Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Fast passivation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

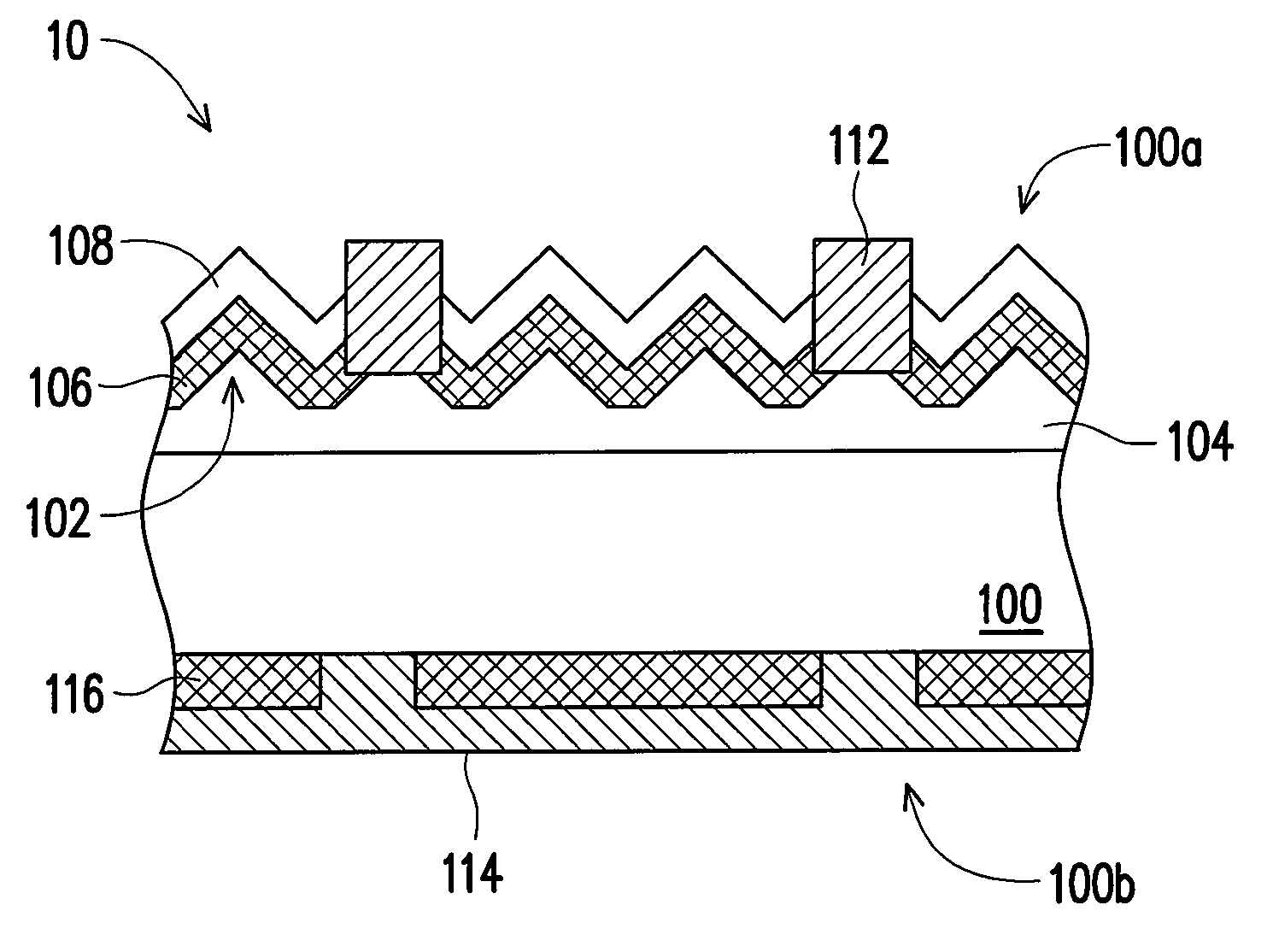

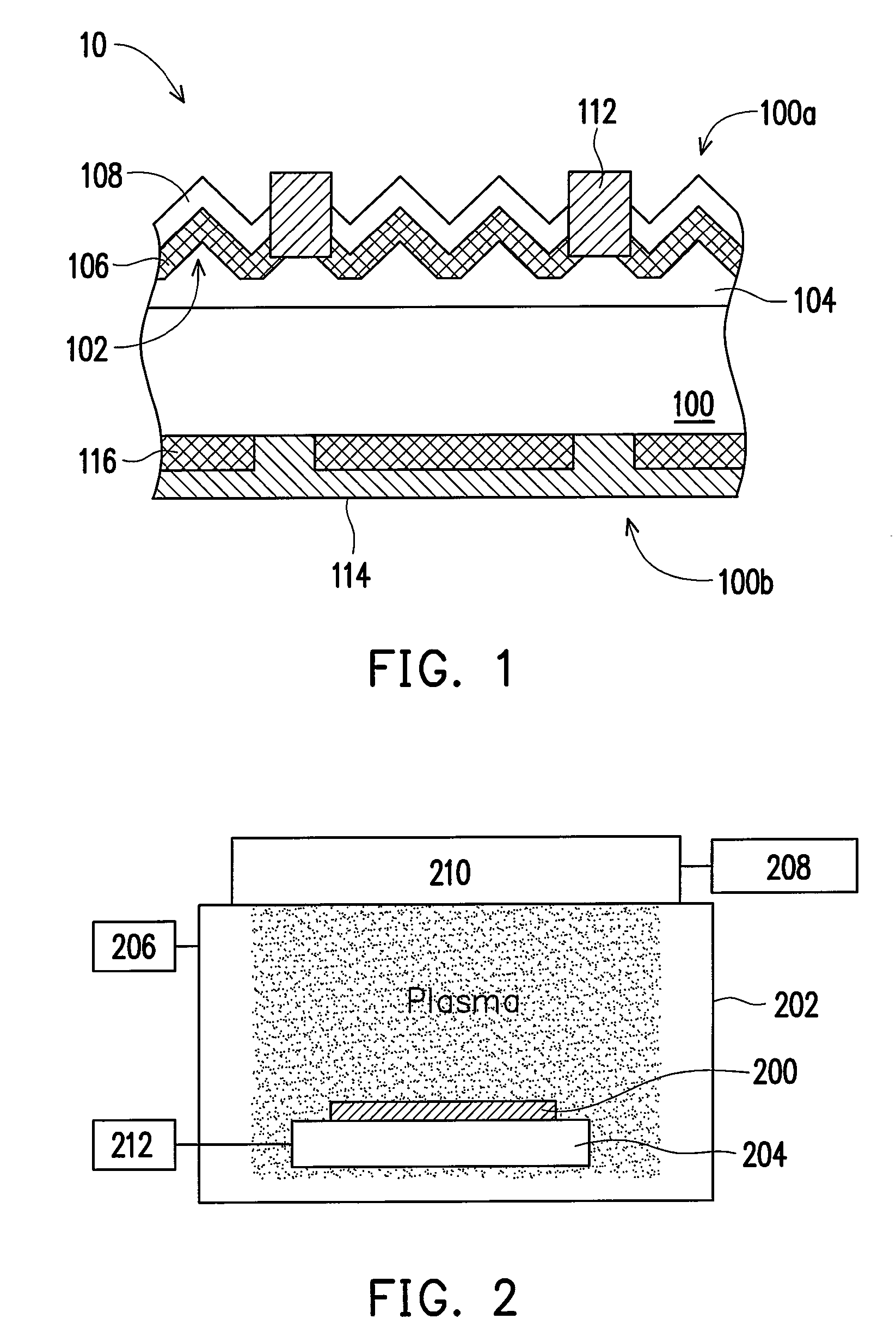

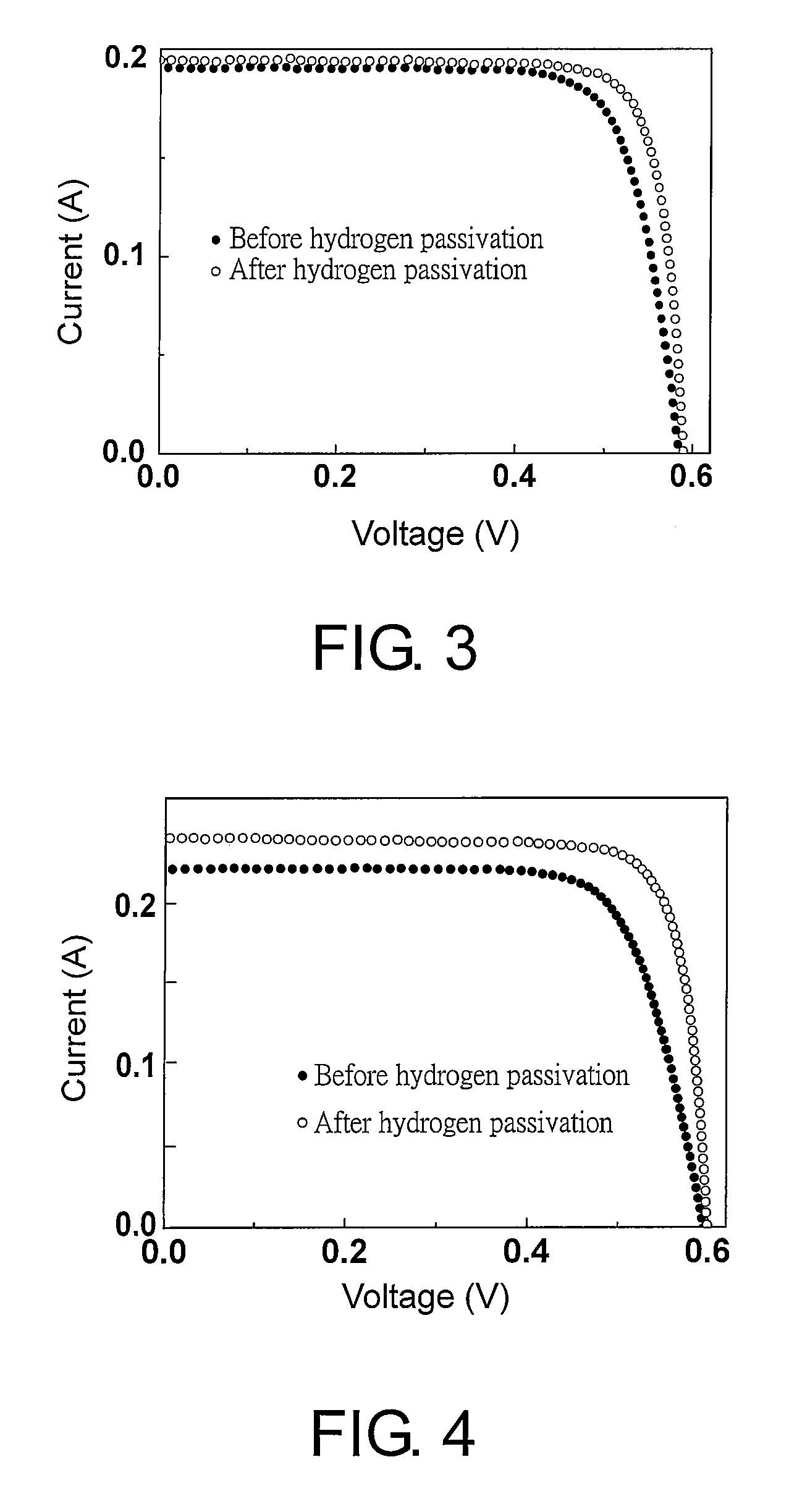

Method of fast hydrogen passivation to solar cells made of crystalline silicon

InactiveUS20090101202A1Improve performanceFast passivationFinal product manufacturePhotovoltaic energy generationCrystallographic defectHydrogen ion

A method of improving efficiency of solar cells made of crystalline silicon, including monocrystalline silicon, multicrystalline silicon and polycrystalline silicon is provided. In the method, a negative bias pulse is applied to solar cells at a predetermined voltage, a predetermined frequency, and a predetermined pulse width while immersing the solar cells in a hydrogen plasma. Hydrogen ions are attracted and quickly implanted into the solar cells. Thus, the passivation of crystal defects in the solar cells can be realized in a short period. Meanwhile, the properties of an antireflection layer cannot be damaged as proper operating parameters are used. Consequently, the serious resistance of the solar cells can be significantly reduced and the filling factor increases as a result. Further, the short-circuit current and the open-circuit voltage can be increased. Therefore, the efficiency can be enhanced.

Owner:IND TECH RES INST +1

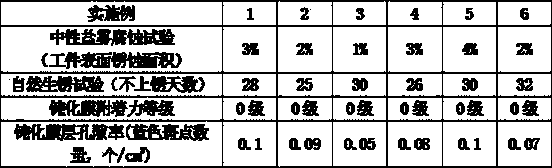

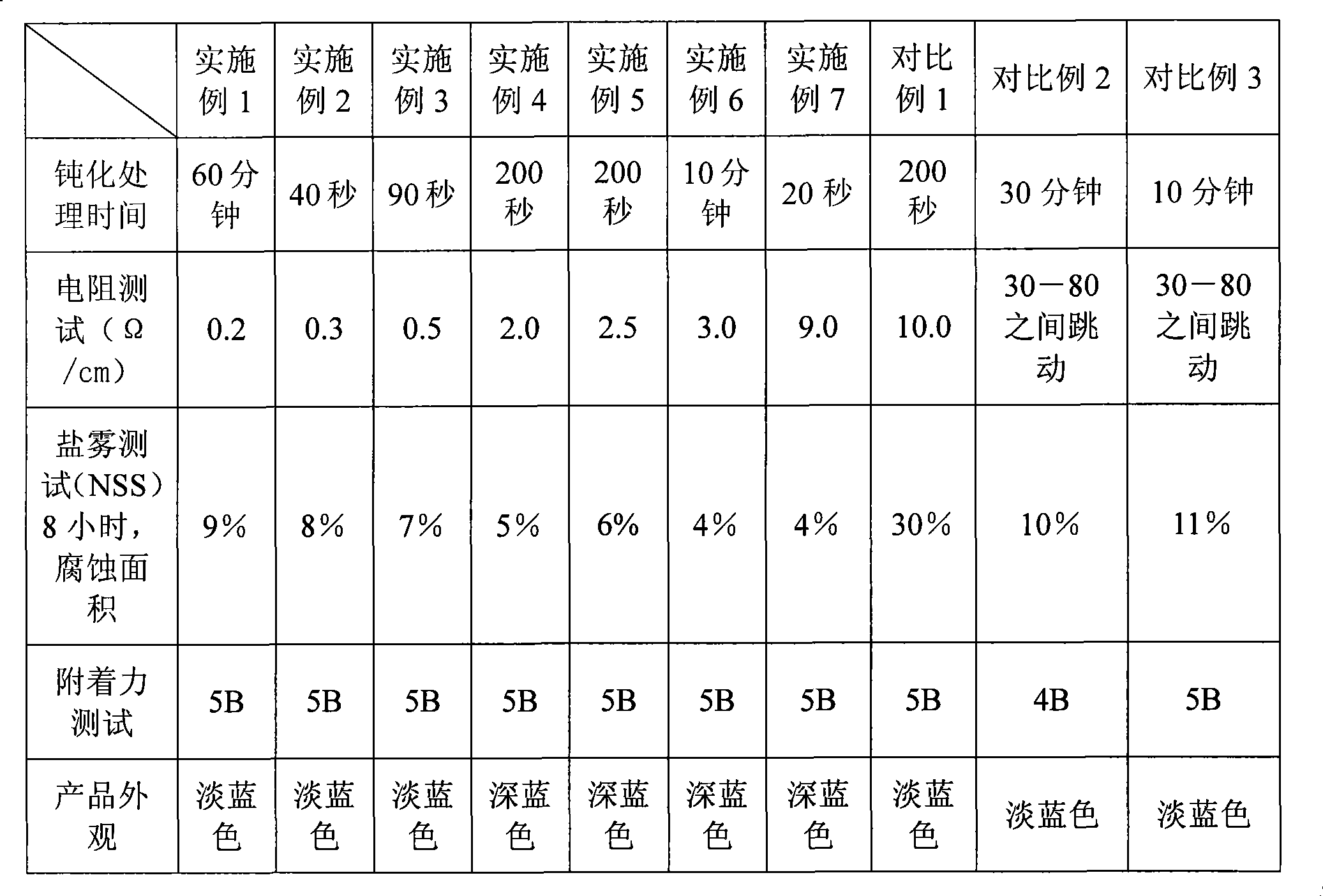

Chromium-free passivation solution as well as preparation and using methods thereof

