Patents

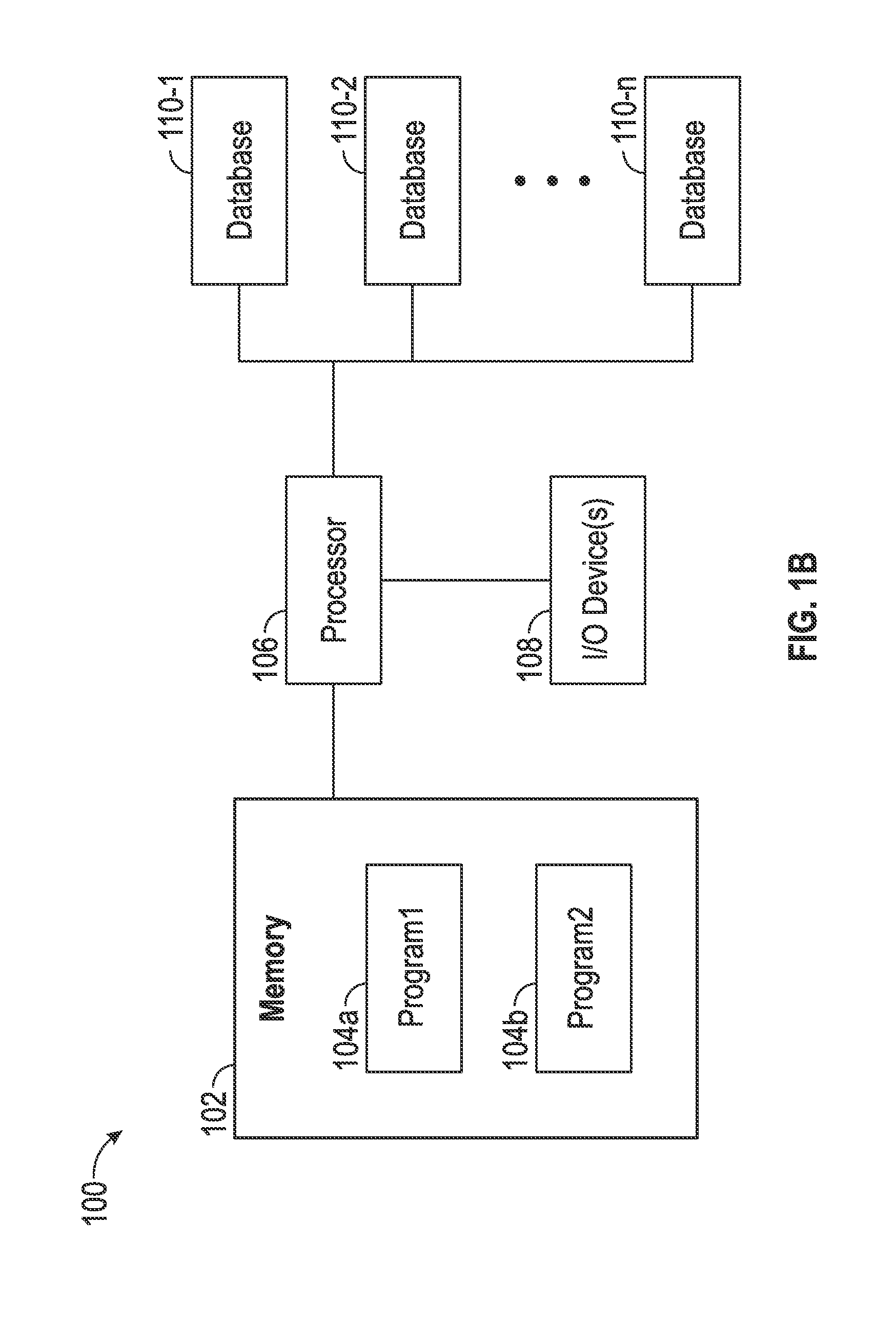

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

81results about "Servomotor parallel arrangements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

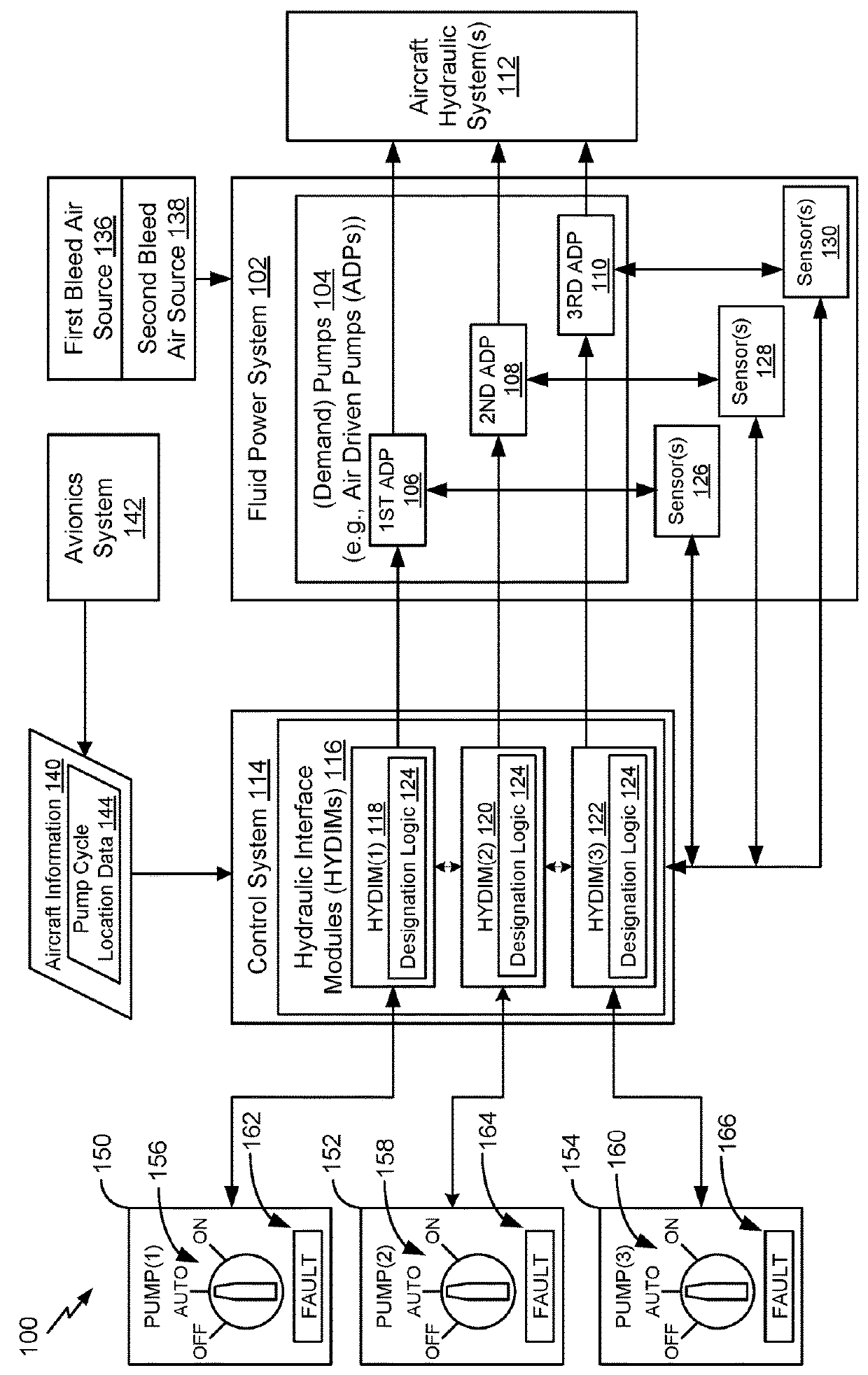

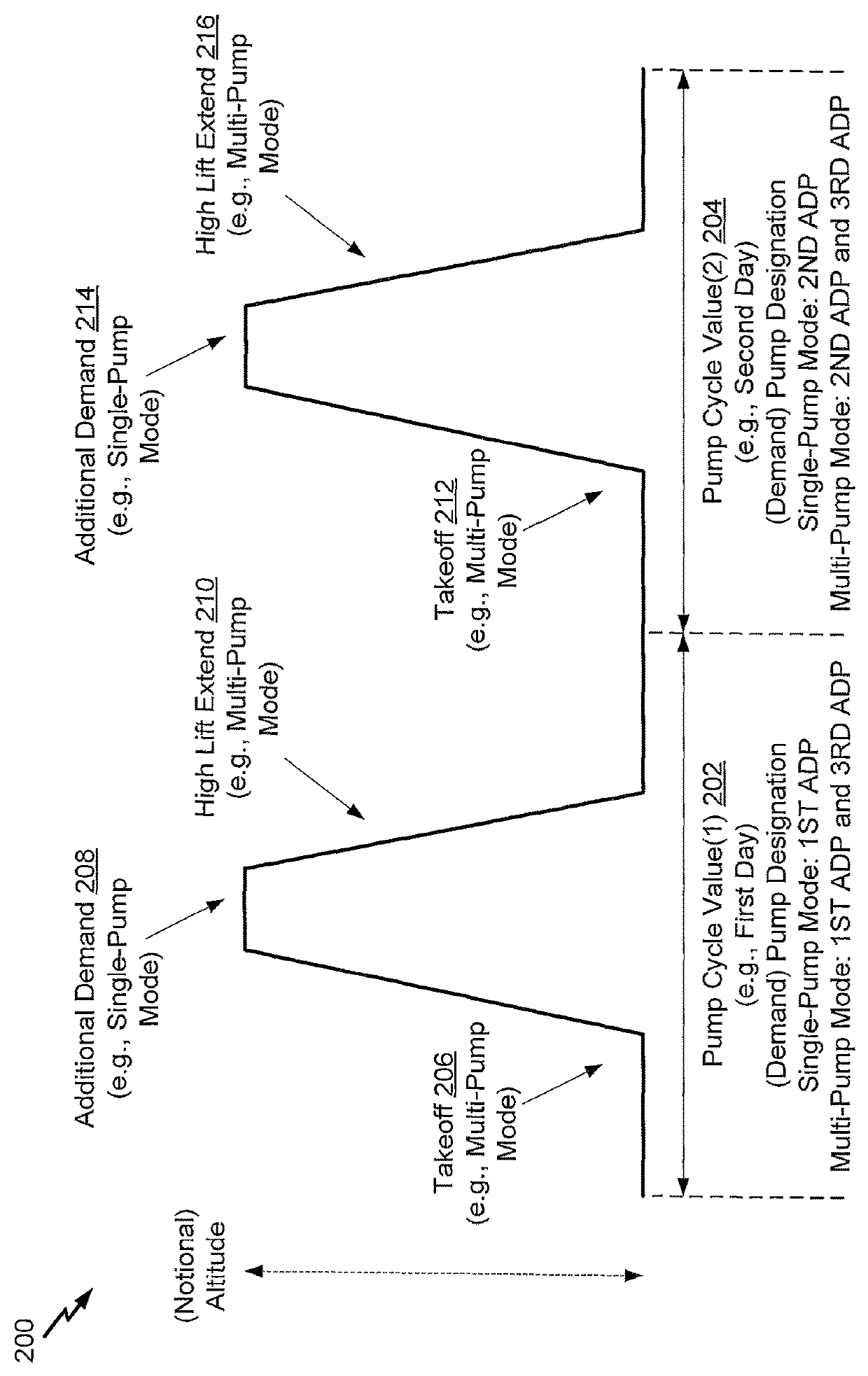

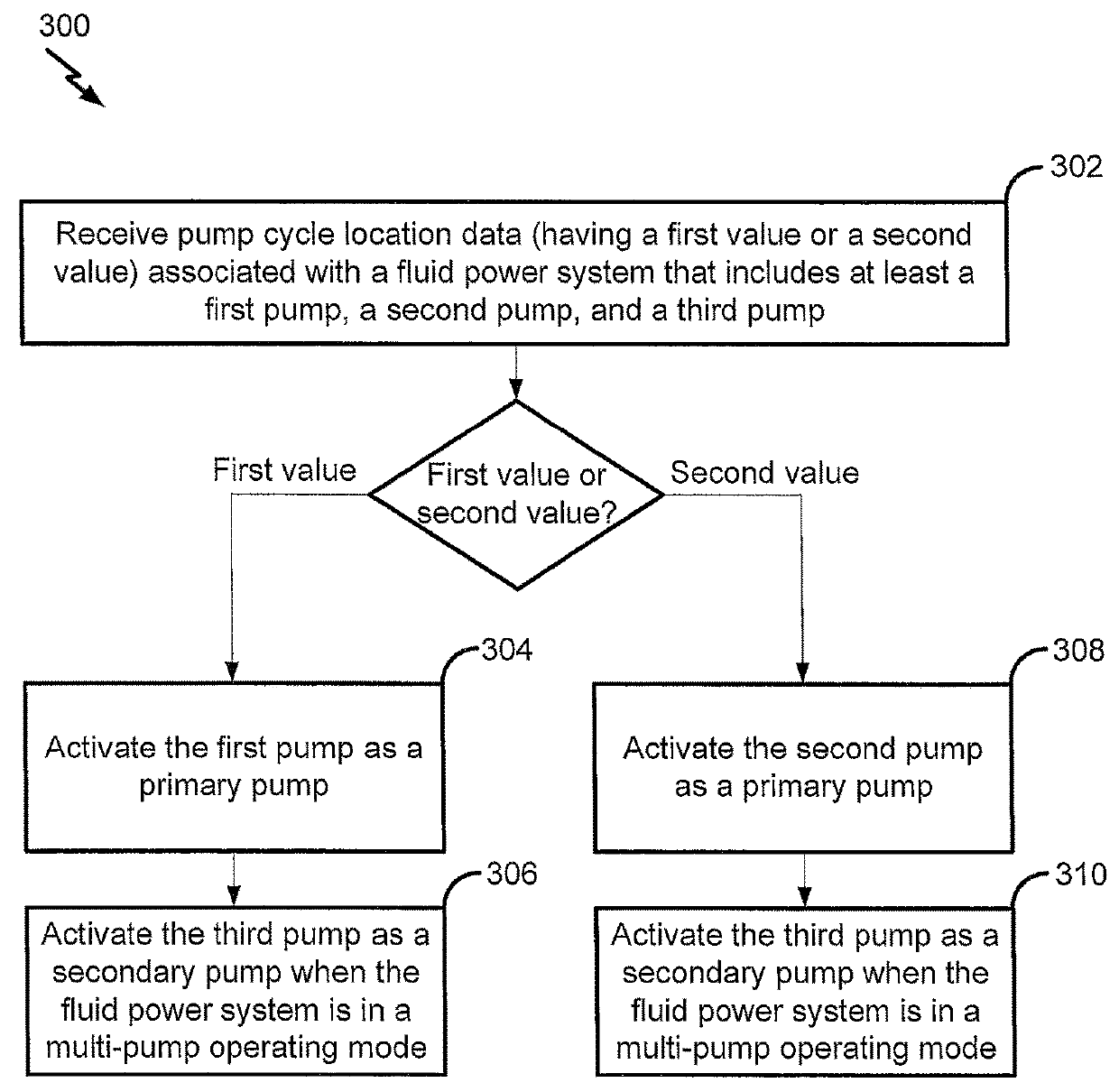

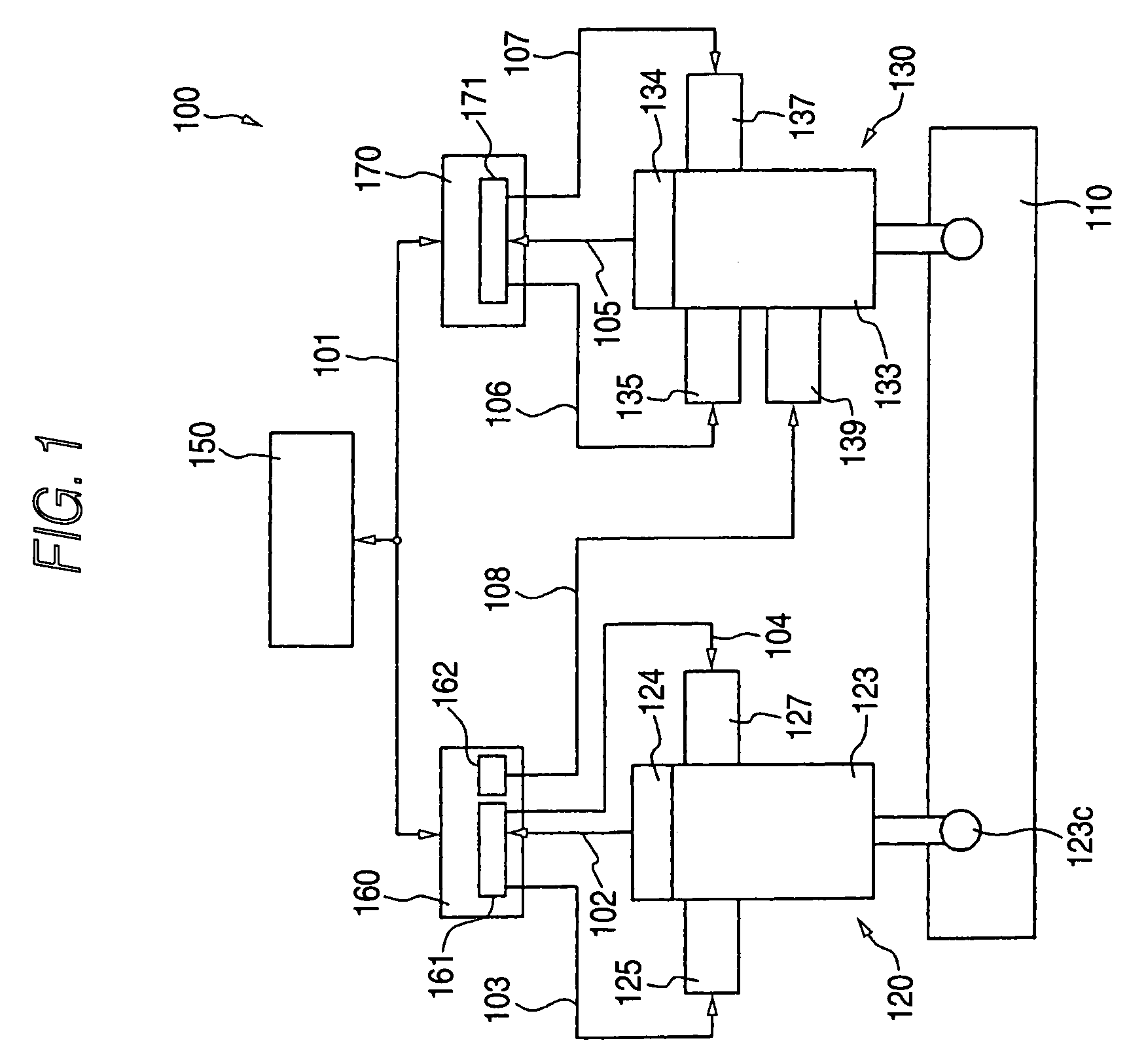

Dynamic activation of pumps of a fluid power system

A method includes receiving pump cycle location data associated with a fluid power system. The fluid power system includes a plurality of pumps (including at least a first pump, a second pump, and a third pump). Based on the pump cycle location data having a first value, the method includes activating the first pump as a primary pump. Based on the pump cycle having a second value, the method includes activating the second pump as the primary pump. The method also includes activating the third pump as a secondary pump when the fluid power system is in a multiple-pump operating mode.

