustion-supporting gas; the spray gun head is provided with a fuel nozzle which is matched with the central pipeline and a combustion-supporting gas nozzle which is matched with the sandwich ring channel; and the combustion-supporting gas nozzle is provided with a through hole nozzle array.

Owner:CHINA ENFI ENGINEERING CORPORATION

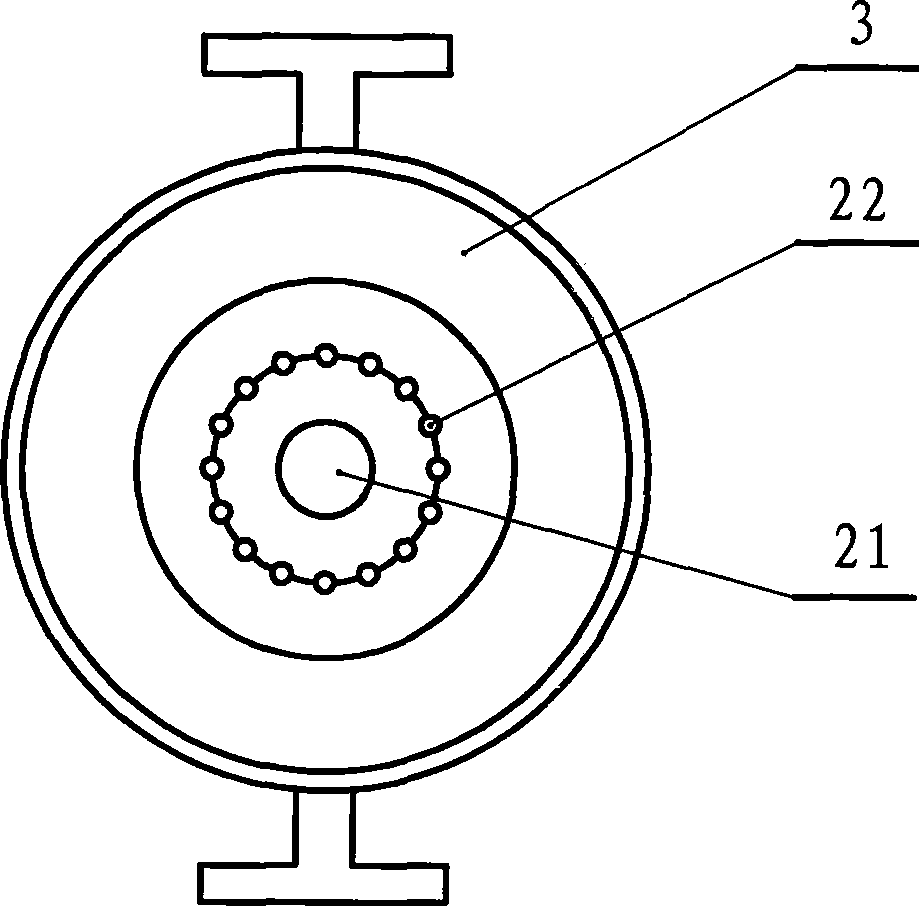

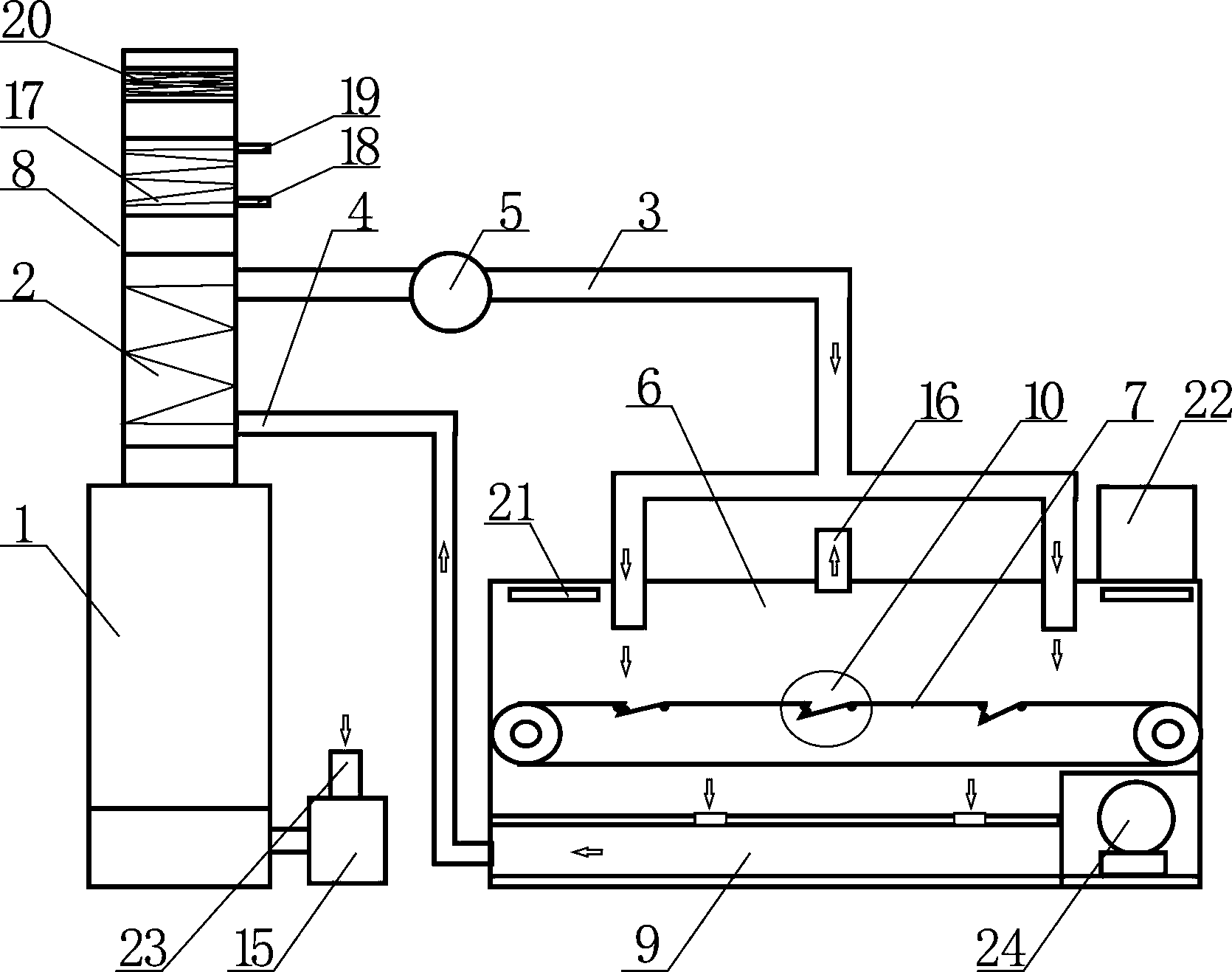

Energy-saving environment-protecting type hot air vegetable drying device

InactiveCN103673545AImprove drying effectHigh calorific valueFood processingDrying gas arrangementsCombustionPulp and paper industry

The invention discloses an energy-saving environment-protecting type hot air vegetable drying device which is mainly composed of a furnace body, a heat exchanger, a hot air supply pipe, a hot air return pipe, an exhaust fan, a hot air drying box, and a conveyor belt using a motor as power. More than two material turning mechanisms are distributed on the conveyor belt at intervals. By the adoption of the structural form, the energy-saving environment-protecting type hot air vegetable drying device has the advantages that the material turning mechanisms are further arranged, so that the vegetable drying effect is greatly improved; a steam tube bank is further arranged at the top of the hot air drying box so as to be favorable to drying vegetables, especially, the steam tube bank is connected with a blower so as to be favorable to dehumidification inside the drying box and enable the waste heat of steam to be fully utilized, and the largest advantage lies in that after being pumped into the furnace body, steam is favorable to combustion-supporting and improves the heat value inside the furnace body; a secondary heater exchanger is further arranged, and waste heat is absorbed by water, so that the waste heat can be fully utilized.

Owner:GUANGDONG OASIS AGRI

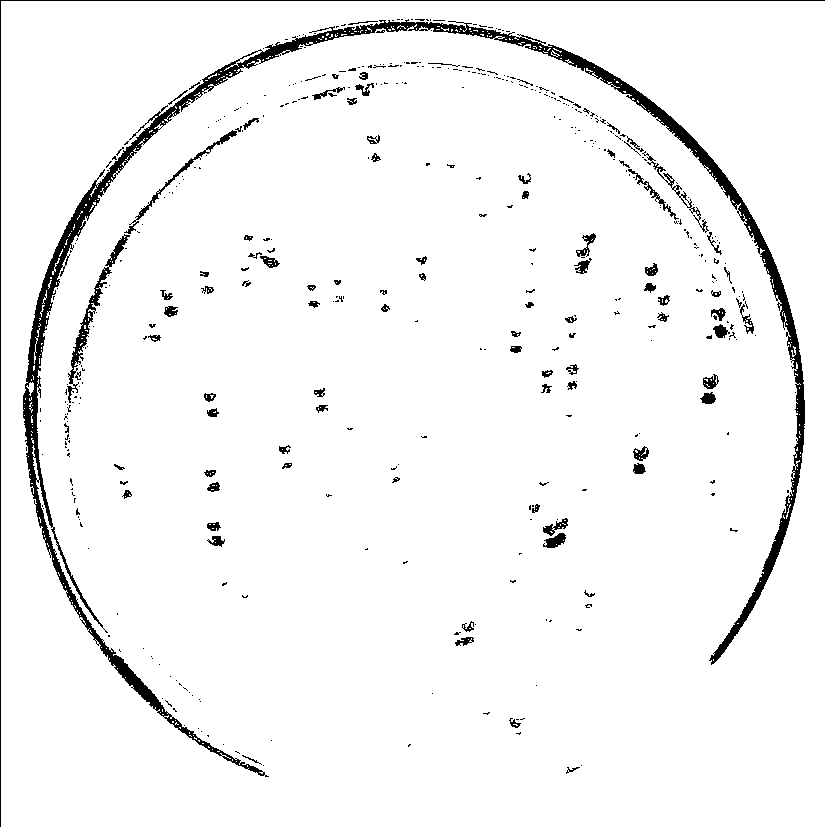

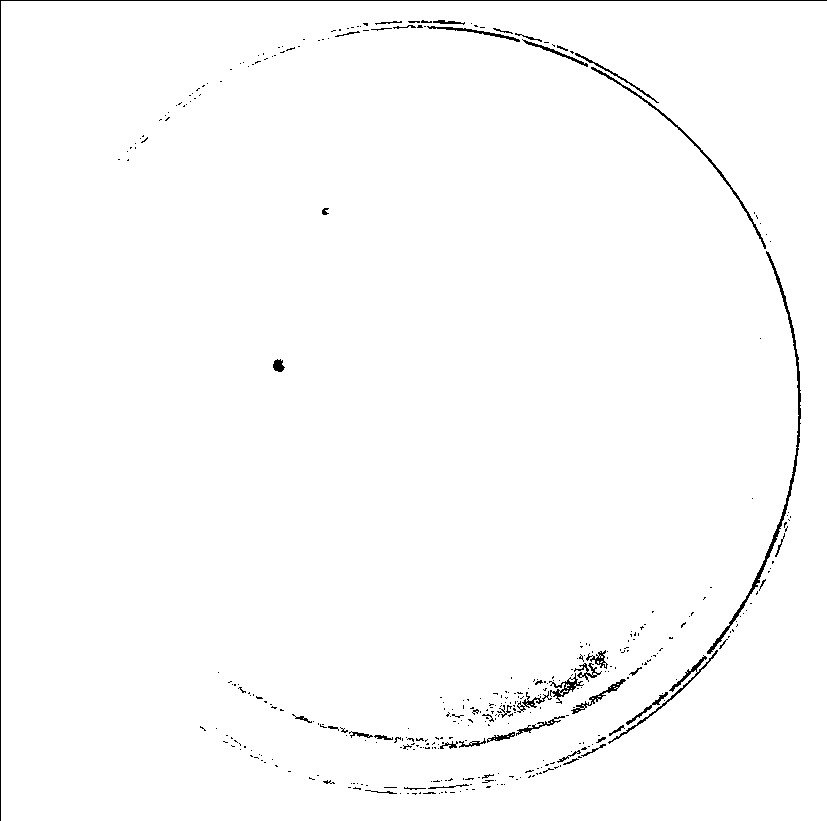

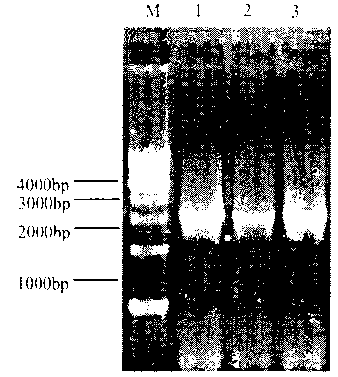

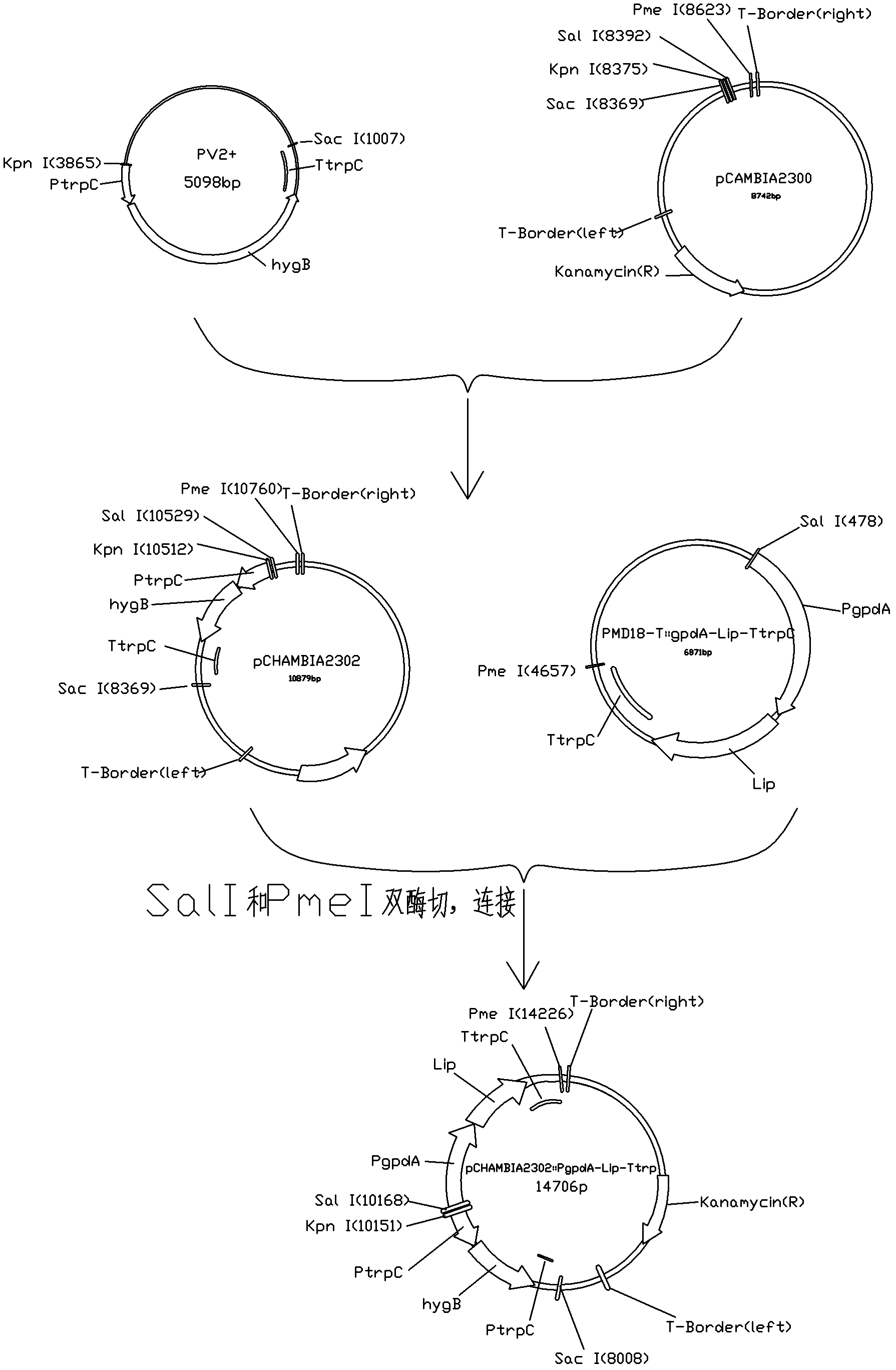

Rhodotorula glutinis oil genetic engineering strain and construction method and application thereof

ActiveCN102796675AImprove the lubrication effectImprove securityFungiMicroorganism based processesBiotechnologyLipid formation

The invention relates to a rhodotorula glutinis oil genetic engineering strain and a construction method and an application thereof. The construction method of the genetic engineering strain is mainly as follows: utilizing rDNA (recombinant deoxyribonucleic acid) of rhodotorula glutinis as a target sequence for homologous integration, using strong promoter genes PGK1 of saccharomyces cerevisiae and malate dehydrogenase genes ME of chaetomium cochloides to construct an expression vector to be introduced into rhodotorula glutinis, and enabling ME genes to obtain high-efficient expression in a rhodotorula glutinis body, wherein the content of lipid in a transformant is improved by 2.5 times in comparison with a wild strain. According to the construction method disclosed by the invention, key enzyme genes and a strong promoter for anabolism of the lipid are introduced on the basis that the anabolism of microbial oil is known, so that the lipid metabolism is regulated and controlled, and the yield of oil is improved. The genetic engineering strain can be applied to production of the microbial oil and development of functional oil related products, such as medicaments, health care products and the like.