ActiveCN104404492AImprove corrosion resistanceStrong adhesionMetallic material coating processesSodium molybdateAcetic acid

The invention provides a chromium-free passivation solution as well as preparation and using methods thereof. The passivation solution is prepared by dissolving a solute composed of multiple substances into deionized water, wherein the solute in the solution comprises the following raw materials according to the ratio: 60-80g / L of sodium molybdate, 5-10g / L of sodium tungstate, 2-7g / L of ethanol, 15-50g / L of acetic acid, 20-40g / L of hydrogen peroxide, 5-10g / L of ethylenediaminetetraacetic acid disodium and the balance of water. The chromium-free passivation solution is firm in adhesive force, low in porosity and corrosion-resistant.

Owner:HUNAN JINYU CHEM

Environment-friendly composite ferrous sulfide passivator and preparation method thereof

InactiveCN104263408AStable in natureFast passivationTreatment apparatus corrosion/fouling inhibitionSodium bicarbonateSpontaneous combustion

The invention discloses an environment-friendly composite ferrous sulfide passivator which is composed of the following components in percentage by mass: 5-10% of sodium pyrosulfate, 10-25% of sodium hypochlorite, 1-10% of trisodium phosphate, 0.5-7% of sodium hydrogen carbonate, 20-35% of sodium hydroxide, 1-2% of potassium ferrate and 30-60% of water; and the environment-friendly composite ferrous sulfide passivator is prepared by uniformly mixing the components according to a specific step order. The environment-friendly composite ferrous sulfide passivator disclosed by the invention is efficient, is free of toxicity, corrosive property and secondary pollution and is capable of quickly passivating ferrous sulfide and effectively preventing spontaneous combustion of ferrous sulfide; the passivator has a good cleaning effect on such malodorant as hydrogen sulfide, ferrous sulfide passivation time is 8-10h and more than 98% of ferrous sulfide is removed, and shutdown time of a device is correspondingly shortened; and a protective film is formed on the surface of passivated metal, so as to effectively prevent metal surface from being further corroded.

Owner:JINAN RUIDONG IND

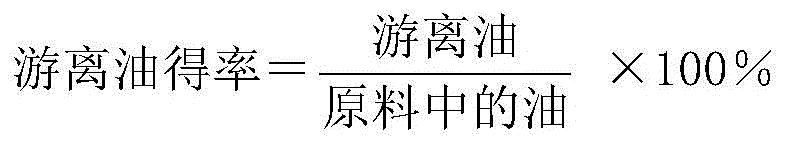

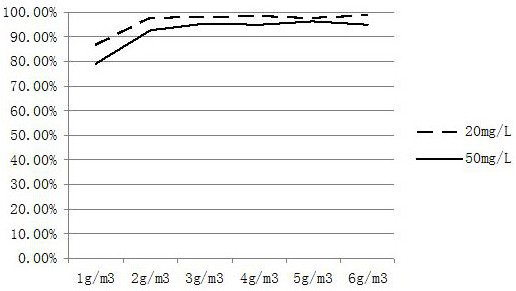

Method for extracting rapeseed oil and passivated myrosinase from rapeseeds

ActiveCN105670769ALoose structurePromote dissolutionFatty-oils/fats refiningFatty-oils/fats productionOil and greaseRapeseed

The invention discloses a method for extracting rapeseed oil and passivated myrosinase from rapeseeds and belongs to the technical field of agricultural resources.The method has the advantages that raw materials are soaked by deionized water, moisture in cells is turned into steam during steam explosion or pressurization heat-moisture treatment, and cell walls are broken to allow the cell structure to be loose and promote the dissolution of grease in the cells; an ethanol solution is used as the oil extraction medium, glucosinolates and most degradation products are allowed to enter a water phase, the glucosinolate and glucosinolate degradation product contents in cake are lowered, and the detoxification procedure of rapeseed cake is reduced; enzyme use is avoided, oil production cycle is shortened, production cost is reduced, oil product quality is optimized, and the problems that the glucosinolate and glucosinolate degradation product contents of the cake obtained by a traditional rapeseed process are high, high-quality protein resources are wasted, a large amount of enzyme needs to be used, cost is high or environment pollution is severe, and the like are solved.

Owner:JIANGNAN UNIV

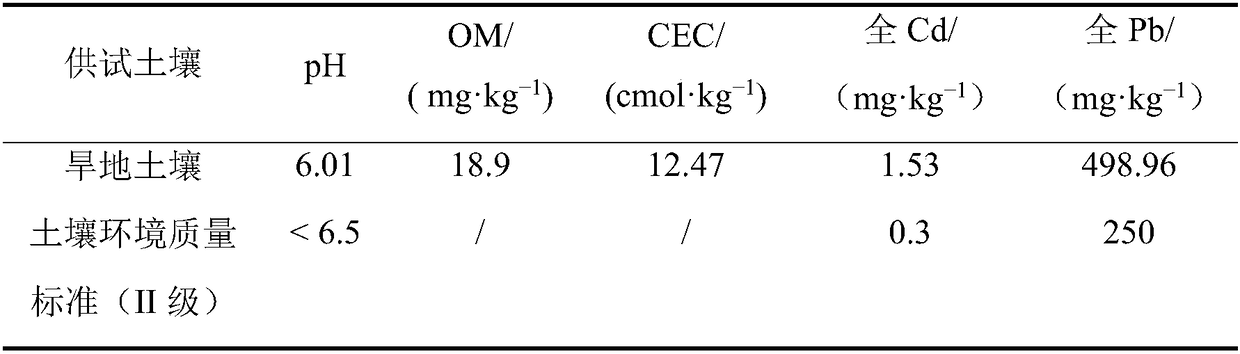

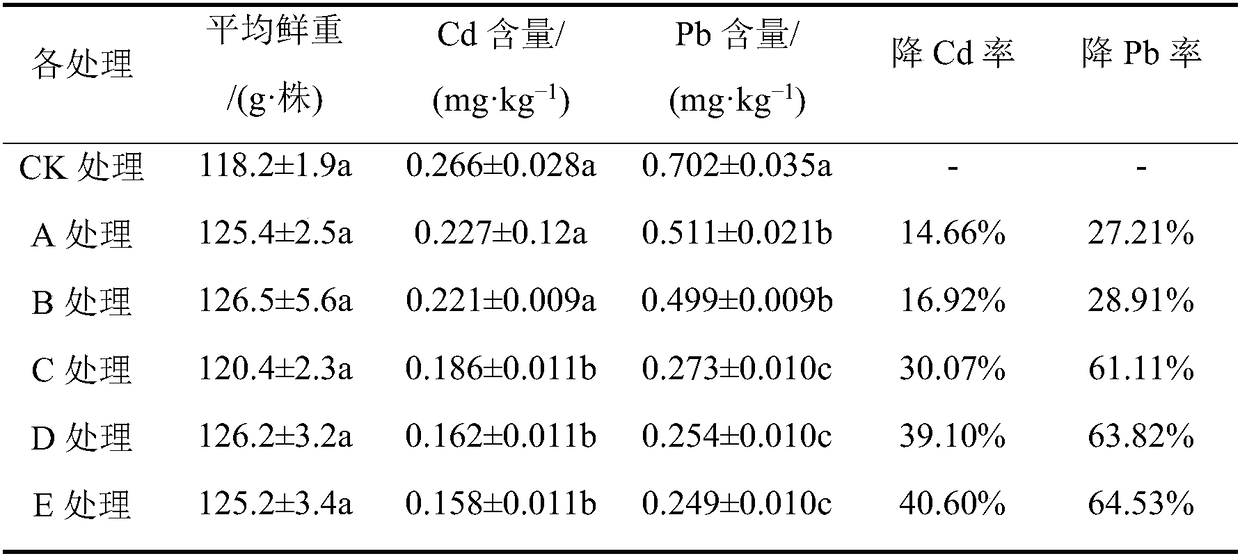

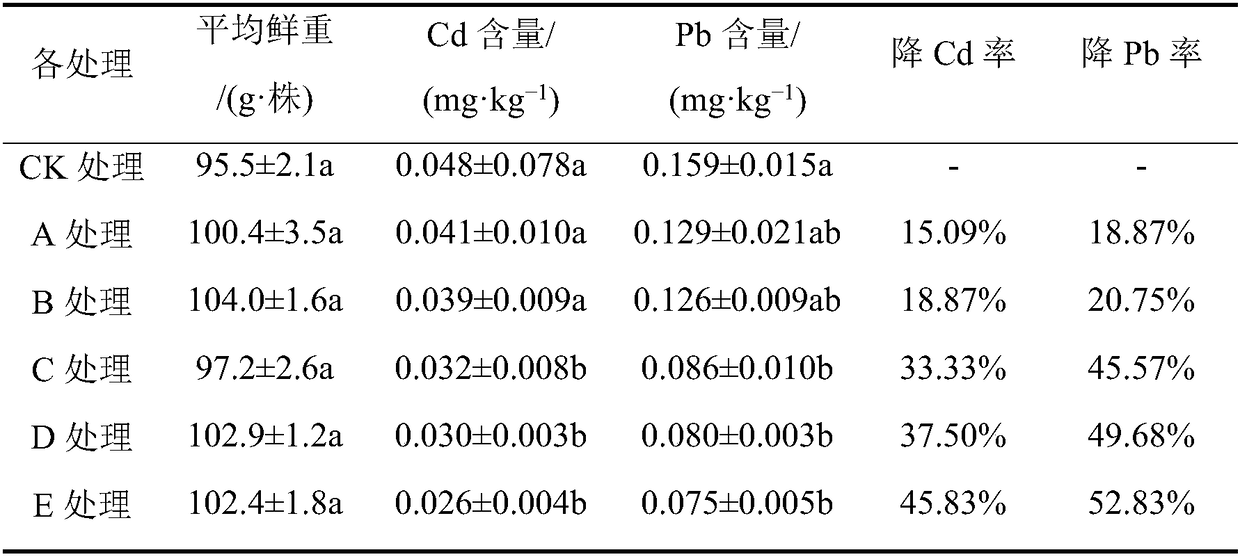

Biochar-based soil conditioner and application thereof

InactiveCN109456125AHigh pHIncrease surface areaCalcareous fertilisersAlkali orthophosphate fertiliserResource utilizationDipotassium phosphate

The invention discloses a biochar-based soil conditioner capable of deactivating dryland soil-contained heavy metals and application thereof. The biochar-based soil conditioner is composed of, by weight percentage, 30-45% of biochar, 5-10% of dipotassium phosphate, 3-5% of potassium sulfate, 10-15% of calcium magnesium phosphate, 5-10% of humic acid, 15-30% of limestone and 5-20% of dolomite. Theapplication method of the biochar-based soil conditioner comprises applying the biochar-based soil conditioner to the surface of soil, ploughing the soil to uniformly mix the biochar-based soil conditioner with the soil, and after 10-20 days of balancing, performing planting or transplanting. The biochar-based soil conditioner can achieve resource utilization of straw, and meanwhile through synergistic effects of the components, achieve the aim of deactivating soil heavy metals, inhibiting heavy metal absorption of vegetables and improving quality of soil and vegetables and further achieve theaim of production and restorage integration of heavy metal contaminated drylands.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

Compound biological preparation and application thereof in treatment of mercury-containing wastewater

Owner:FUYANG HUAIBANG MACHINERY

Passivating treatment solution for surface of zinc or zinc alloy and passivation treatment method

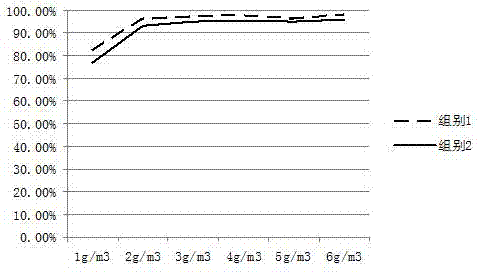

ActiveCN101376969AFast passivationGood corrosion resistanceMetallic material coating processesYttriumWater soluble

The invention relates to passivation solution of the surface of zinc or zinc alloy, which contains passivation main salt, oxidant, complexing agent, accelerant and water, wherein, the passivation main salt is water soluble yttrium salt, and the accelerant is soluble metavanadate. The invention also provides a method for passivating the surface of zinc or zinc alloy with the passivation slution. Using the passivation solution and passivation process to passivate the surface of zinc or zinc alloy has high passivation speed, good corrosion of the passivating film, reduces the harm to the environment and the surface resistance of the zinc or zinc alloy passivating film layer, improves the electronic and electromagnetic conductibility, and reduces the hidden danger to the users.

Owner:江苏三耐特种设备制造有限公司

Production method of quick-cooking rice

InactiveCN102960610AUniform gelatinization inside and outsideImprove performance qualityFood preparationSurface moistureCavitation

The invention relates to a production method of quick-cooking rice. The method is characterized by comprising the following steps of: slowly humidifying and tempering by an atomization method; and evaporating moisture of the rice surface by use of hot air; and processing with ultrasonic wave and microwave, wherein based on the special inside-to-outside heating principle from of microwave and the cavitation effect, resonance effect and warm effect of the ultrasonic wave, the rice grains are moderately gelatinized tiny holes are formed at the same time, and the cooking performance of the rice can be obviously improved. The joint treatment of hot air, microwave and ultrasonic wave also can obviously kill or passivate entomogenous fungi enzyme hidden in the rice grains to improve the storage performance of rice. By humidifying and tempering based on an atomization method, the crackle ratio of rice grains is effectively reduced, and the loss of nutrients is reduced. The method provided by the invention is environment-friendly and pollution-free in rice treatment, and obviously improves the cooking performance and storage performance of the product.