Owner:THE BOEING CO

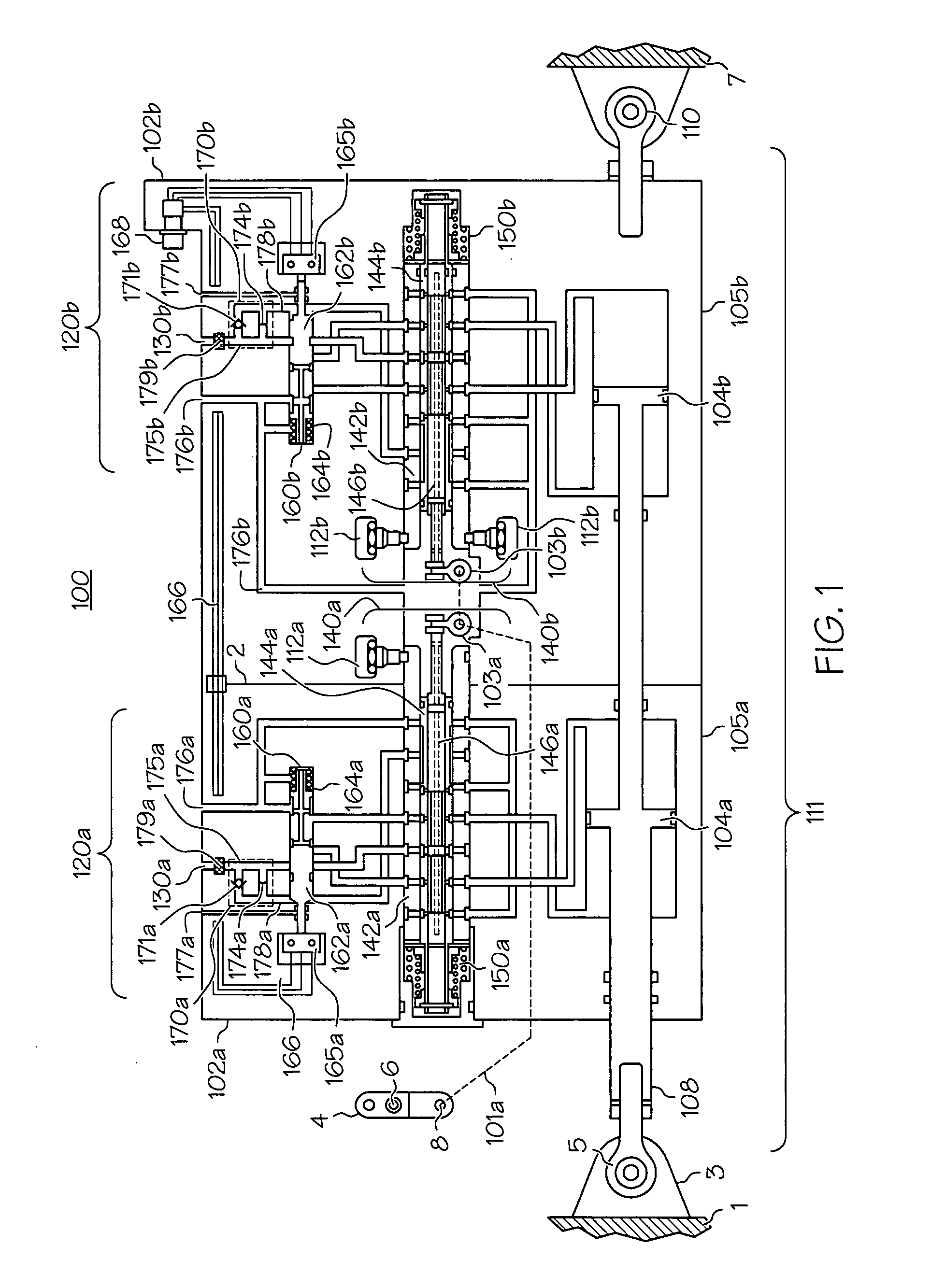

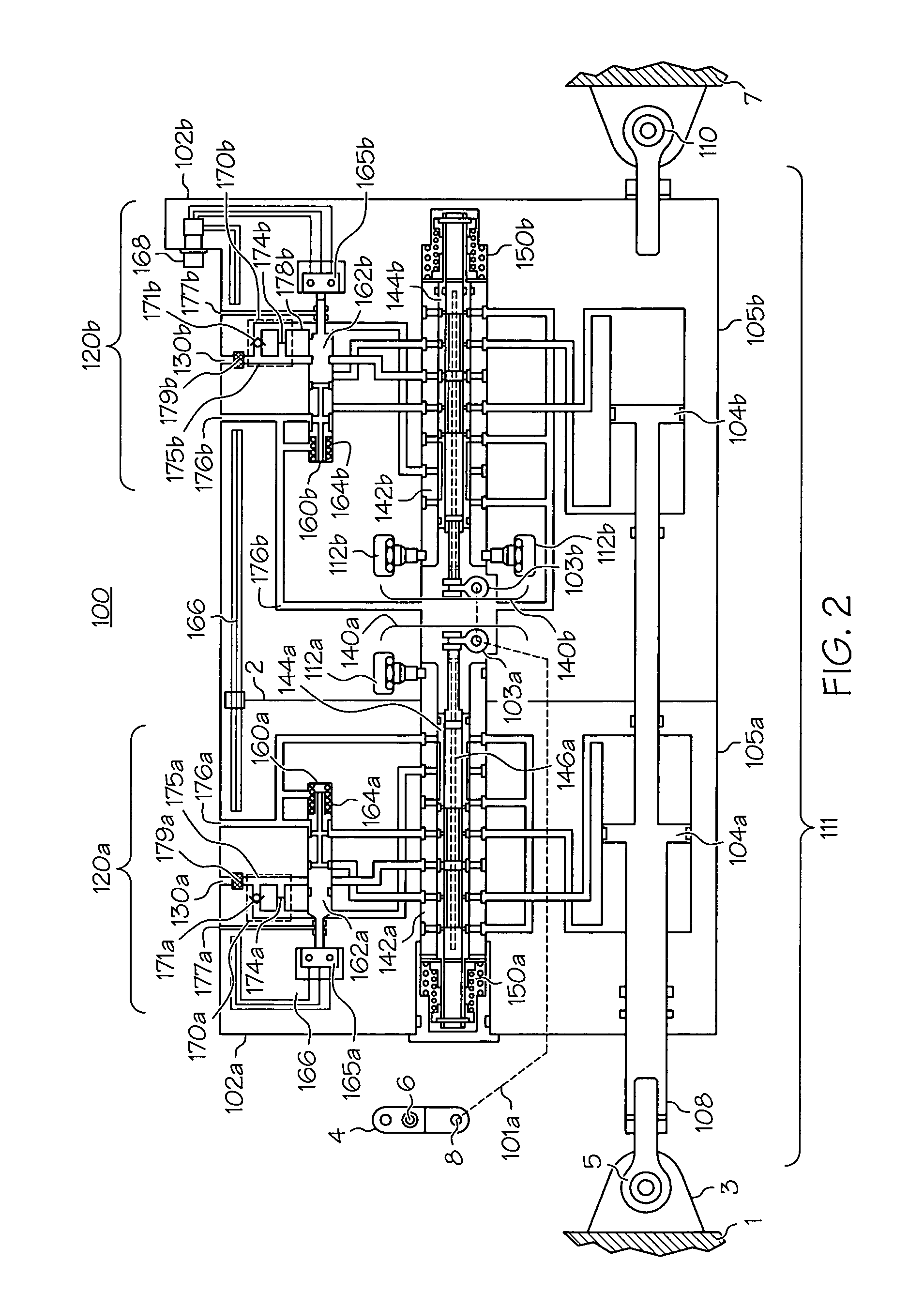

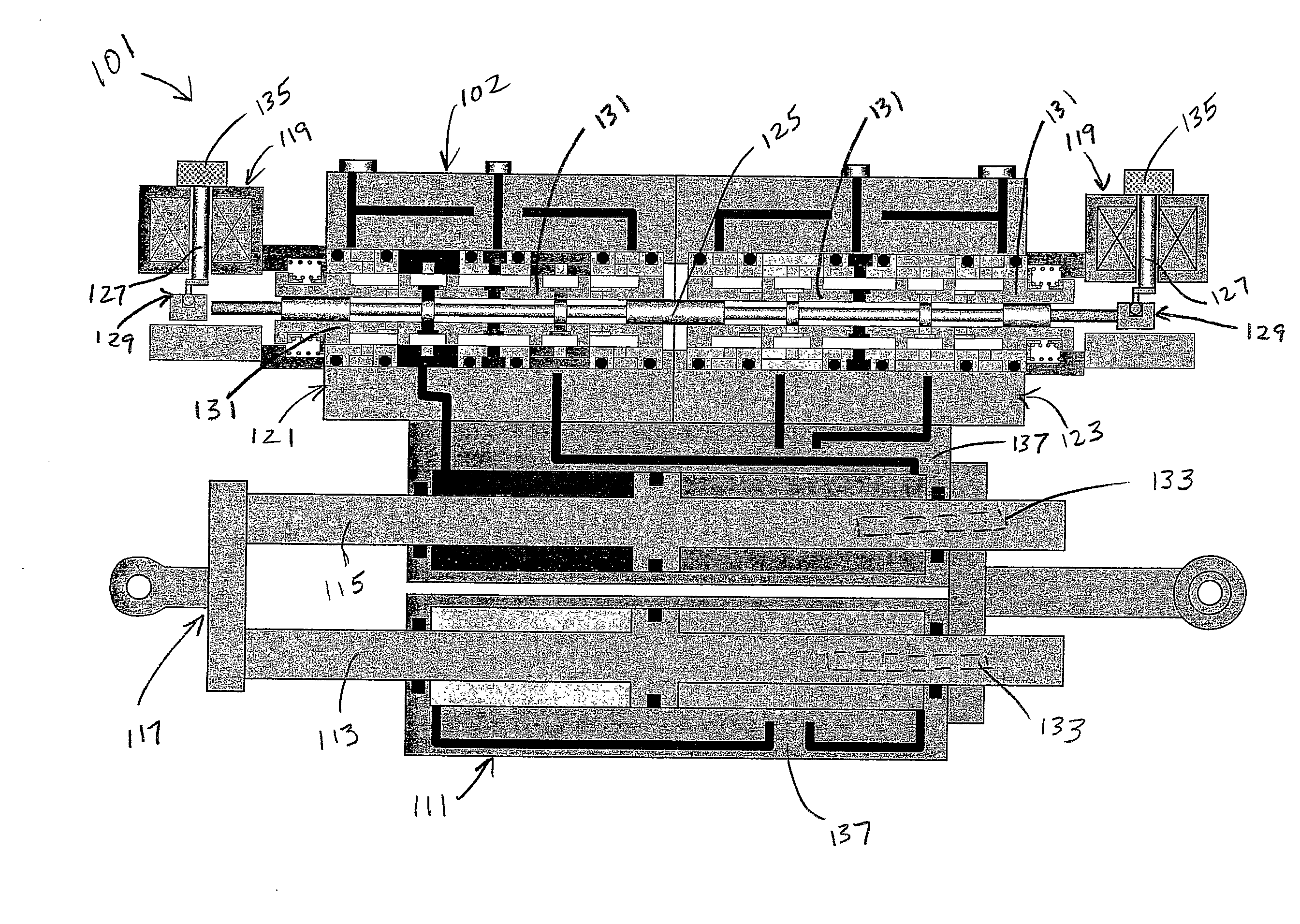

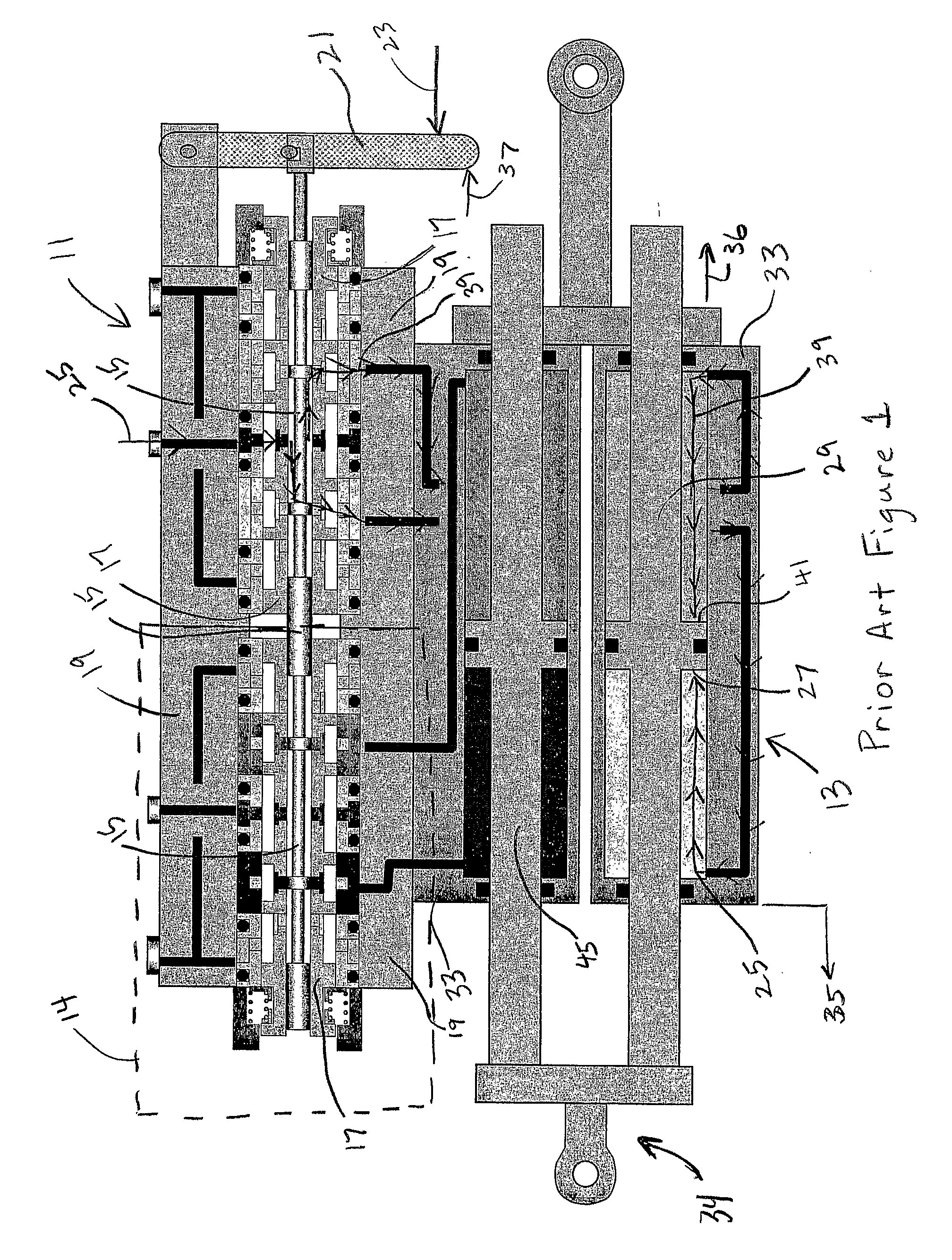

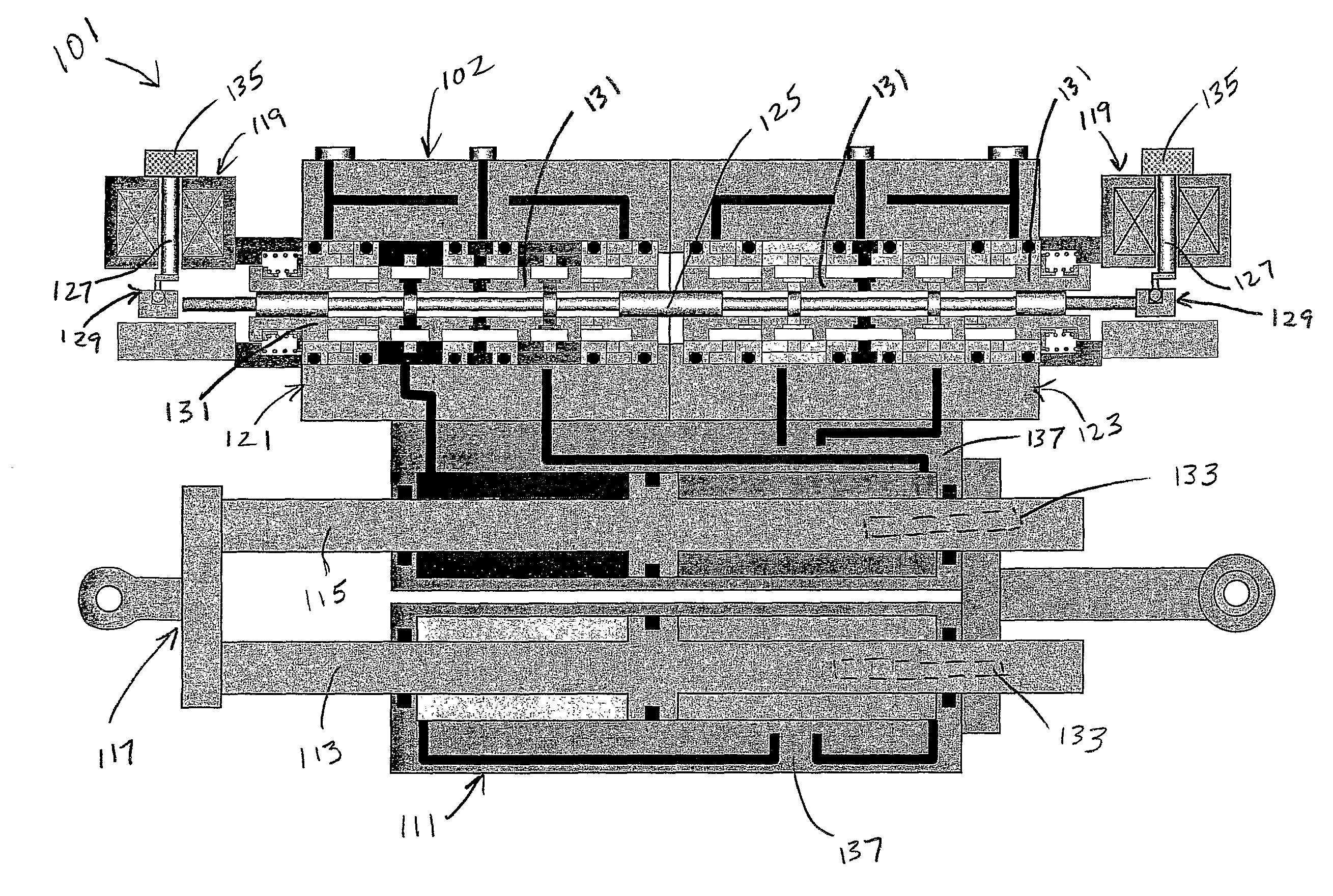

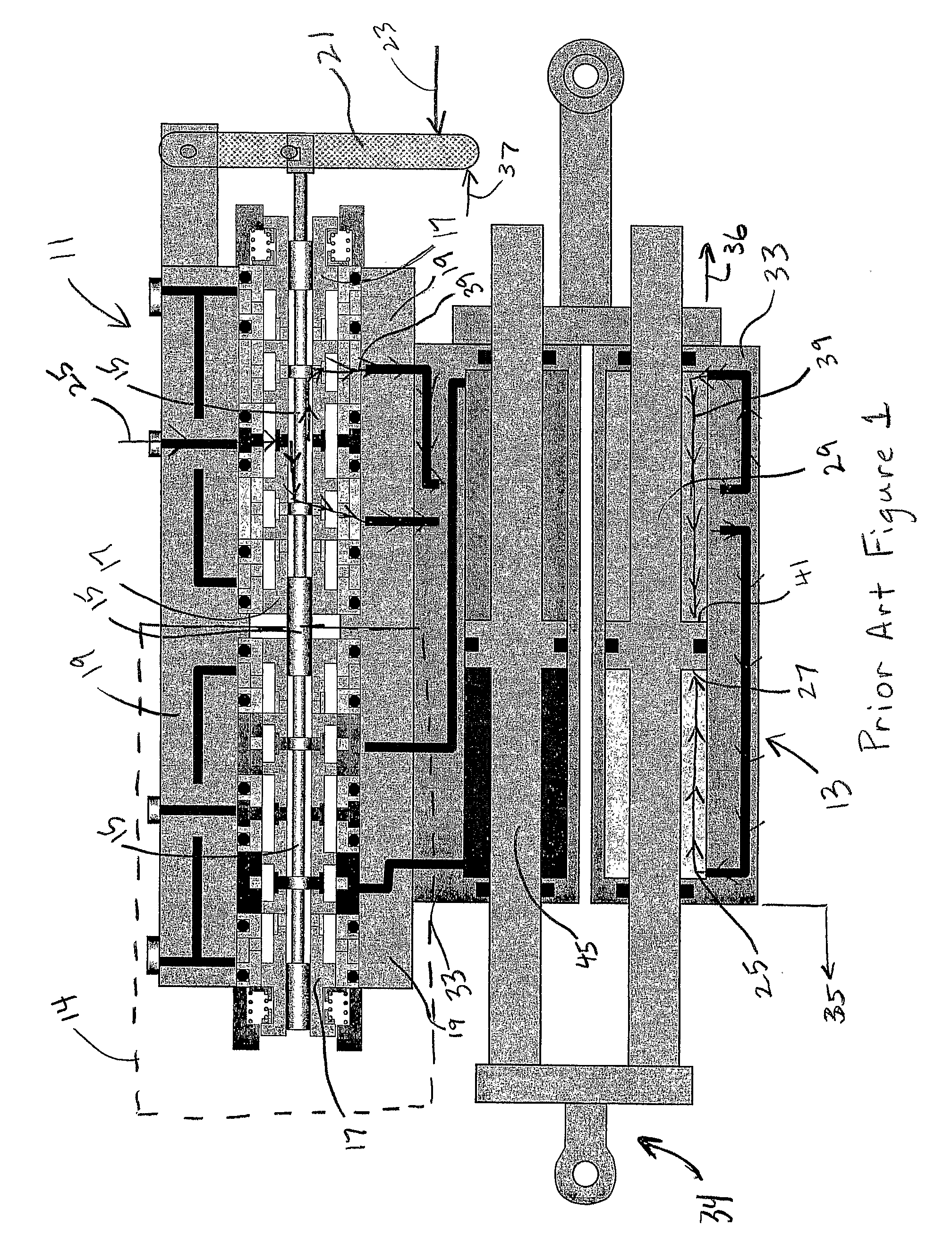

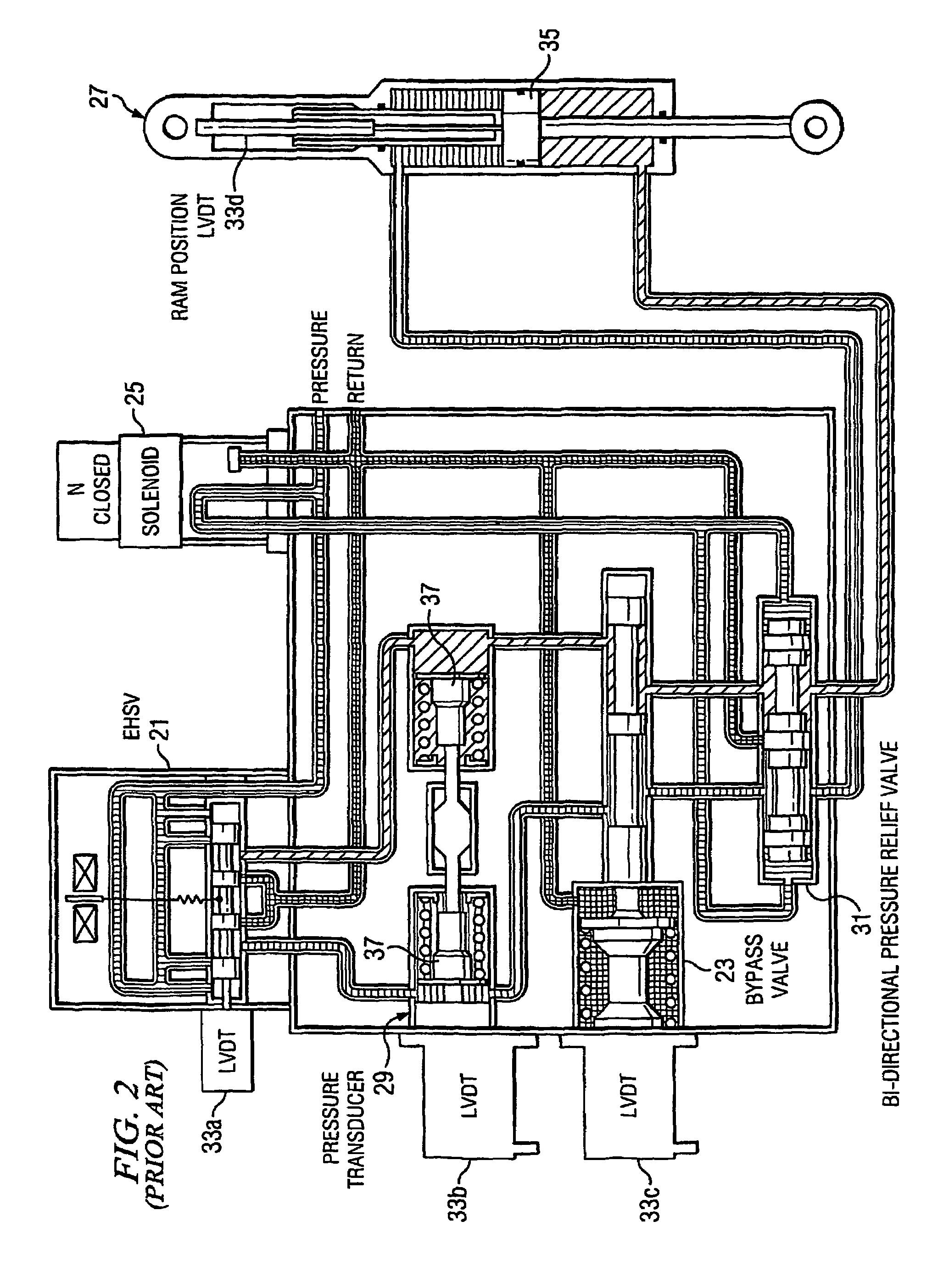

Redundant flow control for hydraulic actuator systems

Two or more flow control valves may be used to provide redundant flow control for a hydraulic actuator or servoactuator. The flow control valves include a sleeve, a bypass control spool, and a primary control spool. Under normal operating conditions, each bypass control spool is stationary relative to the sleeve and the flow control valve functions as a four-way hydraulic flow control valve. Each flow control valve is connected to a bypass-shutoff valve including a bypass spool that is moveable from a shut-off position to a bypass position. Upon supply pressure failure to one flow control valve, the bypass spool moves to the bypass position, reducing pressure in the corresponding actuator piston chambers. When a primary control spool becomes jammed, the corresponding bypass control spool moves within its sleeve allowing a bypass groove to port control pressure to the return line, thereby reducing pressure in the corresponding actuator piston chambers.

Owner:HR TEXTRON

Hybrid electromechanical/hydromechanical actuator and actuation control system

A hybrid actuator assembly includes an actuator housing, an electromechanical actuator, and a hydraulic actuator. The electromechanical actuator is disposed at least partially within the actuator housing and is adapted to be controllably energized. The electromechanical actuator is configured, upon being controllably energized, to supply a first drive force. The hydraulic actuator is disposed at least partially within the actuator housing and is adapted to receive pressurized hydraulic fluid. The hydraulic actuator is configured, upon receipt of pressurized hydraulic fluid, to supply a second drive force.

Owner:HONEYWELL INT INC

Dual Motor Dual Concentric Valve

ActiveUS20080185476A1Scalable/modular redundancyMitigates force fightingFluid-pressure actuator safetyServomotor componentsControl systemEngineering

An actuator control system has a dual concentric servo valve having a spool and at least one motor adapted to selectively displace the spool.

Owner:TEXTRON INNOVATIONS

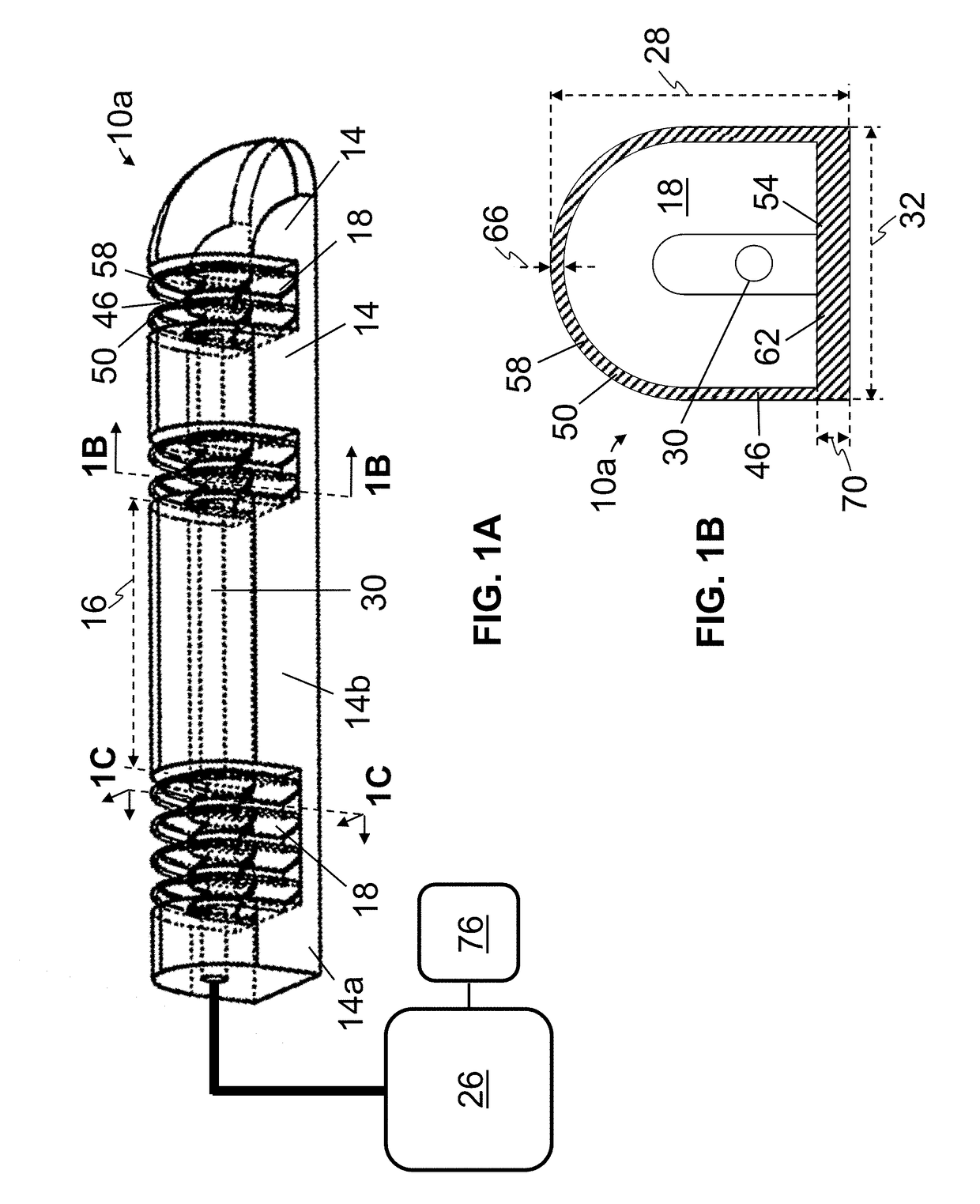

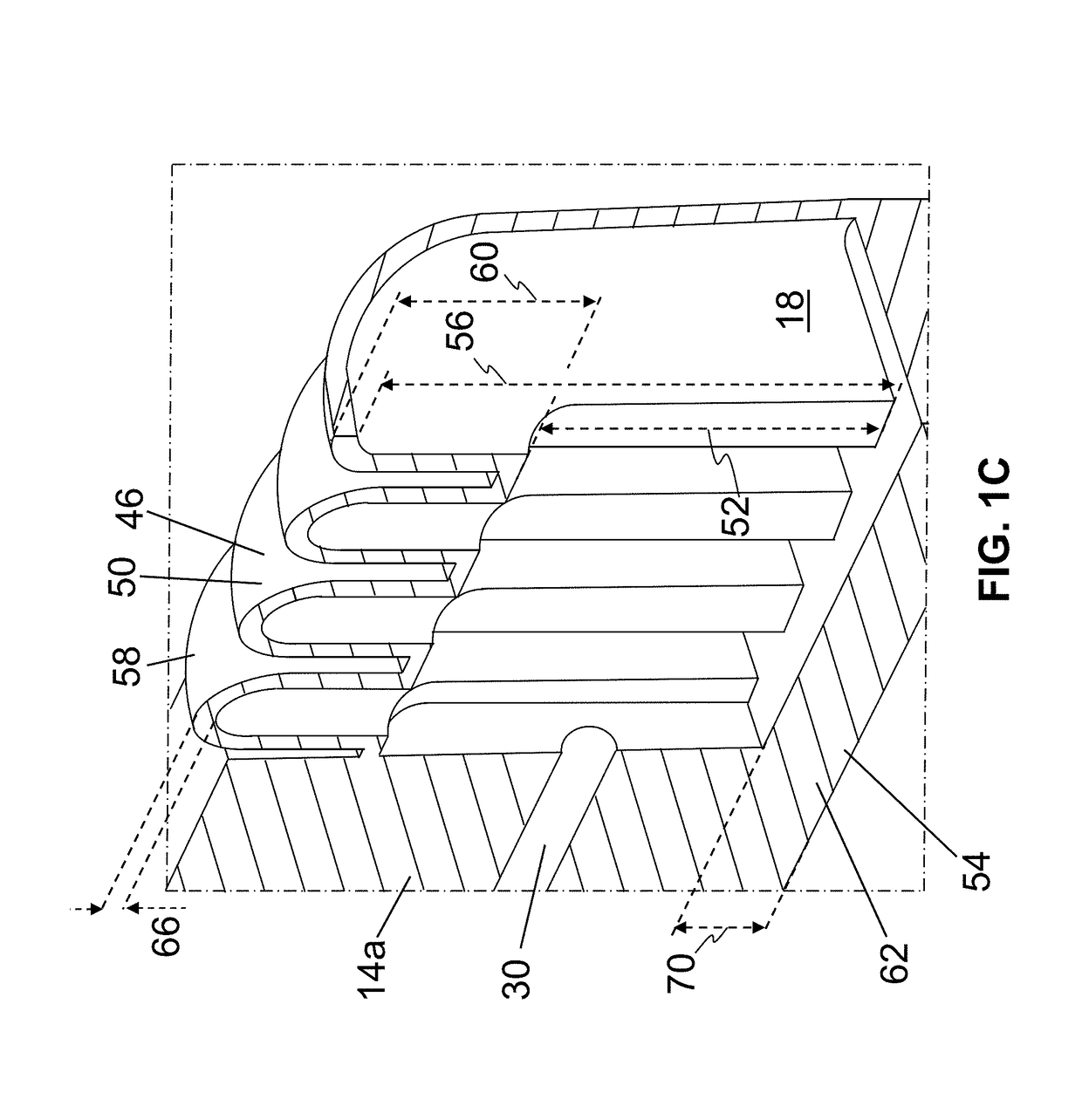

Fluid-driven actuators and related methods

ActiveUS20180303698A1Minimizing mechanical complexityChiropractic devicesServometer circuitsInternal pressureEngineering

This disclosure includes manipulating apparatuses and related methods. Some manipulating apparatuses include an actuator having a semi-rigid first segment, a semi-rigid second segment, and one or more flexible cells disposed between the first segment and the second segment, where the actuator is configured to be coupled to a fluid source such that the fluid source can communicate fluid to vary internal pressures of the one or more cells, and where each cell is configured such that adjustments of an internal pressure of the cell causes angular displacement of the second segment relative to the first segment.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Redundant flow control for hydraulic actuator systems

Two or more flow control valves may be used to provide redundant flow control for a hydraulic actuator or servoactuator. The flow control valves include a sleeve, a bypass control spool, and a primary control spool. Under normal operating conditions, each bypass control spool is stationary relative to the sleeve and the flow control valve functions as a four-way hydraulic flow control valve. Each flow control valve is connected to a bypass-shutoff valve including a bypass spool that is moveable from a shut-off position to a bypass position. Upon supply pressure failure to one flow control valve, the bypass spool moves to the bypass position, reducing pressure in the corresponding actuator piston chambers. When a primary control spool becomes jammed, the corresponding bypass control spool moves within its sleeve allowing a bypass groove to port control pressure to the return line, thereby reducing pressure in the corresponding actuator piston chambers.