Owner:广州溯原生物科技股份有限公司

Manioca biological fuel mixture

InactiveCN1594512AEmission reductionReduce in quantityBiofuelsLiquid carbonaceous fuelsAlcoholJatropha

Owner:四川长江科技有限公司 +1

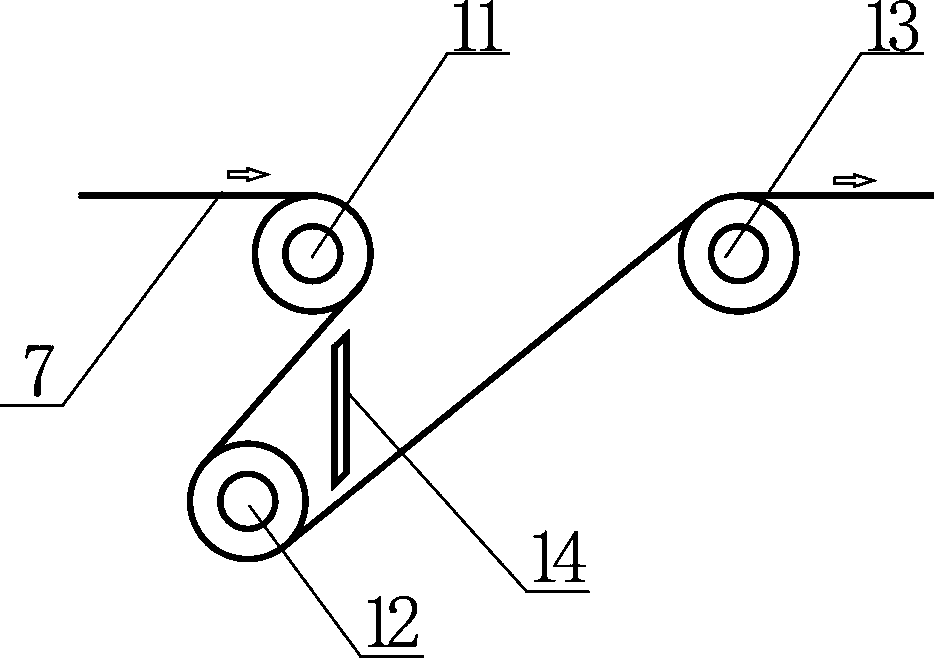

Novel cyclone bias pulverized coal burner

InactiveCN104832918AImprove stabilityEfficient combustionPulverulent fuel combustion burnersAir channelCyclone

The invention discloses a novel cyclone bias pulverized coal burner. The novel cyclone bias pulverized coal burner is characterized by comprising a central pipe, a pulverized coal concentration device, a primary air channel, a pulverized coal bias separating cylinder, a central pipe flaring, a primary air pipe flaring, a secondary air channel, a cyclone, a tertiary air channel and a tertiary air pipe flaring from inside to outside. According to the novel cyclone bias pulverized coal burner, the ignition and the burning of anthracite are supported in a mode of supplementing high-quality bituminous coal, the effect of increasing volatile matters of pulverized coal in a disguised form is achieved in the preliminary burning stage of the pulverized coal, and the timely ignition, the stable burning and the efficient burnout of low-volatile-matter pulverized coal are guaranteed. The novel cyclone bias pulverized coal burner is simple in structure, convenient to transform, and capable of efficiently burning the low-volatile-matter coal and particularly suitable for the structural transformation of burners of medium and small-sized industrial boilers, and can be widely applied to burning of low-volatile-matter anthracite duff for the industrial boilers.

Owner:JIMEI UNIV

Method for preparing biodiesel by catalytic cracking

The invention relates to a method for preparing biodiesel through catalytic cracking from vegetable oil under the action of a catalyst, which comprises the following operation steps: heating the vegetable oil and then performing flash vaporization on the vegetable oil when the temperature is between 130 and 170 DEG C to remove water vapor and light components; heating the vegetable oil after the flash vaporization to react with the catalyst at a temperature of between 360 and 450 DEG C, wherein the space velocity of the catalyst is between 0.5 and 1 ton / hour.ton catalyst; performing secondary catalytic reaction on the reaction products obtained in the step with the same catalyst with the space velocity of between 0.5 and 1 ton / hour.ton catalyst; and performing distillation separation on the prepared catalytic product with the feed temperature of between 350 and 380 DEG C to prepare biological gasoline, the biodiesel and residual oil respectively. The biodiesel prepared by the method has the advantages of excellent environmental protection property, better low temperature engine starting performance, and better lubrification.

