Augmenting flight control surface actuation system and method

A technology of flight control surfaces and actuators, which is applied in the field of flight control surface actuation systems, and can solve problems such as low efficiency and low PCU efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

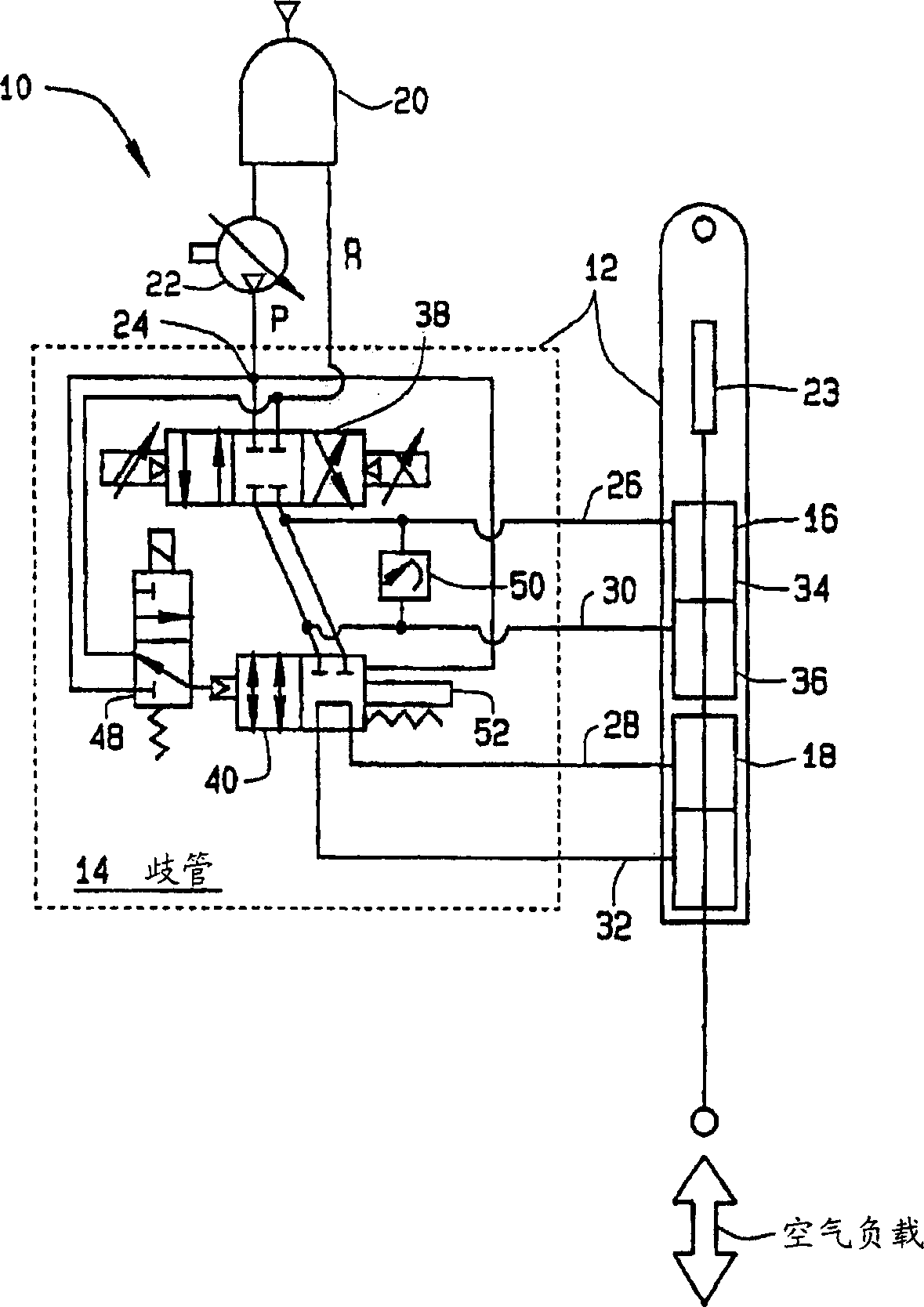

[0016] See attached figure 1 , shows an enlarged flight control surface actuation system, generally indicated at 10, in accordance with a preferred embodiment of the present invention. Typically system 10 includes an enlarged PCU 12 including a manifold 14, a first actuator 16 and a second actuator 18 having an assist mode and a bypass mode. The enlarged PCU 12 is fluidly connected to a pressure source P (eg, a fluid reservoir 20 and a pump 22 ) that provides pressurized working fluid to the enlarged PCU 12 . In use, the mode of operation of the second actuator 18 (i.e. assist and bypass modes) is based at least in part on the internal pressure differential across the first actuator 16 such that the second actuator 18 does not absorb any hydraulic pressure until high loads are required.

[0017] During low load conditions, the second actuator 18 is bypassed and remains in a passive or standby mode so that the first actuator 16 provides power to the flight control surfaces. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com