Owner:HR TEXTRON

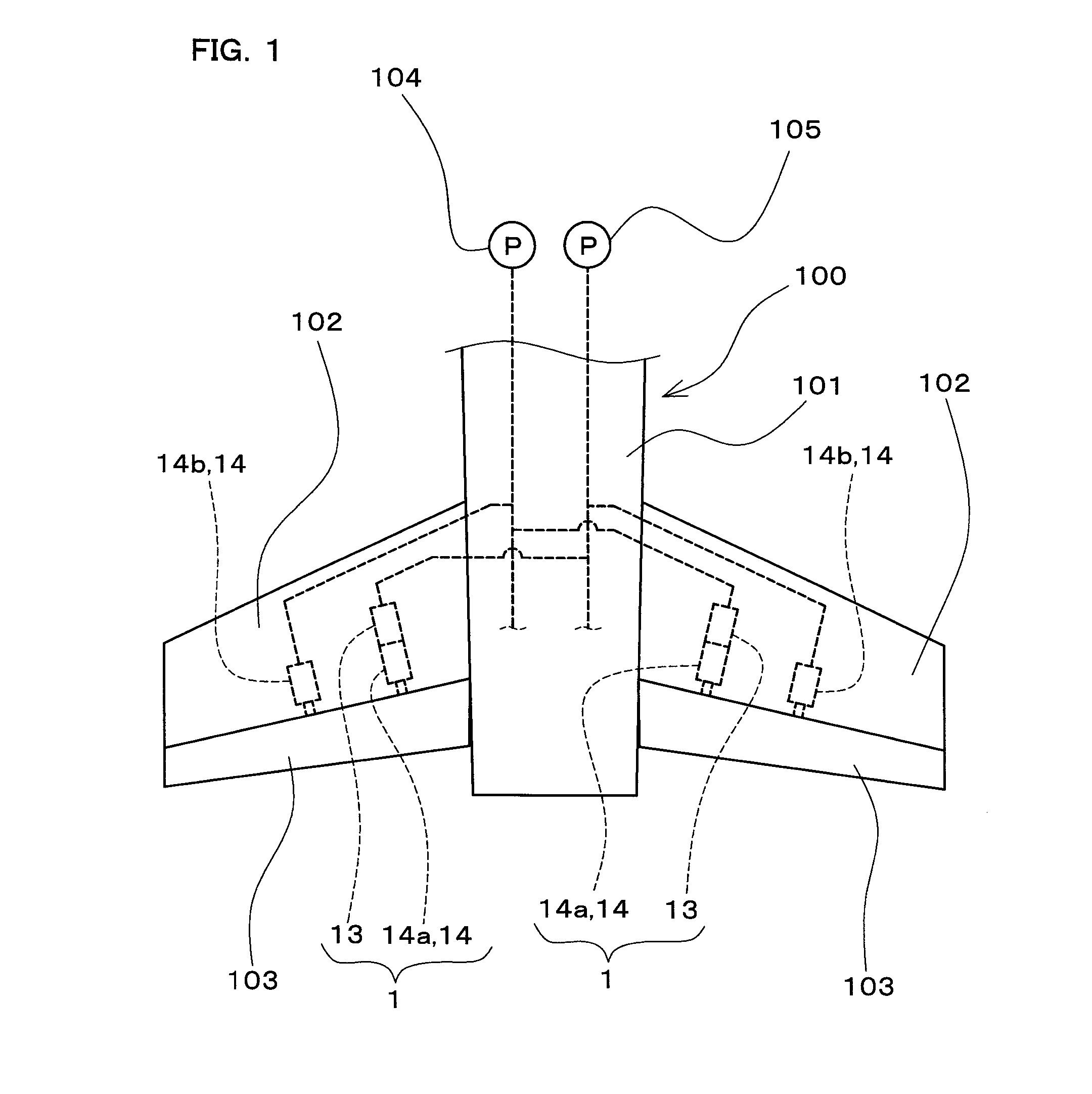

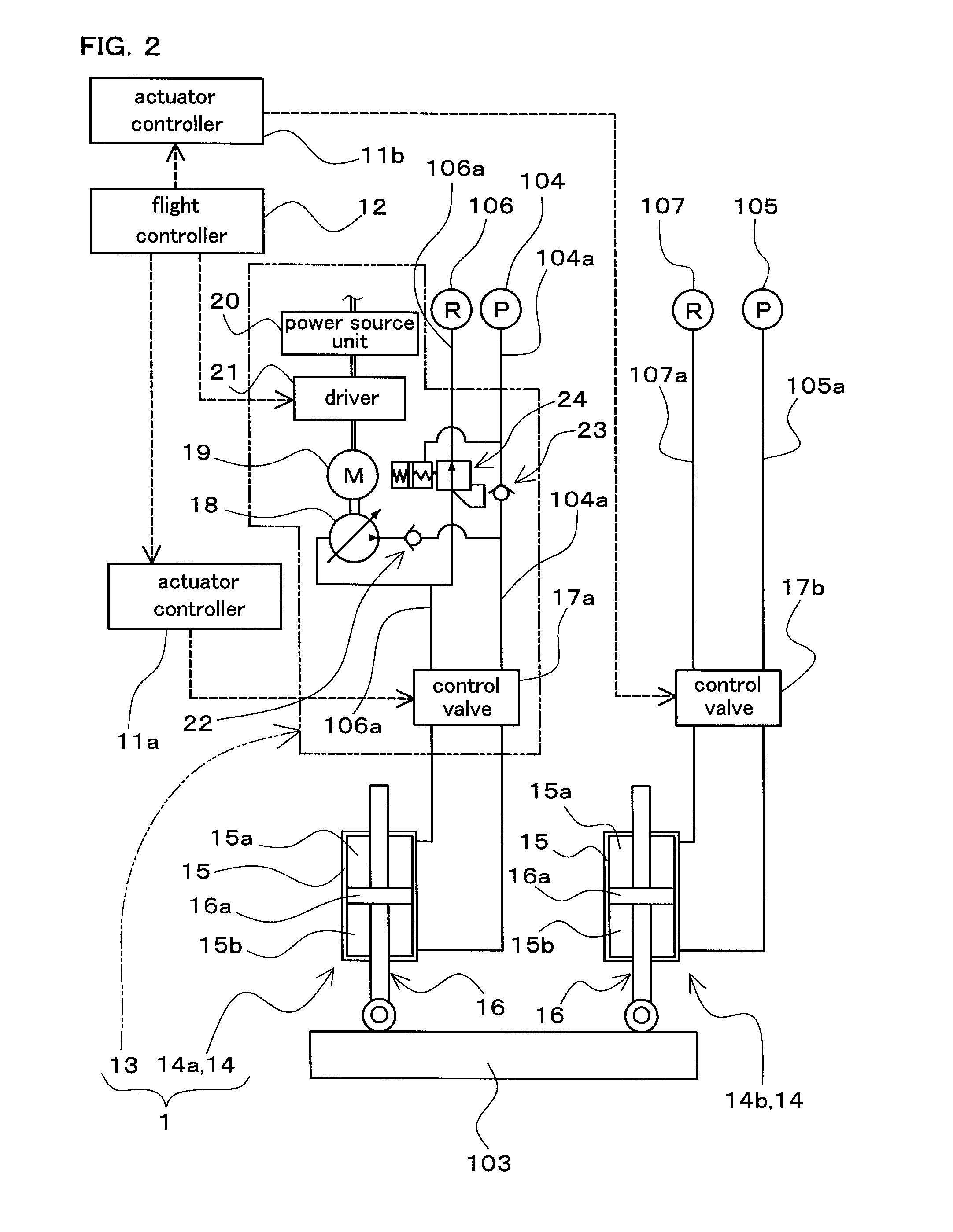

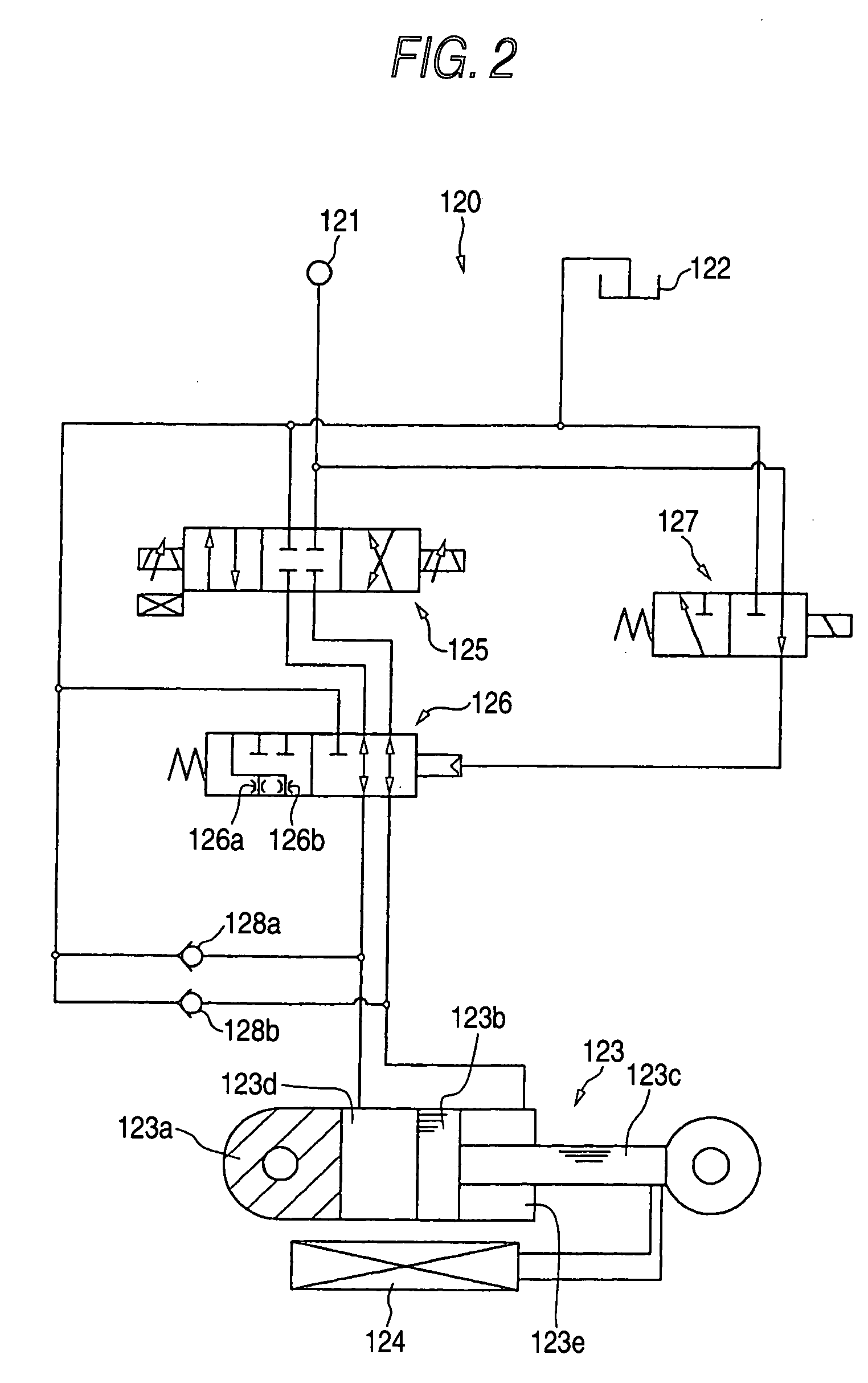

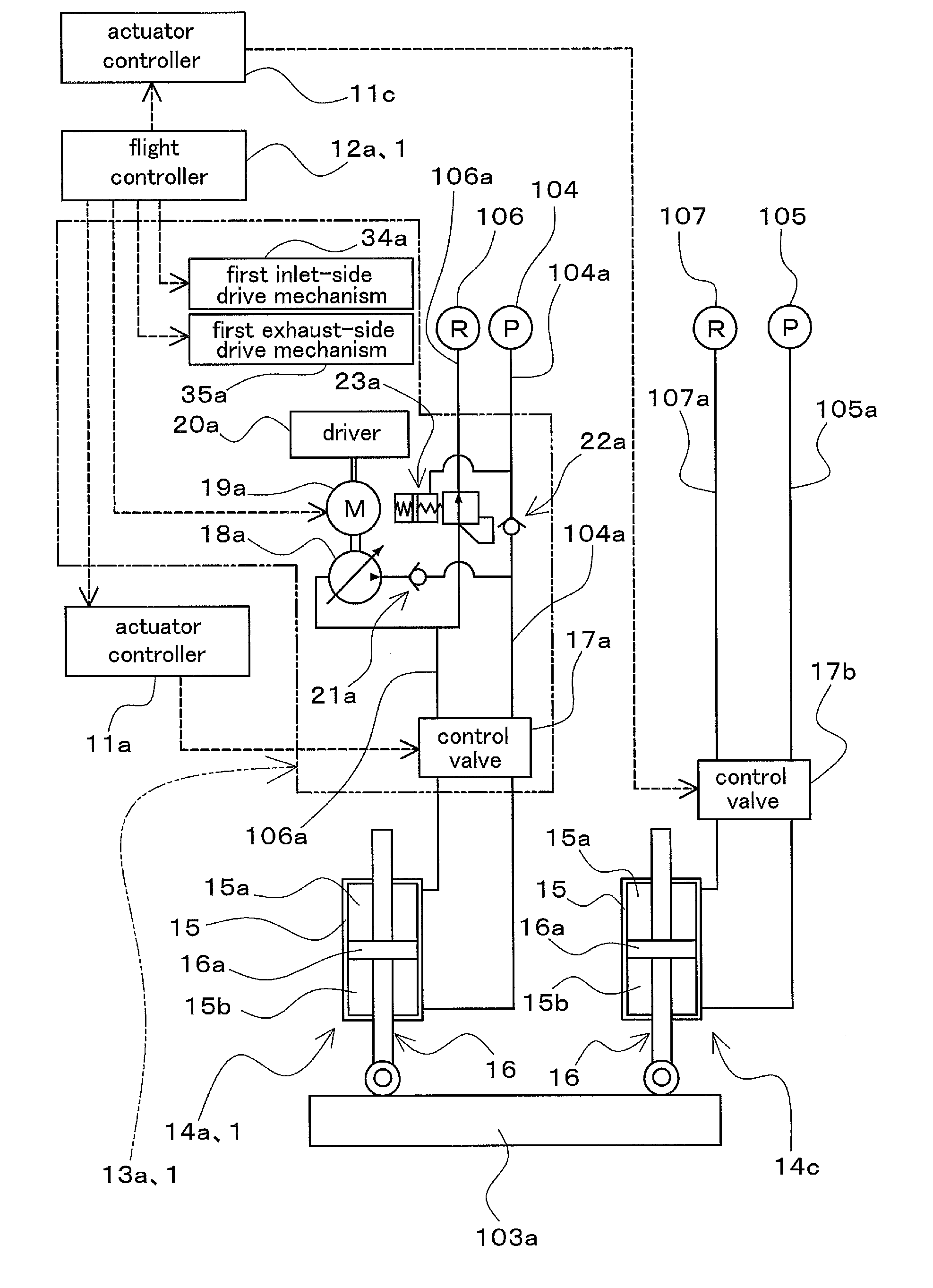

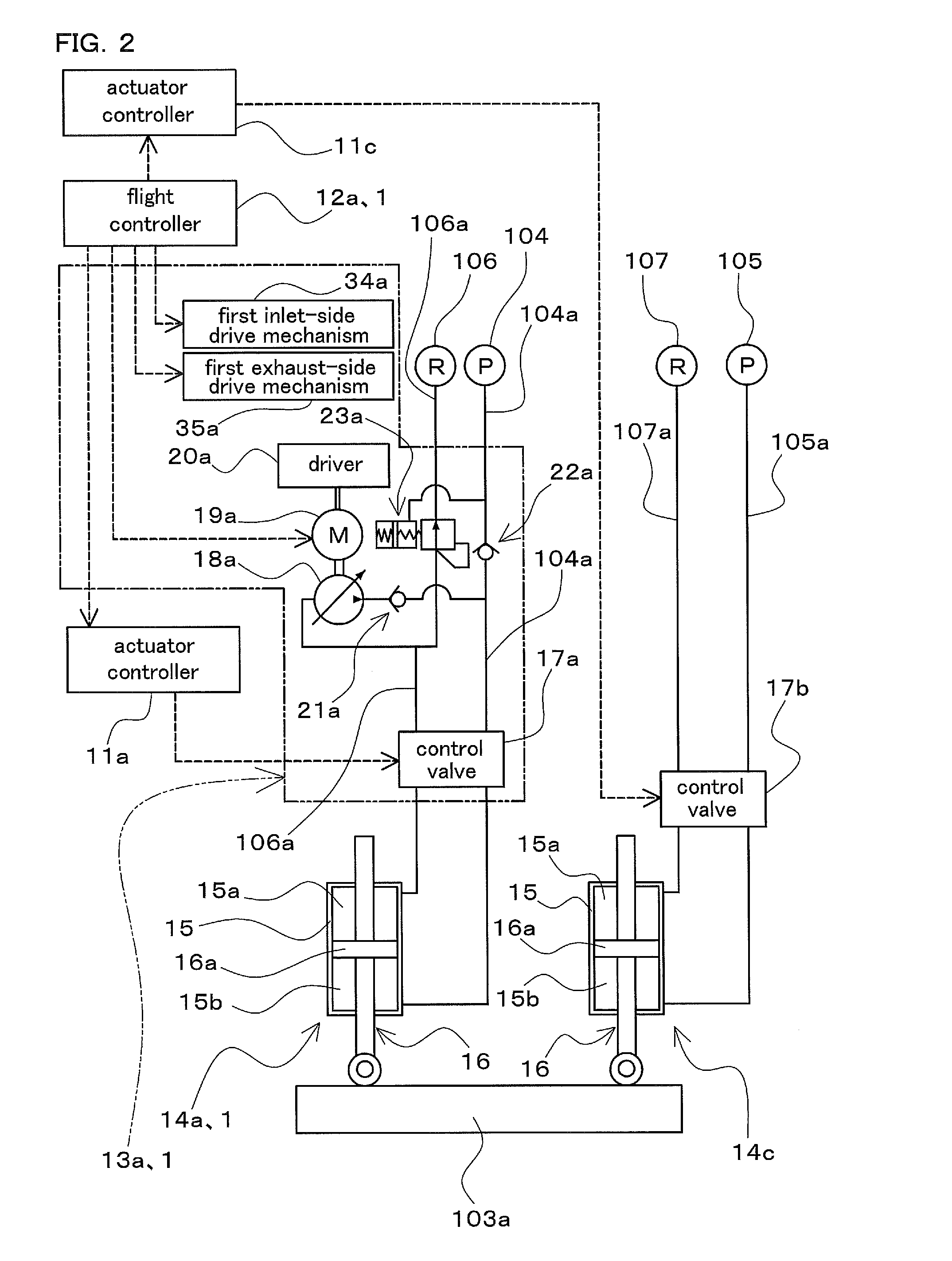

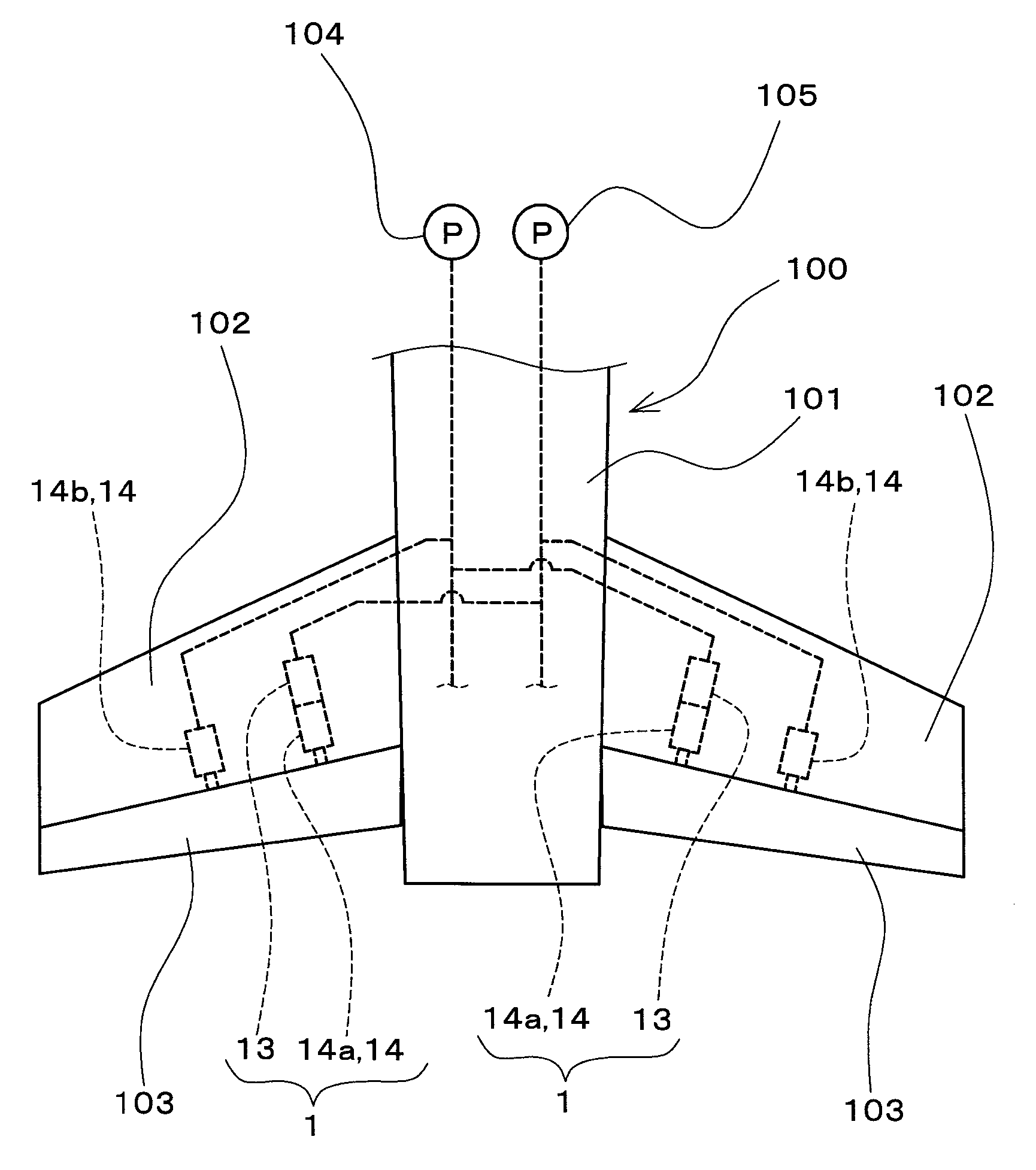

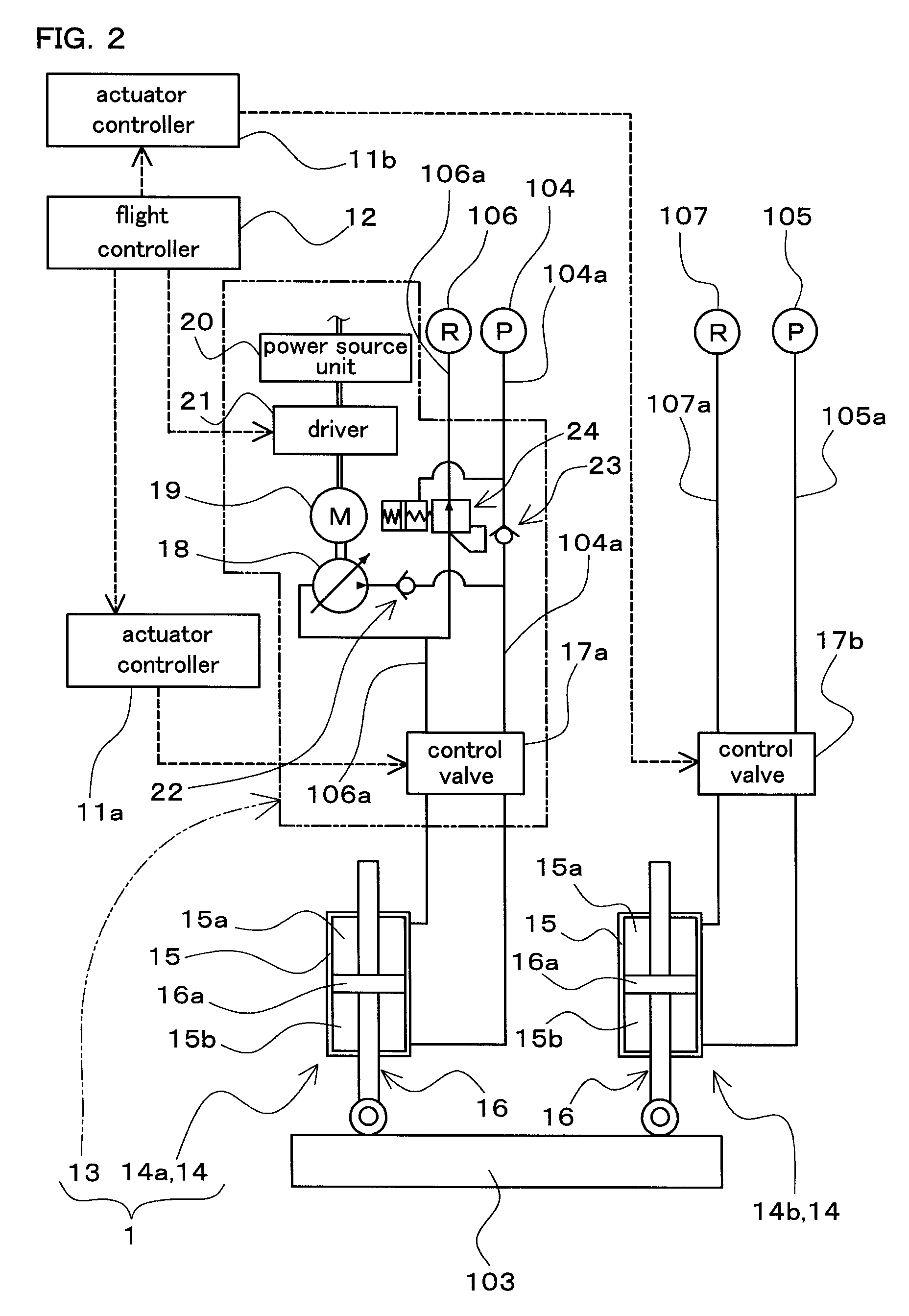

Hydraulic system for aircraft actuators

ActiveUS20110290353A1Reduce energy lossMinimize amount of heat generationFluid-pressure actuator safetyAircraft controlHydraulic pumpRotation velocity

An electric motor drives a variable capacity backup hydraulic pump that can supply pressure oil to an actuator when a loss or reduction occurs in the function of an aircraft central hydraulic power source. A power source unit rectifies electric power supplied from a variable frequency supply. A driver supplies the electric power from the power source unit, and drives the electric motor so as to rotate the pump at a predetermined constant rotational speed. The constant rotational speed is set, based on the change in the efficiency of each of the pump, the electric motor, and the driver with respect to the rotational speed of the pump, such that the overall efficiency, obtained as a product of these efficiencies, has a maximum value.

Owner:NABLESCO CORP

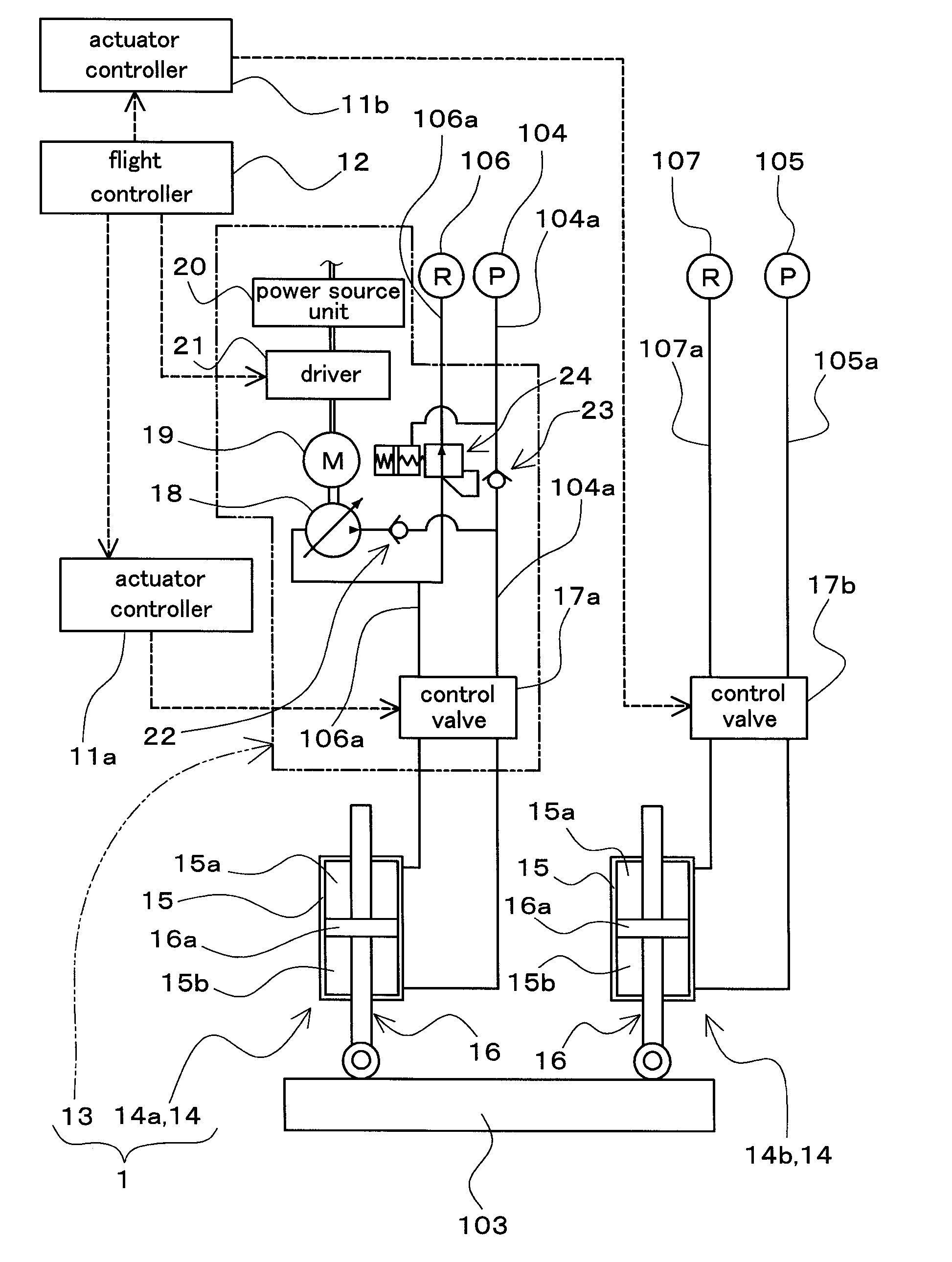

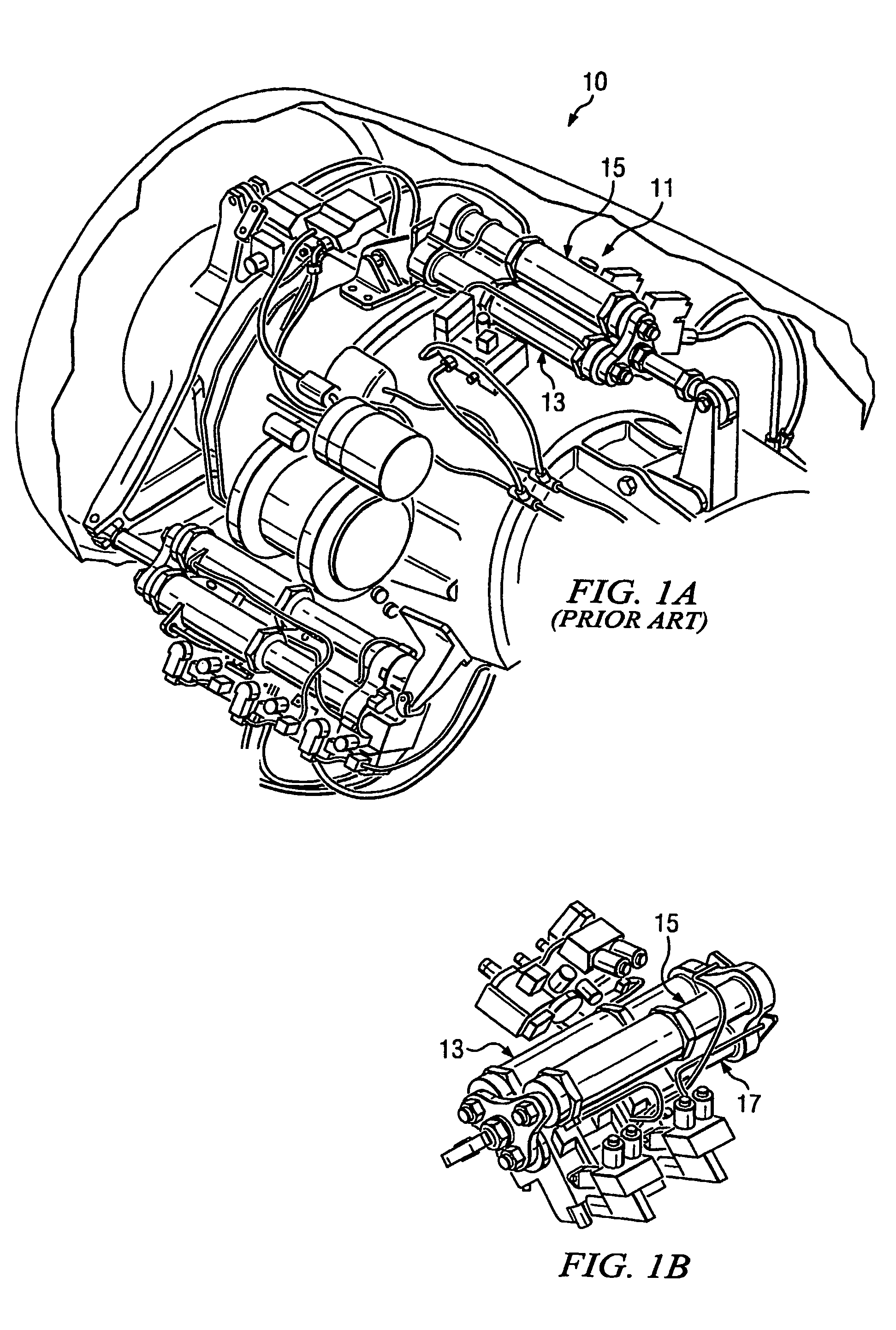

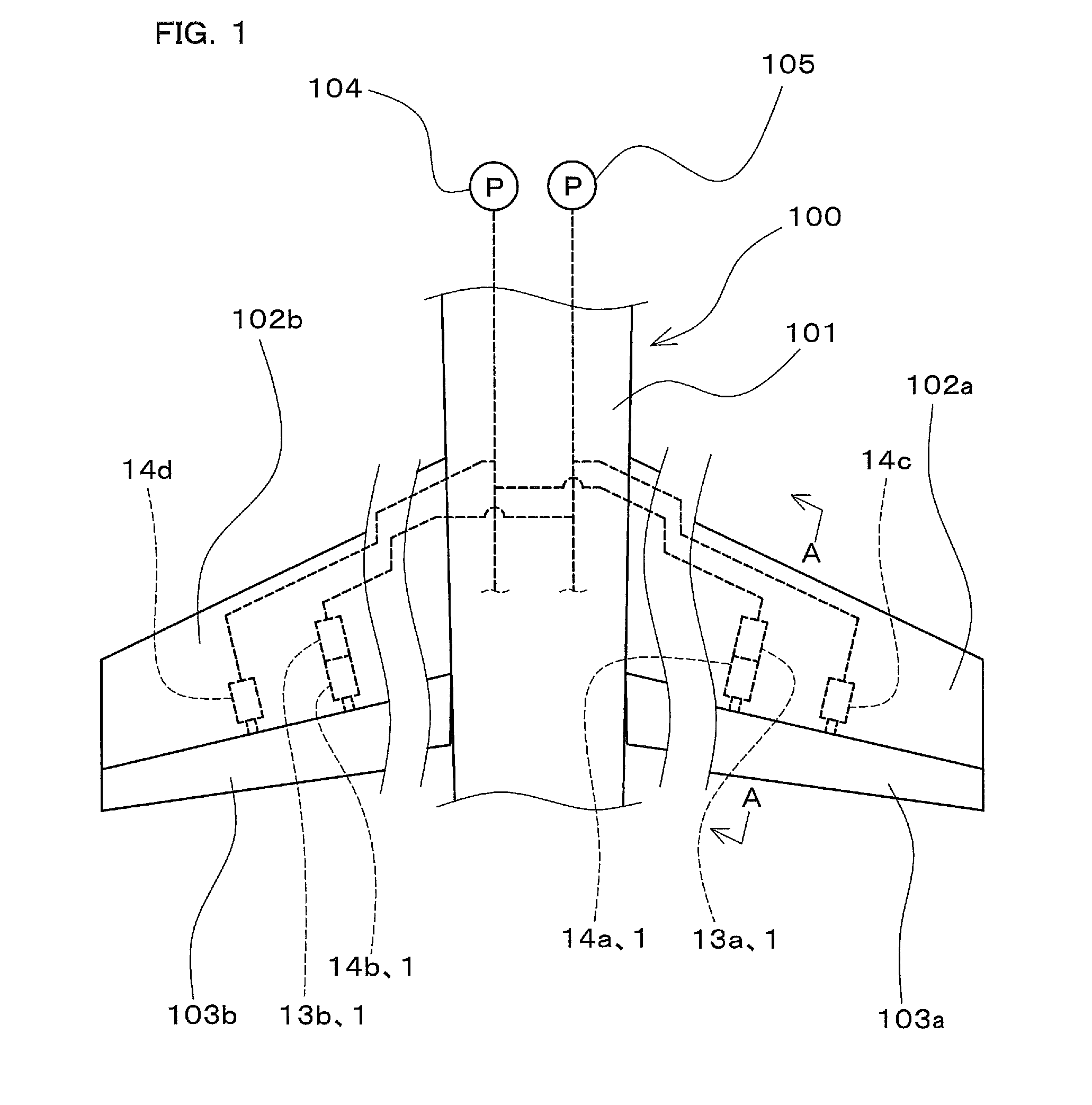

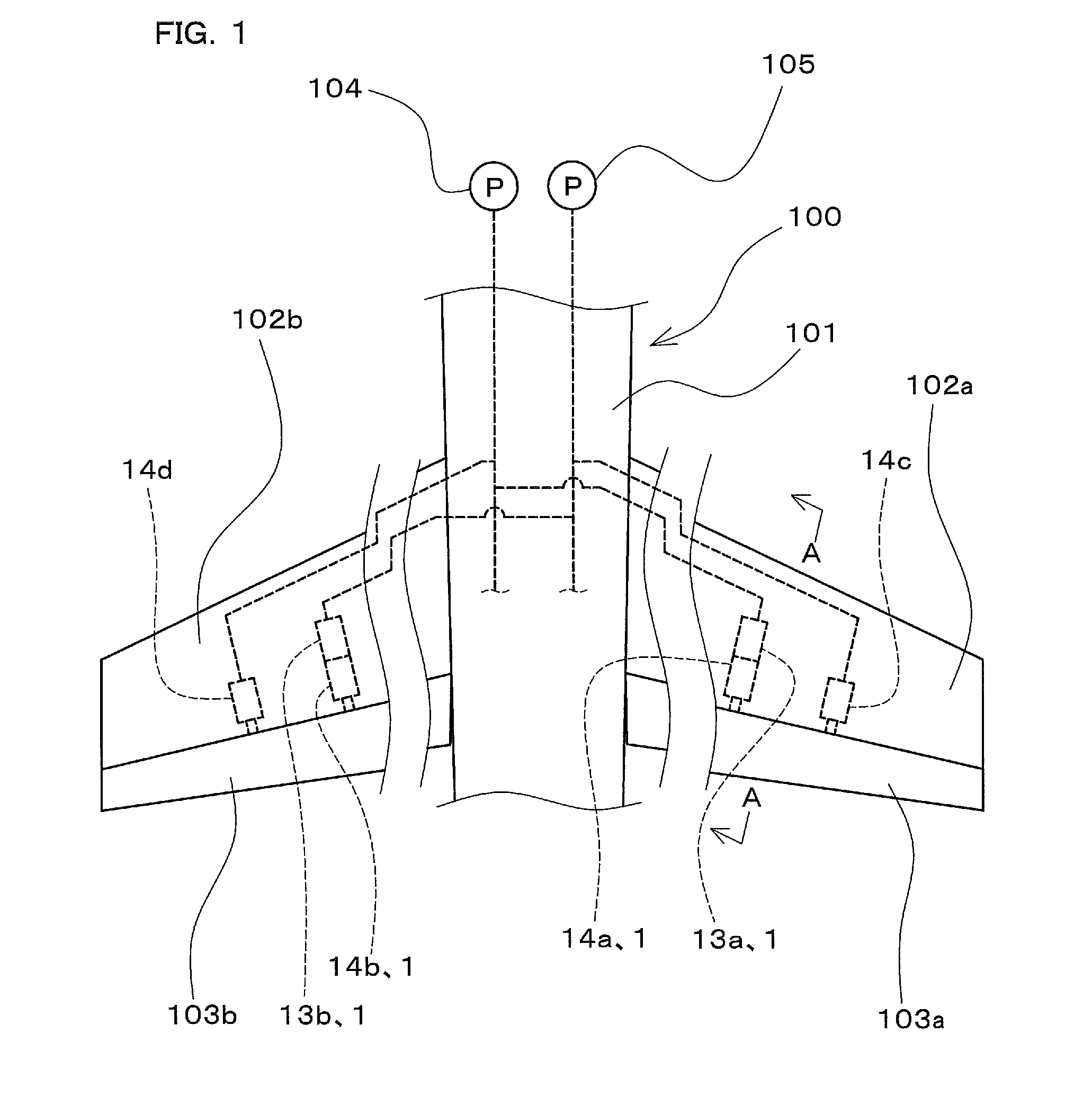

Wing driving apparatus

ActiveUS7175133B2Improve securitySmooth switchingFluid couplingsAircraft stabilisationServo actuatorSolenoid valve

Owner:TEIJIN SEIKI CO LTD

Dual motor dual concentric valve

ActiveUS7828245B2Scalable/modular redundancyEnabling redundancyFluid-pressure actuator safetyServomotor componentsControl systemActuator

An actuator control system has a dual concentric servo valve having a spool and at least one motor adapted to selectively displace the spool.

Owner:TEXTRON INNOVATIONS

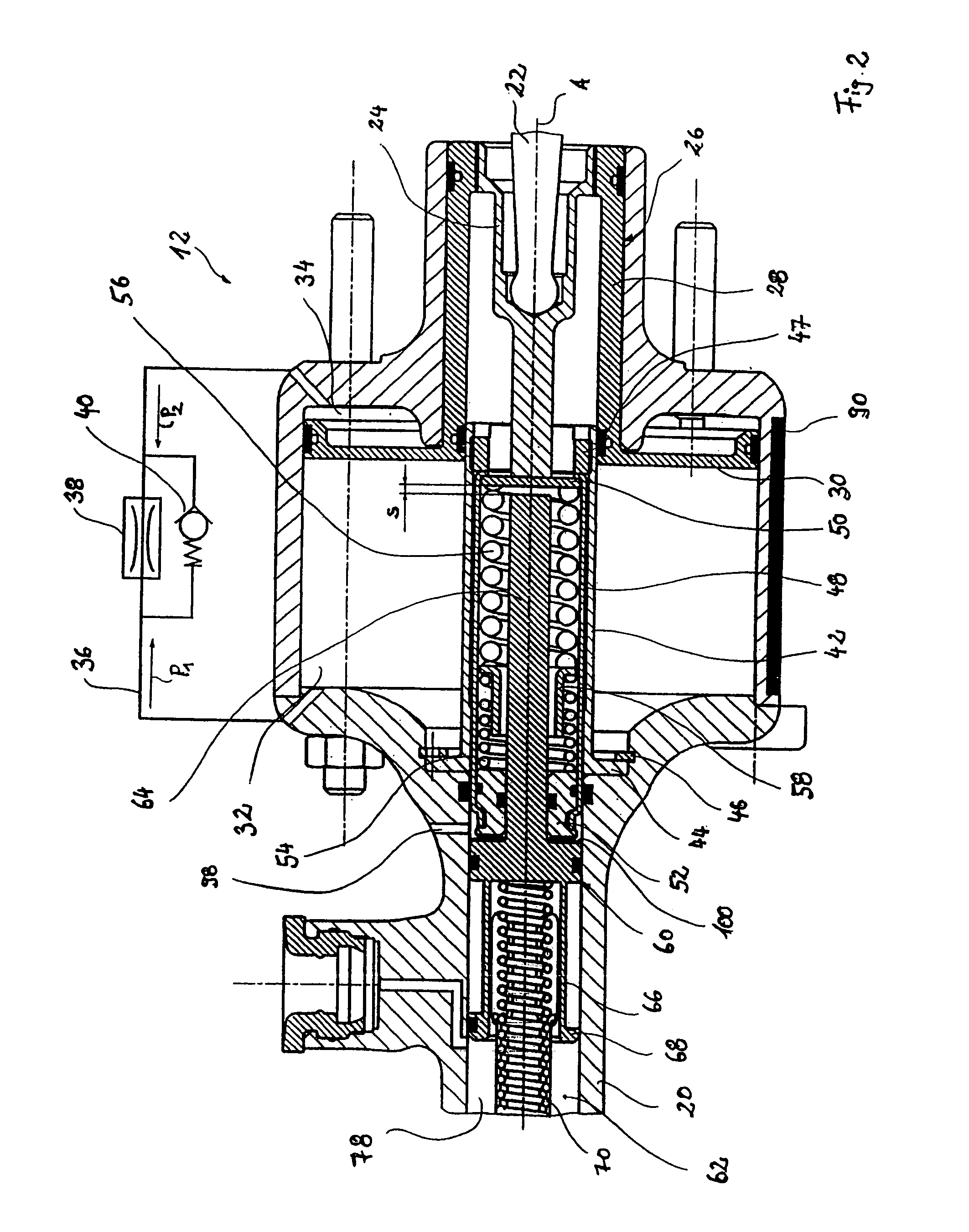

Brake power generator for a hydraulic motor vehicle brake system, and hydraulic motor vehicle brake system

InactiveUS7127891B2Improve response characteristicsSimple designFluid-pressure actuator safetyBraking action transmissionHydraulic motorEngineering

A braking force generator includes a primary piston displaceable in a housing to enclose a primary pressure chamber. A pedal simulation device is connected to the force input element. A pedal actuation detection device detects the pedal actuation and an actuating force booster stage. During normal operation the force input element is mechanically uncoupled from the primary piston, and the actuating force booster stage exerts an actuating force on the primary piston. In the event of failure of the actuating force booster stage the force input element is workingly connectable to the primary piston such that a contact extension extends from the primary piston towards the force input element. During normal operation the contact extension is held by a release gap at a distance from the force input element and in the event of failure of the actuating force booster stage the force input element after travelling the release gap is applied workingly against the contact extension.

Owner:LUCAS AUTOMOTIVE GMBH

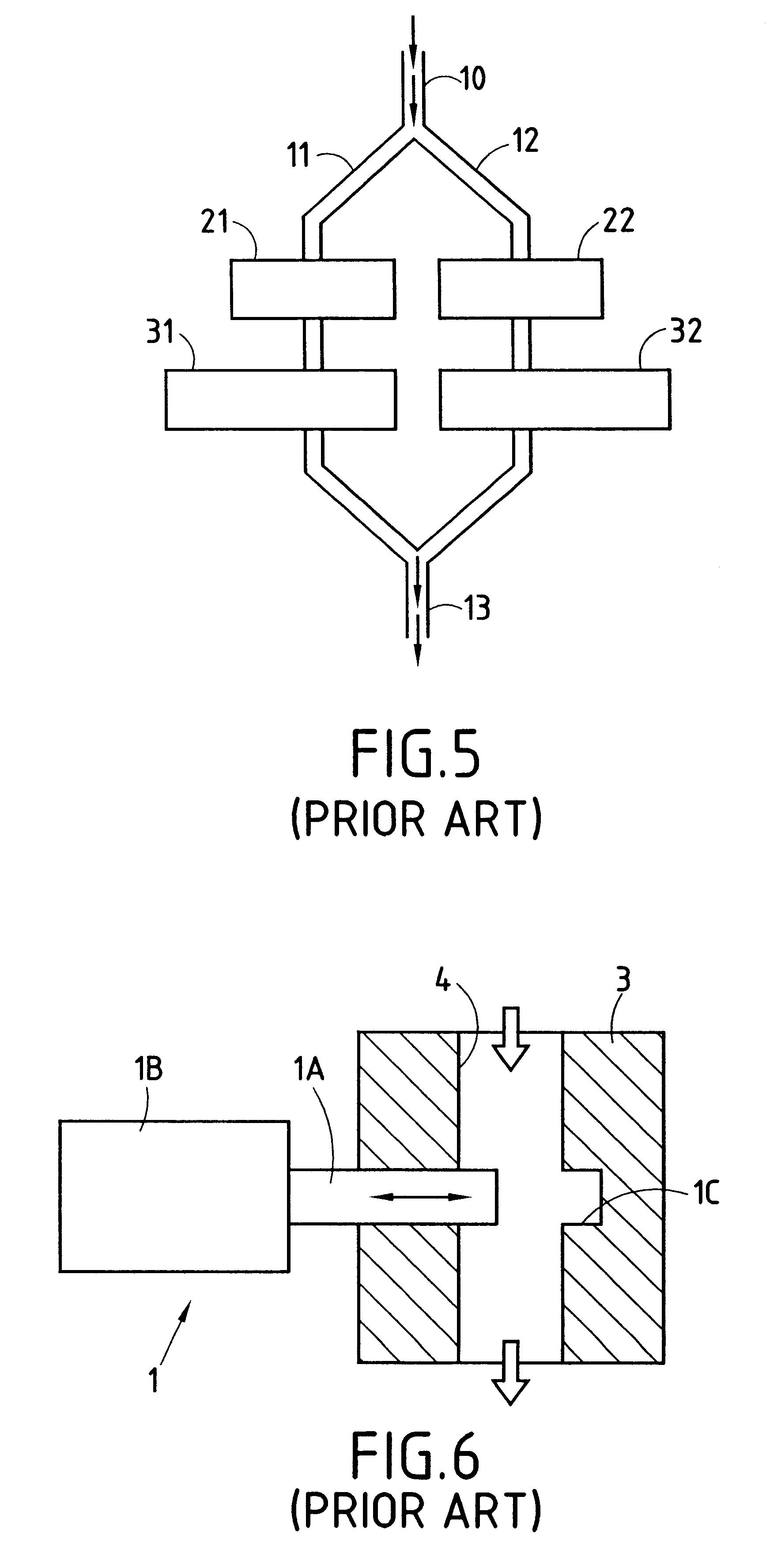

Redundant regulation valve

InactiveUS6223774B1Reduce quality problemsLow costFluid-pressure actuator safetyPlug valvesThrottleReliability engineering

The redundant regulation valve for controlling fluid flow comprises a valve body defining a passage for the flow of the fluid, a main throttle element movable by means of a main control device to selectively obstruct the passage, and a redundant throttle element movable by means of a redundant control device. When the valve is in its closed position in normal operation, the main element and the redundant element are in contact with each other. In this normal closed position, the main element is close to its fully-extended position in the closure direction and it obstructs only about half of the passage, while the redundant element is in a position of medium extension. The stroke of the redundant element is such that the redundant element can be controlled to obstruct the entire passage even when the main element is in its fully-open position.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

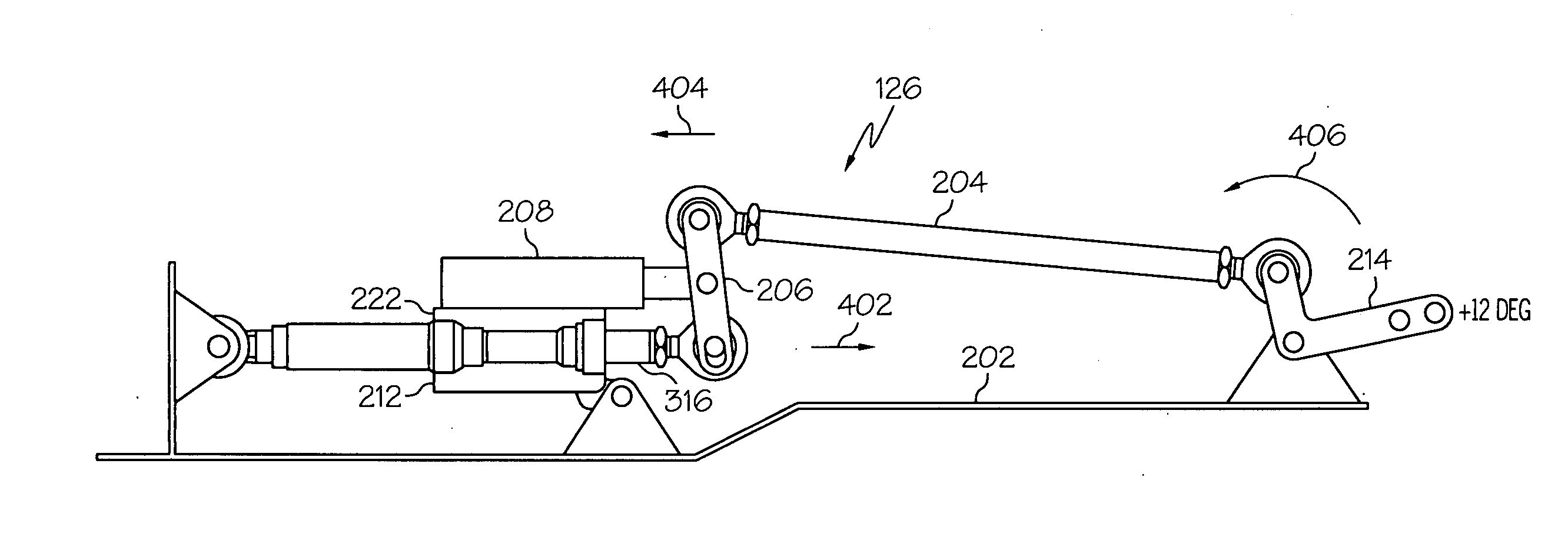

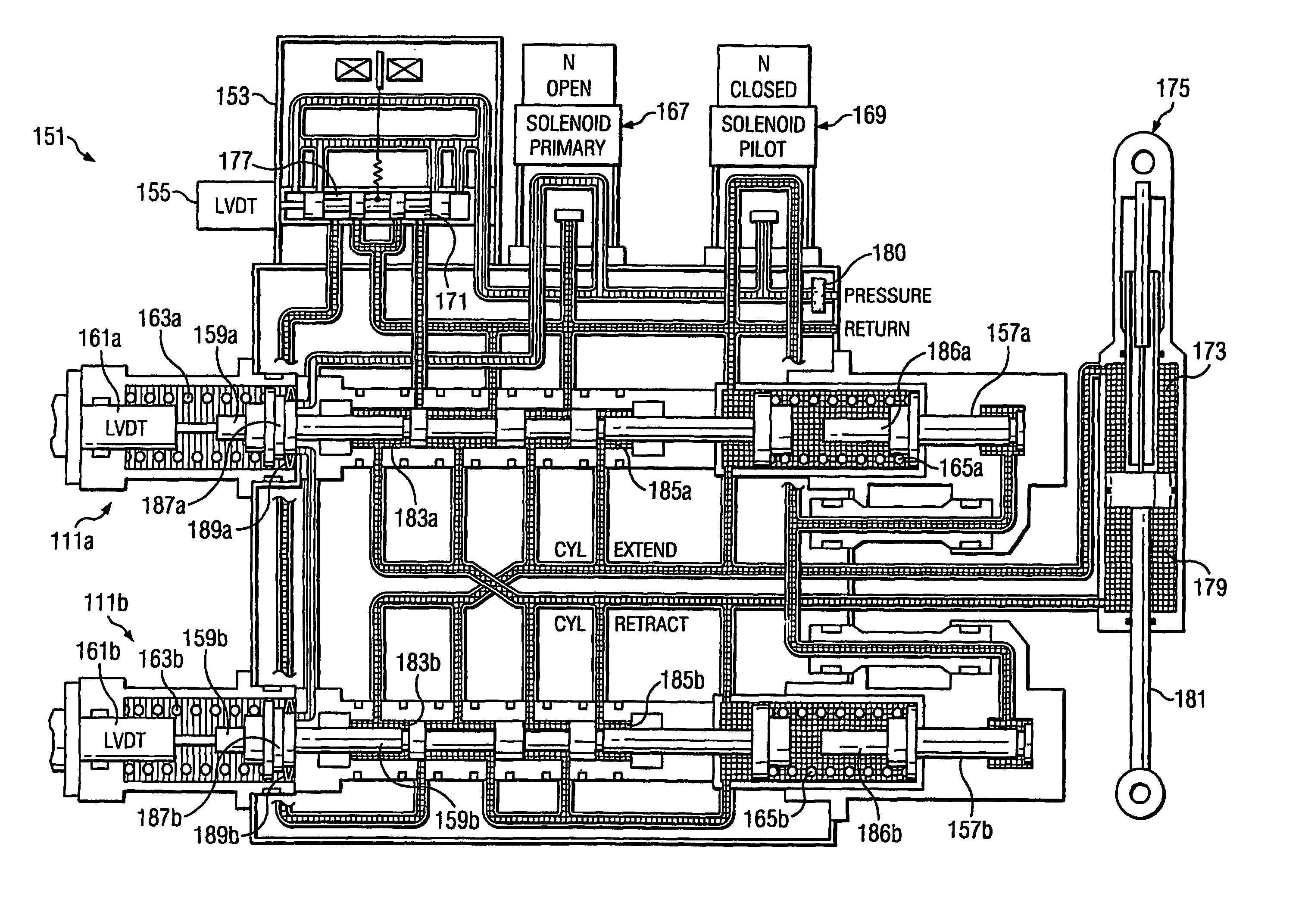

Integrated three function valve

An integrated three function valve (ITFV) that combines the functions of a bypass valve (e.g. 183a, 185a, 161a) into a single assembly is disclosed. The ITFV allows continued operation after any two failures. With the integrated three function valve, no combination of electrical or hydraulic component failures, regardless of expected failure rate, will prevent an actuator from continued safe operation