Owner:王英国 +1

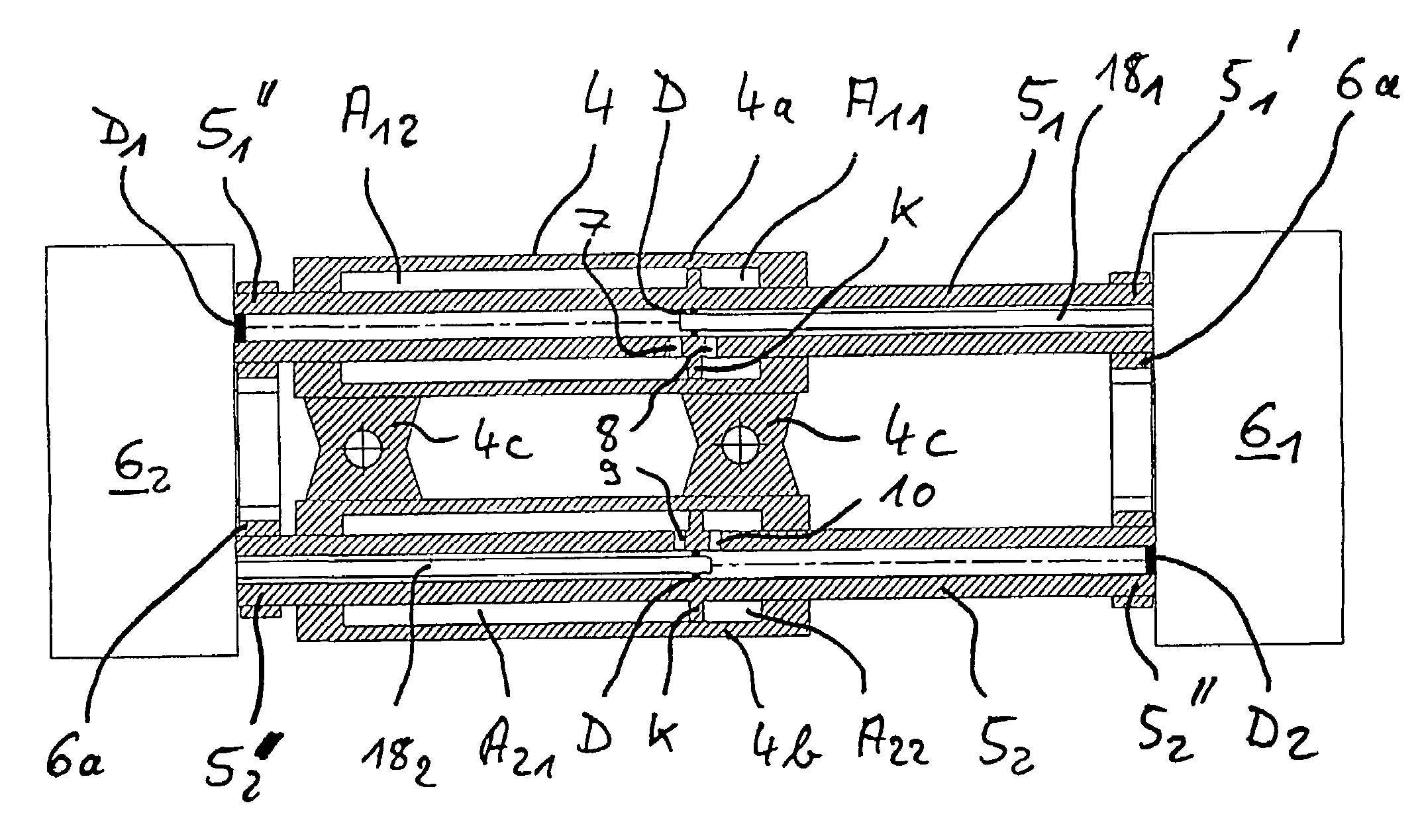

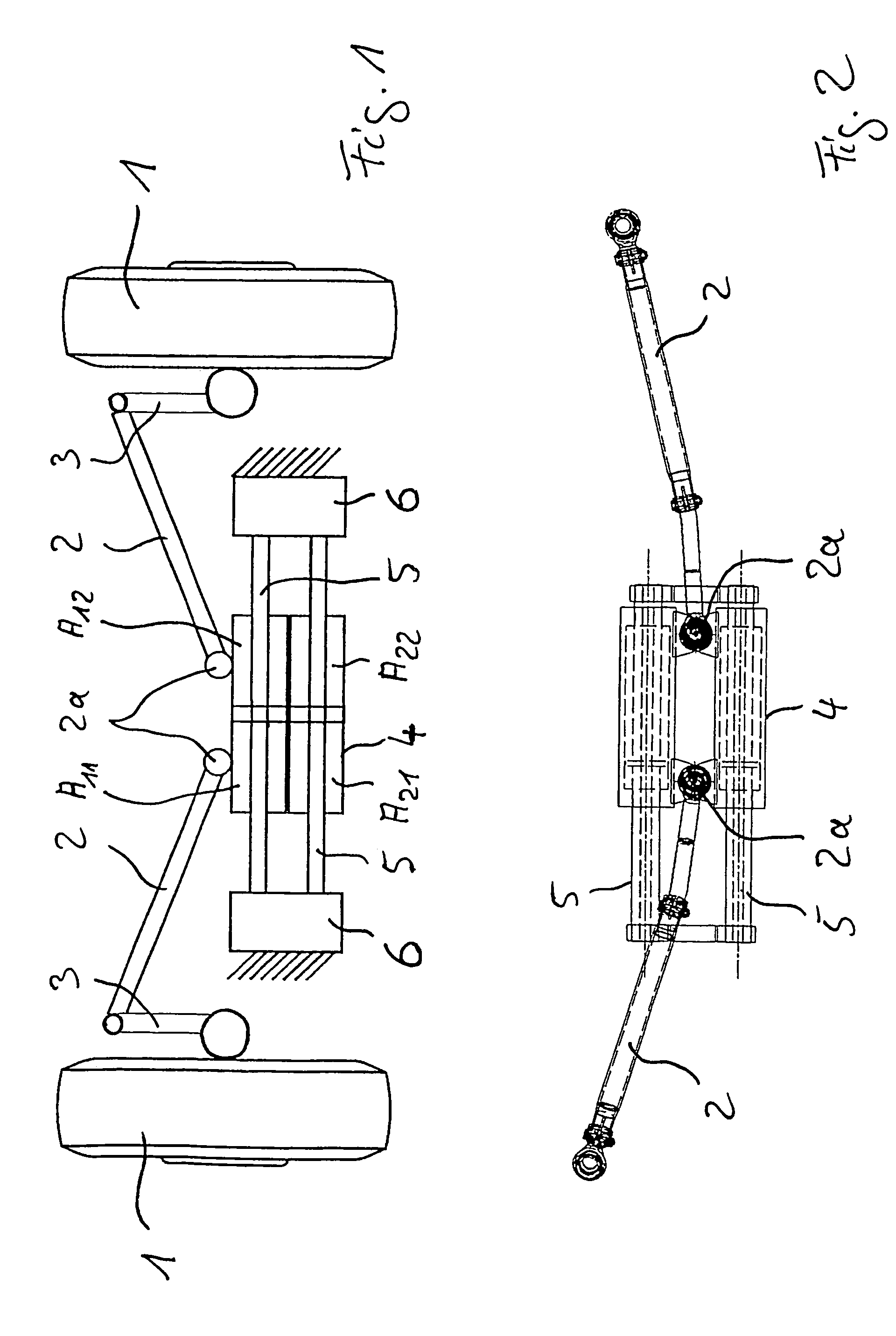

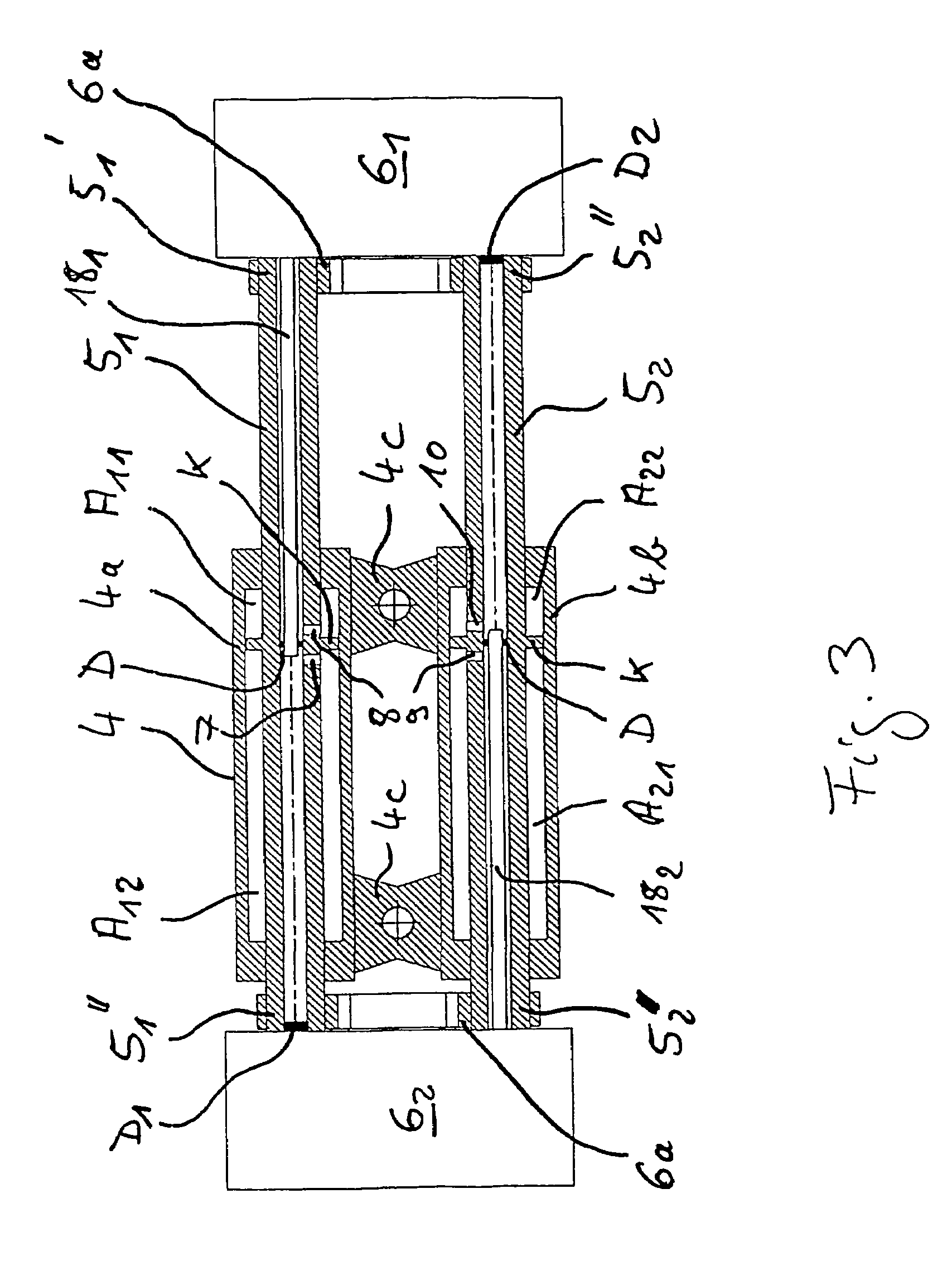

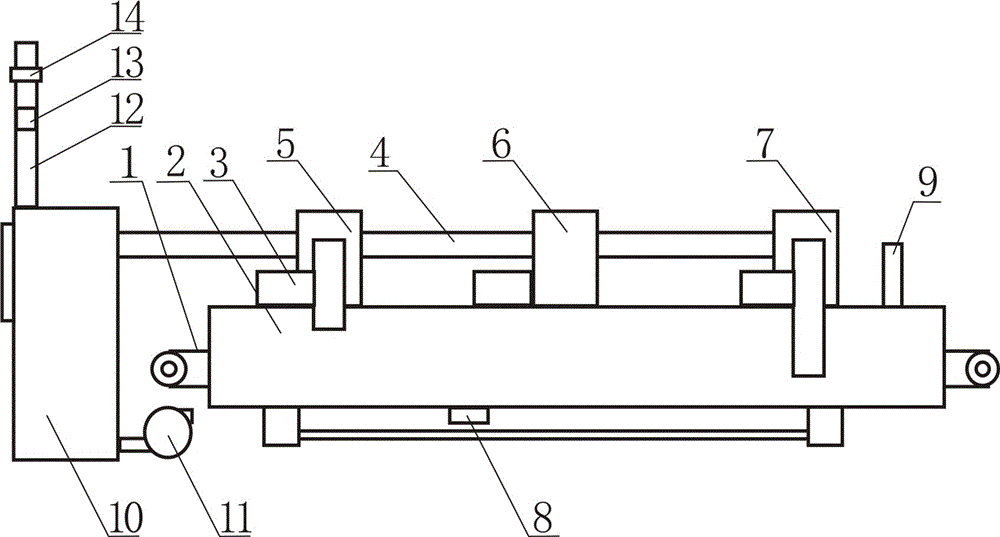

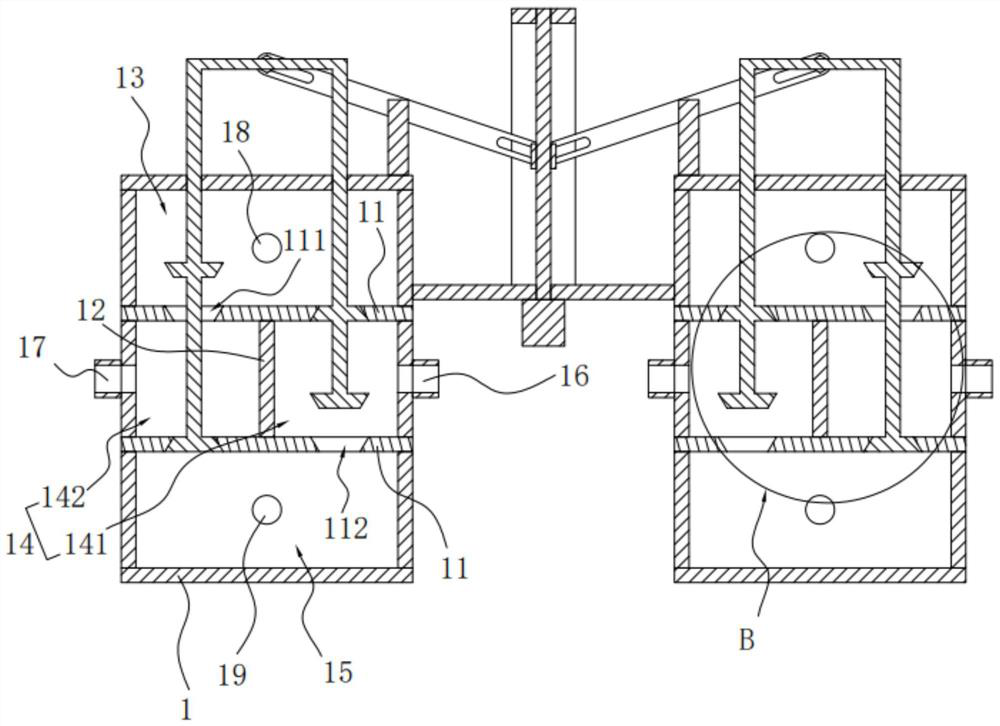

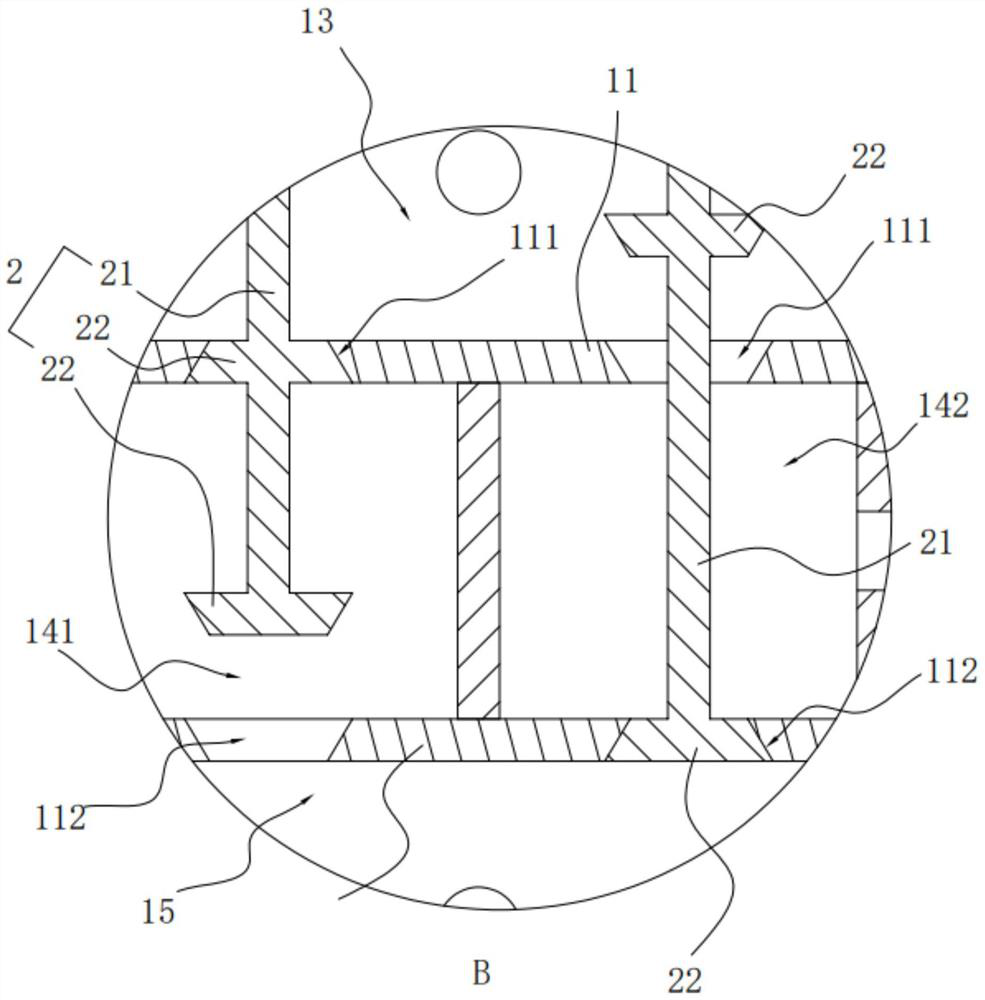

Dual-circuit steer-by-wire steering system comprising a common cradle

InactiveUS7331419B2Good energyGood fuelFluid steeringServomotor parallel arrangementsPiston cylinderHydraulic control unit

The invention relates to a steer-by-wire steering system comprising a hydraulic control unit that acts on the steerable wheels (1, 20), the control unit having at least one cradle (4, 23), which is displaceably mounted on at least one guide rod (5, 24) that passes through the respective cradle (4, 23). The respective cradle (4, 23) and the corresponding guide rod(s) (5, 24) form working chambers (A11, A12, A21, A22) of a piston-cylinder system, whereby each respective guide rod (5, 24) has at least one channel (KA11, KA12, KA21, KA22), each terminating in the vicinity of a working chamber (A11, A12, A21, A22). The cradle or cradles (4, 23) adjust the steerable wheels (1, 20) directly or by means of steering tie rods (2, 21).

Owner:THYSSENKRUPP PRESTA STEERTEC

High-pressure hydrothermal and circulating fluidized bed pyrolysis-assisted rapid harmless sludge treatment process

InactiveCN108218160AMild technical conditionsLow equipment requirementsSludge treatmentSpecial form destructive distillationSorbentDecomposition

The invention relates to a high-pressure hydrothermal and circulating fluidized bed pyrolysis-assisted rapid harmless sludge treatment process. According to the treatment process, Ca(OH)2 is added toenhance the hydrolysis and decarboxylation reactions in a high-pressure hydrothermal sludge pretreatment process, so that the dewatering performance of the sludge is significantly improved, and the cost of sludge pyrolysis pretreatment is lowered; a circulating fluidized bed is high in pyrolysis treatment efficiency and low in energy consumption; the addition of Ca is beneficial to the secondary decomposition of tar during pyrolysis, so that the generation of hazardous waste tar is controlled; furthermore, the pyrolysis process can stabilize the heavy metals in the sludge and effectively decompose the organic pollutants; the pH value of pyrolysis carbon is within a range of 10.6-12.4, so that the pyrolysis carbon can be recovered as an acid contaminated soil improver or adsorbent; the method provided by the invention is energy-saving and efficiency, and realizes the rapid and harmless treatment and resource utilization of the sludge.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

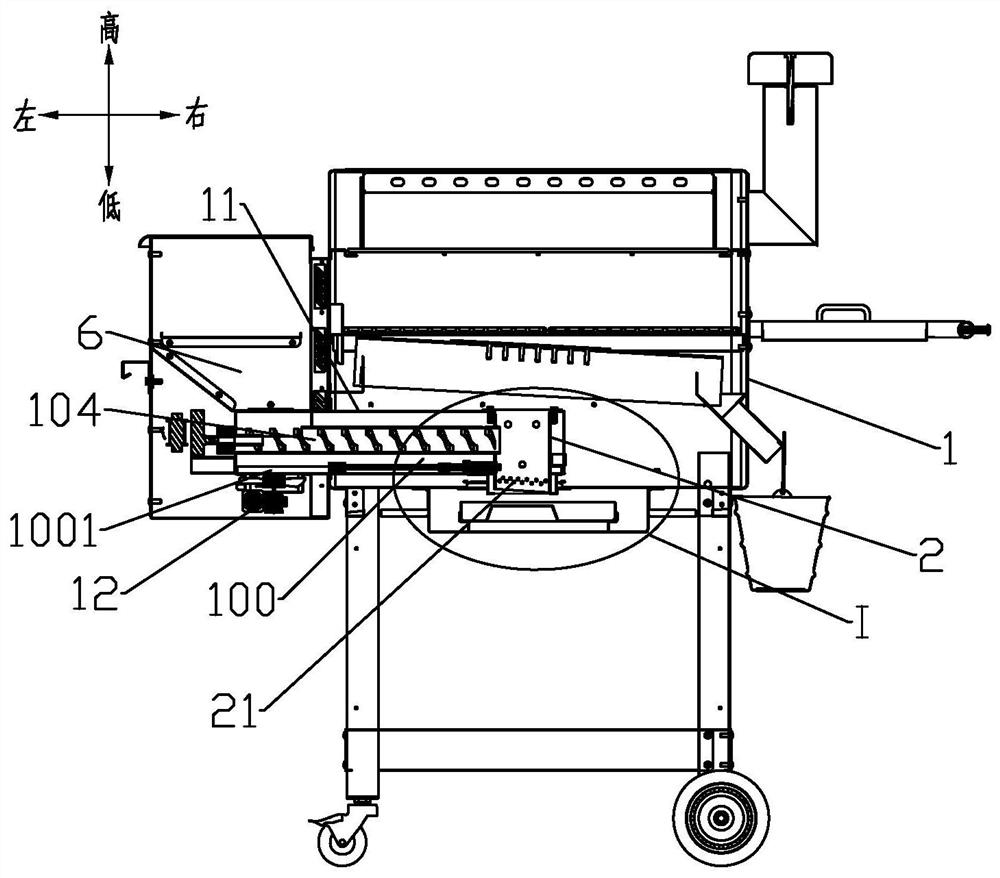

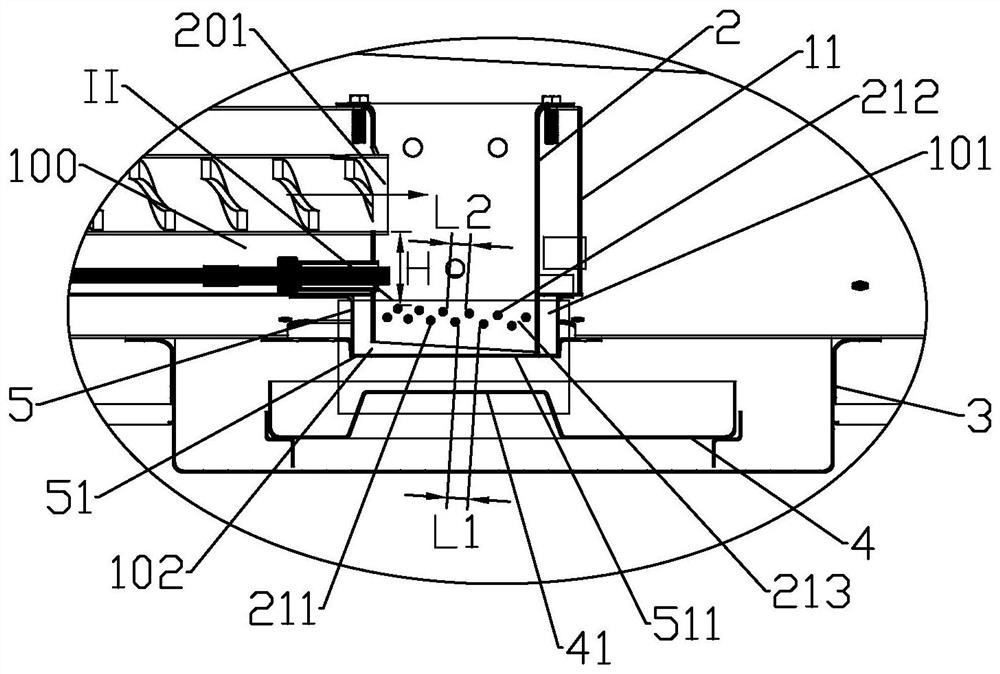

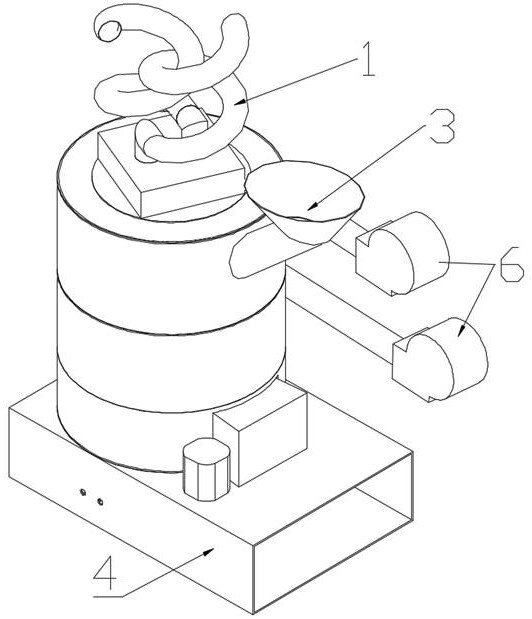

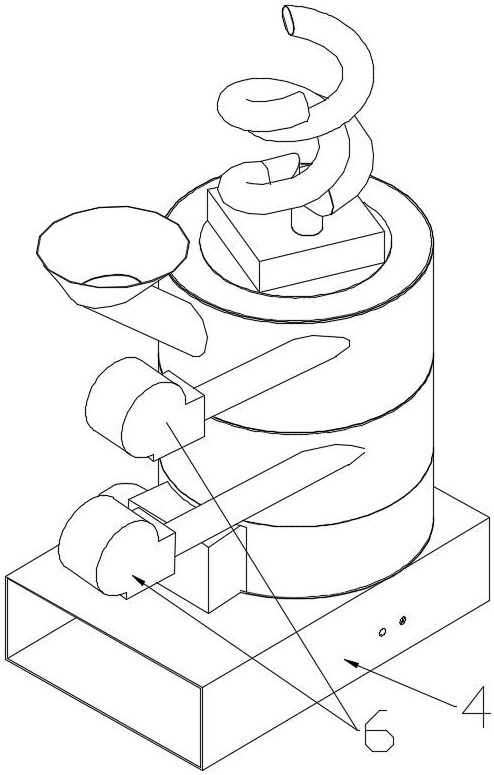

Stick manufacture machine of plant

The invention discloses a plant stick-producing machine, including a crushing device which is driven by a power source and provided with a material inlet and a material outlet, and an extrusion forming device; wherein, the extrusion forming device is composed of an extrusion chamber and an extrusion device arranged in the extrusion chamber; the material outlet of the crushing device is communicated with the material inlet of the extrusion chamber; the side wall of the extrusion chamber is provided with a bond-feeding inlet; while the external wall of the extrusion chamber is provided with a heating device. The plant stick-producing machine of the invention has the advantages that waste combustible such as straws and braches can be made into rod-shaped fuel through crushing device and the extrusion forming device with high automation. The crushing device and the extrusion forming device are wholly-structured and are arranged on an agricultural motor vehicle; and the crushing device and the extrusion forming device are driven by the output power of the agricultural motor vehicle, which greatly facilitates in producing straws in scattered places, such as fields. The plant stick-producing machine has the advantages of purifying environments and saving resources by turning waste materials into useful materials. Therefore, the plant stick-producing machine has good economic benefits and wide social benefits.