Owner:NANCHANG UNIV

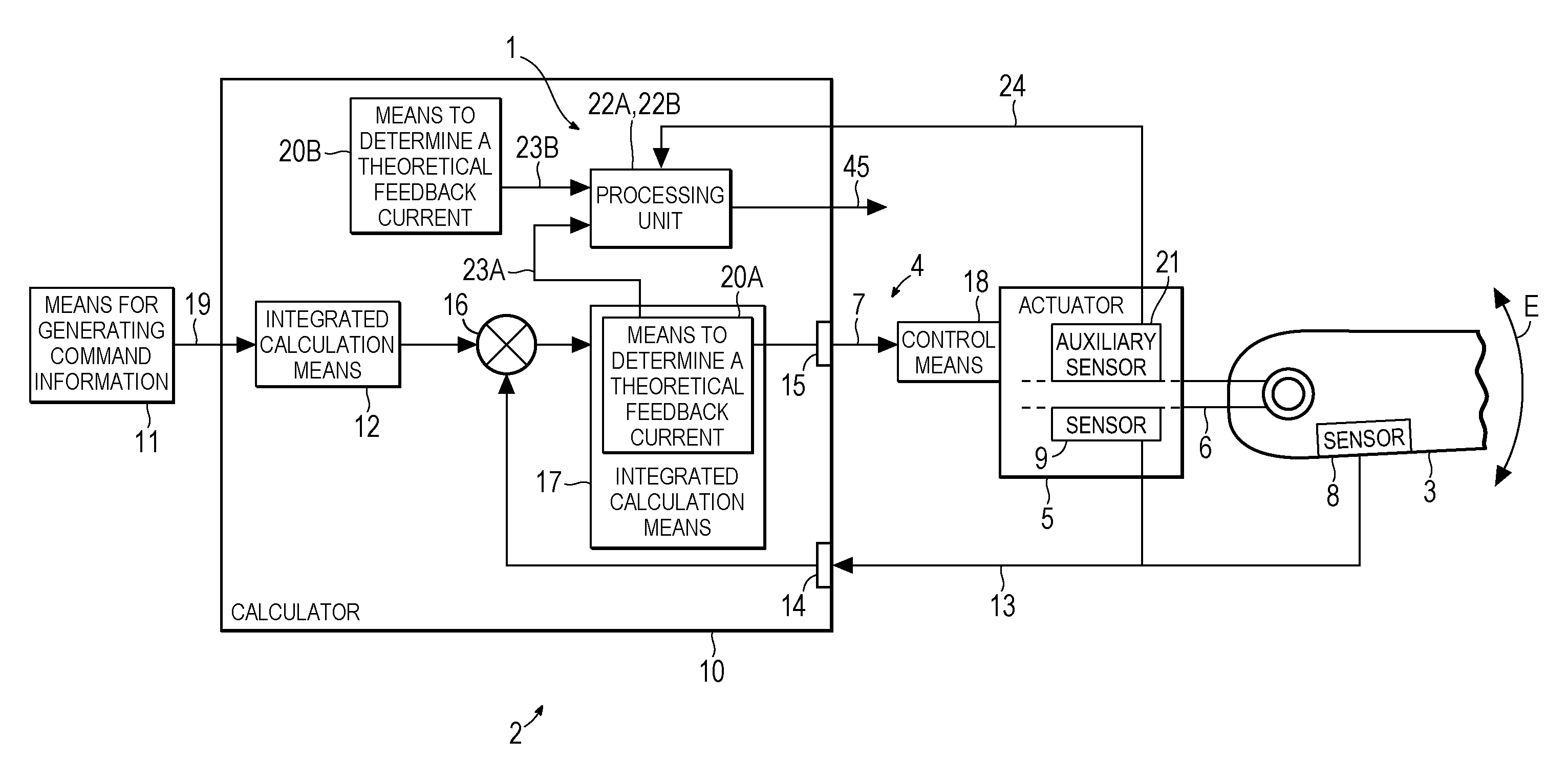

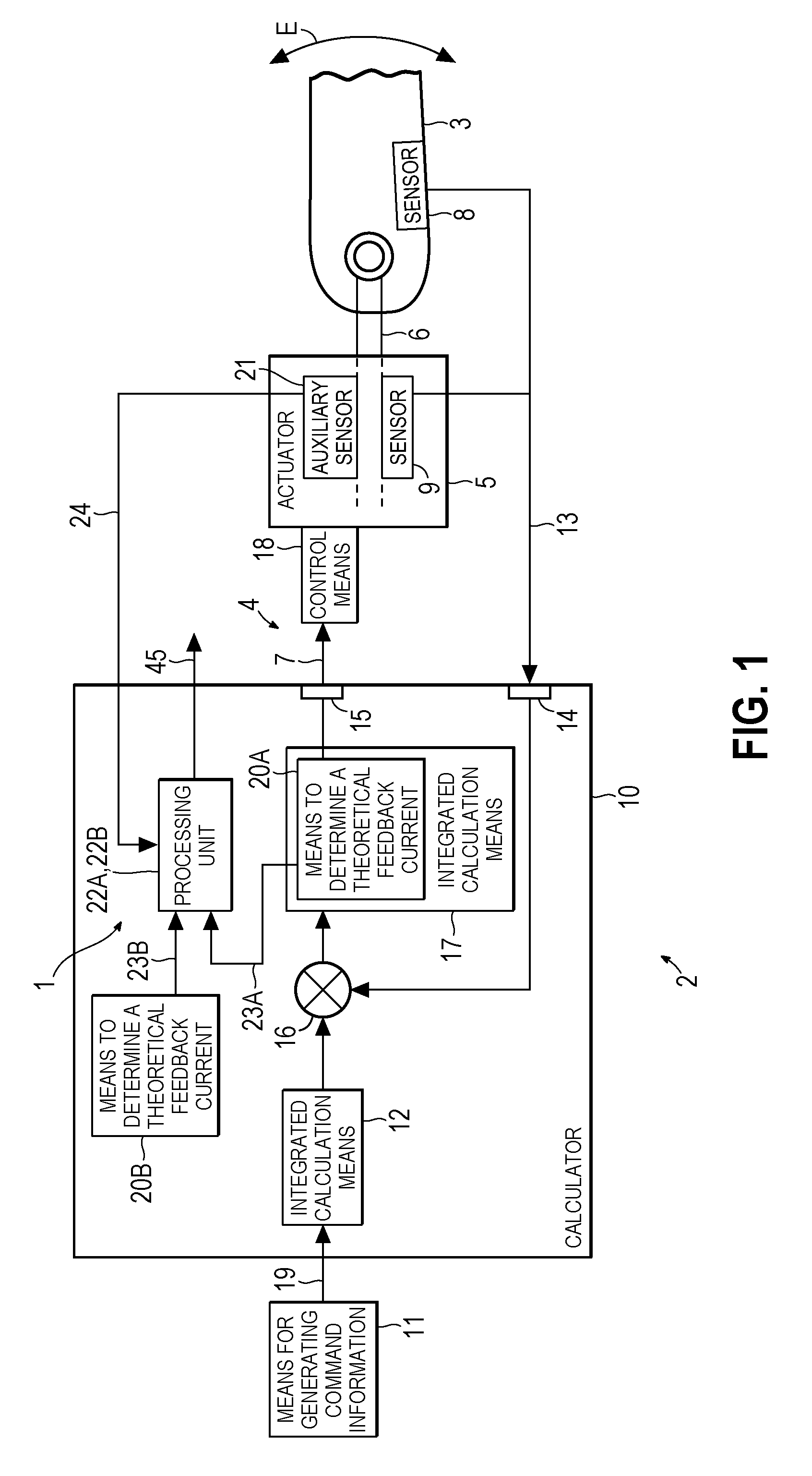

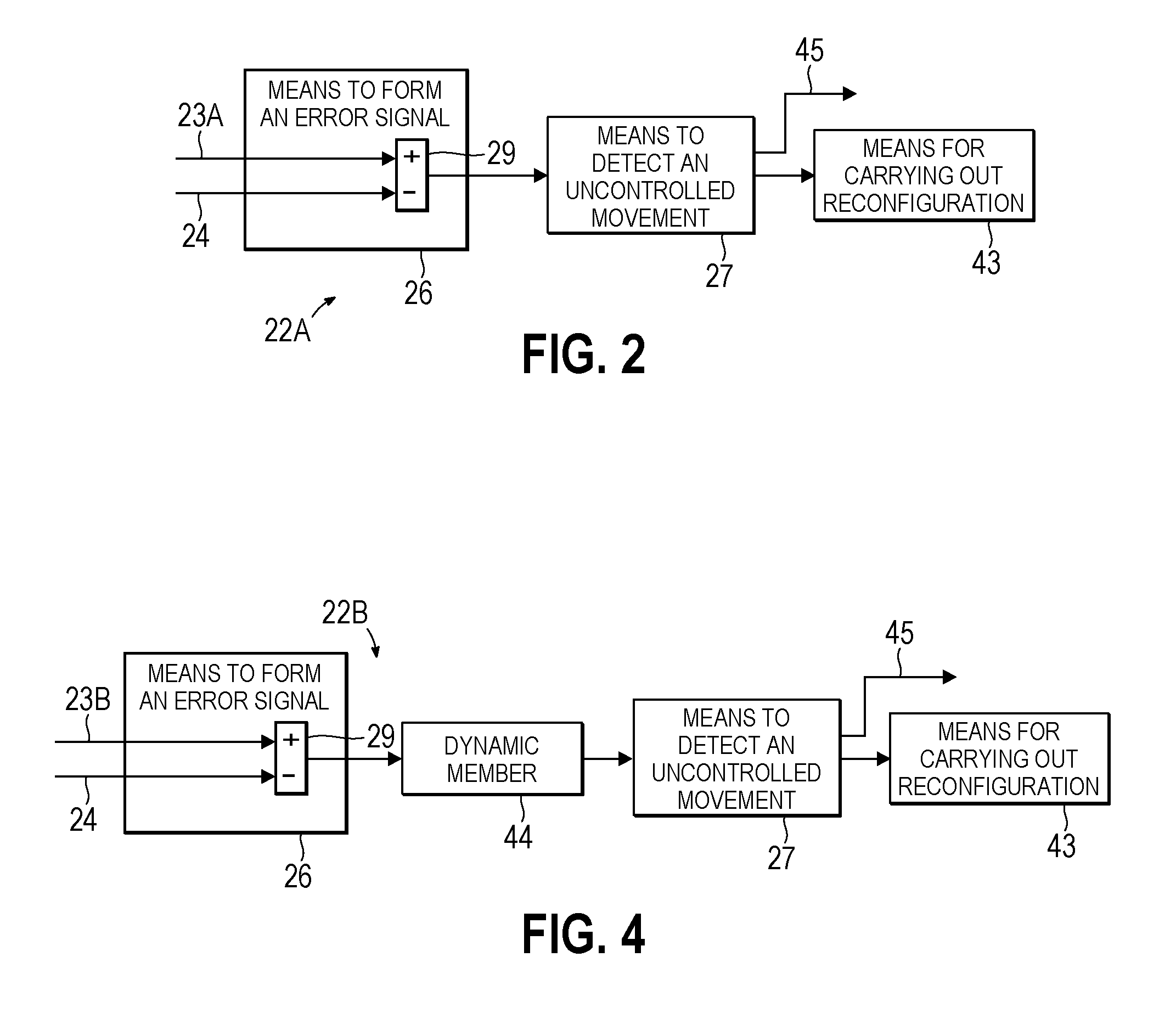

Method and device for detecting an uncontrolled movement of an aircraft control surface

ActiveUS8818573B2Uncontrolled movementQuick checkAircraft stabilisationDigital data processing detailsControl theoryAirplane

A detection device determines whether an uncontrolled movement of a control surface of an aircraft is occurring. The device includes means for calculating the difference between a theoretical command and an actual command in order to form a residual value, and means for detecting an uncontrolled movement of the control surface, if a comparison value depending on this residual value is greater than a threshold value If the comparison value is greater than the threshold value during a confirmation time, then the uncontrolled movement of the control surface of the aircraft is confirmed.

Owner:AIRBUS OPERATIONS (SAS) +2

Preparation method for aluminium alloy radiator passivation solution before lacquering

InactiveCN104328415AImprove corrosion resistanceImprove adhesionMetallic material coating processesAcetic acidSodium molybdate

The invention discloses a preparation method for an aluminium alloy radiator passivating solution before lacquering. The passivating solution comprises 6-8 g / L of sodium molybdate, 4-6 g / L of potassium tetrafluoroborate, 3-5 g / L of magnesium titanate, 8-10 g / L of sodium zirconate, 16-18 g / L of aqueous polyurethane, 12-14g / L of boric acid, 4-6 g / L of acetic acid, 1-2g / L of thiourea and the balance water. The preparation method comprises: weighing all raw materials according to the above proportions, putting in a reaction kettle, heating to 35-45 DEG C, then starting a stirrer, controlling the rotation speed to be 160-180 r / min, stirring for 15-25 min, then cooling to room temperature and putting for 10-12 h.