Owner:BELL HELICOPTER TEXTRON INC

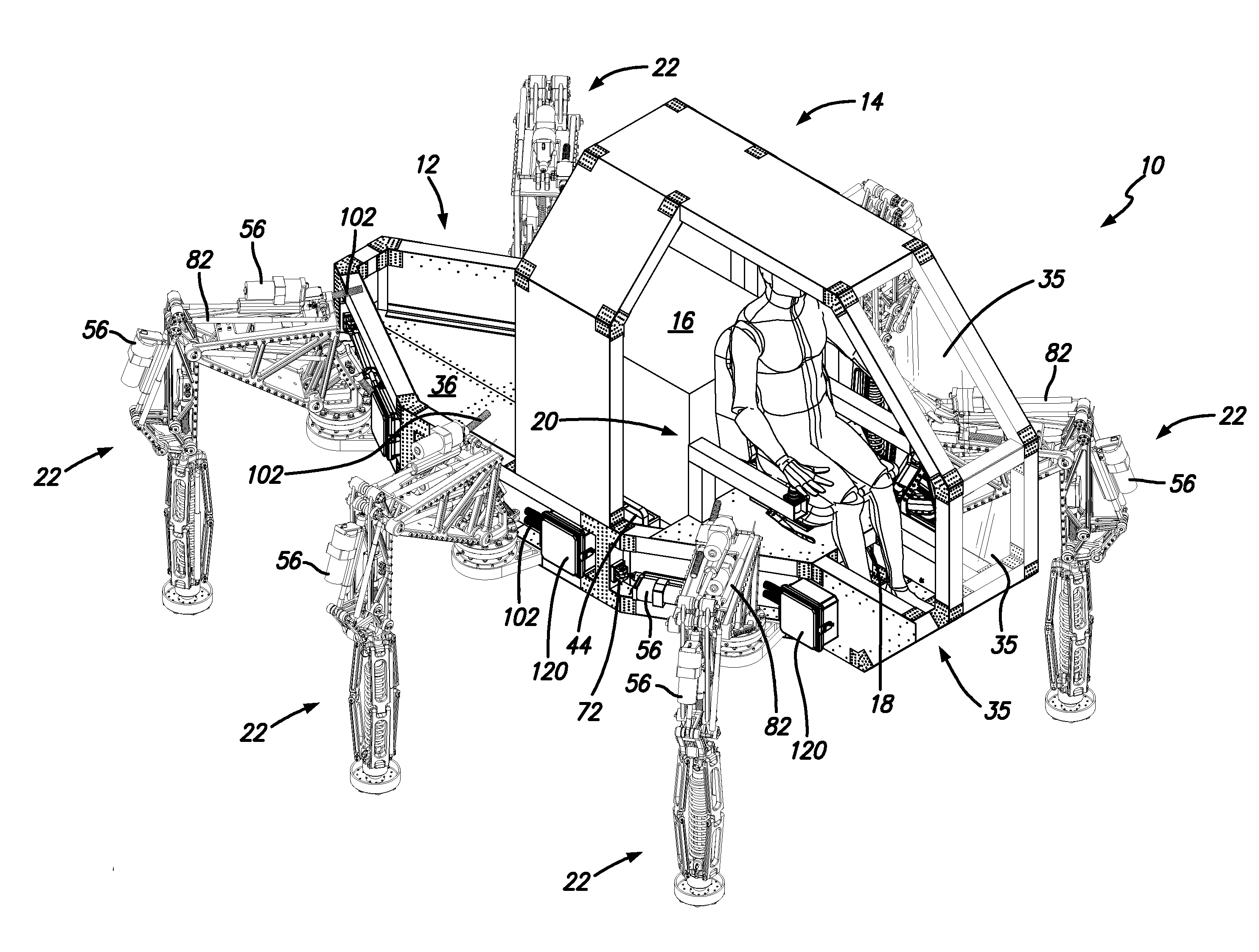

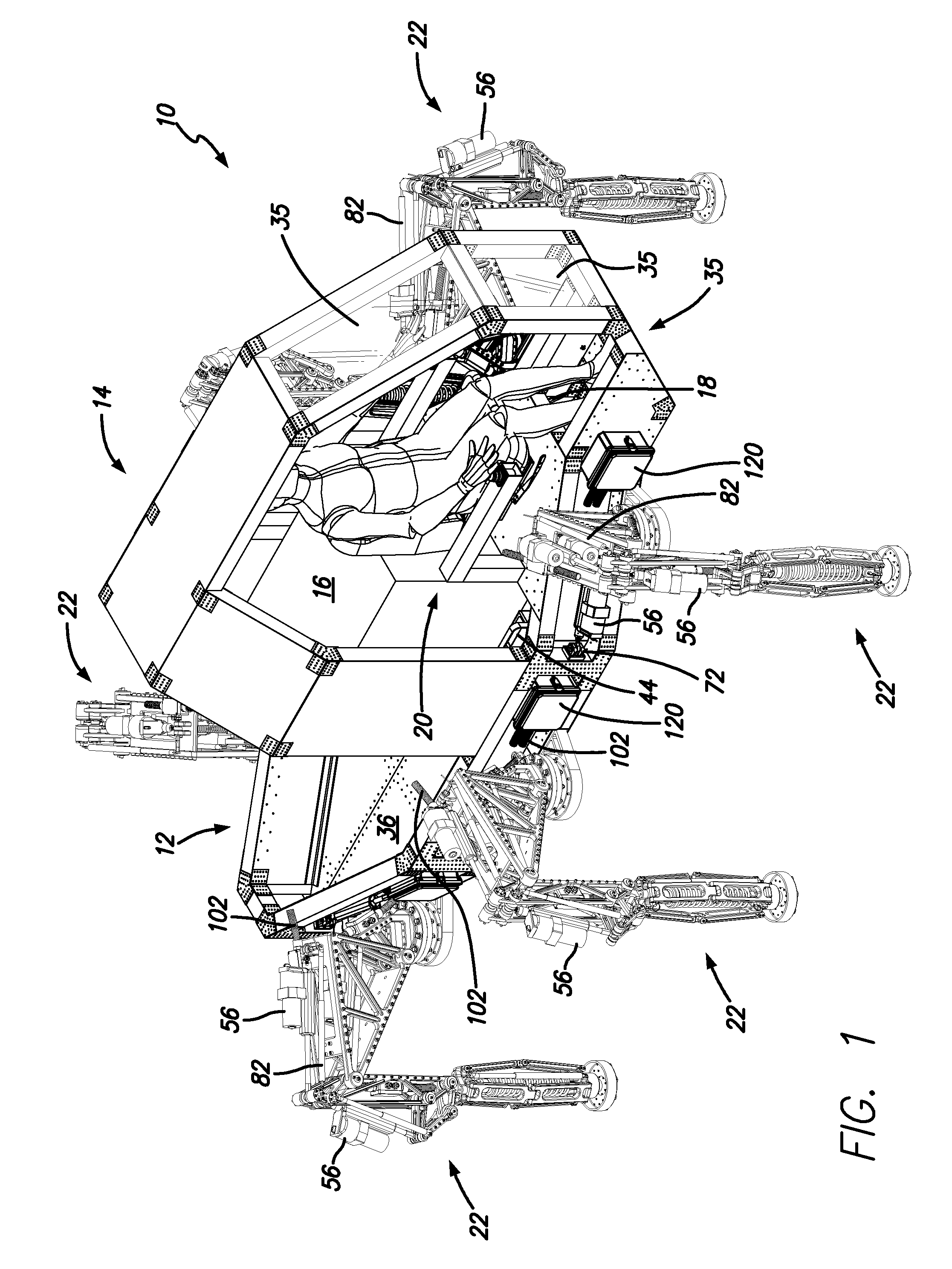

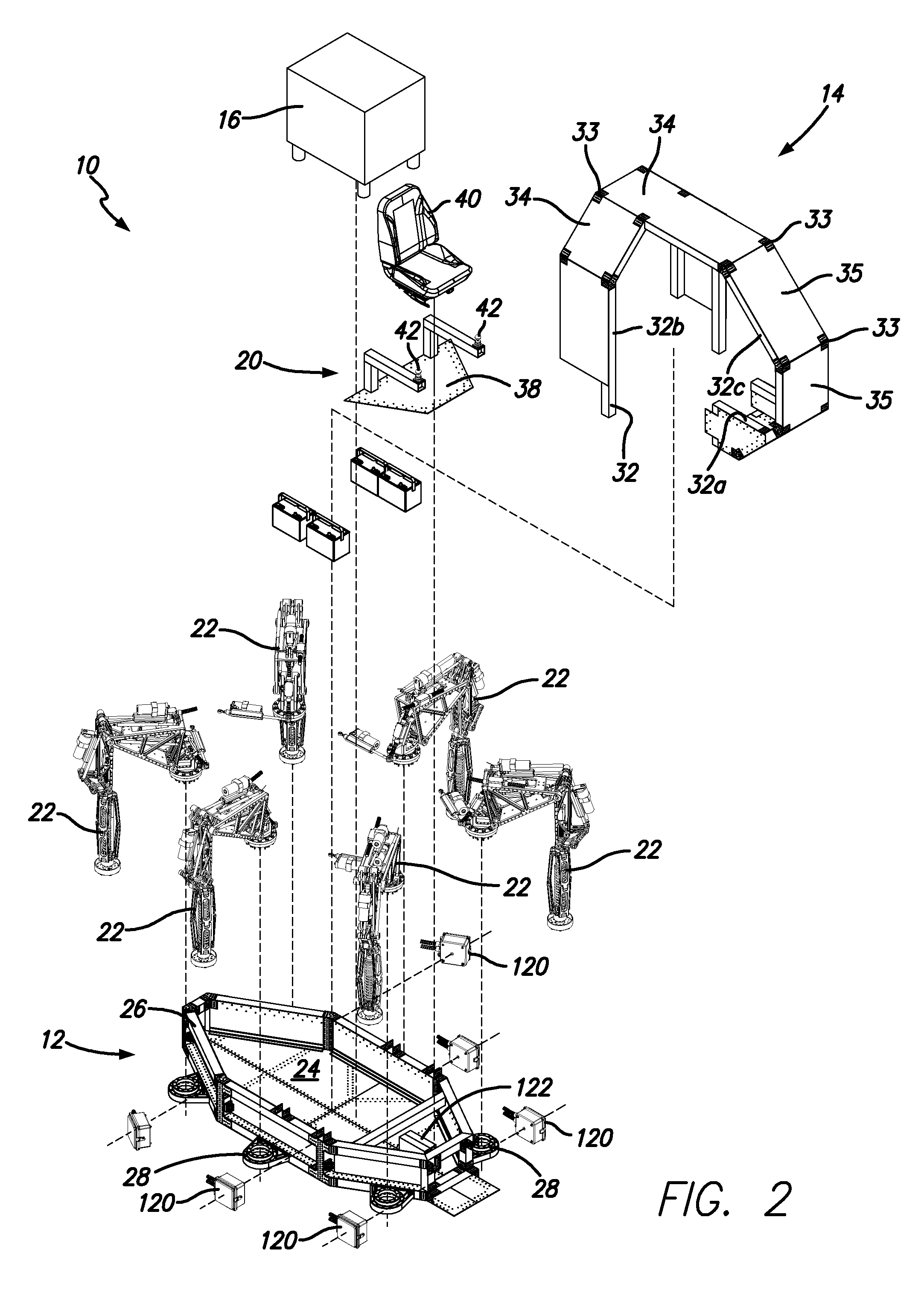

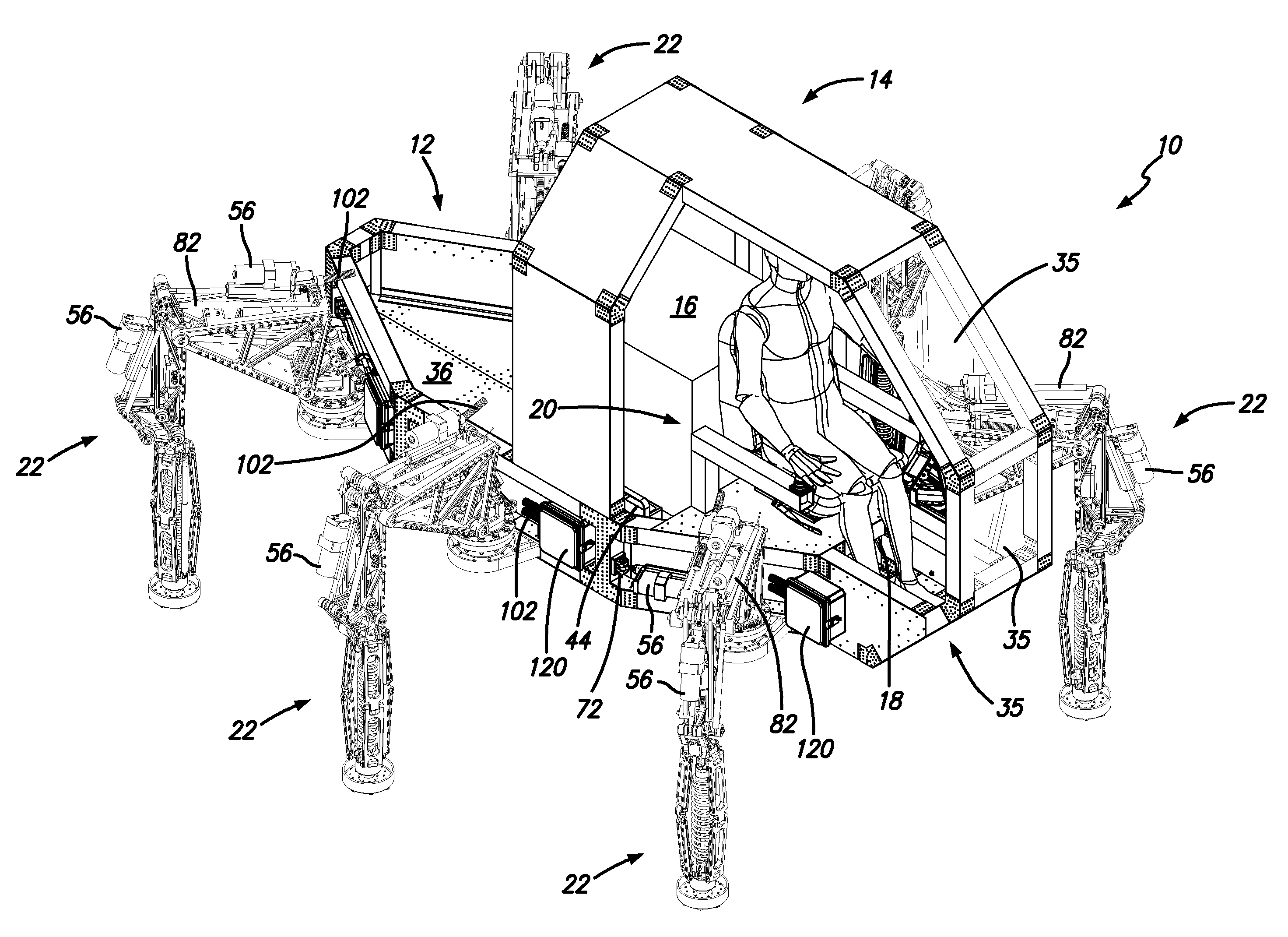

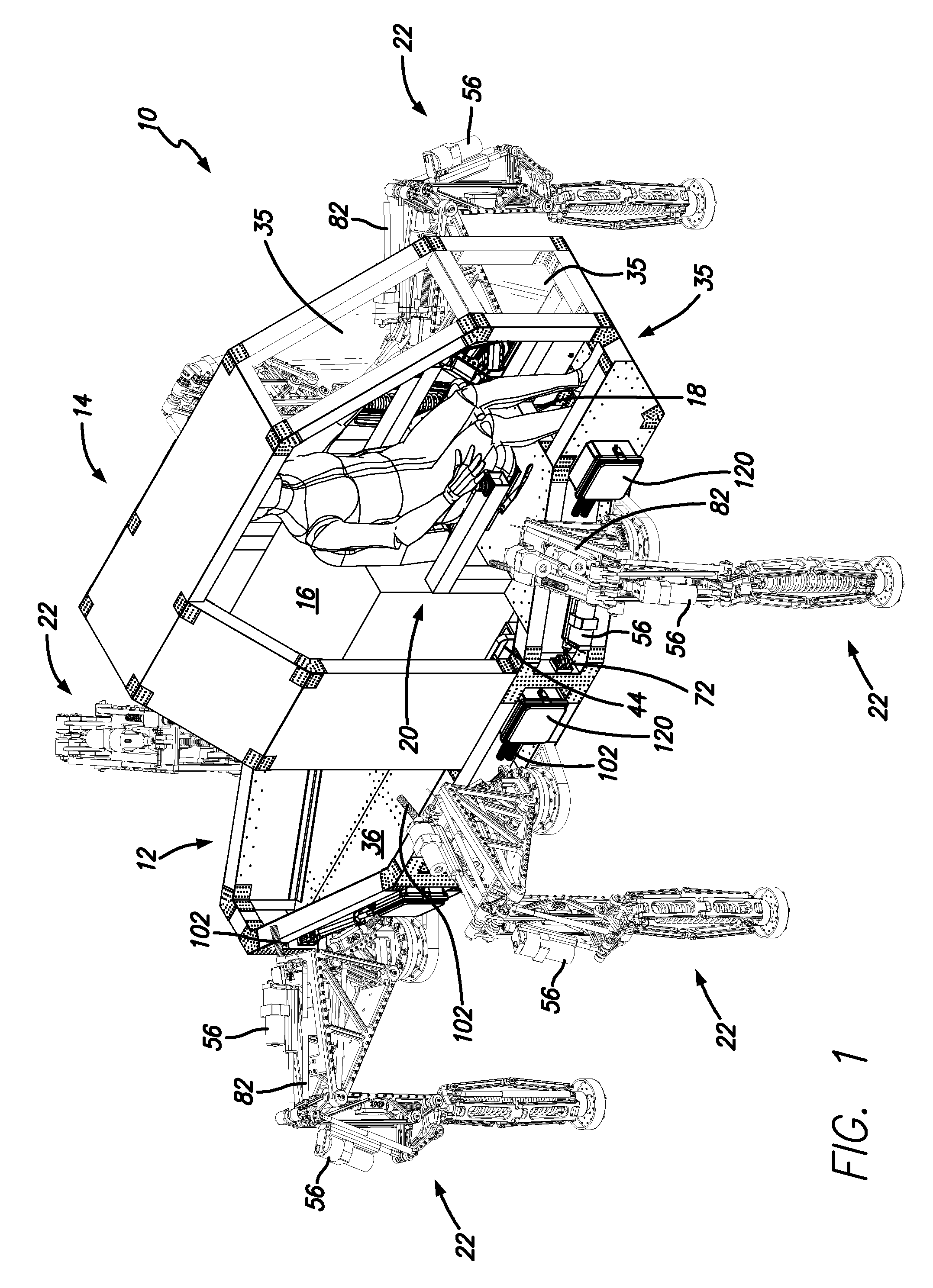

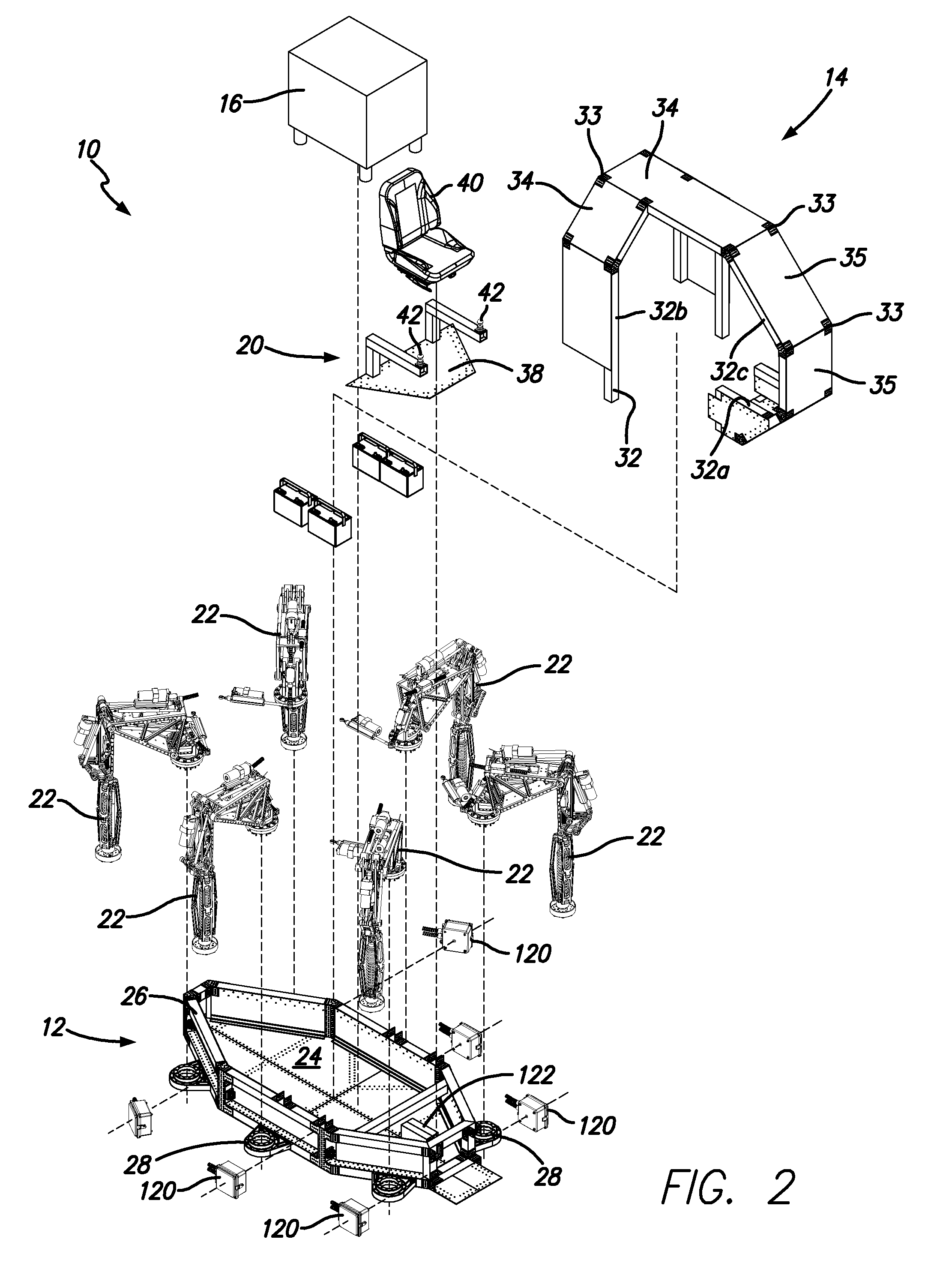

Statically stable walking machine and power system therefor

ActiveUS20150101871A1Improve abilitiesImprove performanceFluid couplingsMechanical machines/dredgersMicrocontrollerElectric power system

A walking machine that includes a chassis with an operator interface, a main controller in data communication with the operator interface, at least two leg members operatively connected to the chassis, and a power system in data communication and electrical communication with the main controller. Each leg member includes a leg control system that includes a leg microcontroller in data communication with the main controller and at least a first electro hydrostatic actuator in electrical communication with the leg microcontroller. The power system includes an electrical generator, power supply electronics in electrical communication with the electrical generator, an electrical storage medium in electrical communication with the electrical generator and in parallel with the power supply electronics, and an electrical power bus for distributing power from the power system to the leg control systems.

Owner:RISKAS BRIAN

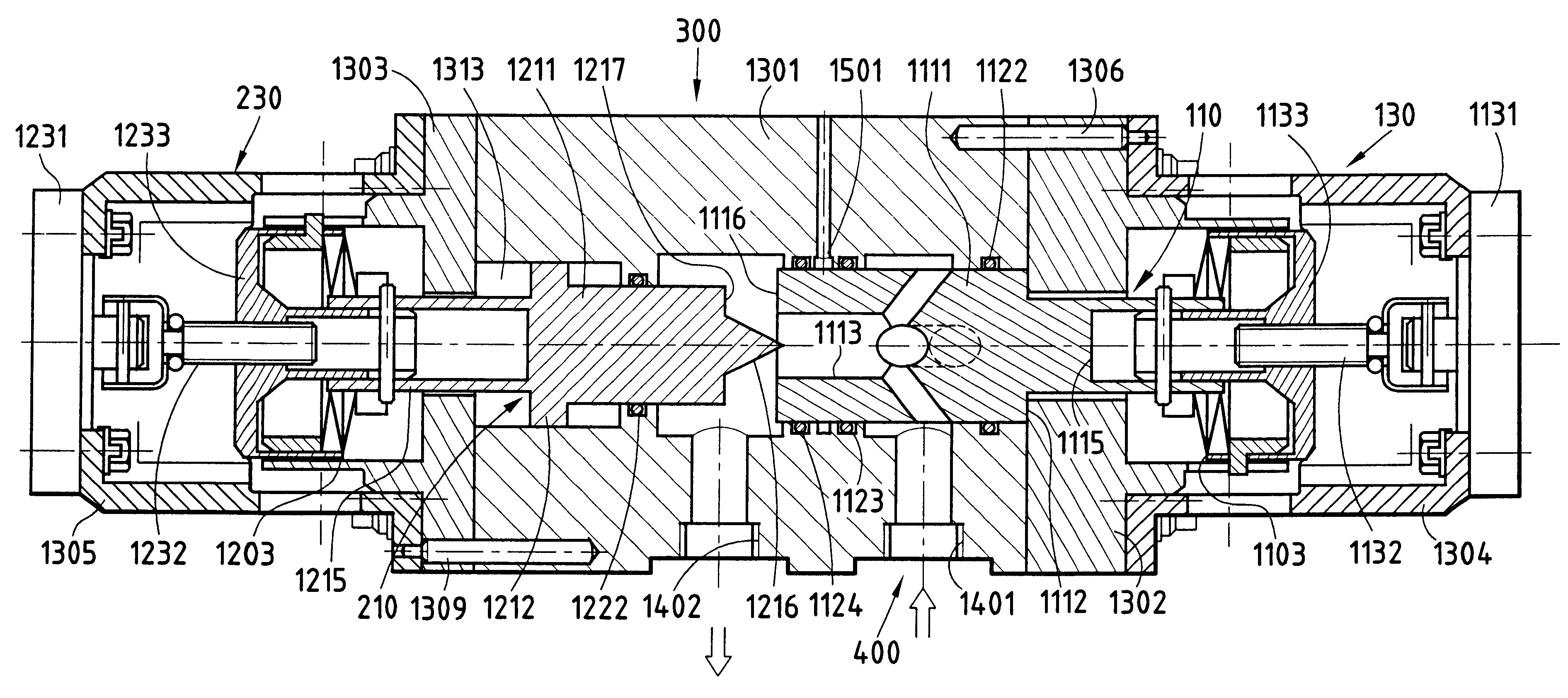

Dual linear actuator

ActiveUS20090013862A1Increase the speed of adjustmentHigh regulating torqueFluid couplingsServomotor componentsLinear motionControl theory

An actuator having two or more interconnected movement components, wherein the movement components are designed as linear actuators with substantially coaxial longitudinal axes or longitudinal axes that are parallel to each other and that are interconnected in longitudinal direction such that their linear movements are superimposed on one another, and such that at least one of the linear actuators can be stopped at one or several predetermined positions.

Owner:AIRBUS OPERATIONS GMBH

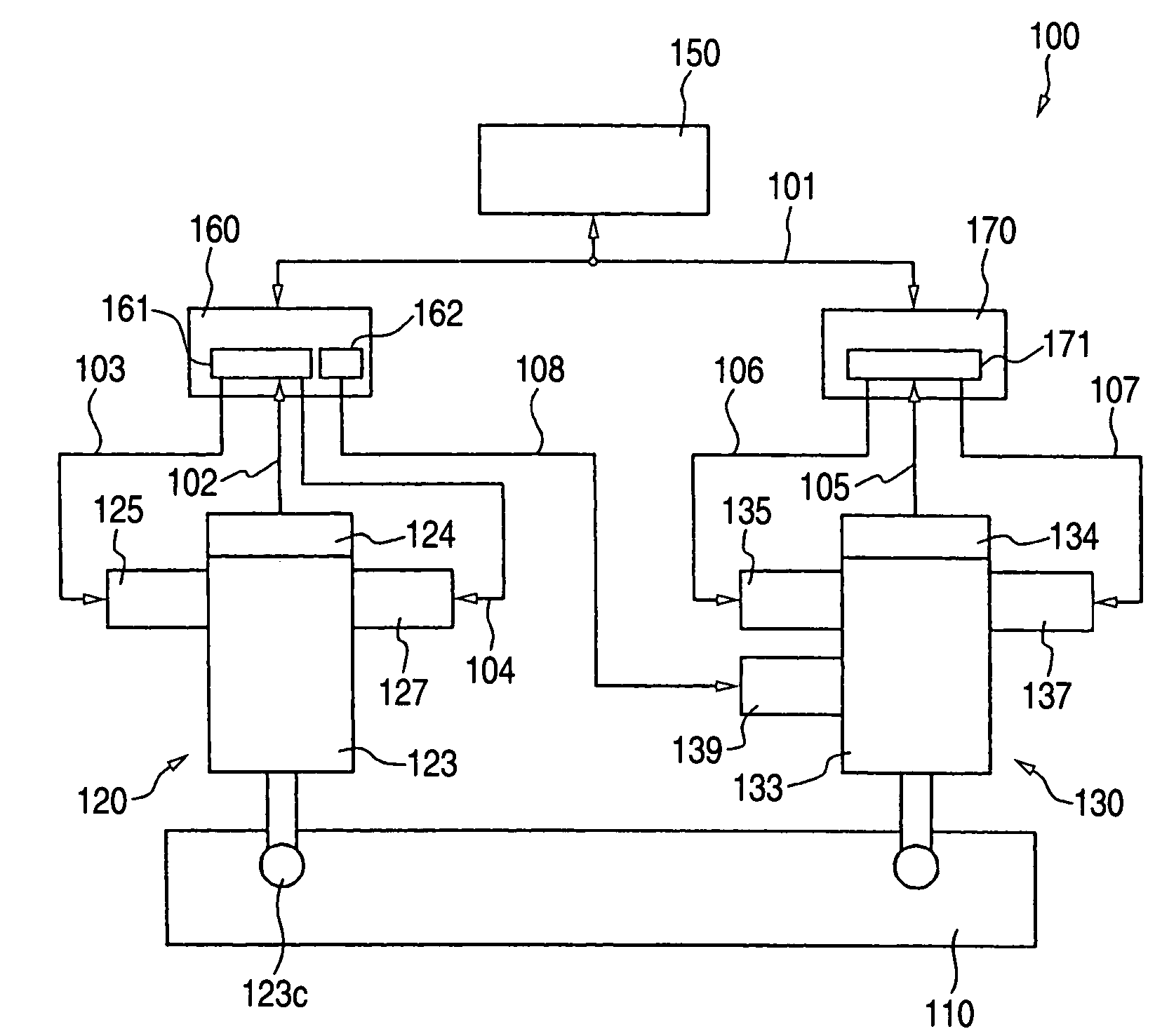

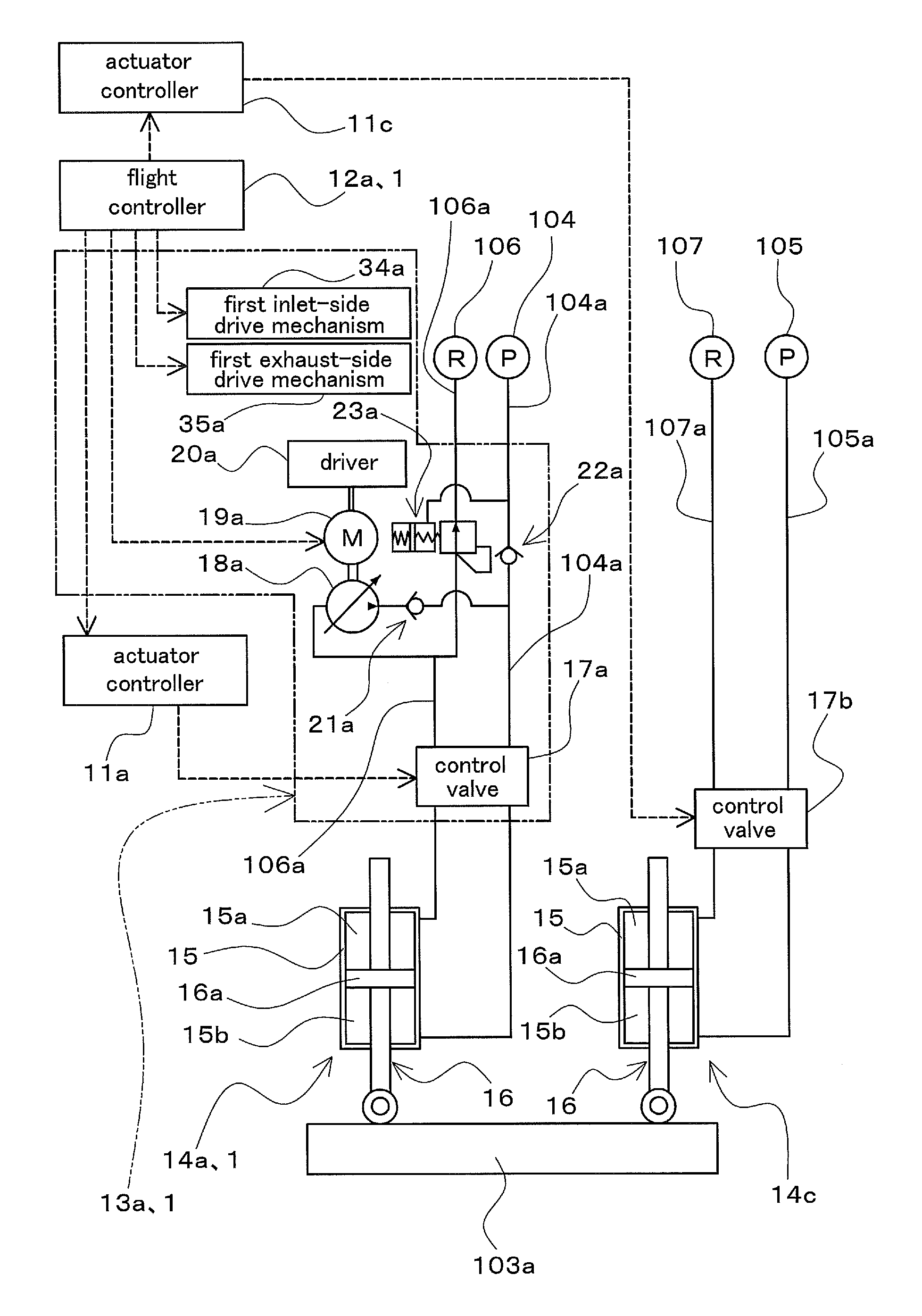

Aircraft actuator hydraulic system

ActiveUS20120001021A1Prevent backflowSuppressing increaseAircraft stabilisationWithout power ampliicationFlight vehicleHydraulic pump

When a loss or degradation in the function of one of a first aircraft central hydraulic power source and a second aircraft central hydraulic power source occurs, a controller performs a control so as to operate the other backup hydraulic pump, out of a first backup hydraulic pump and a second backup hydraulic pump, which is connected downstream of the other hydraulic power source, which is the other of the first and second aircraft central hydraulic power sources. Oil flowing through the other backup hydraulic pump is cooled by an oil cooler of the other hydraulic power source by operation of the other backup hydraulic pump in a state where the other hydraulic power source is being operated.

Owner:NABLESCO CORP

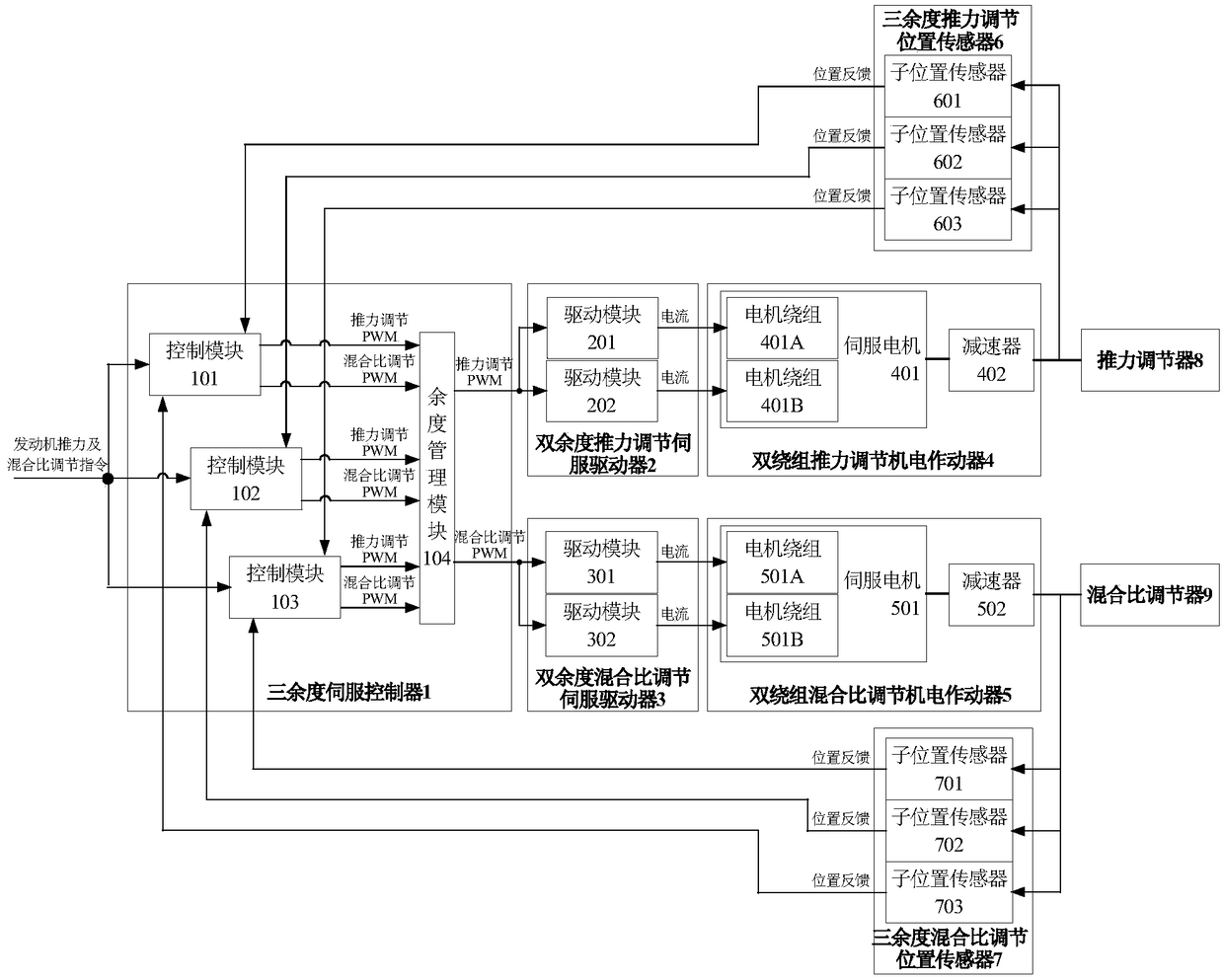

Multi-redundancy electromechanical servo system for adjusting thrust and mixing ratio of liquid-propellant rocket engine

ActiveCN108661823ASimplify gas-liquid systemsSimple control driveSafety arrangmentsError detection/correctionControl signalThree-phase

The invention discloses a multi-redundancy electromechanical servo system for adjusting the thrust and a mixing ratio of a liquid-propellant rocket engine. A three-redundancy servo controller, a double-redundancy servo driver, a double-winding electromechanical actuator, a three-redundancy position sensor, a thrust adjustor and a mixing ratio adjustor are included. An engine thrust and mixing ratio adjusting instruction and a position feedback signal of the three-redundancy position sensor are input to the three-redundancy servo controller; the three-redundancy servo controller outputs a thrust and mixing ratio adjusting PWM wave control signal to the double-redundancy servo driver; the double-redundancy servo driver outputs a three-phase frequency varying and amplitude varying sine wave current to drive the double-winding electromechanical actuator to drive the thrust adjustor and the mixing ratio adjustor to move; and adjusting of the thrust and the mixing ratio of the engine is achieved. The servo system is simple and excellent in control characteristic, has the capacity of controlling two-redundancy fault work and driving one-redundancy fault work, and the reliability of adjusting the thrust and the mixing ratio of the liquid-propellant rocket engine and the using maintenance are remarkably improved.