Owner:张思忠

Combustion boiler of power station

ActiveCN105240818ABurn completelyPrevent backflowBoiler water tubesSteam generation using pressureCombustionPower station

The invention discloses a combustion boiler of a power station. The combustion boiler comprises a furnace body and a cyclone separator, wherein the furnace body comprises a wind distribution device, a combustion furnace and a steam dome; the wind distribution device is located below the combustion furnace; the wind distribution device comprises an igniter and an air pipe; the igniter is connected with the air pipe; a water cooling wall and a filter are arranged on the combustion furnace; the water cooling wall is arranged on the combustion furnace; the filter is located on the left upper end of the water cooling wall; the steam dome is located on the left upper side of the combustion furnace; the steam dome is connected with the water cooling wall; the cyclone separator is located on the right side of the furnace body; the cyclone separator comprises an expansion pipeline, a smoke filter and a material return pipe; the expansion pipeline is located on the right upper side of the cyclone separator, and is connected with the furnace body; the smoke filter is arranged on the cyclone separator; and the material return pipe is located below the cyclone separator. The combustion boiler of the power station has the advantages that fuels can be fully combusted; the utilization efficiency is improved; the energy is saved; and the environment is protected.

Owner:江苏橙果能源环保有限公司

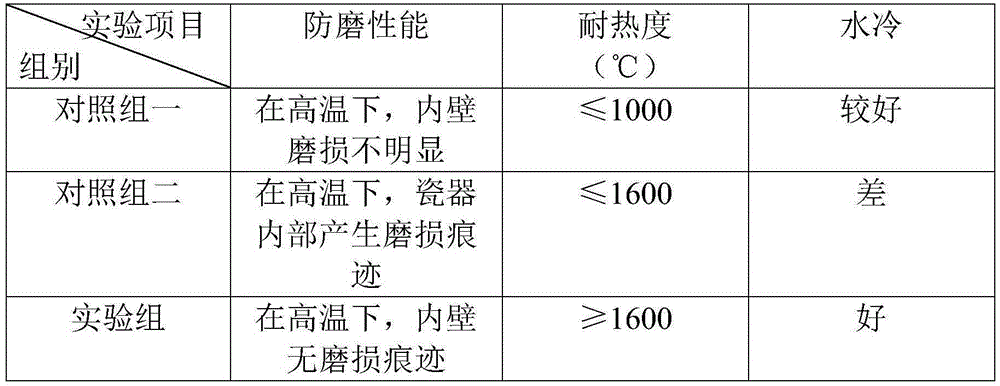

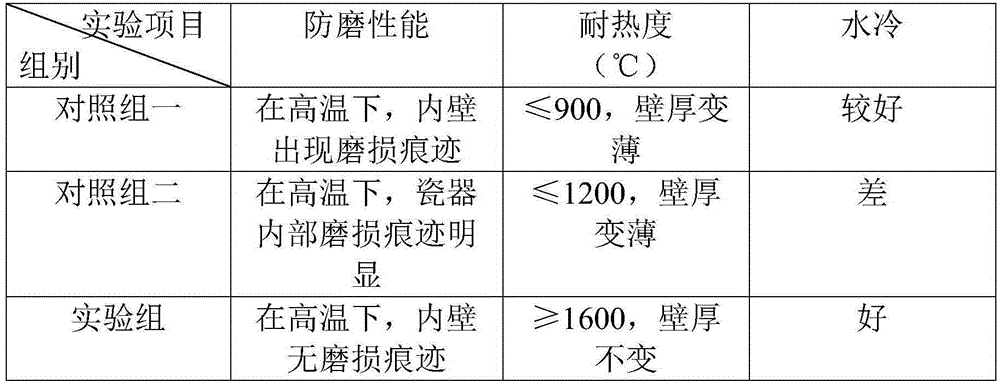

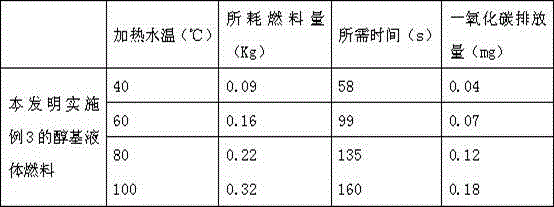

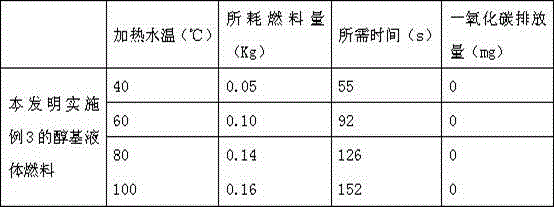

Alcohol-based liquid fuel

InactiveCN106753605AReduce sulfur contentReduce wear rateLiquid carbonaceous fuelsFuel additivesAlcoholJatropha

The invention relates to alcohol-based liquid fuel. The fuel comprises the following raw materials in parts by weight: 80 to 85 parts of methyl alcohol, 5 to 10 parts of water, 1 to 2 parts of petrol, 1 to 3 parts of sodium hydroxide, 1 to 3 parts of castor oil, 3 to 8 parts of jatropha carcas fruit oil, 2 to 5 parts of edible oil, 1 to 3 parts of essence, 1 to 5 parts of industrial salt, and 1 to 5 parts of ethyl alcohol. The fuel has the characteristics that the fuel does not produce poisonous gas when being burnt and is odor-free; the fuel can be completely burnt, the heat value produced through burning is high, the flash point of the fuel can be reduced, the fuel can be easily ignited, can be completely burnt, does not produce poisonous gas, and is low in cost, economical and practical, and green and environmental-friendly.

Owner:吴良善 +2

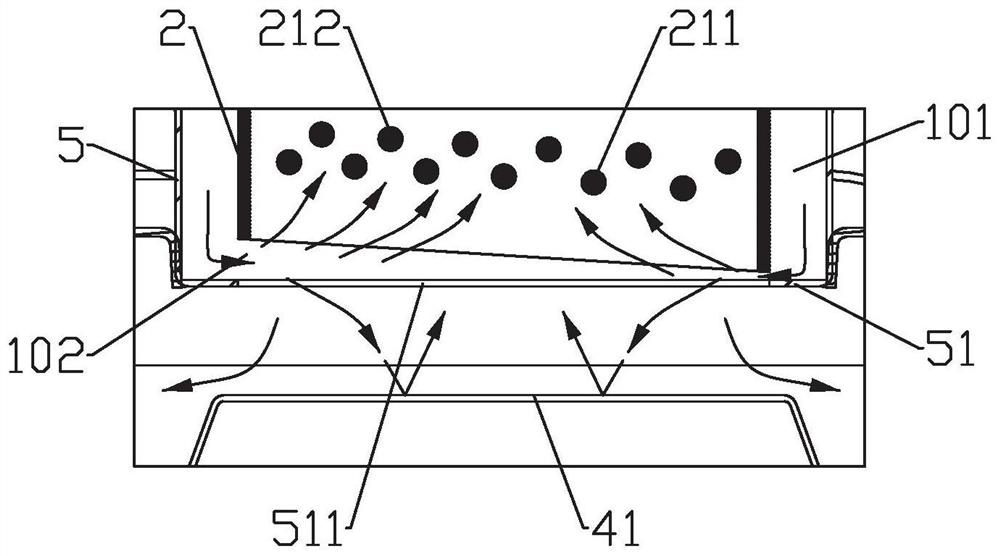

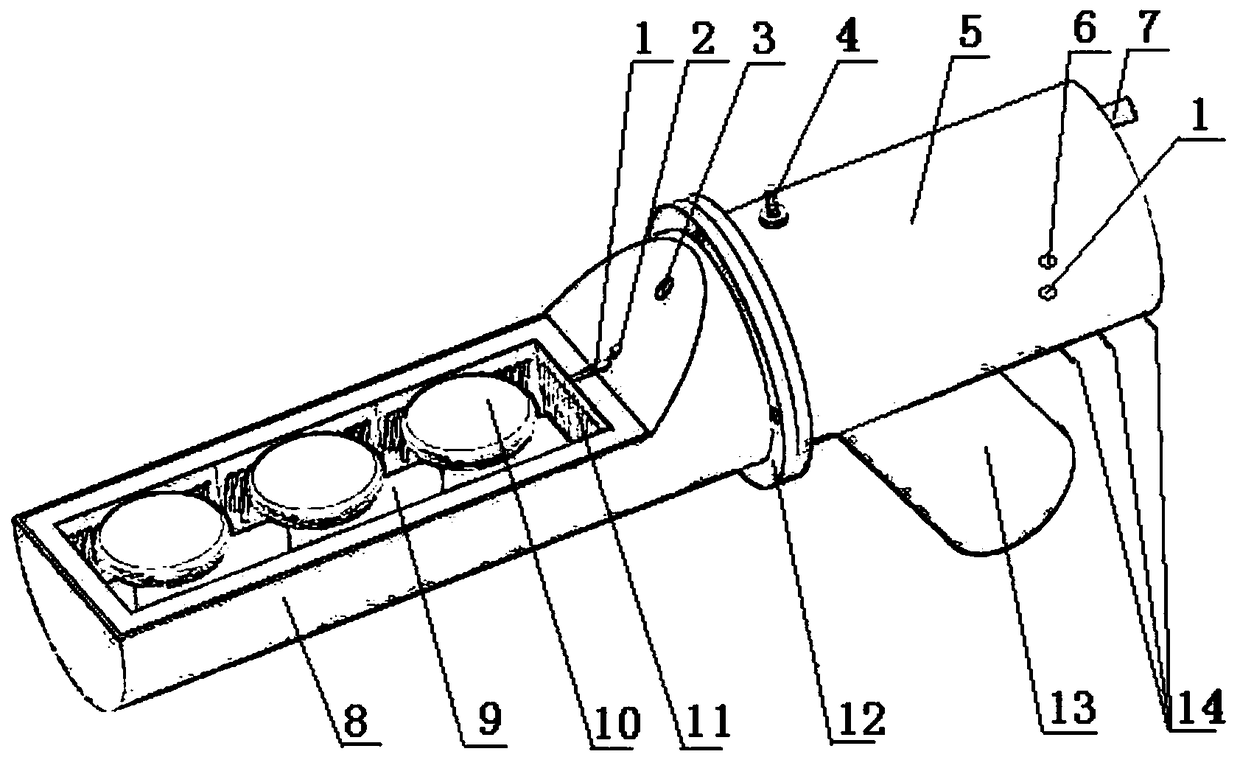

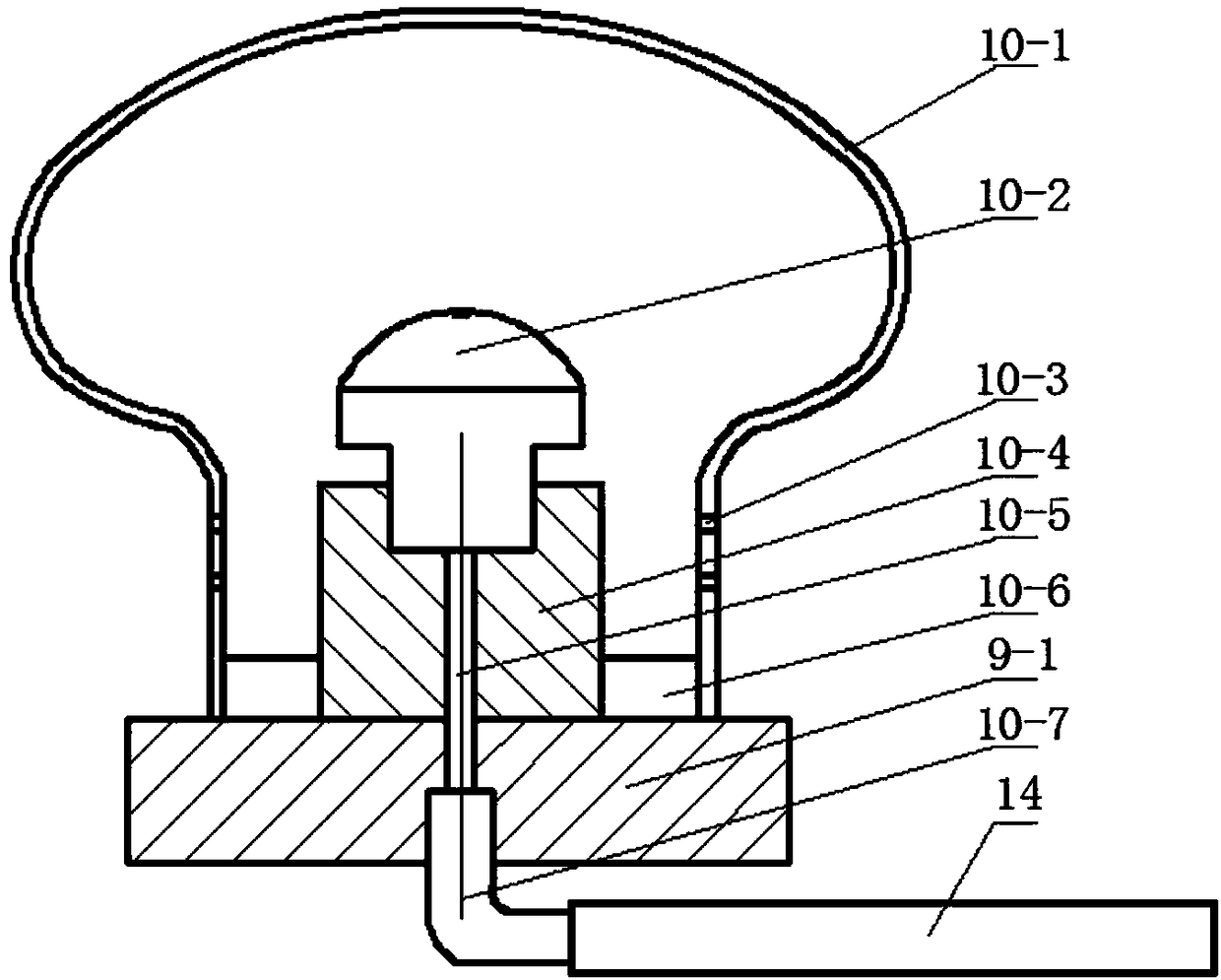

Internal combustion engine energy-saving device

InactiveCN103835843ATo achieve combustionTo achieve the purpose of saving fuelNon-fuel substance addition to fuelInternal combustion piston enginesGas compositionExternal combustion engine

The invention relates to energy-saving devices, in particular to an internal combustion engine energy-saving device. The internal combustion engine energy-saving device comprises a shell with the hollow inside, the two opposite faces of the shell are provided with an air inlet and an air outlet, the air inlet is communicated with an air inlet pipe of an internal combustion engine, the air outlet is communicated with a motor of the internal combustion engine, two cooling fins which are oppositely arranged are arranged between the air inlet and the air outlet inside the shell, and the opposite faces of the two cooling fins are respectively provided with an ozone generating piece. High voltage power sources are arranged between the back-to-back faces of the two cooling fins and the corresponding faces of the shell respectively, the high voltage power sources are electrically connected with an ozone generator, an intelligent controller is arranged on the side face of the shell, and the intelligent controller is electrically connected with the high voltage power sources. Ozone is used for replacing oxygen to be used as combustion-supporting materials, the amount of oxygen is increased, the ozone is used as strong oxidant and can accelerate fuel oxidation reaction, combustion can be conducted better and faster, harmful gas compositions in waste gas are reduced, and the purposes of combustion supporting, pollution reduction and energy saving are achieved.