Owner:无锡永发电镀有限公司

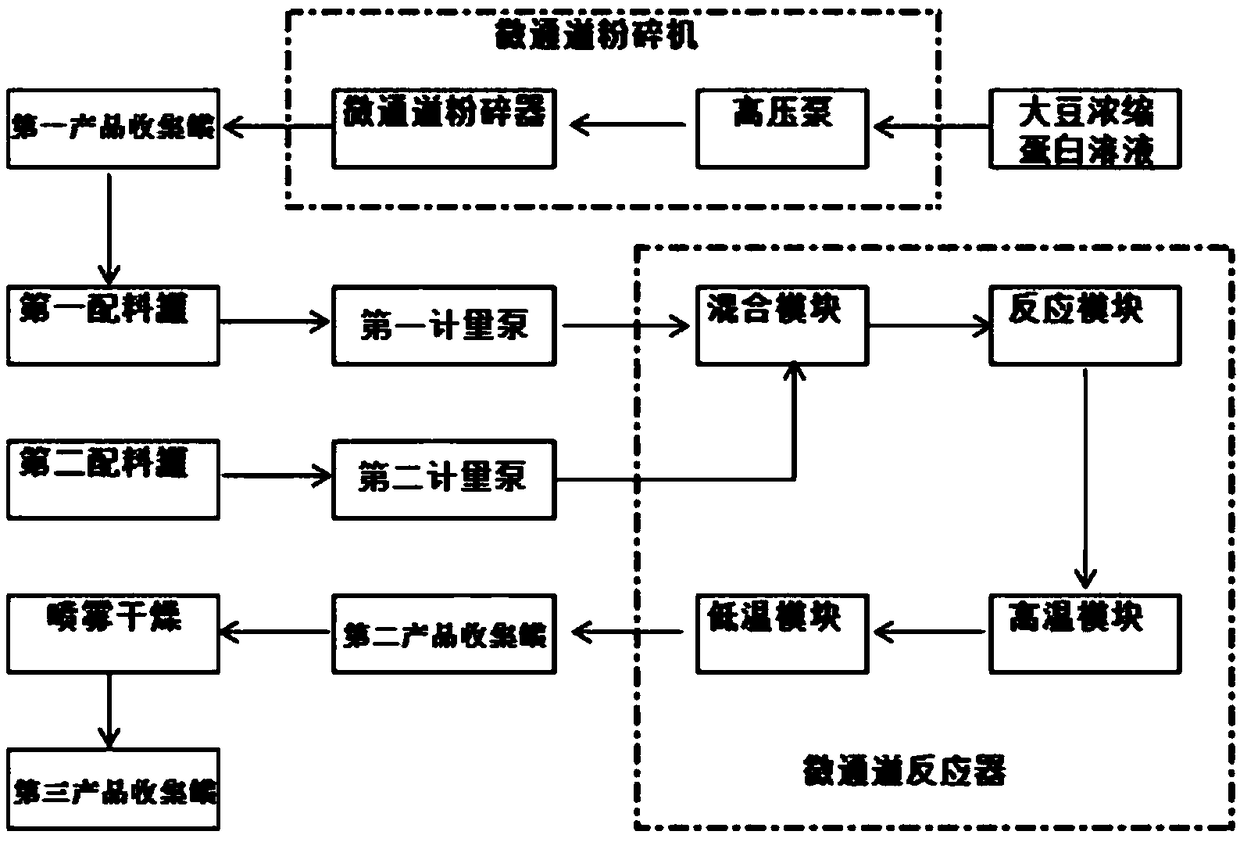

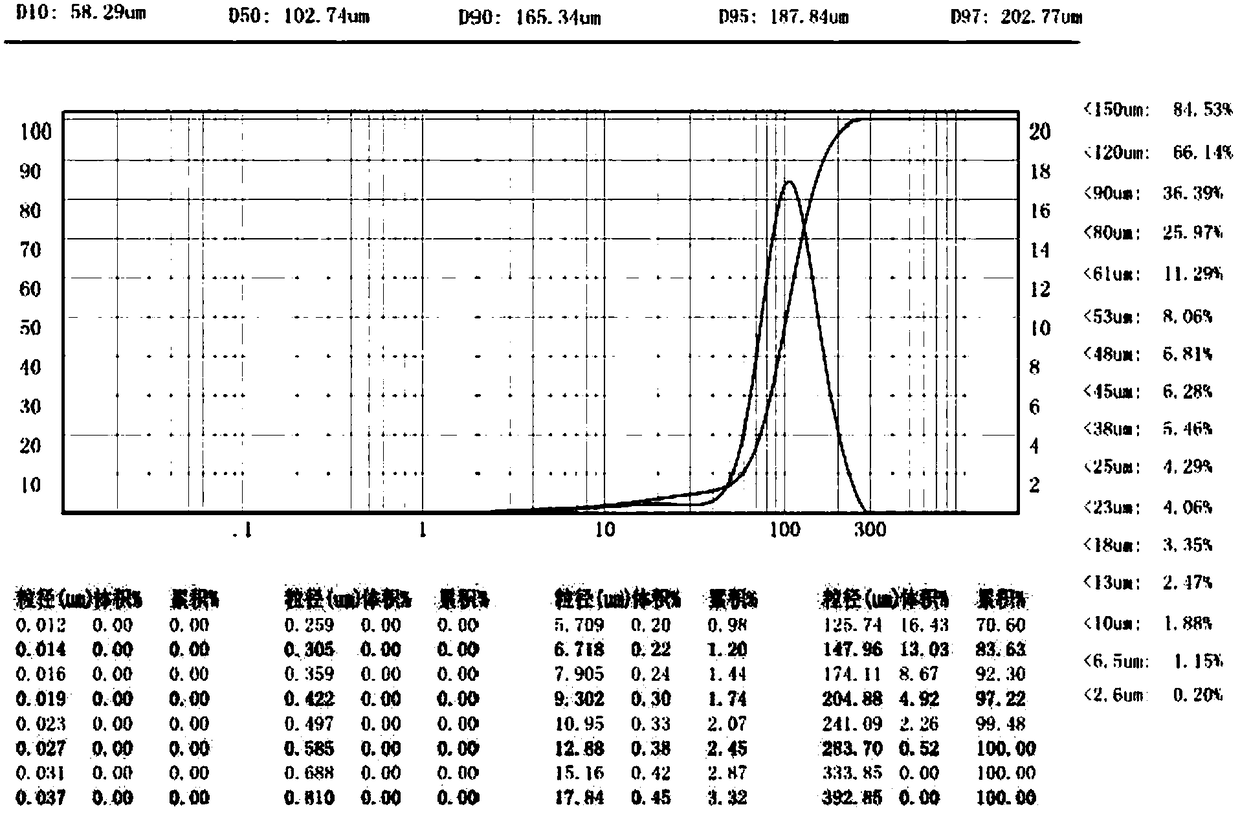

Method for modifying soy protein concentrate

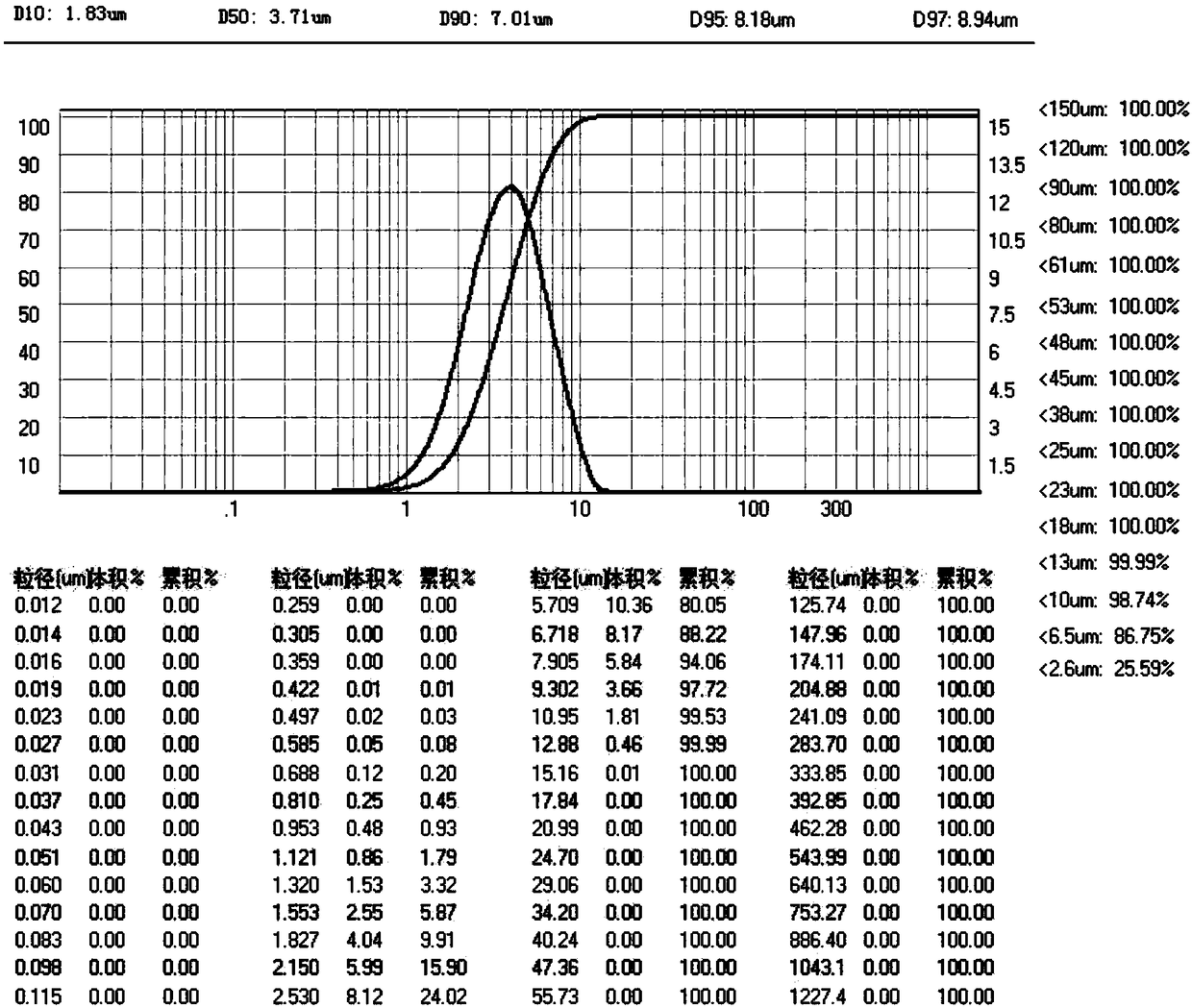

ActiveCN108402277ASmall particle sizeImprove solubilityProtein foodstuffs working-upBiotechnologyProteinase activity

The invention relates to a method for modifying soy protein concentrate. The method comprises the following steps: preparing a soy protein concentrate solution, preparing an enzyme solution, pumping the soy protein concentrate solution into a micro-channel pulverizer, conducting superfine pulverizing, separately pumping the pulverized material and the enzyme solution into a mixing module of a micro-channel reactor, allowing a mixing reaction system to enter a reaction module for reaction, then allowing the reaction system to flow through a high-temperature module to passivate the activity of cellulase and protease, then allowing the obtained reaction system to flow through a low-temperature module, and finally allowing the reaction system to flows out of the micro-channel reactor so as toobtain a modified soy protein concentrate solution. The invention also relates to the application of the soy protein concentrate prepared by the method to the field of food and nutrition health care.The method has the advantages of high reaction speed, high yield and good product quality.

Owner:ENZYMECODE BIOTECHNOLOGY CO LTD

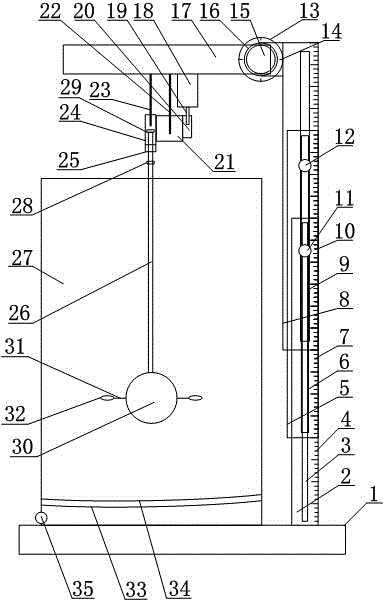

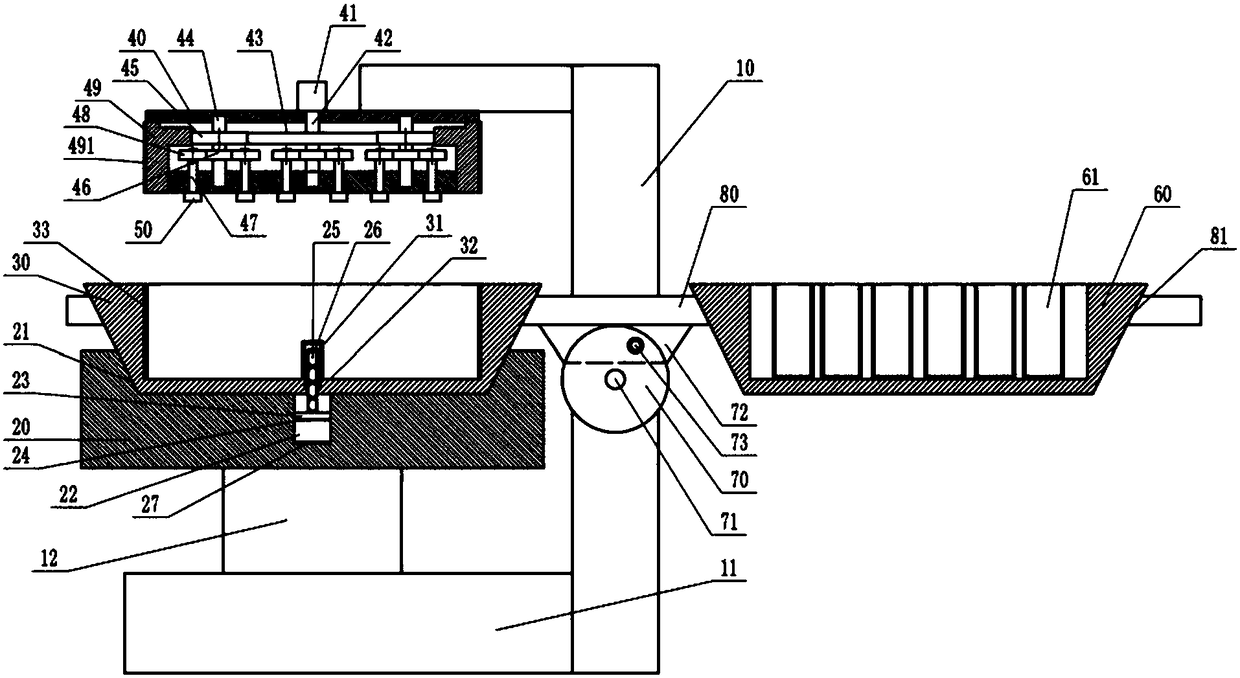

Device for passivating rear tire spokes of electric bicycle

InactiveCN104561982AFast passivationHeight adjustableMetallic material coating processesDrive motorSpoke

The invention discloses a device for passivating rear tire spokes of an electric bicycle. The device comprises a base, wherein a supporting plate is arranged on the base; a base plate is arranged at the top of the supporting plate; a rotating disc is arranged on the base plate and is connected with a top plate; a driving motor is arranged on the top plate and is connected with a driving shaft; a drive roll is arranged at an end part of the driving shaft and is connected with a driving roller; the driving roller is connected with a driven roller; a telescopic rod is sleeved in the driven roller; a passivation tank is arranged on the base; a rotating ball is arranged in the passivation tank; connecting strips are arranged at two sides of the rotating ball; a ferrule is arranged at an end part of each connecting strip; and an end part of the telescopic rod is connected with the rotating ball. By using the device disclosed by the invention, a passivation solution can be stored in the passivation tank to ensure that the rotating ball can be conveniently controlled to soak into or extend out of the passivation tank; the driving motor can be used for driving the telescopic rod to rotate by virtue of the driving shaft, the drive roll and the driving roller, so that the rotating ball can be conveniently controlled to rotate; and the ferrule is used for mounting the rear tire spokes of the electric bicycle, so that fast passivation can be realized.