Owner:XIAN AEROSPACE PROPULSION INST

Aircraft actuator hydraulic system

ActiveUS8418956B2Small sizeIncrease in weightAircraft stabilisationWith power amplificationHydraulic pumpEngineering

When a loss or degradation in the function of one of a first aircraft central hydraulic power source and a second aircraft central hydraulic power source occurs, a controller performs a control so as to operate the other backup hydraulic pump, out of a first backup hydraulic pump and a second backup hydraulic pump, which is connected downstream of the other hydraulic power source, which is the other of the first and second aircraft central hydraulic power sources. Oil flowing through the other backup hydraulic pump is cooled by an oil cooler of the other hydraulic power source by operation of the other backup hydraulic pump in a state where the other hydraulic power source is being operated.

Owner:NABLESCO CORP

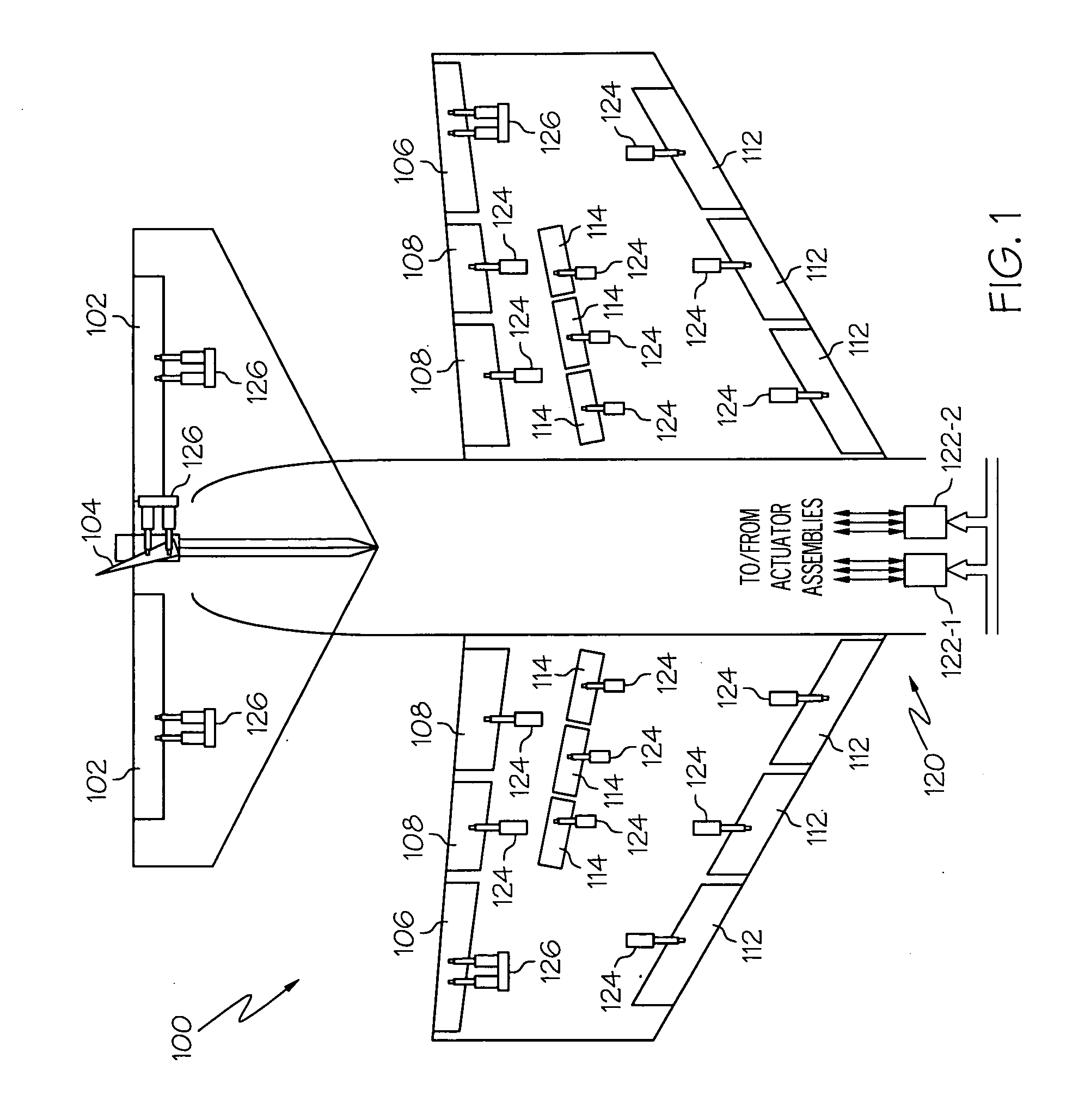

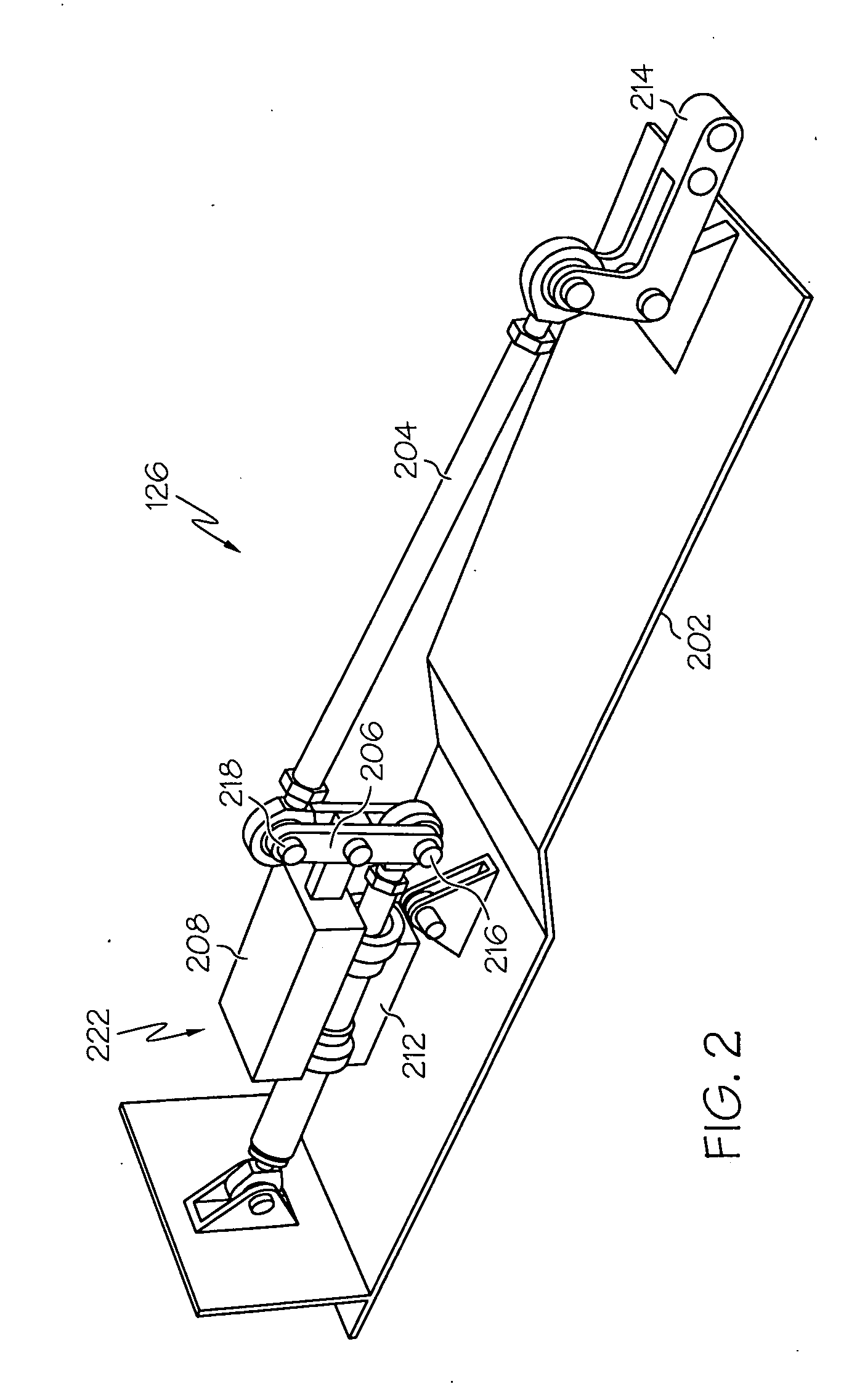

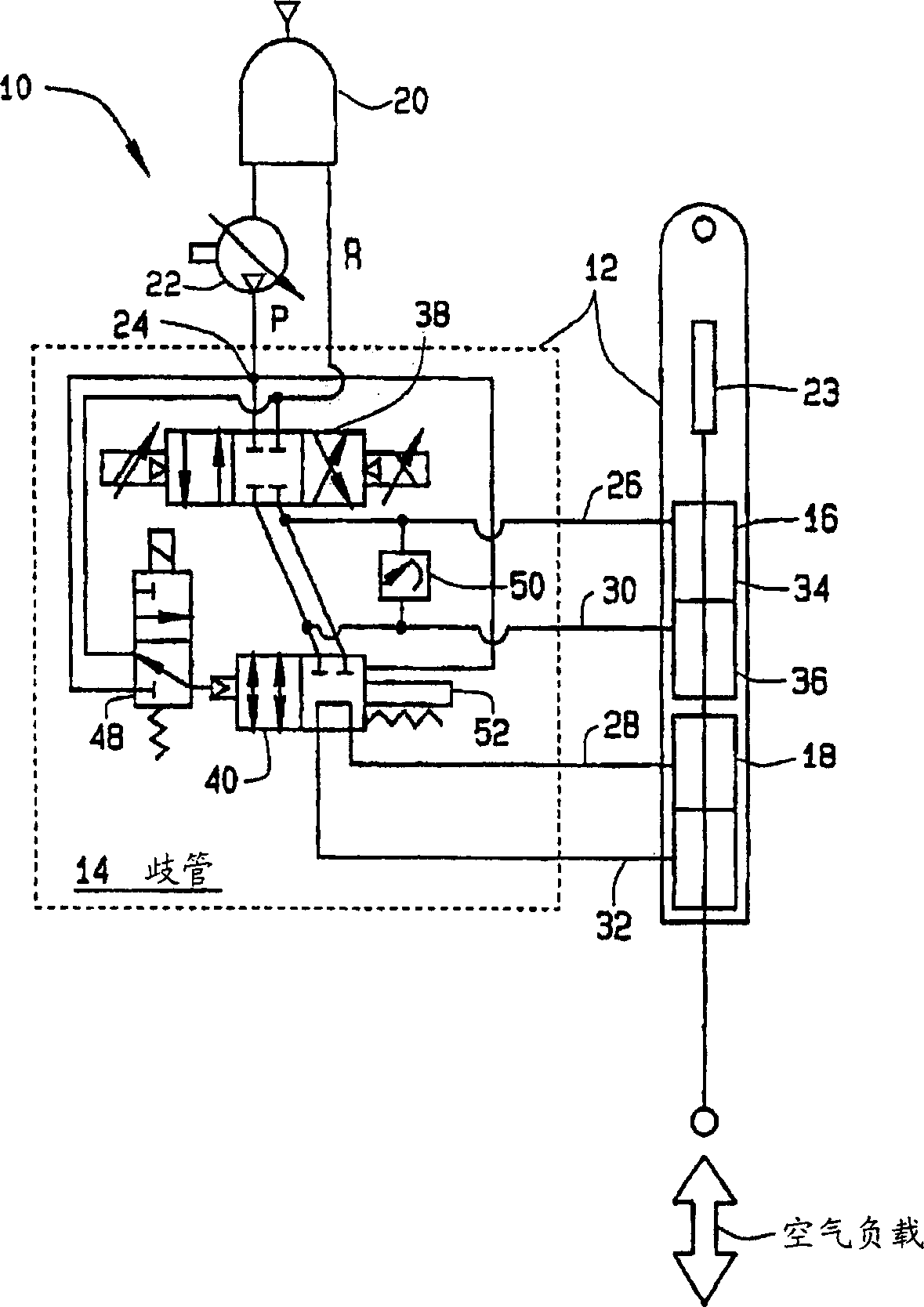

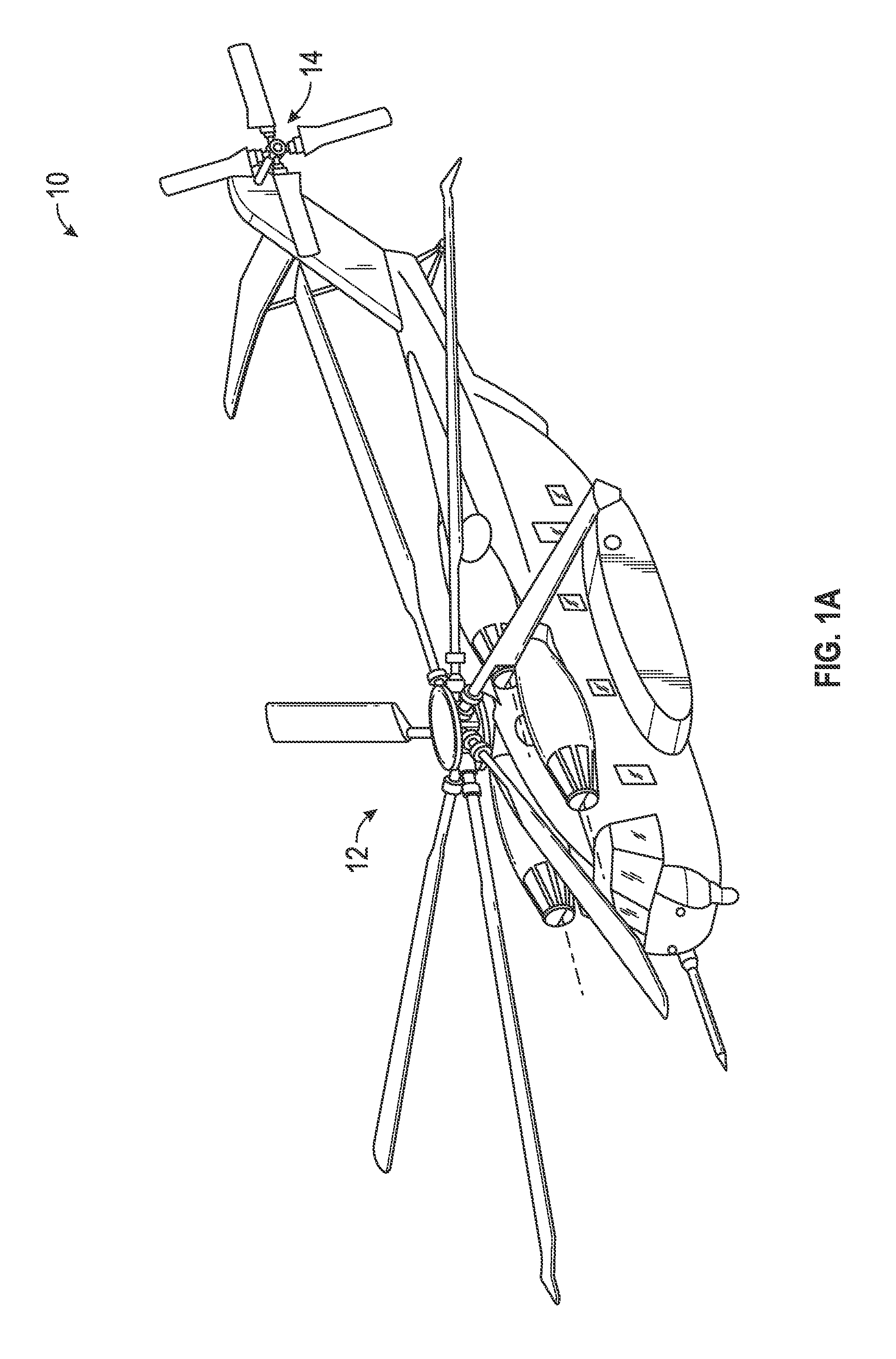

Augmenting flight control surface actuation system and method

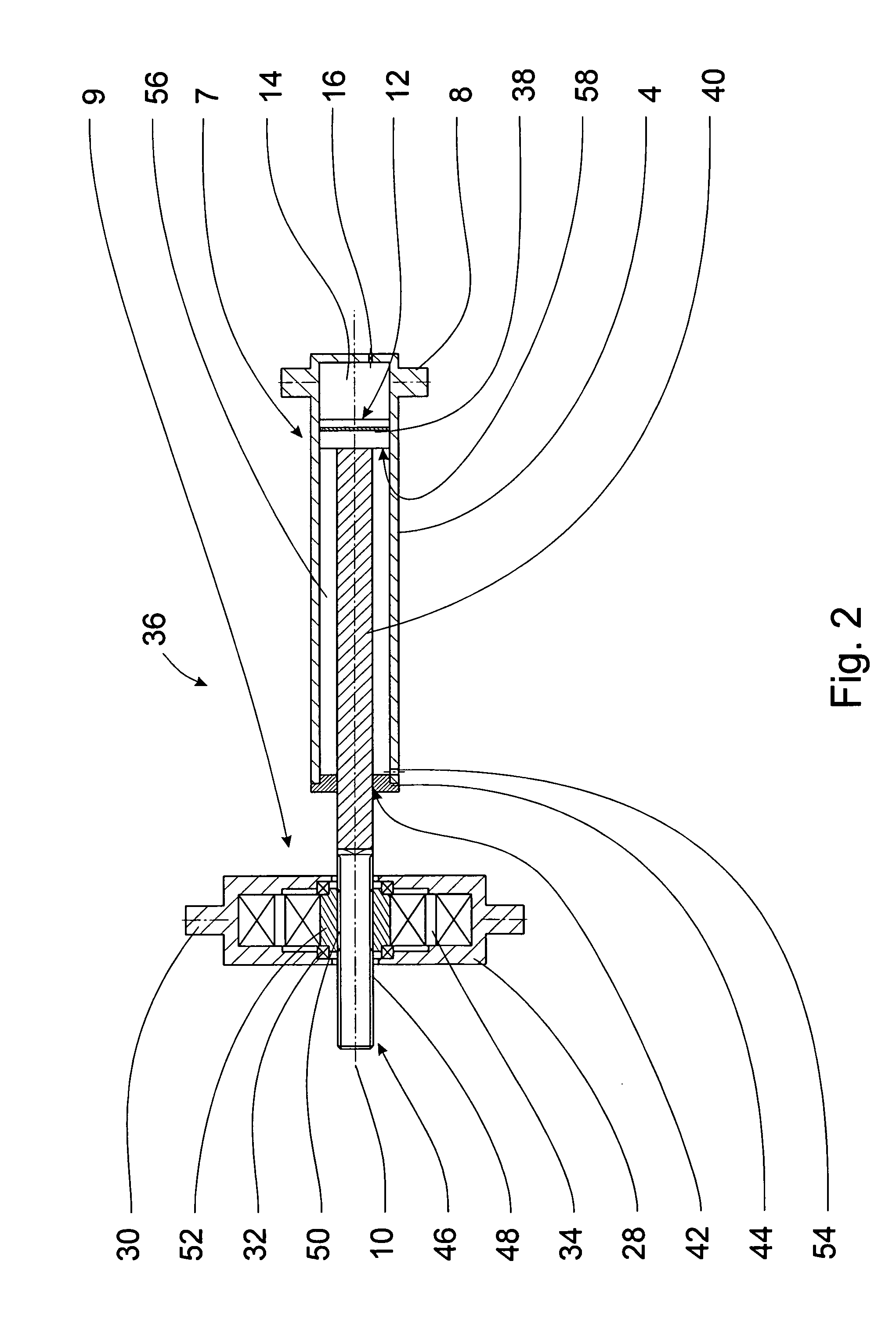

Apparatus (10) for providing actuation power to an aircraft flight control surface. The apparatus includes a first actuator (16) and a second actuator(18), where the second actuator has a bypass mode and an assist mode. The mode of the second actuator is determined by an internal differential pressure across the first actuator. The apparatus further includes a mode select valve (40) for selecting between the bypass mode and the assist mode for the second actuator, and a solenoid valve (48) that when energized causes the mode select valve (40) to select the other mode for the second actuator. When the second actuator is in the bypass mode, the first actuator provides the actuation power for the aircraft flight control surface. But, when the second actuator is in the assist mode, both the first and second actuators provide the actuation power for the aircraft flight control surface. Accordingly, the apparatus allows the flight control surface to be operated in a more efficient manner with less hydraulic flow being required.

Owner:THE BOEING CO

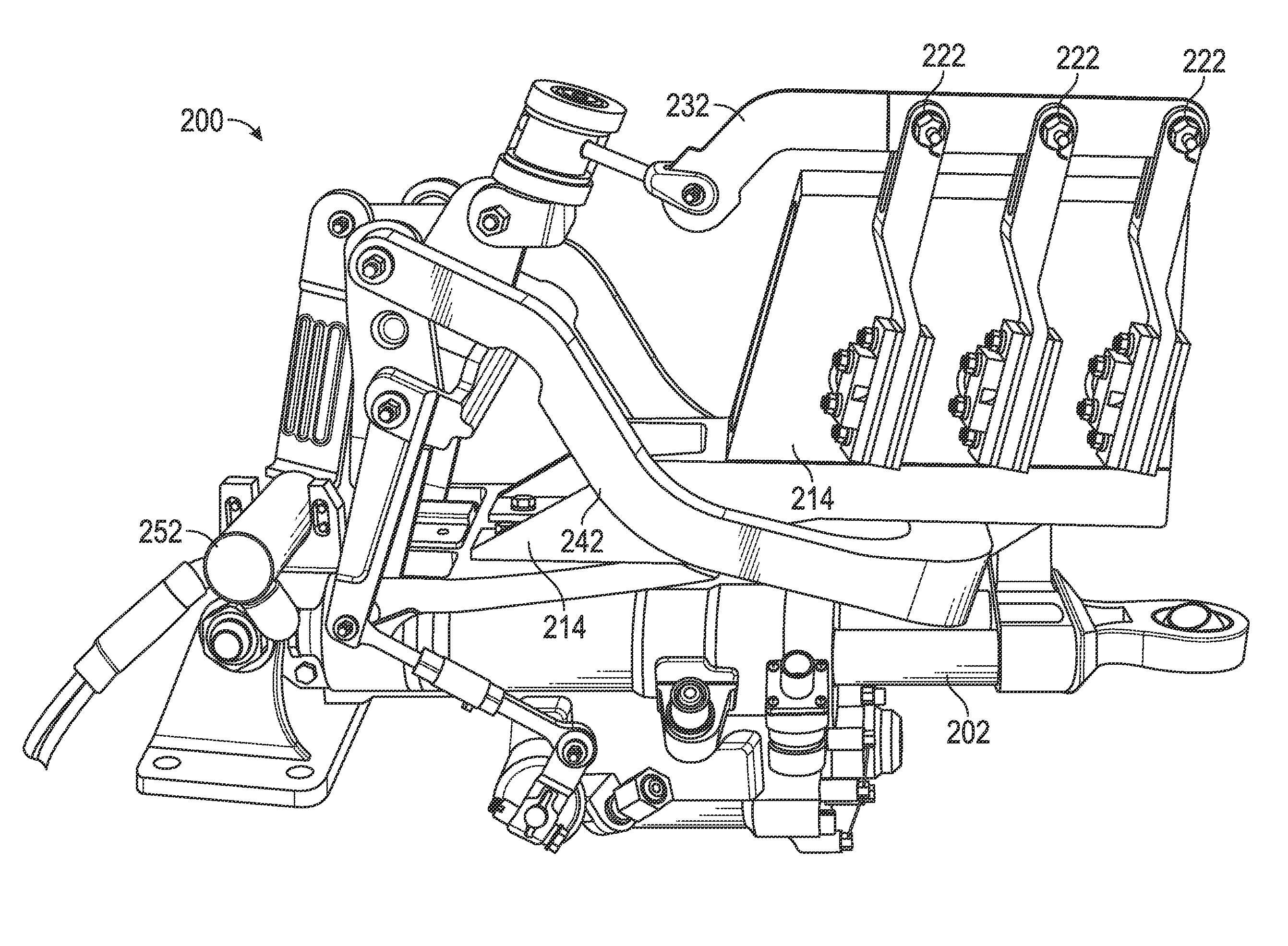

Fly by wire servos with internal loop closure

Embodiments are directed to obtaining a first analog signal corresponding to a position error between a commanded gang output of a plurality of electro-mechanical actuators configured to be run in parallel with one another and a measured gang output of the plurality of electro-mechanical actuators, obtaining a second analog signal corresponding to an output torque, and processing, by a circuit, the first analog signal and the second analog signal to generate and output a discrete that indicates a status of the torque in terms of direction and magnitude.