Owner:徐杰

Blast furnace for iron smelting

InactiveCN112522462APrevent fallingReduced degree of thermal erosionTuyeresBlast furnace detailsHigh pressure oxygenMechanics

The invention relates to the technical field of iron smelting, and discloses a blast furnace for iron smelting. The blast furnace comprises a furnace wall, a hot air pipeline is fixedly mounted at thebottom end of the inner side of the furnace wall, an air cavity pipe is fixedly mounted at the top end of the hot air pipeline, and a circulating water pipe is fixedly mounted at the top end of the air cavity pipe. An air supply pipe and the circulating water pipe are additionally arranged on the hot air pipeline, high-pressure oxygen airflow is conveyed through the air supply pipe, an air wall is formed, primary blocking protection is conducted on the hot air pipeline, furnace burden and furnace slag are prevented from falling off and thermally corroding a pipe body, secondary cooling protection is conducted through cold water flow in the circulating water pipe, and high-temperature falling objects are cooled so that it can be ensured that the thermal corrosion degree is substantially reduced; and by arranging a water partition plate and an air partition plate, the circulating water pipe and the air cavity pipe are divided into four areas, heat contained in water flow circulation andheat emitted by the pipe body are used for conducting heat conduction and heating on oxygen flow, oxygen is added to jetted hot air coal gas, the oxidation reaction of a material column is promoted,and combustion supporting is facilitated.

Owner:刘兰英

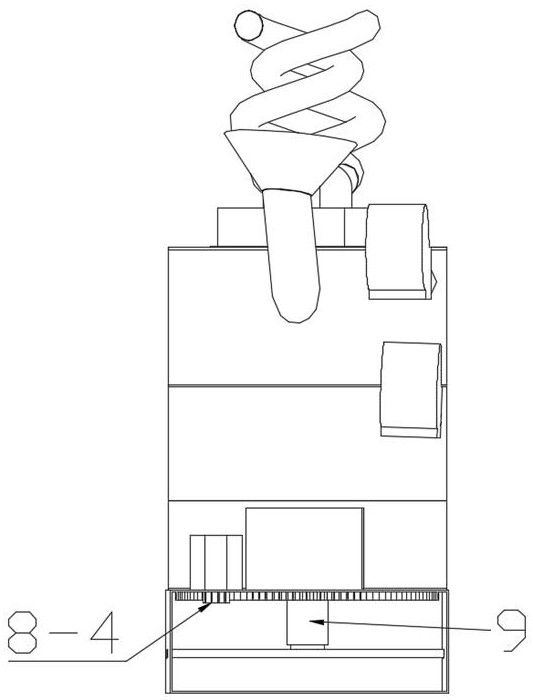

Biomass combustion furnace

ActiveCN112856389ASpeed up evaporationSpeed up vaporizationSolid fuel combustionAir/fuel supply for combustionCombustorEnvironmental engineering

The invention discloses a biomass combustion furnace, belongs to the field of combustion equipment, and solves the problem of poor use experience caused by ash flying in a furnace body or flying into a room in the prior art. According to the technical scheme, the top end of a combustor is open, and a furnace body is provided with an air inlet channel extending to the bottom of the combustor; and a through opening used for air inlet and ash falling is formed in the bottom face of the combustor, a fire grate is arranged above the through opening, a water storage disc and an ash receiving disc are arranged at the bottom of the furnace body, and the ash receiving disc is located below the combustor and faces the through opening. The biomass combustion furnace is mainly used for effectively inhibiting ash flying and improving the combustion-supporting effect.

Owner:深圳市艾斯默克科技有限公司

Non-ferrous metal smelting side blowing furnace spray gun

ActiveCN101382387BImprove combustion performanceSpeed up redox reactionsGaseous fuel burnerCombustionEngineering

The invention proposes a new type of non-ferrous metal smelting side blowing furnace spray gun, which includes a casing structure of the spray gun body and a spray gun head at the front end of the spray gun body. The central pipe of the casing structure has a connection interface for connecting the fuel delivery device. The annular passage has a connecting interface for connecting the combustion-supporting gas, the spray gun head has a fuel nozzle adapted to the central pipe and a combustion-supporting gas nozzle adapted to the interlayer annular passage, and the combustion-supporting gas nozzle has a through-hole nozzle array.