Owner:FOSHAN LANO BIKE CO LTD

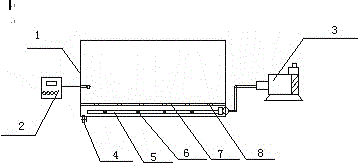

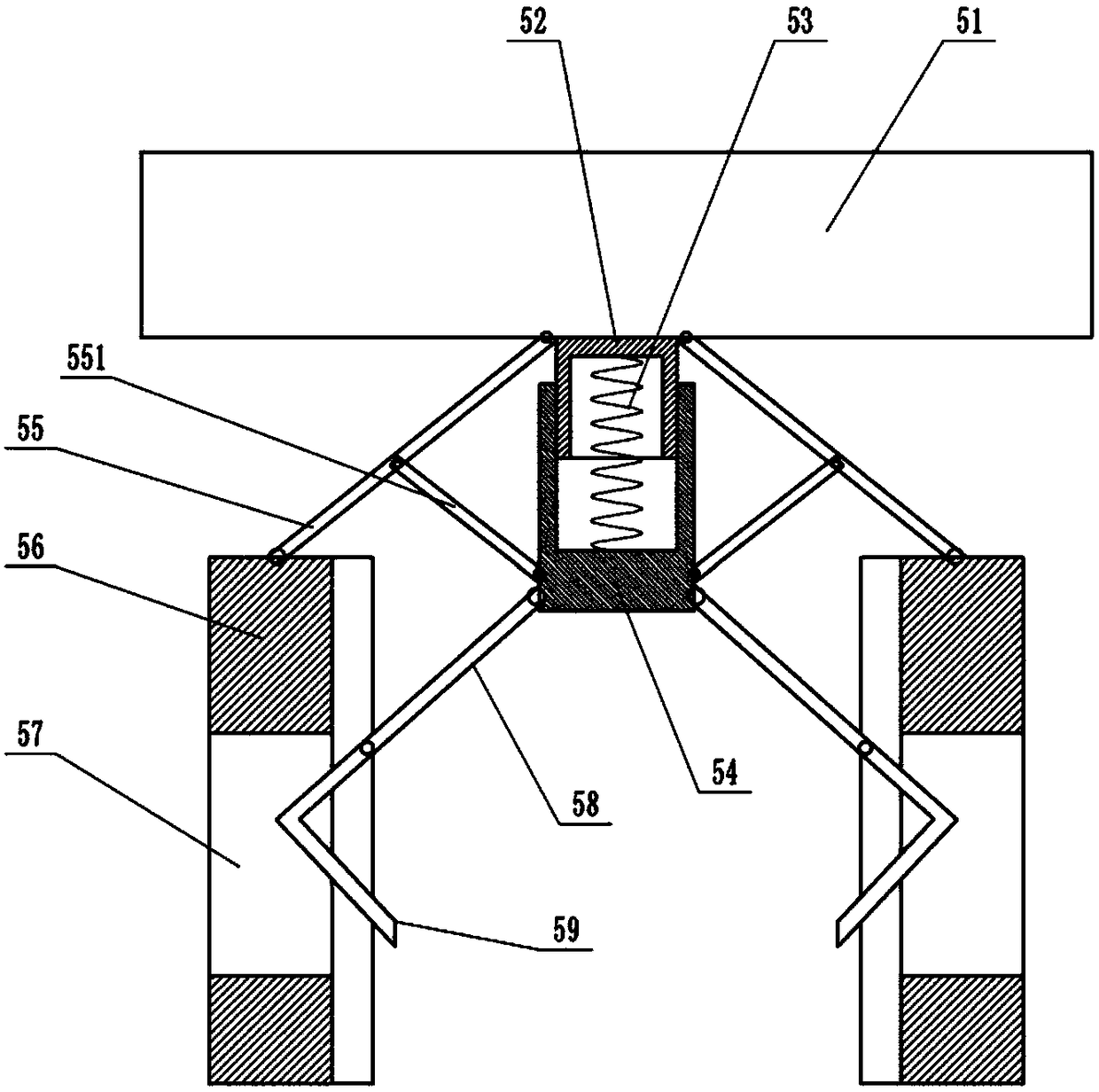

Stirring-type passivation device

InactiveCN104437199AFully passivatedUniform concentrationTransportation and packagingMixersEngineeringAir blower

A stirring-type passivation device is used for workpiece passivation in pretreatment of an electrostatic spraying line. The device comprises a passivation groove; a clapboard is disposed at the bottom of the passivation groove; a plurality of through holes are disposed on the clapboard; the passivation groove is divided into upper space and lower space by the clapboard; an air feed pipe is disposed at the bottom space between the clapboard and the passivation groove; the air feed pipe is connected with an air blower; a plurality of air vents are disposed on the air feed pipe. A concentration controller is also disposed on the passivation groove. A discharge pipe is disposed at the bottom of the passivation groove. The effect is that: through air stirring in the passivation groove, a passivating solution flows in the groove, and thus concentrations of various parts of the groove become uniform; additionally, no precipitation or crystallization is caused through air stirring, and the flowing of the passivating solution can increase the passivation speed; therefore, a washing effect is achieved, and various parts of the workpiece are fully passivated.