Owner:SIKORSKY AIRCRAFT CORP

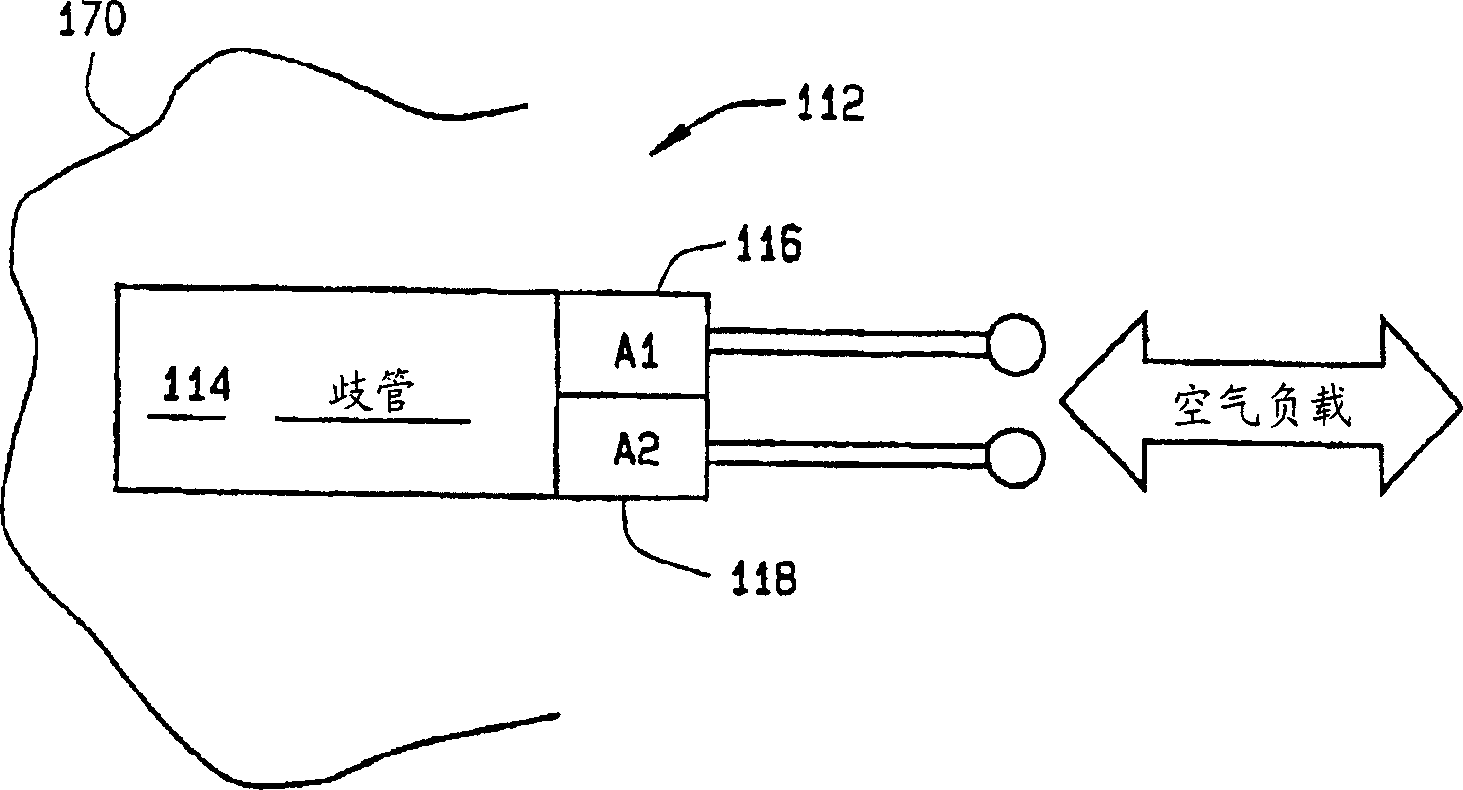

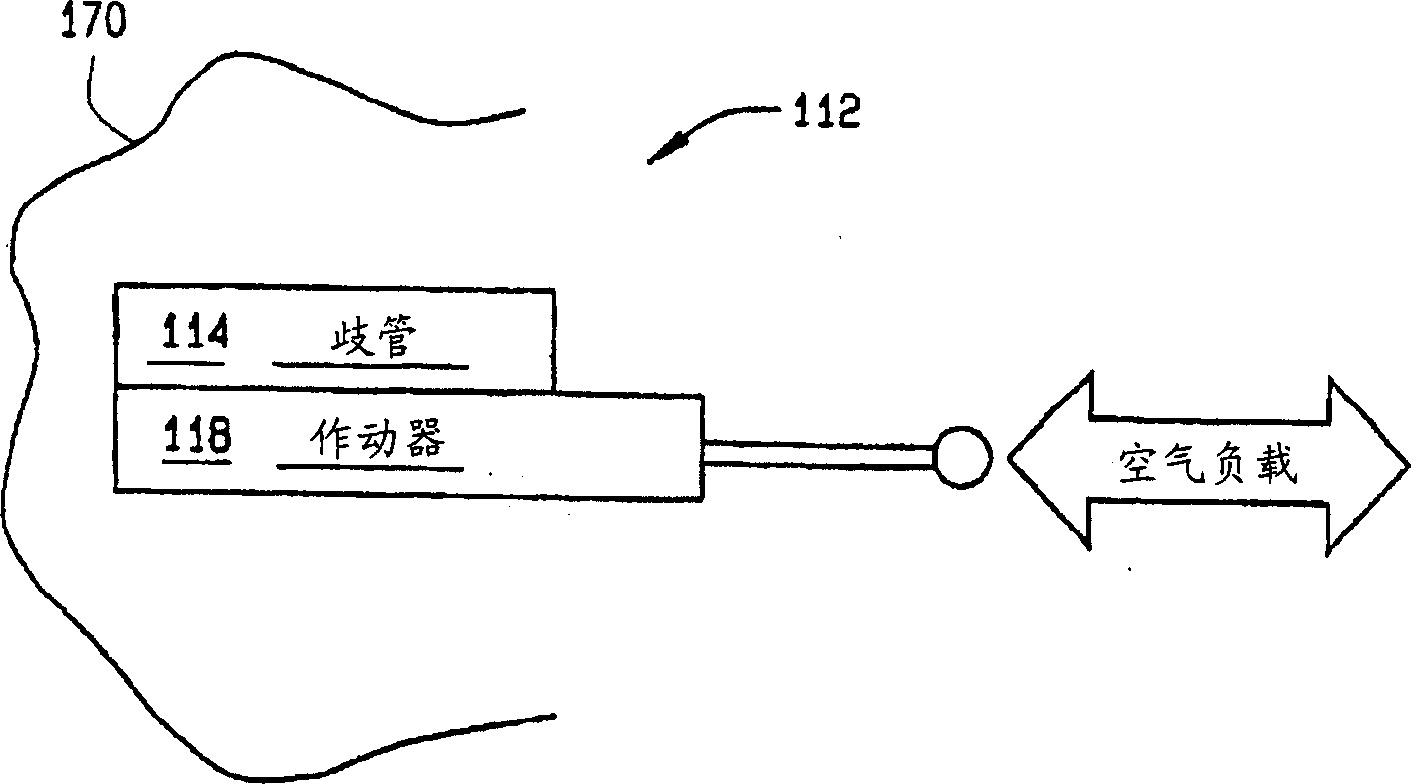

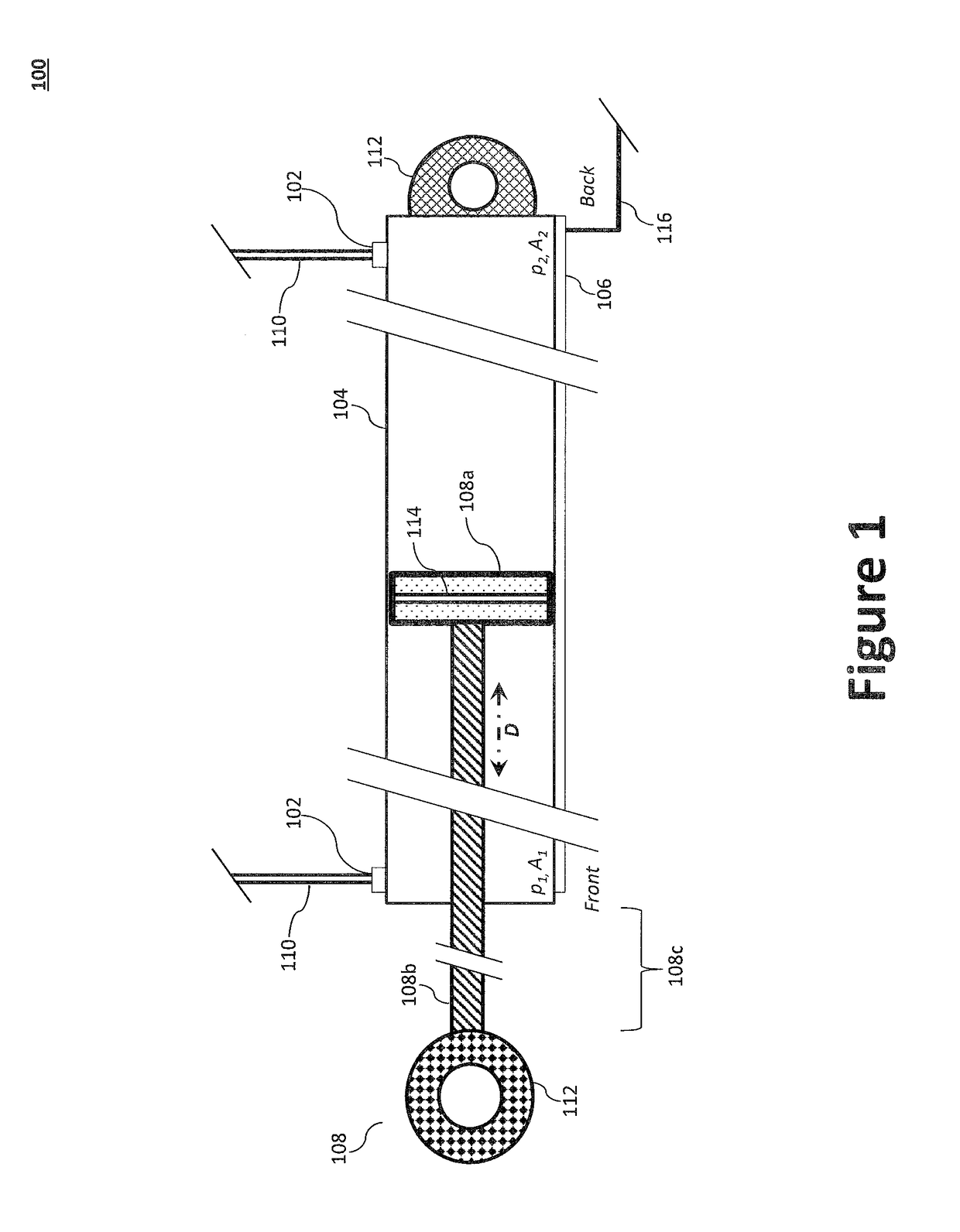

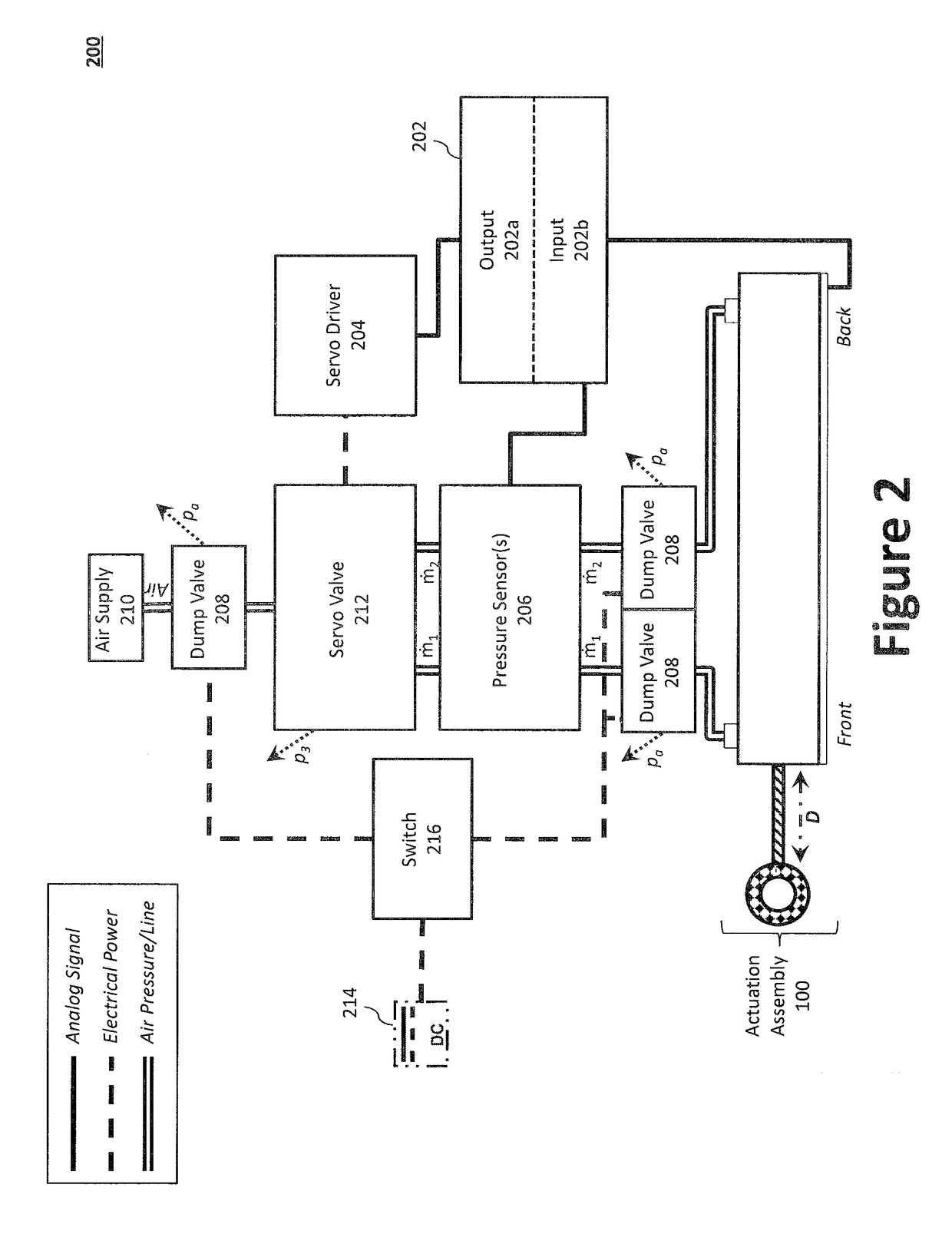

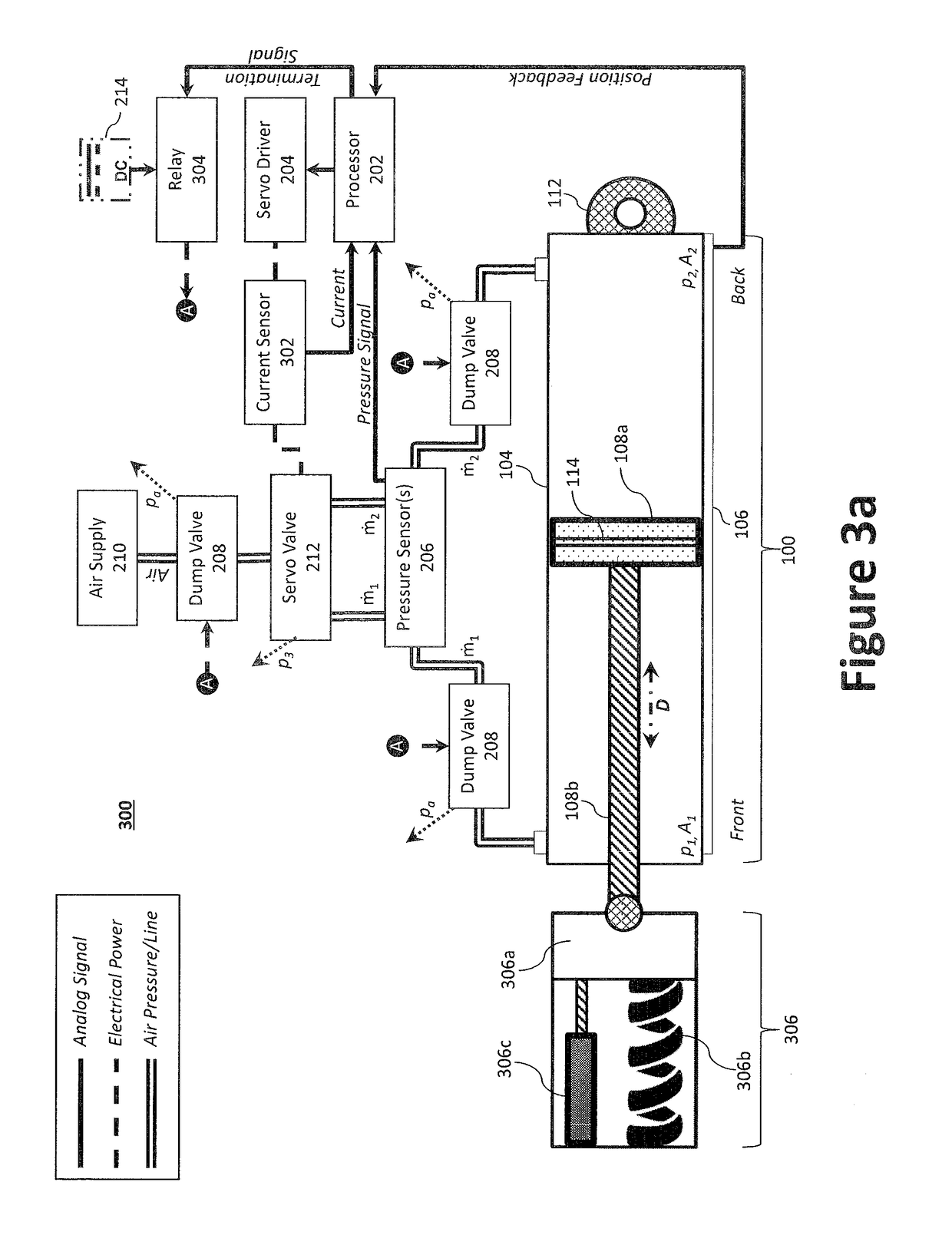

Pneumatic Actuation Systems Having Improved Feedback Control

ActiveUS20180340554A1Easy to FeedbackFluid-pressure actuator safetyFluid-pressure actuator testingCurrent sensorFeedback control

A triplex pneumatic architecture system is disclosed having first, second, and third pneumatic subsystems where triplex redundancy may be accomplished by measuring only one particular node in each system, such as a measured current of the servo valve. Each of the first, second, and third pneumatic subsystems are configured to control a separate redundant pneumatic actuation assembly. Each subsystem may comprise a current sensor to measure a control current from a servo driver to a servo valve that controls the pneumatic actuation assembly to output a measured current value, and a dump valve coupled to a relay. Each processor is configured to generate a termination signal to actuate the first relay to open the first dump valve. The triplex pneumatic architecture system further includes a communication bus to communicatively couple each of the first, second, and third pneumatic subsystems. Each processor is configured to generate the termination signal and to communicate the termination signal to one or more of the relays when one measured current value deviates from the two other measured current values by a predetermined error value.

Owner:AURORA FLIGHT SCI CORP

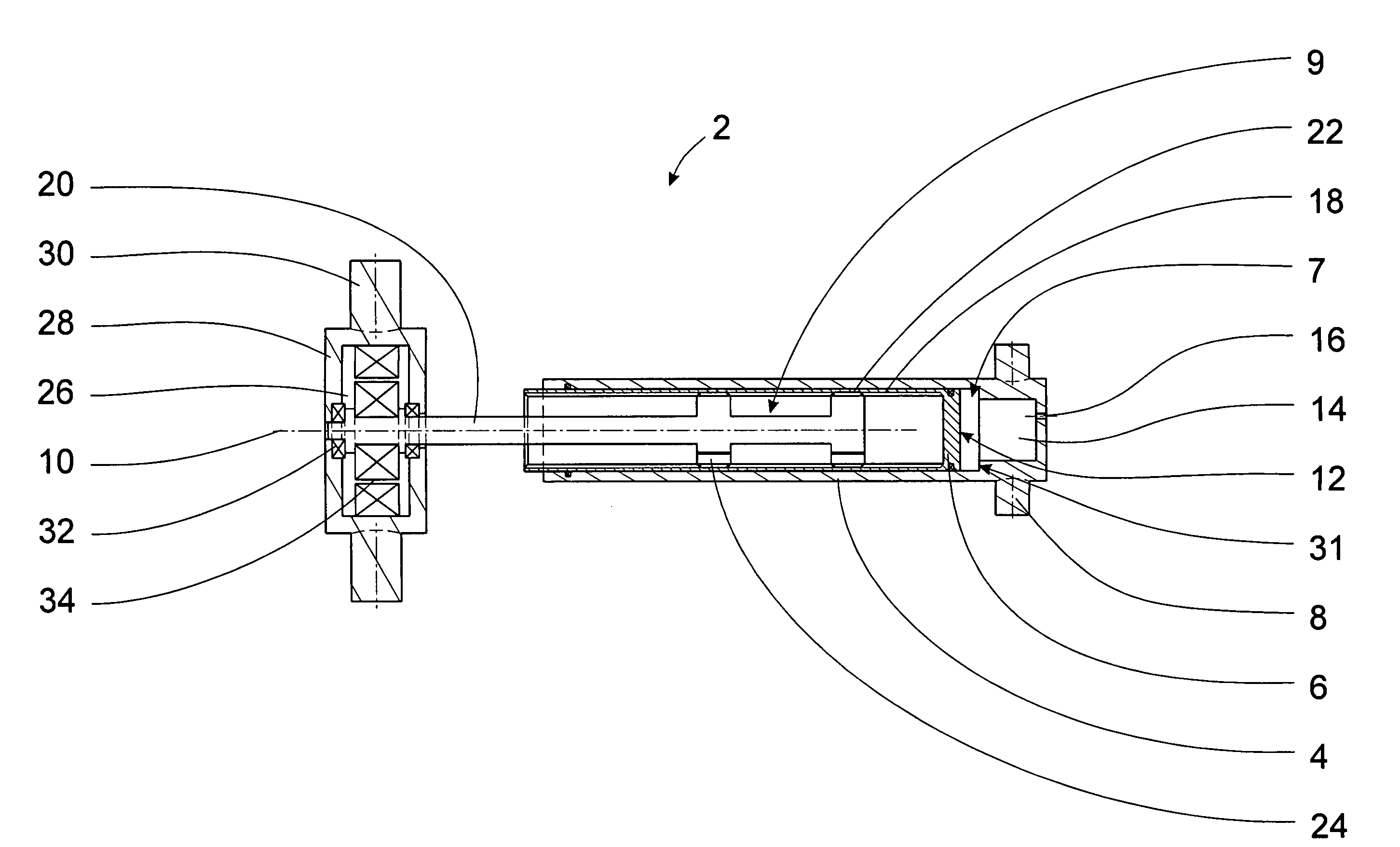

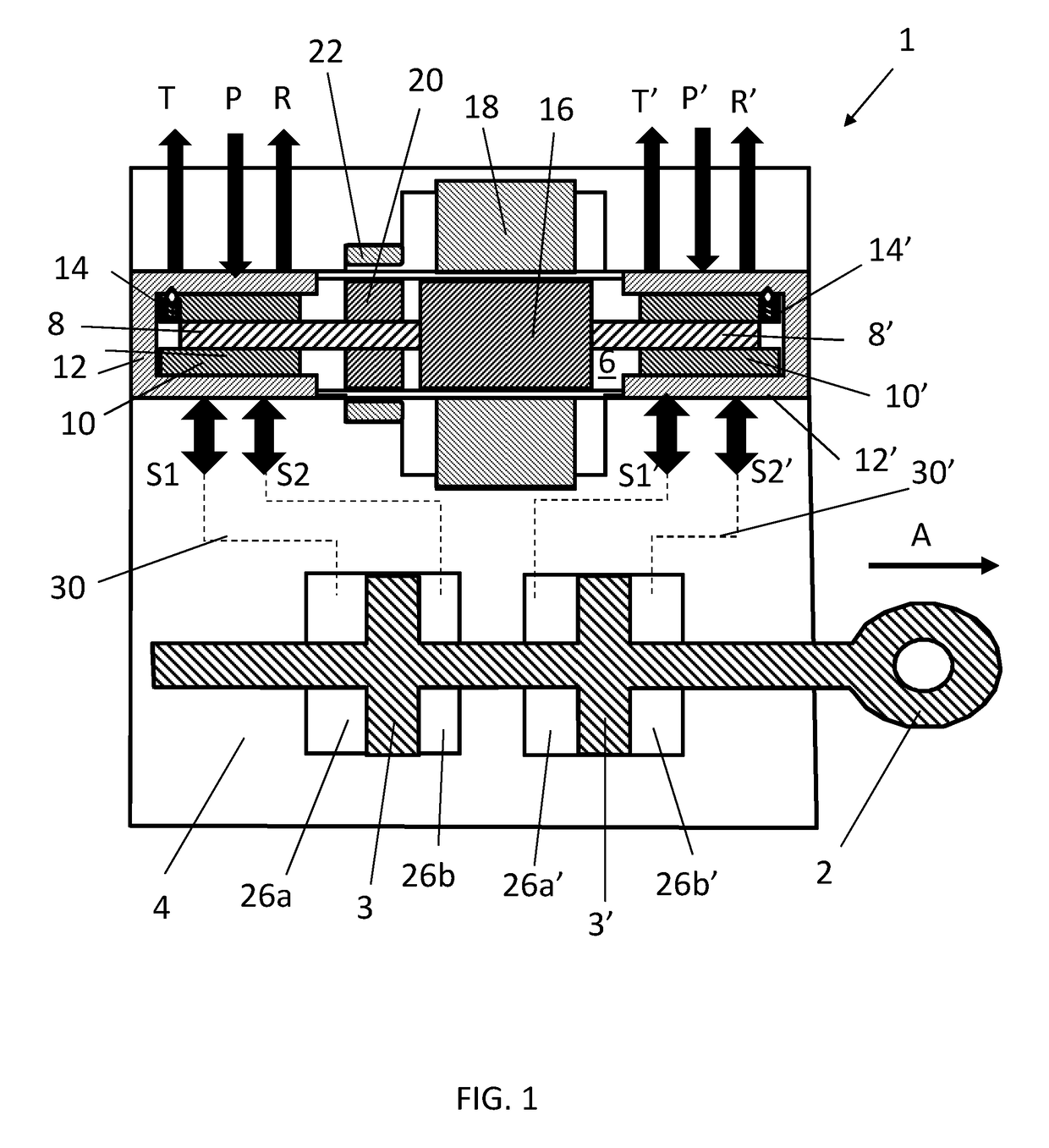

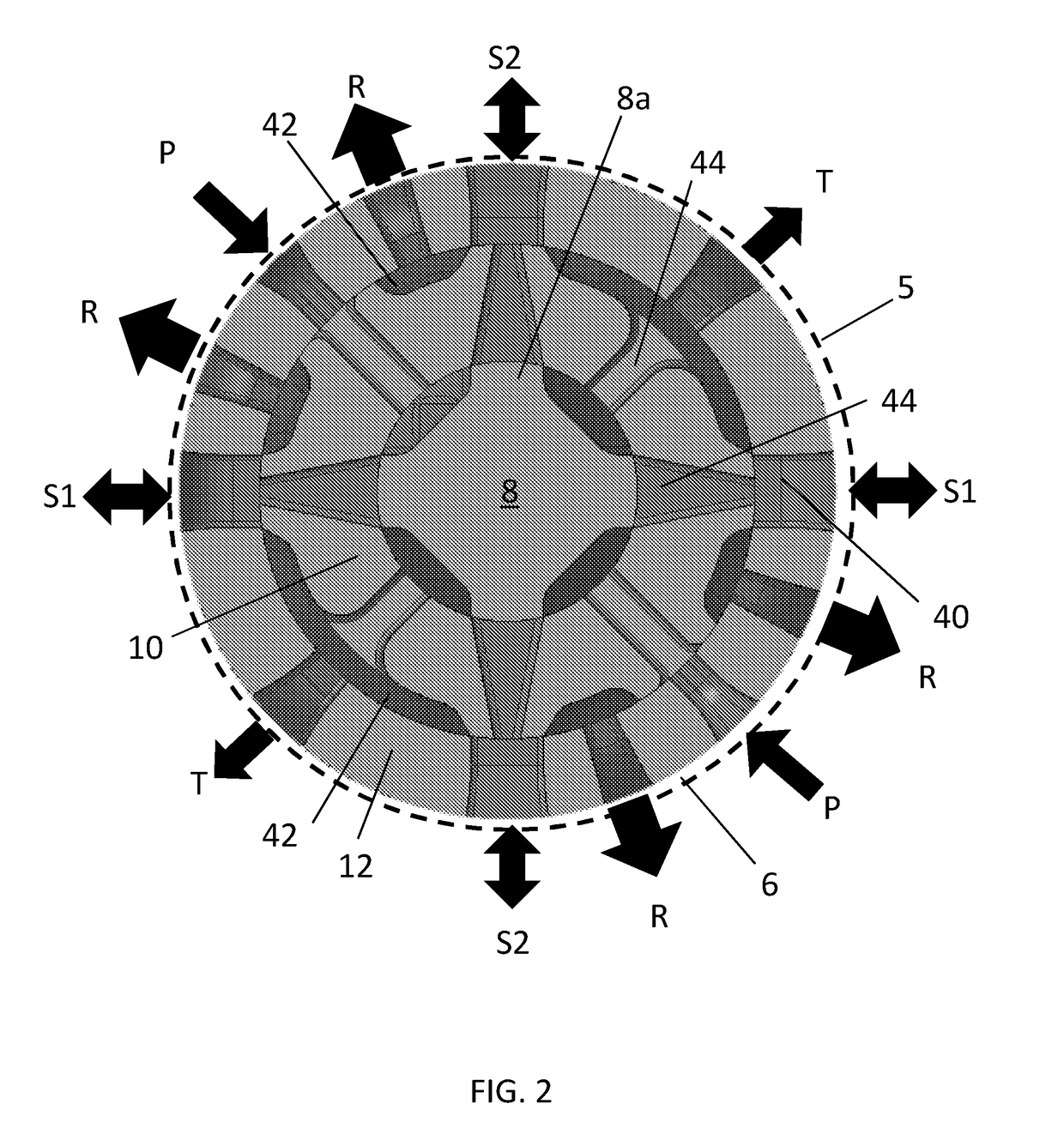

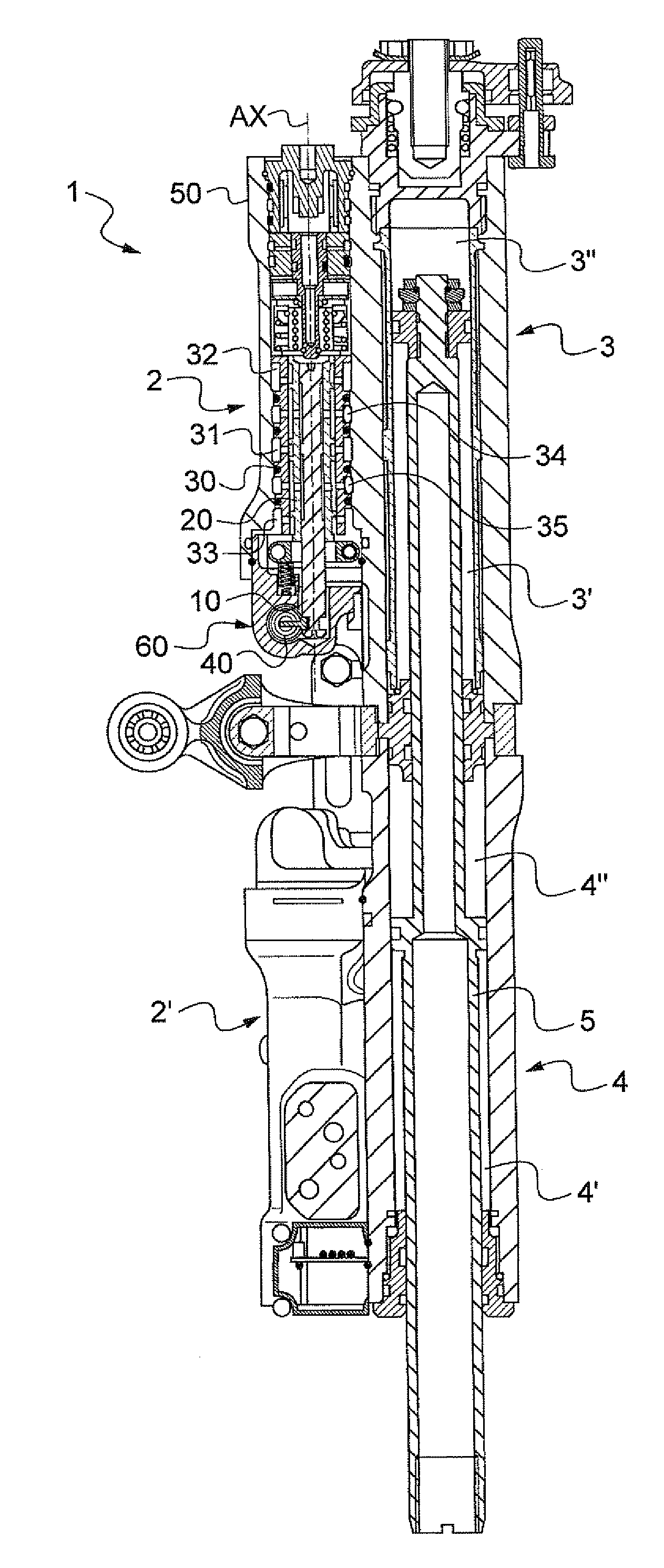

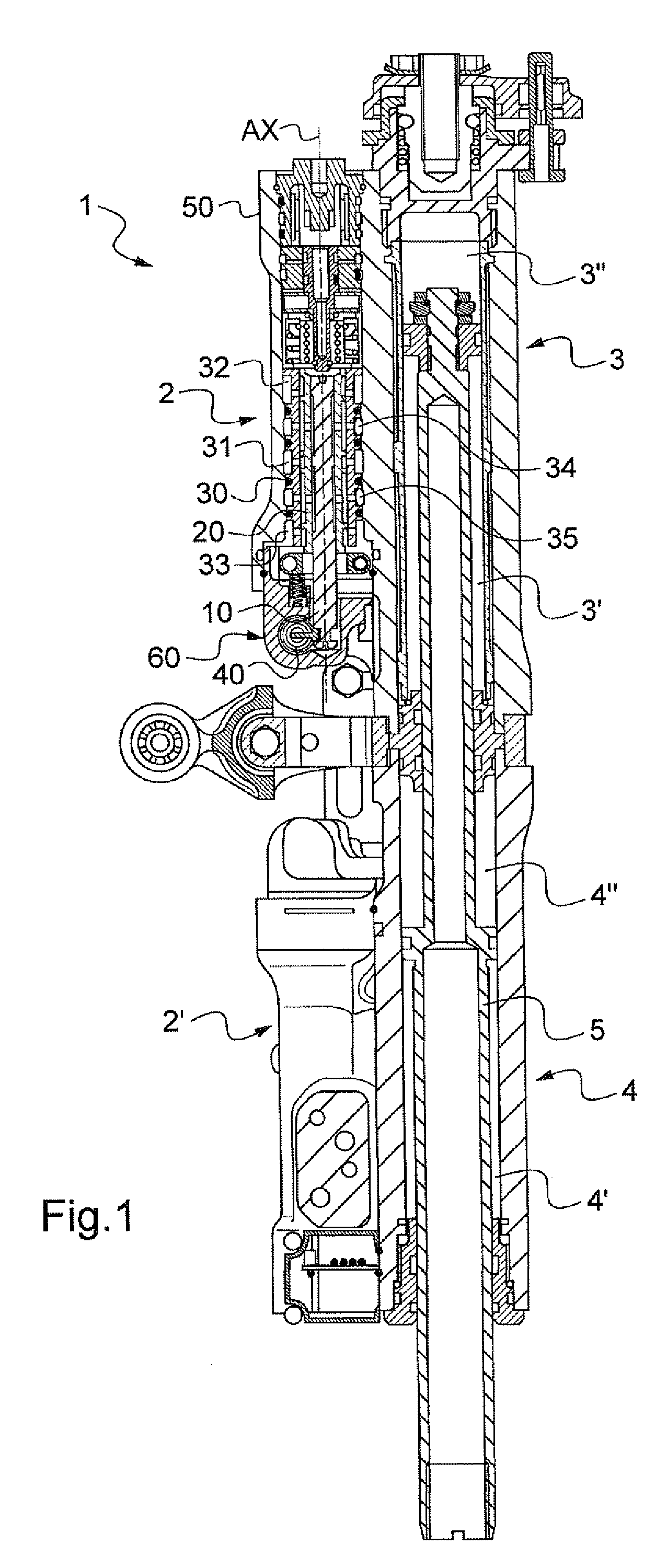

Servo actuators

ActiveUS20180281940A1Easy to controlMinimising increase in sizeServomotor componentsServomotorsServo actuatorControl theory

A servo actuator (1) comprises an actuator housing (4); an actuator member (2) located within the actuator housing (4) and at least one spool (8) located in a cavity (6) formed within the actuator housing (4). The housing (4) also comprises a first set of internal ports including an inlet port (P), an outlet port (T) and a pair of control ports (SI, S2), the inlet port (P) being arranged for connection to a first pressurised supply and a second set of internal ports comprising an inlet port (P′), an outlet port (T′) and a pair of control ports (SI′, S2′), the inlet port (P′) being arranged for connection to a second pressurised supply. In use, movement of the spool (8) alters the flow path of fluid through the first and second set of internal ports to control the movement of the actuator member (2).

Owner:BLAGDON ACTUATION RES

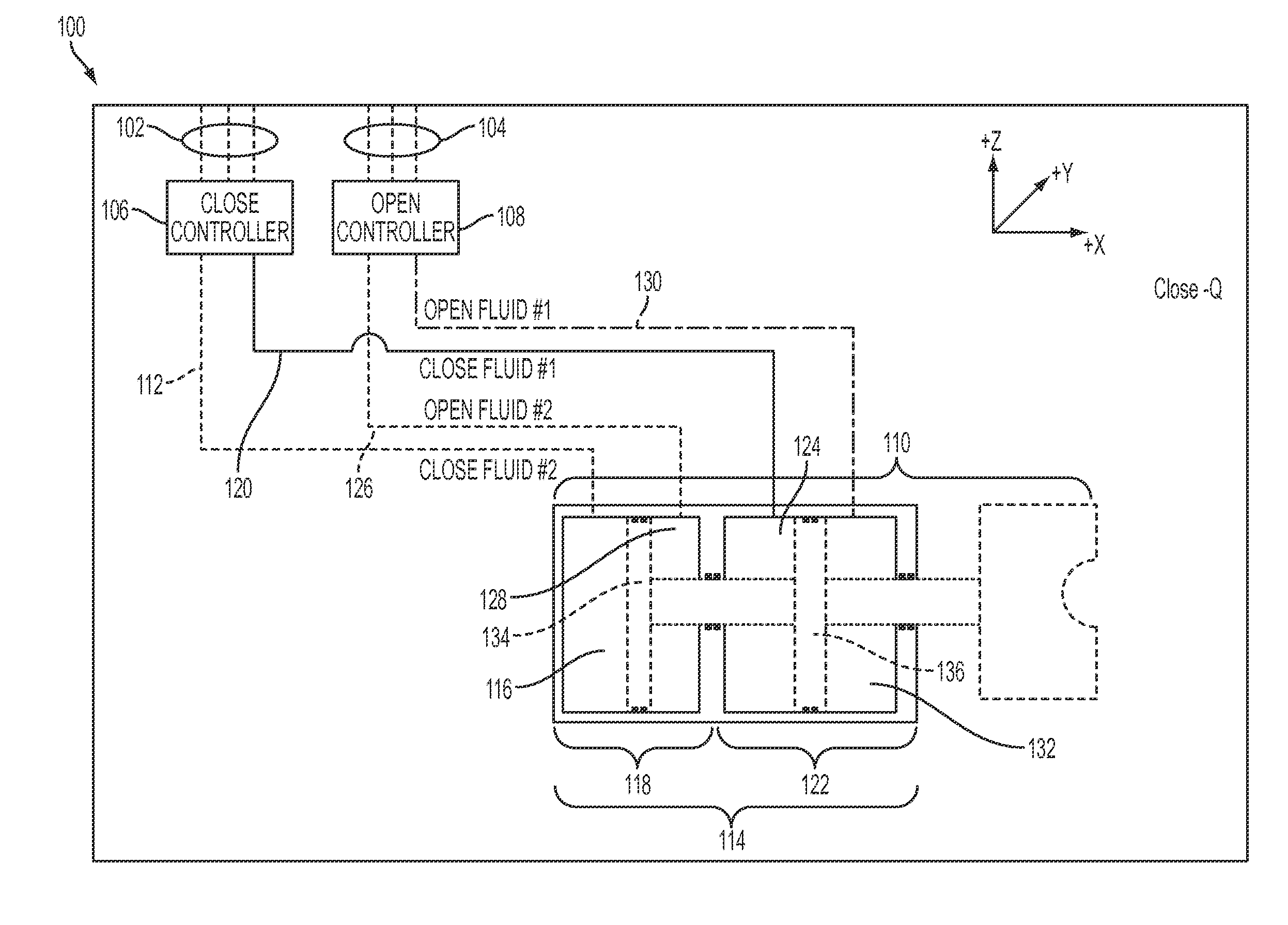

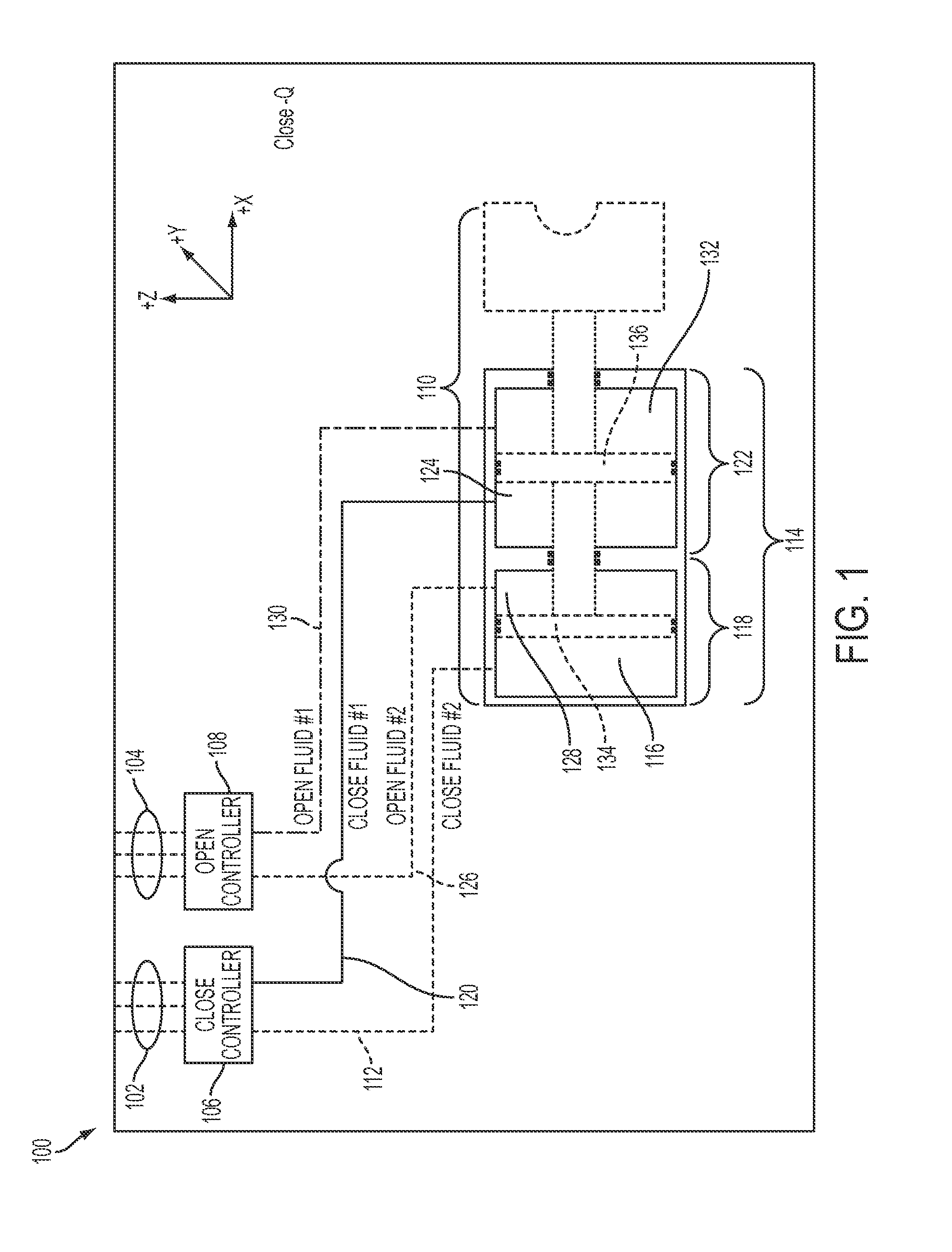

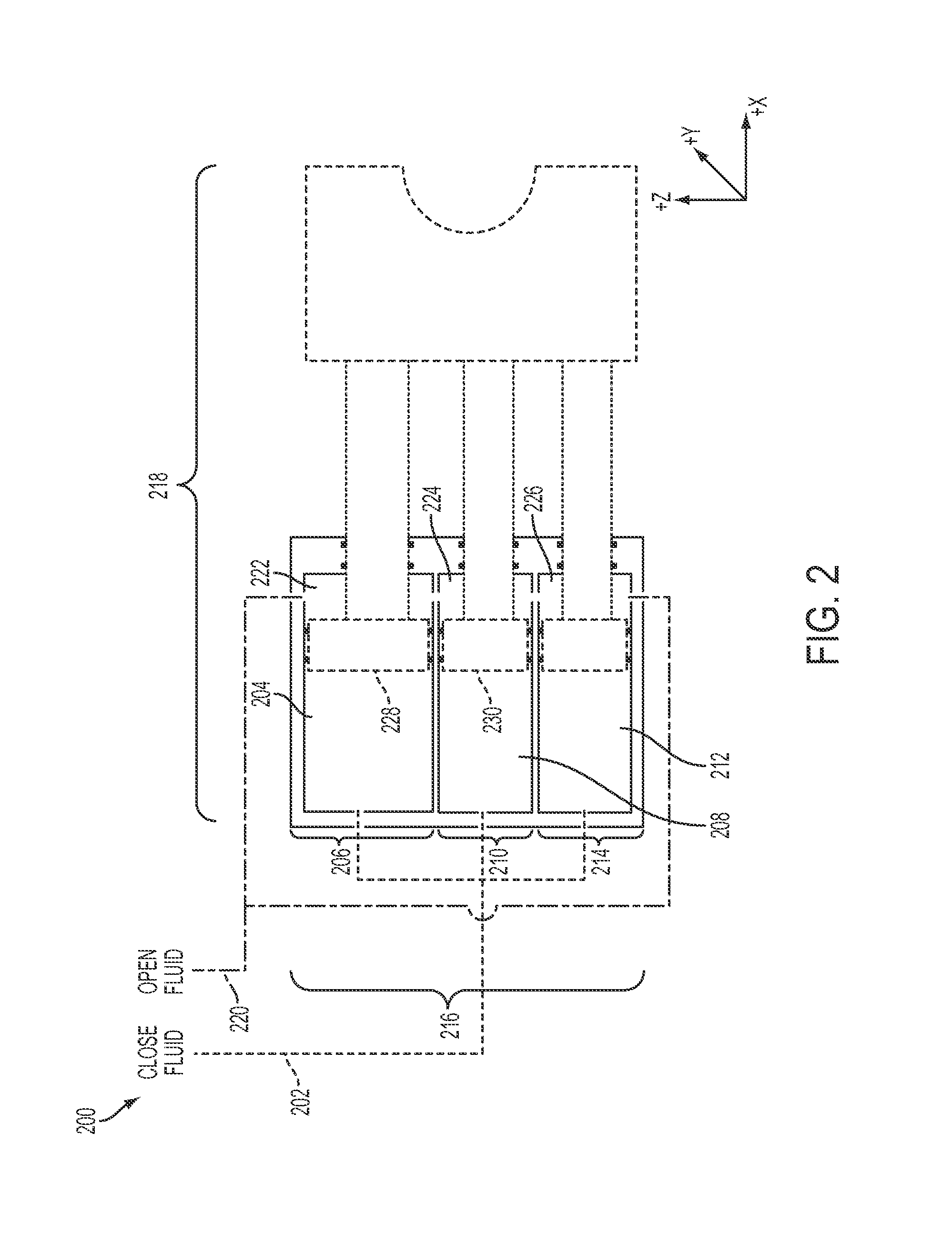

Hydraulic devices and methods of actuating same

ActiveUS20150096435A1Improve reliabilityImprove availabilityFluid-pressure actuator safetyServomotorsHydraulic fluidActuator

This disclosure includes hydraulic apparatuses and methods for redundant actuation of a hydraulic device. Some apparatuses include a hydraulic device having a first hydraulic actuator and a second hydraulic actuator, wherein each of the first and second hydraulic actuators comprises at least a first hydraulic cavity, a second hydraulic cavity, and a piston. Some apparatuses also include a controller coupled to the hydraulic device. In some embodiments, the controller is configured to receive hydraulic fluid from a fluid source via at least two parallel hydraulic lines coupled to the controller, select a first hydraulic line of the at least two parallel hydraulic lines, and transfer the hydraulic fluid from the selected first hydraulic line to a first cavity of the first hydraulic actuator to apply pressure to a first piston to actuate the hydraulic device.