Owner:CHINA ENFI ENGINEERING CORPORATION

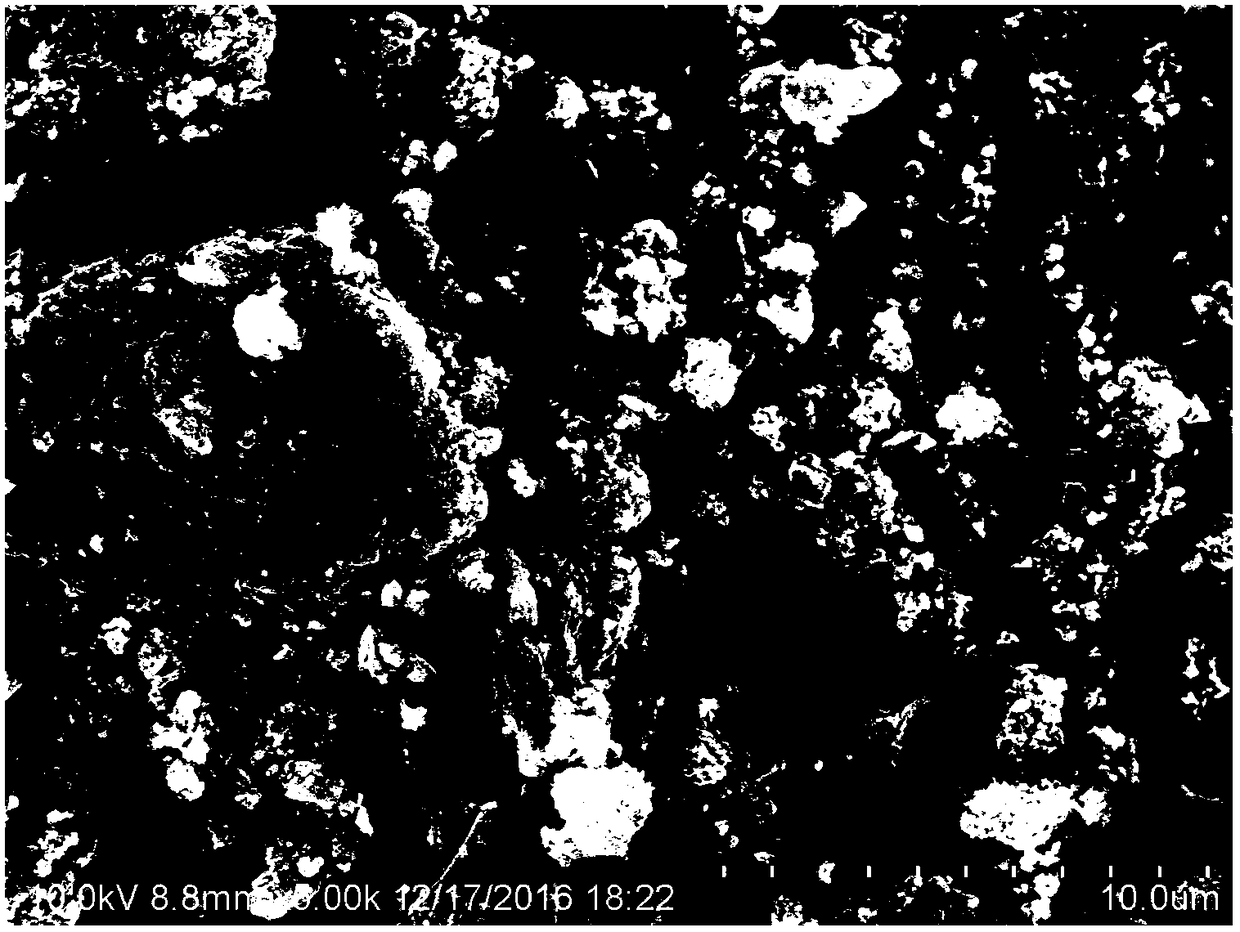

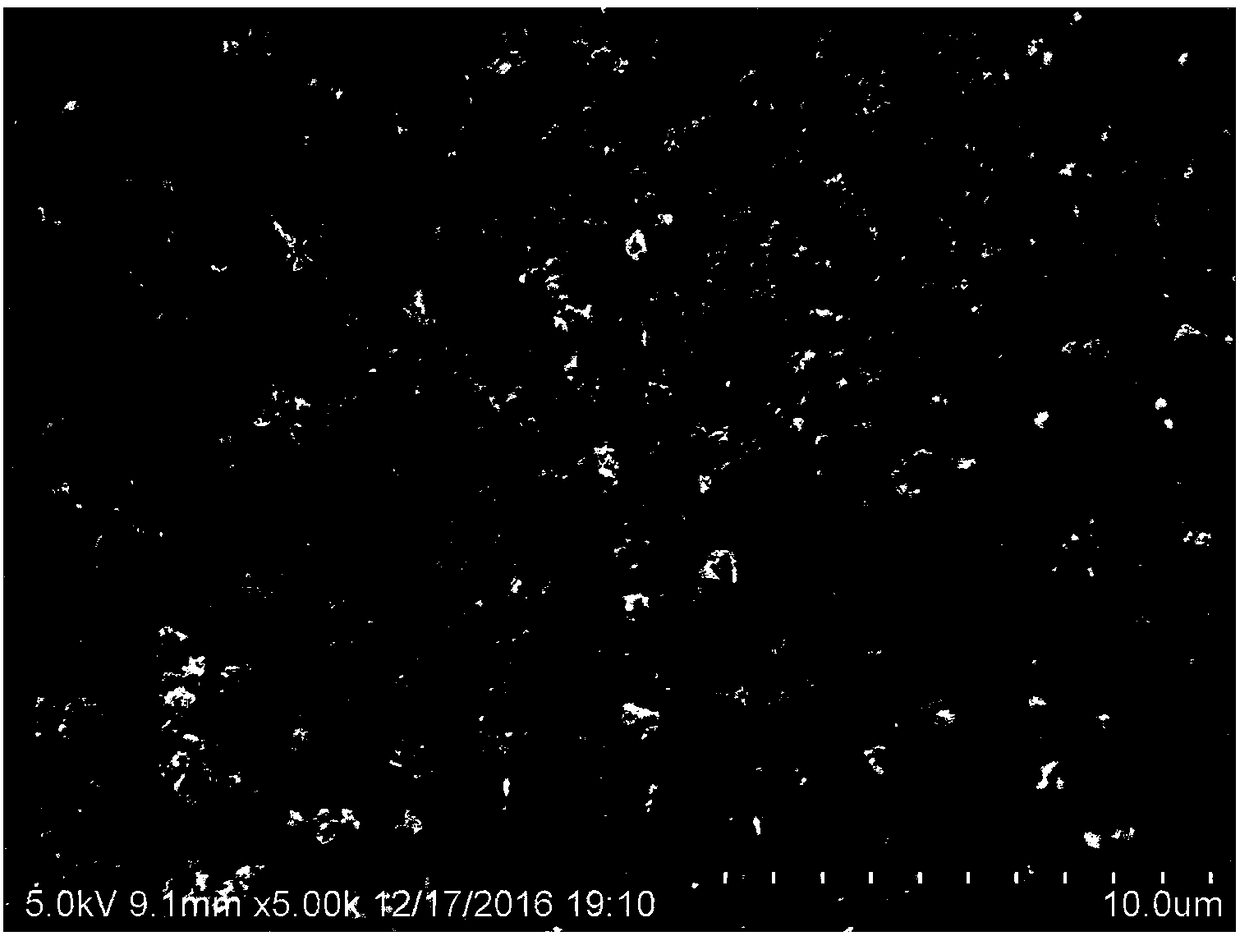

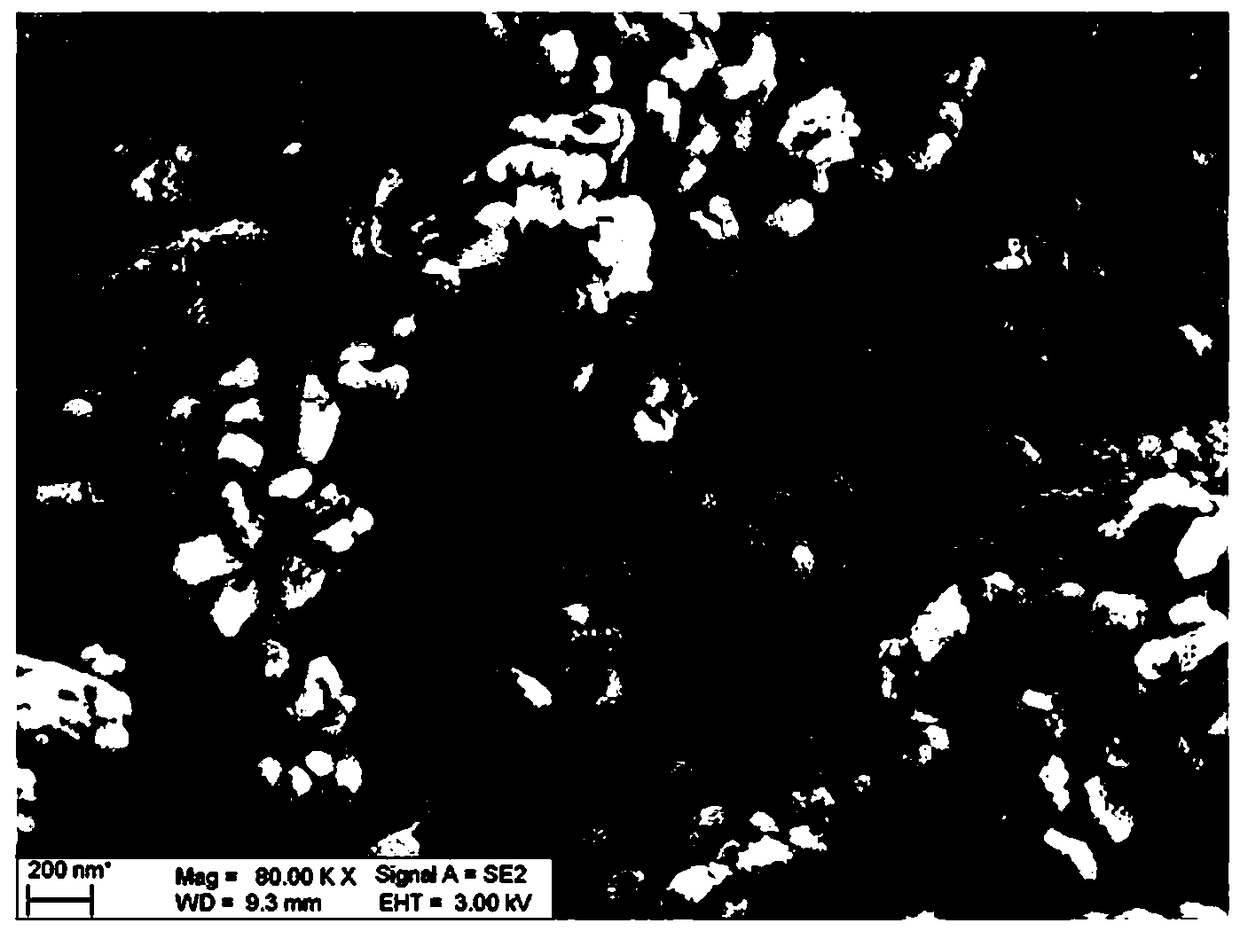

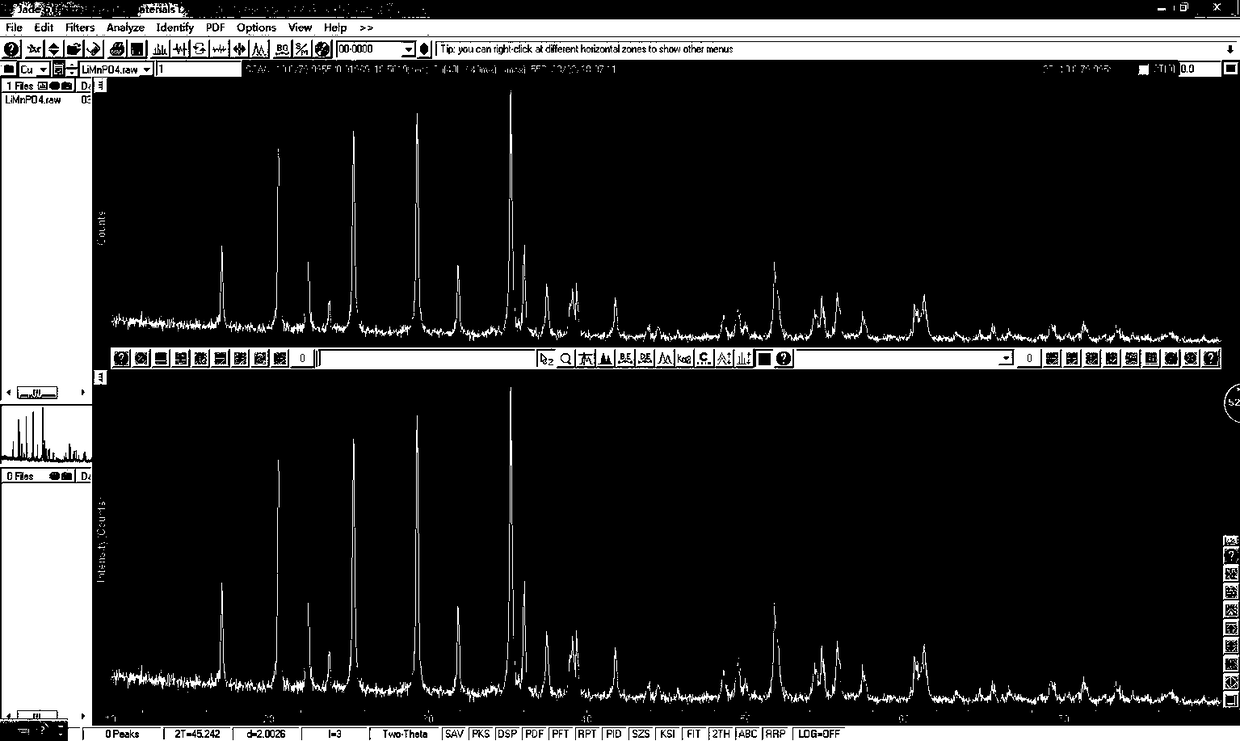

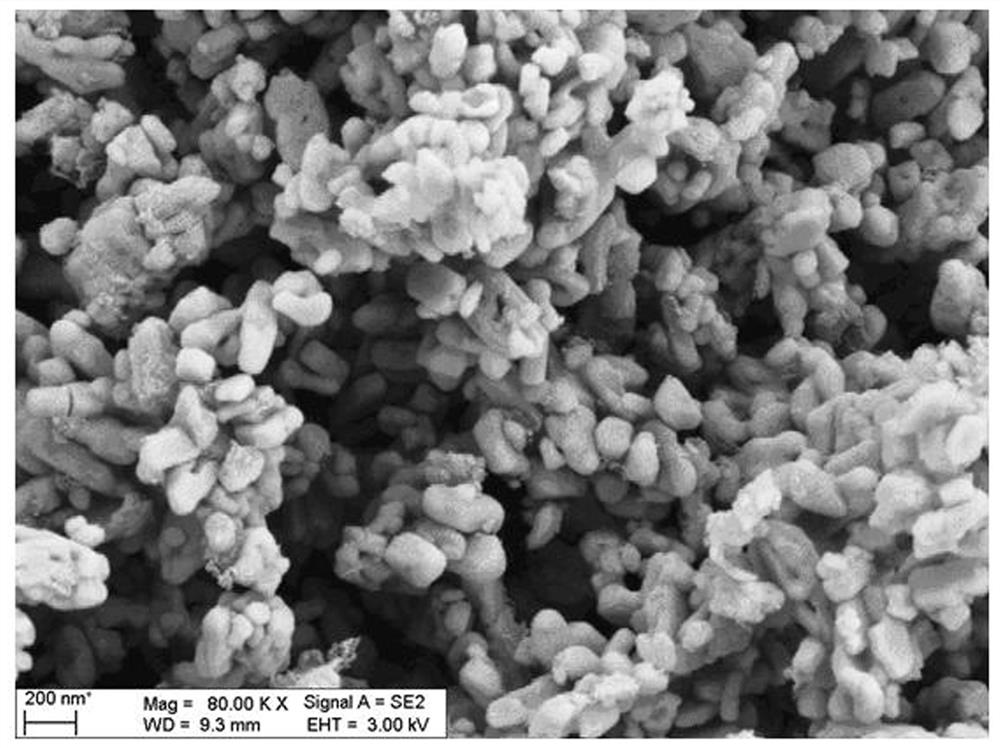

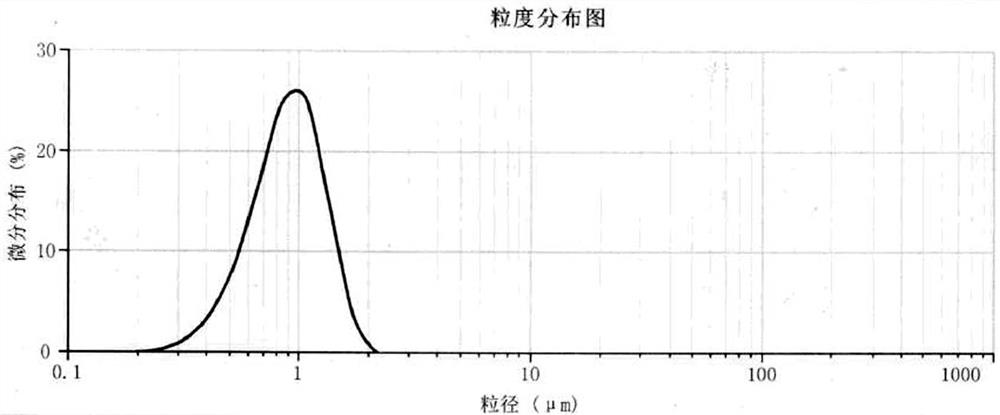

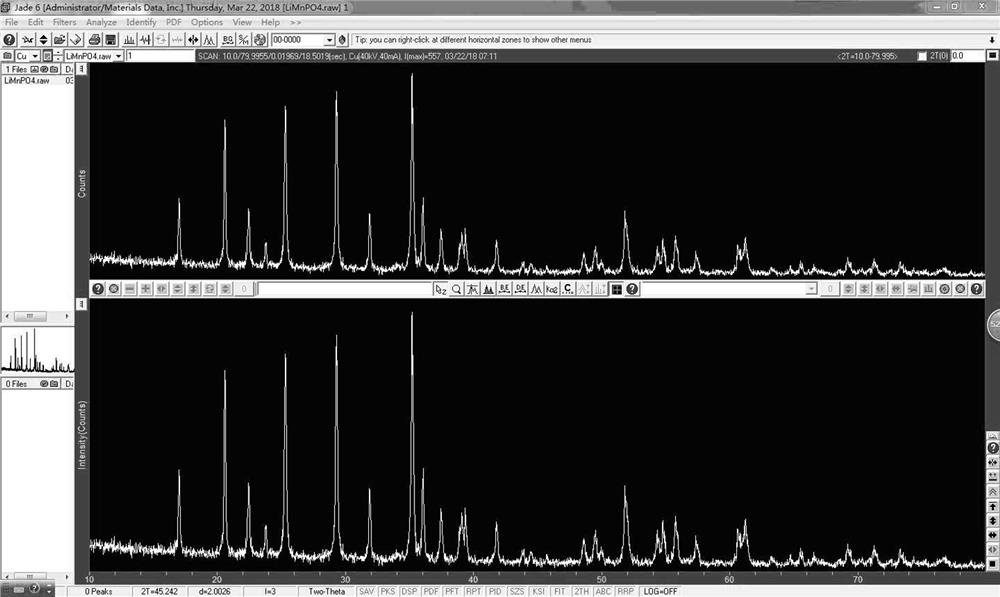

Preparation method of pollution-free low-cost lithium manganese ferric phosphate crystal material

ActiveCN108408709AImprove the level ofWidely sourced, non-toxic and cheapCell electrodesPhosphorus compoundsEnvironmental resistanceLithium hydroxide

The invention discloses a preparation method of a pollution-free low-cost lithium manganese ferric phosphate crystal material. The preparation method includes following steps: selecting iron powder and manganese powder high in purity, wherein granularity is selected from 20-20000 meshes; taking the manganese powder, the iron powder, phosphoric acid and a lithium source solution according to a certain mass ratio, diluting, putting them into an acid-resistant reactor, and stirring to enable the iron powder, the manganese powder and the phosphoric acid to be in sufficient reaction; adding the lithium source solution into obtained reaction precursor size, and sufficiently stirring, wherein the lithium source solution is soluble lithium source lithium hydroxide or lithium acetate; transferringobtained size into a reaction kettle, and starting hydrothermal reaction; performing solid-liquid separation on size obtained after reaction, and subjecting solid lithium manganese ferric phosphate which is separated out to clathration carbonization annealing treatment to obtain the lithium manganese ferric phosphate crystal material. Compared with the prior art, the preparation method has the advantages that cost is low, process operation is convenient, the material is high in commercial value, the preparation process is free of pollution, and current requirements on environment protection are met.

Owner:南阳逢源新能源科技有限公司

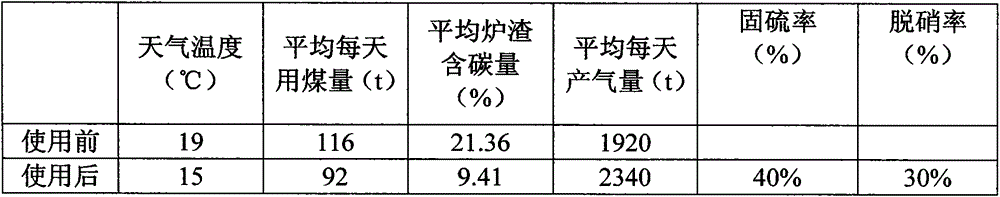

Multifunctional coal-saving synergistic additive

InactiveCN104130819AEmission reductionWide variety of sourcesSolid fuelsSodium acetatePotassium carbonate

The invention discloses a multifunctional coal-saving synergistic additive. The multifunctional coal-saving synergistic additive comprises, by weight, 1-10 parts of a mixed strong oxidant, 1-3 parts of a combustion improver and 1-6 parts of a sulfur-fixation antismoke agent. The mixed strong oxidant comprises potassium permanganate, potassium nitrate, sodium nitrate and potassium perchlorate. The combustion improver comprises sodium chloride and sodium acetate. The sulfur-fixation antismoke agent comprises calcium oxide, potassium carbonate, sodium carbonate, ferrous sulphate and bleaching powder. Through crushing, cooling, condensation and passivation, the multifunctional coal-saving synergistic additive is prepared. The concrete preparation processes are conventional processes and are simple and convenient. Aiming at different types of coal, the multifunctional coal-saving synergistic additive has good effects of supporting combustion and reducing SO2 and NOX discharge, is prepared from the raw materials having wide sources and low prices and has a very great popularization usage value.

Owner:FUJIAN ZHONGMEI CHEM ENVIRONMENTAL PROTECTION TECH CO LTD

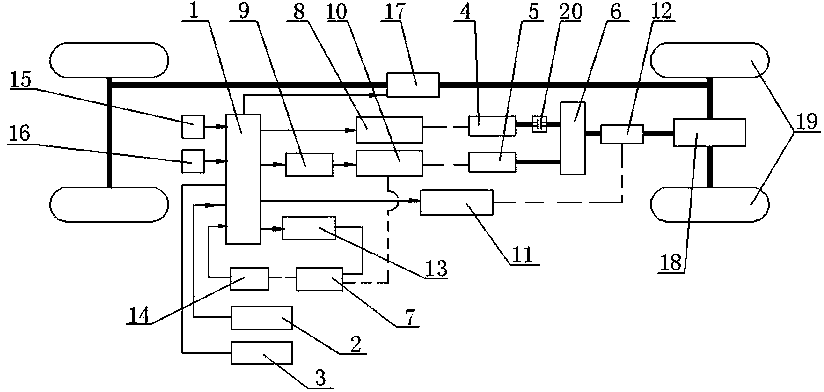

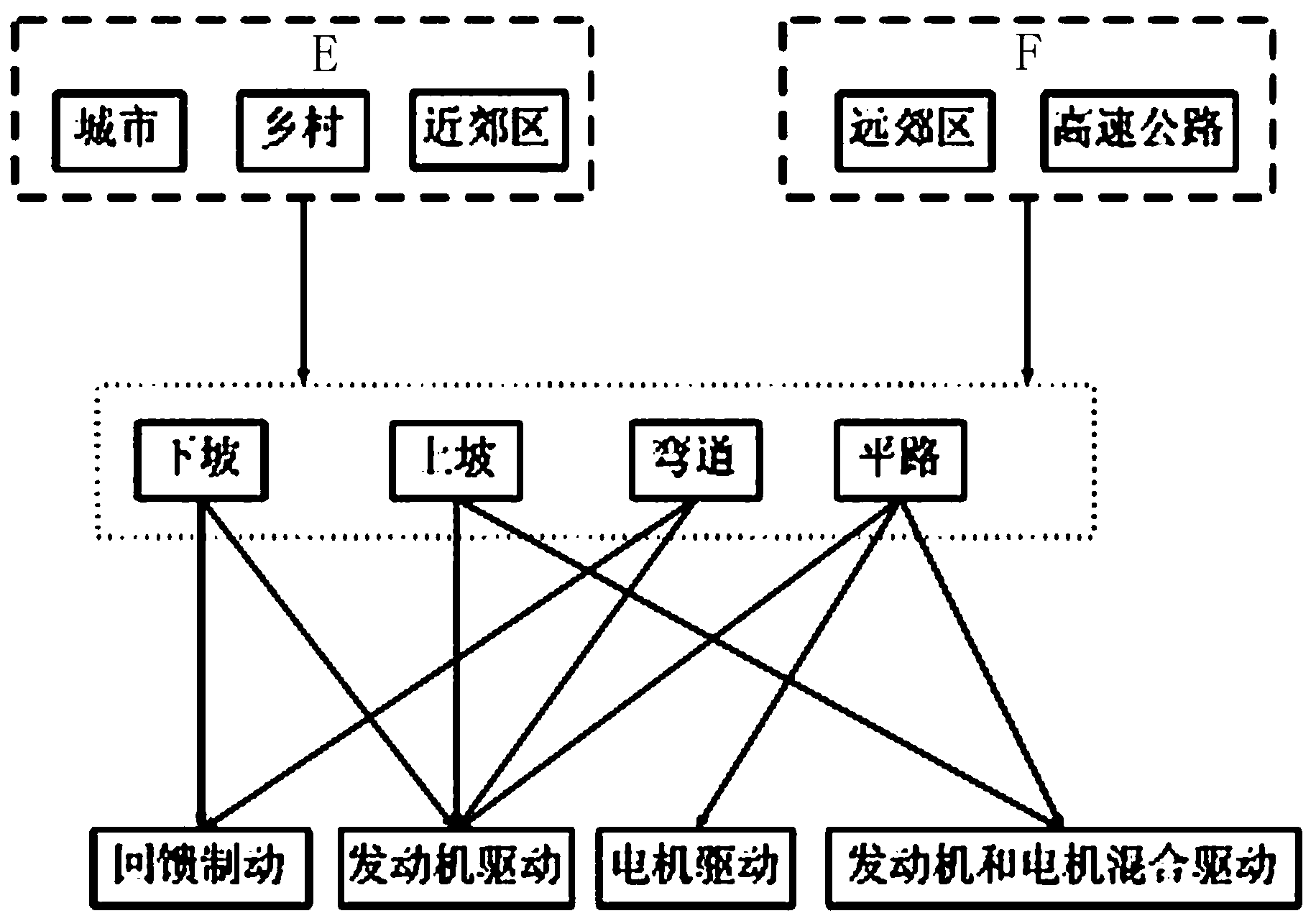

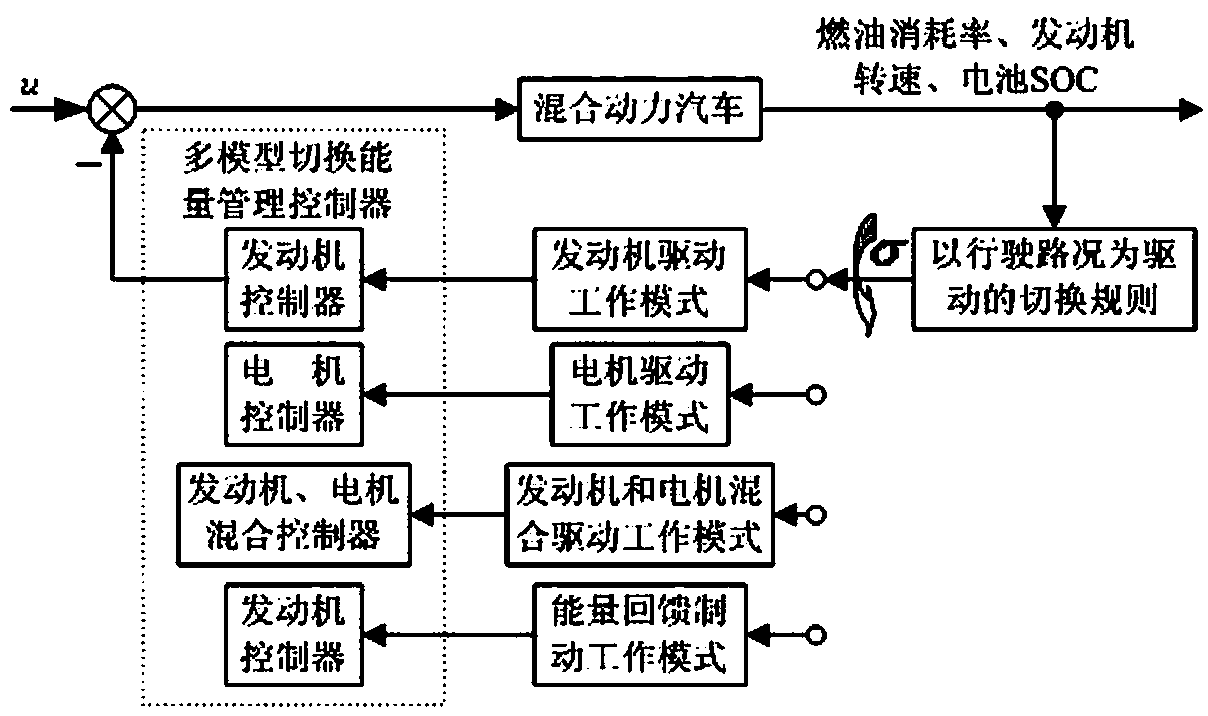

Energy switching control method and energy switching control system for hybrid electric vehicle in multiple operating modes

InactiveCN102556055BImprove battery lifeEmission reductionHybrid vehiclesFuel conservationVehicle driving

Disclosed are an energy switching control method and an energy switching control system for a hybrid electric vehicle in multiple operating modes. The energy switching control method includes the steps: firstly, according to vehicle running environments and road conditions detected in real time by a vehicular GPS (global positioning system) and a sensor, and according to current running road condition information of the hybrid electric vehicle, determining the corresponding operating modes of the vehicle, wherein the operating modes specifically include an engine-driven operating mode, a motor-driven operating mode, an engine and motor hybrid driven operating mode and an energy feedback and regenerative brake operating mode; and then designing a multi-mode switching control rule for the driving modes in terms of the running road conditions, and designing corresponding controllers for the operating modes respectively. According to the running environments and the road conditions, the energy switching control method and the energy switching control system control the optimal vehicle driving modes so as to reduce emission of vehicle exhaust, save fuel oil consumption, accelerate development of environment-friendly vehicles and green vehicles and improve endurance of the hybrid electric vehicle.