Owner:TIANJIN XINGYING SCI & TECH

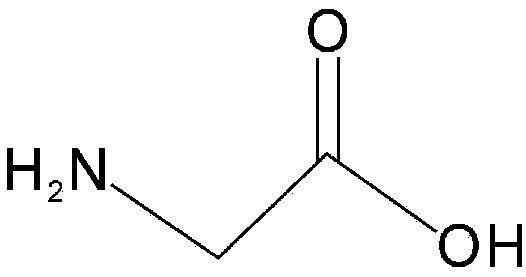

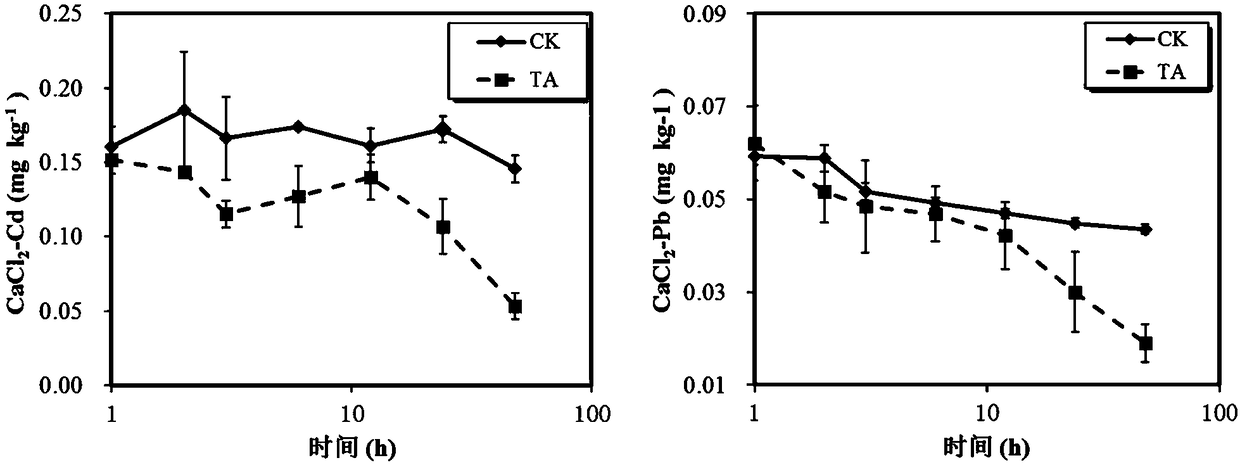

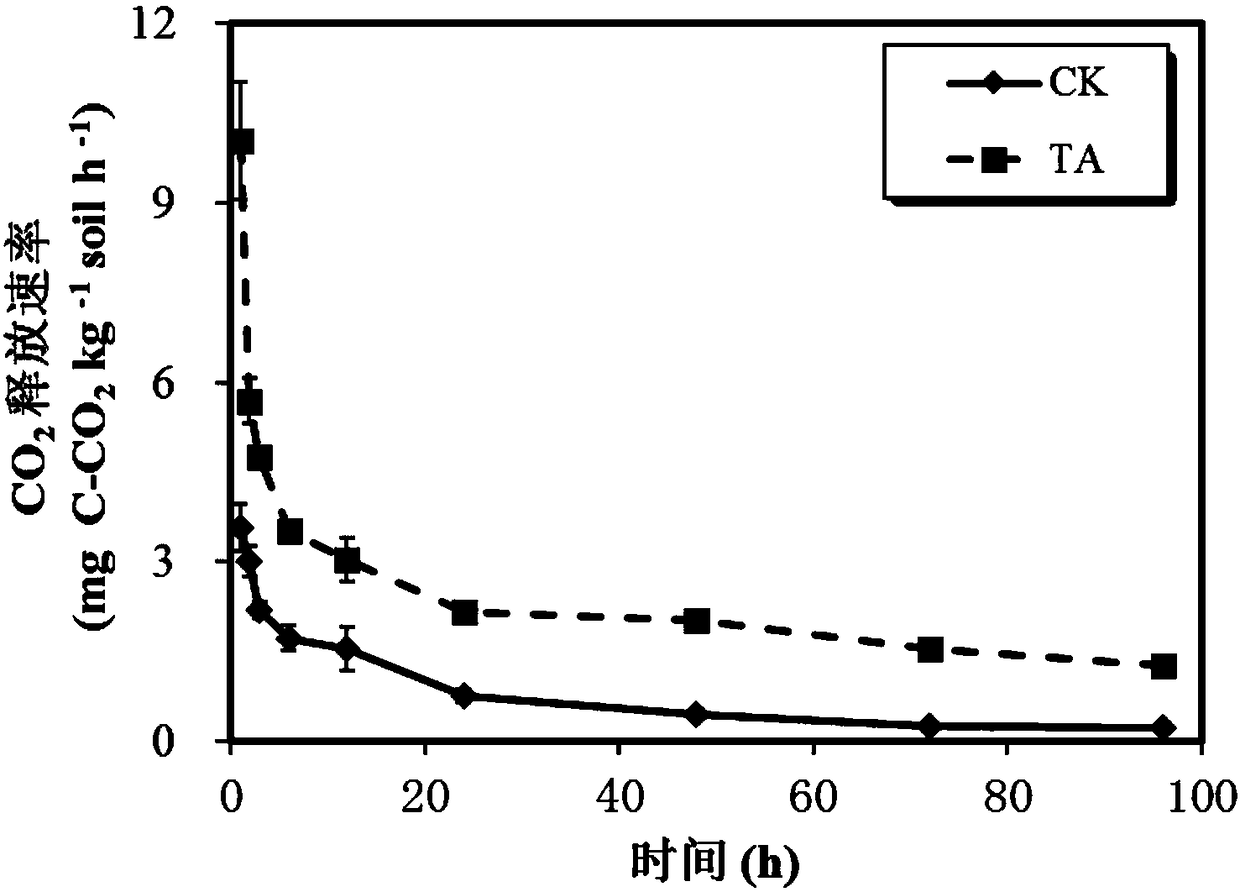

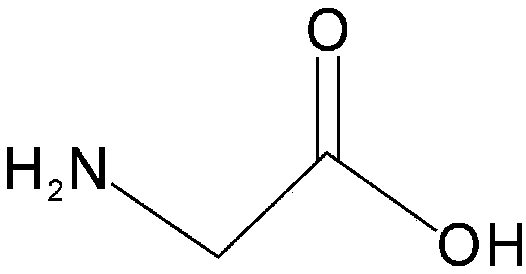

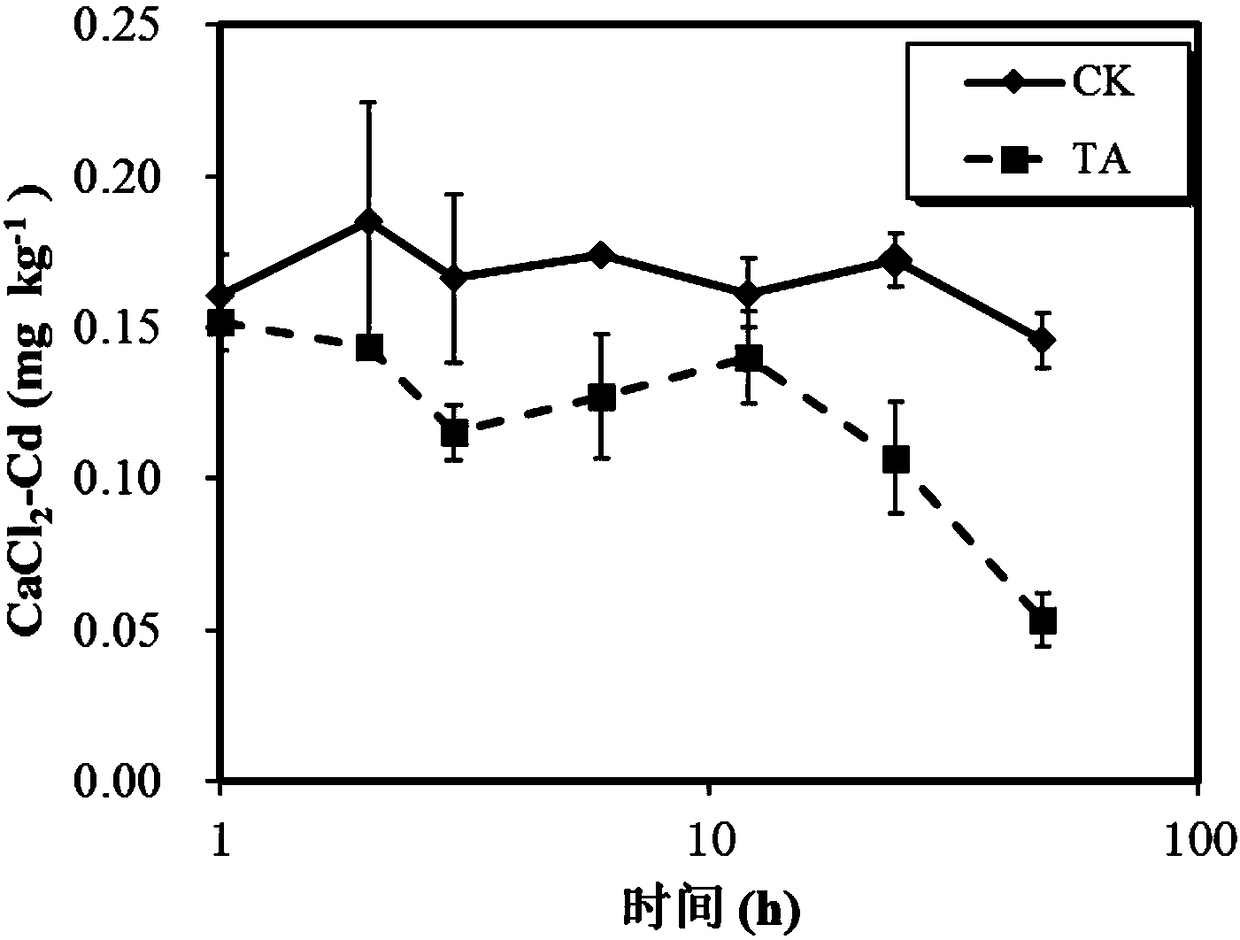

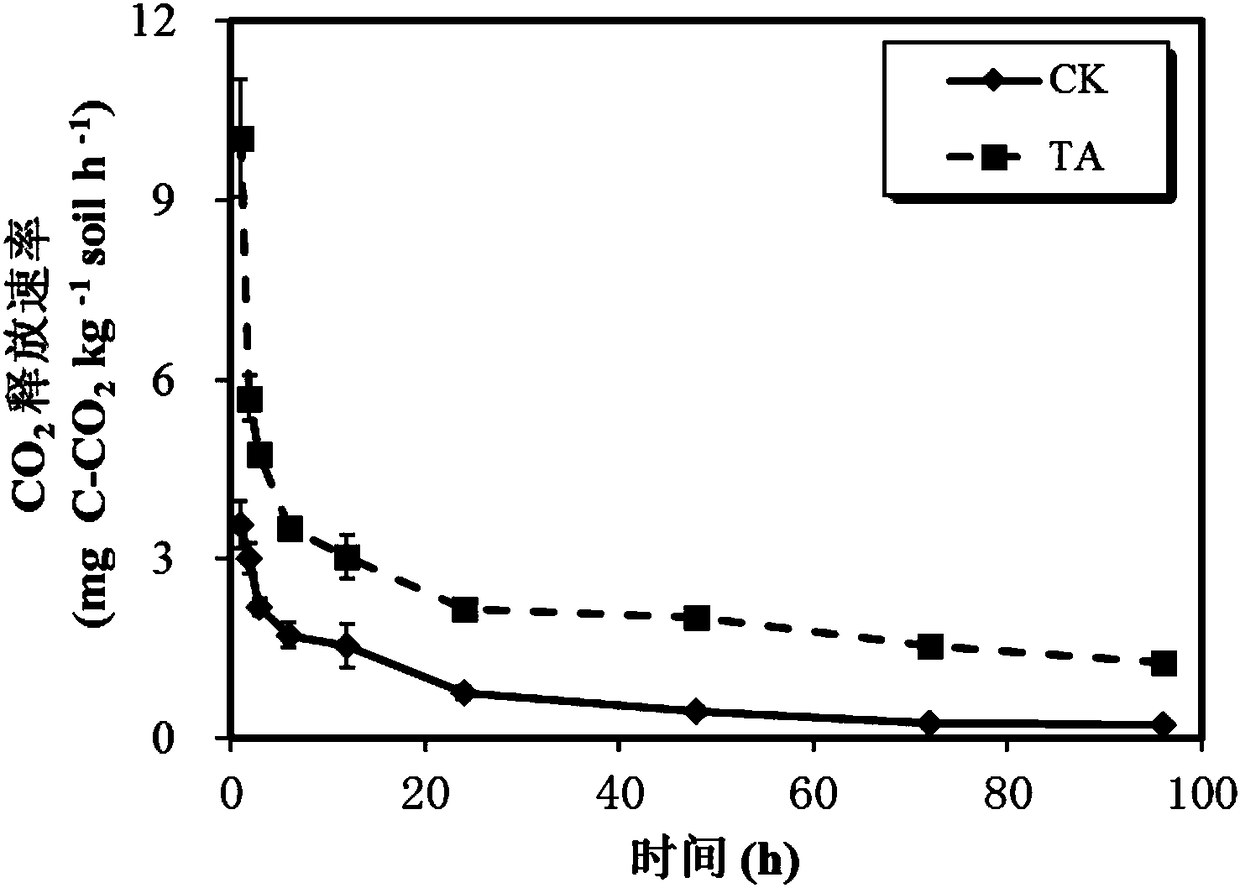

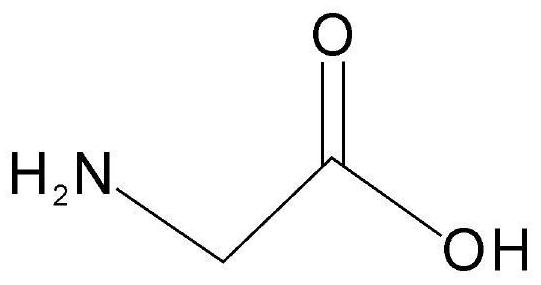

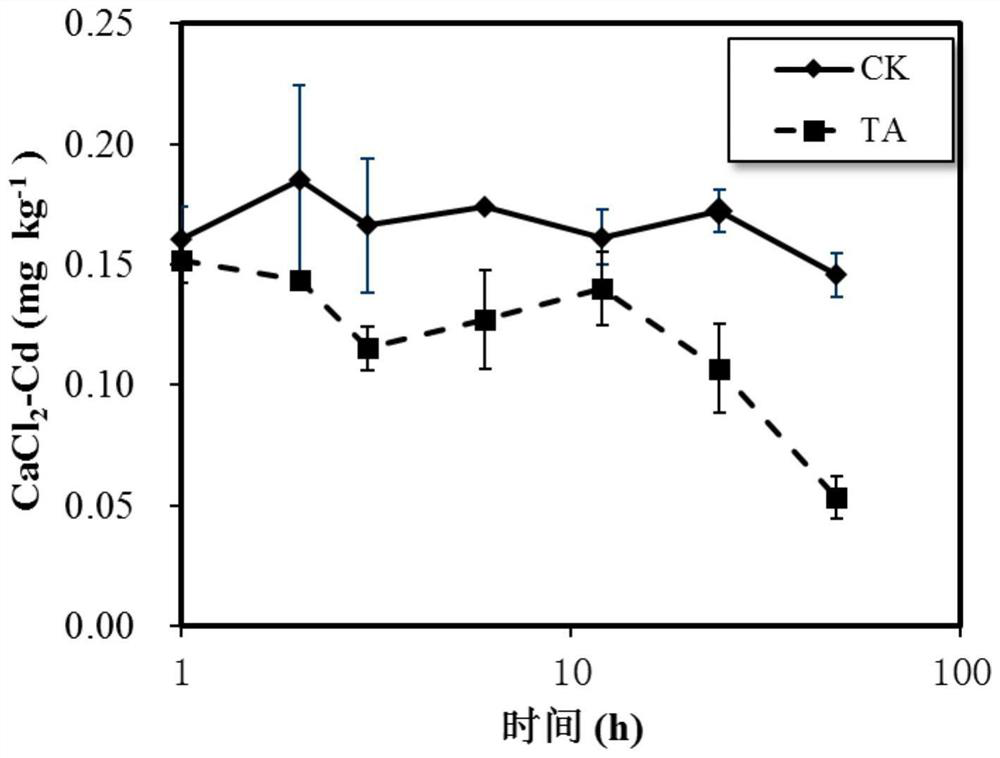

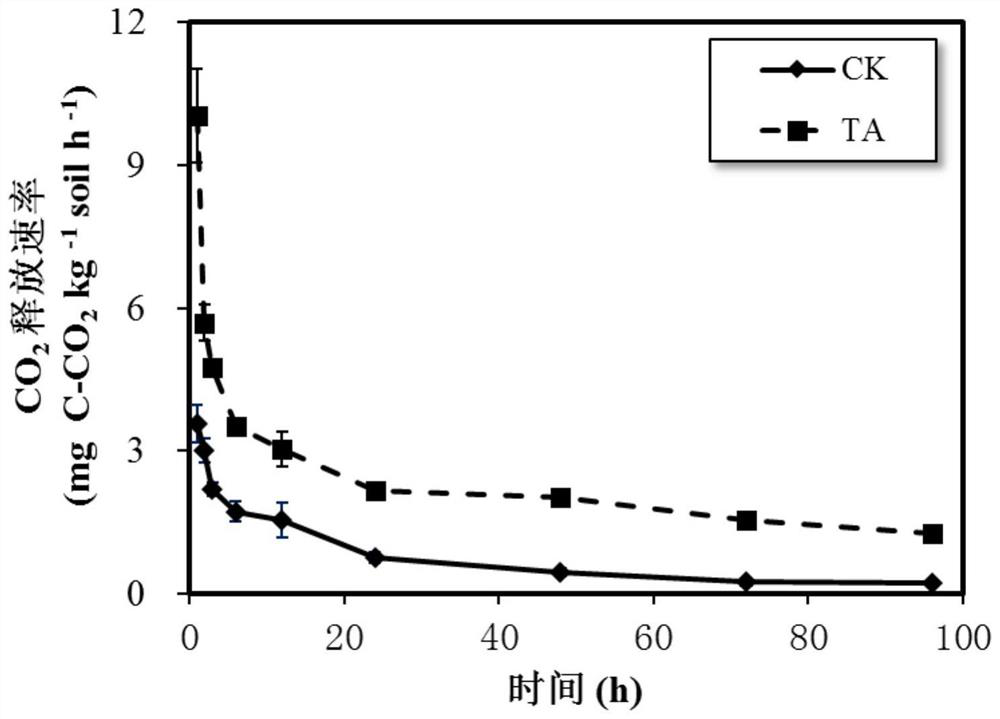

Method for rapidly passivating soil cadmium-lead active components by using glycine

InactiveCN108085007AA new passivation ideaSimple methodAgriculture tools and machinesContaminated soil reclamationGlycineActive component

The invention discloses a method for rapidly passivating soil cadmium-lead active components by using glycine. By adopting the method, heavy metals in the soil can be effectively and rapidly passivated by independently using glycine, more heavy metals are distributed onto soil solids ingeniously by virtue of the glycine complexing and the re-distribution of a complex in the solid phase and the liquid phase of the soil, and a purpose of rapidly and efficiently passivating the heavy metals can be achieved. The method for passivating the heavy metals is simple and low in cost, does not need the complicated material combination, does not need the energy-consuming production process, and does not need an external solid material serving as a precipitating agent. The method is not only rapid andeffective for the pollution of a single heavy metal, but also rapid and significant in the passivation effect for the complicated heavy metal pollution, and has practicability on the problem for treating the soil pollution; and moreover, the secondary pollution is avoided, no adverse impact is caused for the environment, and the method is environment-friendly.

Owner:SOUTH CHINA AGRI UNIV

Processing device for hard alloy cutting tool

ActiveCN108546945AImprove passivation efficiencyPassivation adjustmentMetallic material coating processesAlloyEngineering

The invention belongs to the technical field of cutting tool processing, and in particular, discloses a processing device for a hard alloy cutting tool. The processing device includes a rack, a passivation box, a gear box, a base and a cutting tool box; the gear box is fixed at the upper end of the rack, and the base is fixed at the lower end of the rack; the base is provided with a sliding columnwhich can move up and down, the upper end of the sliding column is fixed with a support seat, the gear box is aligned with the support seat, and the support seat is provided with a concave cavity which is rotatingly matched with the exterior of the passivation box; a column cavity is arranged at the center of the concave cavity; a sliding block is arranged in the column cavity in a manner of sliding up and down and is provided with a support rod; positive and negative thread grooves are arranged on the support rod, and the two thread grooves are connected end to end; the center of the lower end of the passivation box is provided with a sliding cavity; the bottom of the sliding cavity is provided with a sliding hole, and the inner wall of the sliding hole is provided with a bulge. Comparedwith the prior art, the device can passivate the cutting tool with different strength according to needs, so as to achieve the passivation effect required by the cutting tool. At the same time, the device can rapidly passivate the cutting tool in batches, thereby greatly improving the passivation efficiency of the cutting tool.

Owner:株洲思瑞普硬质合金股份有限公司

Aluminum alloy radiator before-paint-spraying passivating solution

InactiveCN104328416AFast passivationReduce processMetallic material coating processesAluminium alloyBoric acid

The invention discloses an aluminum alloy radiator before-paint-spraying passivating solution comprising the following components: 6-8g / L of sodium molybdate, 4-6G / L of potassium fluoborate, 3-5g / L of magnesium titanate, 8-10G / L of sodium zirconate, 16-18G / L of waterborne polyurethane, 12-14g / L of boric acid, 4 6G / L of acetic acid, 1-2g / L of thiourea, and the balance of water.

Owner:无锡永发电镀有限公司

Chromium-free passivation solution, preparation method and application method thereof

ActiveCN104404492BImprove corrosion resistanceStrong adhesionMetallic material coating processesSodium molybdatePorosity

The invention provides a chromium-free passivation solution as well as preparation and using methods thereof. The passivation solution is prepared by dissolving a solute composed of multiple substances into deionized water, wherein the solute in the solution comprises the following raw materials according to the ratio: 60-80g / L of sodium molybdate, 5-10g / L of sodium tungstate, 2-7g / L of ethanol, 15-50g / L of acetic acid, 20-40g / L of hydrogen peroxide, 5-10g / L of ethylenediaminetetraacetic acid disodium and the balance of water. The chromium-free passivation solution is firm in adhesive force, low in porosity and corrosion-resistant.

Owner:HUNAN JINYU CHEM

Electronickelling chromate-free passivator and preparation method thereof

InactiveCN108179410AEnvironmentally friendly ingredientsVolatile gas noMetallic material coating processesSodium phosphatesPersulfate

The invention provides an electronickelling chromate-free passivator and a preparation method thereof. The electronickelling chromate-free passivator comprises the following components of, by weight,12-20 parts of acetic acid, 2-8 parts of sodium citrate, 3-10 parts of cobalt nitrate, 6-15 parts of sodium phosphate, 4-12 parts of phosphoric acid, 1-6 parts of potassium ferricyanide, 4-9 parts ofsodium molybdate, 5-15 parts of water soluble persulfate and 300-1000 parts of water. The electronickelling chromate-free passivator provided by the invention is simple and environmentally friendly incomponent, hexavalent chromium and other toxic substances are not contained, volatile gas and smell are avoided during passivation, environmental friendliness is achieved, passivation speed is high,passivation time is only 5-10 s, a passivated electronickelling product has good corrosion resistance and inoxidizability, and the surface is smooth and glossy.

Owner:WUXI EPIC TECH

Method for rapidly passivating soil cadmium based on amino acid complexing redistribution principle

The invention discloses a method for rapidly passivating soil cadmium based on an amino acid complexing redistribution principle. The method is characterized in that by independently applying glycine,heavy metal cadmium (Cd <2+>) in soil can be effectively and quickly passivated, meanwhile, by ingeniously utilizing glycine complexing and combining that the complex is redistributed on the solid-liquid two-phase soil, more heavy metals are distributed to the solid-phase soil, and finally the purpose of rapidly and efficiently passivating the heavy metals is achieved. According to the method forpassivating the heavy metal cadmium, the method is simple, the cost is low, a complex material combination is not needed, the energy-consumption production process is not needed, an exogenous solid material does not need to be used as a precipitant; and moreover, secondary pollution does not exist, negative effects on the environment do not exist, and the method is environment-friendly.

