Processing device for hard alloy cutting tool

A technology of hard alloy and processing equipment, applied in the direction of metal material coating process, etc., can solve the problems of poor passivation effect and low efficiency, and achieve the effects of simple operation, high efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below by means of specific embodiments:

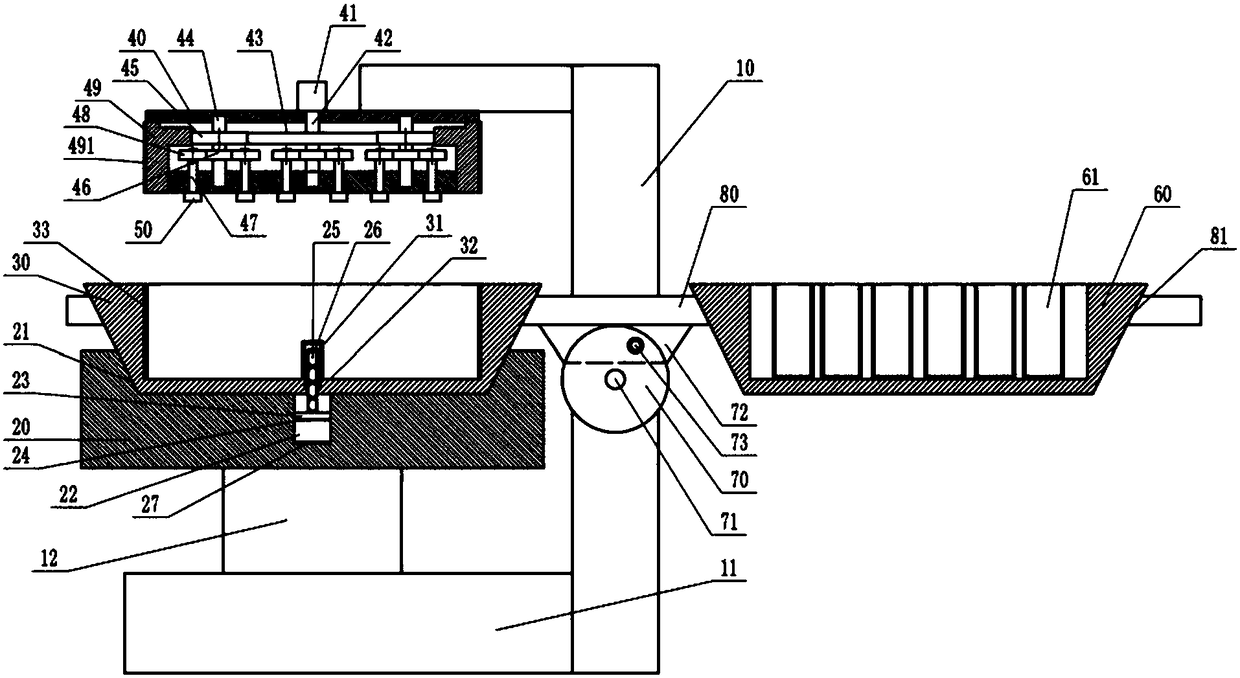

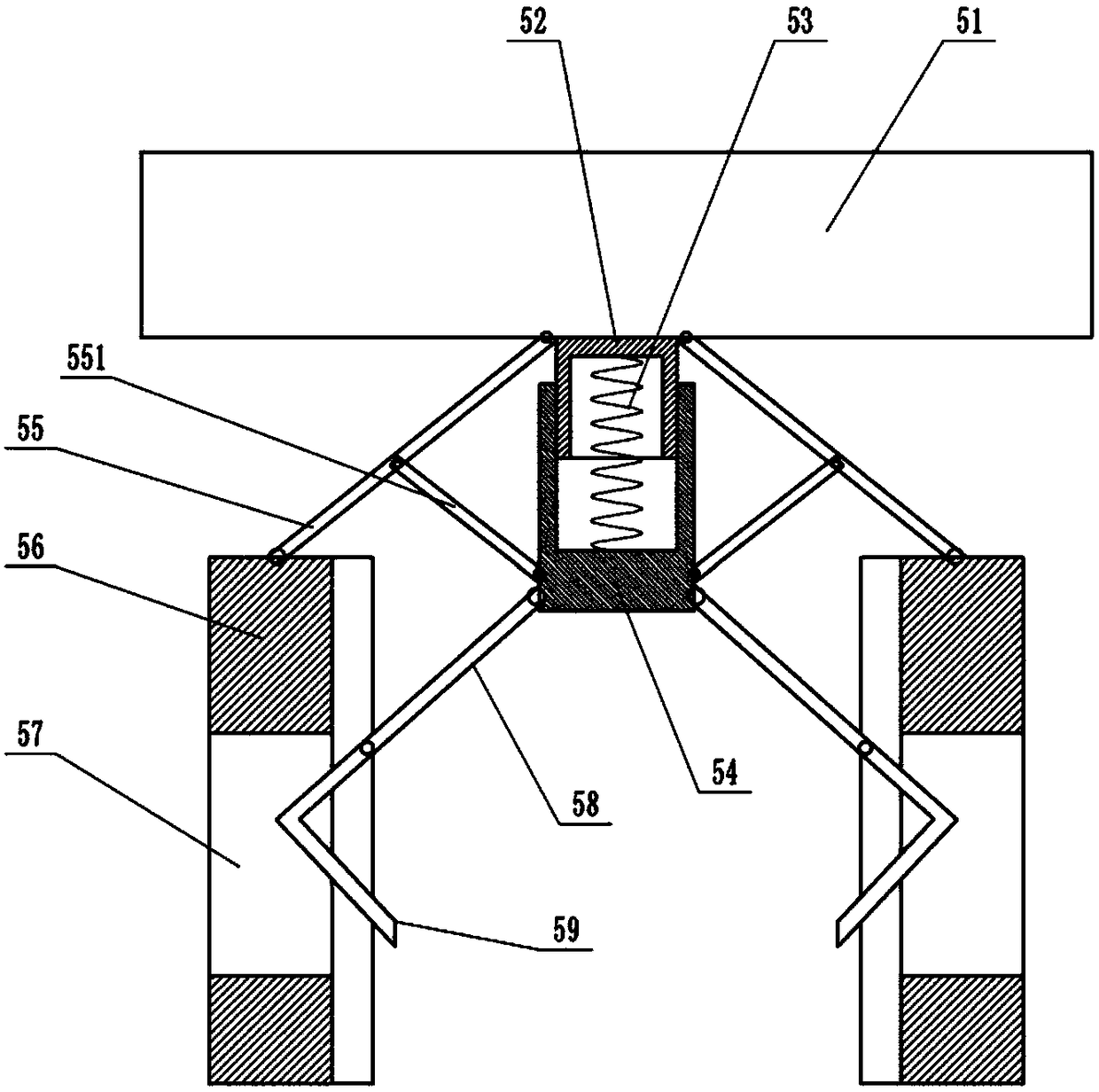

[0033] The reference signs in the accompanying drawings include: frame 10, base 11, sliding column 12, support seat 20, concave cavity 21, column cavity 22, slider 23, magnetic block 24, pole 25, thread groove 26, electromagnetic Iron 27, passivation box 30, sliding cavity 31, sliding hole 32, keyway 33, gear box 40, motor 41, center rod 42, driving gear 43, transmission rod 44, transmission gear 45, main gear 46, turning rod 47, Slave gear 48, ring gear 49, key bar 491, tool chuck 50, fixed plate 51, sleeve 52, spring 53, sleeve cap 54, connecting rod 55, pull rod 551, splint 56, strip groove 57, clamping rod 58, jaws 59, tool case 60, cutter groove 61, main bevel tooth disc 70, cross bar 71, from bevel tooth disc 72, handle 73, turret 80, ring hole 81.

[0034] Such as figure 1 , figure 2 As shown, the processing device for cemented carbide cutting tools includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com