Owner:HENAN UNIV OF SCI & TECH

Method for preparing PET raw materials from leftover materials of polyester fabrics

The invention discloses a method for preparing PET raw materials from leftover materials of polyester fabrics. The method comprises the steps that the leftover materials of the polyester fabrics are crushed, put into a chemical tank to be soaked and pyrolyzed with ethylene glycol, and then filtering, decoloration, purification and polymerization are conducted to obtain the PET raw materials. The smashed leftover materials of the polyester fabrics are put into the chemical tank to be pyrolyzed and dissolved with the ethylene glycol, and then polyester fibers are dissolved into PET monomers. After the polyester fibers are dissolved, the dissolved polyester fibers are still mixed with other plant fibers or chemical fibers, various dyes and other impurities, and a filtering mode is adopted forthoroughly separating the PET monomers. A purification technology further needs to be adopted for purification on the PET monomers after filtering, decoloration and separation to obtain the polymerization monomers with purified PET. The pure PET monomers obtained through purification are subjected to a polymerization technology to obtain the PET raw materials. The PET raw materials are obtained through polymerization, the viscosity and the like can be adjusted according to product requirements to obtain the PET raw materials with different kinds of viscosity, and different requirements for application in fiber spinning, thin film preparing, bottle blowing, sheet squeezing, modification and the like are met.

Owner:PLASTIC UNION NEW MATERIAL TECH HUBEI

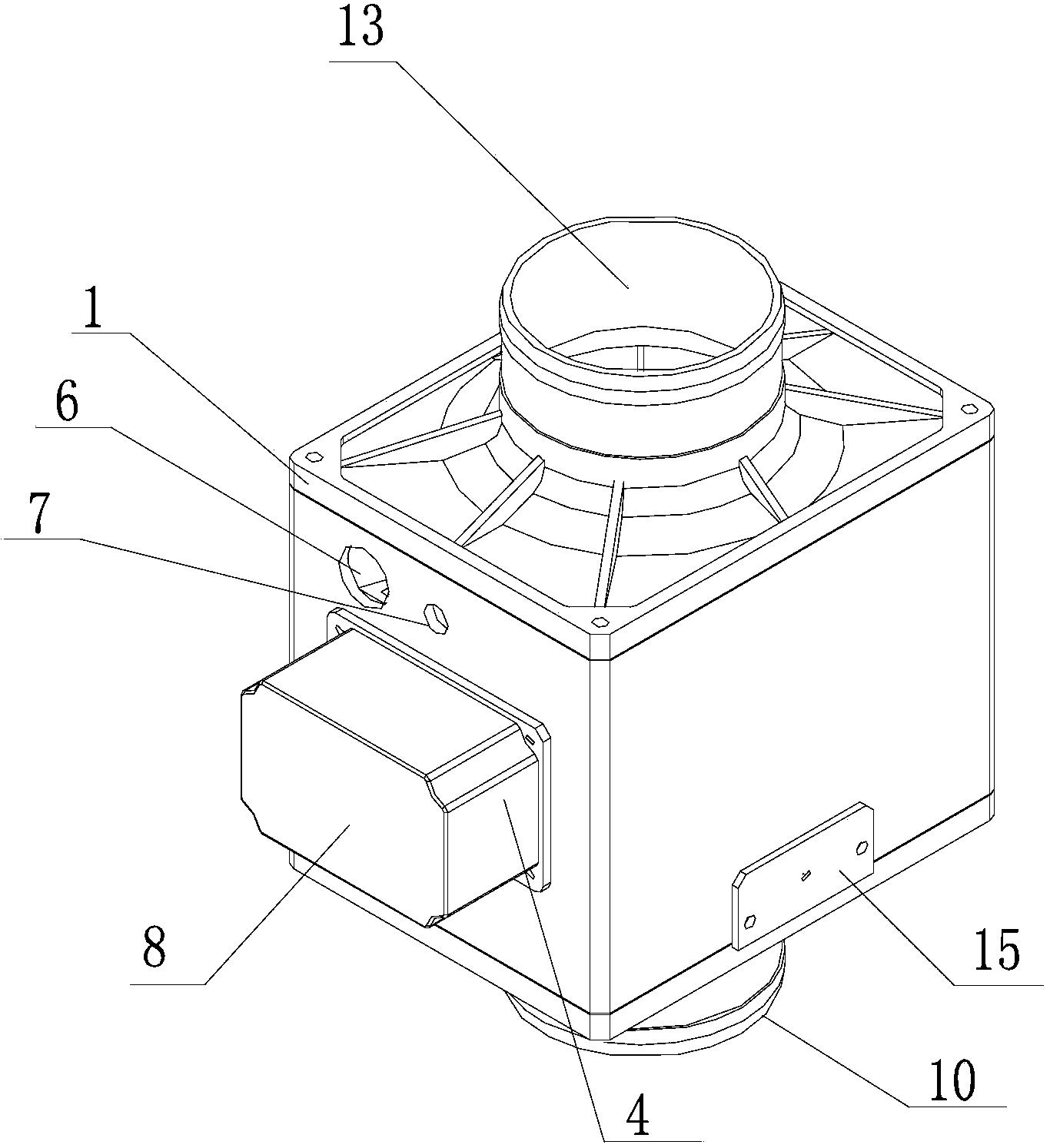

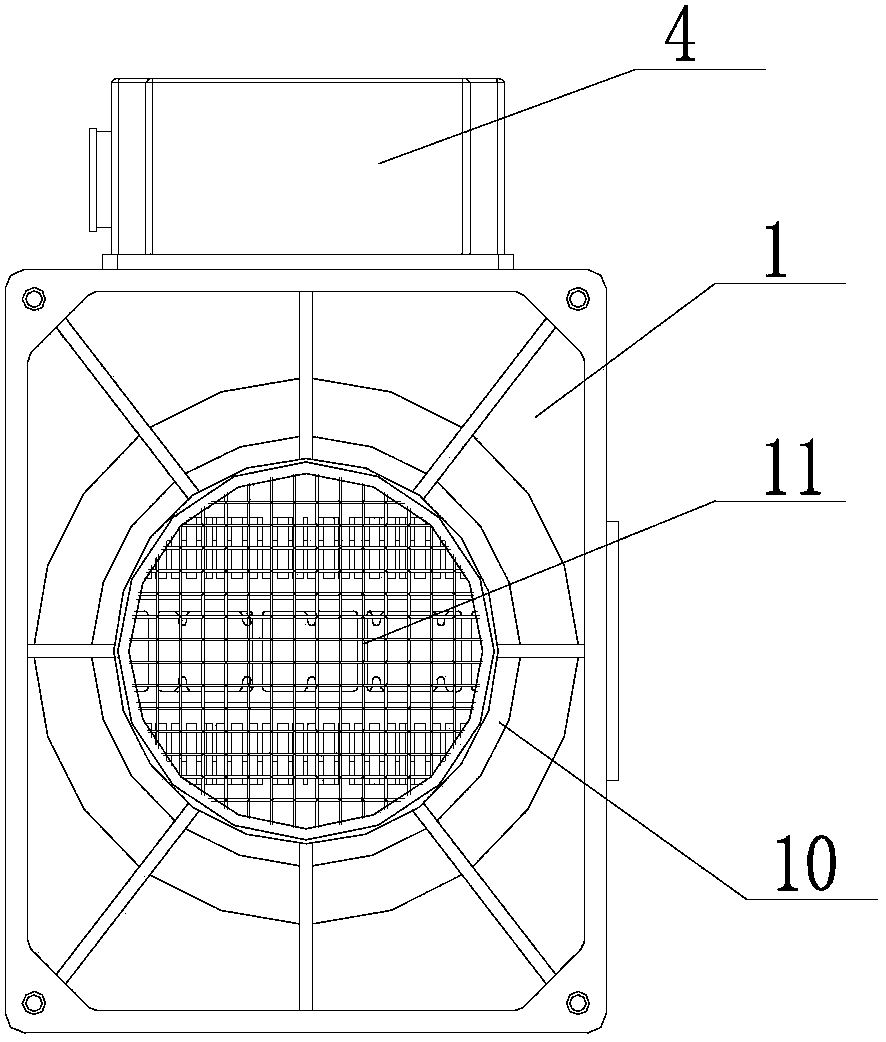

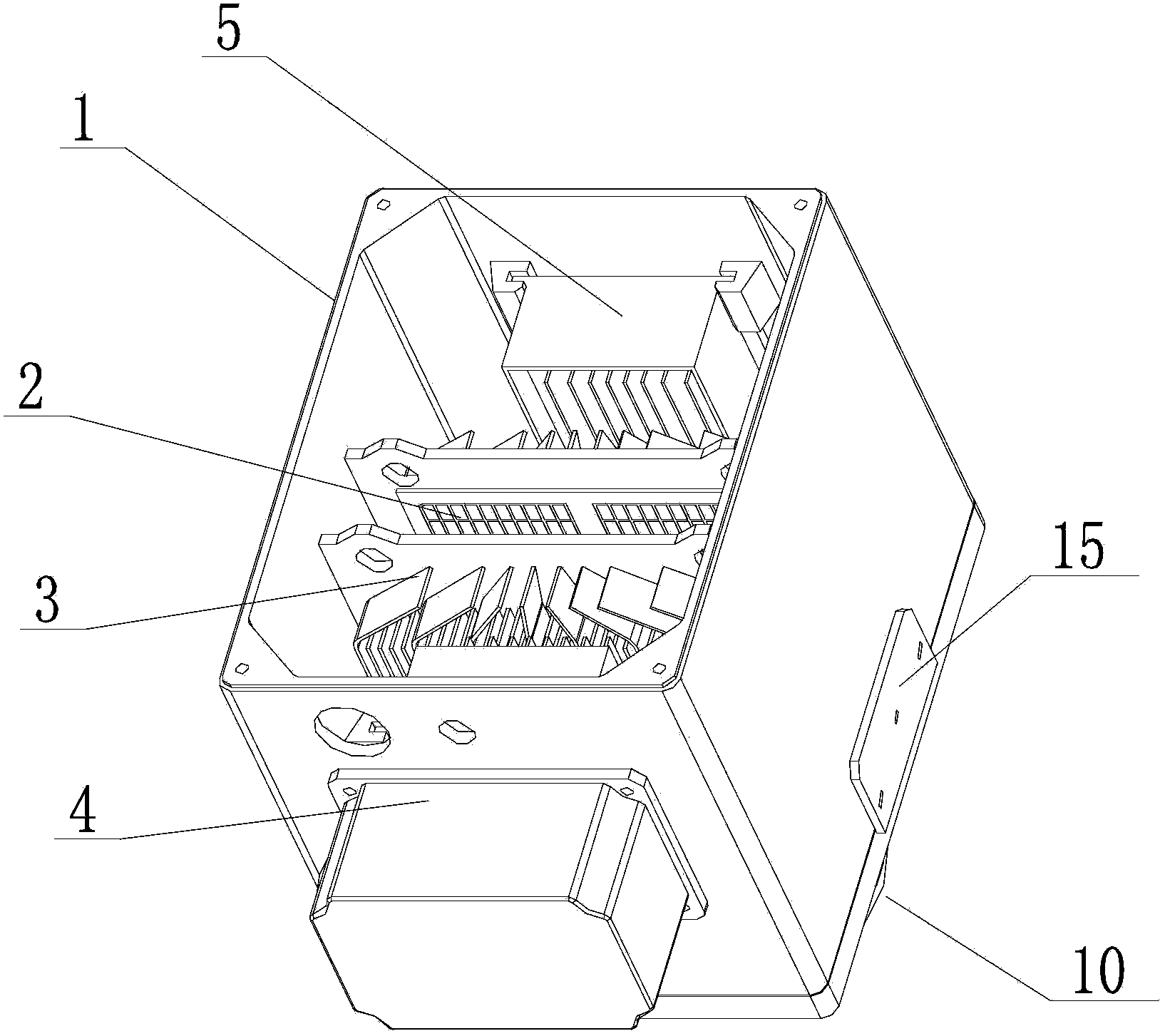

Liquid fuel gasification combustor suitable for mixed alcohol oil and capable of achieving complete combustion

Owner:天津清欣热能科技有限公司

Oil-furnace-heat-supply type dryer

InactiveCN105276948AEasy to dryThe top of the drying chamber is equipped with a dehumidifier to facilitateDrying gas arrangementsDrying machines with progressive movementsCombustionPulp and paper industry

The invention discloses an oil-furnace-heat-supply type dryer. The oil-furnace-heat-supply type dryer comprises a drying bin, an oil-furnace heat supply device and a conveying mesh belt, and the conveying mesh belt horizontally penetrates the drying bin. The oil-furnace heat supply device comprises a plurality of heat exchangers, a hot oil guide pipe and an oil furnace. An air blower is further arranged on the oil furnace, and a moisture pumping pipe is communicated with an air inlet of the air blower. The moisture pumping pipe is additionally arranged at the top of the drying bin and can discharge steam in the drying bin, and drying of fruits is facilitated; particularly, the moisture pumping pipe is connected with the air blower, dehumidifying in the drying bin is facilitated, and waste heat of the steam can be further fully used; after the steam is pumped into the oil furnace, combustion supporting can be facilitated, and the heat value in the oil furnace can be increased; as a smoke filter and a heat exchanging device are additionally arranged in a chimney of the oil furnace, waste heat is fully used, and environmental pollution is prevented; and as a heated oil circulation system is matched with a heat sink, the heat energy can be fully used, and the aims that production cost is reduced and the drying efficiency is improved are achieved.