Owner:SOUTH CHINA AGRI UNIV

Ethylene cracking and cleaning agent and preparation method thereof

ActiveCN103147086AFast passivationPrevent spontaneous combustionSpontaneous combustionCleansing Agents

The invention discloses an ethylene cracking and cleaning agent and a preparation method thereof. The ethylene cracking and cleaning agent is prepared from Tween 80, citric acid, sodium persulfate, potassium permanganate and secondary deionized water, wherein the percentage by weight of each component is as follows: the Tween 80 accounts for 15-25%, the citric acid accounts for 0.4-0.6%, the sodium persulfate accounts for 15-25%, cinnamaldehyde accounts for 4-6%, the potassium permanganate accounts for 1-2%, and the secondary deionized water accounts for 40-50%. The ethylene cracking and cleaning agent disclosed by the invention has the beneficial effects of high efficiency, no toxicity, no corrosion, no secondary pollution and fast passivation action against ferrous sulfide, and can effectively prevent spontaneous combustion of the ferrous sulfide; the using method is simple, large process adjustment is not required, and only small alteration is needed on the basis of an existing device; the ethylene cracking and cleaning time is 8-10 hours, more than 90% of the ferrous sulfide can be removed, and the shutdown time of the device is correspondingly reduced; a protective film can be formed on the surface of metal after cleaning, so that the surface of the metal can be effectively prevented from being further corroded; and a mixed solution after being treated by the cleaning agent can be directly discharged without the impact on a sewage treatment field.

Owner:山东瑞东环保科技有限公司

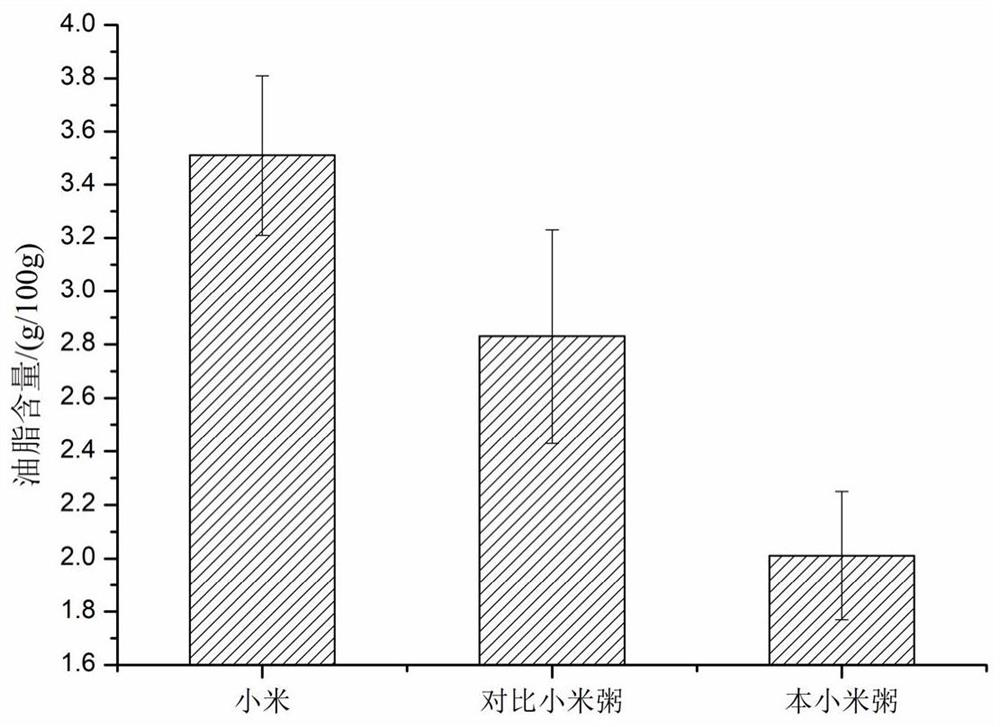

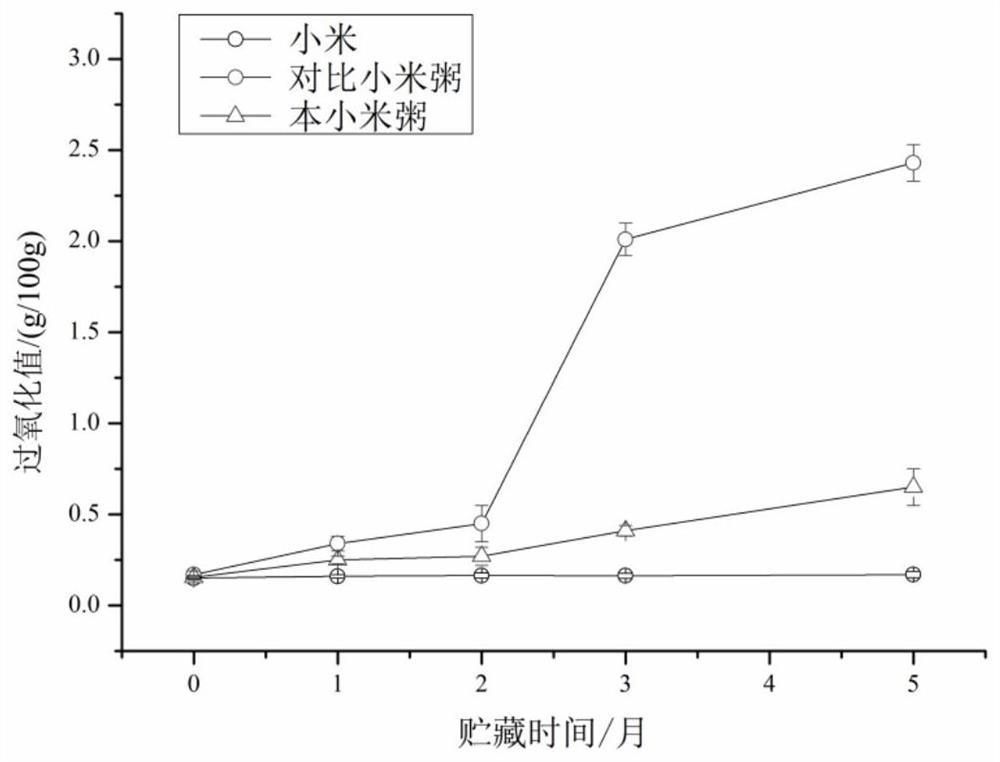

Instant millet porridge and preparation method therefor

PendingCN112120149AInhibit lipase activityInhibit thermal oxidationFood scienceBiotechnologyAnimal science

The invention relates to the technical field of food processing and particularly relates to instant millet porridge and a preparation method therefor. The method comprises the steps of subjecting millet to color-sorting impurity removal, then, removing surface bran layers through ultrasonic treatment and auxiliary low-temperature short-time soaking, subjecting water-absorbed millet to infrared-baking enzyme deactivation, then, carrying out heated gelatinization, rapidly cooling water-absorbed and complete-gelatinized millet porridge with cold air, spraying an oxidation resisting emulsion to surfaces, then, carrying out hot-air drying, sorting dried millet grains, and then, carrying out blending and nitrogen-charged packaging. The instant millet porridge is prepared from the following raw materials in percentage by weight: 90-95 of millet, 0.1-0.3 of citric acid, 5-10 of soluble soybean polysaccharides, 0.02-0.04 of theaflavin, 0.03-0.05 of curcumin and 0.3-0.5 of hydrolyzed soybean lecithin. According to the instant millet porridge produced by the method, oxidation of grease of the millet is effectively inhibited, and the product is high in rehydration speed, soft in texture, purein flavor, moderate in cost and convenient in eating.

Owner:SHANXI AGRI UNIV

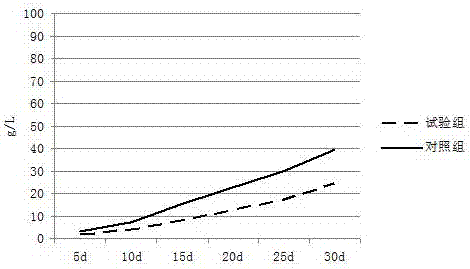

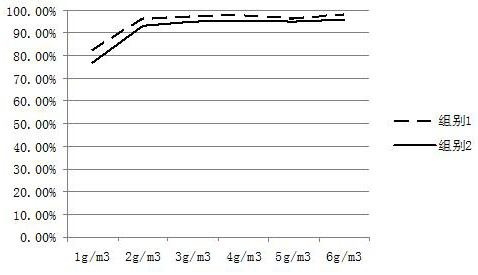

A process for repairing mercury-containing wastewater

ActiveCN107176693BEasy to operateRealize the purpose of environmental protection and green restorationWater contaminantsBiological water/sewage treatmentBioremediationBiological organism

The invention belongs to the field of wastewater treatment, and discloses a process for restoring mercury-containing wastewater. The process comprises the following steps of 1): pretreatment: filtering and depositing the mercury-containing wastewater, removing a large-particle substance and floccule, and then regulating pH (potential of Hydrogen) to be 6.5 to 7.2; 2), biological treatment: making the pretreated wastewater subjected to the pretreatment enter a biological restoration pool, adding a compound microbial inoculum according to the amount that 2g to 3g is added into the wastewater per cubic meter, and lasting a treatment time for 72 to 96 hours. A method for restoring the mercury-containing wastewater, which is provided by the invention, is simple and convenient to operate, is economical, high-efficiency, environment-friendly and low-cost, and is wide in application range; the purpose of environment-friendly and green restoration can be realized.

Owner:杭州富阳优信科技有限公司

A method for extracting rapeseed oil and inactivating glucosidase from rapeseed

ActiveCN105670769BLoose structurePromote dissolutionFatty-oils/fats refiningFatty-oils/fats productionRapeseedEnvironmental engineering

The invention discloses a method for extracting rapeseed oil and passivated myrosinase from rapeseeds and belongs to the technical field of agricultural resources.The method has the advantages that raw materials are soaked by deionized water, moisture in cells is turned into steam during steam explosion or pressurization heat-moisture treatment, and cell walls are broken to allow the cell structure to be loose and promote the dissolution of grease in the cells; an ethanol solution is used as the oil extraction medium, glucosinolates and most degradation products are allowed to enter a water phase, the glucosinolate and glucosinolate degradation product contents in cake are lowered, and the detoxification procedure of rapeseed cake is reduced; enzyme use is avoided, oil production cycle is shortened, production cost is reduced, oil product quality is optimized, and the problems that the glucosinolate and glucosinolate degradation product contents of the cake obtained by a traditional rapeseed process are high, high-quality protein resources are wasted, a large amount of enzyme needs to be used, cost is high or environment pollution is severe, and the like are solved.

Owner:JIANGNAN UNIV

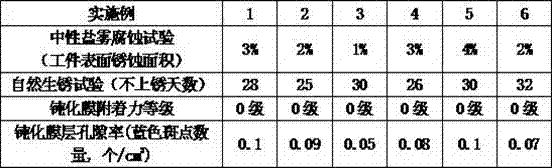

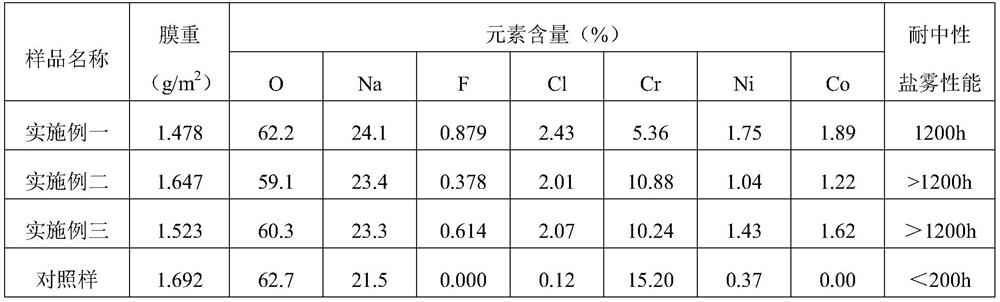

Passivator used for powder zincizing metal workpiece and preparing method and application of passivator

ActiveCN111893473AFast passivationEasy to prepareSolid state diffusion coatingZinc metalWater chlorination

The invention discloses a passivator used for a powder zincizing metal workpiece and a preparing method and application of the passivator. Each liter of passivator comprises the following raw materials including 5 g-26 g of chromium trichloride, 10 g-20 g of sodium nitrite, 2 g-4 g of nickel chloride, 5 g-8 g of cobalt chloride, 2 g-6 g of ammonium bifluoride, 15 mL-25 mL of hydrogen peroxide andthe balance water. The invention further provides a preparing method of the above passivator and the application of the passivator in powder zincizing metal workpiece passivating treatment. By means of the passivator, the chromium trichloride is adopted as the main film forming compound, nickel chloride and cobalt chloride are introduced, and under the effect of the sodium nitrite, a passivating effect is achieved both on a zinc layer and a zinc-iron alloy layer on the surface of the powder zincizing metal workpiece. The neutral salt mist resisting performance of the metal workpiece obtained after passivating treatment of the passivator can reach 1200 h or above, and the corrosion resistance of the metal workpiece is improved. The passivator does not contain hexavalent chromium, carcinogenic raw materials do not exist, environment pollution is reduced, the passivating effect is good, and the application range is wide.