Owner:TRANSOCEAN INNOVATION LABS

Hydraulic system for aircraft actuators

InactiveUS9103338B2Suppress oil temperature riseMinimize amount of heat generationFluid-pressure actuator safetyAircraft controlHydraulic pumpEngineering

Owner:NABLESCO CORP

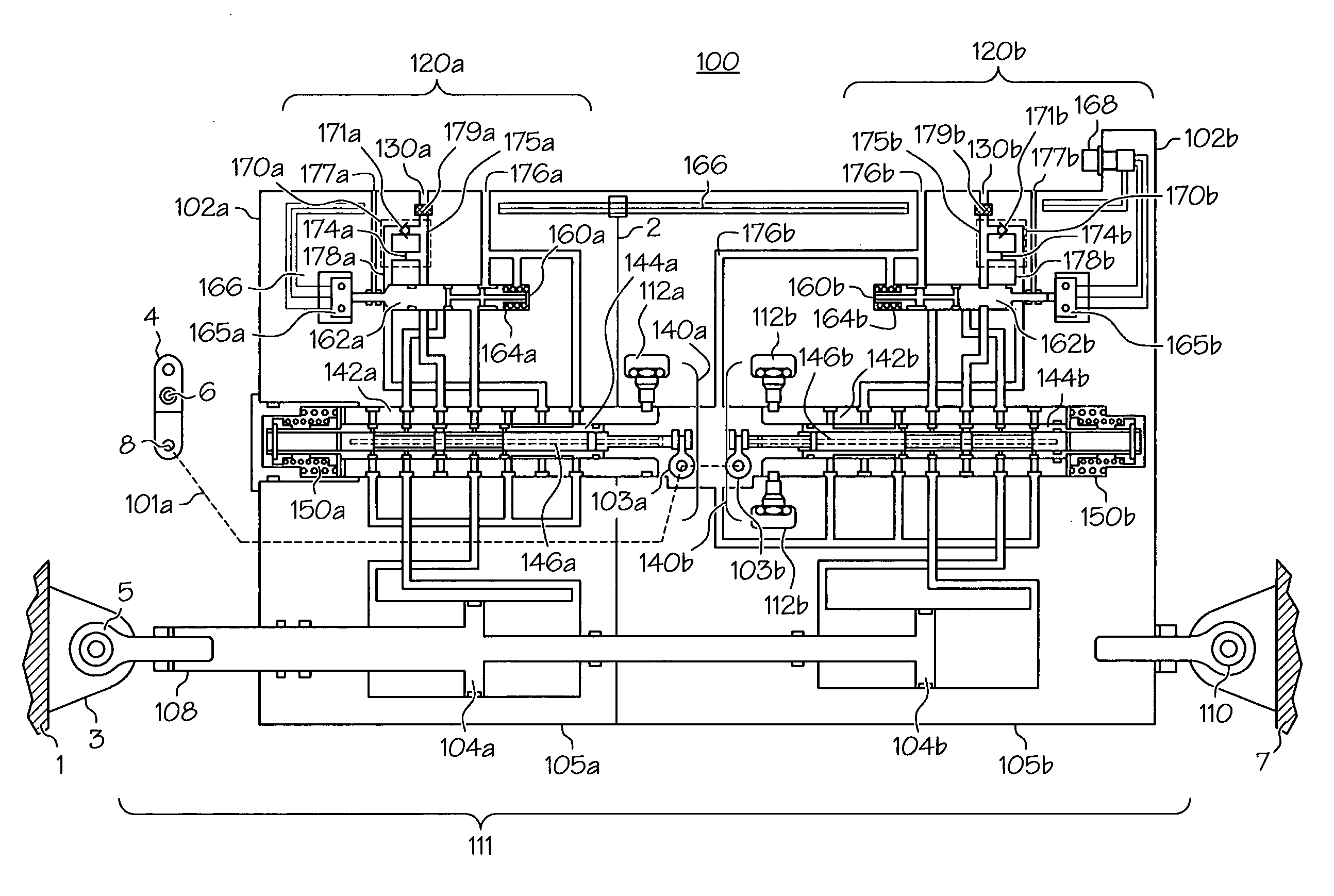

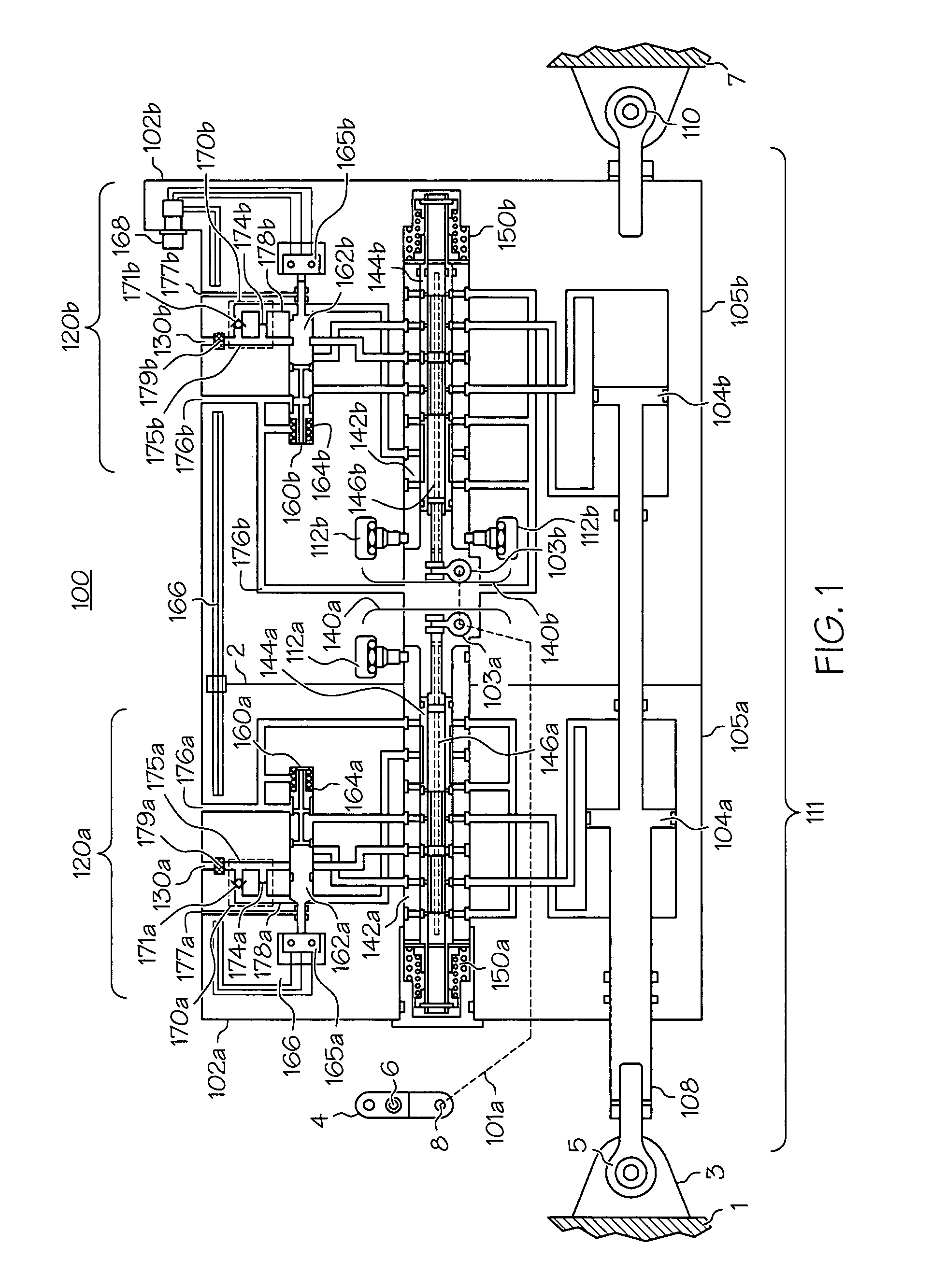

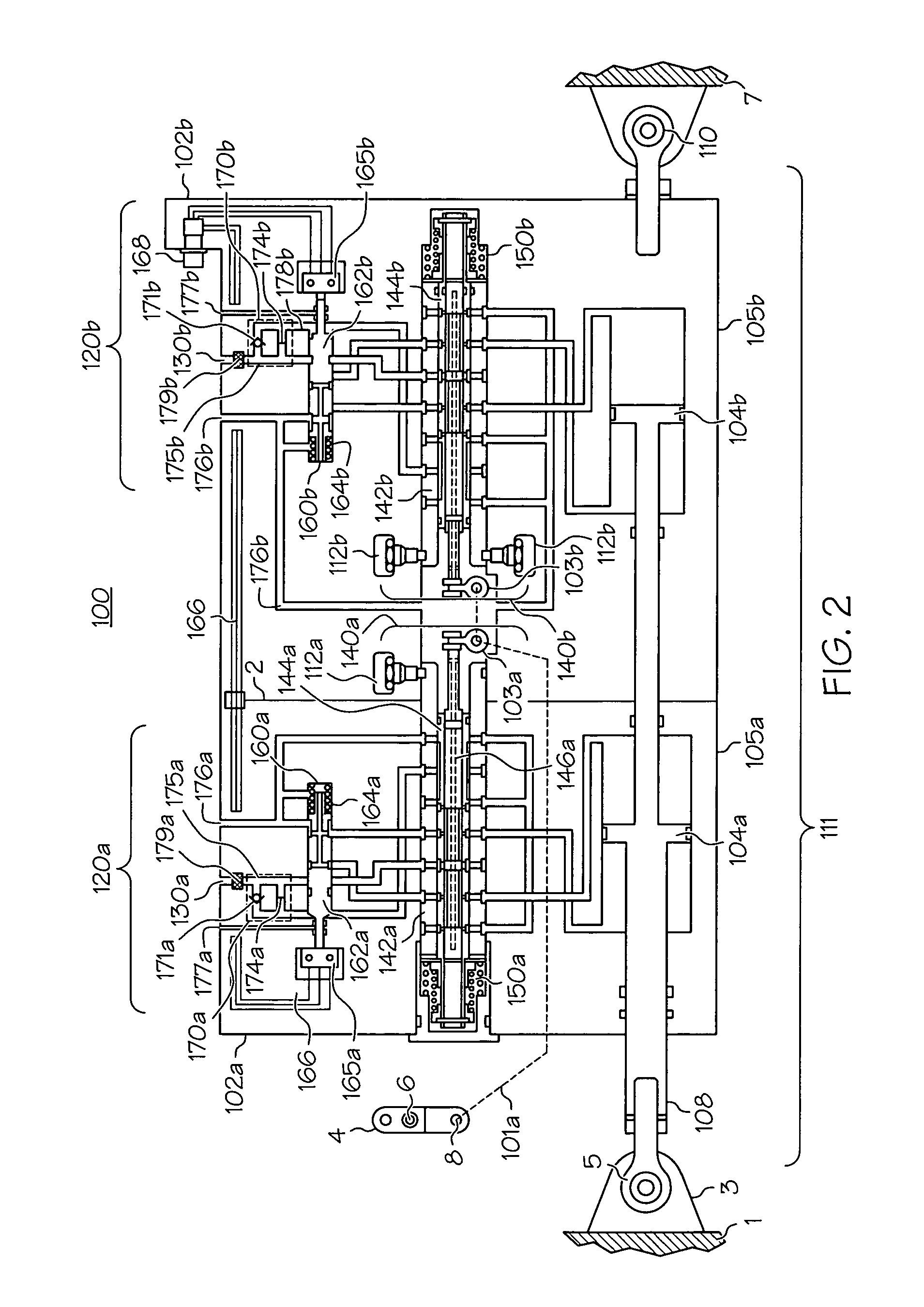

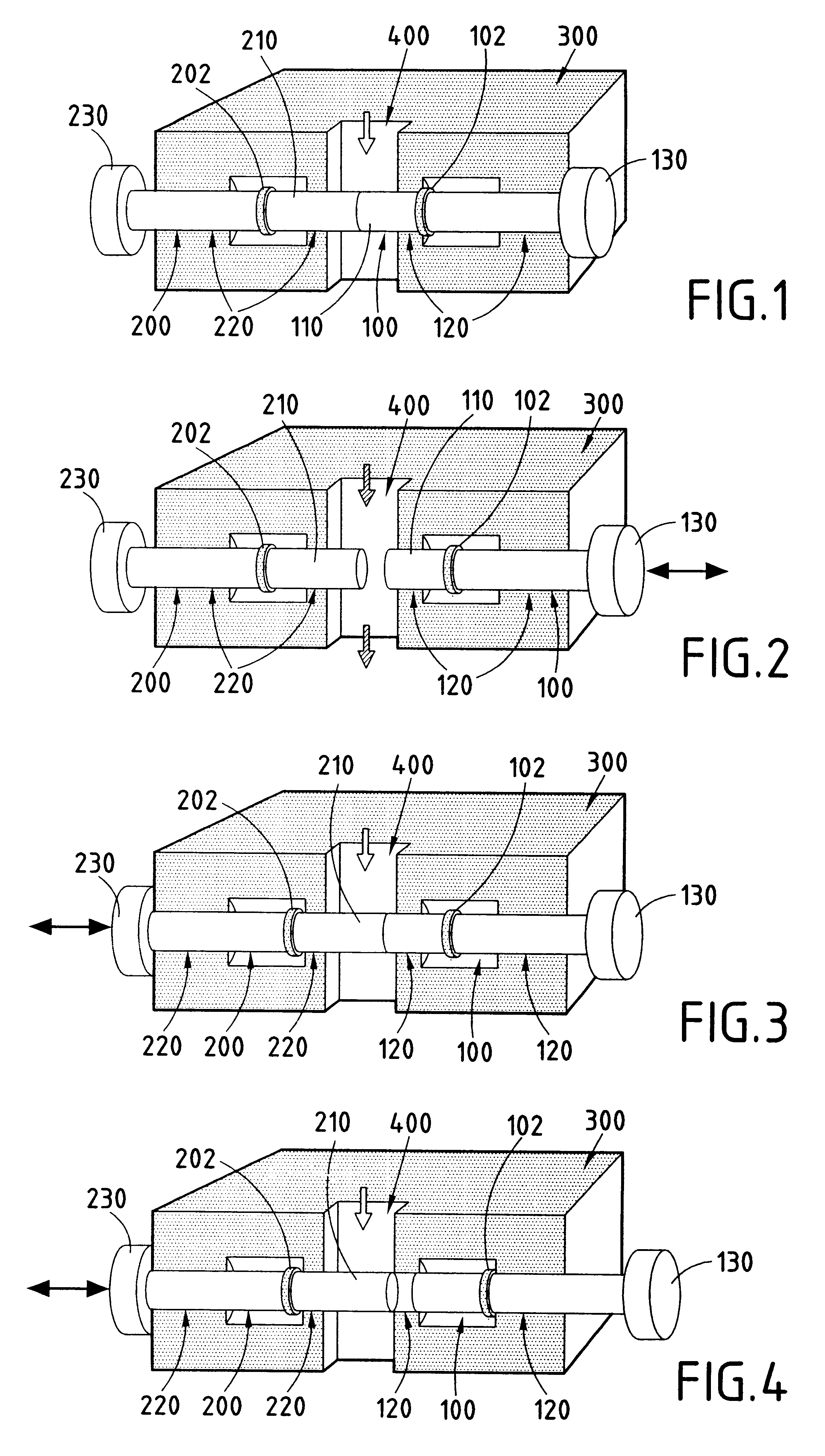

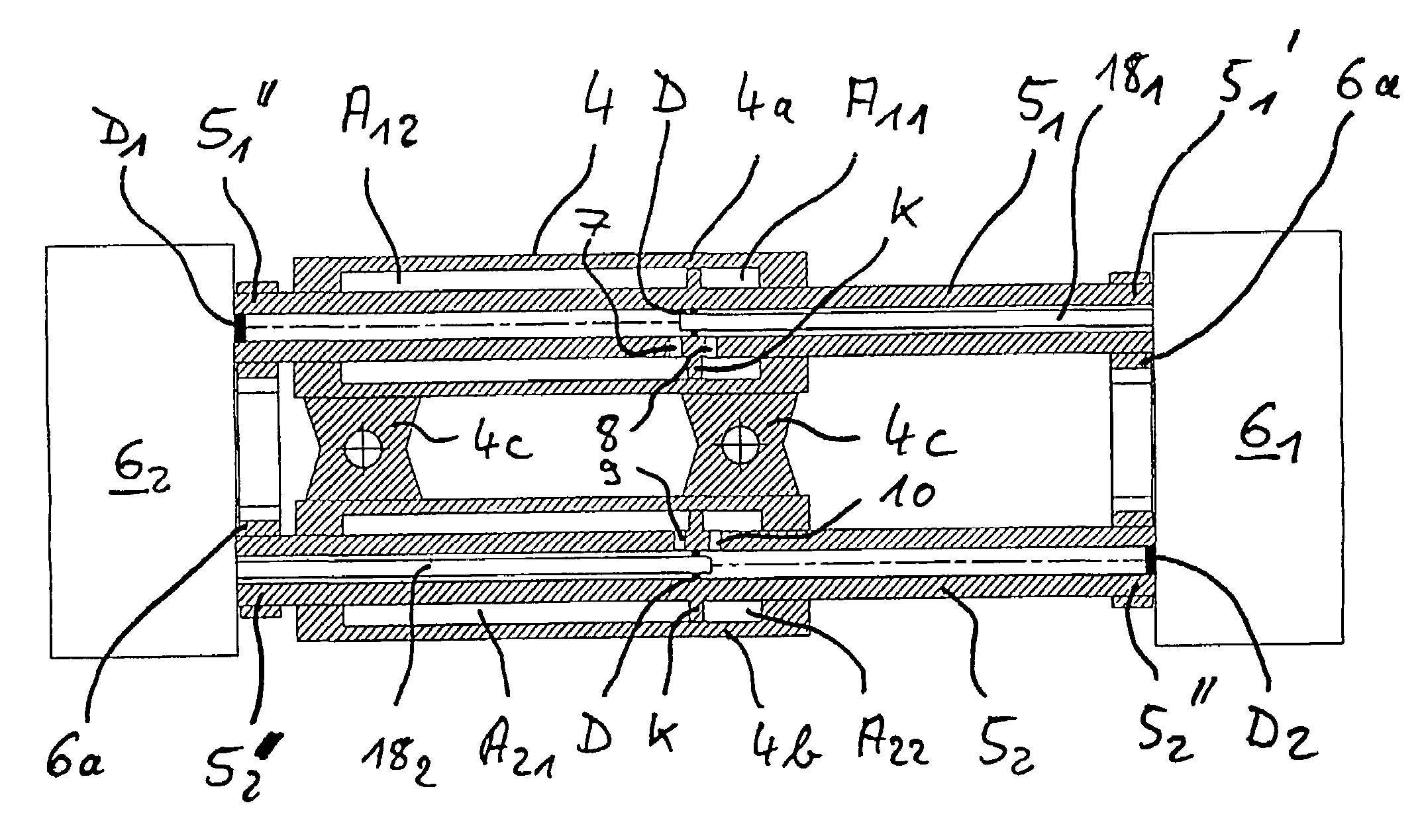

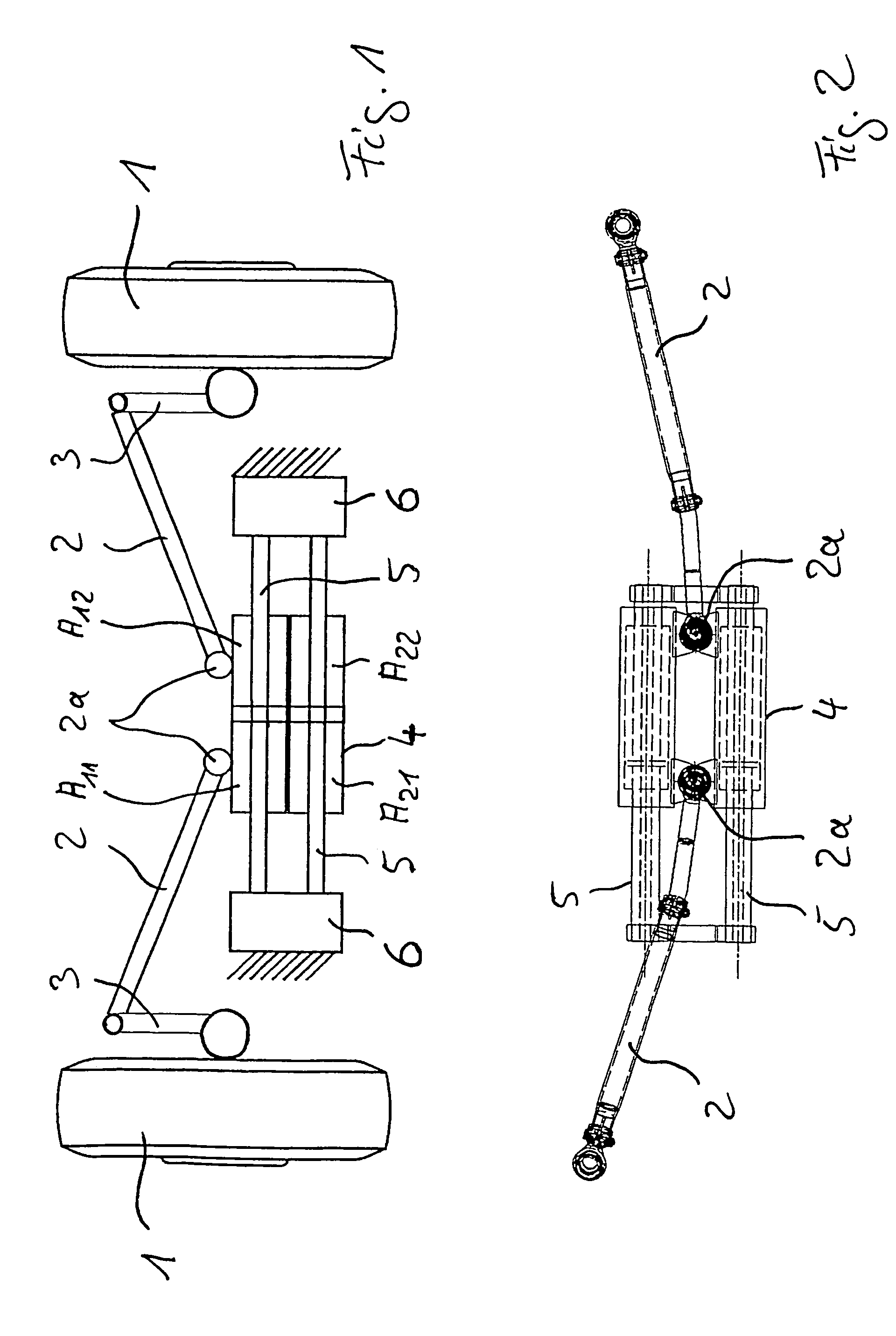

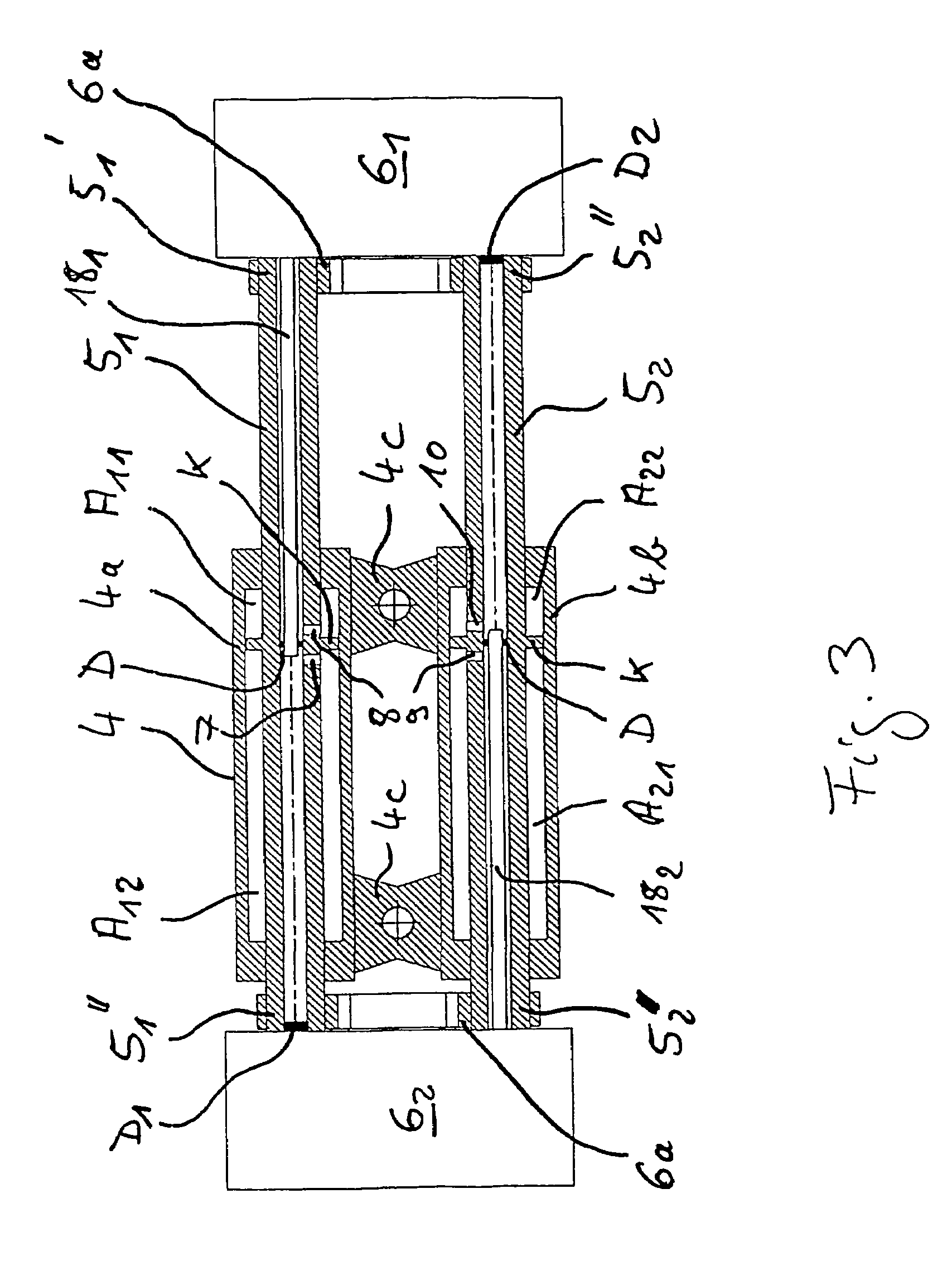

Dual-circuit steer-by-wire steering system comprising a common cradle

InactiveUS7331419B2Good energyGood fuelFluid steeringServomotor parallel arrangementsPiston cylinderHydraulic control unit

The invention relates to a steer-by-wire steering system comprising a hydraulic control unit that acts on the steerable wheels (1, 20), the control unit having at least one cradle (4, 23), which is displaceably mounted on at least one guide rod (5, 24) that passes through the respective cradle (4, 23). The respective cradle (4, 23) and the corresponding guide rod(s) (5, 24) form working chambers (A11, A12, A21, A22) of a piston-cylinder system, whereby each respective guide rod (5, 24) has at least one channel (KA11, KA12, KA21, KA22), each terminating in the vicinity of a working chamber (A11, A12, A21, A22). The cradle or cradles (4, 23) adjust the steerable wheels (1, 20) directly or by means of steering tie rods (2, 21).

Owner:THYSSENKRUPP PRESTA STEERTEC

Statically stable walking machine and power system therefor

ActiveUS9222493B2Improve system efficiencyHeavy loadMechanical machines/dredgersServomotor parallel arrangementsMicrocontrollerElectric power system

A walking machine that includes a chassis with an operator interface, a main controller in data communication with the operator interface, at least two leg members operatively connected to the chassis, and a power system in data communication and electrical communication with the main controller. Each leg member includes a leg control system that includes a leg microcontroller in data communication with the main controller and at least a first electro hydrostatic actuator in electrical communication with the leg microcontroller. The power system includes an electrical generator, power supply electronics in electrical communication with the electrical generator, an electrical storage medium in electrical communication with the electrical generator and in parallel with the power supply electronics, and an electrical power bus for distributing power from the power system to the leg control systems.

Owner:RISKAS BRIAN

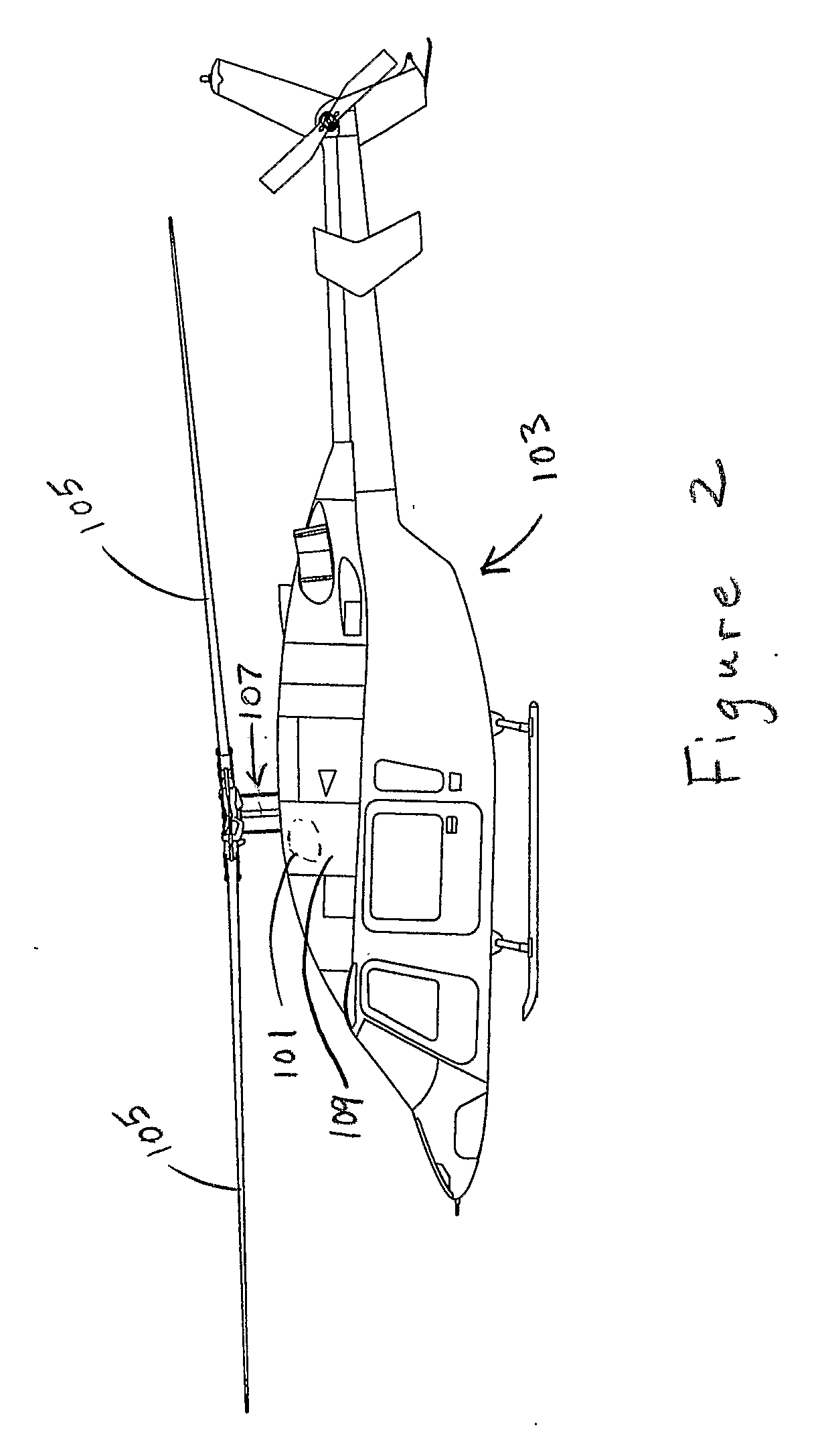

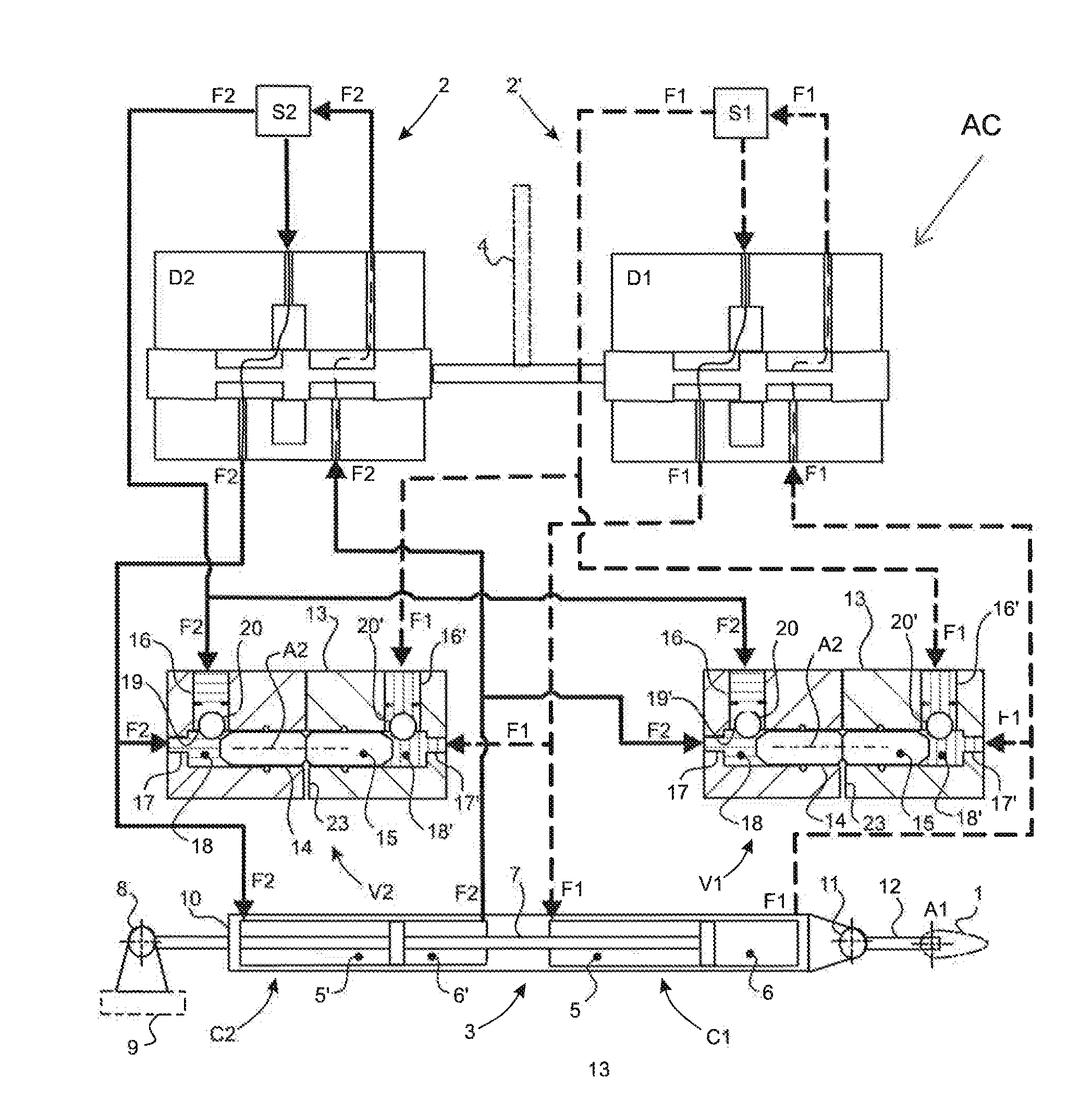

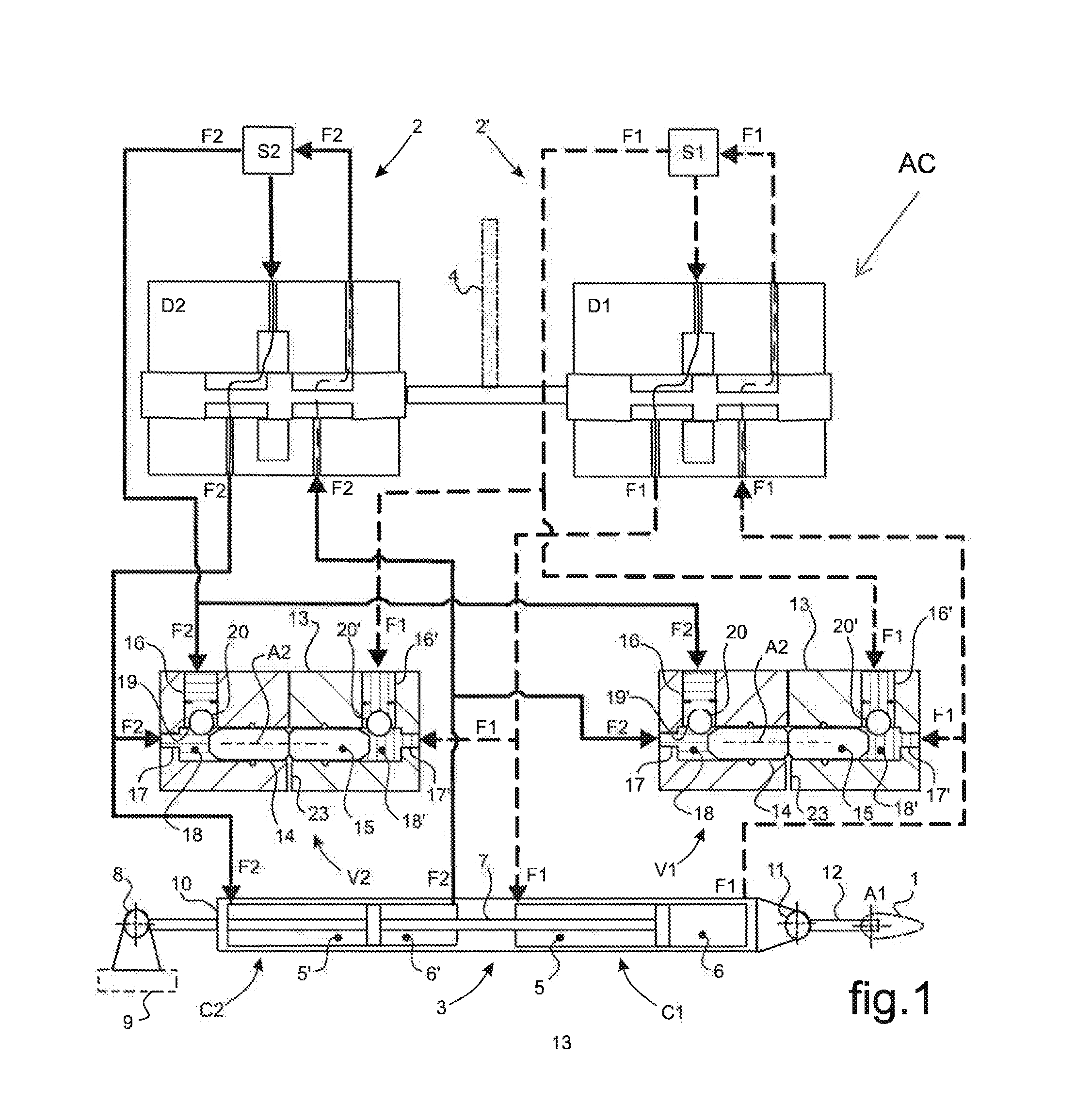

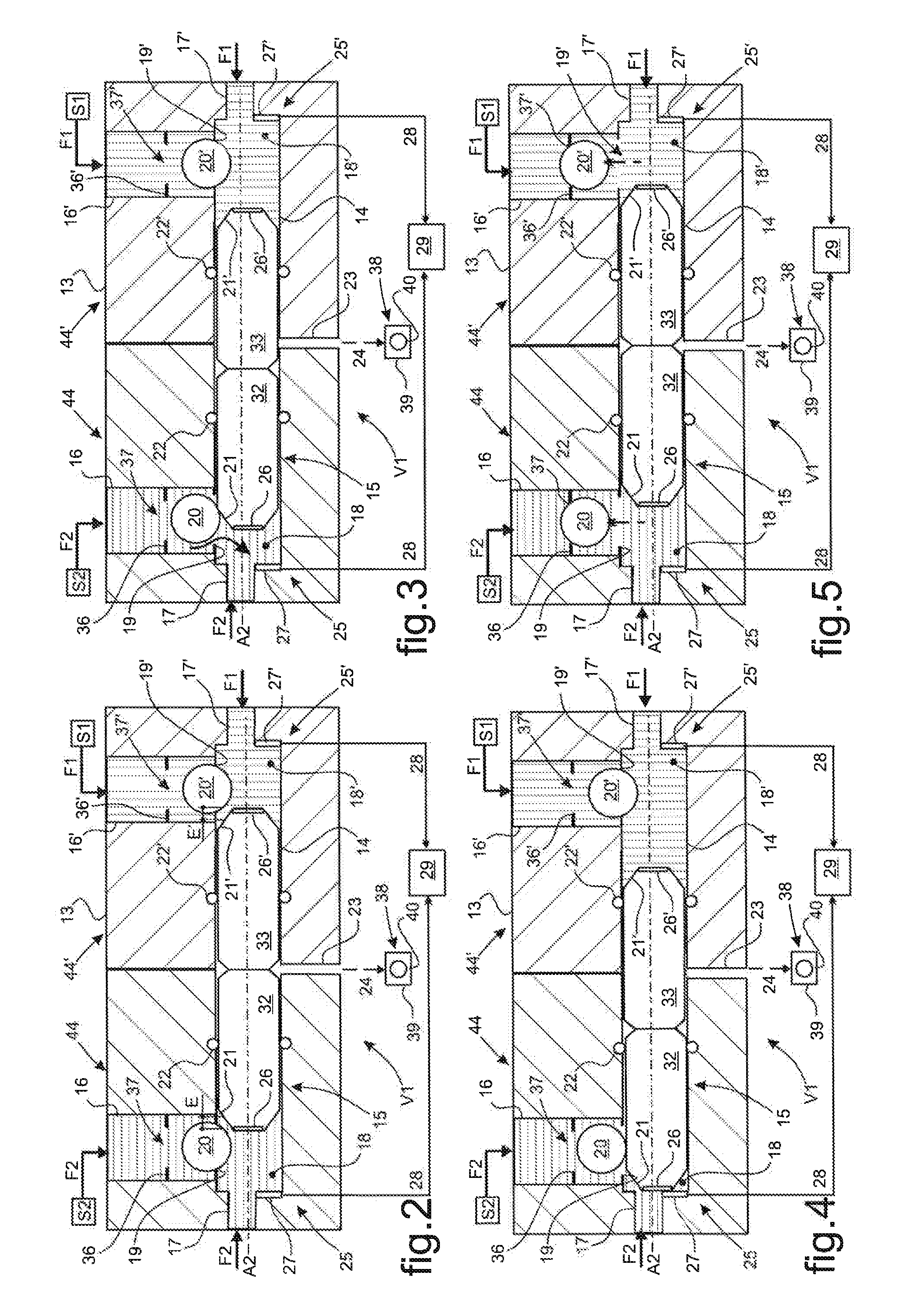

Pressure-balance valve for balancing fluid feed to actuator cylinders of a servo-control for controlling rotor blades of a rotorcraft