Owner:广东玖乐食品产业有限公司

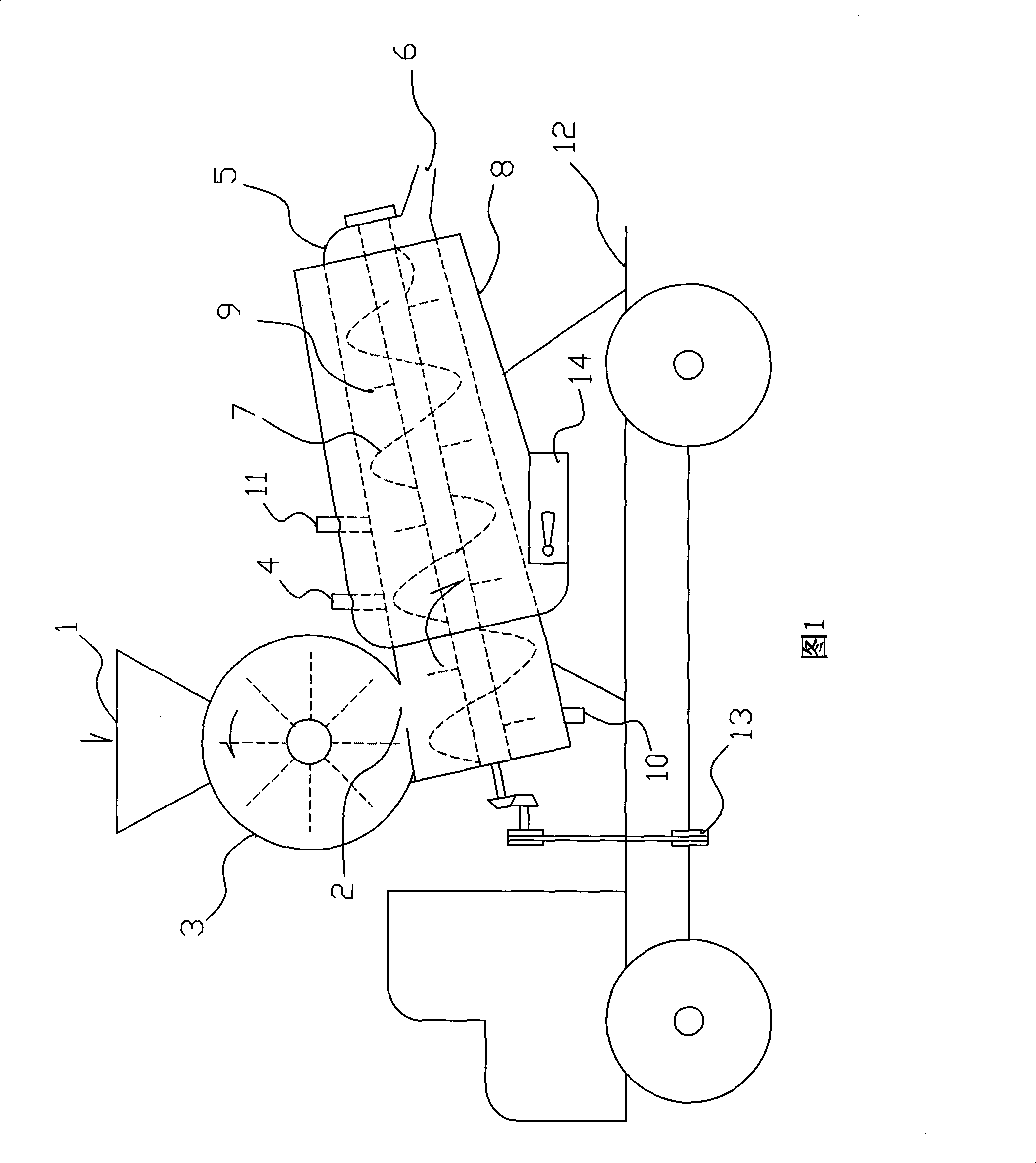

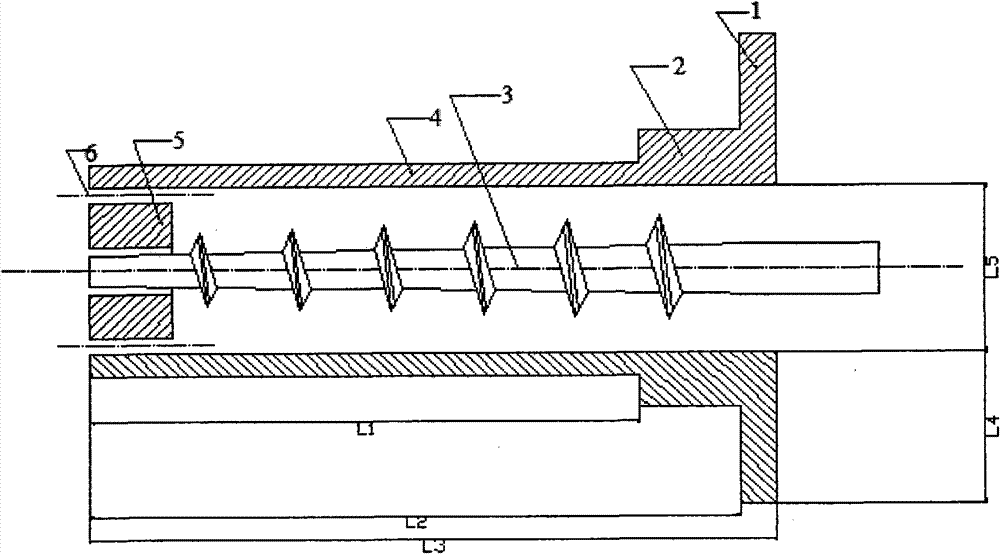

Productive technology of tubular biomass fuel

InactiveCN101838571BSimple structureIncrease productivityBiofuelsSolid fuelsHelical bladeEngineering

The invention relates to a productive technology of tubular biomass fuel and a forming machine thereof. The productive technology comprises processes of crushing, separating, drying, collecting, dividing material, forming and bagging. The invention adopts the full automation operation, presses scattered, dried and crushed biomass materials with no definite shape into the tubular fuel with certaindensity. The forming machine comprises a principal shaft and a helical blade, a shell, a sleeve, a template and a forming hole. The crushed biomass raw material is pushed into the sleeve under the effect of a spiral spindle, squeezed out by the forming hole on a pressing mold and becomes cylindrical, prismatic or six-side tubular forming fuel; the length of a fuel rod can be cut off according to requirement. A material dividing platform mainly comprises a material bag, a platform and a material dividing opening and is used for distributing and combining different raw materials according to a certain proportion. The invention has the advantages of simple structure, low cost, convenient operational management, high production efficiency, safe and reliable use and the like.

Owner:长沙北极熊节能环保技术有限公司

Synchronous reversing valve for oxygen-enriched heating furnace

InactiveCN113124202ASynchronization of state switchingRealize synchronous switchingOperating means/releasing devices for valvesMultiple way valvesHeating furnaceVALVE PORT

The invention discloses a synchronous reversing valve for an oxygen-enriched heating furnace, and relates to a fluid switching valve for the oxygen-enriched heating furnace. According to the key points of the technical scheme, the synchronous reversing valve comprises two valve bodies, valve elements and a power mechanism; each valve body is internally provided with two valve elements; the power mechanism is used for driving the four valve elements on the two valve bodies to synchronously act; two partition plates are arranged in each valve body and distributed in the vertical direction to divide each valve body into a fluid cavity, a switching cavity and a tail gas cavity from top to bottom; a switching plate is arranged between the two partition plates and divides the switching cavity into a first cavity body and a second cavity body; two valve inlet holes formed in each top partition plate are formed in the tops of the first cavity and the second cavity, and two valve outlet holes formed in each bottom partition plate are formed in the bottoms of the first cavity and the second cavity; and state switching of the two valve bodies is driven by the same power mechanism, so that good synchronization of state switching of the valve bodies can be kept.

Owner:张作帅

Preparation process of a pollution-free and low-cost lithium manganese iron phosphate crystal material

ActiveCN108408709BImprove the level ofWidely sourced, non-toxic and cheapCell electrodesPhosphorus compoundsO-Phosphoric AcidLithium hydroxide

The invention discloses a process for preparing a pollution-free and low-cost lithium manganese iron phosphate crystal material, which is completed through the following steps: select iron powder and manganese powder with high purity, and the particle size is selected between 20 mesh and 20000 mesh; according to a certain quality Select manganese powder, iron powder, phosphoric acid and lithium source solution, after dilution, put them in an acid-resistant reactor and stir to fully react iron powder, manganese powder and phosphoric acid; add lithium source solution to the obtained reaction precursor slurry and stir well , the selected lithium source solution is a soluble lithium source lithium hydroxide or lithium acetate; the obtained slurry is transferred into the reactor to start the hydrothermal reaction; the obtained slurry after the reaction is subjected to solid-liquid separation, and the separated solid lithium manganese iron phosphate Carry out clathrate carbonization annealing treatment, prepare lithium manganese iron phosphate crystal material. Compared with the prior art, the invention has lower cost and convenient process operation, and not only the manufactured lithium manganese iron phosphate crystal material has higher commercial value, but also has no pollution in the manufacturing process and meets the current environmental protection requirements.

Owner:南阳逢源新能源科技有限公司

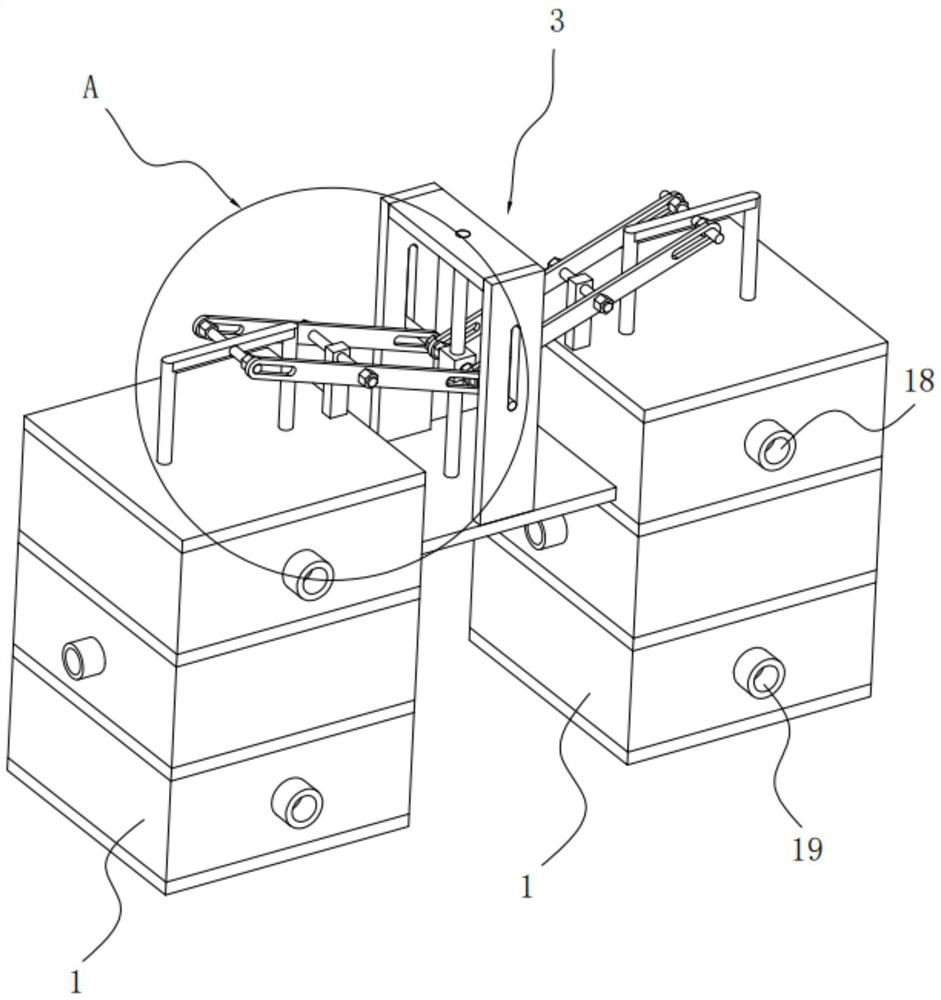

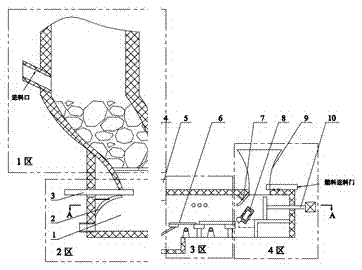

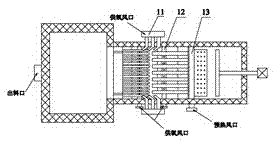

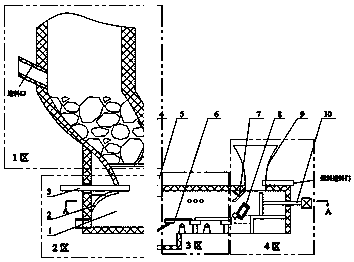

Aluminum ingot heating and melting furnace using biomass fuel

ActiveCN106855355ASimple compositionWell-built and system-integrated featuresCrucible furnacesFuel supplyCombustion chamber

The invention discloses an aluminum ingot melting furnace using biomass fuel. The furnace is composed of a row material heating zone, a furnace bottom melting tank, a combustion chamber and a fuel supply zone, and of an L-shaped structure comprehensively. The row material heating zone and the furnace bottom melting tank are vertically overlaid, and therefore an L-shaped vertical part is formed, the main function of the part is to contain row materials and to absorb increased heat of convective heat, and the furnace chamber of the melting tank contains molten metal liquid. A convective heat heating control door is of a retractable structure which controls the temperatures of the row material heating zone and the melting tank. The other end of the melting tank is connected with the combustion chamber. Spacings of bottom combustion chamber furnace grates are sparse in the front and dense at the back, and the top of a feeding section is provided with a fuel expulsion guide plate to firmly compact the sparse biomass fuel pushed in. A side wall combustion oxygen supply air-line system and a furnace grate combustion oxygen supply air-line system play the role of supporting combustion. The fuel supply zone comprises a turnover box furnace grate, a fuel packing funnel and a fuel propulsion system, and a box furnace grate preheating air-line system and the combustion chamber are connected in a spliced mode to form an L-shaped bottom structure. The aluminum ingot heating and melting furnace using the biomass fuel is simple in structure, and easy to mount, debug, use, and maintain, and has good promotion value in industry.

Owner:CHINA JILIANG UNIV

A melting furnace that uses biomass fuel to heat and melt aluminum ingots

ActiveCN106855355BIncrease fire intensityHigh densityCrucible furnacesMelting tankCombustion chamber

Owner:CHINA JILIANG UNIV

Heat supply device capable of automatically falling ash

PendingCN113983480AGood fuelEasy to cleanTobacco preparationIndirect carbon-dioxide mitigationThermodynamicsCombustor

The invention discloses a heat supply device capable of automatically falling ash. A radiator is positioned at the upper end of a combustor, the combustor comprises an inner container, a hearth is arranged in the inner container, a fuel adding port leading to the hearth is arranged on the inner container, and an ash box is arranged below the hearth. The heat supply device is characterized in that a furnace jacket is arranged outside the inner container, an A-path air supply channel and a B-path air supply channel which are used for providing hot air for the hearth are arranged on an interlayer between the inner container and the furnace jacket, and a blower device of the A-path air supply channel and the B-path air supply channel is arranged on the furnace jacket; the A-path air supply channel enters the hearth from the interlayer to an air inlet hole formed in the furnace wall of the lower part of the inner container to form primary hot air, and the B-path air supply channel enters the hearth from the interlayer to an air inlet hole formed in the furnace wall of the middle part of the inner container to form secondary hot air; a grate bridge for automatically falling ash is arranged below the hearth. Secondary layered hot air can be effectively utilized for supporting combustion, fuel can be fully combusted, heat energy of clean charcoal can be exchanged to the tobacco loading chamber to the maximum extent, and stove ash can be conveniently cleaned in the using process.

Owner:GUIYANG OFFICE OF GUIZHOU TOBACCO CORP +1

Expansion of application of penicillium lipase in biodiesel preparation

The invention provides a method for obtaining highly expressed lipase bacterial strain and an application of the highly expressed lipase obtained by the method in biodiesel production, the method comprises the following steps: a step of raw material pretreatment comprises the processes of filtering biolipid and removing the impurities, stirring for emulsification; a step of ester interchange reaction comprises the processes of adding grease and methanol or ethanol in a reaction container according to mol ratio of 1:1-3, then adding the modified expansion Penicillium lipase and an organic solvent, sealing and mixing for reacting for 6-24 hours under the reaction condition of 20-50 DEG C, adding methanol or ethanol again during the reaction process, wherein the mol ratio of methanol or ethanol to grease added in each time is 1-3:1; and a step of biodiesel acquisition comprises the processes of separating the lipase from a reactant after the reaction is completed, performing centrifugation for layering on the reaction products, standing and separating the crude glycerine at the lower layer, distilling the upper layer liquid, and recovering the organic solvent to obtain the finished product biodiesel.

Owner:SHENZHEN LEVEKING BIOLOGY ENG

Method for preparing biodiesel by ester exchange

InactiveCN101475825BReduce air toxicityIncrease oxygen contentBiofuelsLiquid hydrocarbon mixture productionBiodieselGlycerol

The invention relates to a method for preparing biodiesel through ester exchange, which comprises the following steps: mixing grease, methanol and catalyst according to the mol ratio of 9-15: 0.7-1.3:0.035-0.5; heating the obtained mixture to perform reaction at a temperature of between 150 and 190 DEG C and at a reaction pressure of between 0.7 and 1.3 MPa for 20 to 40 minutes, then distilling and separating the mixture to prepare glycerol, methanol and crude biodiesel; and redistilling the obtained biodiesel and controlling the temperature between 150 and 190 DEG C so as to prepare the biodiesel and the byproduct residual oil. The method for preparing the biodiesel through the ester exchange has the reaction conversion rate reaching more than 90 percent, and the product is environment-friendly with good lubricity.

Owner:王英国 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com