Owner:青岛隆世泰环保科技有限公司

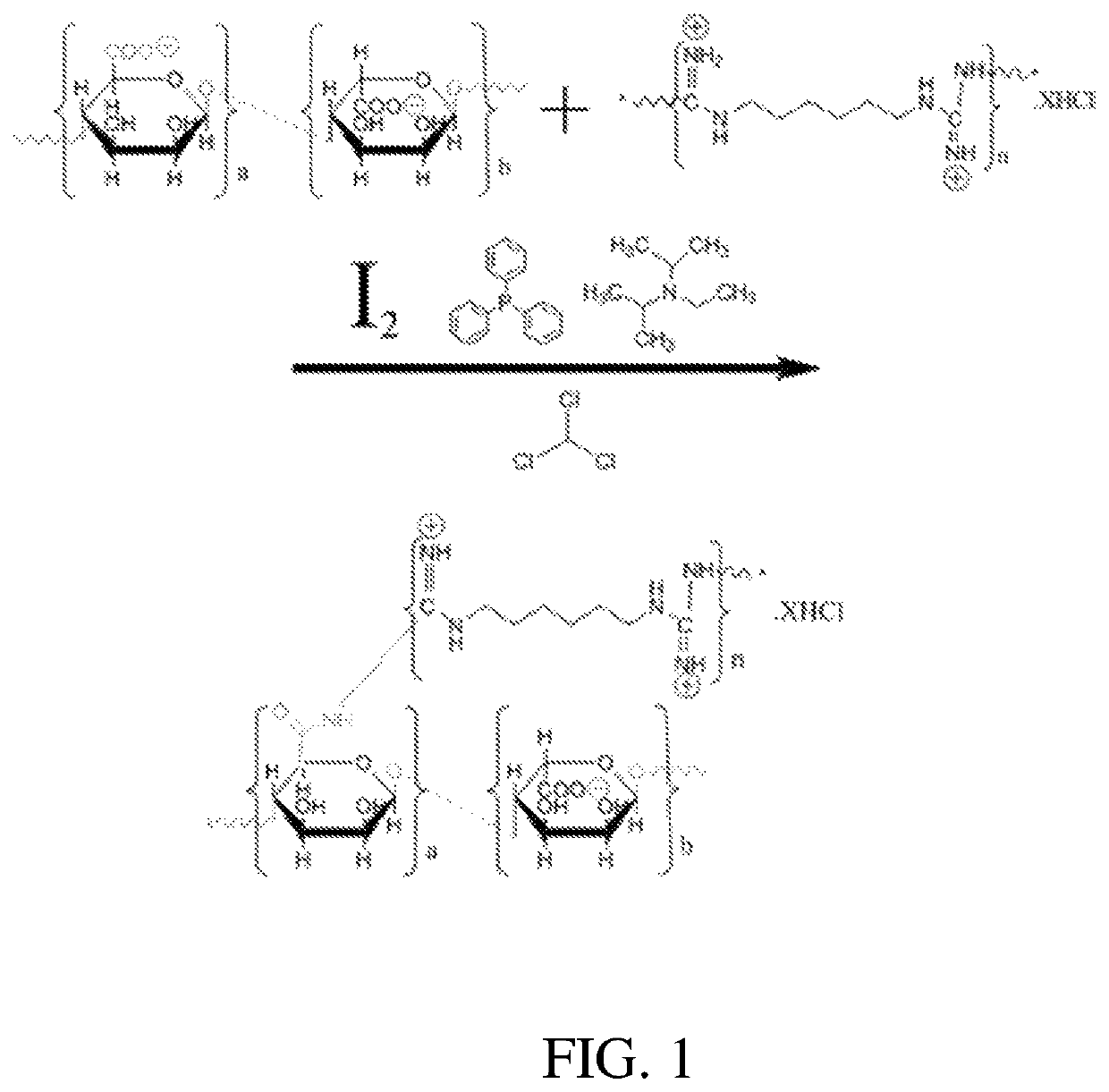

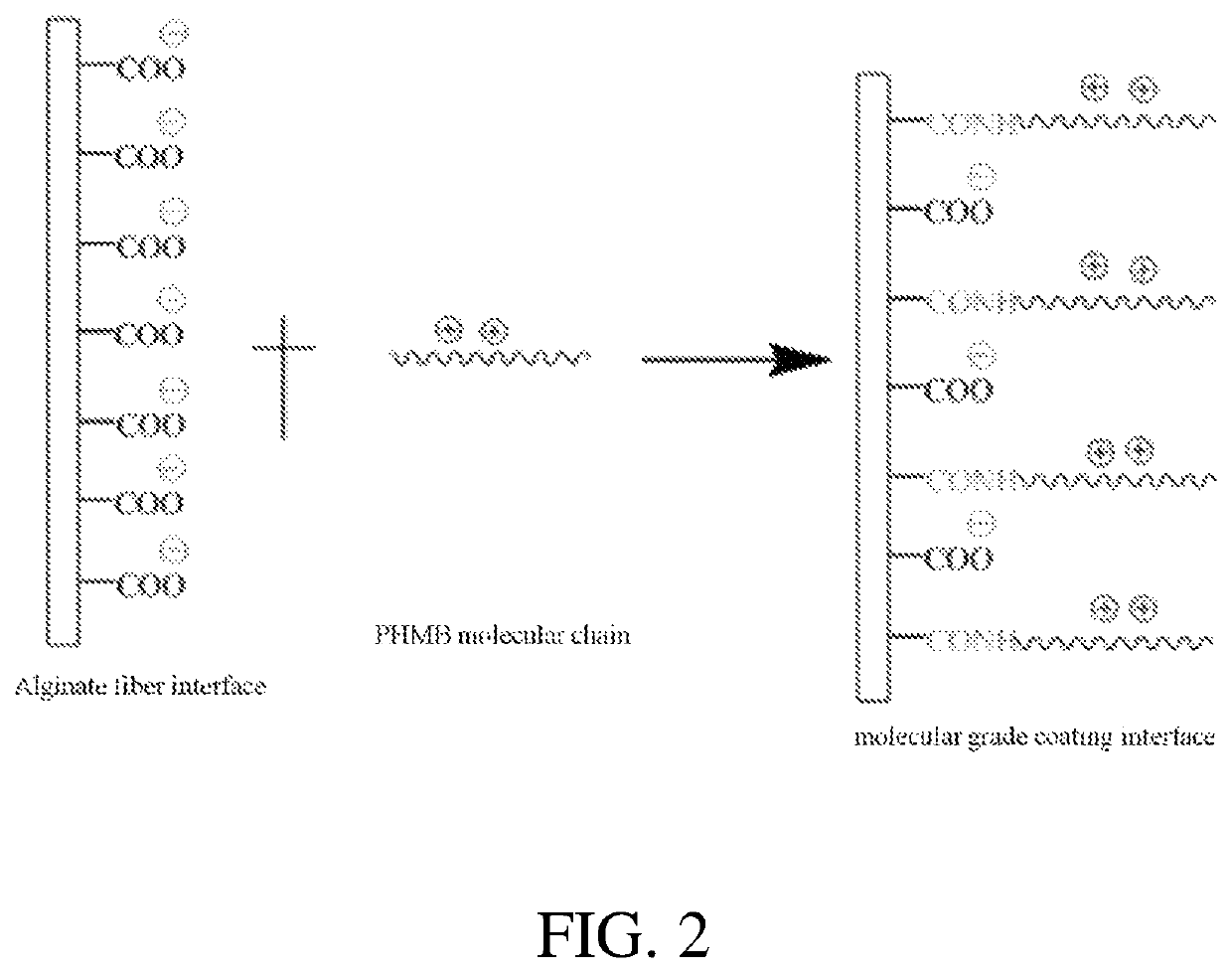

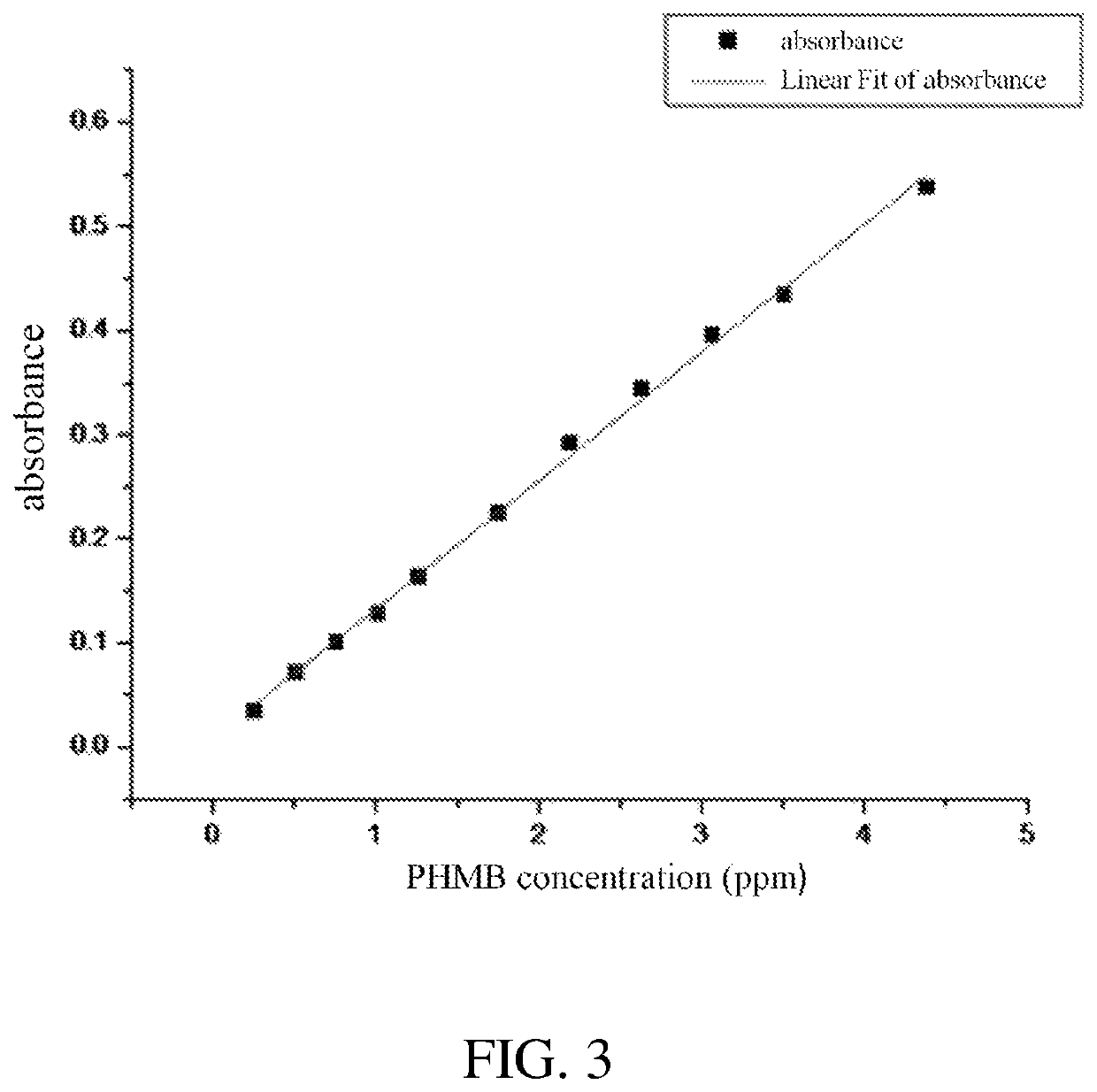

Antimicrobial alginate fiber, and preparation method for and use of dressing thereof

ActiveUS11131040B2Good wound care propertyGood hygroscopicityBiochemical fibre treatmentAlginate artificial filamentsBiotechnologyPolyhexamethylene guanidine

The present disclosure provides an antimicrobial alginate fiber, a method for manufacturing an antimicrobial alginate fiber dressing thereof, and an application thereof. When the cationic polymer polyhexamethylene guanide salt is mixed with the anionic polymer alginate, the antimicrobial activity of the guanide salt is quickly passivated. The present disclosure achieves a lower content of polyhexamethylene guanide salt in an alginate dressing with good long-term antimicrobial activities. The polyhexamethylene guanide salt has a low dissolution rate, and significantly reduces a potential risk of carcinogenicity, mutagenicity and reproductive toxicity.

Owner:HUIZHOU HUAYANG MEDICAL EQUIP

Ethylene cracking and cleaning agent and preparation method thereof

ActiveCN103147086BFast passivationPrevent spontaneous combustionSpontaneous combustionCleansing Agents

The invention discloses an ethylene cracking and cleaning agent and a preparation method thereof. The ethylene cracking and cleaning agent is prepared from Tween 80, citric acid, sodium persulfate, potassium permanganate and secondary deionized water, wherein the percentage by weight of each component is as follows: the Tween 80 accounts for 15-25%, the citric acid accounts for 0.4-0.6%, the sodium persulfate accounts for 15-25%, cinnamaldehyde accounts for 4-6%, the potassium permanganate accounts for 1-2%, and the secondary deionized water accounts for 40-50%. The ethylene cracking and cleaning agent disclosed by the invention has the beneficial effects of high efficiency, no toxicity, no corrosion, no secondary pollution and fast passivation action against ferrous sulfide, and can effectively prevent spontaneous combustion of the ferrous sulfide; the using method is simple, large process adjustment is not required, and only small alteration is needed on the basis of an existing device; the ethylene cracking and cleaning time is 8-10 hours, more than 90% of the ferrous sulfide can be removed, and the shutdown time of the device is correspondingly reduced; a protective film can be formed on the surface of metal after cleaning, so that the surface of the metal can be effectively prevented from being further corroded; and a mixed solution after being treated by the cleaning agent can be directly discharged without the impact on a sewage treatment field.

Owner:山东瑞东环保科技有限公司

A method for rapid passivation of soil cadmium based on the principle of complexation and redistribution of amino acids

ActiveCN108296276BEffective passivationFast passivationContaminated soil reclamationGlycineSoil science

The invention discloses a method for rapidly passivating soil cadmium based on an amino acid complexing redistribution principle. The method is characterized in that by independently applying glycine,heavy metal cadmium (Cd <2+>) in soil can be effectively and quickly passivated, meanwhile, by ingeniously utilizing glycine complexing and combining that the complex is redistributed on the solid-liquid two-phase soil, more heavy metals are distributed to the solid-phase soil, and finally the purpose of rapidly and efficiently passivating the heavy metals is achieved. According to the method forpassivating the heavy metal cadmium, the method is simple, the cost is low, a complex material combination is not needed, the energy-consumption production process is not needed, an exogenous solid material does not need to be used as a precipitant; and moreover, secondary pollution does not exist, negative effects on the environment do not exist, and the method is environment-friendly.

Owner:SOUTH CHINA AGRI UNIV

A compound biological preparation and its application in treating mercury-containing wastewater

ActiveCN107099483BCompatibility is reasonableStrong synergyFungiBacteriaBiochemical engineeringMicrobiology

The invention belongs to the technical field of biology and discloses a compound biological preparation. A preparation method of the compound biological preparation includes the steps of firstly, culturing strains; secondly, evenly mixing and concentrating; thirdly, mixing, heating and stirring; fourthly, coating, crosslinking and drying. The compound biological preparation is reasonable in compatibility, strong in synergic effect, high in mercury degrading ability and capable of being used for treating mercury-containing wastewater.

Owner:FUYANG HUAIBANG MACHINERY

Novel environmentally-friendly passivating agent

InactiveCN102061464BMeet the requirements of the European ROHS directiveSolve the problem of hanging water corrosionMetallic material coating processesO-Phosphoric AcidPhosphate

The invention discloses a novel environmentally-friendly passivating agent, which is characterized by comprising 30 to 40 g / L of sodium silicate, 10 to 20 g / L of phosphate, 5 to 10 g / L of accelerant and 0.5 to 1 g / L of surfactant, wherein the mass ratio of the silicate to the phosphate is 2-3: 1; the accelerant is potassium chlorate; the surfactant consists of 1.8 to 2.2 weight parts of OP-10, 0.8 to 1.2 weight parts of TX-100 and 0.8 to 1.2 weight parts of NP-5; and the pH value of the mixed solution is adjusted to be between 3 and 5 by using phosphoric acid. Compared with the prior art, thepassivating agent quickly passivates the surfaces of steel parts, and does not cause environmental pollution and the like.

Owner:佛山市中国地质大学研究院

Green passivating agent for metal doors and windows

InactiveCN108658794ACorrosion resistanceFast passivation rateCarboxylic acid nitrile preparationOrganic compound preparationButeneMaterials science

The invention discloses a green passivating agent for metal doors and windows and relates to the technical field of treatment of the metal doors and windows. The green passivating agent contains 2-hydroxyl-3-butene-1-amine hydrochloride. Passivating liquid provided by the invention is green and safe; raw material sources are wide, the passivating speed is rapid, the efficiency is high and the quality of a passivating film is stable.

Owner:界首市创新门窗有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com