ActiveUS20150292527A1Avoid passingEasy to installFluid couplingsServomotor componentsEngineeringPressure difference

A pressure-balance valve for balancing the pressures of fluids admitted into the pressure-balance valve via respective second ducts. The pressure-balance valve has both a chamber for guiding movement in translation of a piston, and also fluid flow paths, each comprising a said second duct and a first duct for admitting a fluid coming from the same fluid source as the fluid flowing in its second duct. Each of the first ducts is provided with a shutter co-operating with a ramp arranged on the piston. Movement of the piston in translation as a result of a pressure difference between the fluids respectively admitted into the second ducts causes one of the shutters to slide along the corresponding ramp and consequently allows additional fluid to be delivered from a first duct to the second duct of the same fluid flow path.

Owner:EUROCOPTER

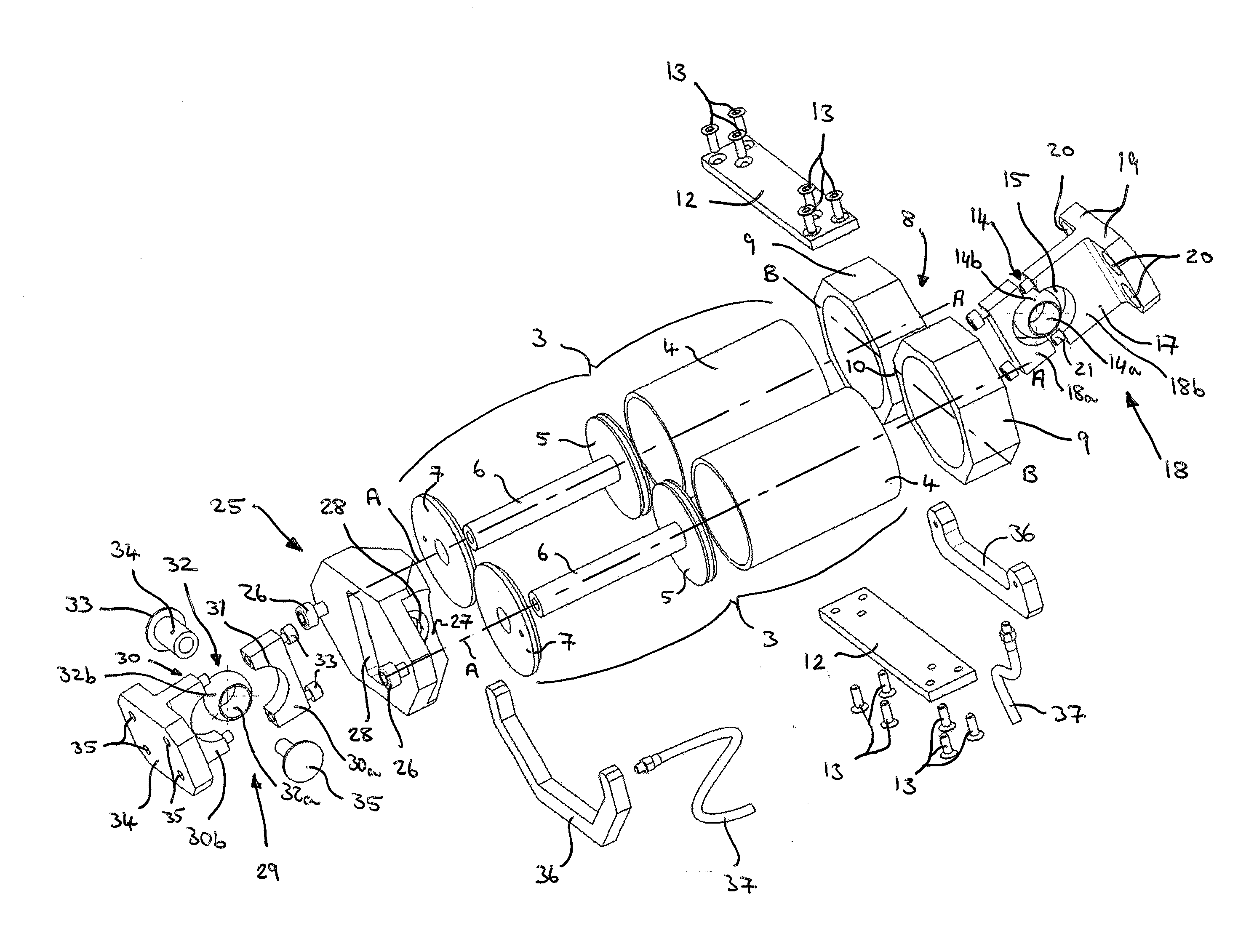

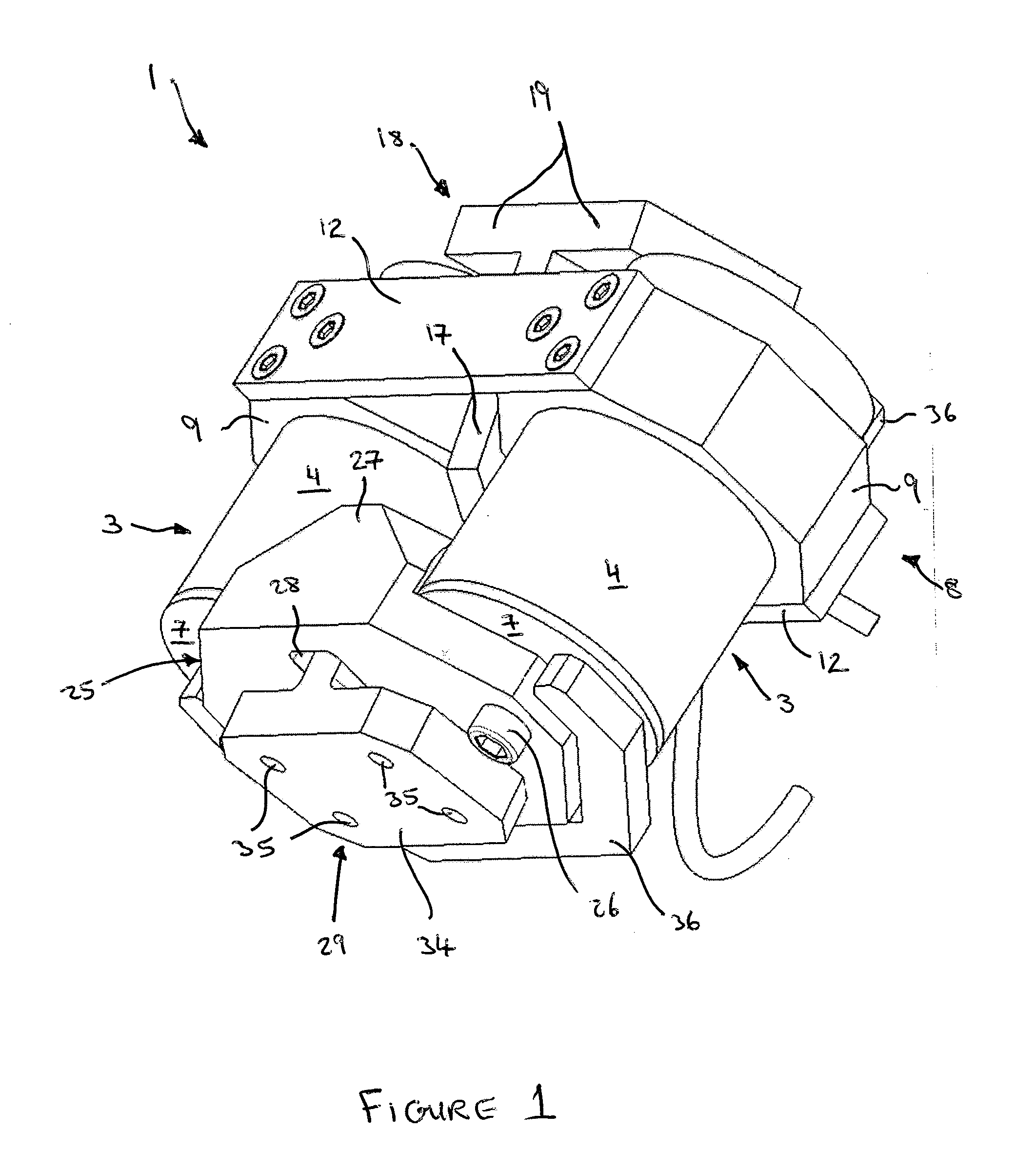

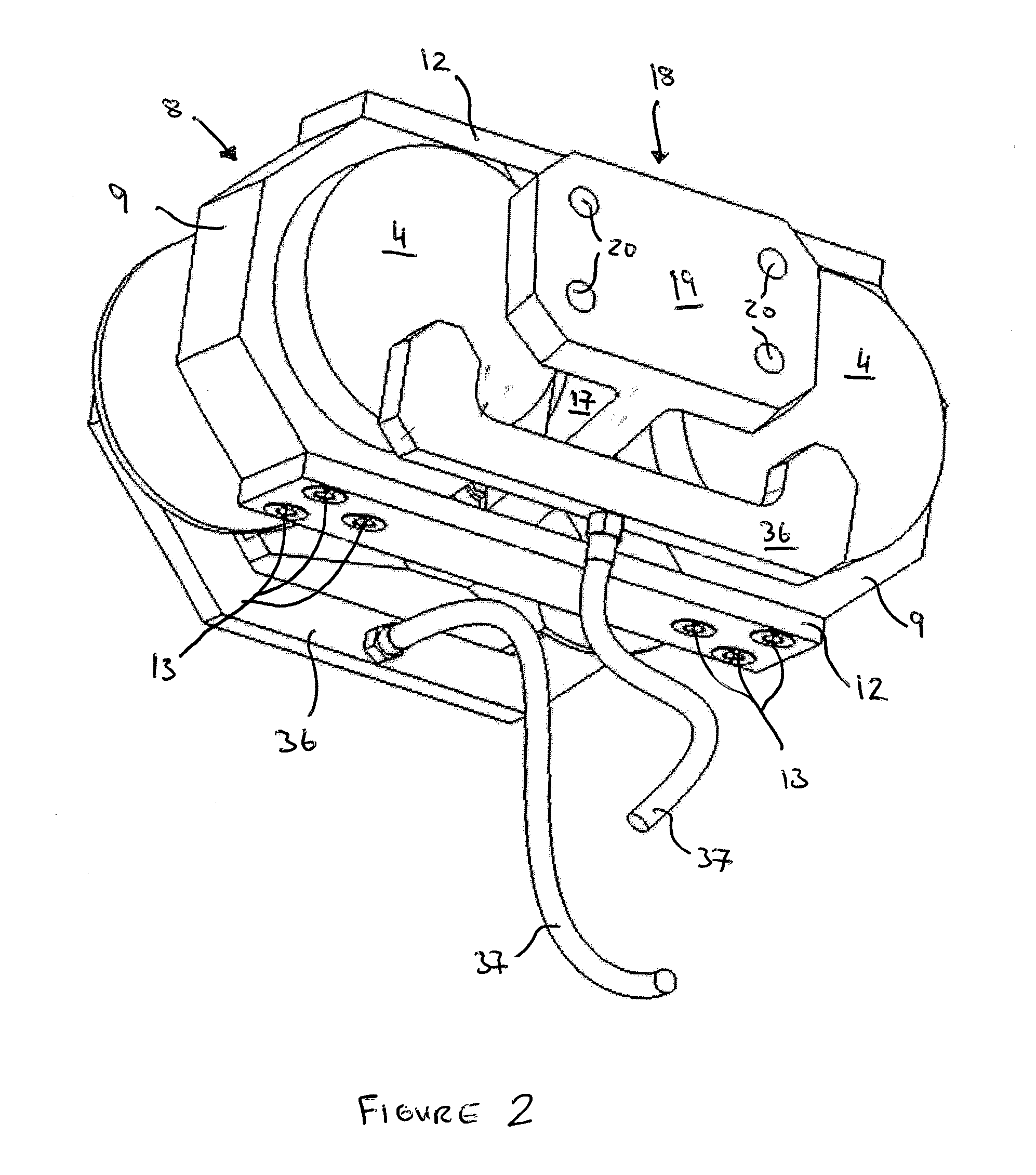

Bearing assembly

A bearing assembly for mounting a pair of spaced parallel actuators (3) between a wing and a control surface of an aircraft so that the actuators control deployment of said control surface from the wing in tandem is disclosed. The bearing assembly comprises a fixed member (18) for attachment to the aircraft and a movable member (8) attachable to the actuators. The fixed and movable members are coupled via a part-spherical bearing (14) and are configured such that the part-spherical bearing is located in the space between the actuators (3).

Owner:AIRBUS OPERATIONS LTD

Hydraulic distributor provided with a device for detecting seizing

ActiveUS7984670B2Controlling the riskEasy to moveFluid-pressure actuator safetyValve arrangementsEngineeringDistributor

The present invention relates to a hydraulic distributor (2) of a servo-control (1) of an aircraft, the hydraulic distributor comprising main distributor member (10) and emergency distributor member (20) that are coaxial, said emergency distributor member (20) being caused to move by said main distributor member (10) in the event of said main distributor member (10) seizing, said hydraulic distributor being provided with a detector device (60) for detecting said seizing. The detector device (60) is provided with a reed switch (66) and with amplification means (62, 69, 68) for amplifying said movement of the emergency distributor member, said amplification means comprising a lever (62) having a magnetized free end (62′) that activates said reed switch (66) in the event of said emergency distributor member (20) moving.

Owner:EUROCOPTER

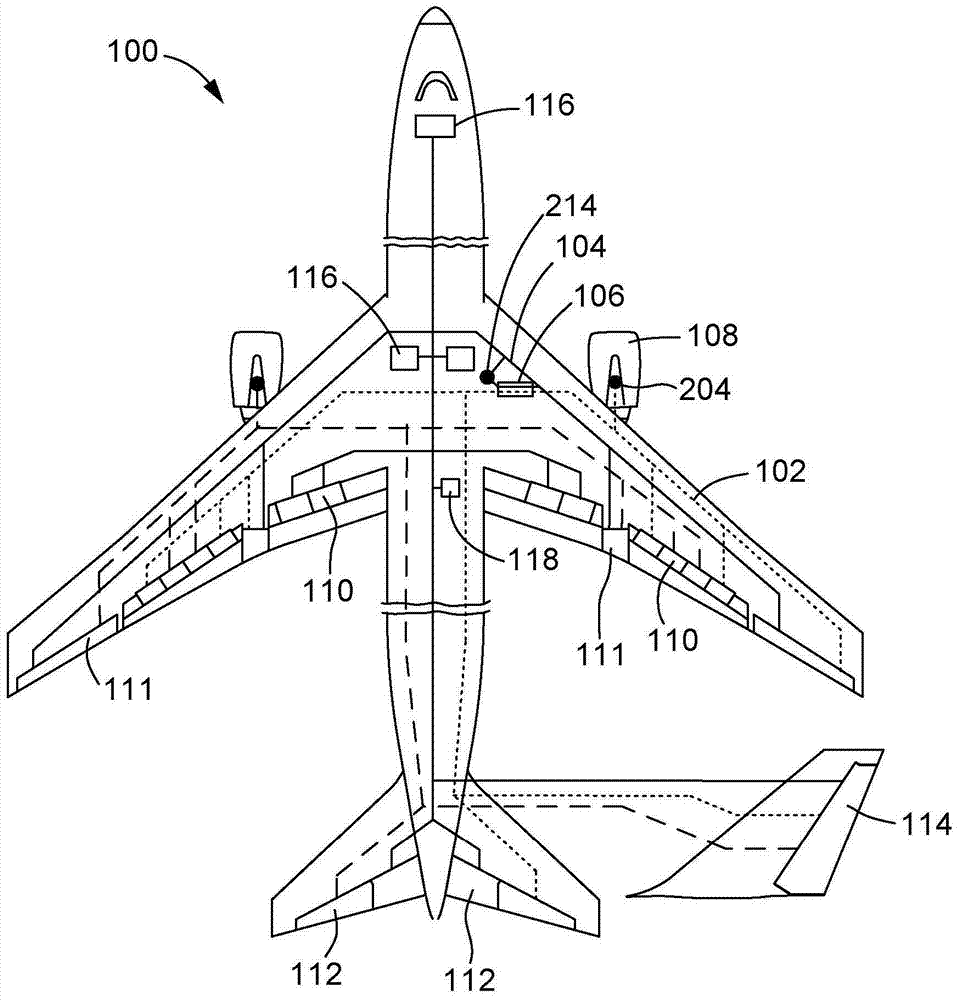

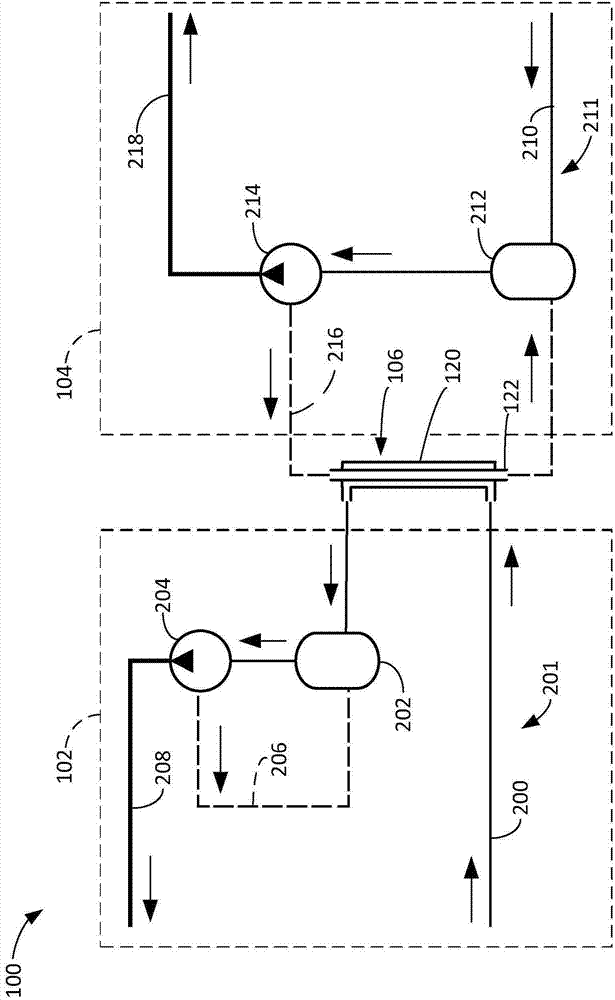

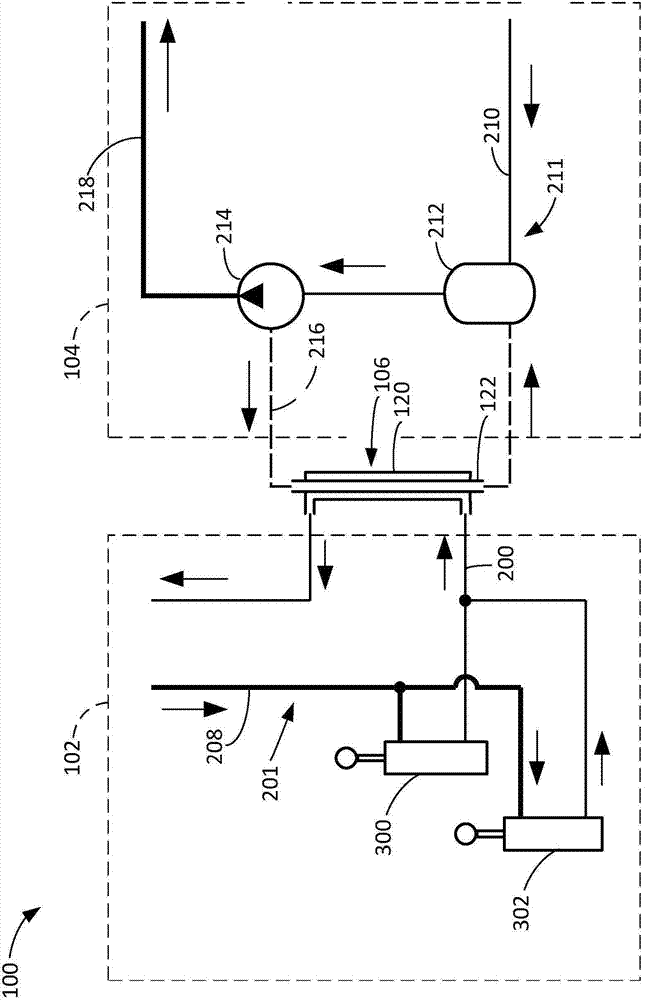

System and method for heat balance and transport for aircraft hydraulic systems

The invention relates to a system and a method for heat balance and transport for aircraft hydraulic systems. A thermal management system includes a first hydraulic system for circulating a first hydraulic fluid at a first temperature and a second hydraulic system for circulating a second hydraulic fluid at a second temperature that is higher than the first temperature. The thermal management system also includes a sealed heat transfer device coupled between the first hydraulic system and the second hydraulic system. The sealed heat transfer device is not in flow communication with either of the first hydraulic system and the second hydraulic system. The sealed heat transfer device is configured to transfer heat from the second hydraulic fluid to the first hydraulic fluid.

Owner:THE BOEING CO

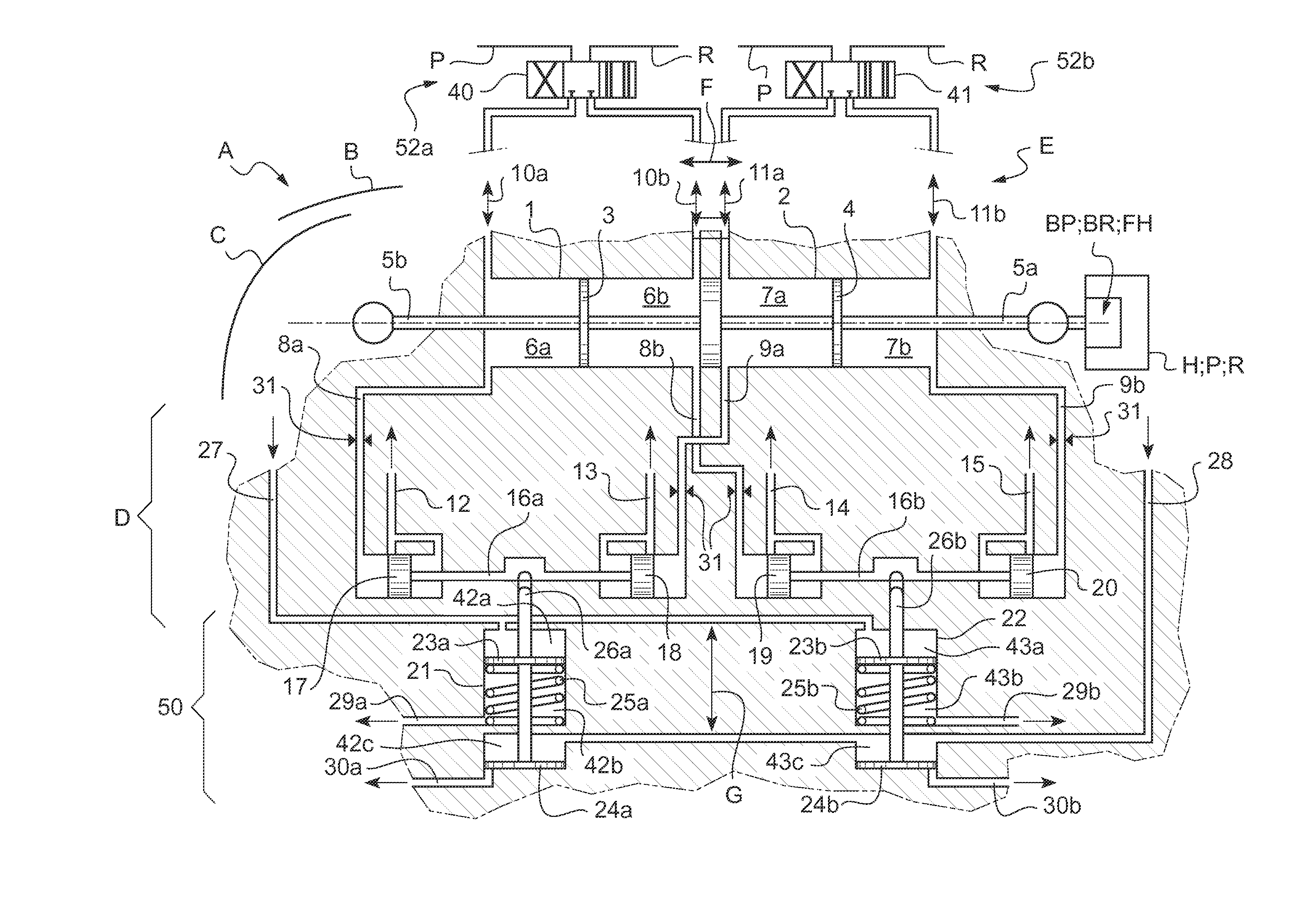

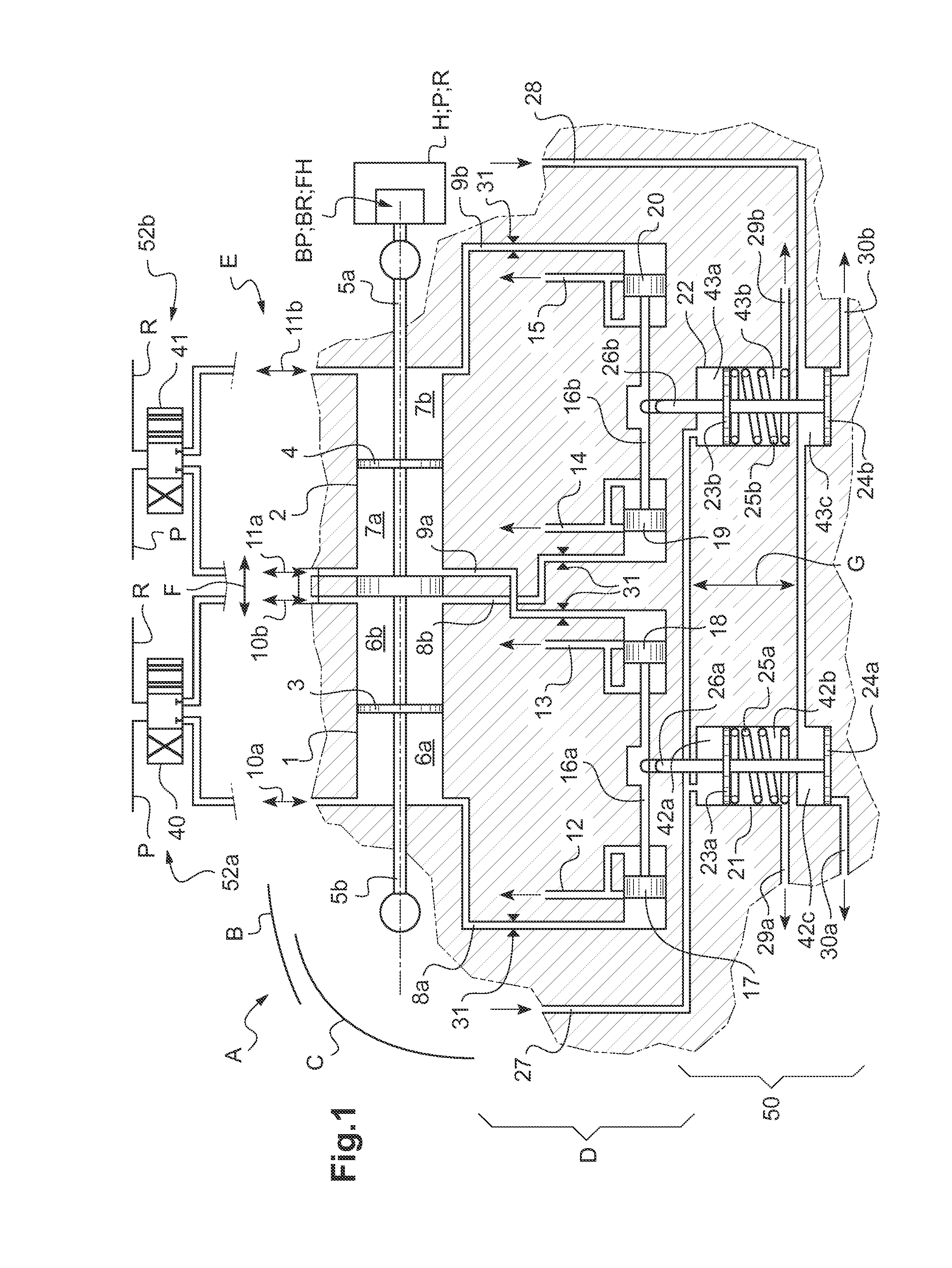

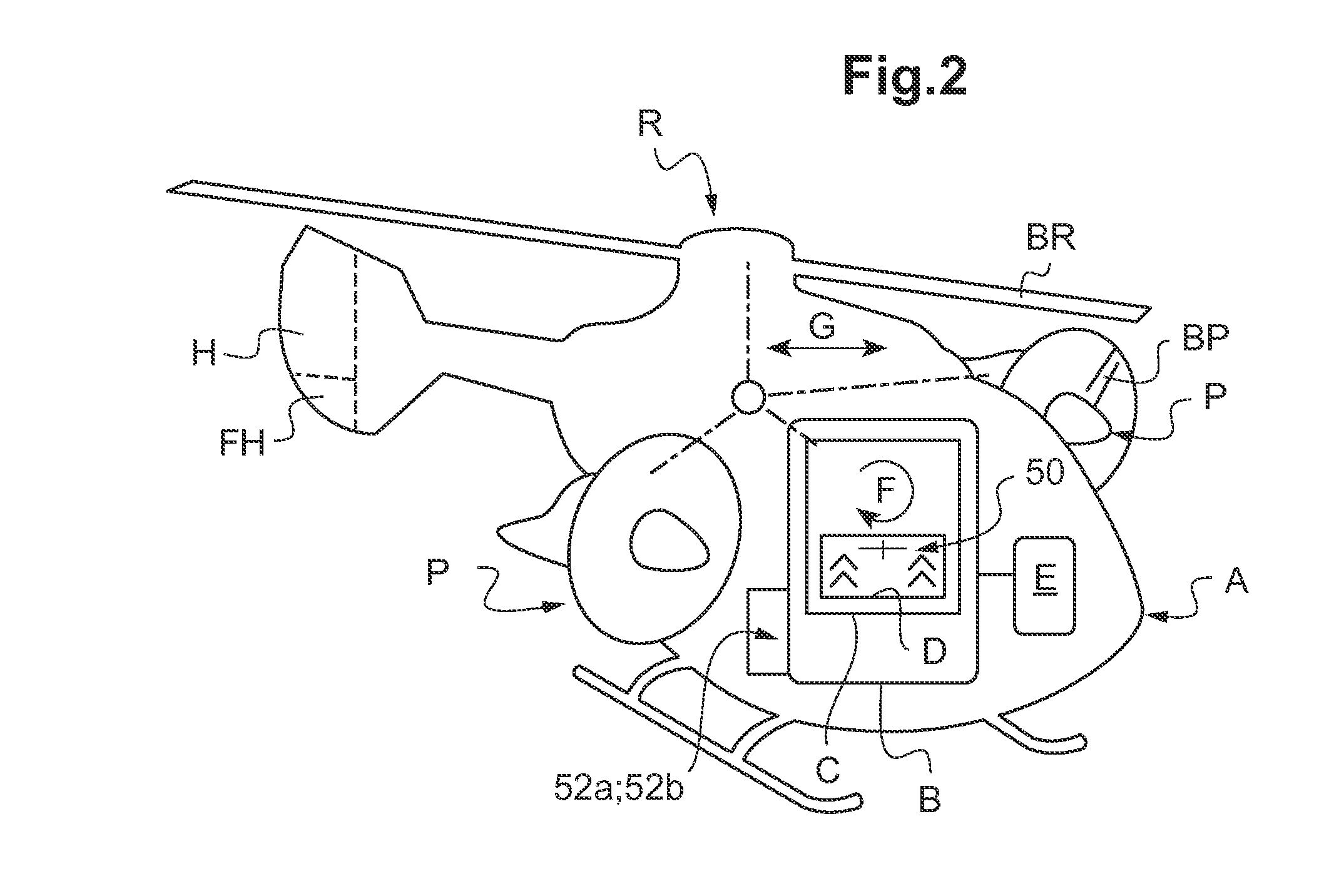

Flexible response secured mechanical balancing for multiple control actuators with a common output

ActiveUS20150075149A1Improve accuracyReduce frictionFluid couplingsServometer circuitsDifferential pressureActuator

A flexible response secured mechanical balancing device (D) for multiple hydraulic control actuators (1-2) with a common output member (5a-b). The balancing device (D) provides flexible / continuous fluid-pressure force fight compensation. Balance valves (17-20) are commanded to balance fluid-pressure from a first fluid-pressure network (52a) of a second actuator (2). Each fluid-pressure commanded balance valve (17-20) is arranged to allow relief of differential pressure, directly into a dedicated first (52a) or second fluid-pressure network (52b). A fluid-pressure controlled locking device (21-22) is allowing inhibiting the corresponding pairs of balance valves (17-20) e.g. in case of loss of fluid-pressure. The invention typically applies to vehicles (A) including: aircrafts, rotorcrafts, drones.

Owner:AIRBUS HELICOPTERS DEUT GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com